Page 1

TECHNOLOGY

WAVEFORM CONTROL TECHNOLOGY

TM

Waveform Control Technology

Just as computer companies

recognize the importance of

providing their customers with

multi-functional equipment,

Lincoln Electric realizes that our

customers want the power to

choose what fits them best. As

companies broaden their product

offerings, this desire has turned

into necessity.

In the past, different equipment

has been required for different

welds. Customers often needed

several models of welding

equipment to perform a variety of

welding procedures.

Waveform Control Technology

revolutionizes the way welding

equipment is chosen. Waveform

Control Technology welding

systems support 8 processes,

over 80 weld procedures, and the

option to fine-tune or develop new

welding programs. Waveform

Control Technology is available

in semi-automatic, hard

automation, or robotic systems.

We’ve put the power of choice

back into the hands of the

operators. Choose wisely. Choose

Waveform Control Technology.

SIMPLIFIED PROCESS SELECTION

Metal transfer modes may be controlled to extend the stable operating range

of the welding process.

ADAPTABILITY

Shapes the arc using computer software. A single machine can quickly and

easily adapt to:

• A wide range of applications

• Varying materials specifications

• Varied weld positions

• Appearance requirements

WELD QUALITY

Optimized metal transfer reduces spatter and improves arc stability.

PRODUCTIVITY

Higher deposition rates are possible at heat input equal to or less than

traditional CV processes.

CUSTOMIZABLE

Output parameters may be adjusted for given welding waveform conditions

and joint design to meet weld specifications and production rates.

Alterations to the waveform can be made during the weld,

using software created by Lincoln Electric.

TM

The future of welding is here.

®

NX-1.10 11/03

Page 2

TECHNOLOGY

Waveform Control Technology

What

is Waveform Control?

Waveform Control Technology

is the ability to customize

waveform output. It is the ability

to choose a weld program from

a pre-defined set of programs,

and to manipulate the

parameters of that program

to best fit your application.

Lincoln Electric strives to

understand the customer’s

needs in order to make the job

easier. That is why Waveform

Control Technology was

designed: to empower the

people who use the equipment,

our customers.

Waveform Control Technology

allows the user to choose from

a library of pre-programmed

weld “modes” that have been

developed by expert welders.

