Lincoln Electric POWER WAVE C300 CE Operator's Manual

IM2033

04/2010

Rev. 0

POWER WAVE C300 CE

OPERATOR’S MANUAL

ENGLISH

THE LINCOLN ELECTRIC COMPANY

22801 St. Clair Ave., Cleveland Ohio 44117-1199 USA

www.lincolnelectric.eu

English English

I

THE LINCOLN ELECTRIC COMPANY

EC DECLARATION OF CONFORMITY

Manufacturer and technical

documentation holder:

The Lincoln Electric Company

Address:

22801 St. Clair Ave.

Cleveland Ohio 44117-1199 USA

EC Company:

Lincoln Electric Europe S.L.

Address:

c/o Balmes, 89 - 80 2a

08008 Barcelona SPAIN

Hereby declare that welding equipment: Power Wave C300 CE, including options and accessories

Sales code:

K2865, code may also contain prefixes and suffixes

Is in conformity with Council Directives

and amendments:

EMC Directive 2004/108/EC

Low Voltage Directive 2006/95/EC

Standards: EN 60974-1, Arc Welding Equipment – Part 1: Welding Power

Sources, 2005

EN 60974-10 Arc Welding Equipment – Part 10: Electromagnetic

compatibility (EMC) requirements, 2003

Frank Stupczy,

Manufacturer

Dario Gatti,

European Community Representative

Compliance Engineering Manager European Engineering Director Machines

18 March 2010 19 March 2010

MCD234

English English

II

12/05

THANKS!

For having choosen the QUALITY of the Lincoln Electric products.

• Please Examine Package and Equipment for Damage. Claims for material damaged in shipment must be notified

immediately to the dealer.

• For future reference record in the table below your equipment identification information. Model Name, Code &

Serial Number can be found on the machine rating plate.

Model Name:

………………...…………………………….…………………………………………………………………………………………..

Code & Serial number:

………………….………………………………………………..

…………………………………………………….……………..

Date & Where Purchased:

…………………………………………………………………...

……………………….…………………………………………..

ENGLISH INDEX

Safety .............................................................................................................................................................................. 1

Installation and Operator Instructions .............................................................................................................................. 2

Electromagnetic Compatibility (EMC) ............................................................................................................................ 13

Technical Specifications .................................................................................................................................................. 1

WEEE .............................................................................................................................................................................. 1

Spare Parts ...................................................................................................................................................................... 2

Electrical Schematic ........................................................................................................................................................ 2

Accessories ..................................................................................................................................................................... 2

English English

1

Safety

11/04

WARNING

This equipment must be used by qualified personnel. Be sure that all installation, operation, maintenance and repair

procedures are performed only by qualified person. Read and understand this manual before operating this equipment.

Failure to follow the instructions in this manual could cause serious personal injury, loss of life, or damage to this

equipment. Read and understand the following explanations of the warning symbols. Lincoln Electric is not responsible

for damages caused by improper installation, improper care or abnormal operation.

WARNING: This symbol indicates that instructions must be followed to avoid serious personal injury,

loss of life, or damage to this equipment. Protect yourself and others from possible serious injury or

death.

READ AND UNDERSTAND INSTRUCTIONS: Read and understand this manual before operating

this equipment. Arc welding can be hazardous. Failure to follow the instructions in this manual could

cause serious personal injury, loss of life, or damage to this equipment.

ELECTRIC SHOCK CAN KILL: Welding equipment generates high voltages. Do not touch the

electrode, work clamp, or connected work pieces when this equipment is on. Insulate yourself from

the electrode, work clamp, and connected work pieces.

ELECTRICALLY POWERED EQUIPMENT: Turn off input power using the disconnect switch at the

fuse box before working on this equipment. Ground this equipment in accordance with local electrical

regulations.

ELECTRICALLY POWERED EQUIPMENT: Regularly inspect the input, electrode, and work clamp

cables. If any insulation damage exists replace the cable immediately. Do not place the electrode

holder directly on the welding table or any other surface in contact with the work clamp to avoid the

risk of accidental arc ignition.

ELECTRIC AND MAGNETIC FIELDS MAY BE DANGEROUS: Electric current flowing through any

conductor creates electric and magnetic fields (EMF). EMF fields may interfere with some

pacemakers, and welders having a pacemaker shall consult their physician before operating this

equipment.

CE COMPLIANCE: This equipment complies with the European Community Directives.

FUMES AND GASES CAN BE DANGEROUS: Welding may produce fumes and gases hazardous to

health. Avoid breathing these fumes and gases. To avoid these dangers the operator must use

enough ventilation or exhaust to keep fumes and gases away from the breathing zone.

ARC RAYS CAN BURN: Use a shield with the proper filter and cover plates to protect your eyes from

sparks and the rays of the arc when welding or observing. Use suitable clothing made from durable

flame-resistant material to protect you skin and that of your helpers. Protect other nearby personnel

with suitable, non-flammable screening and warn them not to watch the arc nor expose themselves to

the arc.

