Page 1

and

and

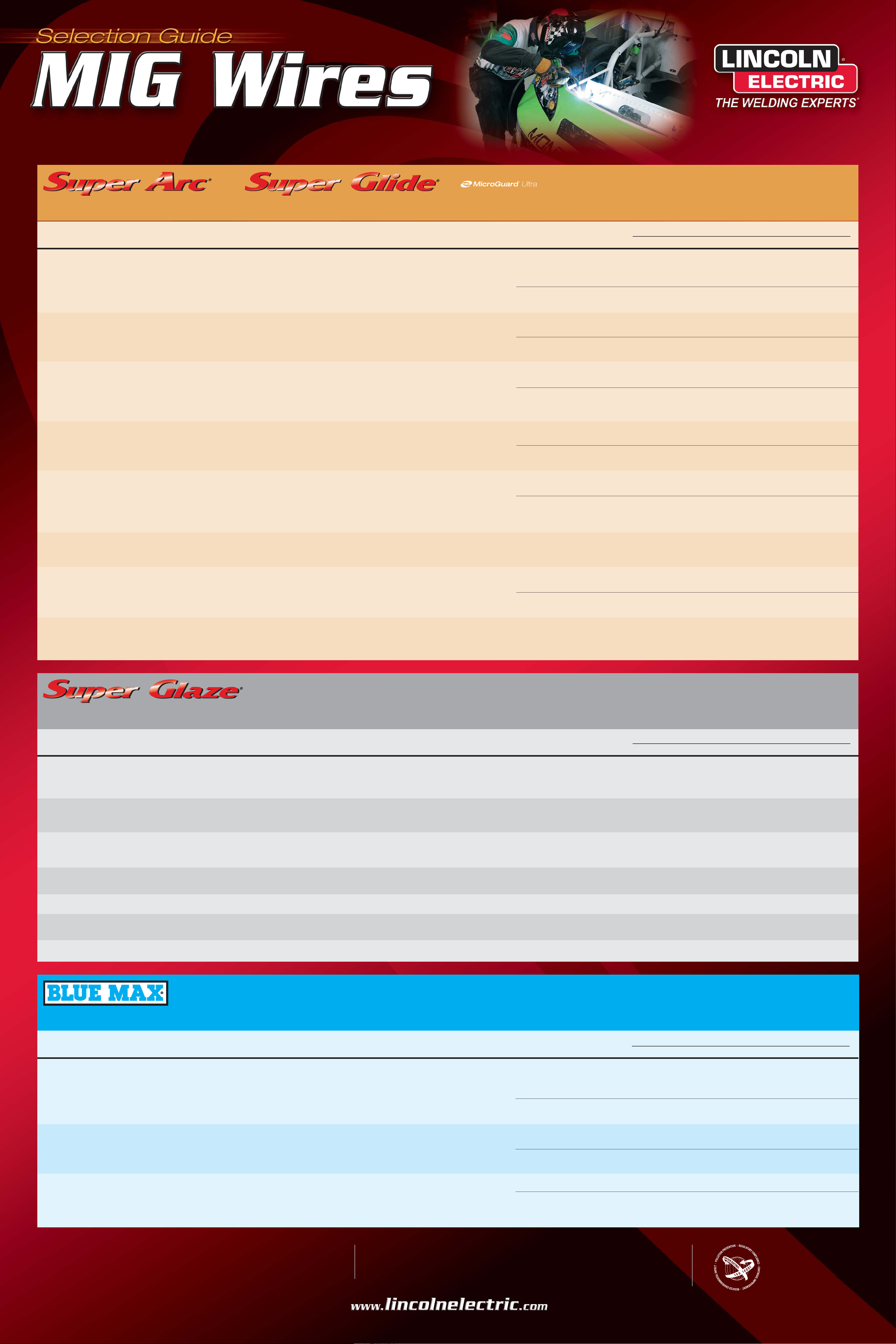

Mild Steel and Low Alloy Wires

Mild Steel and Low Alloy Wires

surface treatment, with proprietary arc enhancement agents, facilitates excellent weld puddle control, very

good wetting action, straight bead edges and a wider operating range. Plus, the exceptional feeding characteristics of Super Arc

®

Super Glide

, made possible by MicroGuard®Ultra surface treatment, translate to reduced down-time and high operator appeal.

