Page 1

APPLICATION

WAVEFORM CONTROL TECHNOLOGY

TM

Making Fillet Welds with Power Wave AC/DC 1000™ System

Welding Guide

Now from Lincoln - the power

to increase productivity with

Power Wave technology!

Lincoln Power Wave technology

based upon the new Power Wave

AC/DC 1000™ power source

provides the opportunity to

significantly lower the cost of

making fillet welds and at the

same time, makes many of the

issues that cause weld defects

a thing of the past. In some

respects, the Power Wave AC/DC

1000™ describes both a new

generation of equipment and

a new technology for

controlled welding.

Now, from a single power source

it is possible to choose the very

best type of arc characteristic for

the particular job at hand. The

Power Wave AC/DC 1000™

system allows the choice of the

appropriate voltage-current

relationship at the mere “flick

of a switch”.

advantages

CHOICE AT THE “FLICK OF A SWITCH”

• Constant current (sometimes referred to as variable voltage).

• Constant voltage.

• Square Wave AC.

UNLIMITED AC OUTPUT TAILORING

• Choice of AC frequency (from 10 Hz to 100 Hz).

• Wave balance control to allow more or less DC

positive component.

• Offsetting the AC wave to change the magnitude of the

negative or positive component.

40% Increase in Travel Speed

5/16” (8mm) Horizontal Fillet Weld

5/32” (4mm) Dia. Electrode

525 Amperes (Both Welds)

REDUCTION IN DEFECTS

• Virtual elimination of arc-striking problems.

• Virtual elimination of arc blow.

LOWER COSTS

• Documented productivity increases over conventional

submerged arc welding.

Patented. This product is protected by one or more of the following United States patents: 6,809,292;

6,795,778; 6,700,097; 6,697,701; 6,683,278; 6,660,966; 6,600,134; 6,683,278; 6,596,570; 6,570,130;

6,536,660; 6,489,952; 6,472,634; 6,636,776; 6,486,439; 6,441,342; 6,365,874; 6,291,798; 6,207,929;

6,111,216; 4,927,041; 4,861,965 and other pending U.S. patents. Similar patents are maintained in

other countries.

The future of welding is here.

NX-3.50 5/05© Copyright 2005 The Lincoln Electric Company. All rights reserved.

®

Page 2

WAVEFORM CONTROL TECHNOLOGY

TM

Making Fillet Welds with Power Wave AC/DC 1000™ System

Welding Guide

APPLICATION

2/10

DC welding has almost always been the preferred

choice for producing submerged arc welds. Some of

these reasons are:

contaminants, organic and/or inorganic contaminants

in or on the steel and greater potential for slag

entrapment because of the larger and “colder” weld

puddle. DC negative has always been the method of

1. Lowest capital cost for equipment.

2. Greater arc stability than with AC.

3. Virtual elimination of arc striking problems.

4. Power issues (single phase vs. three phase

balanced power)

choice for welding off-analysis steel or dirty steel

where it is desirable to have minimum dilution. But

with Power Wave AC/DC 1000™ technology, this is

no longer the best option. The Power Wave AC/DC

1000™ provides the capability of easily using the best

welding mode for the job at hand.

While DC negative may offer the highest deposit rate

per ampere, it is seldom used for automatic welding

that must meet stringent code requirements. This is

because DC negative is more prone to magnetic arc

interference (arc blow), porosity resulting from

Understanding Power Wave AC/DC 1000

To fully understand the potential for possible

productivity gains using the Power Wave AC/DC

1000™ system, understanding the major AC

components and what they contribute is helpful.