Then, Waveform Control

Technology offers the

opportunity to change those

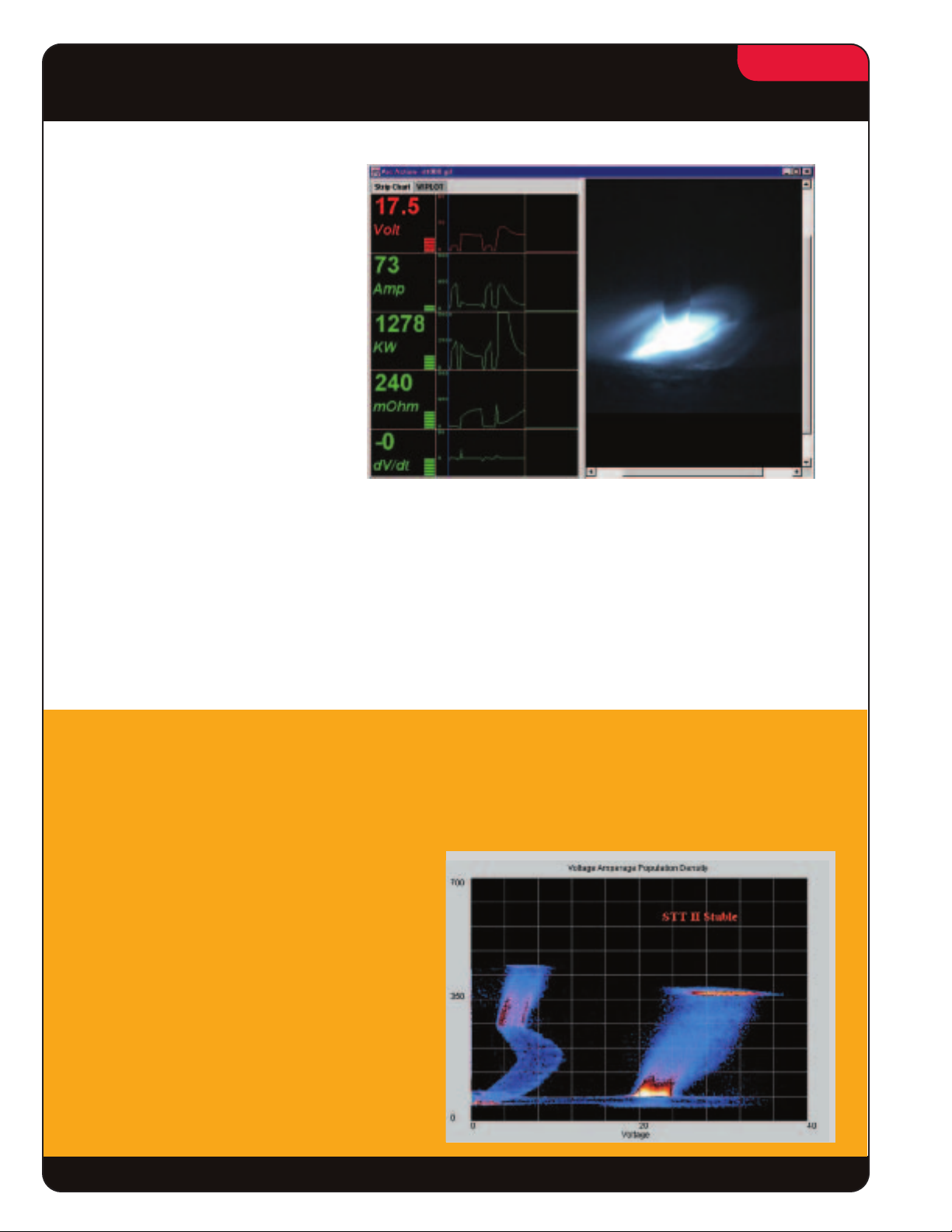

The Arc Action Tool shows the behavior of the arc in the form of a Voltage/Amperage

(VI) plot. To further illustrate what the changes in voltage and current mean to the arc,

Lincoln Electric uses high-speed photography to capture arc behavior.

values, within a programmed range,

to find the combination of wire feed

speed, voltage, current, and arc

control that the application requires.

But Lincoln has even taken it one

step further. Waveform Control

Technology also provides the ability

2/8

to use a single source to perform

Stick, TIG, MIG/MAG, Flux-cored,

and Submerged Arc welding

procedures. With a Waveform

Control Technology product, the

days of configuring different systems

to make different welds are over.

How

Waveform Control Works

There are many physical forces that affect the welding arc and the transfer of metal from the electrode to the

weld puddle. Surface tension, magnetic, and aerodynamic forces are the most significant. The welding current

directly affects the magnetic and aerodynamic forces in the welding arc. The welding current and surface tension

forces can be balanced to control metal transfer within the arc.

High-speed electronics monitor the electrical signals

from the welding arc and make appropriate changes

to the current waveform. The electronics must be

fast, accurate, and rugged to control the arc and

withstand the harsh welding environment.

Amperage

The future of welding is here.

