Page 1

POWER WAVE WELDING SYSTEMS

WITH POWER FEED 10 AND 10 DUAL

™

™

Premium MIG Welding Systems

Page 2

2

R

Simple. Innovative. Technologically

Advanced. These are all words that

describe the Power Wave welding

systems. These next generation

systems utilize Waveform Control

Technology™ for the finest welding

arc in the industry.

POWER SOURCE

The Power Wave 455 is a high

efficiency inverter designed for

unprecedented ease of use and

performance.

Sophisticated software in the unit

controls the welding waveform for

reduced arc spatter, fumes, and an

exceptionally smooth arc.

WIRE FEEDER

The Power Feed 10 and the Power

Feed 10 Dual set the standard for

easy to use, rugged wire feeders.

They are perfectly matched for use

with the Power Wave 455, resulting in

a simple, high performance welding

package that is built to last.

SYSTEM WIDE

• Power Wave welding performance

in a simple, easy to use system.

• Set-up flexibility with one control

cable that connects any combination

of equipment.

• Control cables can connect as

extension cords up to 200 feet.

• Can be easily upgraded from simple

to high capabilities.

• Flexible platform can be easily

changed from bench to boom, CV

to Pulse, etc.

• Spacious inverter design for easy

service.

• 3 year warranty on parts and labor.

• Manufactured under a quality

system certified to ISO9002

requirements.

CONTROLS

• All controls are located on the wire

feeder to eliminate confusion.

• Control box is removable for bench

or boom mounting.

• Two large displays and knobs for

gloved hands.

• Presettable wire feed speed or

amps, and voltage or trim. Actual

values displayed while welding, and

for 5 seconds after welding has

stopped.

• Capable of running from basic CV to

high performance pulse programs.

• English or metric display.

• Control upgrades in less than

5 minutes.

WIRE FEEDER

• Four driven rolls in a heavy duty

drive system. No tools needed for

wire size changeover.

• Split wire guide for trouble-free

loading and feeding. Perfect wire

alignment and support.

• Powerful drive motor for large wires

and high speeds in one model.

• Tachometer feedback for precise

wire feeding.

• Wire reel stand holds 10-60 lb. wire

packages on a 2” spindle. Bench

feeder mounts on power source.

Power Feed 10 may be used with or

without optional swivel platform.

ADVANTAGE

LINCOLN

The Power Feed 10 and the Power

Feed 10 Dual wire feeders feature

easy to understand controls and the

Lincoln four driven roll feed head.

These wire feeders have the strength

and speed for the most demanding

feeding applications, whether it’s for

high speed or for large diameter wires.

Choose Power Feed 10 Dual when

applications require two different wires

to be utilized with no changeover time.

POWER WAVE WELDING SYSTEMS

LISTED

U

L

R

170G

Page 3

TECHNICAL

SPECIFICATIONS

Rated DC Output

Input Amps at Rated DC Output

Product Ordering Input AC Amps/Volts/

208 230 380 415 460 575

Output Weight Dimensions

Name Information Voltage Duty Cycle Range (net) HxWxD

Power K1517-5 208/230/460 60 Hz: 5-570 247 lbs. 26 x 20 x 33 in.

Wave 3 Phase 450/38/100% 70 65 -- -- 35 -- Amps (112 kg) (660 x 508 x

455 50/60 Hz 570/40/60% 87 82 -- -- 48 -- 838 mm)

50 Hz:

400/38/100% 72 67 -- -- 36 --

500/43/60% 79 74 -- -- 41 --

K1517-2 460/575 450/38/100% -- -- -- -- 36 30 254 lbs.

3 Phase 570/43/60% -- -- -- -- 48 40 (115 kg)

60 Hz

K1517-3 380-415 CE 400/36/100% -- -- 36 33 -- -- 5-520 256 lbs.