The major components consist of:

1. Square wave (vs. a conventional sine wave)

2. Square wave balance

3. Square wave offset

4. Square wave frequency

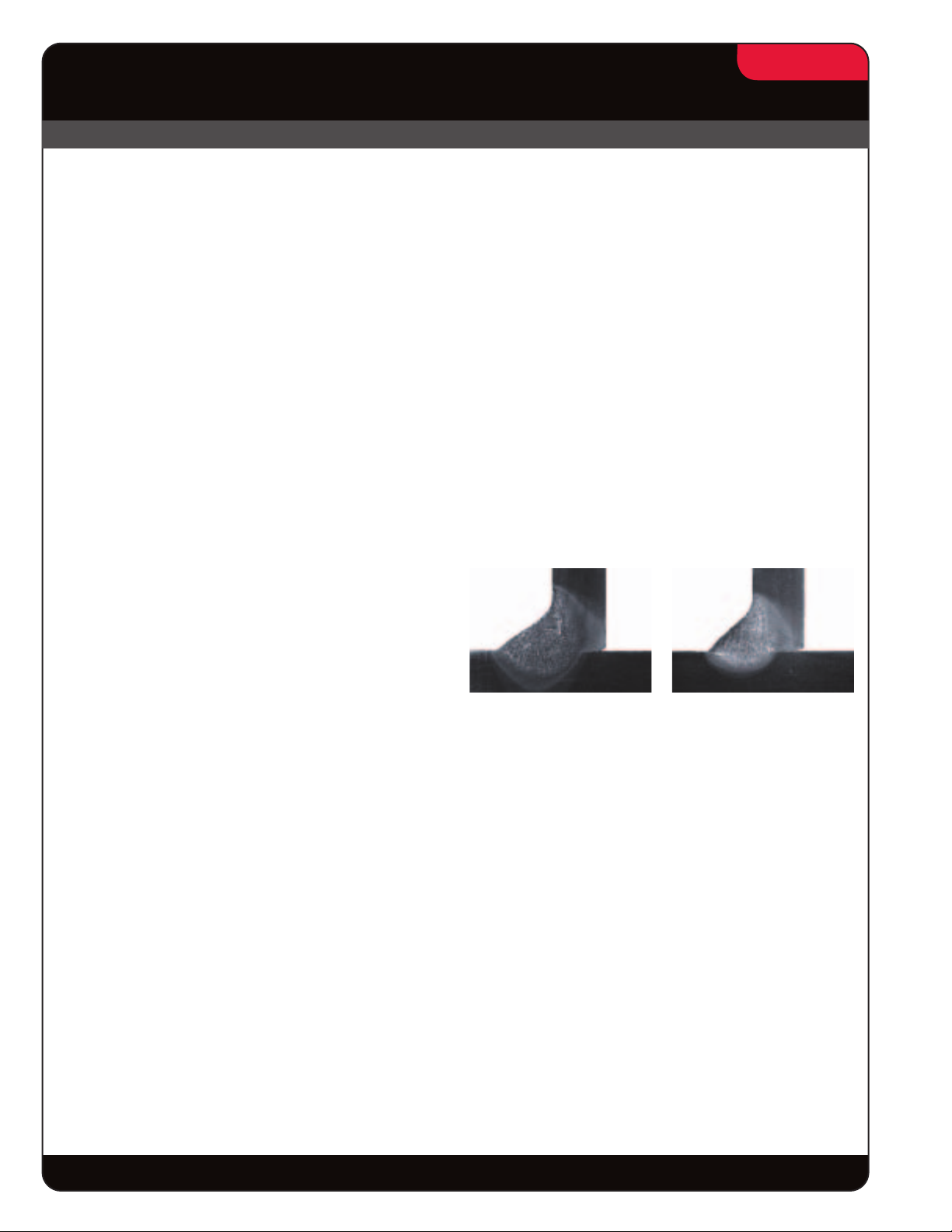

Figure 1 shows photographs of two 5/16” (8mm)

1

horizontal fillet welds

. One is made using a good

DC+ procedure and one using a square wave 25%

balanced, (-)10% offset and 30 Hz. Both are excellent

fillets but the square wave procedure is forty percent

faster! Note that the amperage used is virtually the

same, 520 vs. 527 amperes.

40% faster travel speeds by using Power Wave AC/DC

1000™ Square Wave procedures over DC+ procedures.

DC+

527 Amps

Figure 1

™

AC/DC

520 Amps

1

These welds comply with the geometry requirements for leg and throat dimensions of all AWS codes.