®

Page 3

TECHNOLOGY

Waveform Control Technology

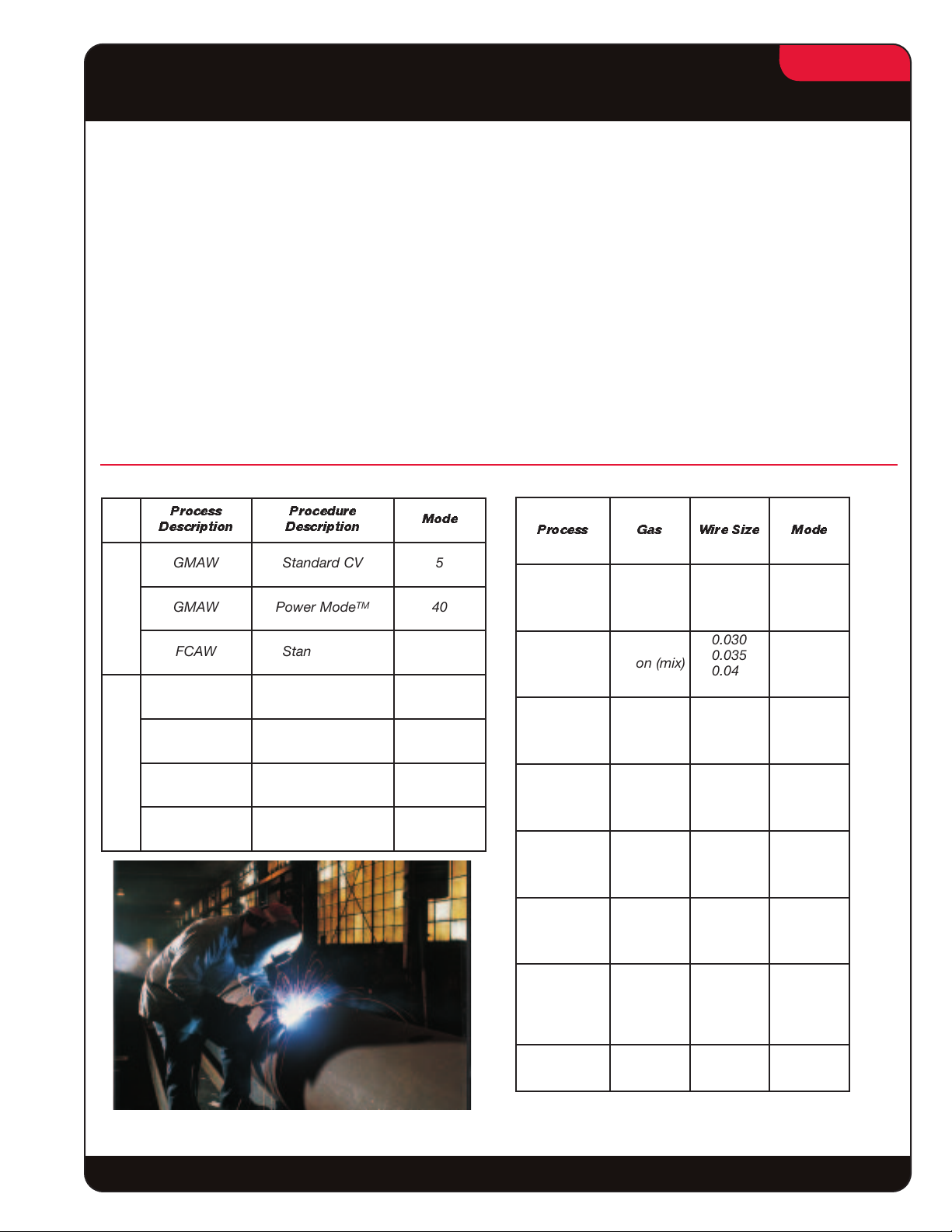

Waveform Control Weld Programs

Equipped with our most up-to-date welding programs,

Waveform Control Technology systems suit the

majority of welding applications. The flexibility of

choosing from a variety of welding programs not only

increases productivity, but also promotes consistently

high-quality welds.

Power MIG 300, Invertec V350-PRO, and

Power Wave welding systems are all Waveform

Control Technology systems. They come fully loaded

with a software library that is accessible from the

user interface. With the Power Wave, software

programming enables the flexibility of uploading the

weld programs to a PC, or Ethernet and DeviceNet

applications (hard automation).

General Weld Programs Steel Weld Programs

Process

Description

Procedure

Description

Mode

The programs listed in the following tables were

developed by Lincoln Electric.* It is important to note

that, although we attempted to provide a broad

operating window for each program, they were

developed using Lincoln consumables. Therefore,

Lincoln Electric cannot guarantee that these

procedures will operate at optimum level when used

with non-Lincoln Electric electrodes.

A mode number is assigned to each weld program.

The following lists include the most commonly used

weld programs, and are grouped according to

material. Find the mode number for your material and

program specifications, then select that mode

number on the welding system user interface.

Process Gas Wire Size Mode

3/8

Constant Voltage

Constant Current

GMAW Standard CV 5

GMAW Power Mode

FCAW Standard CV 6

STICK Soft (7018) 1

STICK Crisp (6010) 2

TIG Touch Start TIG 3

GOUGE 9

TM

40

GMAW

GMAW Argon (mix)

Pulse (Crisp) Argon (mix)

Pulse (Soft) Argon (mix)

®

STT

(No Tailout)

®

STT II

Rapid Arc

Robotic STT

CO

2

CO2,

Argon/CO

CO2,

Argon/CO

Argon/CO

CO2,

Argon/CO

0.030

0.035

0.045

0.052

0.030

0.035

0.045

0.052

0.030

0.035

0.045

0.052

0.035

0.045

0.052

0.035

0.045

2

0.030

0.035

0.045

2

0.052

0.035

0.035

0.045

2

0.045

0.052

0.035

0.045

2

93

10

20

24

94

11

21

25

95

12

22

26

14

19

28

109

125

110

110

126

126

13

15

17

18

27

109

125

Steel Welding Application

The future of welding is here.

