Page 1

Welding Guide

LEARNING TO STICK WELD

%&%.0,

'00-333)(+#,)+%)%#0.(##,*/!&%04

&,.!$$(0(,+!)/!&%04(+&,.*!0(,+

Welding Safety

Interactive Web Guide

for mobile devices

LTW2 | Issue D ate 07/13

© Lincoln Global, Inc. All Rights Reserved.

Page 2

The serviceability of a product or structure utilizing this type of

information is and must be the sole responsibility of the builder/user.

Many variables beyond the control of The Lincoln Electric Company

affect the results obtained in applying this type of information. These

variables include, but are not limited to, welding procedure, plate

chemistry and temperature, weldment design, fabrication methods,

and service requirements.

WARNING

This statement appears where the information must be followed

exactly to avoid serious personal injury or loss of life.

CAUTION

This statement appears where the information must be followed to

avoid minor personal injury or damage to this equipment.

DON’T get too close to the arc. Use

corrective lenses if necessary to

stay a reasonable distance away

from the arc.

READ and obey the Material Safety

Data Sheet (MSDS) and the warning

label that appears on all containers

of welding materials.

USE ENOUGH VENTILATION or

exhaust at the arc, or both, to keep

the fumes and gases from your breathing zone and the general area.

IN A LARGE ROOM OR OUTDOORS, natural ventilation may be

adequate if you keep your head out of the fumes (see below).

USE NATURAL DRAFTS or fans to keep the fumes away from your

face.

If you de velop unusual symptoms, see your supervisor. Perhaps the

welding atmosphere and ventilation system should be checked.

PROTECT your eyes and face with welding helmet

properly fitted and with proper grade of filter plate

(See ANSI Z49.1).

PROTECT your body from welding spatter and arc

flash with protective clothing including woolen

clothing, flame-proof apron and gloves, leather

leggings, and high boots.

PROTECT others from splatter, flash, and glare with

protective screens or barriers.

IN SOME AREAS, protection from noise may be

appropriate.

BE SURE protective equipment is in good condition.

ALSO, WEAR SAFETY GLASSES IN WORK

AREA AT ALL TIMES.

DO NOT WELD OR CUT containers or materials which have

previously been in contact with hazardous substances unless they are

properly cleaned. This is extremely dangerous.

DO NOT WELD OR CUT painted or plated parts unless special

precautions with ventilation have been taken. They can release highly

toxic fumes or gases.

Additional precautionary measures

PROTECT compressed gas cylinders from excessive heat, mechanical

shocks, and arcs; fasten cylinders so they cannot fall.

BE SURE cylinders are never grounded or part of an electrical circuit.

REMOVE all potential fire hazards from welding area.

ALWAYS HAVE FIRE FIGHTING EQUIPMENT READY FOR

IMMEDIATE USE AND KNOW HOW TO USE IT.

Page 3

LEARNING TO STICK WELD

Learn to Stick Weld .......................................................................................................1

Arc Welding Circuit....................................................................................................1

What Happens in the Arc ..........................................................................................1

Correct Welding Position...........................................................................................2

Correct Way to Strike an Arc ....................................................................................2

Correct Arc Length ....................................................................................................2

TABLE OF CONTENTS

Page

Practice .....................................................................................................................3

Common Metals..................................................................................................3

Joint Types and Positions.................................................................................4

Butt Joint...........................................................................................................4

Penetration .......................................................................................................4

Fillet Joint..........................................................................................................4

Multi Pass Welds ................................................................................................5

Welding in the Vertical Position ..........................................................................5

Vertical-Up Welding ............................................................................................5

Vertical-Down Welding .......................................................................................5

Overhead Welding ..............................................................................................6

Welding Sheet Metal...........................................................................................6

Hardfacing ..........................................................................................................6

How to hardface the Sharp Edge........................................................................6

Hardfacing of Idler and Roller .............................................................................7

Welding Cast Iron ...............................................................................................7

Cast Iron Plate Preparation ................................................................................8

3

Page 4

LEARNING TO STICK WELD

To electrical

(earth) ground.