The future of welding is here.

®

Page 3

WAVEFORM CONTROL TECHNOLOGY

TM

Making Fillet Welds with Power Wave AC/DC 1000™ System

Welding Guide

APPLICATION

3/10

Square Wave vs. Sine Wave

Figure 2 shows one cycle of a true 60 Hz sine wave

with a square wave superimposed upon it. Note that

while the rms2value and the peak values are the same

for both waves, the transition time for peak-to-peak is

much shorter for the square wave. The transition

period is what has always caused instability with

conventional AC welding but with the rapid transition

associated with the Power Wave AC/DC 1000™, arc

stability is increased.

Square Wave Balance

Square wave balance can allow the arc to act more

as a DC negative or DC positive arc, thus increasing

deposition rate or increasing penetration. This is

always expressed as a percentage of the DC +

component. i.e., (25% Balance means that only 25%

of the cycle will be positive while 75% of the cycle will

be negative, etc.)

Figure 3 shows two 3/8” (10mm) flat positioned fillet

welds. Both were made at 814 amperes but the square

wave AC 25% balance wave is made 17% faster.

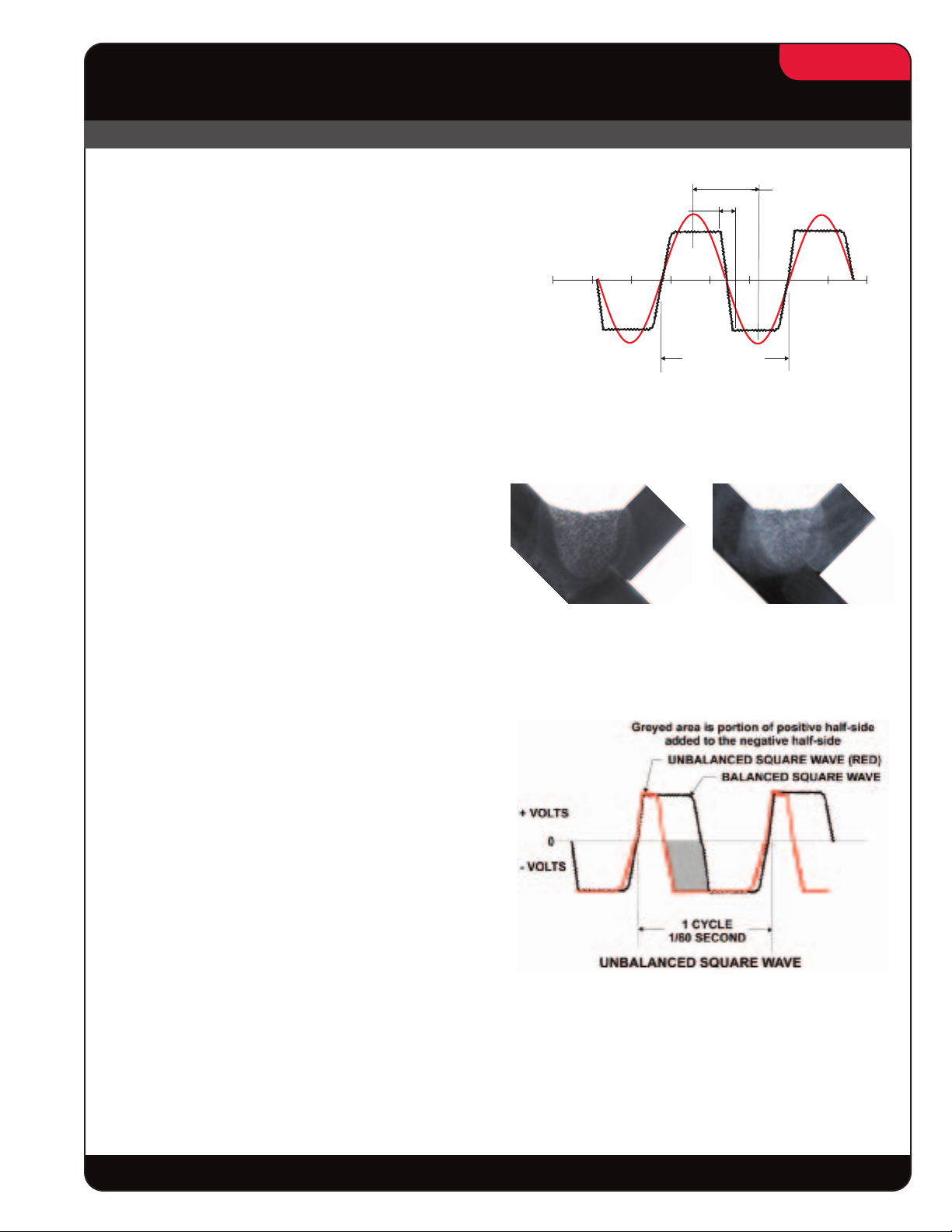

Figure 4 graphically shows the significance that square

wave balance can and does play. Note that only 25%

of the time is the arc positive while 75% of the time

it is negative. This flexibility can be used to tailor the

arc to achieve best results by increasing deposition,

decreasing penetration or decreasing deposition and

increasing penetration.

SQUARE WAVE

TRANSITION

REGION

+ VOLTS

0

- VOLTS

1 CYCLE

1/60 SECOND

60 Hz SINE WAVE vs 60 Hz SQUARE WAVE

Figure 2

DC+ AC 25% Balanced

Figure 3

SINE WAVE

TRANSITION

REGION

Figure 4

2

Rms: root-mean-square value of current or voltage. For example, when someone refers to, “110 volts,” this is actually an rms value as is

“30 volts AC”, etc.

The future of welding is here.

®

Page 4

WAVEFORM CONTROL TECHNOLOGY

TM

Making Fillet Welds with Power Wave AC/DC 1000™ System

Welding Guide

Square Wave Offset Effect

