Lincoln Electric POWERTEC i380C ADVANCED, POWERTEC i450C ADVANCED Operator's Manual

POWERTEC i380C & i450C ADVANCED

OPERATOR’S MANUAL

IM3102

10/2019

REV03

Linc

oln Electric Bester Sp. z o.o.

ul. Jana III Sobieskiego 19A, 58-263 Bielawa, Poland

www.lincolnelectric.eu

ENGLISH

THANKS! For having chosen the QUALITY of the Lincoln Electric products.

Please Examine Package and Equipment for Damage. Claims for material damaged in shipment must be notified

immediately to the dealer.

For future reference record in the table below your equipment identification information. Model Name, Code &

Serial Number can be found on the machine rating plate.

Model Name:

………………...…………………………….…………………………………………………………………………………………..

Code & Serial number:

………………….……………………………………………….. …………………………………………………….……………..

Date & Where Purchased:

…………………………………………………………………... ……………………….…………………………………………..

12/05

ENGLISH INDEX

Technical Specifications ...................................................................................................................................................... 1

Electromagnetic Compatibility (EMC) .................................................................................................................................. 3

Safety .................................................................................................................................................................................. 4

Introduction ......................................................................................................................................................................... 6

Installation and Operator Instructions .................................................................................................................................. 6

WEEE ............................................................................................................................................................................... 31

Spare Parts ....................................................................................................................................................................... 31

Authorized Service Shops Location .................................................................................................................................. 31

Electrical Schematic .......................................................................................................................................................... 31

Accessories ....................................................................................................................................................................... 32

