Lincoln Electric Invertec V350-PRO, Power Wave 455M/STT, Power Wave, Power Wave 355M AC/DC 1000, Power MIG 350MP Specification Sheet

...Page 1

TECHNOLOGY

POWER ELECTRONICS TECHNOLOGY

Inverters and Choppers

Technology creates change.

The ability to evolve along

with change is what

distinguishes a successful

product from the rest.

Power source design is

almost entirely devoted

to reliability. Fast power

conversion is important to

obtaining a smooth

welding output, but we

also know that speed is

inconsequential without

reliability. No matter how

fast your machine operates,

if it is not durable, then it is

not usable for welding. And

if it is not welding, you are

not meeting your

production goals and

making a living.

The Chopper

Technology

Ranger

the same control over

the welding arc as an

inverter machine

The inverter technology in

the Invertec

gives it equivalent power

®

in the

®

305D offers

®

V350-PRO

capabilities as a

conventional

transformer/rectifier

such as the Lincoln

CV-305, but in

a much smaller and

portable machine.

The future of welding is here.

QUICKER RESPONSE

High-speed power conversion allows for quick response to changing

arc conditions.

SMALLER FOOTPRINT

Power electronic components are compact, making equipment size smaller and

therefore more portable.

UNIVERSAL INPUT VOLTAGE

Capable of operating from 208 to 575 volts on virtually any power supply for

versatile, consistent performance.

HIGHLY EFFICIENT

Smaller transformer coils, higher thermal conductivity, and higher operating

frequencies means more efficient output power, and more economical use

of power. This translates to decreased utility costs and increased power

source efficiency.

WAVEFORM CONTROL TECHNOLOGY®COMPATIBLE

Waveform Control Technology®gives the operator improved control over the

characteristics of the welding arc.

®

NX-1.30 6/06

Page 2

POWER ELECTRONICS TECHNOLOGY

TECHNOLOGY

Inverter Technology

What is

Inverter Technology?

Inverter-based welding power

sources operate at frequencies

above 20 kHz, whereas

traditional power sources

operate at a line frequency

of 50 or 60 Hz. Some of the

advantages an inverter has

are smaller magnetic

components (chokes and

transformers), higher

efficiency, and a fast

response to the welding arc.

Inverter power sources were

first introduced into the

welding industry in the early

1980s. The initial attraction of

the inverter was its small size

and easy portability. For

example, a rectifier-based

machine, like the Lincoln CV305,

weighs four times more than the

Invertec V350-PRO. Less space

is needed and the inverter unit is

easily moved around the job site.

As the popularity and reliability of

Inverter Technology

The Invertec®V350-PRO

The Power Wave

the inverter increased, the capabilities

were expanded. Inverters are now

designed for many different

processes: SMAW, GTAW, FCAW,

SAW, and are capable of operating in

®

355M

Inverter Technology is

showcased in Lincoln’s

®

Invertec

Power Wave

V350-PRO, and

®

welding systems

2/8

The Power Wave®455M/STT

The Power Wave

extreme environments. Over the last

decade, Lincoln Electric has invested

heavily in developing inverter

technology, producing highly reliable

inverter machines.

®

AC/DC 1000™

How

Inverter Works

Incoming 50 to 60 Hz alternating

current (AC) is converted

to direct current (DC) by a full

wave rectifier.

The future of welding is here.

The DC power is inverted into high-frequency AC power,

using semiconductor switches above 20 kHz. High-speed

switching improves welding. Switching above 20 kHz

improves efficiency, reduces weight, and is above the

maximum frequency people can hear. Digital controls

dictate the switching rate of the transistors.

The high-frequency AC voltage

requires a step-down

transformer. The transformer

takes high voltage, high

frequency AC and converts it to

low voltage, high frequency AC.

The current is “smoothed”

by a rectifying and

filtering circuit to make it

suitable for welding.

®

Page 3

POWER ELECTRONICS TECHNOLOGY

TECHNOLOGY

Inverter Technology

Using

Inverter Technology

For Multi-Process Welding

Inverters are capable of multiple process welding, providing

optimum arc characteristics for each process.

For Reduced Electrical Power Consumption

Copper conductors, compact transformers, and smaller coils

translate to energy savings.

For Waveform Control Technology*

Inverter machines are software programmable, which means

that they are equipped to use Waveform Control Technology

to manipulate output weld characteristics.

For Networking Capability*

Multiple inverter machines can be networked together over a

Local Area Network (LAN) or Wide Area Network (WAN) with

an Ethernet/DeviceNet Gateway board.