LEARNING TO STICK WELD

No one can learn to weld simply by reading about it. Skill

comes only with practice. The following pages will help the

inexperienced welder to understand welding and develop

his skill. For more detailed information, order a copy of

“New Lessons in Arc Welding”, available from the James F.

Lincoln Foundation.

The operator’s knowledge of arc welding must go beyond the arc

itself. If you want to get the most out of your welding practice, your

knowledge of welding must go beyond the arc. You also need to

understand how to control the arc, and this requires knowledge of the

welding circuit and the equipment that provides the electric current

used in the arc. Figure 1 is a diagram of the welding circuit. The

circuit begins where the electrode cable is attached to the welding

machine and ends where the work cable is attached to the welding

machine. Current flows through the electrode cable to the electrode

holder, through the holder to the electrode and across the arc. On the

work side of the arc, the current flows through base metal to the work

cable and back to the welding machine. The circuit must be complete

for the current to flow. To weld, the work clamp must be tightly

connected to clean base metal. Remove paint, rust, etc. as necessary

to get a good connection. Connect the work clamp as close as

possible to the area you wish to weld. Avoid allowing the welding

circuit to pass through hinges, bearings, electronic components or

similar devices that can be damaged.

This arc-welding circuit has a voltage output of up to 79 volts, which

is enough to shock.

The electric arc is made between the work and the tip end of a small

metal wire - the electrode - which is clamped in a holder. The holder

is held by the welder.