English English

I

Technical Specifications

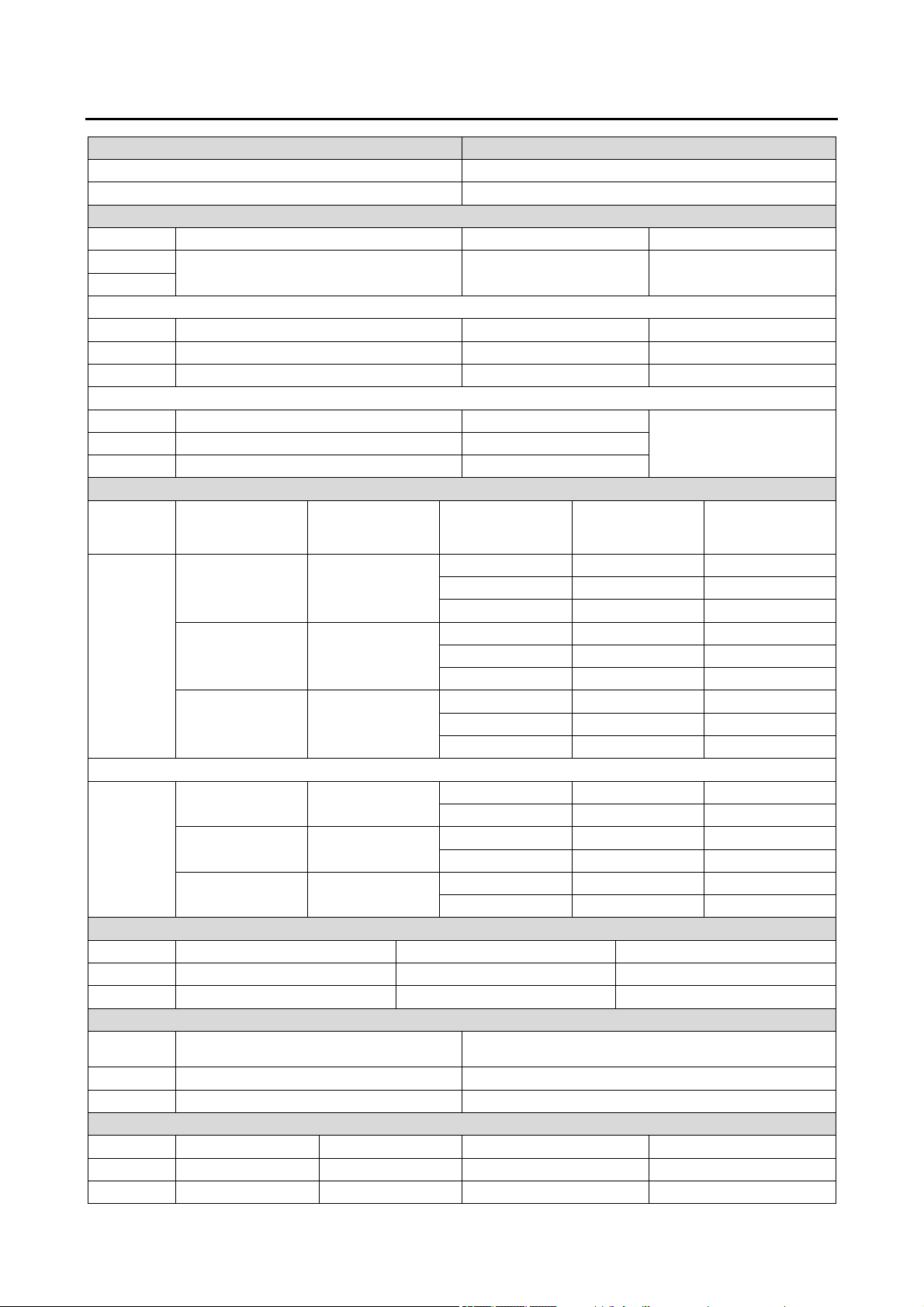

NAME INDEX

POWERTEC i380C ADVANCED K14180-1

POWERTEC i450C ADVANCED K14181-1

INPUT

Input Voltage U1 EMC Class Frequency

K14180-1

K14181-1

Input Power (40°C) Input Amperes I

K14180-1 17,1 kVA @ 40% Duty Cycle 26 A 0,92

K14181-1 20,7 kVA @ 40% Duty Cycle 29,8 A 0,92

Idle Power Efficiency

K14180-1 30W 85%

K14181-1 30W 92%

K14180-1

K14181-1

GMAW FCAW SMAW

K14180-1 20A÷380A 20A÷380A 10A÷380A

K14181-1 20A÷450A 20A÷450A 10A÷450A

K14180-1 25A, 400V AC 4 Conductor, 2,5mm2

K14181-1 32A, 400V AC 4 Conductor, 4,0mm2

Weight Height Width Length

K14180-1 69,2 kg 870 mm 560 mm 900 mm

K14181-1 80,4 kg 870 mm 560 mm 900 mm

Fuse Type: Time-Delay or Circuit Breaker

400V ± 15%, 3-phase A 50/60Hz

PF

1max

RATED OUTPUT

Duty Cycle 40°C

(based on a 10

min. period)

40% 380A 33,0Vdc

60% 320A 30,0Vdc

100% 240A 26,0Vdc

40% 380A 33.0Vdc

60% 320A 30,0Vdc

100% 240A 26,0Vdc

40% 380A 35,2Vdc

60% 320A 32,8Vdc

100% 240A 29,6Vdc

80% 450A 36,5Vdc

100% 420A 35,0Vdc

80% 450A 36.5Vdc

100% 420A 35,0Vdc

80% 450A 38,0Vdc

100% 420A 36,8Vdc

DIMENSION

Output Current Output Voltage

Power Lead

GMAW

FCAW

SMAW

GMAW

FCAW

SMAW

Open Circuit

Voltage

54Vdc (peak)

48Vdc (RMS)

54Vdc (peak)

48Vdc (RMS)

54Vdc (peak)

48Vdc (RMS)

60Vdc (peak)

49Vdc (RMS)

60Vdc (peak)

49Vdc (RMS

60Vdc (peak)

49Vdc (RMS

WELDING CURRENT RANGE

RECOMMENDED INPUT CABLE AND FUSE SIZES

Type D

English 1 English

WIRE FEED SPEED RANGE / WIRE DIAMETER

WFS Range Drive Rolls Drive roll diameter

K14180-1 1 ÷ 20,32m/min 4 Ø37

K14181-1

Solid Wires Aluminum Wires Cored Wires

K14180-1 0.8 ÷ 1.4 mm 1.0 ÷ 1.2 mm 0.9 ÷ 1.2 mm

K14181-1 0.8÷1.6m 1.0 ÷ 1.6 mm 0.9 ÷ 1.6 mm

Protection Rating Maximum Gas Pressure Operating Humidity (t=20°C)

K14180-1

K14181-1

Operating Temperature Storage Temperature

K14180-1

K14181-1

1 ÷ 22 m/min 4 Ø37

IP23 0,5MPa (5 bar) ≤ 90 %

from -10 ºC to +40 ºC from -20 ºC to +55 ºC

English 2 English

Electromagnetic Compatibility (EMC)

This machine has been designed in accordance with all relevant directives and standards. However, it may still generate

electromagnetic disturbances that can affect other systems like telecommunications (telephone, radio, and television) or

other safety systems. These disturbances can cause safety problems in the affected systems. Read and understand this

section to eliminate or reduce the amount of electromagnetic disturbance generated by this machine.

WARNING

Provided that the public low voltage system impedance at the point of common coupling is lower than:

56,4 mΩ for the POWERTEC i380C ADVANCED;

23 mΩ for the POWERTEC i450C ADVANCED.

This equipment is compliant with IEC 61000-3-11 and IEC-3-12 and can be connected to public low voltage systems. It is

the responsibility of the installer or user of the equipment to ensure, by consultation with the distribution network operator if

necessary, that the system impedance complies with the impedance restrictions.

Consider the following guidelines to reduce electromagnetic emissions from the machine.

Connect the machine to the input supply according to this manual. If disturbances occur if may be necessary to take

additional precautions such as filtering the input supply.

The output cables should be kept as short as possible and should be positioned together. If possible connect the

work piece to ground in order to reduce the electromagnetic emissions. The operator must check that connecting the

work piece to ground does not cause problems or unsafe operating conditions for personnel and equipment.

Shielding of cables in the work area can reduce electromagnetic emissions. This may be necessary for special

applications.

WARNING

The Class A equipment is not intended for use in residential locations where the electrical power is provided by the public

low-voltage supply system. There may be potential difficulties in ensuring electromagnetic compatibility in those locations,

due to conducted as well as radiated disturbances.