WELDING SPARKS CAN CAUSE FIRE OR EXPLOSION: Remove fire hazards from the welding

area and have a fire extinguisher readily available. Welding sparks and hot materials from the welding

process can easily go through small cracks and openings to adjacent areas. Do not weld on any

tanks, drums, containers, or material until the proper steps have been taken to insure that no

flammable or toxic vapors will be present. Never operate this equipment when flammable gases,

vapors or liquid combustibles are present.

WELDED MATERIALS CAN BURN: Welding generates a large amount of heat. Hot surfaces and

materials in work area can cause serious burns. Use gloves and pliers when touching or moving

materials in the work area.

SAFETY MARK: This equipment is suitable for supplying power for welding operations carried out in

an environment with increased hazard of electric shock.

English English

2

CYLINDER MAY EXPLODE IF DAMAGED: Use only compressed gas cylinders containing the

correct shielding gas for the process used and properly operating regulators designed for the gas and

pressure used. Always keep cylinders in an upright position securely chained to a fixed support. Do

not move or transport gas cylinders with the protection cap removed. Do not allow the electrode,

electrode holder, work clamp or any other electrically live part to touch a gas cylinder. Gas cylinders

must be located away from areas where they may be subjected to physical damage or the welding

process including sparks and heat sources.

NOISE APPEARES DURING WELDING CAN BE HARMFUL: Welding arc can cause noise with high

level of 85dB for 8-hour week day. Welders operating welding machines are obligated to wear the

proper ear protectors /appendix No. 2 for the Decree of the Secretary of Labor and Social Policy from

17.06 1998 – Dz.U. No. 79 pos. 513/. According to the Decree the Secretary of Health and Social

Welfare from 09.07.1996 /Dz.U. No. 68 pos. 194/, employers are obligated to carry examinations and

measurements of health harmful factors.

MOVING PARTS ARE DANGEROUS: There are moving mechanical parts in this machine, which

can cause serious injury. Keep your hands, body and clothing away from those parts during machine

starting, operating and servicing.

Installation and Operator Instructions

Read this entire section before installation or operation

of the machine.

Location and Environment

THE POWER WAVE® C300CE will operate in harsh

environments. Even so, it is important that simple

preventative measures are followed in order to assure

long life and reliable operation.

• The machine must be located where there is free

circulation of clean air such that air movement in the

back, out the sides and bottom will not be restricted.

• Dirt and dust that can be drawn into the machine

should be kept to a minimum. The use of air filters

on the air intake is not recommended because

normal air flow may be restricted. Failure to

observe these precautions can result in excessive

operating temperatures and nuisance shutdown.

• Keep machine dry. Shelter from rain and snow. Do

not place on wet ground or in puddles.

• Do not mount the POWER WAVE® C300 CE over

combustible surfaces. Where there is a combustible

surface directly under stationary or fixed electrical

equipment, that surface shall be covered with a

steel plate at least 1.6mm thick, which shall extend

not less than 150mm beyond the equipment on all

sides.

Lifting

WARNING

FALLING EQUIPMENT can cause injury.

Lift only with equipment of adequate lifting capacity.

• Be sure machine is stable when lifting.

• Do not operate machine while suspended when

lifting.

Both handles should be used when lifting POWER

WAVE® C300 CE. When using a crane or overhead

device a lifting strap should be connected to both

handles. Do not attempt to lift the POWER WAVE

®

C300 CE with accessories attached to it.

Stacking

The POWER WAVE® C300 CE cannot be stacked.

Tilting

Place the machine directly on a secure, level surface or

on a recommended undercarriage. The machine may

topple over if this procedure is not followed.

Duty Cycle and Overheating

The POWER WAVE® C300 CE is rated at 250A - 26.5V

@ 100% duty cycle. It is further rated to provide 300A –

29V @ 40% duty cycle.

The duty cycle is based on a ten-minute period. A 40%

duty cycle represents 6 minutes of welding and 4

minutes of idling in a 10-minute period.

Example: 40% Duty Cycle:

Welding for 4 minutes. Break for 6 minutes.

Minutes or decrease

Duty Cycle

Preparation for Work

Input and Ground Connections

WARNING

Only a qualified electrician should connect the input

leads to the POWER WAVE® C300 CE. Connections

should be made in accordance with all local and national

electrical codes and the connection diagram located on

the inside of the reconnect access door of the machine.

Failure to do so may result in bodily injury or death.

Machine Grounding

The frame of the welder must be grounded. A ground

terminal marked with a ground symbol is located next to

the input power connection block. See your local and

English English

3

national electrical codes for proper grounding methods.

High Frequency Protection

The EMC classification of the POWER WAVE® C300 CE

is Industrial, Scientific and Medical (ISM) group 2, class

A. The POWER WAVE® C300 CE is for industrial use

only (see Electromagnetic Compatibility EMC Safety

Section).

Locate the POWER WAVE® C300 CE away from radio

controlled machinery. The normal operation of the

POWER WAVE® C300 CE may adversely affect the

operation of RF controlled equipment, which may result

in bodily injury or damage to the equipment.

Input Connection

• 4.6m power cord is provided and wired into the

machine.

• Single Phase Input - Not supported.

• Three Phase Input - Connect green/yellow lead to

ground per National Electric Code. Connect grey,

brown and black leads to power.