3 Phase 500/40/60% -- -- 48 44 -- -- Amps (116 kg)

50 Hz

Wire Speed Wire Size Range Dimensions

Ordering Range in. (mm) Net H x W x D

Power Feed 10 Information IPM (m/min)

Solid Cored

Weight in. (mm)

(1)

Includes wire drive, control box, 8 ft. Linc-Net™ control

and weld cable, and wire reel stand.

(2)

Includes wire drive, control box, 8 ft. and 25 ft. Linc-Net

control cables.

(3)

Requires wire drive to control box Linc-Net cable:

For 8-9 ft. boom: K1543-16

For 10-18 ft. boom: K1543-25

(4) Boom ready wire feeder for installation on a Zipline boom. See

bulletin E8.201.

Control Box Only

(3)

K1539-2

12 ft. Zipline Ready Pkg.

(4)

K1538-5

16 ft. Zipline Ready Pkg.

(4)

K1538-6

Wire Drive Only

(3)

K1540-2

Power Feed 10 Dual

Low Speed Gear

50-800 ipm

(1.2 - 20.3 m/min)

High Speed Gear

75-1200 ipm

(1.9 - 30.5 m/min)

(Both gears

included)

Low Speed Gear

50-800 ipm

(1.2 - 20.3 m/min)

High Speed Gear

75-1200 ipm

(1.9 - 30.5 m/min)

(Both gears

included)

BOOM READY MODELS:

16-18 ft. Generic K1538-4

Boom Package

(2)

BENCH MODEL

(1)

K1541-2

.023-3/32 .035-1/8

(0.6-2.4) (0.9-3.0)

.023-1/16 .035-5/64

(0.6-1.6) (0.9-2.0)

.023-3/32 .035-1/8

(0.6-2.4) (0.9-3.0)

.023-1/16 .035-5/64

(0.6-1.6) (0.9-2.0)

62 lbs. 18.5 x 13.5 x 30.5

(1)

(28.1 kg) (470 x 343 x 775)

106 lbs. 20 x 23 x 34

(1)

(48 kg) (508 x 584 x 864)

8.5 lbs. 13 x 8.5 x 4

(3.8 kg) (330 x 216 x 102)

30 lbs. 7.6 x 12.9 x 13.7

(13.6 kg) (193 x 328 x 348)

Wire Drive Only

(3)

K1685-1

12 ft. Zipline Ready Pkg.

(4)

K1683-2

16 ft. Zipline Ready Pkg.

(4)

K1683-3

BOOM READY MODELS:

16-18 ft. Generic K1683-1

Boom Package

(2)

BENCH MODEL

(1)

K1686-1

54 lbs. 8.8 x 10 x 16.5

(24.5 kg) (222 x 254 x 419)