11/04

WARNING

While a high electromagnetic field occurs, a welding current can fluctuate.

English 3 English

Safety

01/11

WARNING

This equipment must be used by qualified personnel. Be sure that all installation, operation, maintenance and repair

procedures are performed only by qualified person. Read and understand this manual before operating this equipment.

Failure to follow the instructions in this manual could cause serious personal injury, loss of life, or damage to this equipment.

Read and understand the following explanations of the warning symbols. Lincoln Electric is not responsible for damages

caused by improper installation, improper care or abnormal operation.

WARNING: This symbol indicates that instructions must be followed to avoid serious personal injury,

loss of life, or damage to this equipment. Protect yourself and others from possible serious injury or

death.

READ AND UNDERSTAND INSTRUCTIONS: Read and understand this manual before operating

this equipment. Arc welding can be hazardous. Failure to follow the instructions in this manual could

cause serious personal injury, loss of life, or damage to this equipment.

ELECTRIC SHOCK CAN KILL: Welding equipment generates high voltages. Do not touch the

electrode, work clamp, or connected work pieces when this equipment is on. Insulate yourself from

the electrode, work clamp, and connected work pieces.

ELECTRICALLY POWERED EQUIPMENT: Turn off input power using the disconnect switch at the

fuse box before working on this equipment. Ground this equipment in accordance with local electrical

regulations.

ELECTRICALLY POWERED EQUIPMENT: Regularly inspect the input, electrode, and work clamp

cables. If any insulation damage exists replace the cable immediately. Do not place the electrode

holder directly on the welding table or any other surface in contact with the work clamp to avoid the

risk of accidental arc ignition.

ELECTRIC AND MAGNETIC FIELDS MAY BE DANGEROUS: Electric current flowing through any

conductor creates electric and magnetic fields (EMF). EMF fields may interfere with some

pacemakers, and welders having a pacemaker shall consult their physician before operating this

equipment.

CE COMPLIANCE: This equipment complies with the European Community Directives.

ARTIFICIAL OPTICAL RADIATION: According with the requirements in 2006/25/EC Directive and

EN 12198 Standard, the equipment is a category 2. It makes mandatory the adoption of Personal

Protective Equipments (PPE) having filter with a protection degree up to a maximum of 15, as

required by EN169 Standard.

FUMES AND GASES CAN BE DANGEROUS: Welding may produce fumes and gases hazardous to

health. Avoid breathing these fumes and gases. To avoid these dangers the operator must use

enough ventilation or exhaust to keep fumes and gases away from the breathing zone.

ARC RAYS CAN BURN: Use a shield with the proper filter and cover plates to protect your eyes from

sparks and the rays of the arc when welding or observing. Use suitable clothing made from durable

flame-resistant material to protect you skin and that of your helpers. Protect other nearby personnel

with suitable, non-flammable screening and warn them not to watch the arc nor expose themselves to

the arc.

WELDING SPARKS CAN CAUSE FIRE OR EXPLOSION: Remove fire hazards from the welding

area and have a fire extinguisher readily available. Welding sparks and hot materials from the welding

process can easily go through small cracks and openings to adjacent areas. Do not weld on any

tanks, drums, containers, or material until the proper steps have been taken to insure that no

flammable or toxic vapors will be present. Never operate this equipment when flammable gases,

vapors or liquid combustibles are present.

WELDED MATERIALS CAN BURN: Welding generates a large amount of heat. Hot surfaces and

materials in work area can cause serious burns. Use gloves and pliers when touching or moving

materials in the work area.

English 4 English

CYLINDER MAY EXPLODE IF DAMAGED: Use only compressed gas cylinders containing the

correct shielding gas for the process used and properly operating regulators designed for the gas and

pressure used. Always keep cylinders in an upright position securely chained to a fixed support. Do

not move or transport gas cylinders with the protection cap removed. Do not allow the electrode,

electrode holder, work clamp or any other electrically live part to touch a gas cylinder. Gas cylinders

must be located away from areas where they may be subjected to physical damage or the welding

process including sparks and heat sources.

MOVING PARTS ARE DANGEROUS: There are moving mechanical parts in this machine, which can

cause serious injury. Keep your hands, body and clothing away from those parts during machine

starting, operating and servicing.

HOT COOLANT CAN BURN SKIN: Always be sure coolant is NOT HOT before servicing the cooler.

SAFETY MARK: This equipment is suitable for supplying power for welding operations carried out in

an environment with increased hazard of electric shock.

The manufacturer reserves the Right to make changes and/or improvements in design without upgrade at the same time

the operator’s manual.

English 5 English

Introduction

General Description

The welding machines POWERTEC i380C ADVANCED

and POWERTEC i450C ADVANCED enables welding:

GMAW (MIG/MAG),

FCAW (Flux-Cored),

SMAW (MMA),

The following equipment has been added to

POWERTEC i380C ADVANCED and

POWERTEC i450C ADVANCED:

Work lead – 3m,

Gas hose – 2m,

Driving roll V1.0/V1.2 for solid wire (mounted in the

wire feeder).

Recommended equipment, which can be bought by

user, was mentioned in the chapter "Accessories".

Installation and Operator Instructions

Read this entire section before installation or operation

of the machine.

Location and Environment

This machine will operate in harsh environments.