Offset is expressed as a percentage between -25%

and +25% of the rms

negative. In other words, -25% means the normal

positive component of each cycle is held to 25% of

the normal rms value and the negative component

becomes 75%. In some respects, when offset is

adjusted to maximum values, the arc action almost

becomes analogous to that of a pulsed arc. Negative

values contribute to increasing deposition to levels

closely approaching the values obtainable with DC

negative welding. See Figure 5.

Figure 6 shows two welds: the same 3/8” (10mm) flat

position fillet as Figure 3, but this time made using a

setting of 25% balance, (-)10% offset. Note that this

results in an additional gain of 12% in travel speed!

This is a net gain of 29% over DC+.

2

value that is kept positive or

50% Positive

0

Tot al

Amps

50% Negative

Square Wave - Current Offset

Figure 5

Comparison of offset vs normal balanced wave

APPLICATION

Square Wave - Normal Curve

Square Wave - Negative Offset

1 CYCLE

1/60 SECOND

4/10

Tot al

Amps

The increased deposits possible using a combination

of wave balance and wave offset may raise the

question about root penetration. While at present the

major welding codes do not allow sizing a fillet weld

based on root penetration, some producers of

proprietary products do. Figure 7 shows the depth of

penetration as compared to DC+ for a number of

settings. This shows a variation of only .05” (1.3mm) in

penetration, a variation of nine to ten percent. All of

the welds were made when the plate was at room

temperature and at 54.25Kj heat input.

Square Wave

Mode

Penetration-mm 5.53 4.06 4.06 4.02 4.43

DC+

Balanced

SW AC

25% Balanced

DC+ SW AC with Offset

AC 25% Balance

(-)10% Offset

Figure 6

SW AC

25% Balanced

(-) 10% Offset

SW AC

25% Balanced

(-) 20% Offset

Penetration vs. Various Modes

Figure 7

All welds made using 5/32” (4mm) Diameter Electrode

525 Amperes, 31 Volts, 1.25” (31.8mm) ESO

18 ipm (457.2mm/min) Travel Speed

54.25 Kj Heat Input

The future of welding is here.