Advantages

Of Inverter Technology

Reliable

Every inverter undergoes rigorous testing to ensure

product reliability.

Compact and Portable

Smaller chokes, transformers, and rectifiers, give the inverter

equivalent power to older SCR machines, without the added

size and weight.

Fast Response to Welding Arc

®

Digital controls regulate the output very accurately so the

welding performance is consistent from machine to machine.

Universal Input Voltage**

The inverter can run on any power supply that supplies

between 208 to 575 volts.

Efficient

The smaller chokes and transformers of the inverter yield an

efficiency rating of 87% to 90%, which means the inverter

consumes less energy to convert the same amount of energy

as SCR-based machines.

3/8

* Applies only to Power Wave Welding Systems F355i, 355M, 455M, 455M/STT, 655

Robotic, and Power Wave AC/DC 1000.

**Power Wave 655 Robotic and Power Wave AC/DC 1000 operate from 460 to 575 volts.

The future of welding is here.

The Power Wave

technology to produce consistent

welds with a variety of weld processes.

®

455M uses Inverter

®

Page 4

POWER ELECTRONICS TECHNOLOGY

TECHNOLOGY

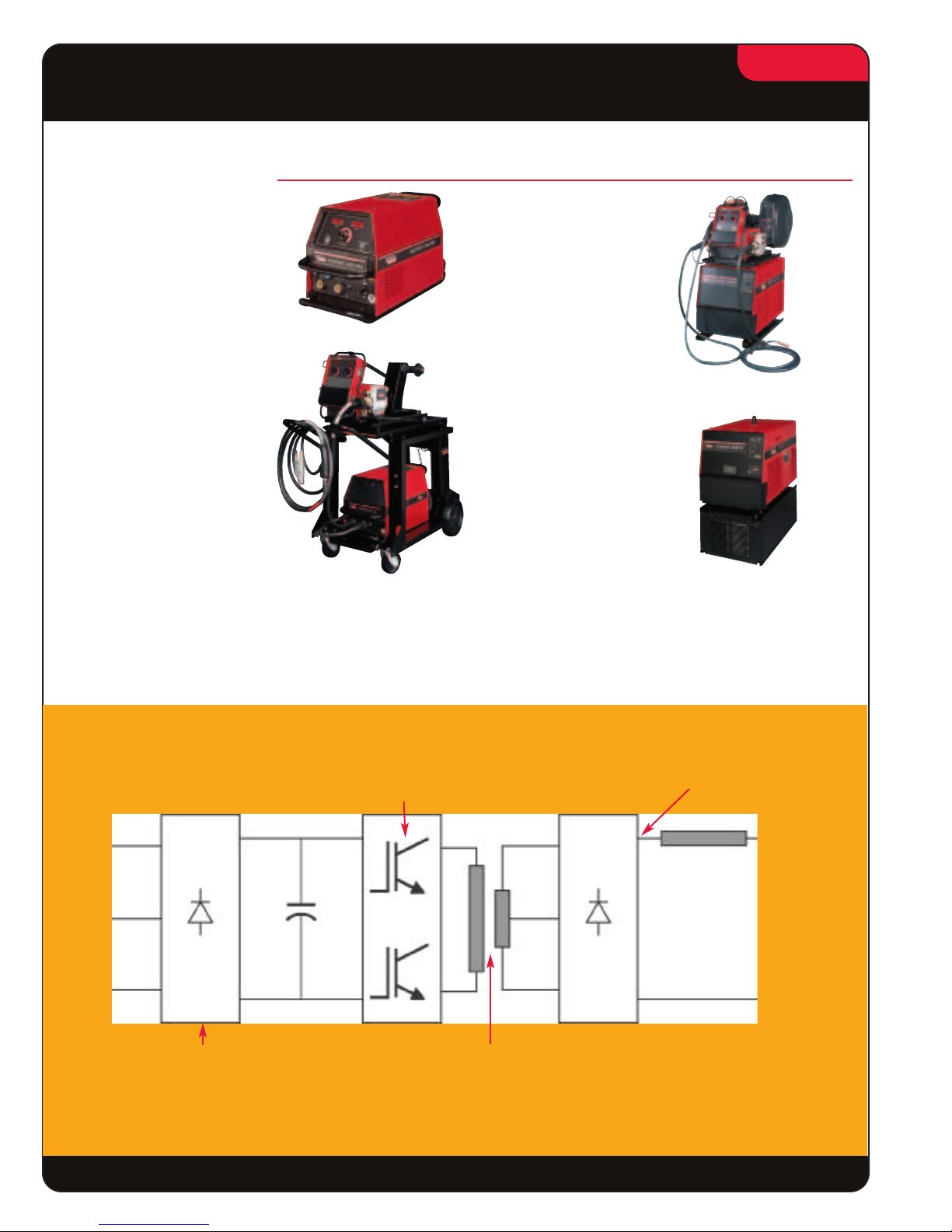

Chopper Technology

What

Is Chopper Technology?