However, it is important that simple preventative

measures are followed to assure long life and reliable

operation.

Do not place or operate this machine on a surface

with an incline greater than 15° from horizontal.

Do not use this machine for pipe thawing.

This machine must be located where there is free

circulation of clean air without restrictions for air

movement to and from the air vents. Do not cover

the machine with paper, cloth or rags when switched

on.

Dirt and dust that can be drawn into the machine

should be kept to a minimum.

This machine has a protection rating of IP23. Keep it

dry when possible and do not place it on wet ground

or in puddles.

Locate the machine away from radio controlled

machinery. Normal operation may adversely affect

the operation of nearby radio controlled machinery,

which may result in injury or equipment damage.

Read the section on electromagnetic compatibility in

this manual.

Do not operate in areas with an ambient temperature

greater than 40°C.

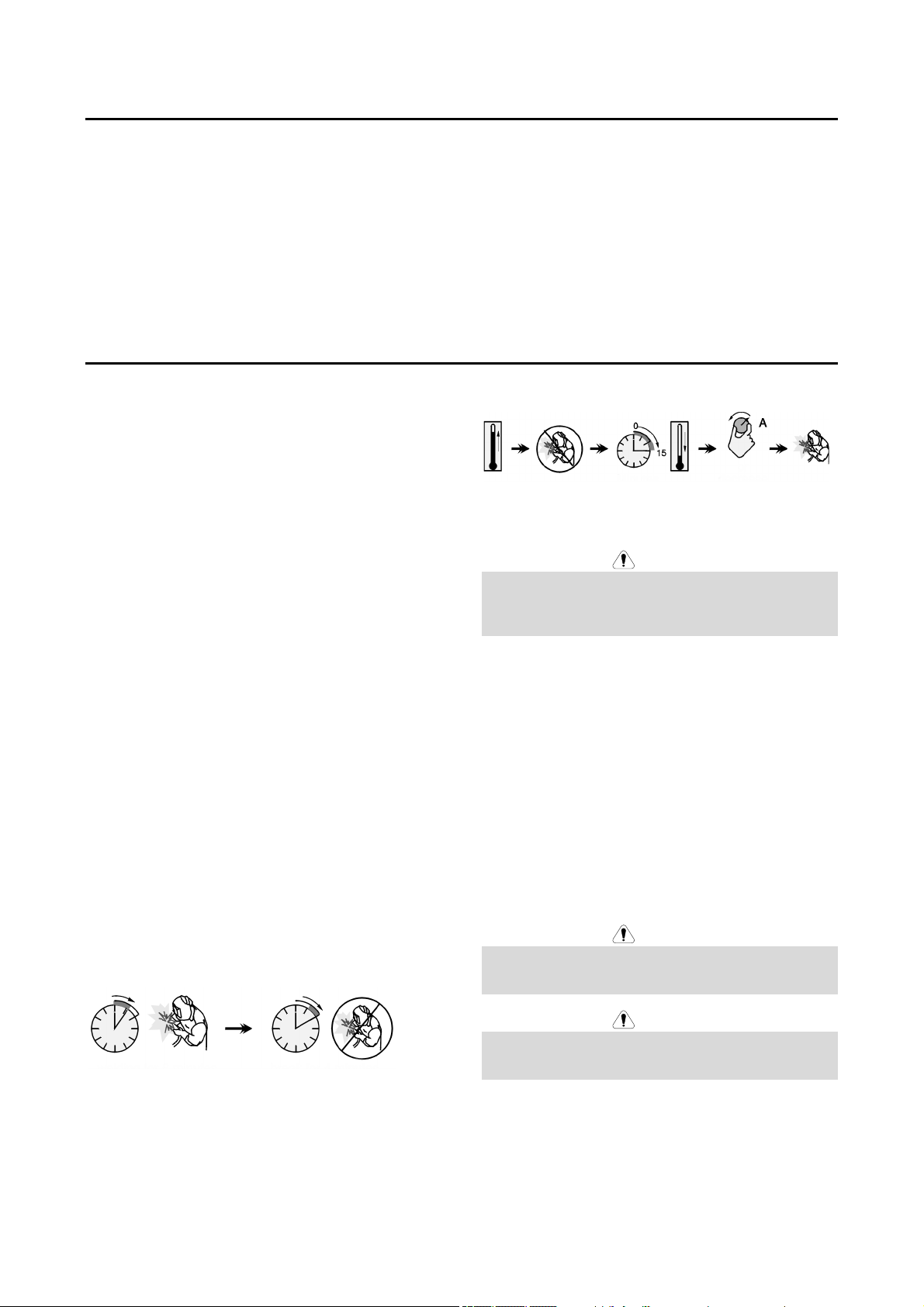

Duty cycle and Overheating

The duty cycle of a welding machine is the percentage of

time in a 10 minute cycle at which the welder can

operate the machine at rated welding current.

Example: 60% duty cycle

Welding for 6 minutes. Break for 4 minutes.

Excessive extension of the duty cycle will cause the

thermal protection circuit to activate.

Minutes or decrease

Input Supply Connection

Only a qualified electrician can connect the welding

machine to the supply network. Installation had to be

made in accordance with the appropriate National

Electrical Code and local regulations.