3

POWER SOURCE

WIRE FEEDER

Page 4

4

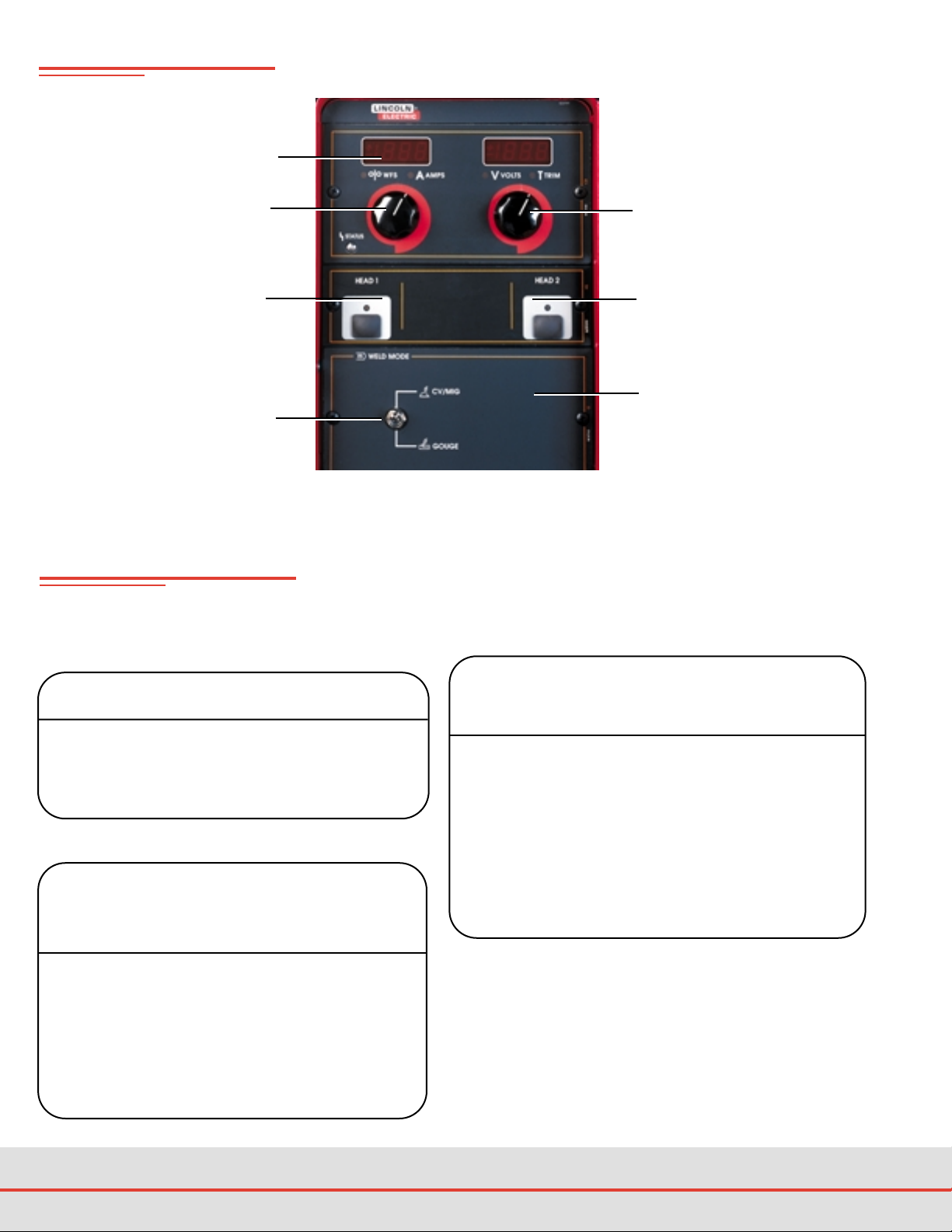

A CLOSER LOOK

Large, Easy To Read

Digital Meter

Large, Easy To Use

Voltage/ Trim

Control

Large, Easy To Use

Wire Feed Speed/

Control Amperage

Dual Head Select Panel

(Standard on Power Feed 10 Dual Models)

Optional Procedure Control

Panel Area

Optional Process Control

Panel Area

Weld Mode Selector Switch

(Standard on Power Feed 10 and 10 Dual)

Power Feed 10 Dual Control Box

Power Wave 455/Power Feed 10 - Industry Standard

This is the ideal system for MIG and flux-cored welding.

Power Wave 455 power source . . . . . .K1517-5

Power Feed 10 wire feeder. . . . . . . . . .K1541-2

.045 Drive Roll Kit . . . . . . . . . . . . . . . . .KP1505-045S

Magnum 400 Gun & Cable asbly . . . . .K471-21

(1)

Gas Regulator, Adjustable . . . . . . . . . .K586-1

Power Wave 455/Power Feed 10 - Deluxe Pulse

System

For the ultimate in pulsing performance, this system

provides the options and flexibility needed for multiple

processes and pulsing.