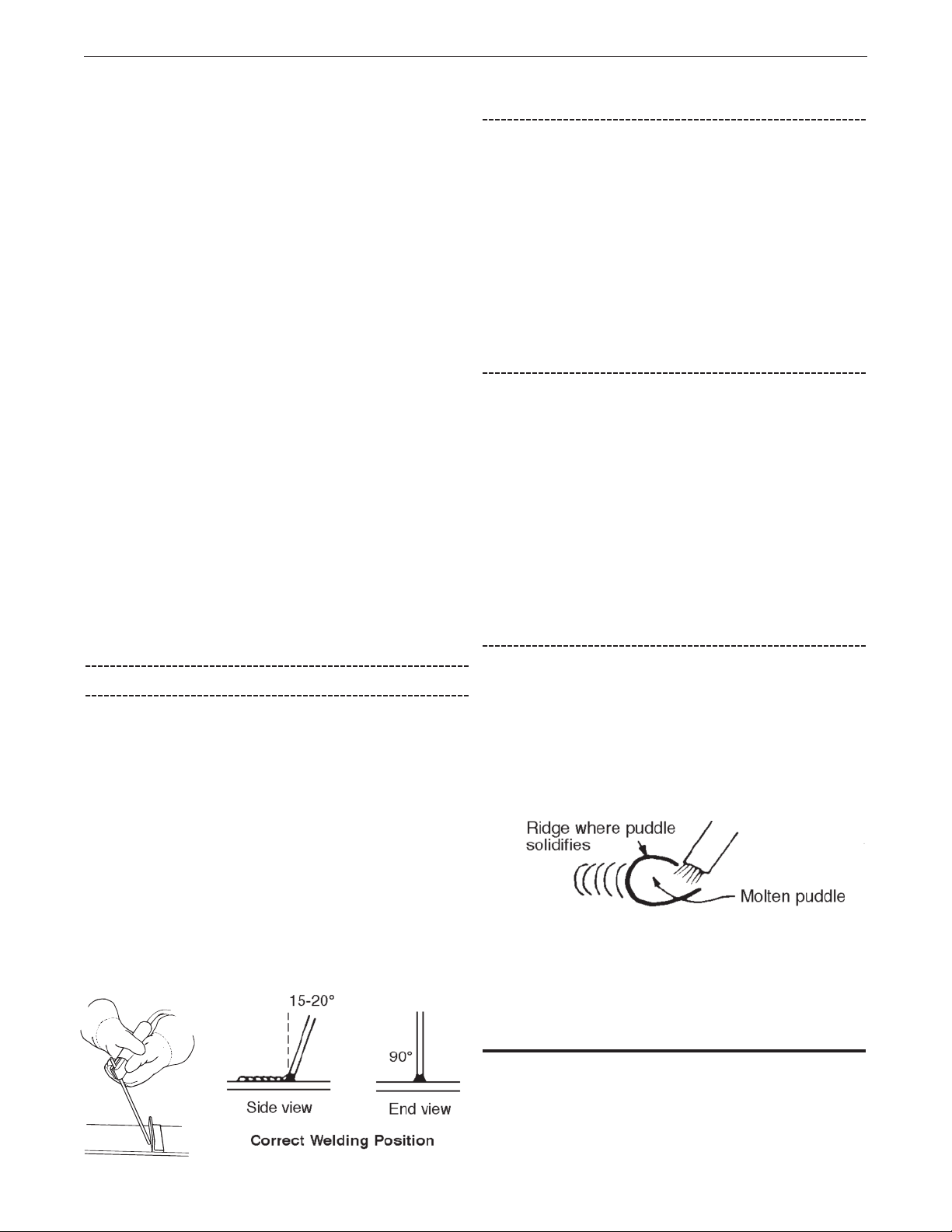

What Happens in the Arc?

Figure 2 illustrates the action that takes place in the electric arc. It

closely resembles what is actually seen during welding.

FIGURE 2—The welding arc

The “arc stream’’ is seen in the middle of the picture. This is the

electric arc created by the electric current flowing through the space

between the end of the electrode and the work. The temperature of

this arc is about 6000°F. (3315°C.), which is more than enough to

melt metal. The arc is both very bright and very hot. If you look at the

arc with your naked eye, you risk several hours’ or days’ worth of

pain and poor, blurry vision. A welding helmet with a very dark lens,

specifically designed for arc welding, must be used whenever viewing

the arc.

Have you ever watched water flow from a garden hose onto soft soil

or earth? Eventually, the water will build up enough to displace and

dig into the soil beneath it. It may even form a small crater that then

fills with water. The arc works the same way, melting the base metal

and actually digging into it as it moves across the surface of the base

metal. The molten metal forms a molten pool or crater and tends to

flow away from the arc. As it moves away from the arc, it cools and

solidifies. A slag forms on top of the weld to protect it during cooling.

WARNING

ELECTRIC SHOCK CAN KILL.

CAREFULLY REVIEW THE ARC WELDING

SAFETY PRECAUTIONS AT THE BEGINNING

OF YOUR OPERATOR’S MANUAL.

A gap is made in the welding circuit (see figure 1) by holding the tip of

the electrode 1/16-1/8” away from the work or base metal being

welded. The electric arc is established in this gap and is held and

moved along the joint to be welded, melting the metal as it is moved

Arc welding is a manual skill requiring a steady hand, good physical

condition, and good eyesight. The operator controls the welding arc

and, therefore, the quality of the weld made .

FIGURE 1—The welding circuit for Shielded Metal

Arc Welding(SMAW)

ARC RAYS CAN BURN

EYES AND SKIN.

PROTECT YOURSELF AND OTHERS, READ

“ARC RAYS CAN BURN” AT THE FRONT OF THE

OPERATOR’S MANUAL SUPPLIED WITH THE

WELDER.

1

Page 5

LEARNING TO STICK WELD

The function of the covered electrode is much more than simply to

carry current to the arc. The electrode is composed of a core of metal

wire around which has been extruded and baked a chemical

covering. The core wire melts in the arc, and tiny droplets of molten

metal shoot across the arc into the molten pool. The electrode

provides additional filler metal for the joint to fill the groove or gap

between the two pieces of the base metal. The covering also melts or

burns in the arc. It has several functions. It makes the arc steadier,

provides a shield of smoke-like gas around the arc to keep oxygen

and nitrogen in the air away from the molten metal, and provides a

flux for the molten pool. The flux picks up impurities and forms the

protective slag. The principal differences between various types of

electrodes are in their coatings. By varying the coating, it is possible

to greatly alter the operating characteristics of electrodes. By understanding the differences in the various coatings, you will gain a better

understanding of selecting the best electrode for the job you have at

hand. In selecting an electrode, you should consider the following

aspects:

1. The type of deposit you want, e.g. mild steel,

stainless, low alloy, hardfacing

2. The thickness of the plate you want to weld

3. The position it must be welded in (downhand, out of

position)

4. The surface condition of the metal to be welded

5. Your ability to handle and obtain the desired

electrode

The following four simple manipulations are of prime importance.