*These programs may not be available in certain machines.

®

Page 4

TECHNOLOGY

Waveform Control Technology

Aluminum Weld Programs Stainless Steel Weld Programs

Process Gas Wire Size Mode

3/64

1/16

GMAW Argon

Pulse Argon

Pulse-on-Pulse

TM

Argon

3/64

1/16

0.035

0.035

3/64

1/16

3/64

1/16

0.035

0.035

0.035

3/64

1/16

0.035

3/64

1/16

Alloy Weld Programs

71

73

75

77

148

151

72

74

76

78

149

152

98

99

100

101

102

103

Process Gas Wire Size Mode

0.030

GMAW Argon (mix)

GMAW

Pulse

Pulse

Pulse

®

STT

Argon/He/CO

Argon/He/CO

Argon/CO

Argon/O

Argon/He/CO

2

2

0.035

0.045

0.030

0.035

2

0.045

0.030

0.035

2

0.045

0.030

0.035

0.045

0.030

0.035

0.045

0.030

0.035

2

0.045

4/8

61

31

41

63

33

43

64

34

44

66

36

46

62

32

42

109

109

125

Process Gas Wire Size Mode

Nickel Pulse Argon/He

Silicon/Bronze

Pulse

Argon 0.035 192

0.035

0.045

170

175

Metal Core Weld Programs

Process Gas Wire Size Mode

0.045

0.052

1/16

0.045

0.052

1/16

GMAW

Pulse

Argon/CO

Argon/CO

2

2

81

83

85

82

84

86

Aluminum Welding Application

The future of welding is here.

Stainless Steel Welding Application

®

Page 5

TECHNOLOGY

Waveform Control Technology

Using Waveform Control

The amount of current applied in varying time

intervals can be charted as a waveform. This

waveform characterizes the weld output. Changing

specific values during specific periods of the

waveform directly affects the characteristics of the

weld. Lincoln Waveform Control Technology Welding

Systems use high-speed electronics to monitor the

electrical signals from the welding arc and make

appropriate changes to the current waveform. All the

desired factors which control the welding arc from

“arc start to arc stop” are written in software.

Changes to the waveform can be made in real-time,

(that is, during the weld), or after the weld if it is

evident that the weld does not meet requirements.

Arc Control: Controlling the Waveform

Waveform Control Technology Welding Systems provide the

operators with a simple control knob, “Arc Control”, also

known as “Inductance” or “Wave Control”. It allows the

operator to vary the arc characteristics from “soft” to “crisp”

in most weld modes. It is adjustable from -10.0 to +10.0,

with a nominal setting of 00.0. The following are descriptions

of the arc control functions for different weld processes.

Arc Force - (SMAW)

Range: -10 (soft) to +10 (crisp)

Arc force adjusts the short circuit current for a soft arc, or

a forceful driving arc, to prevent sticking and shorting of

electrodes. Arc force is especially effective for the

root pass on pipe with a stainless electrode, and helps

minimize spatter.

Pinch - (GMAW CV)

Range: -10 (soft) to +10 (crisp)

Pinch controls the current applied at a short circuit during

short arc welding.

Frequency Modulation - (GMAW-PP)

Range: -10 (low frequency) to +10 (high frequency)

Frequency Modulation controls the spacing of the ripples in

the pulse-on-pulse weld. Low frequency modulation is used

for slow travel speeds, while high frequency modulation is

used for narrower welds.

Pulse Frequency - (GMAW-P)

Range: -10 (low frequency) to +10 (high frequency)

Pulse frequency controls arc “stiffness” The lower the

frequency of the pulse, the wider and softer the arc.

Trim - (Synergic GMAW, GMAW-P)

Range: 0.5 to 1.5

Trim controls the length of the arc. Trim values less than 1.00

decrease the arc length, while values greater than 1.00

increase the arc length.

Waveform Control

Software

WaveDesigner

Lincoln Electric created the Wave Designer software

program to simplify the operator’s experience with

controlling various attributes of the waveform. Wave

Designer is a tool that allows the manipulation of

current waveforms and arc characteristics with a live

welding arc. It can also monitor and analyze the critical

parameters of the actual waveform at high resolution.