®

and

WFS,

Diameter

Electrode AWS General Shielding Volts &

Name Class Description Gas Amps .025" .030" .035" .045" .052" 1/16"

Mild Steel Wire

Super Arc®L-50

Super Glide

Super Arc

®

S3 ER70S-3 100% CO

®

L-54 ER70S-4 100% CO

®

ER70S-3 100% CO

Our most popular MIG wire, Super Arc®L-50®, premium copper coated wire, is an excellent choice for 70,000 psi (483 MPa) tensile strength,

carbon steel base materials. Super Arc

for use on clean, oil-free, and rust-free base material. Will tolerate light millscale. Super Arc

®

L-50®has moderate levels of silicon and manganese for deoxidation and cleaning action. Designed

®

L-50®also has an excellent reputation for feed-

ability and trouble-free performance. Shielding gases include argon/carbon dioxide blends, argon/oxygen blends, straight carbon dioxide.

®

Super Glide

carbon steel base materials. Super Glide

S3, our premium bare MIG wire, like our Super Arc®L-50®, is an excellent choice for 70,000 psi (483 MPa) tensile strength,

®

S3 has moderate silicon and manganese deoxidizer levels and has an excellent reputation for feedability and trouble-free performance. Designed for use on clean, oil-free, and rust-free base material. Will tolerate light millscale. Super Glide

S3 MIG wire is an excellent choice when a bare or non-copper coated ER70S-3 wire is preferred. Shielding gases include argon/carbon

dioxide blends, argon/oxygen blends, straight carbon dioxide, and three or four-part gas mixes.

Super Arc

®

L-54 premium copper coated MIG wire is your first choice when welding on metals with a light to medium presence of millscale.

For best performance, use on clean, oil-free, and rust-free base material. Improved wetting at the toes of a weld when compared to welds

made with ER70S-3 electrode. Super Arc

®

L-54 has higher silicon and manganese deoxidizer levels than AWS ER70S-3 electrodes to tolerate

moderate levels of millscale. Shielding gases include argon/carbon dioxide blends, argon/ oxygen blends, straight carbon dioxide, and three

or four-part gas mixes.

2

75-80%Ar / Balance CO

2

WFS — 75-300 100-250 125-200 — —

Volts — 16-22 17-22 18-22 — —

Amps — 35-130 80-175 145-200 — —

80-95%Ar / Balance CO

95-98%Ar / Balance O

2

2

WFS — — 375-600 350-500 300-485 210-290

Volts — — 23-30 26-31 29-32 25-30

Amps — — 195-275 285-340 300-430 325-430

2

75-80%Ar / Balance CO

®

80-95%Ar / Balance CO

95-98%Ar / Balance O

2

2

2

WFS — 75-300 100-250 125-200 — —

Volts — 16-22 17-22 18-22 — —

Amps — 35-130 80-175 145-200 — —

WFS — — 375-600 350-500 300-485 210-290

Volts — — 23-30 26-31 29-32 25-30

Amps — — 195-275 285-340 300-430 325-430

2

75-80%Ar / Balance CO

2

WFS — 75-300 100-250 125-200 — —

Volts — 16-22 17-22 18-22 — —

Amps — 35-130 80-175 145-200 — —

80-95%Ar / Balance CO

95-98%Ar / Balance O

2

2

WFS — — 375-600 350-500 300-485 210-290

Volts — — 23-30 26-31 29-32 25-30

Amps — — 195-275 285-340 300-430 325-430

L-56

®

ER70S-6 100% CO

Lincoln’s

of millscale. For best performance use on clean, oil-free, and rust-free base material. Best weld appearance and toe wetting when compared to

ER70S-3 and ER70S-4 classifications. Super Arc

arc characteristics are trademarks of Super Arc

carbon dioxide, and three or four-part gas mixes.