Without complete mastery of these four, further welding is more or

less futile. With complete mastery of the four, welding will be easy.

2. The Correct Way to Strike an Arc

Be sure the work clamp makes good electrical contact to

the work.

Lower your autodarkening or fixed shade welding helmet.

Scratch the electrode slowly over the metal and you will see

sparks flying. While scratching, lift the electrode 1/8"

(3.2mm) to establish the arc.

NOTE: If you stop moving the electrode while scratching,

the electrode will stick.

NOTE: Most beginners try to strike the arc by making a fast jabbing motion

down onto the plate. Result: They either stick or their motion is so fast

that they break the arc immediately.

3. The Correct Arc Length

The arc length is the distance from the tip of the electrode

core wire to the base metal.

Once the arc has been established, maintaining the correct

arc length becomes extremely important. The arc should be

short, approximately 1/16 to 1/8" (1.6 to 3.2mm) long. As the

electrode burns off, it must be fed to the work to maintain

correct arc length.

The easiest way to tell whether the arc has the correct

length is by listening to its sound. A nice, short arc has a

distinctive, “crackling” sound, very much like eggs frying in

a pan. The incorrect, long arc has a hollow, blowing or

hissing sound.

4. The Correct Welding Speed

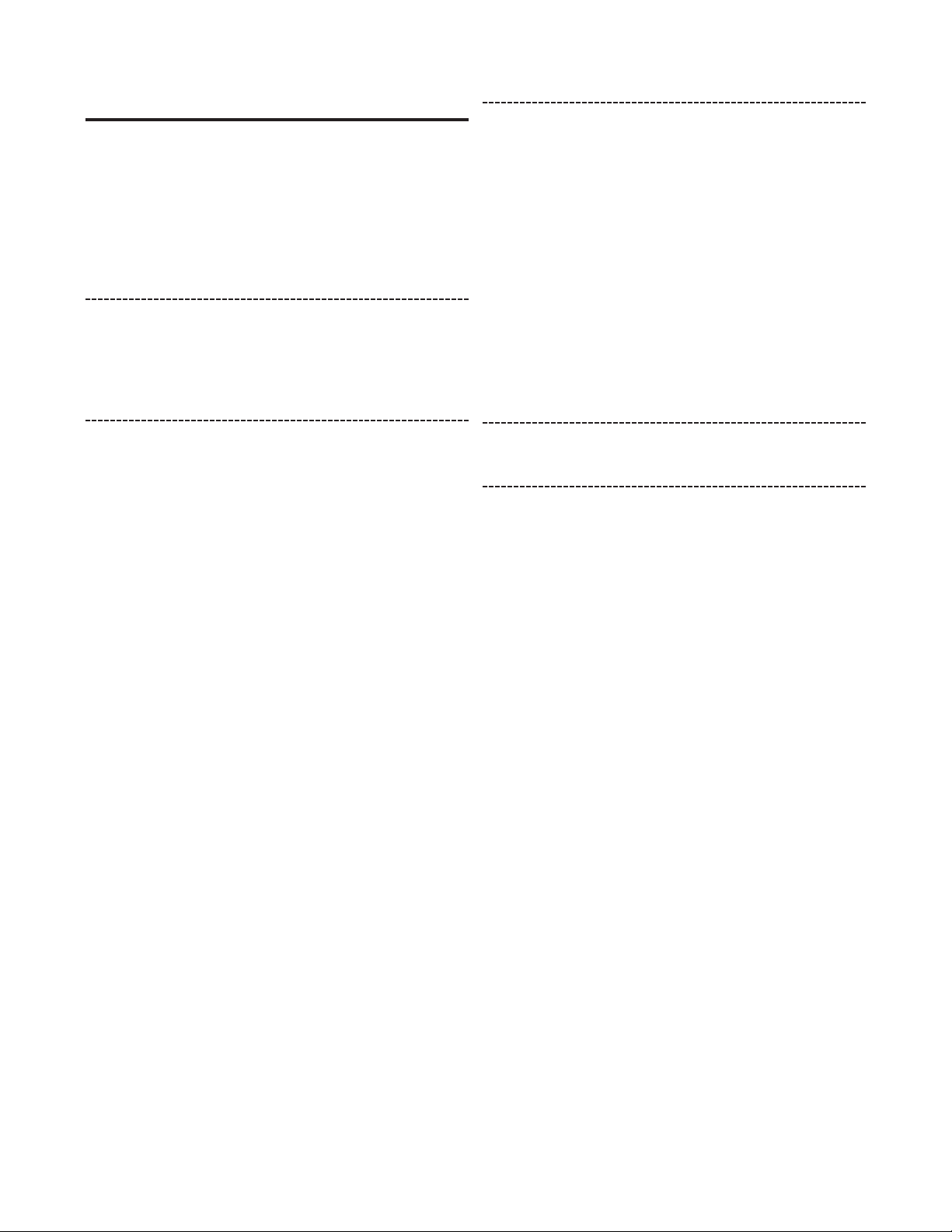

1. The Correct Welding Position

At first, you may find it easier to use the two-handed

technique shown below. This requires the use of a welding

helmet.

a. Hold the electrode holder in your right hand.

b. Touch your left hand to the underside of your right.

c. Put the left elbow against your left side.

(For welding left-handed it is the opposite.)

If you are using a hand shield, hold the electrode holder in

your right hand and the hand shield in your left. (For welding

left-handed it is the opposite.)

Whenever possible, weld from left to right (if right-handed).

This enables you to see clearly what you are doing.

Hold the electrode at a slight angle as shown.

The important thing to watch while welding is the puddle of

molten metal right behind the arc. Do NOT watch the arc

itself. It is the appearance of the puddle and the ridge where

the molten puddle solidifies that indicate correct welding

speed. The ridge should be approximately 3/8" (9.5mm)

behind the electrode.

The tendancy is to weld too fast, resulting in a thin, uneven,

“wormy” looking bead. Watching the molten metal.

IMPORTANT: For general welding it is not necessary to weave the arc; neither