• The POWER WAVE® C300 CE automatically

adjusts to work with different input voltages. No

reconnect switches settings are required.

WARNING

The POWER WAVE® C300 CE ON/OFF switch is not

intended as a service disconnect for this equipment.

Power Cord Replacement

If the input power cord is damaged or needs to be

replaced an input power connection block is located in

the access panel under the wire spool.

WARNING

ALWAYS CONNECT THE POWER WAVE

GROUNDING LUG (LOCATED INSIDE THE ACCESS

PANEL) TO A PROPER SAFETY (EARTH) GROUND.

Shielding Gas Connection

Customer must provide a cylinder of shielding gas, a

pressure regulator, any flow control valve.

Connect a supply hose from the gas cylinder flow valve

outlet to the 5/8-18 female inert gas fitting on the back

panel of the POWER WAVE® C300 CE.

• MAXIMUM INLET PRESSURE IS 6.9 BAR.

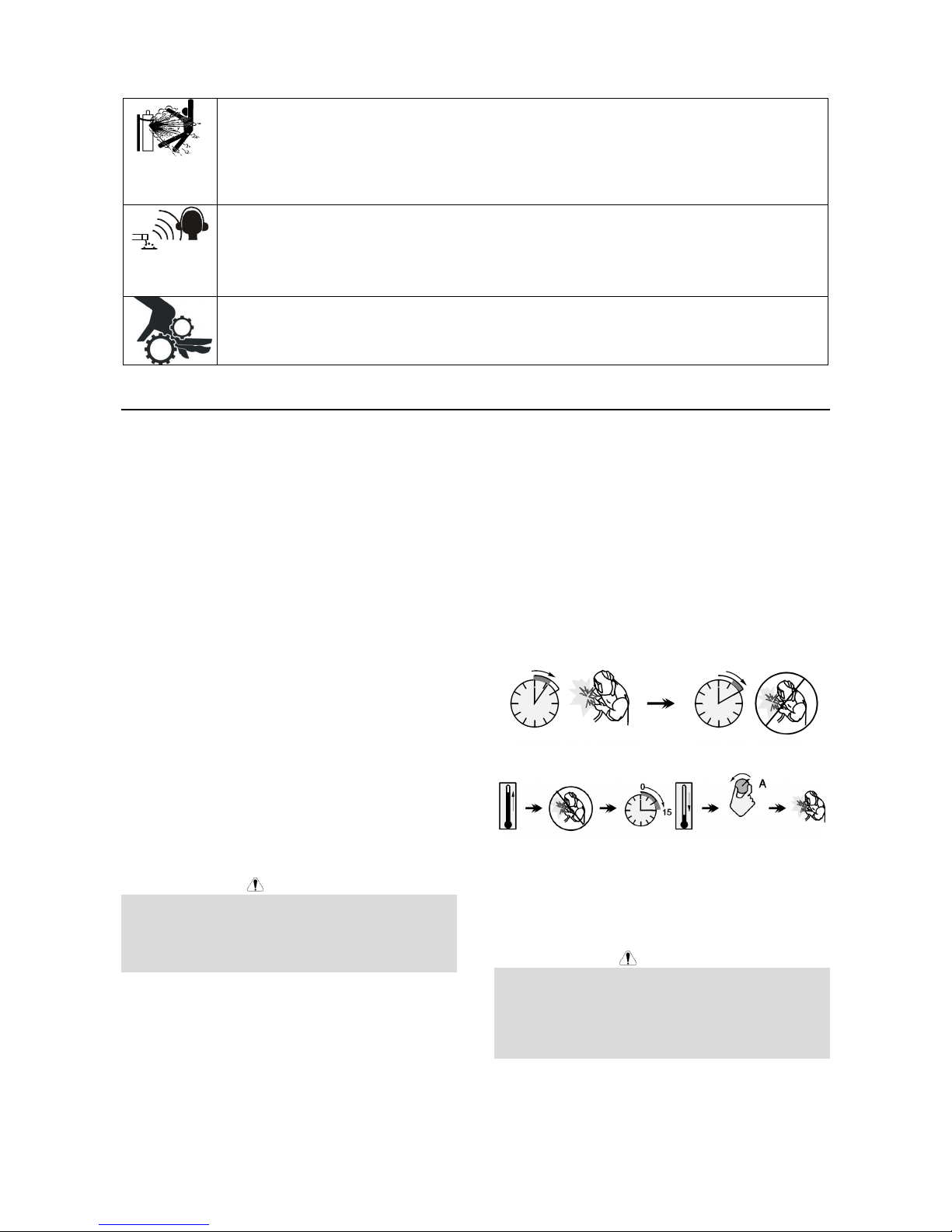

Procedure to Install Drive Rolls and Wire

Guides

1. Turn power off at the welding power source.

2. Release the idle roll pressure arm.

3. Remove the outer wire guide by turning the knurled

thumbscrews counter-clockwise to unscrew them

from the feed plate.

4. Rotate the triangular lock and remove the drive rolls

(See Figure 1).

Unlocked position Locked position

Figure 1

5. Remove the inner wire guide.

6. Insert the new inner wire guide, groove side out,

over the two locating pins in the feed plate.