®

S6 ER70S-6 100% CO

Lincoln’s

of millscale. For best performance use on clean, oil-free, and rust-free base material. S6 will tolerate higher levels of surface contaminants

®

premium copper coated MIG wire, Super Arc®L-56®is an excellent choice for welding on metals with a medium to high presence

®

L-56®has high silicon and manganese deoxidizer levels. Superior feedability and excellent

®

L-56®. Shielding gases include argon/carbon dioxide blends, argon/oxygen blends, straight

®

premium bare, mild steel MIG wire, Super Glide®S6 is an excellent choice for welding on metals with a medium to high presence

75-80%Ar / Balance CO

80-95%Ar / Balance CO

95-98%Ar / Balance O

75-80%Ar / Balance CO

2

2

Super Arc

®

Super Glide

than ER70S-3 or S-4 electrodes. Best weld appearance and toe wetting when compared to ER70S-3 and ER70S-4 classifications. High silicon

and manganese deoxidizer levels. Super Glide

ferred. Shielding gases include argon/carbon dioxide blends, argon/oxygen blends, straight carbon dioxide, and three or four-part gas mixes.

®

S6 MIG wire is the choice for you when a bare or non-copper coated ER70S-6 wire is pre-

80-95%Ar / Balance CO

95-98%Ar / Balance O

Low Alloy Wire

®

Super Arc®LA-75 ER80S-Ni1 80-95%Ar / Balance CO

Super Arc

mechanical properties are achieved with a 98-95% argon, 2-5% oxygen shielding gas blend. Can be welded with 90% argon, 10% carbon

dioxide gas blend, as well as 75% argon, 25% carbon dioxide mixture. Charpy V-Notch impact testing meets or exceeds 20 ft. lbs. (27 J)

at -50°F (-46°C). Provides best weld deposit with atmospheric corrosion resistance for ASTM A588 weathering steels.

Super Arc

®

LA-90 ER80S-D2 100% CO

ER90S-D2 75-80%Ar / Balance CO

(ER90S-G) Amps — — 80-175 145-200 — —

Super Arc

psi (552-620 MPa) minimum. The addition of 0.5% molybdenum provides strength after stress relief. Ideal selection when welding ASTM

A182, A217, A234 and A335 high temperature pipe, fittings, flanges and valves, and A336 pressure vessel forgings. Best mechanical

properties are achieved with an 98-95% argon, 2-5% oxygen shielding gas blend.

LA-75 is a premium copper coated, low alloy MIG wire certified to meet 80,000 psi (552 MPa) minimum tensile strength. Optimal

®

LA-90 is our premium copper coated, low alloy MIG wire manufactured to meet tensile strength requirements of 80,000 to 90,000

95-98%Ar / Balance O

2

80-95%Ar / Balance CO

95-98%Ar / Balance O

WFS 100-250 75-300 100-250 125-200 — —

2

Volts 17-19 16-22 17-22 18-22 — —

Amps 35-90 35-130 80-175 145-200 — —

2

2

WFS — — 375-600 350-500 300-485 210-290

Volts — — 23-30 26-31 29-32 25-30

Amps — — 195-275 285-340 300-430 325-430

WFS 100-250 75-300 100-250 125-200 — —

2

Volts 17-19 16-22 17-22 18-22 — —

Amps 35-90 35-130 80-175 145-200 — —

2

2

WFS — — 375-600 350-500 300-485 210-290

Volts — — 23-30 26-31 29-32 25-30

Amps — — 195-275 285-340 300-430 325-430

2

2

WFS — — 130-600 300-450 — —

Volts — — 15-30 20-30 — —

Amps — — 70-260 210-300 — —

WFS — — 100-250 125-200 — —

2

2

2

Volts — — 17-22 18-22 — —

WFS — — 375-600 350-500 300-485 210-290

Volts — — 23-30 26-31 29-32 25-30

Amps — — 195-275 285-340 300-430 325-430

Super Arc

®

LA-100 ER100S-G 90-95%Ar / Balance CO

(ER110S-G) 95-98%Ar / Balance O

MIL-100S-1 Amps — — — 210-300 — 280-450

(military)

Super Arc

those materials that require a minimum yield strength of 82,000 psi (565 MPa). Excellent for welding on ASTM A514, A543, A724 and A782

quenched and tempered plate or HY-80 base material. LA-100 provides excellent impact properties under higher heat input conditions. Best

mechanical properties are achieved with an 98-95% argon, 2-5% oxygen shielding gas blend or 95% argon/5% oxygen. Also meets MIL-E-

®

LA-100, our premium copper coated, low alloy MIG wire is designed for use on 100,000 psi (690 MPa) tensile base material and

2

2

WFS — — — 300-450 — 170-300

Volts — — — 20-30 — 21-29

23765/2C, /2D, /2E specifications as a MIL-100S-1 classification.

