Lincoln Electric Welding Inverter and Chopper User Manual

TECHNOLOGY

POWER ELECTRONICS TECHNOLOGY

Inverters and Choppers

Technology creates change.

The ability to evolve along

with change is what

distinguishes a successful

product from the rest.

Power source design is

almost entirely devoted

to reliability. Fast power

conversion is important to

obtaining a smooth

welding output, but we

also know that speed is

inconsequential without

reliability. No matter how

fast your machine operates,

if it is not durable, then it is

not usable for welding. And

if it is not welding, you are

not meeting your

production goals and

making a living.

The Chopper

Technology

Ranger

the same control over

the welding arc as an

inverter machine

The inverter technology in

the Invertec

gives it equivalent power

®

in the

®

305D offers

®

V350-PRO

capabilities as a

conventional

transformer/rectifier

such as the Lincoln

CV-305, but in

a much smaller and

portable machine.

QUICKER RESPONSE

High-speed power conversion allows for quick response to changing

arc conditions.

SMALLER FOOTPRINT

Power electronic components are compact, making equipment size smaller and

therefore more portable.

UNIVERSAL INPUT VOLTAGE

Capable of operating from 208 to 575 volts on virtually any power supply for

versatile, consistent performance.

HIGHLY EFFICIENT

Smaller transformer coils, higher thermal conductivity, and higher operating

frequencies means more efficient output power, and more economical use

of power. This translates to decreased utility costs and increased power

source efficiency.

WAVEFORM CONTROL TECHNOLOGY®COMPATIBLE

Waveform Control Technology®gives the operator improved control over the

characteristics of the welding arc.

The future of welding is here.

NX-1.30 6/06

®

POWER ELECTRONICS TECHNOLOGY

TECHNOLOGY

Inverter Technology

What is

Inverter Technology?

Inverter-based welding power

sources operate at frequencies

above 20 kHz, whereas

traditional power sources

operate at a line frequency

of 50 or 60 Hz. Some of the

advantages an inverter has

are smaller magnetic

components (chokes and

transformers), higher

efficiency, and a fast

response to the welding arc.

Inverter power sources were

first introduced into the

welding industry in the early

1980s. The initial attraction of

the inverter was its small size

and easy portability. For

example, a rectifier-based

machine, like the Lincoln CV305,

weighs four times more than the

Invertec V350-PRO. Less space

is needed and the inverter unit is

easily moved around the job site.

As the popularity and reliability of

Inverter Technology

The Invertec®V350-PRO

The Power Wave

the inverter increased, the capabilities

were expanded. Inverters are now

designed for many different

processes: SMAW, GTAW, FCAW,

SAW, and are capable of operating in

®

355M

Inverter Technology is

showcased in Lincoln’s

®

Invertec

Power Wave

V350-PRO, and

®

welding systems

2/8

The Power Wave®455M/STT

The Power Wave

extreme environments. Over the last

decade, Lincoln Electric has invested

heavily in developing inverter

technology, producing highly reliable

inverter machines.