Power Wave 455 power source . . . . . .K1517-5

Power Feed 10 wire feeder . . . . . . . . . .K1541-2

Undercarriage . . . . . . . . . . . . . . . . . . .K1570-1

Dual Procedure/Memory Panel . . . . . . .K1542-9

MSP2 Pulse Panel . . . . . . . . . . . . . . . .K1542-12

Swivel Platform . . . . . . . . . . . . . . . . . . .K1557-1

.045 Drive Roll Kit . . . . . . . . . . . . . . . . .KP1505-045S

Magnum 400 Gun & Cable asbly . . . . .K471-21

(1)

Gas Regulator, Adjustable . . . . . . . . . .K586-1

SYSTEM

SELECTION

Power Wave 455/Power Feed 10 Dual - Deluxe Pulse

System

Power for those demanding jobs. A dual feeder for running

two different wires from the same power source.

Power Wave 455 power source . . . . . . . . .K1517-5

Power Feed 10 Dual wire feeder . . . . . . . . .K1686-1

Undercarriage . . . . . . . . . . . . . . . . . . . . . . .K1570-1

MSP2 Pulse Panel . . . . . . . . . . . . . . . . . . .K1542-12

.045 Drive Roll Kit . . . . . . . . . . . . . . . . . . . .KP1505-045S

1/16” Cored Drive Roll Kit . . . . . . . . . . . . . .KP1505-1/16C

Magnum 400 Gun & Cable asbly . . . . . . . .K471-21

(1)

Magnum 550 Gun & Cable asbly . . . . . . . .K598-7

Gun Receiver Bushing for Magnum 550 . . .K1500-3

Gun Connector Kit for Magnum 550 . . . . . .K613-7

Gas Regulator, Adjustable . . . . . . . . . . . . . .K586-1

(2)

Typical MIG welding systems.

(1)

Fully assembled, no gun connector required.

(2)

Two required.

Page 5

5

OPTIONAL

CONTROL PANELS

DUAL PROCEDURE PANEL

This panel stores two procedures in memory. The user may

select procedure “A” or “B” at the switch with a separate gun

mounted switch, or while welding with any welding gun.

Order K1542-5.

DUAL PROCEDURE / MEMORY

Six different welding procedures and processes may be stored

for recall. Includes Dual Procedure. Memories 2-6 may be

accessed with an “open air” trigger pull using any welding gun.

Order K1542-9.

DUAL PROCEDURE / MEMORY

Four welding procedures and processes may be stored for

recall. Includes Dual Procedure for each wire drive. Gun 1 and

2 have 2 procedures each, and each have access to 4 more

from memory.

Order K1542-13.

DUAL HEAD SELECT PANEL

Allows control box (K1539-2) to control two separate wire

drives (K1540-2). Comes standard with Power Feed 10 Dual .

Optional on Power Feed 10.

Order K1542-14

PROCEDURE CONTROL PANELS

POWER FEED 10

POWER FEED 10 DUAL

Page 6

6

M PANEL

This optional control panel allows the user to select the type of

output desired: CV-MIG/CV Gas-Shielded, Flux-Cored

(Outershield,Metal-Cored), Flux-Cored (Innershield), or CCStick (Soft)/Gouge. The “Arc Control “ varies inductance in the

CV modes and arc force in the CC-Stick mode.

Order K1542-6.

MSP2 PANEL

This optional control panel has the complete setup selections

of the MX panel. This panel also adds synergic CV and pulse

welding programs. Required to use Wave Designer software.

Order K1542-12.

MX2 PANEL

This optional control panel adds CC-Stick (crisp) mode and a

flexible welding setup.

Shielding gas preflow: 0.1 to 2.5 seconds or OFF.

Run-in wire feed speed: Adjustable for optimum start 75 to 150

inches per minute or OFF.

Arc Control: Inductance control adjusts arc characteristics to

operators preference.

Burnback: Time the arc stays on after the wire feed stops. 0.1

to 0.25 seconds or OFF.

Post Flow: Time the shielding gas flows after the weld stops.

0.1 to 10.0 seconds or OFF.

Crater Fill: Allows a second procedure used in the 4-step

trigger mode. Use for aluminum crater fill welding or a

second procedure.