7. Install a drive roll on each hub assembly secure with

the triangular lock.

8. Install the outer wire guide by aligning it with the

pins and tightening the knurled thumbscrews.

9. Close the idle arm and engage the idle roll pressure

arm. Adjust the pressure appropriately.

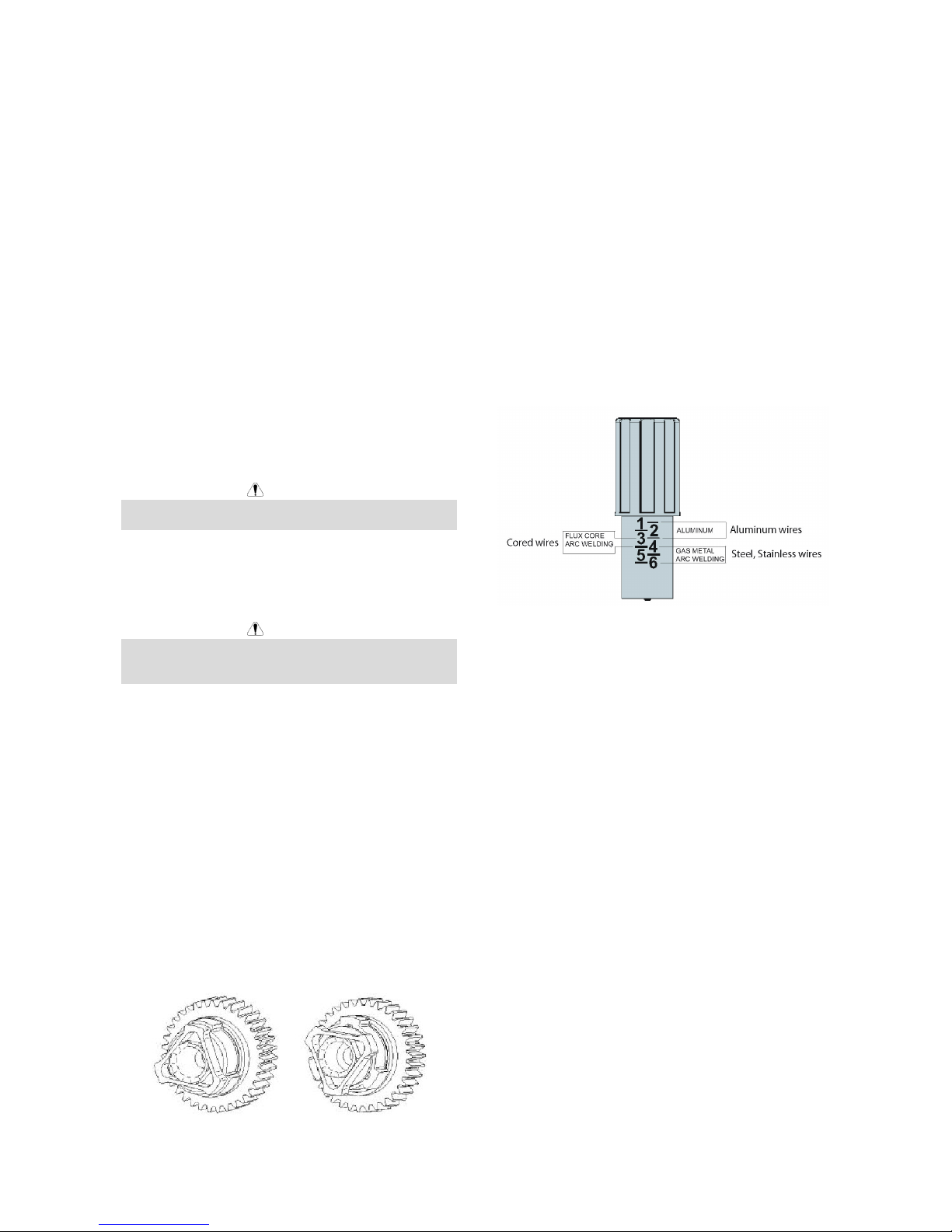

Pressure Arm Adjustment

The pressure arm controls the amount of force the drive

rolls exert on the wire. Proper adjustment of the

pressure arm gives the best welding performance.

Set the pressure arm as follows (see Fig A.3):

• Aluminum wires: between 1 and 3

• Cored wires: between 3 and 4

• Steel, Stainless wires: between 4 and 6

Figure 2

Operation – General

Power-up Sequence

When the POWER WAVE® C300 CE is powered it can

take as long as 30 seconds for the machine to be ready

to weld. During this time period the user interface will

not be active.

Product Description

The POWER WAVE® C300 CE is a high performance

multi-process machine with GMAW, FCAW, SMAW, DC

TIG, and pulse capability. It will offer a premier welding

performance solution for specific areas such as

aluminum, stainless, nickel where size and weight are an

issue.

The POWER WAVE® C300 CE will provide the

following:

• Power - 300A @ 40%, 250A @ 100%.

• Multi Input Voltage with no reconnect - 208-575V,

50-60 Hz input, 3Phase Power.

• < 95% Power factor – optimizes available electrical

capacity.

