Page 1

2GIG-DW30-345

OUTDOOR WIRELESS CONTACT SENSOR MANUAL

Installation Instructions

The Outdoor Wireless Contact (2GIG-DW30-345) is designed for installation on gates, doors, and other items that open and close.

It communicates with the control panel using the 345

MHz frequency. When the magnet (which is mounted

near the sensor) moves away from or closer to the

door contact’s sensor, signals are transmitted to the

control panel. The sensor also has an external input

that accepts connections from Normally Closed (NC)

dry contact devices. For added protection, it is also

equipped with a cover and wall tamper.

Box Contents

• Outdoor Sensor

• Magnet

• Lithium AA Batteries (2x)

• Mounting screws

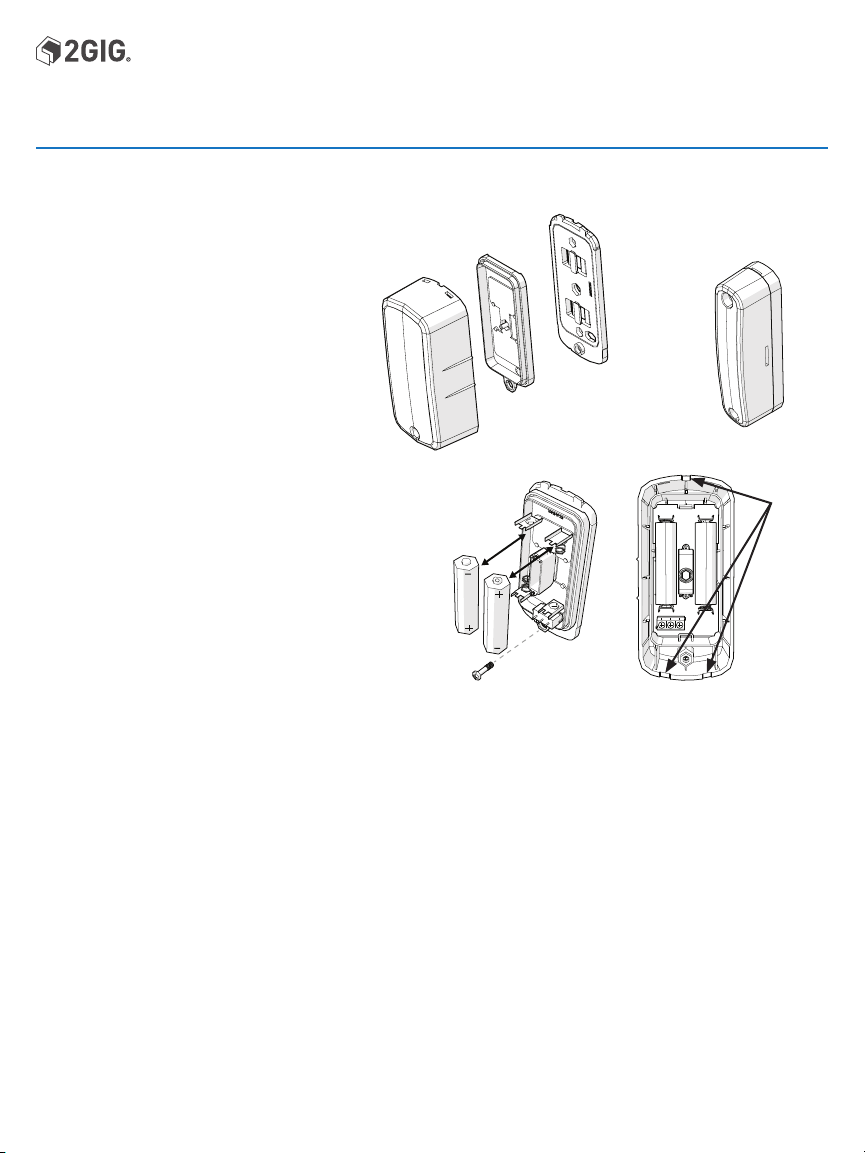

Installing the Batteries

1. Loosen the cover screw.

2. Choose any pry point, then use a small screwdriver to

remove the Sensor Mounting Plate

3. Remove the Sealing Cover.

4. Install the two Lithium Ion batteries.

5. Align the Sealing Cover to the screw hole in the sensor cover,

then press to close.

