Lincoln Electric Precision 275 User Manual

Precision TIG®275

1

PHASE

AC

D

C

60

Hz

50

Hz

The Power To Perform!

With NEW patented Micro-Start II™ Technology and our New and Improved

AC Auto Balance

and welding at low amperages and improved AC aluminum welding performance. New features, simple controls, innovative accessory storage, and

attractive and consistent welds–it all adds up. Whatever the TIG welding

application–fabrication, aerospace, production, motorsports, or vocational

education–choose the Precision TIG

arc performance.

Processes

Stick, TIG

Advantage Lincoln

®

on board, the Precision TIG®275 delivers unrivaled starting

SM

®

275 for outstanding features and precise

TIG WELDERS

Output

Input

Precision Arc Performance:

• Patented Micro-Start II™ Technology delivers extremely stable low

amperage starting, welding and cratering for both AC and DC

welding.

• Selectable welding modes such as high frequency, scratch start, and

Touch Start TIG™.

• Higher duty cycles – 275A @ 40% duty cycle.

• Widest welding range in its class 2-340 amps for both AC and DC.

• Excellent stick welder – even with Fleetweld

Automatic Hot Start™ and Auto Adaptive Arc Force™ controls

®

5P (E6010) with new

(1)

.

Simple Controls – Easy to Use:

• Redesigned controls are simple and well spaced for effortless setting

changes.

• Hidden menu button features up to 7 programmable parameters

without cluttering the control panel

• NEW and Improved Auto Balance

(1)

.

®

has been readjusted to have more

penetration and improved bead appearance.

(1)

Requires optional Advanced Process Panel for full control availability.

TECHNICAL SPECIFICATIONS

Professional Features:

• The K2618-1 Ready-Pak

®

model Precision TIG®275

(208/230/460/1/60). Under-Cooler Cart Water Cooler, Foot Amptrol®,

Gas Regulator/Flowmeter & Hose Kit, PTW-20 Pro-Torch™ TIG Torch

(250 amp, 25 ft.), Zippered Torch Cover, Parts Kit, Water Hose (2

included) 15 ft., and 15 ft. 2/0 Work Cable and Clamp.

• 115 volt auxiliary power receptacles. Great for powering an optional

water cooler or power tools.

• Add an optional Under-Cooler Cart for extra storage and water-cooled

applications.

• Built-in storage compartment for torch consumables.

• Water-cooled torch connections with no adapters required – side

mounted, out of the way, and well protected.

• Neat/organized cable management with integrated torch holster.

Superb Quality:

• Fan-As-Needed™ (F.A.N.) prevents overheating. F.A.N. reduces power

consumption, noise, motor wear, and dust in the machine.

• CSA C/US certified.

• Three-Year Lincoln Warranty on parts and labor. Two-year extended

warranty available in the U.S.

Product Product Current/Voltage/Duty Cycle Input Current @ H x W x D Net Weight

Name Number Input Power (104°F, 40°C) Rated Output Output Range inches (mm) lbs (kg)

®

Precision TIG

Precision TIG

Ready-Pak

275 K2619-1 208/230/460/1/60 275A/31V/40% 80/72/36A with PFC DC: 2-340A 31 x 22 x 26 397

K2619-2 460/575/1/60 275A/31V/40% 35/28A with PFC

K2620-1 220-230/380-400/ 275A/31V/40% 80/46/43A with PFC

®

275 K2618-1 208/230/460/1/60 275A/31V/40% 80/72/36A with PFC 49.7 x 28 x 41 641

®

Package 104/94/47A w/o PFC (1262 x 711 x 1041) (291)

415/1/50/60 95/55/50A w/o PFC

Rated Output Dimensions

104/94/47A w/o PFC AC: 2-340A (787 x 559 x 660) (180)