• Environmentally Hardened - IP23 rated for operating

in difficult environments.

• Ethernet connectivity – allows access to the Power

Wave utilities software tools.

• Line Voltage Compensation.

• ArcLink

®

platform.

• Electronic over current protection.

• Input over voltage protection.

• F.A.N. (fan as needed). Cooling fan runs when the

English English

4

output is energized 15 seconds following the strike

of the welding arc and will continue to run 5 minutes

following the end of the weld.

The following capabilities are supported:

• Push-pull (12-pin) connection - Panther™ and

Cougar™.

• Remote foot pedal or hand amptrol.

• Standard MIG gun trigger connection.

• Watercooler CoolArc 50.

WARNING

The POWER WAVE® C300 CE is not recommended for

pipe thawing.

Equipment Limitations

• Maximum spool size is 305mm diameter.

• Maximum spool weight is 20kg.

• Wire welding processes are limited to positive

polarity only.

• Does not operate on single phase power.

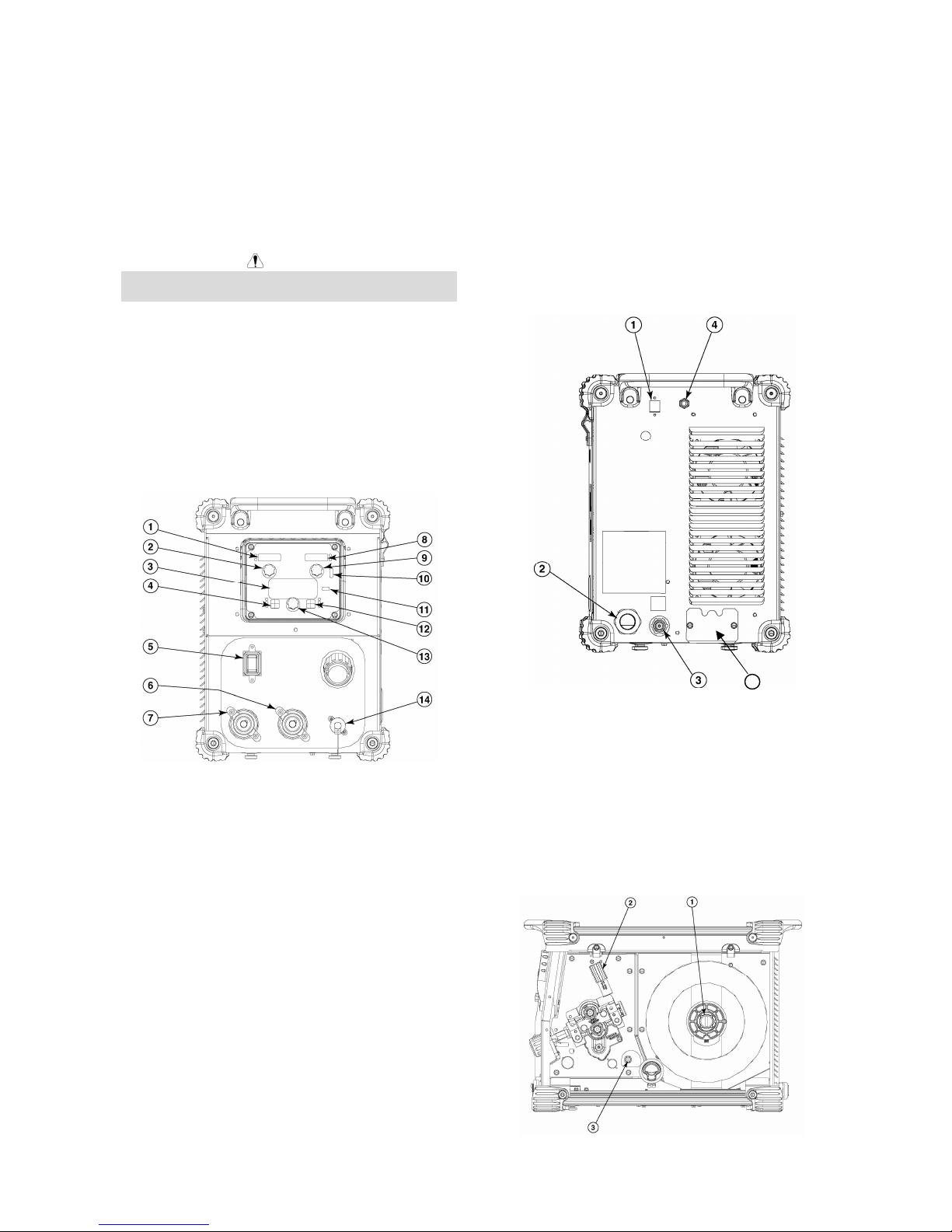

Case Front Controls

All operator controls and adjustments are located on the

case front of the Power Wave.

Figure 3

1. Left Display - Shows wire feed speed or amperage.

2. Left Knob - Adjusts value in left display.

3. Main Display - Shows detailed welding and

diagnostic information.

4. Left Button - Changes the Main display to show the

Weld Mode, Inductance or UltimArc™ Control or

Memories.

5. On/Off Switch - Controls power to the Power Wave

C300CE.