Check the input voltage, phase and frequency supplied to

this machine before turning it on. Verify the connection of

ground wires from the machine to the input source. The

welding machine POWERTEC i380C ADVANCED,

POWERTEC i4500C ADVANCED must be connected to

a correctly installed plug-in socket with an earth pin.

Input voltage is 400 Vac 50/60Hz. For more information

about input supply refer to the technical specification

section of this manual and to the rating plate of the

machine.

Make sure that the amount of mains power available

from the input supply is adequate for normal operation of

the machine. The necessary delayed fuse or circuit

breaker and cable sizes are indicated in the technical

specification section of this manual.

The welding machine can be supplied from a power

generator of output power at least 30% larger than input

power of the welding machine.

When powering the machine from a generator be sure to

turn off welder first, before generator is shut down, in

order to prevent damage to welder!

Output Connections

Refer to points [3], [4] and [6] of the Figures below.

Duty Cycle

WARNING

WARNING

WARNING

English 6 English

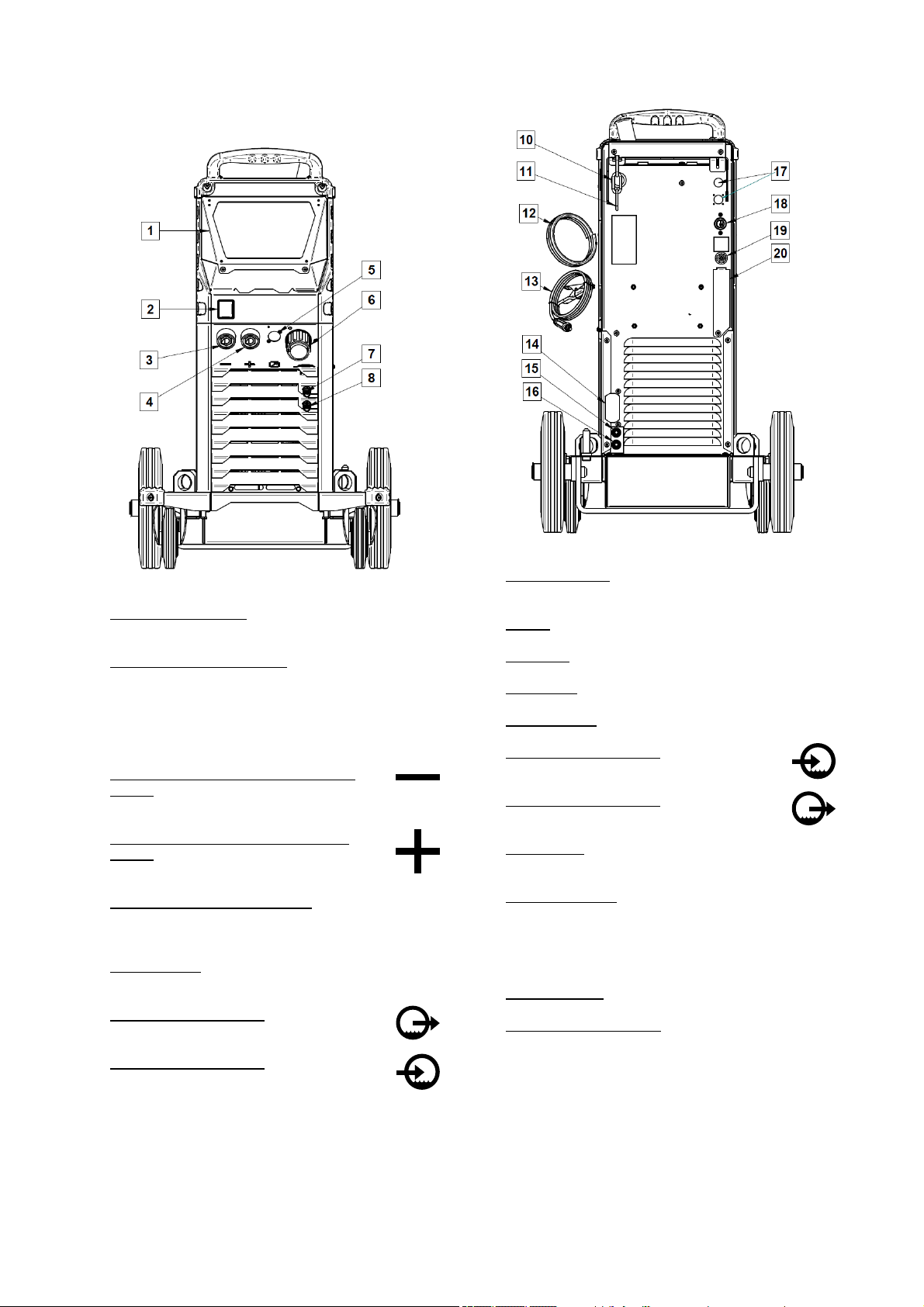

Controls and Operational Features

Front Panel

Rear panel

Figure 1.

1. User Interface Cover. Cover shielding user interface.

U7 User Interface is described in separate chapter.

2. Power Switch ON/OFF (I/O): Controls the input

power to the machine. Be sure the power source is

connected to the mains supply before turning power

on ("I"). After input power is connected and the

power switch is turned on, the indicator will light up to

indicate the machine is ready to weld.