6. Engage Sensor tabs into mating holes in Sensor Mounting

Plate and swing closed. Secure with cover screw.

SENSOR

SEALING

COVER

Mounting Guidelines

Mount the Sensor within 100 ft (30 m) of the control panel. Although the transmitter may have a range of 350 ft (106.7 m) open

air, the sensor location can have a significant effect on range. In open / unobstructed situations, the transmitter range may be

greater. In adverse wireless conditions, changing the sensor orientation may lead to improved range.

Testing the Outdoor Wireless Contact

Before mounting the Outdoor Wireless Contact at the desired location, perform a walk test to verify that it can establish good

Radio Frequency (RF) communication with the control panel.

Utilize a Repeater (P/N: 2GIG-RPTR1-345) if the RF communication is insufficient for the desired location.

NOTE: To fully test the Outdoor Wireless Contact, see the control panel’s Installation and Programming Guide.

• Mount the device on a vertical surface (at a sufficient height) where water, snow and ice buildup won’t interrupt operation.

NOTE: Adding silicone caulk surrounding the rubber wire seal on the Sealing Cover will increase protection against water.

• Mount the Magnet on the magnet sensing side of the Sensor. On wooden surfaces a gap of approximately 2” is possible.

This will be decreased when mounting on metal surfaces.

• Mount the Sensor on the stationary surface, and mount the Magnet on the moving surface.

• Mount the Magnet and Sensor parallel with one another.

• If installed on a wooden surface, mount the sensor and magnet on the inside of the structure (if possible).

NOTE: Use screws suitable for the mounting surface.

• If mounted on a curved surface, use zip ties and/or suitable screws to fasten the Sensor and Magnet.

Tamper Protection:

The tamper switch will activate if the cover is removed or if the sensor is detached from its mounting location.