6. “+” Output Stud - Connection for electrode

positive.

7. “-” Output Stud - Connection for electrode

negative.

8. Right Display - Shows voltage or trim.

9. Right Knob - Adjusts value in right display.

10. Thermal Light - Indicates when machine has

thermal fault.

11. Set-Up - Lights when machine is in set-up mode.

12. Right Button - Changes the Main display to arc

start, arc end and trigger options.

13. MAIN KNOB - Changes the values on the Main

display.

14. 12-pin Connector - Connection for cross switch

gun, push pull guns, remotes.

Case Back Controls

Figure 4

1. Ethernet Connector

2. Power Cord

3. Gas Connection

4. Circuit Breaker

5. Cooler connections

Internal Controls

English English

5

Figure 5

1. Spindle Brake

2. Wire Drive Pressure Arm

3. Cold Inch / Gas Purge Switch

Definition of Welding Modes

Non-Synergic Welding Modes

• A Non-synergic welding mode requires all welding

process variables to be set by the operator.

Synergic Welding Modes

• A Synergic welding mode offers the simplicity of

single knob control. The machine will select the

correct voltage and amperage based on the wire

feed speed (WFS) set by the operator.

Basic Welding Controls Weld Mode

Selecting a weld mode determines the output

characteristics of the Power Wave power source. Weld

modes are developed with a specific electrode material,

electrode size, and shielding gas. For a more complete

description of the weld modes programmed into the

Power Wave at the factory, refer to the Weld Set

Reference Guide supplied with the machine or available

at www.powerwavesoftware.com.

Wire Feed Speed (WFS)

In synergic welding modes (synergic CV, GMAW-P),

WFS is the dominant control parameter. The user

adjusts WFS according to factors such as wire size,

penetration requirements, heat input, etc. The Power

Wave then uses the WFS setting to adjust the voltage

and current according to settings contained in the Power

Wave. In non-synergic modes, the WFS control

behaves like a conventional power source where WFS

and voltage are independent adjustments. Therefore, to

maintain proper arc characteristics, the operator must

adjust the voltage to compensate for any changes made

to the WFS.

Amps

In constant current modes, this control adjusts the

welding current.

Volts

In constant voltage modes, this control adjusts the

welding voltage.

Trim

In pulse synergic welding modes, the Trim setting

adjusts the arc length. Trim is adjustable from 0.50 to

1.50. 1.00 is the nominal setting and is a good starting

point for most conditions.

Inductance and UltimArcTM Control

UltimArcTM Control allows the operator to vary the arc

characteristics from “soft” to “crisp”. UltimArc™ Control

is adjustable from –10.0 to +10.0 with a nominal setting

of 0.0.

SMAW (Stick) Welding

SMAW is most often used for outdoor construction, pipe

welding and general repairs. The POWER WAVE®

C300 CE controls Amperage, Output Control and Arc

Force during SMAW welding.

During SMAW welding the wire drive remains idle.