Order K1542-11.

OPTIONAL

CONTROL PANELS

PROCESS CONTROL PANELS

POWER FEED 10 & 10 DUAL

Page 7

NEW WIRE DRIVE

ADVANTAGES

• Four gear driven rolls. No tools

needed to snap rolls on or off. Each

roll has two grooves of the same

size to double feed life.

• Revolutionary Split Wire Guide

precisely aligns and supports wire

through the entire system.

Maximizes support and minimizes

problems.

• Two piece split wire guide construction provides easy access for

inspection, cleaning or changing to

different wire sizes.

• User can change external speed

range gear quickly. Feeder can be

low speed/high torque or high

speed.

• Entire feed head can be removed

for fast, easy servicing. Ideal for

production shops where downtime

must be minimized.

• Simple, symmetric design of feed

heads allows for quick removal and

replacement.

• Feed head assembly can rotate to

minimize gun cable kinks and

bends. Reduces gun stresses and

improves feedability.

• Incoming bushings are available to

accept guide bushings and conduits

often used with larger pay-off wire

packages.

• Simple wire drive roll pressure

adjustment knob with indicator bar.

• Rugged electrically insulated door

protects drive system with simple

positive locking.

• Gun receiver bushing provides low

cost adapters for Magnum or competitive guns, along with easy interchangeability, better mechanical

support and reliable electrical

current transfer.

Entire wire path

is visible for

easy access.

Drive rolls flip up

for easy access.

Removable

outer wire guide

for easy access

to wire.

Changeable

external gear for

quick speed

range change.

7

Page 8

MAGNUM GUNS

The following guns come pre-assembled

with liner and gun connector that is

compatible with the Tweco #2-#4 gun

receiver bushing (K1500-2). They connect directly to the standard Power Feed

10 and 10 Dual. Gun cables are 15 ft.

length:

K471-21 Magnum 400 .035-.045

K471-22 Magnum 400 .052-1/16”

K471-23 Magnum 400 1/16-5/64”

K497-20 Magnum 200 .025-.030

K497-21 Magnum 200 .035-.045

FEED PLATE GUN

RECEIVER BUSHINGS

One of the following Gun Receiver

Bushings is required for connecting

gun and cable assemblies to the

feed plate.

Feed Plate Gun Receiver

Bushing K1500-X.

K1500-2 comes standard with

feed head (as shown).

Connector Kit for

Magnum Guns

(K466-10 or K613-7)

K1500-3

K1500-4K1500-2K1500-1

K1500-1 Gun Receiver

Bushing (Optional)

• Magnum 200, 300 and 400

gun and cable assemblies

with K466-1 connector kit.

• Lincoln Innershield

®

gun and

cable assembly.

• Fast-Mate

™

gun and cable

assembly with K489-2

Fast-Mate Adapter Kit.

• Magnum 550 gun and cable

assembly with K613-1.

K1500-2 Gun Receiver

Bushing

(1)

(Standard)

• Magnum 200 and 400 fully

assembled guns (K497-2X

and K471-2X). See below.

• Magnum 200, 300 and 400

gun and cable assemblies

with K466-10 connector kit.

• Guns with Tweco

®

#2, #3

and #4 connectors.

(1)

This gun receiver bushing

comes standard with each

feed head.

K1500-3 Gun Receiver

Bushing (Optional)

• Magnum 550 gun and cable

assembly with K613-7

connection.

• Guns with Tweco #5

connectors.

K1500-4 Gun Receiver

Bushing (Optional)

• Magnum 200, 300 and 400

gun and cable assemblies

with K466-3 connector kit.

• Guns with Miller

®

connectors

(for new, longer connectors).

K489-7 Fast Mate Gun

Receiver Bushing

• Magnum gun and cable

assemblies with Fast Mate

connectors.