®

Page 5

WAVEFORM CONTROL TECHNOLOGY

TM

Making Fillet Welds with Power Wave AC/DC 1000™ System

Welding Guide

Square Wave Frequency

While frequency is historically accepted to be fifty

or sixty hertz, the Power Wave AC/DC 1000™ can

function at any chosen frequency between zero (DC)

and 100 hertz. Frequency can play an important role

in a specific welding procedure. Relative to a “normal”

sixty hertz, deposition rates can be slightly increased

or decreased as can penetration. Frequency alters

the total time for the arc to be at peak values. As the

frequency decreases, more time is available at peak

value and – more importantly – less time is spent in

the transition region. The converse occurs as

frequency is increased. Figure 8 (frequency effect)

illustrates this by showing what occurs during one

complete cycle.

As the frequency of the AC wave is altered, the

amount of time spent at peak current and voltage

values and the amount of time spent transitioning

from positive to negative values also changes.

APPLICATION

5/10

In general, as the frequency is lowered, more time is

spent at peak values and less time transitioning. As

the frequency is increased, the opposite occurs.

This can be of considerable help when making fillet

welds between thick and thin members in reducing

burn-through and undercut resulting from overheating

the thinner member, as might be the case when

welding stiffeners to girder web plates. This is further

illustrated in Figure 10, (Penetration vs Frequency).

Conventional sine waves (in red) are superimposed

Figure 8

schematically with Power Wave square waves to illustrate

the frequency effect. The voltage and current values are

identical for all three curves.

The future of welding is here.

®

Page 6

WAVEFORM CONTROL TECHNOLOGY

TM

Making Fillet Welds with Power Wave AC/DC 1000™ System

Welding Guide

APPLICATION

6/10

Penetration vs. Frequency

Figure 9 compares three .31” (7.9mm) horizontal fillet

welds made at 10, 70 and 90 Hz. All were made at the

same heat input and travel speed. Penetration ranges

from 2.1mm to 3.2mm in depth.

Frequency-Hz

Penetration-mm

525 Amperes, 1.0 (25mm), 21 ipm (827mm/min) Travel Speed

10

2.5

5/32” (4.0mm) Diameter Electrode

AC 25% Balanced, (-)10% Offset, Hz (shown above)

Deposition Rates vs. Frequency

Frequency also plays a role in total deposition rate.

Deposition rates may increase about 6% as the

frequency is lowered. Deposition rate decreases

slightly as frequency is increased. This could be

significant, when producing large single pass

fillet welds.

70

3.2

Figure 9

90

2.1

Welding Mode

Penetration-mm

DC+

SW AC 25% BAL

(-) 10% OFFSET

20 Hz

SW AC 25% BAL

(-) 10% OFFSET

40 Hz

SW AC 25% BAL

(-) 10% OFFSET

70 Hz

SW AC 25% BAL

(-) 10% OFFSET

80 Hz

5.40 3.83 3.91 3.87 4.10 4.02

DC-

Figure 10

Penetration vs Frequency

5/32” (4.0mm) Electrode, 1.25” (31.8mm) ESO

526 Amperes, 31 Volts, 18 ipm (457mm/min) Travel

54.4 Kj Heat Input

The future of welding is here.

®

Page 7

WAVEFORM CONTROL TECHNOLOGY

TM

Making Fillet Welds with Power Wave AC/DC 1000™ System

Welding Guide

Power Wave AC/DC 1000™ Deposition Rate

Illustrating the ability of Power Wave AC/DC 1000™

technology to significantly increase fillet-welding

productivity, Figure 11 shows the deposition rate vs.

amperes for 5/32” (4mm) diameter electrode. This

figure can be used to predict the increased deposit

rate while maintaining a constant current.

APPLICATION

7/10

Figure 11

The future of welding is here.

®

Page 8

WAVEFORM CONTROL TECHNOLOGY

TM

Making Fillet Welds with Power Wave AC/DC 1000™ System

Welding Guide

Some Fillet Weld Results`

A number of fillet welds made with the Power Wave

AC/DC 1000™ are shown as examples. All of these

welds comply with the AWS D1.1 Structural Steel

Code and the AWS D1.5 Bridge Code and those

codes that clone or refer to the AWS Codes.