Basic Operation

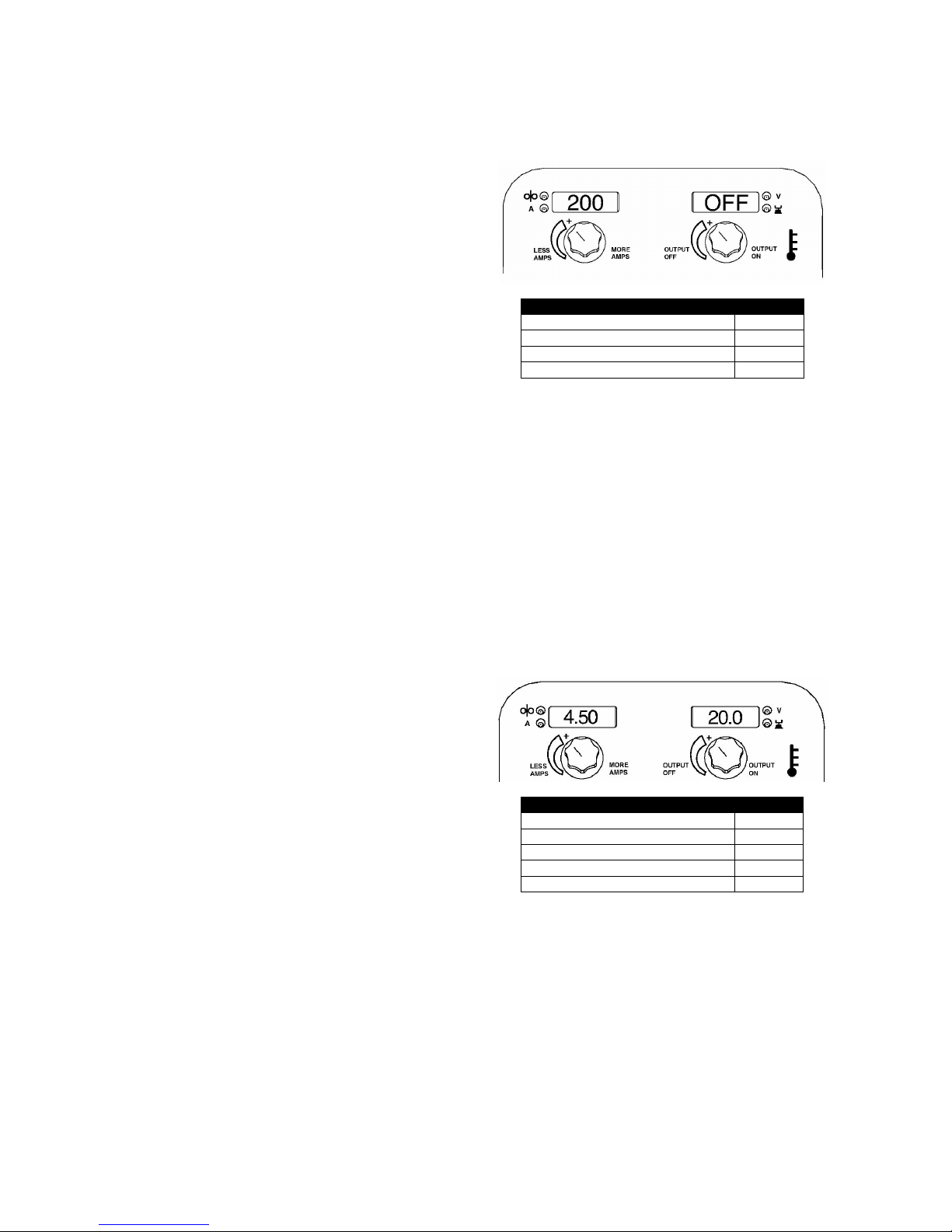

CC STICK MODE

Process

Mode

Stick Soft (7018) 1

Stick Crisp (6010) 2

Stick Pipe 4

Non-Synergic GMAW and FCAW

Welding

In non-synergic modes, the WFS control is similar to a

conventional CV power source where WFS and voltage

are independent adjustments. Therefore to maintain the

arc characteristics, the operator must adjust the voltage

to compensate for any changes made to the WFS.

UltimArc™ Control, adjusts the apparent inductance of

the wave shape. The UltimArc™ Control adjustment is

similar to the “pinch” function in that it is inversely

proportional to inductance. Therefore, increasing

UltimArc™ Control greater than 0.0 results in a crisper

arc (more spatter) while decreasing the UltimArc™

Control to less than 0.0 provides a softer arc (less

spatter).

Basic Operation

WELD MODE

Process

Mode

GMAW, STANDARD CV 5

GMAW, POWER MODE 40

FCAW, (SS) STANDARD CV 6

FCAW, (GS) STANDARD CV 7

GMAW (MIG) Synergic Welding

In synergic welding modes, WFS is the dominant control

parameter. For each wire feed speed, a corresponding

voltage is programmed into the machine at the factory.

The user adjusts WFS according to factors such as wire

size, material thickness, penetration requirements, etc.

The Power Wave then uses the WFS setting to select

the appropriate voltage. The voltage selected will be a

nominal voltage. The user can adjust the voltage higher

or lower to compensate for material condition or

individual preference.

UltimArc™ Control, adjusts the apparent inductance of

the wave shape. The UltimArc™ Control adjustment is

similar to the “pinch” function in that it is inversely

English English

6

proportional to inductance. Therefore, increasing

UltimArc™ Control greater than 0.0 results in a crisper

arc (more spatter) while decreasing the UltimArc™

Control to less than 0.0 provides a softer arc (less

spatter).