3. Negative Output Socket for the Welding

Circuit: For connecting an electrode holder

with lead / work lead.

4. Positive Output Socket for the Welding

Circuit: For connecting an electrode holder

with lead / work lead.

5. Remote Control Connector Plug: To install Remote

Control Kit. This connector allows connection

Remote Control. See "Accessories" chapter.

6. EURO Socket: For connecting a welding gun (for

GMAW / FCAW process).

7. Quick Connect Coupling: Coolant outlet

(supplies cool coolant to the torch/gun).

8. Quick Connect Coupling: Coolant inlet

(takes warm coolant from torch/gun).

Figure 2.

10. Wire Liner Entry: Enables installing liner for welding

wire delivered in drum package.

11. Chain: To protect gas bottle.

12. Gas hose.

13. Work Lead.

14. Cover bracket: To install cooler cable holder bracket.

15. Quick Connect Coupling: Coolant inlet

(supplies cool coolant to the torch/gun).

16. Quick Connect Coupling: Coolant outlet

(takes warm coolant from torch/gun).

17. Supply Plug: For CO2 gas heater kit (see

“Accessories” chapter).

18. Power Lead (5m): Connect the supply plug to the

existing input cable that is rated for the machine as

indicated in this manual, and conforms to all

applicable standards. This connection shall be

performed by a qualified person only.

19. Gas Connector: Connection for gas line.

20. Gas Flow Regulator Plug: Gas flow regulator can be

purchased separately (see “Accessories” chapter).

English 7 English

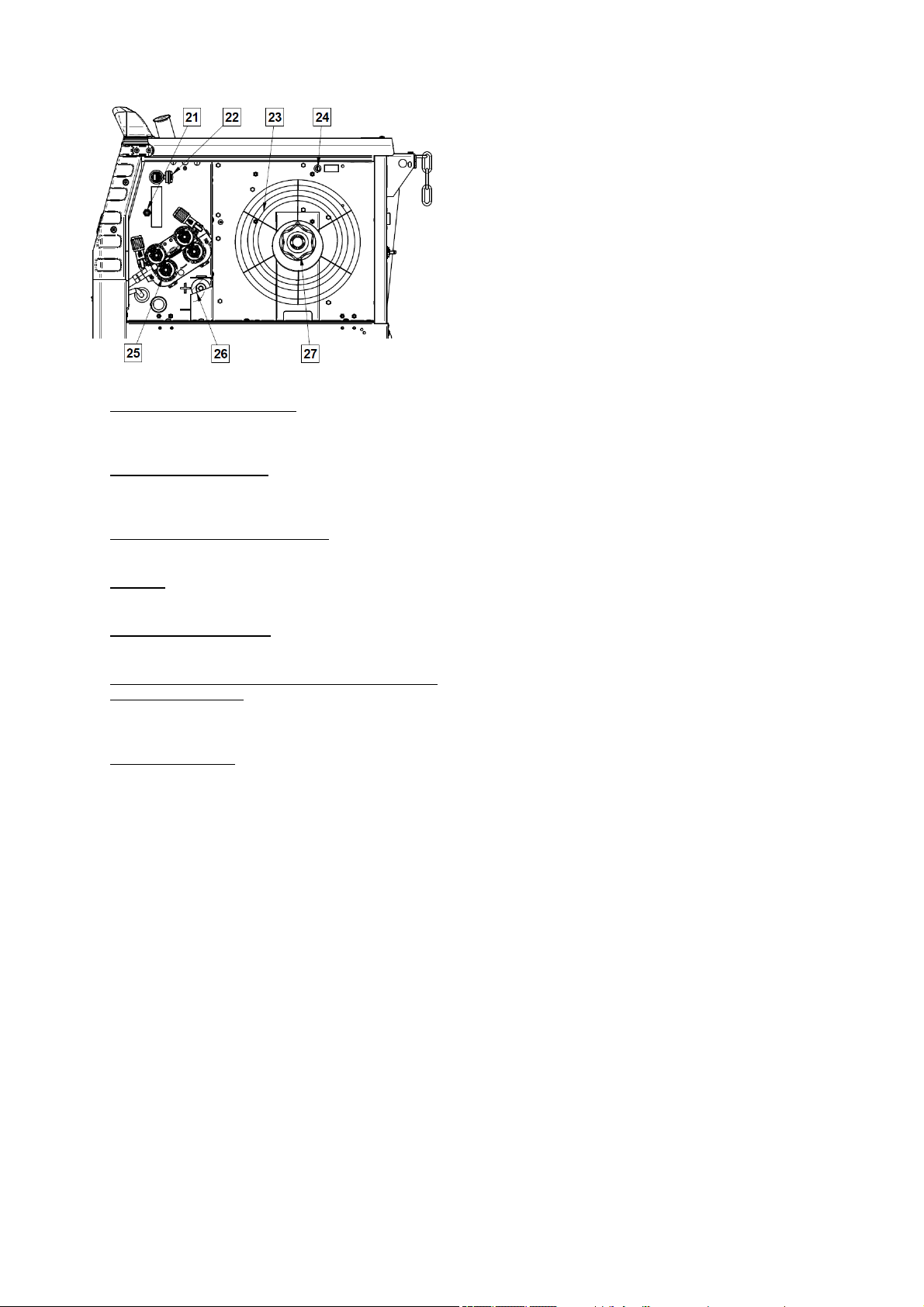

Internal Controls

Figure 3.