Super Glaze®controls the problems usually associated with aluminum wire feeding such as birdnesting, tangling and burnback, by providing fewer surface imperfections

and feeding the wire with less force than typical competitive products.

Aluminum MIG Wire

Aluminum MIG Wire

Diameter

Electrode AWS General Shielding Volts &

Name Class Description Gas Amps .030" .035" .040" 3/64" 1/16"

Aluminum MIG Wire

Super Glaze®1100 ER1100 100% Ar Volts 15-19 15-20 18-23 19-24 22-27

Super Glaze®1100 is highly resistant to chemical corrosion and has good crack resistance. Suitable for electrical and chemical applications

utilizing aluminum base metal with little or no alloying elements. Like all 1XXX filler alloys, Lincoln’s

®

Super Glaze®1100 is the softest

Ar/He Mixtures Amps 70-135 90-140 110-220 140-250 200-300

aluminum MIG wire and requires extra care to ensure good feeding.

Super Glaze

®

4043 ER4043 100% Ar Volts 15-19 15-20 18-23 19-24 22-27

Super Glaze

melting point and more fluidity than the 5XXX series filler alloys and is preferred by welders because of its favorable operating characteristics.

ER4043 type wires are also less sensitive to weld cracking with the 6XXX series base alloys. Super Glaze

®

4043 is a great choice for the welding of heat-treatable base alloys and more specifically the 6XXX series alloys. It has a lower

®

4043 is suitable for sustained

Ar/He Mixtures Amps 70-135 90-140 110-220 140-250 200-300

elevated temperature service, i.e. above 150°F (65°C).

Super Glaze

®

4047 ER4047 100% Ar Volts 15-19 15-20 18-23 19-24 22-27

A lower melting point and higher fluidity are two advantages Super Glaze

produces very clean weld deposits and possesses excellent operator appeal. It can be used as a substitute for an ER4043 type wire to increase

silicon in the weld metal, minimize hot cracking, and produce higher fillet weld shear strength. Super Glaze

®

4047 has over its cousin Super Glaze®4043. Super Glaze®4047

®

4047 is suitable for sustained

Ar/He Mixtures Amps 70-135 90-140 110-220 140-250 200-300

elevated temperature service, i.e. above 150°F (65°C).

Super Glaze

®

5183 ER5183 100% Ar Volts 15-19 15-20 18-23 19-24 22-27

Super Glaze

materials when required tensile strengths are 40,000 psi (276 MPa) or greater. Typical applications are in the marine and cryogenic industries,

®

5183 is designed to weld high magnesium alloys to meet higher tensile strength requirements. Use on 5083 and 5654 base

Ar/He Mixtures Amps 70-135 90-140 110-220 140-250 200-300

and high strength structural aluminum fabrication.

Super Glaze

Super Glaze

®

5356 ER5356 100% Ar Volts 15-19 15-20 18-23 19-24 22-27

Super Glaze

alloys when 40,000 psi (276 MPa) tensile strength is not required. 5356 is often chosen for its high shear strength.

®

5554 ER5554 100% Ar Volts 15-19 15-20 18-23 19-24 22-27

Super Glaze

often used for automotive wheels, over-the-road trailers, and rail tank cars where the weld filler metal chemistry must closely match the base

®

5356 is our most popular aluminum MIG wire. It is a great general purpose filler alloy designed for the welding of 5XXX series

®

5554 is intended as a matching filer alloy when welding 5454 base alloys. This alloy is a lower magnesium content alloy and is

Ar/He Mixtures Amps 70-135 90-140 110-220 140-250 200-300

Ar/He Mixtures Amps 70-135 90-140 110-220 140-250 200-300

material chemistry to maximize corrosion performance.

Super Glaze

®

5556 ER5556 100% Ar Volts 15-19 15-20 18-23 19-24 22-27

Super Glaze

amounts of magnesium or manganese compared to Super Glaze

®

5556 weld deposits will provide matching tensile strengths for the 5XXX alloys, such as 5083 and 5654. Contains increased

®

5356.