SENSOR

MOUNTING

PLATE

MAGNET

Pry points

1 Copyright © 2018 Nortek Security & Control LLC

Page 2

Outdoor Wireless Contact | Installation Instructions

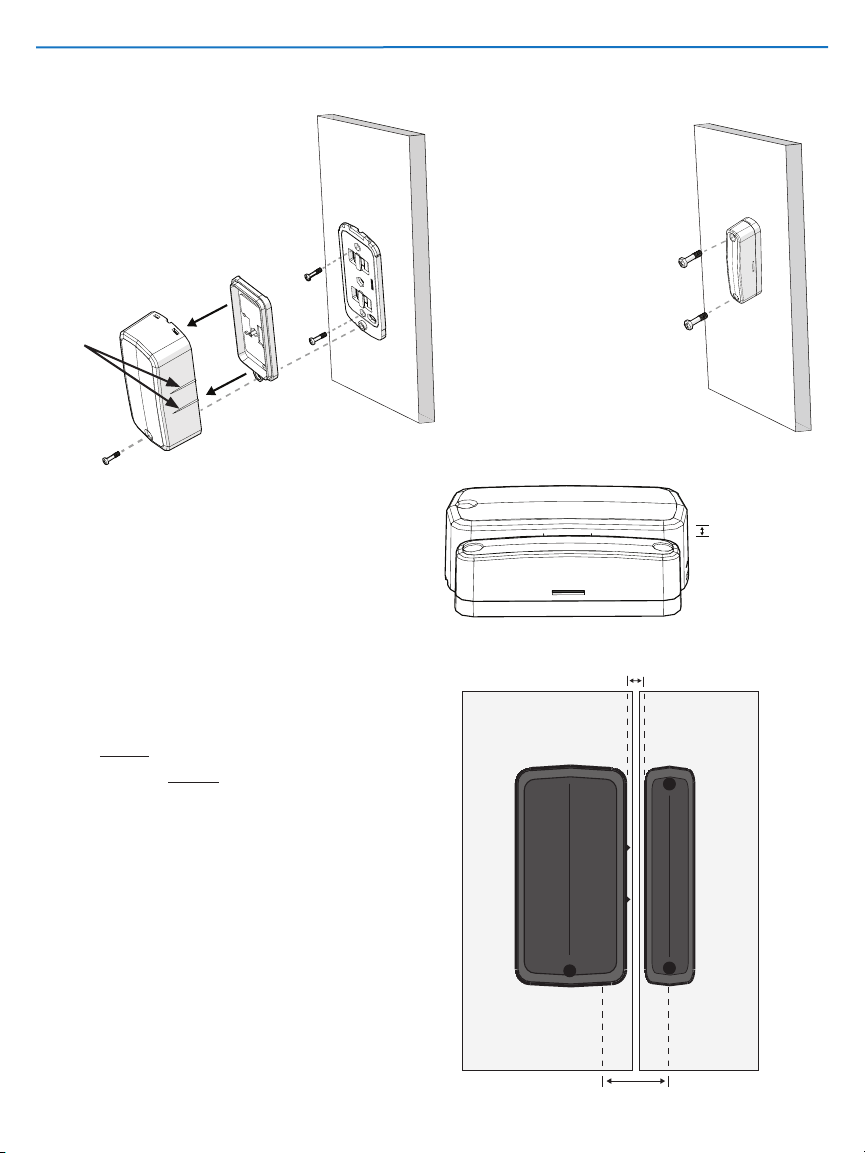

Mounting the Sensor on a Flat Surface.

1. Loosen the cover screw and remove the

Sensor Mounting Plate.

2. Ensure that the Magnet Direction Marks

are aligned toward the desired magnet

location.

3. Screw the Mounting plate into the

desired surface.

4. Replace the Sensor onto the Mounting

plate and tighten the cover screw.

5. Secure the magnet into place.

Magnet

direction

marks

Sensor and Magnet Mounting Height

Ideally, the Sensor and Magnet should be mounted on

surfaces of equal height.

When mounted at a level height, the 1/4” preferred mounting

height offset should be attained.

A height offset that exceeds 1/4” may decrease detection

capabilities.

Mounting the Magnet on a Flat Surface.

1. Ensure that the magnet marks are aligned

to the desired magnet location.

2. Mount the sensor into the desired

surface using the two screws.

Recommended Gap = 0.25"

1/4”

Recommended

Sensor and Magnet Mounting Distance

The preferred mounting distance between the Sensor and

Magnet is 1/4 inch.

The maximum gap is 2 inches.

2 Copyright © 2018 Nortek Security & Control LLC

Mounted Surface Mounted Surface

Maximum Gap = 2"

Page 3

Mounting on a Curved Surface

Strap ties and cable ties used for mounting are not supplied.

Recommended are:

• Self-locking stainless steel strap ties (recommended)

• Heavy duty Nylon 6/6 lN and Temperature Rated cable ties

(0.5 inch wide)

• A combination of screws and ties.

Figure 1: Example: SelfLocking Stainless Steel Strap

EXTERNAL WIRING - May be used with external closed contact switches.

Note: Use minimum of 22AWG jacketed

cable. The contact switch must be a Form

C (SPDT) type.

UL: Maximum wire length cannot exceed 3 feet.

1. Strip the cable jacket back about four

inches to provide adequate space for

Sealing Cover removal while changing

CLOSED (NC)

COMMON

OPEN (NO)

Connect Wires to the Terminal Block

batteries.

2. Feed the cable through the access hole

in Sensor Mounting Plate. Use the cable

notch on mounting plate to pass through

the jacketed portion of cable, then attach

the Sensor Mounting Plate.

3. Route the cable to the external contact

switch and fasten at intervals to secure

the cable.

SEALING COVER

A

d

d

4. Remove the Sealing Cover and feed the

wires through the rubber wire seal. If

installed, remove the batteries.

5. Connect the wires to terminal block in the

battery chamber, then install the batteries.

SENSOR

6. Replace the Sealing Cover.

Note: The cover screw hole should line up with the screw hole in the sensor cover. Press to close. Apply silicone caulking to

the rubber wire seal.

7. Engage the tabs in the Sensor Mounting Plate to the slots in the sensor, and swing closed. Secure with cover screw.

Cau

lki

CONNECT TO EXTERNAL

CONTACT SWITCH

SENSOR

MOUNTING PLATE

n

g

t

o

S

eal

i

n

g

C

o

v

e

r

PAINTING THE SENSOR

The sensor and magnet may be painted to match the color of the mounting surface. Only paints made for plastic may be used.