forwards and backwards nor sideways. Weld along at a steady pace. You

will find it easier.

NOTE: When welding on thin plate, you will find that you will have to increase

the welding speed, whereas when welding on heavy plate, it is necessary

to go more slowly in order to get good penetration.

2

Page 6

LEARNING TO STICK WELD

PRACTICE

Use the following exercise to spend a little more time practice in the

four skills that enable you to maintain:

1. Correct Welding Position

2. Correct Way To Strike An Arc

3. Correct Arc Length

4. Correct Welding Speed

Use the following:

Mild Steel Plate 3/16" (4.8mm) or heavier

Electrode 1/8" (3.2mm) Fleetweld® 180

Current Setting: 105 Amps AC or 95 Amps DC(+)

Do the following:

1. Learn to strike the arc by scratching the electrode over

the plate. Be sure the angle of the electrode is correct.

Use both hands.

2. When you can strike an arc without sticking, practice

the correct arc length. Learn to distinguish it by its

sound.

3. When you are sure that you can hold a short, crackling

arc, start moving. Look at the molten puddle constantly,

and look for the ridge where the metal solidifies.

4. Run beads on a flat plate. Run them parallel to the top

edge (the edge farthest away from you). This gives you

practice in running straight welds, and also, it gives you

an easy way to check your progress. The 10th weld will

look considerably better than the first weld. By

constantly checking on your mistakes and your

progress, welding will soon be a matter of routine.

Common Metals

Most metals found around the farm or small shop are low

carbon steel, sometimes referred to as mild steel. Typical

items made with this type of steel include most sheet metal,

plate, pipe and rolled shapes such as channels, angle irons

and “I’’ beams. This type of steel can usually be easily

welded without special precautions. Some steel, however,

contains higher carbon. Typical applications include wear

plates, axles, connecting rods, shafts, plowshares and

scraper blades. These higher carbon steels can be welded

successfully in most cases; however, care must be taken to

follow proper procedures, including preheating the metal to

be welded and, in some cases, carefully controlling the

temperature during and after the welding process. For

further information on identifying various types of steels and

other metals, and for proper procedures for welding them,

we again suggest you purchase a copy of (“New Lessons in

Arc Welding” available from the James F. Lincoln arc

welding foundation).