Lincoln Electric’s Chopper

Technology is the simplest form

of high frequency power

conversion. A chopper is

composed of a transistor

switch and a diode. DC input

power is “chopped” to a lower

output voltage, and a choke is

placed in the path of the output

to smooth current variation.

Choppers were developed for

engine driven welders to offer

the same control over the

welding arc as the inverter

machines. This allows more

consistent arc performance

across product lines. Choppers

are ideal for the customer

searching for an inexpensive

option for low cost, high quality

arc performance.

Chopper Technology

Vantage

®

Series

®

®

Chopper Board

Chopper Technology is

showcased in Lincoln’s

Vantage, Ranger, Multi-Weld

and Power MIG 350MP

Power MIG

®

350MP

4/8

How

Chopper Technology Works

When the transistor switch

is open, current stored in

the inductor sustains

current in the arc.

Incoming AC

power is

converted to

direct current (DC)

by a full wave

rectifier.

®

Ranger

DC voltage is applied through a

solid state switch, which

controls the welding arc by

opening and closing, regulating

the amount of current that is

250 & 305D

When the switch is

closed, current is

applied through the

inductor to the arc.

applied to the arc.

Inductor

The repetition of this

cycle of switch

closure is at least

20 kHz, which allows

fast control of the arc.

Multi-Weld

®

The future of welding is here.

®

Page 5

POWER ELECTRONICS TECHNOLOGY

Chopper Technology

®

TECHNOLOGY

5/8

Using

Chopper Technology

For the "On-The-Go" Welder

Chopper Technology is the field welder’s answer to

superior arc performance. Engine drives allow for the

flexibility of operating in conditions where “plugging in”

is not an option. Lincoln engine drives provide excellent

arc characteristics through Chopper Technology, while

providing high-capacity AC generator power.

Chopper Technology also allows multiple welding arcs

to operate from a single power supply using Multi-Weld

350 units.

®

Advantages

Of Chopper Technology

Flexible

• Engine-driven Chopper Technology®power sources are not

limited by the weld environment or access to a power line.

• Chopper Technology

powered welder, the Power MIG 350MP.

Fast Control over Welding Arc

• Fast response time of the Chopper Technology®circuit

allows greater operator control over the welding arc.

Chopper Technology®allows up to four Multi-Weld 350 machines

to draw power from a single SAE

®

®

is also available in an electric

®

400 power supply.

Lincoln engine-driven welders such as

the Vantage

virtually any work environment.

Chopper Technology

consistent arc control, while providing

high-capacity AC generator power.

The future of welding is here.

®

500 can be used in

®

enables fast and

®

Page 6

POWER ELECTRONICS TECHNOLOGY

TECHNOLOGY

Design

Power Electronics Design

The reliability of a welding power source is critical. Electronics improvements are the foremost

method of continually improving the reliability, efficiency, and performance of our power sources.

Lincoln invested in improving the dependability, durability, and efficiency of its inverters. Lincoln engineers

developed innovative solutions for power conversion. Extensive research is conducted in the electronics,

EMC, and power laboratories.

The Electronics Lab

is equipped to support the design and analysis

of analog and digital control systems.

The EMC Lab

is equipped to conduct electro-magnetic

interference testing.

The Power Lab

is equipped to build and test full-scale

prototype machines rapidly to support the

development of new power conversion

techniques. As new power electronic

components emerge they are evaluated

and implemented.

6/8

Reliability Testing

During Product Design

Infrared thermal analysis is done

on power electronic assemblies in

the power electronics lab. This is

done at both the PC board level

and the machine level.

Environmental Stress

Screening (ESS) subjects the

machine to extreme conditions

of temperature and humidity.

The future of welding is here.

Mechanical tests such as vibration and drop

testing provide evidence to the machine’s

durability and resistance to breaking.

®

Page 7

POWER ELECTRONICS TECHNOLOGY

TECHNOLOGY

Reliability

From initial design to product build, we ensure that every power source we release to a customer meets

our standards for reliability and efficiency.