21. Cold Inch/ Gas Purge Switch: This switch enables

wire feeding or gas flow without turning on output

voltage.

22. USB Receptacle Type A: For USB memory stick

connection. For machine software update and

service purpose.

23. Spooled Wire (for GMAW / FCAW): The machine

does not include a spooled wire.

24. Fuse F1: Use the 2A/400V (6,3x32mm) low blow

fuse

25. Wire drive feeding system: 4-Roll wire drive

mechanisms with quick-change feed rolls.

26. Terminal Block of Changing Polarity Plug (for GMAW

/ FCAW-SS process): This terminal block enables to

set the welding polarity (+ ; -), which will be given at

the welding gun

27. Wire Spool Support: Maximum 16kg spools. Accepts

plastic, steel and fiber spools onto 51 mm spindle.

Note: Plastic Brake Nut has a Left-hand thread.

English 8 English

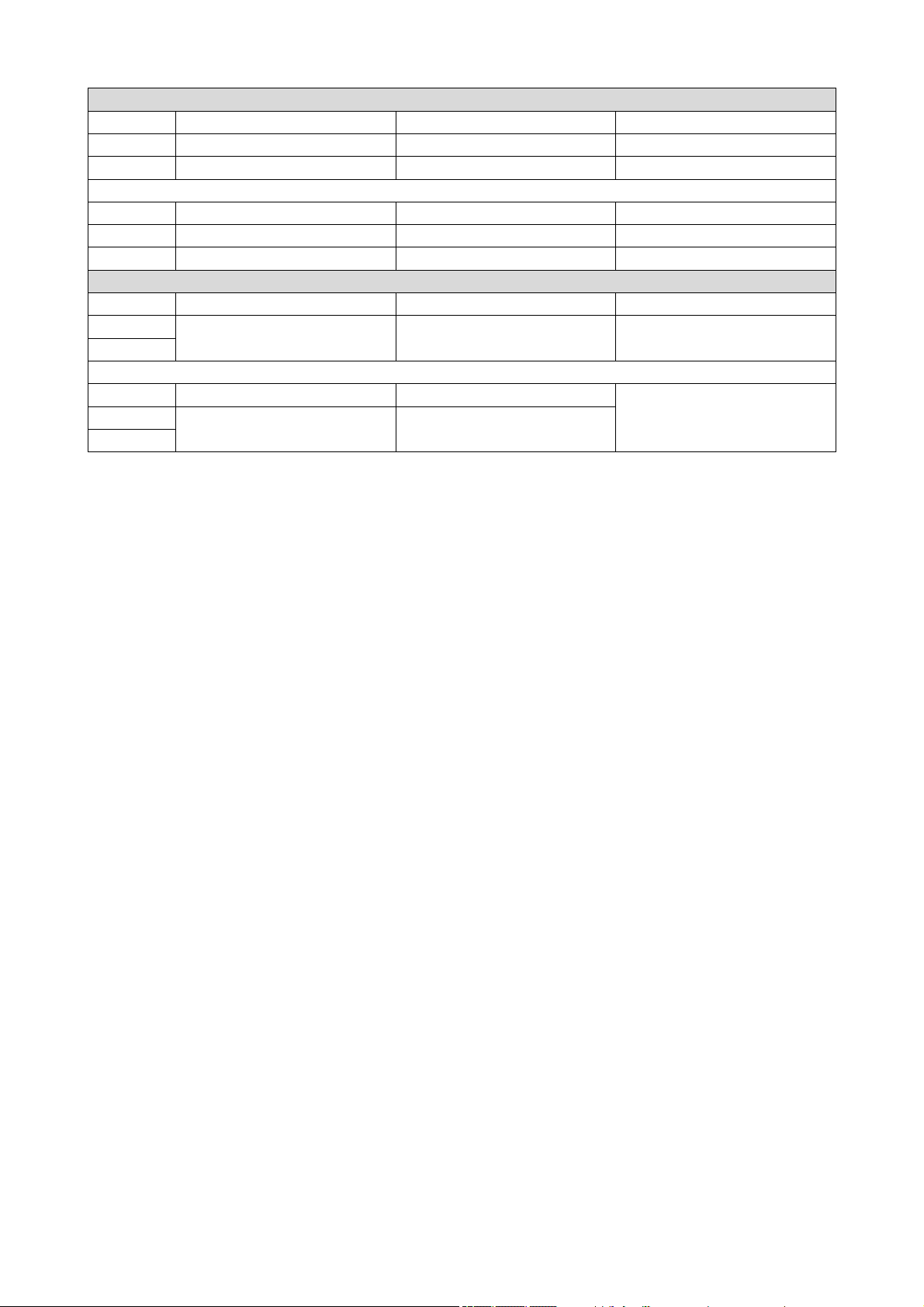

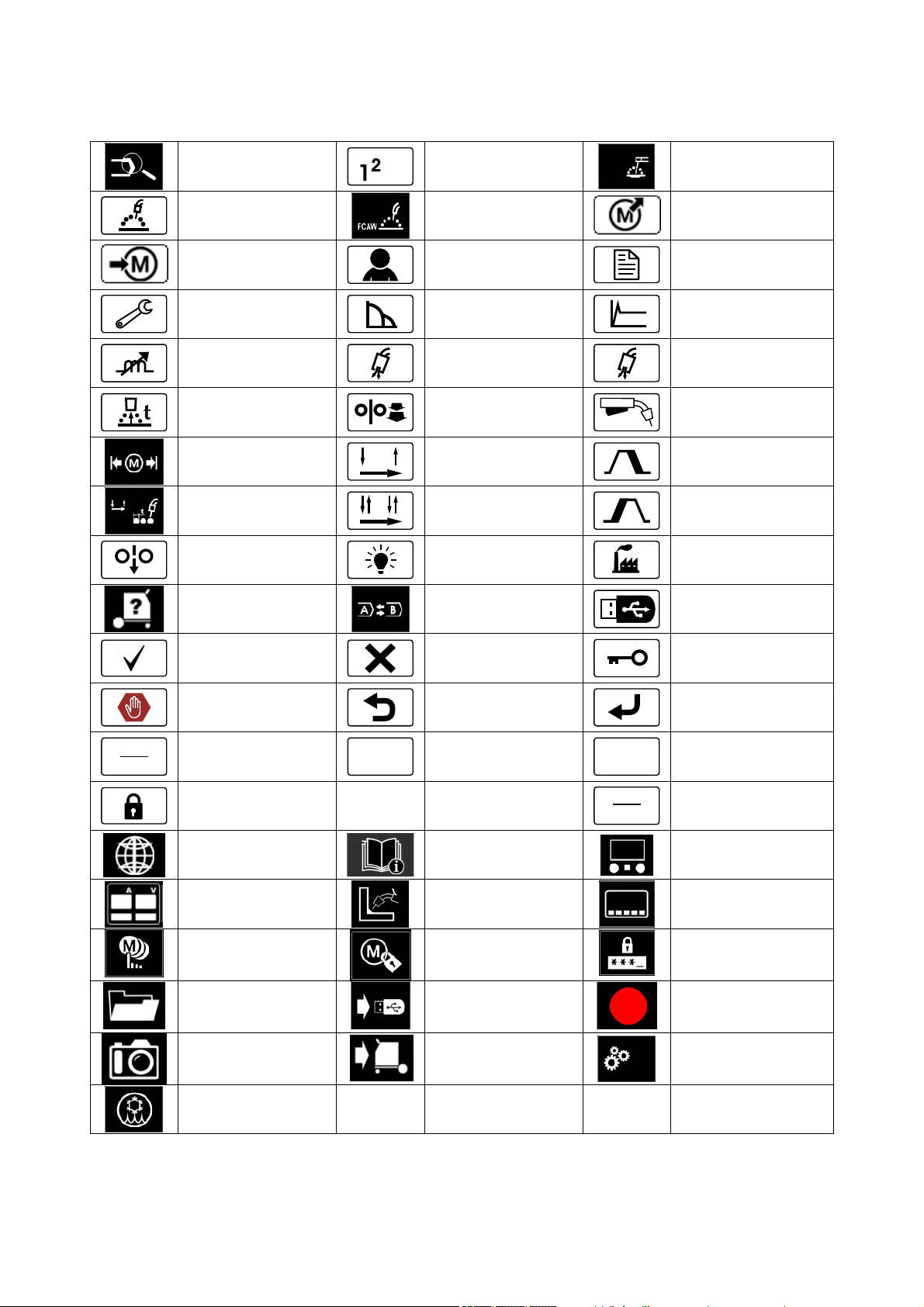

Guide’s Marking Interface

n

A

Table 1. Symbols description

Select Welding Process

GMAW Process

(MIG/MAG)

Save to the User

Memory

.

.

.

3

Select Welding Program

FCAW Process

User Setup

SMAW Process

(MMA)

Recall from the User

Memory

Advanced Setup

mi

in

Configuration

Pinch

t1

Burnback Time

Memory Limits

Spot Welding Settings

Cold Feed

View Software and

Hardware Version

Information

Check Mark

Error

Wire Feed Speed

in [in/min]

V

Locked

Arc Force

Preflow Time

Run-in WFS

2-Step

4-Step

Brightness Level

A/B Procedure

Resignation Mark

ESCape Button

Welding Voltage

A

m

min

Hot Start

Postflow Time

t2

Select Function of Gun

Trigger (2-Step / 4-Step)

Crater Procedure

Start Procedure

Restore Factory Setting

USB Memory

Access control

Confirm Button

Welding Current

Wire Feed Speed

in [m/min]

Set the Language

Standard UI look

Enable/ Disable Jobs

Mode or Select Jobs for

Jobs Mode

Weld History

SnapShot

Support

Advanced UI look

Enable/ Disable Jobs

Save

Save

Load

Display Configuration

Settings

Select Item

Lock

Service weld logs

Service Menu

Cooler

User Interface Advanced (U7)

English 9 English

Loading...

Loading...