Regardless of the type of metal being welded, it is important

in order to get a quality weld that it be free of oil, paint, rust

or other contaminants.

3

Page 7

LEARNING TO STICK WELD

JOINT TYPES AND

POSITIONS

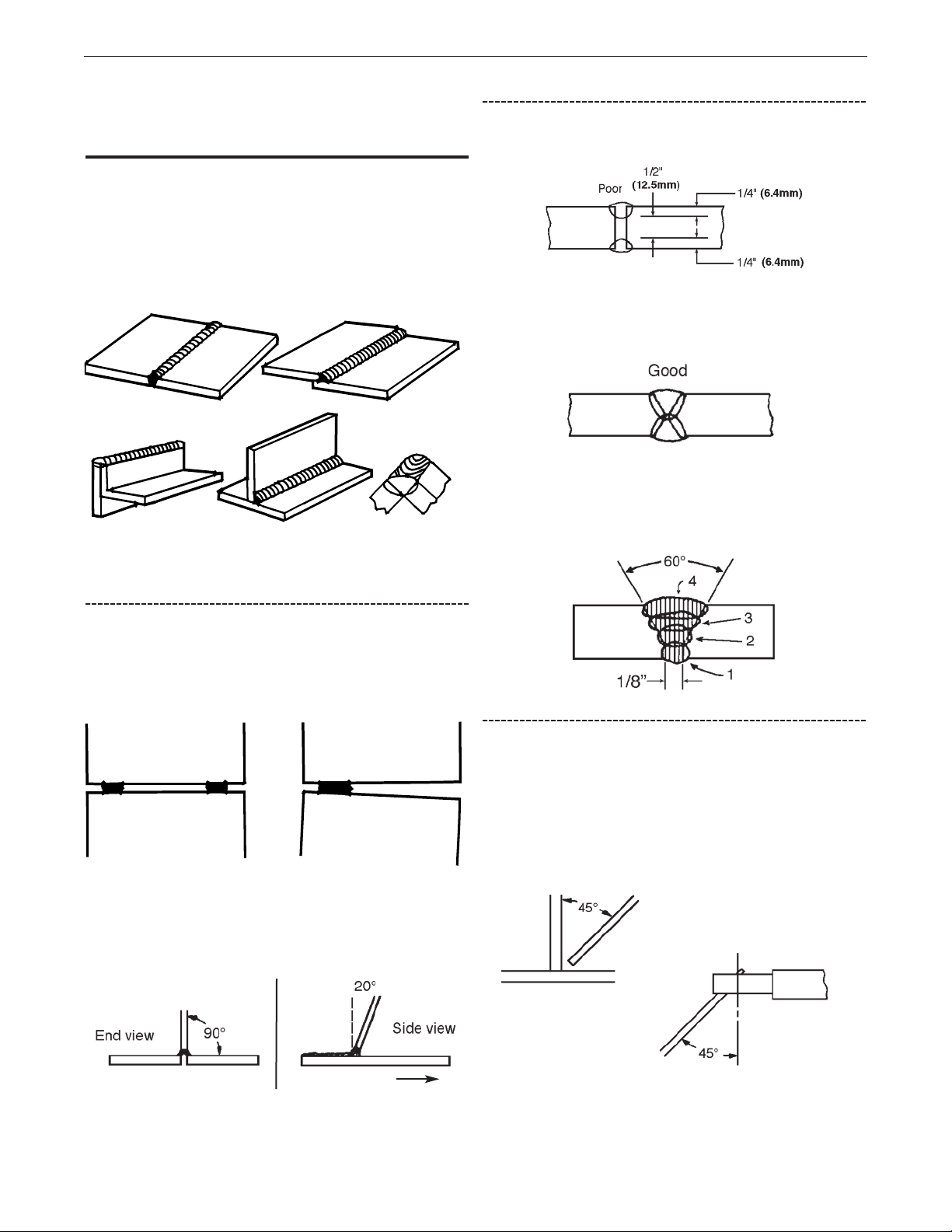

Five types of welding joints are: Butt joint, Fillet joint, Lap joint, Edge

joint and Corner joint. See Figure 3.