Power Section designed around high

speed switching modules

• Lincoln manufactures its own integrated modules,

which allows us to optimize each module for

reliability

and performance.

Designed to withstand extreme

environmental conditions

• All PC boards are trayed

and potted.

• The transformers and

chokes go through a

double dipped varnish

impregnation process.

• Harness connectors

are made with locking

pins and sealed with

electrical grease.

Designed with

Fan As Needed (FAN

• This reduces the amount of debris that gets drawn

into the machine by turning the fan off when it is

not needed.

• The fan turns on before components get too hot,

thus increasing life expectancy of the electronics.

• Reduces the power used during machine idle.

TM

) Circuitry

All electrical components are derated

for added reliability

• All electrical components are designed to operate at

voltages lower than their rated voltages and

temperatures below their rated temperatures.

Designed for stable operation

• Patented dual current transformers prevent

current imbalance.

• Active balancing technology is utilized for keeping

the voltages balanced under all conditions.

Control system utilizes common PC

boards and software

• Able to accommodate feature enhancements and

optimizations from other products for longer life of

the inverter.

Designed for protection if a fault occurs

• Thermal protection, misconnection protection,

secondary over-current protection, and primary

over-current protection are all standard in

inverter machines.

7/8

Reliability Testing

During Product Build

Each Power Wave

machine is weld-tested.

The future of welding is here.

Dielectric tests provide evidence that

electrical insulation will withstand the

rigors of the welding environment.

The burn-in cycle is conducted to

ensure machine performance matches

Lincoln Electric requirements.

®

Page 8

POWER ELECTRONICS TECHNOLOGY

TECHNOLOGY

Power Electronics Products

Lincoln Welding Systems

Power Electronics

Chopper Products

Lincoln Electric power sources equipped with Chopper Technology®include

the Ranger

350MP and Multi-Weld®.

Inverter Products

Lincoln products equipped with Inverter

Technology include the Power Wave

AC/DC 1000™, Invertec®V350-PRO,

Power Wave

Wave

®

and Vantage®engine driven welders, as well as the Power MIG

®

®

®

355M, and the Power

455M.

8/8

WHAT IS NEXTWELD?

The challenges facing industrial

fabricators today are growing in number

and complexity. Rising labor, material

and energy costs, intense domestic and

®

global competition,

a dwindling pool of

skilled workers,

more stringent and

specific quality

demands all

contribute to a

more difficult

welding

environment today.

Through our

commitment to

extensive research and investments in

product development, Lincoln Electric

has established an industry benchmark

for applying technology to improve the

quality, lower the cost and enhance the

performance of arc welding processes.

Advancements in power electronics,

digital communications and Waveform

Control Technology

®

are the foundation

for many of the improvements.

NEXTWELD brings you a series of

Process, Technology, Application and

Success Story documents like this one.

NEXTWELD explains how technologies,

products, processes and applications are

linked together to answer the important

questions that all businesses face:

• How can we work faster, smarter,

more efficiently?

• How can we get equipment and

people to perform in ways they’ve

never had to before?

• How do we stay competitive?

Customer Assistance Policy

The business of The Lincoln Electric Company is manufacturing and selling high quality welding

equipment, consumables, and cutting equipment. Our challenge is to meet the needs of our

customer and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric

for advice or information about their use of our products. We respond to our customers based

on the best information in our possession at that time. Lincoln Electric is not in a position to

warrant or guarantee such advice, and assumes no liability, with respect to such information or

advice. We expressly disclaim any warranty of any kind, including any warranty of fitness for any

customer’s particular purpose, with respect to such information or advice. As a matter of

practical consideration, we also cannot assume any responsibility for updating or correcting any

such information or advice once it has been given, nor does the provision of information or

advice create, expand or alter any warranty with respect to the sale of our products.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold

by Lincoln Electric is solely within the control of, and remains the sole responsibility of the

customer. Many variables beyond the control of Lincoln Electric affect the results obtained in

applying these types of fabrication methods and service requirement.

Subject to change - This information is accurate to the best of our knowledge

at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

The future of welding is here.

NEXTWELD is the future of welding but

its benefits are available to you today.

Ask your Lincoln Electric representative

how to improve the flexibility, efficiency

and quality of your welding operations to

reduce your cost of fabrication.

THE LINCOLN ELECTRIC COMPANY

www.lincolnelectric.com

1.216.481.8100

®

Loading...

Loading...