Follow the manufacturer's instructions for preparing the plastic, applying the paint and recommended drying times.

NOTE: DO NOT USE METALLIC PAINT COLORS.

3 Copyright © 2018 Nortek Security & Control LLC

Page 4

Specifications

Wireless Signal Range 350 ft (106.7 m) open air

with Wireless Control

Panel

Code Outputs Open, Restore,

Supervisory, Low

Battery, External Open,

External Restore,

Tamper, tamper Restore

Transmitter Frequency 345 MHz

Unique ID Codes Over one (1) million

different code

combinations

Supervision Interval 70 minutes.

External Input Accepts N/C dry contact

devices

Magnet Dimensions (L x W x H) 4.06 x 0.98 x 1.1” (103 x

25 x 28 mm)

Magnet Type Rare Earth

Magnet Gap Up to 2"

Sensor Dimensions (L x W x H) 4.57 x 2.13 x 1.54” (116 x

54 x 39 mm)

Housing Material ASA

Color Black

Operating Temperature -40ºF to 150 ºF (-40ºC

to 66 ºC)

Relative Humidity 0 ~ 100%

IP Rating Tested to IP56

Battery (Included) Two (2) Lithium AA

Certifications FCC, IC

REGULATORY INFORMATION

This equipment has been tested and found to comply with the limits for Class B Digital

Device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures.

Reorient or relocate the receiving antenna

Increase the separation between the equipment and receiver

Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected

Consult the dealer or an experienced radio/TV technician for help.

Any changes or modications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils

radio exempts de licence. Ľexploitation est autorisée aux deux conditions suivantes:

(1) ľappareil ne doit pas produire de brouillage, et (2) ľutilisateur de ľappareil doit

accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible ďen

compromettre le fonctionnement.

FCC COMPLIANCE STATEMENT

This device complies with FCC Rules and Regulations as Part 15 devices as well as

Industry Canada license exempt RSS Rules and Regulations. Operation is subject to the

following two (2) conditions: This device may not cause harmful interference. This device

must accept any interference received, including interference that may cause undesired

operation.

INDUSTRY CANADA (IC) COMPLIANCE

This device complies with Industry Canada license-exempt RSS standard(s). Operation

is subject to the following two conditions: (1) this device may not cause interference,

and (2) this device must accept any interference, including interference that may cause

undesired operation of the device. Repairs to certied equipment should be made by

an authorized Canadian maintenance facility designated by the supplier. Any repairs or

alterations made by the user to this equipment, or equipment malfunctions, may give the

telecommunications company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections of

the power utility, telephone lines and internal metallic water pipe system, if present,

are connected together. This precaution may be particularly important in rural areas.

Users should not attempt to make such connections themselves, but should contact the

appropriate electric inspection authority, or electrician, as appropriate.

LIMITED WARRANTY

This Nortek Security & Control LLC product is warranted against defects in material

and workmanship for two (2) years. This warranty extends only to wholesale customers

who buy direct from Nortek Security & Control LLC or through Nortek Security & Control

normal distribution channels. Nortek Security & Control does not warrant this product to

consumers. Consumers should inquire from their selling dealer as to the nature of the

dealer’s warranty, if any.

There are no obligations or liabilities on the part of Nortek Security & Control for

consequential damages arising out of or in connection with use or performance of this

product or other indirect damages with respect to loss of property, revenue, or prot, or

cost of removal, installation, or reinstallation. All implied warranties for functionality, are

valid only until the warranty expires. This Nortek Security & Control Warranty is in lieu of all

other warranties expressed or implied.

4 Copyright © 2018 Nortek Security & Control LLC

Nortek Security & Control LLC | 2GIG

5919 Sea Otter Place, Suite 100

Carlsbad, Ca. 92010

For technical support in the USA and Canada:

855‐2GIG‐TECH (855‐244‐4832)

Email: 2gigtechsupport@nortekcontrol.com

Visit www.nortekcontrol.com for technical support hours of operation

For technical support outside of the USA and Canada:

Contact your regional distributor

Visit www.dealer.2gig.com for a list of distributors in your region

10021755A

Loading...

Loading...