K489-7

8

Page 9

4 Roll, and Split Wire Guide

Solid Steel Wire, Smooth V Groove

.023-.030 (0.6-0.8mm) Solid KP1505-030S

.035 (0.9mm) Solid KP1505-035S

.040-.045 (1.0-1.2mm) Solid KP1505-045S

.052 (1.4mm) Solid KP1505-052S

1/16” (1.6mm) Solid KP1505-1/16S

Cored Steel Wire, Knurled V Groove

.030-.035 (0.8-0.9mm) Cored KP1505-035C

.040-.045 (1.0-1.2mm) Cored KP1505-045C

.052 (1.4mm) Cored KP1505-052C

1/16” (1.6mm) Cored KP1505-1/16C

7/64” (2.8mm) Hardfacing (Smooth U Groove) KP1505-7/64H

Cored or Solid Steel Wire, Knurled V Groove

.068-.072 (1.8mm) KP1505-068

5/64” (2.0mm) KP1505-5/64

3/32” (2.4mm) KP1505-3/32

7/64” (2.8mm) cored only KP1505-7/64

.120-1/8” (3.2mm) cored only KP1505-120

Aluminum Wire, Smooth U Groove

.035 (0.9mm) KP1507-035A

.040 (1.0mm) KP1507-040A

3/64” (1.2mm) KP1507-3/64A

1/16” (1.6mm) KP1507-1/16A

3/32” (2.4mm) KP1507-3/32A

DRIVE ROLLS AND

SPLIT WIRE GUIDE KITS

KP1505

KP1507

For Aluminum Wires For Solid and Cored Wires

9

Page 10

10

RECOMMENDED

OPTIONS

SPINDLE ADAPTER

For 14 lb. (6 kg) Innershield Coils

Permits 14 lb. (6 kg) Innershield

electrode coils to be mounted on 2”

(51mm) O.D. spindles. Order K435.

COIL ADAPTER

60 lb. Coil Adapter

Adapts 60 lb. Lincoln coils of

electrode to 2” (51mm) spindle.

Order K1504-1.

K363P

K1504-1

Water Connection Kit

Includes quick connect fittings on

front and back of wire drive for use

with water-cooled guns and Magnum

Coolers. Kit provides for one gun.

Order K590-6.

Swivel Platform

Mounts to the lift bail on the power

source and bottom of the Power

Feed 10. Wire feeder may be lifted off

if needed. Compatible with Light Duty

Caster Kit. Includes “lazy susan” parts

tray. Order K1557-1. (Power Feed

10 only.)

Plastic Wire Cover

Protects wire from dust and dirt and

provides electrical isolation.

For up to 44 lb. wire packages,

Order K1634-1.

For up to 60 lb. wire packages,

Order K1634-2.

K1557-1

K438

These come standard with both

bench and boom versions of the

Power Feed 10 and Power Feed 10

Dual wire feeders. The Linc-Net control cable has several advantages over

existing control cables:

• Common cable for all parts - The

same cable can be used between

the power source and wire feeder in

a bench system and between the

power source, control box and wire

drive in a boom system.

LINC-NET

CONTROL CABLES

• Extension cord flexibility - These

control cables can be connected

end-to-end for length flexibility. A

single, custom length cable is no

longer needed.

• Extended lengths - These cables

can be connected up to 200 ft.

between any 2 components. This

allows more flexibility in locating the

power source and wire feeder.

Ordering Information:

Linc-Net Receptacles

Provides Linc-Net receptacles for

converting a Power Feed 10 bench

model to a boom model.

Order K1548-1.

Control Cable Only

K1543-8 8 ft. cable length

K1543-16 16 ft. cable length

K1543-25 25 ft. cable length

K1543-50 50 ft. cable length

K1543-100 100 ft. cable length

Control and Weld Cables (4/0 size)

K1544-8 8 ft. cable length

K1544-16 16 ft. cable length

K1544-25 25 ft. cable length

K1544-50 50 ft. cable length

TM

60 lb. (27.2 kg) Adapter

Adapts 50-60 lb. (22.7-27.2 kg)

Lincoln Readi-Reel coils of electrode

to 2” (51mm) spindle. Order K438.