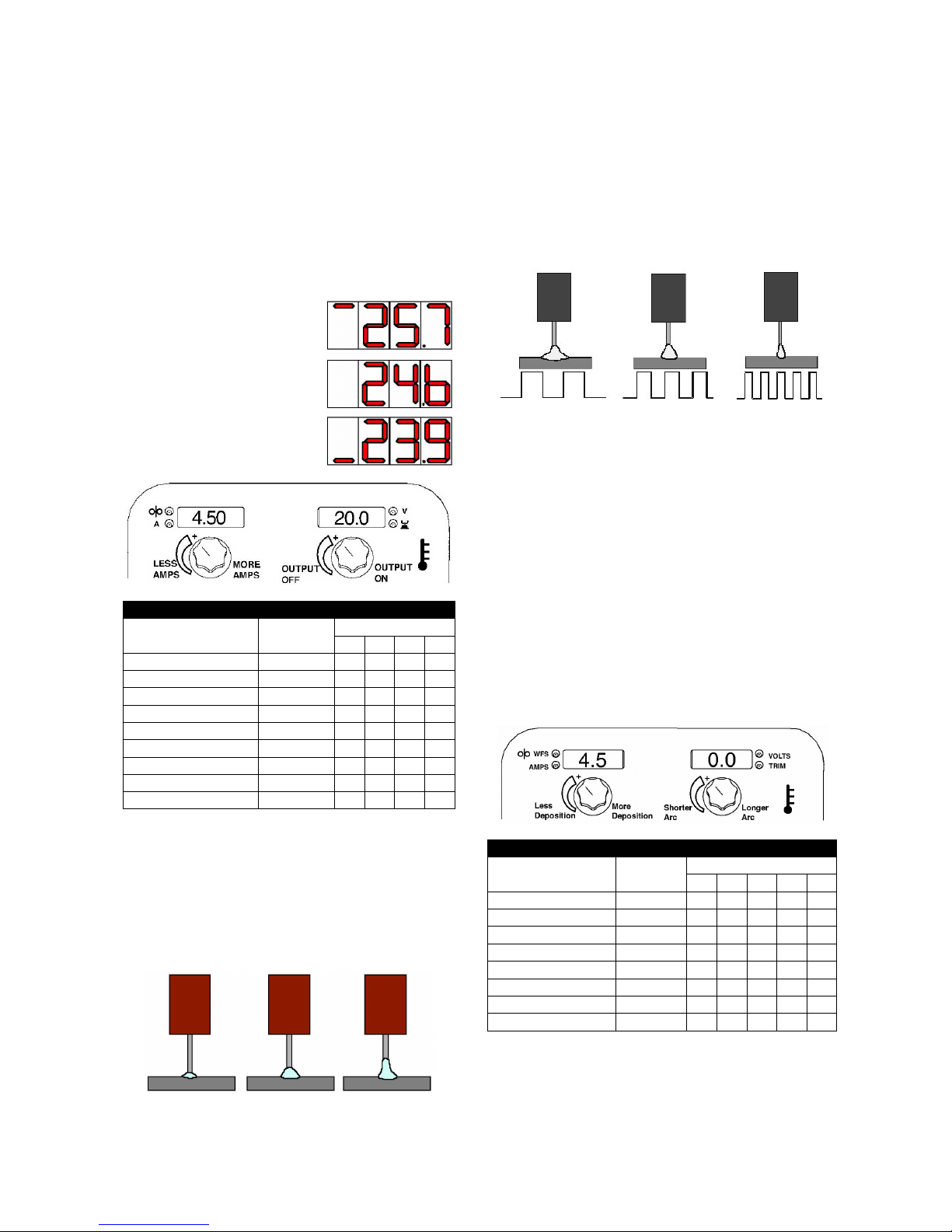

Synergic CV programs feature an ideal voltage best

suited for most procedures. Use this voltage as a

starting point and adjust if needed for personal

preferences.

When the voltage knob is rotated, the display will show

an upper or lower bar indicating if the voltage is

above or below the ideal voltage.

• Preset voltage above ideal

voltage (upper bar

displayed).

• Preset voltage at ideal

voltage (no bar displayed).

• Preset voltage below ideal

voltage (lower bar

displayed).

Basic Operation

WELD MODE

Electrode Gas

Wire Size

0,8 0,9 1,0 1,2

Steel CO2 93 14 10 20

Steel ArMIX 94 15 11 21

Stainless ArCO2 61 - 31 41

Stainless Ar/He/CO2 63 - 33 43

Aluminum AlSi Ar - - - 71

Aluminum AlMg Ar - - 151 75

MetalCore ArMIX - - - 81

CordWire CO2 - - - 90

CordWire ArMIX - - - 91

Steel and Stainless Synergic GMAW-P

(Pulsed MIG)

Pulse welding modes are synergic; using wire feed

speed as the main control parameter. As the wire feed

speed is adjusted, the power source adjusts the

waveform parameters to maintain good welding

characteristics. Trim is used as a secondary control to

change the arc length for material conditions or

individual preference (see figure 6).

Trim .50

Arc Length

Short

Trim 1.00

Arc Length

Medium

Trim 1.50

Arc Length

Long

UltimArc™ Control

UltimArc™ Control adjusts the focus or shape of the arc.

UltimArc™ Control is adjustable from -10.0 to +10.0 with

a nominal setting of 0.0. Increasing the arc control

increases the pulse frequency and background current

while decreasing the peak current.

This results in a tight, stiff arc used for high speed sheet

metal welding. Decreasing the arc control decreases the

pulse frequency and background current while

increasing the peak current. This results in a soft arc

good for out of position welding.

Ultimate™

Control –10.0

Low frequency

Wide

Ultimate™

Control OFF

Medium frequency

and Width

Ultimate™

Control +10.0

High frequency

Focused

Figure 7

The Power Wave utilizes adaptive control to compensate

for changes in the electrical stick-out (distance from the

contact tip to the work piece) while welding. The Power

Wave waveforms are optimized for a 1,6 to 1,9mm stick

out depending on the wire type and wire feed speed.

The adaptive behaviour supports a range of stick outs

from approximately 1,27 to 3,1mm. At low or high wire

feed speeds, the adaptive range may be less due to

physical limitations of the welding process.

Steel and Stainless GMAW-P (Pulsed

MIG) Welding

Basic Operation

WELD MODE

Electrode Gas

Wire Size

0,8 0,9 1,0 1,2 1,4

Steel (Crisp) ArMIX 95 16 12 22 Steel (Rapid Arc) ArMIX - 17 13 18 Stainless ArCO2 66 - 36 46 Stainless Ar/He/CO2 64 - 34 44 MetalCore ArMIX - - 82 84

Ni Alloy 70Ar/30He - - - 175 Si Bronze Ar - - 192 - Copper ArHe - - 195 196 -

Figure 6.

Loading...

Loading...