FIGURE 3

Of these, the Butt Joint and Fillet Joint are the two most common

welds.

Butt joint Lap joint

Penetration

Unless a weld penetrates close to 100%, a Butt Joint will be weaker

than the material welded together.

In this example, the total weld is only 1/2” (12.5mm) the thickness of

the material; thus the weld is only approximately half as strong as the

metal.

In this example, the joint has been flame beveled or ground prior to

welding so that 100% penetration could be achieved. The weld, if

properly made, is as strong or stronger than the original metal.

Edge joint Fillet joint Corner joint

Butt Joints

Place two plates side by side, leaving 1/16” (1.6mm) (for thin metal)

to 1/8” (3.2mm) (for heavy metal) space between them in order to get

deep penetration.

Securely clamp or tack weld the plates at both ends, otherwise the

heat will cause the plates to move apart. See Figure 4.

FIGURE 4

Now weld the two plates together. Weld from left to right (if right

handed). Point the Stick electrode between the two plates, keeping

the Electrode Holder tilted in the direction of travel.

Fillet Joints

When welding a Fillet Joint, it is very important to hold the electrode

at a 45° angle between the two sides, or the metal will not distribute

itself evenly.

To make it easy to get the 45° angle, it is best to put the electrode in

the holder at a 45° angle, as shown:

Weld Direction

Watch the molten metal to be sure it distributes itself evenly on both

edges and in between the plates. This is referred to as the “pull

technique”. On thin gauge sheet metal, use the “push technique”.