ArcScope

The ArcScope utility allows the operator to view the

actual arc voltage in real-time. This provides the

necessary information to manipulate the arc

characteristics to achieve a quality weld.

Custom Waveforms

Customized welding software means even the most

difficult materials can be welded with the Power

Feed/Power Wave system. Copper, Nickel, and Silicon

Bronze are a few of the unusual alloys the Waveform

Control system welds with ease when special software

is loaded. Lincoln Electric will build custom waveforms for

those customers experiencing difficulty with unique

materials or joint configurations.

Wave Designer and

ArcScope display

real-time readouts of

welding arc activity.

5/8

The future of welding is here.

®

Page 6

TECHNOLOGY

Waveform Control Technology

Process Controls

Pulse-On-Pulse

Unlike standard pulse welding, which uses a single

pulse wave shape, Pulse-On-Pulse uses a sequence of

varying pulse wave shapes to produce a GTAW-like

bead appearance to readily produce top quality

aluminum welds with excellent appearance, little spatter,

and good bead shape. The waveform control in PulseOn-Pulse welding is frequency modulation. Frequency

modulation controls the spacing of the ripples in the

weld. Use low values for slow travel speeds and wide

welds, and high values for fast travel speeds and

narrower welds.

®

STT

STT uses current controls to adjust the heat, so changes

in electrode extension do not affect heat input. The

Waveform Controls associated with STT welding are

Peak Current, Background Current, and Tail-Out. Peak

current controls the arc length, which affects the shape

of the root face; Background current controls heat input,

which affects the back bead; Tailout current also

contributes to control of heat input.

Power Mode

The Power Mode uses Power (V x I = W) to regulate the

arc length. The preset power setpoint is the main

control. Increasing the power setpoint forces the power

source to adjust BOTH voltage and current to maintain

the watt energy programmed for that setpoint.

Increasing the power setpoint will increase voltage and

decrease current simultaneously.

Tandem MIG

Tandem MIG uses two independently generated arcs

contributing to the same weld puddle. Tandem MIG can

operate in one of two configurations: a lead CV arc with

a pulsed trail, or two synchronized pulsed arcs. The

Waveform Controls for Tandem MIG are pulse

frequency, background current and trim, which control

heat input and arc stiffness.

AC/DC Submerged Arc

Submerged Arc welding involves as many as five

independently generated arcs contributing to the same

weld puddle, under a blanket of flux. Waveform Control

allows for infinite phase shifting of the AC waveform

through the frequency modulation control. Also, ultimate

control of deposition and penetration can be obtained by

adding positive or negative DC offsets to the waveform.

TM

The STT Waveform controls heat input

and reduces spatter and fume

TM

The Tandem MIG relies on Waveform Control

to synchronize its dual arc system

6/8

AC/DC Submerged Arc uses Waveform control

for infinite phase-shifting to accommodate up

The future of welding is here.

to 5 arcs without arc blow

®

Page 7

TECHNOLOGY

Waveform Control Products

Power Wave 455M

Power Wave 455M/STT

These Power Waves are designed to be part of a

modular, multi-process welding system.

• The Power Wave 455M and 455M/STT are high

performance, digitally controlled inverter welding

power sources capable of complex, high-speed

waveform control.

• Digital Communications enable the Power Wave to

connect seamlessly to robot controllers and hard

automation PLCs. Semi-automatic applications are

also supported.

• Optional DeviceNet and Ethernet communication

modules provide

networking capabilities

and allow process and

production monitoring.

• Software-based controls

can be upgraded as new

features become

available.

Power Wave 355/Power FeedTM10M

The Power Wave 355 is the smaller, lighter version of the

Power Wave 455M – same machine, just leaner and lighter.

• The Power Wave 355/Power Feed™ 10M welding system

is factory-programmed with over 60 standard welding

programs to optimize the arc for a variety of materials or

applications, including steel, stainless steel, aluminum,

nickel alloys and others.

• ArcLink Digital Communication between components

allows unprecedented waveform control and expansion

capability. Simply select a program and you have the right

arc characteristics for your application.

• The software is upgradeable, so your Power Wave 355

will grow with your

business. If you want

to reduce costs by

buying a versatile

machine that will do

multiple jobs and last

for years to come, the

high efficiency Power

Wave 355 delivers.