®

AC/DC 1000™

How

Inverter Works

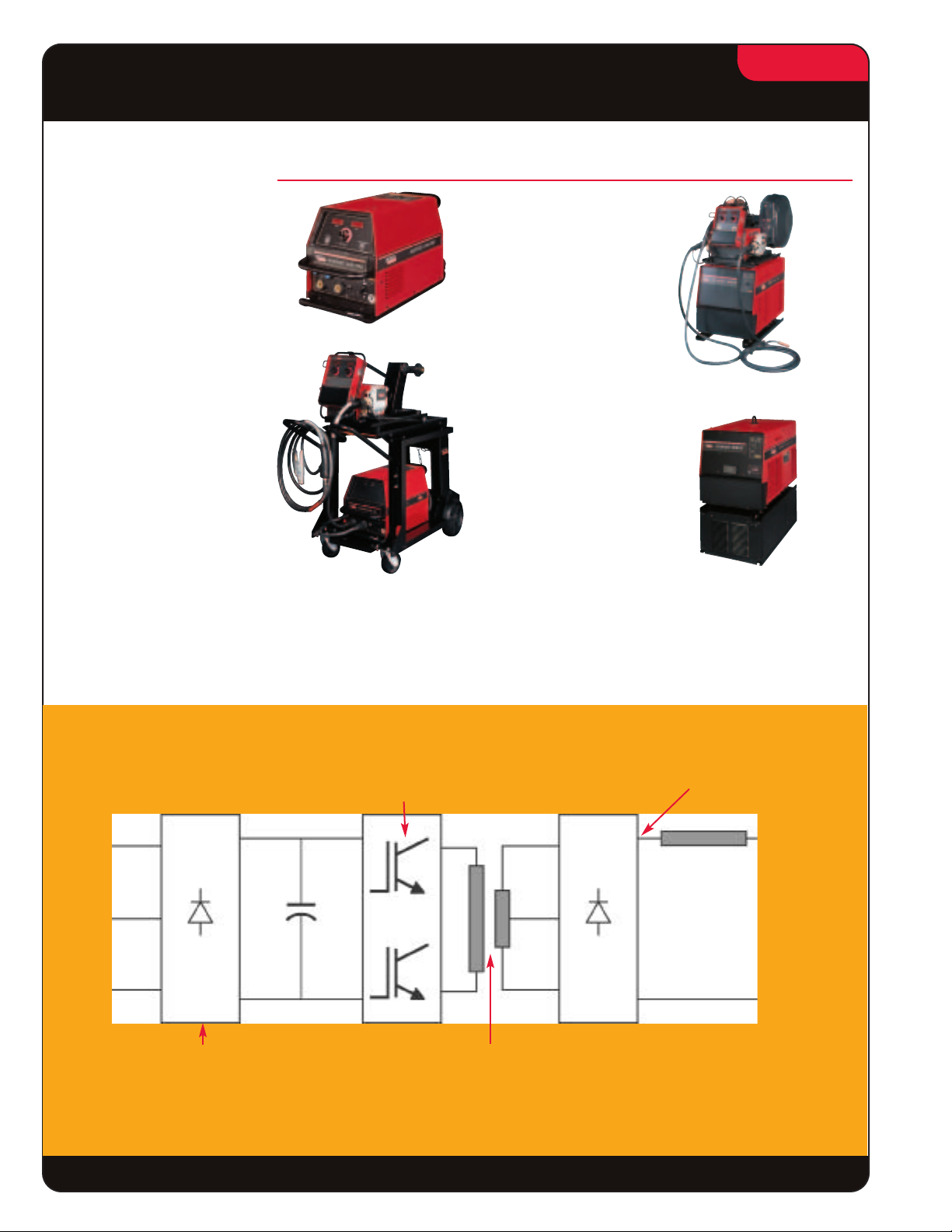

Incoming 50 to 60 Hz alternating

current (AC) is converted

to direct current (DC) by a full

wave rectifier.

The future of welding is here.

The DC power is inverted into high-frequency AC power,

using semiconductor switches above 20 kHz. High-speed

switching improves welding. Switching above 20 kHz

improves efficiency, reduces weight, and is above the

maximum frequency people can hear. Digital controls

dictate the switching rate of the transistors.

The high-frequency AC voltage

requires a step-down

transformer. The transformer

takes high voltage, high

frequency AC and converts it to

low voltage, high frequency AC.

The current is “smoothed”

by a rectifying and

filtering circuit to make it

suitable for welding.

®

POWER ELECTRONICS TECHNOLOGY

TECHNOLOGY

Inverter Technology

Using

Inverter Technology

For Multi-Process Welding

Inverters are capable of multiple process welding, providing

optimum arc characteristics for each process.

For Reduced Electrical Power Consumption

Copper conductors, compact transformers, and smaller coils

translate to energy savings.

For Waveform Control Technology*

Inverter machines are software programmable, which means

that they are equipped to use Waveform Control Technology

to manipulate output weld characteristics.

For Networking Capability*

Multiple inverter machines can be networked together over a

Local Area Network (LAN) or Wide Area Network (WAN) with

an Ethernet/DeviceNet Gateway board.

Advantages

Of Inverter Technology

Reliable

Every inverter undergoes rigorous testing to ensure

product reliability.

Compact and Portable

Smaller chokes, transformers, and rectifiers, give the inverter

equivalent power to older SCR machines, without the added

size and weight.

Fast Response to Welding Arc

®

Digital controls regulate the output very accurately so the

welding performance is consistent from machine to machine.

Universal Input Voltage**

The inverter can run on any power supply that supplies

between 208 to 575 volts.

Efficient

The smaller chokes and transformers of the inverter yield an

efficiency rating of 87% to 90%, which means the inverter

consumes less energy to convert the same amount of energy

as SCR-based machines.

3/8

The Power Wave

technology to produce consistent

welds with a variety of weld processes.

* Applies only to Power Wave Welding Systems F355i, 355M, 455M, 455M/STT, 655

Robotic, and Power Wave AC/DC 1000.

**Power Wave 655 Robotic and Power Wave AC/DC 1000 operate from 460 to 575 volts.

The future of welding is here.

®

455M uses Inverter

®

Loading...

Loading...