Ar/He Mixtures Amps 70-135 90-140 110-220 140-250 200-300

Blue Max®stainless steel MIG wires can be used for all position welding. Globular and spray transfer are recommended for downhand and horizontal only.

Short circuiting mode and pulsed arc can be used for out-of-position welding. Gas shielding mixtures recommended are either argon and oxygen blend for

®

welding.

Diameter

Stainless Steel MIG Wire

Stainless Steel MIG Wire

spray and pulsed transfer, or a helium-rich blend for short circuiting and STT

WFS,

Electrode AWS General Shielding Volts &

Name Class Description Gas Amps .025" .030" .035" .045" .052" 1/16"

Stainless Steel MIG Wire

Blue Max®MIG ER308Si (Short Circuiting Mode) WFS — — 140-425 100-275 — —

308LSi ER308LSi 90%He/7.5%Ar/2.5%CO

This premium quality MIG wire is for joining 304 and 304L and other common “18-8” austenitic stainless steels. It is specially processed for

superior feeding and arc stability.

2

Volts — — 19-23 19-23 — —

Amps — — 55-170 100-185 — —

(Spray Transfer) WFS — — 400-475 240-360 — 175-300

98%Ar/2%CO

2

Volts — — 23-25 24-26 — 26-32

Amps — — 180-210 195-260 — 260-390

Blue Max

309LSi ER309LSi 90%He / 7.5%Ar/2.5%CO

®

MIG ER309Si (Short Circuiting Mode) WFS — — 120-425 100-275 — —

Blue Max

specially processed to provide superior feeding and arc stability.

®

MIG 309LSi is a premium quality MIG wire ideally suited for joining mild steel or low alloy steel to stainless steel. This wire is

(Spray Transfer) WFS — — 400-475 240-360 — 175-300

98%Ar/2%CO

Blue Max

316LSi ER3016LSi 90%He/7.5%Ar/2.5%CO

®

MIG ER316Si (Short Circuiting Mode) WFS — — 120-425 100-275 — —

When joining 316 and 316L stainless steels with the MIG process, Blue Max

specially processed to provide superior feeding and arc stability.

®

MIG 316LSi is the answer. This premium quality wire is

2

(Spray Transfer) WFS — — 400-475 240-360 — 175-300

CUSTOMER ASSISTANCE POLICY

The business of The Lincoln Electric Company

to exceed their expectations. On occasion, purchasers may ask Lincoln Electric®for advice or information about their use of our products. We respond to our customers based on the best information in our

possession at that time. Lincoln Electric

any kind, including any warranty of fitness for any customer’s particular purpose, with respect to such information or advice. As a matter of practical consideration, we also cannot assume any responsibility

for updating or correcting any such information or advice once it has been given, nor does the provision of information or advice create, expand or alter any warranty with respect to the sale of our products.

Lincoln Electric

variables beyond the control of Lincoln Electric®affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

®

is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric®is solely within the control of, and remains the sole responsibility of the customer. Many

®

is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the needs of our customers and

®

is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or advice. We expressly disclaim any warranty of

98%Ar/2%CO

IMPORTANT

Arc Welding is safe when sufficient measures are taken to protect the welder from potential hazards. Recognize and safeguard yourself against these hazards, such as electric shock, overexposure to arc

radiation, fumes and gases. Every welder should be familiar with the ANSI Z49.1 documents, “Safety in Welding and Cutting”, available from the American Welding Society, Miami, Florida. Also request

bulletins E205 “Arc Welding Safety” and E201 “Arc Welding Safety Chart”, available from The Lincoln Electric Company

2

®

.

2

Volts — — 19-23 19-23 — —

Amps — — 55-170 100-185 — —

Volts — — 23-25 24-26 — 26-32

Amps — — 180-210 195-260 — 260-390

2

Volts — — 19-23 19-23 — —

Amps — — 55-170 100-185 — —

Volts — — 23-25 24-26 — 26-32

180-210 195-260 260-390

CERTIFICATIONS

ISO 14001 and 9001 certified – manufactured to standards for

environmental and quality management systems.

WC-19M 8/06

Loading...

Loading...