All fillet welds conform to the acceptable size and

gauge size requirements of the code.There has been

no intent to match any specific mechanical properties,

however, the welding consumables used to produce

these welds are commonly used.

Figure 12: Horizontal, 5/16” (8mm) fillet welds, shows

an increase of 40% in travel speed over DC+. Both

welds made with 5/32” (4mm) diameter electrode at

527 amperes.

The weld on the right is AC Balanced 25%, (-) 10% offset,

The weld on the left is DC+, 15 ipm travel.

Figure 12

30 Hz., 21 ipm travel.

APPLICATION

8/10

Figure 13: Flat positioned 1/2” (13mm) fillet welds

show an increase of 44% in travel speed over DC+.

Both welds made using 3/16” (4.8mm) diameter

electrode at 885 amperes.

Figure 14: Horizontal 1/4” (6mm) fillet welds, with an

increase of 32% in travel speed over DC+.

The weld on the left is with DC+, at 10.4 ipm travel.

Figure 13

The weld on the right is with AC 25% Balanced,

(-)20% Offset, 30Hz, at 15 ipm.

Figure 14

The weld on the left is with DC+.

The weld on the right is with AC 25% Balanced,

(-)10% Offset, 60Hz.

The future of welding is here.

®

Page 9

WAVEFORM CONTROL TECHNOLOGY

TM

APPLICATION

Making Fillet Welds with Power Wave AC/DC 1000™ System

Welding Guide

CONVERTING TO A POWER WAVE PROCEDURE

An easy approach to making a conversion to a Power

Wave AC/DC 1000™ procedure is to use this table as

a general guide and follow these steps:

1. Start with the existing variable voltage DC positive

procedure as the reference procedure.

2. Move to AC balanced square wave mode and use

the reference travel speed and voltage.

3. Adjust frequency from 30 to 90 Hz. (stop if the

current value begins to drop).

4. Shift the AC balance to 25%,

a. Increase voltage 2-3 volts,

b. Increase travel speed 1.2 times reference value.

5. Add 5 to 10% negative (minus) offset,

a. Increase voltage an additional 1-2 volts,

b. Raise travel speed to 1.3 times reference speed.

This will yield a good starting point for converting a DC+

fillet welding procedure. Fine tuning these steps will

yield the maximum increase with equal or improved

weld appearance.

% Positive % Offset

100 DC+ NA 1.0 Reference

50 0 1.11 +0

25 0 1.20 +3

25 -10 1.30 +4

0 DC- NA 1.35 +3

Deposition

Rate

9/10

Arc Volt

Change

Easy Welding Procedure Setup

The Power Wave AC/DC 1000™ system is the easiest

system ever produced when it comes to changing from

one welding procedure to another.

• No need to move (change) welding cables even when

changing polarity or changing from constant current to

constant voltage.

• No need to internally reconnect power carrying taps or

bus bars, hence, in many instances no need for a

maintenance electrician.

• Control all output functions on the control panel.

• Fully supported by Lincoln’s Power Wave Submerged

Arc Utilities software where demanding applications

require activity reporting or even remote procedure

verification (see Nextweld NX3.20 brochure).The heart

of the system is the Power Wave AC/DC 1000™ featuring:

• Balanced input line-draw even when welding with AC.

• High 86% electrical efficiency contributes to keeping

energy charges low.

• 95% power factor assures minimizing excess ampere

draw from the supply lines.

• Continuous output rating 1000 amperes assures the

system is ready-to-go full time.

The future of welding is here.