Max. OCV: 75V

47/38A w/o PFC

Publication E3.42 11/07

www.lincolnelectric.com

A CLOSER LOOK

ARC PERFORMANCE

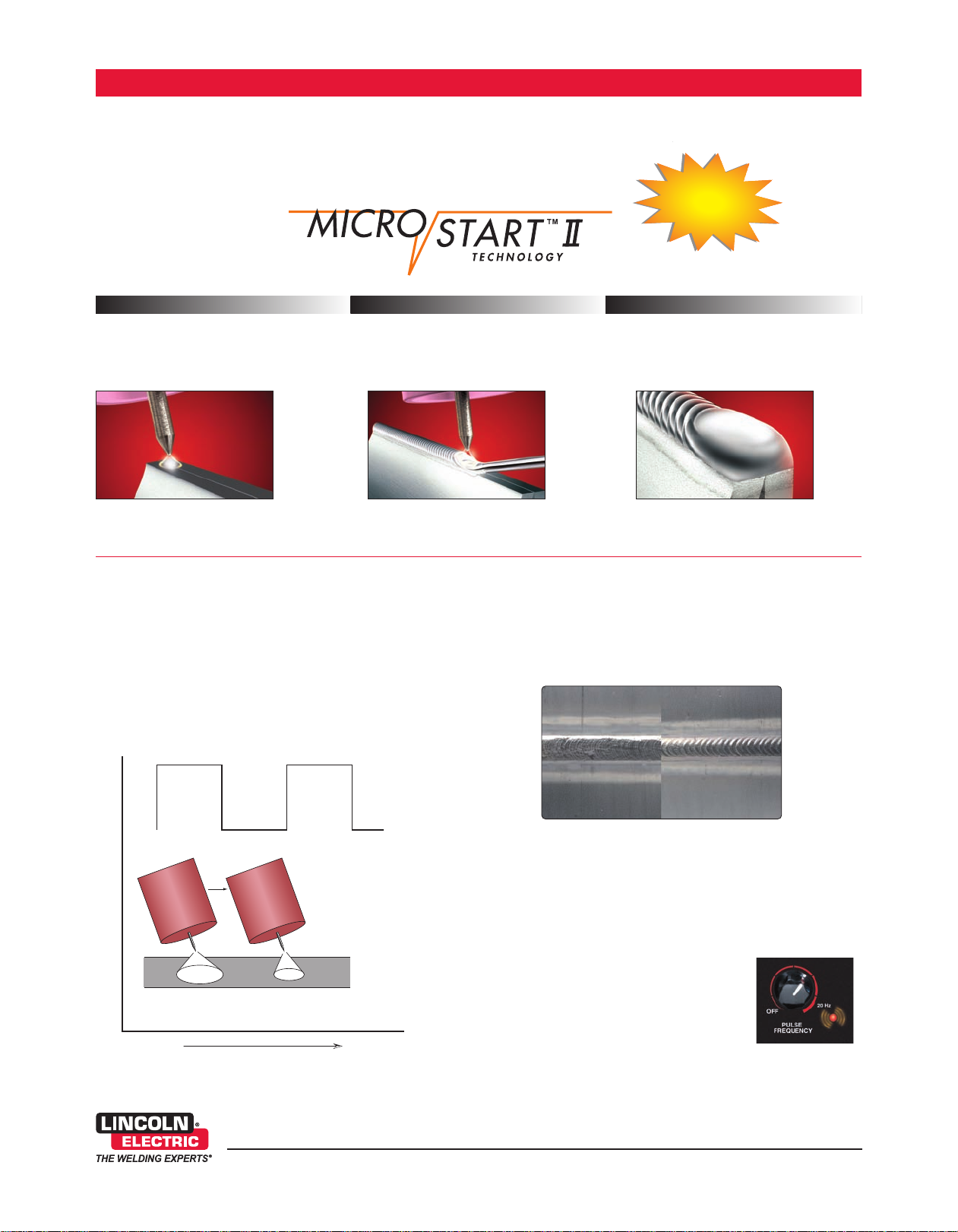

Micro-Start II™ Technology — More than just a starting aid.

Better control for starting, arc stability and crater fill.

Great Starting Stable, Focused Arc Precise Crater Fill

NOW

INCLUDES

AC

AC

forALUMINUM

WELDING

Micro-Start II™ Technology minimizes high

frequency and ‘hot starts’ to deliver soft arc starts

without arc wandering for AC and DC welding.

Micro-Start II™ Technology aids arc stability

THROUGHOUT THE WELD CYCLE –

even at the lowest amperage!

“Set It/See It” Pulse Control — Make attractive and consistent welds!

What Is It?

Pulse welding systems vary weld current between peak (high heat)

and background current (low heat) levels. Adjusting the pulse frequency controls the level of heat input applied to the weld relative

to the weld travel speed.

Results

Better control of heat input in the weld, resulting in:

• Reduced warping and burnthrough on thin materials.

• Smaller heat-affected zone – good for thin material.

• Smaller bead profile without compromising proper penetration.

PULSE FREQUENCY:

Number of Pulses Per Second

Peak

Micro-Start II™ Technology

controlled ramp down helps precisely fill

the weld crater for quality results.

Smaller Heat

Smaller Heat

Affected Zone

Affected Zone

Welding Current

Time

High Heat

(Peak)

Background

Low Heat

(Background)

Smaller Bead Profile

Smaller Bead Profile

Standard TIG Weld

(at 60 amps)

Pulsed TIG Weld

(at 60 amps)

Great For

• Thin materials – Faster pulse settings help to narrow the bead

profile and minimize the heat-affected zone and resulting warping

or burnthrough.

• Consistent appearance – Slower pulse settings aid in timing the

application of filler metal to produce the consistent stacked bead

appearance associated with high quality TIG

welding.

• Maintaining a steady welding rhythm.

Easy “Set It/See It” Operation:

• Flashing indicator light lets you see the

pulse rate before you strike an arc.

Precision TIG®275

[2]

www.lincolnelectric.com

A CLOSER LOOK

AC Auto Balance®Controls —

Automatically sets the optimal cleaning vs. penetration

level for aluminum welding!

What Is It?

When aluminum welding, the positive (+) portion of the AC welding

amperage cleans the oxides from the aluminum surface. The negative (-) portion delivers more heat input, increasing penetration

level.

Patented AC Auto Balance®automatically sets the ratio of

cleaning action (+) versus penetration (-) based on amperage.

Manual balance control provides the flexibility to customize

the arc to your preference.

More Cleaning (+)

TIME

Easy Operation:

• Set it and forget it or override when you choose to customize

the settings.

Maximum Cleaning Setting

Maximum Penetration

Setting

Auto Balance Setting

WELDING

AMPERAGE

Less Penetration(-)

Less Cleaning (+)

TIME

WELDING

AMPERAGE

More Penetration (-)

PERFORMANCE

• Excellent stick welding performance.

— Weld steel, stainless and low allow metals with ease.

— Weld sheet metal, pipe and heavy plate.

— Weld with Lincoln®Blue Max®Stainless, Excalibur®Low

Hydrogen and Fleetweld®5P welding electrodes.

• Wider output range — for maximum flexibility:

— 2-340A DC, 2-340 AC.

• More amperage than nearest competitor at 40% duty cycle — 25

amps more!

• Lower input current draw compared to nearest competitor — up to

10% less current with 40% more duty cycle.

[3]

AC Auto Balance®is especially useful on

critical aluminum applications.

Precision TIG®275

www.lincolnelectric.com

Loading...

Loading...