7/8

Power Wave 655R

The Power Wave 655R was designed for Robotic and

Hard Automation applications that require extra power

(650 Amps at 100% Duty Cycle)

• Digital Communications enable the Power Wave to

connect seamlessly to robot controllers and hard

automation PLCs. Semi-automatic applications are

also supported.

• The Ethernet/DeviceNet Gateway provides networking

capabilities and allows

process and production

monitoring.

• Software-based controls

can be upgraded as new

features become

available.

• The Power Wave 655R

has an output range of

20 to 880 Amps.

Power MIG 300

The Power MIG 300 – a single phase, multi-process,

synergic power source/wire feeder combination

welding package for the professional welder.

The Power MIG 300 offers:

• Superior multi-process welding.

• Synergic design for ultimate control over the arc,

by automatically

aligning wire feed

speed and voltage.

• Top-quality aluminum

welds with push-pull

wire feed capability,

not typically available

in competitive

models.

• True MIG pulsing and

Pulse-on-Pulse™

capabilities, which

ensure that superior

feeding is matched

by high quality arc

performance.

The future of welding is here.

®

Page 8

TECHNOLOGY

Waveform Control Products

8/8

WHAT IS NEXTWELD?

Power Wave AC/DC 1000

The Power Wave AC/DC is a modular

welding system with a single range of

control from 100 to 1000 Amps per arc at

100% duty cycle

The Power Wave AC/DC provides:

• DC+, DC- and Variable frequency up to

200 Hertz

• Flexible Waveform Control

• Variable Frequency

• Variable independent amplitudes

• Variable timing

• The Power Wave AC/DC is 100%

software controlled

The challenges facing industrial

fabricators today are increasingly

difficult. Rising labor, material, and

energy costs, intense domestic and

global competition,

a dwindling pool of

skilled workers,

more stringent and

specific quality

demands.

Through our

commitment to

extensive research

and investments in

product

Power Wave F355i

The Power Wave F355i is fully integrated with the FANUC ARC Mate™

R-J3iB controller and designed for the most demanding robotic applications.

• This compact unit delivers 350 Amps

@ 60% duty cycle for MIG, Pulsed MIG

or Flux-Cored welding applications.

• The Power Wave F355i/ARC Mate

R-J3iB communicates via ArcLink™,

allowing all welding procedures

and process controls to be managed

through the ARC Mate robot teach

pendant – one central control forsetup,

process control and diagnostics.

development,

Lincoln Electric has

established an industry benchmark for

applying technology to improve the

quality, lower the cost and enhance the

performance of arc welding processes.

Advancements in power electronics,

digital communications and Waveform

Control Technology

TM

are the foundation

for many of the improvements.

NEXTWELD brings you a series of

Process, Technology, Application and

Success Story documents like this one.

NEXTWELD explains how technologies,

products, processes and applications are

linked together to answer the important

questions that all businesses face:

• How can we work faster, smarter,

more efficiently?

• How can we get equipment and

people to perform in ways they’ve

never had to before?

* Ethernet access is available through the Ethernet port of the R-J3iB

• How do we stay competitive?

NEXTWELD is the future of welding but

Customer Assistance Policy

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment,

consumables, and cutting equipment. Our challenge is to meet the needs of our customer and to exceed

their expectations. On occasion, purchasers may ask Lincoln Electric for advice or information about their

use of our products. We respond to our customers based on the best information in our possession at that

time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with

respect to such information or advice. We expressly disclaim any warranty of any kind, including any

warranty of fitness for any customer’s particular purpose, with respect to such information or advice. As a

matter of practical consideration, we also cannot assume any responsibility for updating or correcting any

such information or advice once it has been given, nor does the provision of information or advice create,

expand or alter any warranty with respect to the sale of our products.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln

Electric is solely within the control of, and remains the sole responsibility of the customer. Many variables

beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication

methods and service requirement.

Subject to change - This information is accurate to the best of our knowledge at the time of printing.

Please refer to www.lincolnelectric.com for any updated information.

its benefits are available to you today.

Ask your Lincoln Electric representative

how to improve the flexibility, efficiency

and quality of your welding operations to

reduce your cost of fabrication.

THE LINCOLN ELECTRIC COMPANY

www.lincolnelectric.com

1.216.481.8100

The future of welding is here.

®

Loading...

Loading...