READI-REEL ADAPTERS

30 lb. (14 kg) Readi-Reel Adapter

Adapts 22-30 lb. (10-14 kg) Lincoln

Readi-Reel coils of electrode to 2”

(51mm) spindle. Order K363P.

Page 11

Caster Kit - Light Duty

Mounts to the wire reel stand on the

Power Feed 10 and Power Feed 10

Dual. Allows for easy movement of

wire feeder. Order K1556-1.

Insulated Lift Bail

Allows the entire wire

feeder to be hung from

a crane or hook.

Order K1555-1.

(Power Feed

10 only.)

Undercarriage

Includes mounting frame, front casters, rear wheels and handle for hand

towing. Order K163.

Feed Plate Incoming Bushing

Connects directly to Magnum plastic

conduit (not included), for use in boom

systems, long distances, or large payoff packages.

For .025-1/16” wire, Order K1546-1.

For 1/16-1/8” wire, Order K1546-2.

K1546-1

K683-3

11

RECOMMENDED

OPTIONS

Undercarriage

Platform undercarriage for mounting

two gas cylinders at rear of welder.

Order K1570-1.

Wire Straightener

For use with 10-Series wire drives or

separately mounted. Straightens

cored wire up to 1/8” (3.2mm) and

solid wire up to 3/32” (2.4mm).

Incoming and outgoing bushings are

compatible with existing incoming and

gun receiver bushings.

Order K1733-1.

Dual Procedure Switch

Allows the use of two welding procedures with one Lincoln Magnum gun.

15 ft. (7.6m). Must be used with

optional Dual Procedure Panel or Dual

Procedure with Memory Panel.

Order K683-3.

Gas Guard Regulator

For CO2and Argon blend gases.

Reduces surge caused by excess

pressure in supply hose. Includes

adjustable flow regulator with removable adjustor key. Used with standard

regulator. Kit provides for one gun.

Order K659-1.

K1556-1

K1733-1

Page 12

THE

LINCOLN ELECTRIC

COMPANY

Local Sales and Service through Global

Subsidiaries and Distributors

Cleveland, Ohio 44117-1199 U.S.A

TEL: 216.481.8100

FAX: 216.486.1751

WEB SITE: www.lincolnelectric.com

CC/CV Welders

E5.160 12/99

DISTRIBUTED BY:

SOFTWARE

Wave Designer Software

Wave Designer software allows you to

program your own waveforms. It puts

the power of waveform control in your

hands, allowing you to customize

Lincoln’s highly successful welding

waveforms to meet your exact needs.

Once you have made the simple

connection from your PC to your

Power Wave 455, designing a waveform is easy.

Two software packages are available:

Wave Designer Software

Permits manipulation of several wave

shape parameters including peak

current, background current, peak

pulse width and pulse. Allows for

optimization of arc length.

Order K1705-1.

Wave Designer Pro Software

All the features of Wave Designer, plus

Arc Scope™, the arc analysis tool for

those who need to monitor more than

voltage and current. Arc Scope also

tracks arc power, arc resistance and

energy input. Order K1705-2.

For more information, request

literature S2.20.

Customer Assistance Policy

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment.

Our challenge is to meet the needs of our customers and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric for

advice or information about their use of our products. We respond to our customers based on the best information in our possession at that time.

Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or advice. We

expressly disclaim any warranty of any kind, including any warranty of fitness for any customer’s particular purpose, with respect to such information or advice. As a matter of practical consideration, we also cannot assume any responsibility for updating or correcting any such information or

advice once it has been given, nor does the provision of information or advice create, expand or alter any warranty with respect to the sale of our

products.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of,

and remains the sole responsibility of the customer. Many variables beyond the control of Lincoln Electric affect the results obtained in applying

this type of fabrication methods and service requirements.

Loading...

Loading...