®

Page 10

WAVEFORM CONTROL TECHNOLOGY

TM

Making Fillet Welds with Power Wave AC/DC 1000™ System

Welding Guide

APPLICATION

10/10

Power Wave AC/DC 1000

™

System Cost Recapture Analysis*

Example: Using a burden charge of 40.00 $/Hr., an operating factor of 40%

and the need to produce either of the following welds:

Producing 1/2” (13mm) flat positioned fillet welds

Present weld: DC+, 885 amps, 10.40 in/min . . . . . . . . . . . . . . . . . . . . . . . . . . .1.92 $/Ft

Power Wave Weld: 885 amps (25% bal, -20% off, 30Hz), 14.2 in/min . . . . . . .1.41 $/Ft

Dollar Saving per Foot of Weld . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.50 $/Ft

Annual Saving based upon a 2000 hour-year . . . . . . . . . . . . . . . . . . . . . . . . . .$28,400

Less than 11 months to recapture the cost of the

Power Wave AC/DC 1000™ and returns a 36.5 percent

increase in production capacity!

Producing 5/16” (8mm) horizontal fillet welds

Present weld: DC+, 525 amps, 15.0 in/min . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.33 $/Ft

Power Wave Weld: 525 amps (25% bal, -10% off, 30Hz), 21.0 in/min . . . . . . .0.95 $/Ft

Dollar Saving per Foot of Weld . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.38 $/Ft

Annual Saving based upon a 2000 hour-year . . . . . . . . . . . . . . . . . . . . . . . . . .$31,920

Less than 10 months to recapture the cost of the

Power Wave AC/DC 1000™ and with a 40 percent

increase in production capacity!

To maintain or improve your competitive edge, contact the

nearest Lincoln Electric Technical Sales Representative to

discuss and start the process toward lower welding costs

and increased productivity.

*Based upon present cost of an equipment setup that includes Power Wave AC/DC 1000™,

Power Feed 10A Controller, Travel Carriage, and essential accessory items including vertical and

horizontal adjusters, contact nozzle and wire reel. Prices for other packages will vary. The cost of

other equipment packages may alter the time to recapture the purchase cost.

Customer Assistance Policy

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment,

consumables, and cutting equipment. Our challenge is to meet the needs of our customer and to exceed

their expectations. On occasion, purchasers may ask Lincoln Electric for advice or information about their

use of our products. We respond to our customers based on the best information in our possession at that

time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with

respect to such information or advice. We expressly disclaim any warranty of any kind, including any

warranty of fitness for any customer’s particular purpose, with respect to such information or advice. As a

matter of practical consideration, we also cannot assume any responsibility for updating or correcting any

such information or advice once it has been given, nor does the provision of information or advice create,

expand or alter any warranty with respect to the sale of our products.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by

Lincoln Electric is solely within the control of, and remains the sole responsibility of the customer. Many

variables beyond the control of Lincoln Electric affect the results obtained in applying these types of

fabrication methods and service requirement.

Subject to change - This information is accurate to the best of our knowledge at the time of printing.

Please refer to www.lincolnelectric.com for any updated information.

WHAT IS NEXTWELD?

The challenges facing industrial

fabricators today are increasingly

difficult. Rising labor, material, and

energy costs, intense domestic and

global competition,

a dwindling pool of

skilled workers,

more stringent and

specific quality

demands.

Through our

commitment to

extensive research

and investments in

product

development,

Lincoln Electric has

established an industry benchmark for

applying technology to improve the

quality, lower the cost and enhance the

performance of arc welding processes.

Advancements in power electronics,

digital communications and Waveform

Control Technology™ are the foundation

for many of the improvements.

NEXTWELD brings you a series of

Process, Technology, Application and

Success Story documents like this one.

NEXTWELD explains how technologies,

products, processes and applications are

linked together to answer the important

questions that all businesses face:

• How can we work faster, smarter,

more efficiently?

• How can we get equipment and

people to perform in ways they’ve

never had to before?

• How do we stay competitive?

NEXTWELD is the future of welding but

its benefits are available to you today.

Ask your Lincoln Electric representative

how to improve the flexibility, efficiency

and quality of your welding operations to

reduce your cost of fabrication.

THE LINCOLN ELECTRIC COMPANY

www.lincolnelectric.com

1.216.481.8100

The future of welding is here.

®

Loading...

Loading...