4

Page 8

LEARNING TO STICK WELD

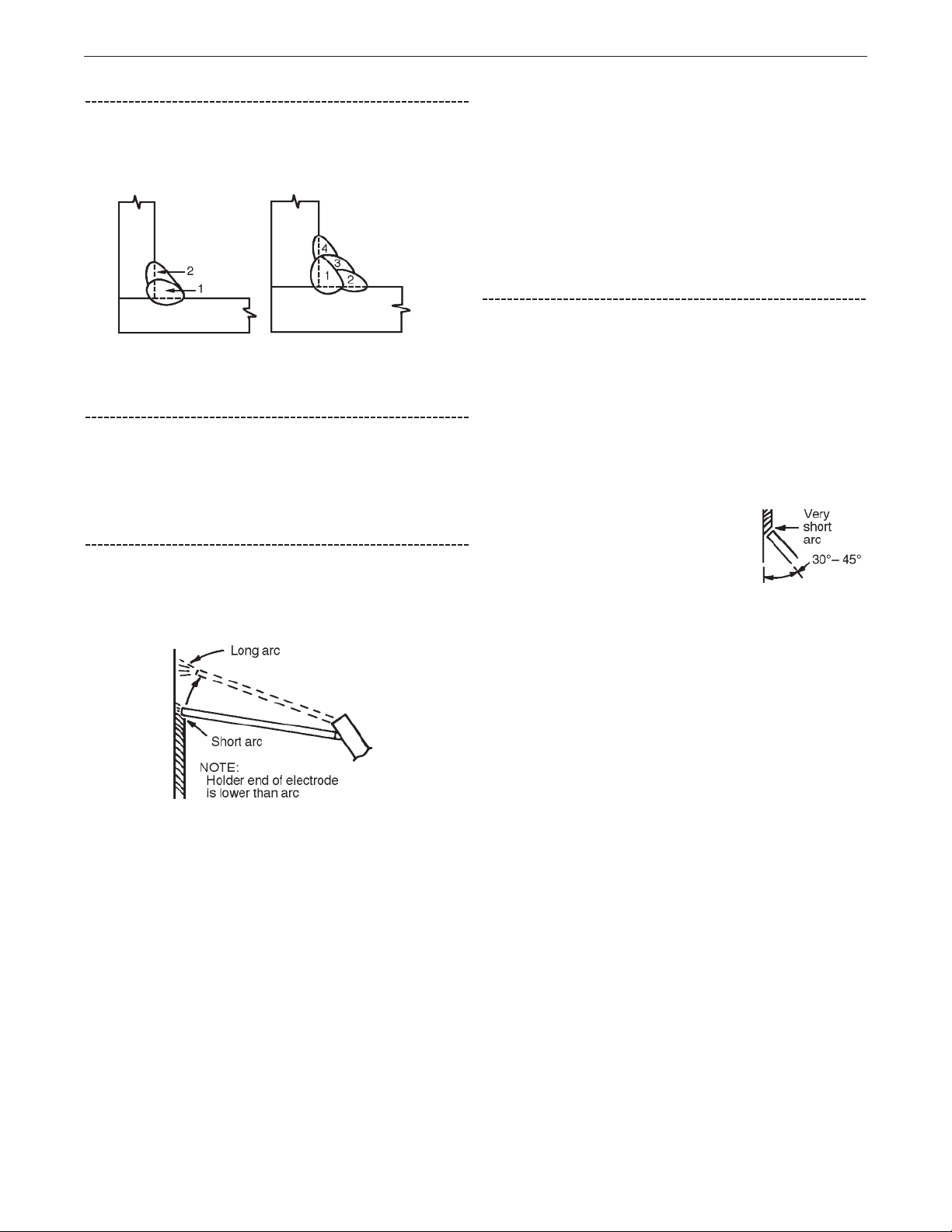

Multiple Pass Welds

Make multiple pass horizontal fillet joints as shown in the sketch. Put

the first bead in the corner with fairly high current. Hold the electrode

angle needed to deposit the filler beads as shown putting the final

bead against the vertical plate.

Welding in the Vertical Position

Welding in the vertical position can be done either vertical-up or

vertical-down. Vertical-up is used whenever a large, strong weld is

desired. Vertical-down is used primarily on sheet metal for fast, low

penetrating welds.

Vertical-Up Welding

The challenge, when welding vertical-up, is to put the molten metal

where it is wanted and make it stay there. If too much molten metal is

deposited, gravity will pull it downwards and make it “drip.’’

Therefore a certain technique has to be followed:

metal. As soon as it has solidified, the arc is SLOWLY brought

back, and another few drops of metal are deposited. DO NOT

FOLLOW THE UP AND DOWN MOVEMENT OF THE ARC WITH THE

EYES. KEEP THEM ON THE MOLTEN METAL.

8. When the arc is brought back to the now solidified puddle, IT

MUST BE SHORT, otherwise no metal will be deposited, the

puddle will melt again, and it will “drip.”

9. It is important to realize that the entire process consists of SLOW,

DELIBERATE movements. There are no fast motions.

Vertical-Down Welding

Vertical-down welds are applied at a fast pace. These welds are

therefore shallow and narrow, and as such are excellent for sheet

metal. Do not use the vertical-down technique on heavy metal. The

welds will not be strong enough.

1. Use 1/8” (3.2mm) or 3/32" (2.4mm) Fleetweld® 180 electrode.

2. On thin metal, use 60-75 amps. (14 ga 75 amps — 16 ga 60

amps.)

3. Hold the electrode in a 30-45° angle with the tip of the electrode

pointing upwards.

4. Hold a VERY SHORT arc, but do not let the

electrode touch the metal.

5. An up and down whipping motion will help

prevent burn-through on very thin plate.

6. Watch the molten metal carefully.

The important thing is to continue lowering the entire arm as the weld

is made so the angle of the electrode does not change. Move the

electrode so fast that the slag does not catch up with the arc.

Vertical-down welding gives thin, shallow welds. It should not be used

on heavy material where large welds are required.

1. Use 1/8" (3.2mm) at 90-105 amps or 3/32" (2.4mm) at 60 amps

®

Fleetweld

180 electrode.

2. When welding, the electrode should be kept horizontal or pointing

slightly upwards. (See drawing.)

3. The arc is struck and metal deposited at the bottom of the two

pieces to be welded together.

4. Before too much molten metal is deposited, the arc is SLOWLY

moved 1/2”-3/4" (12.5-19mm) upwards. This takes the heat

away from the molten puddle, which solidifies. (If the arc is not

taken away soon enough, too much metal will be deposited, and

it will “drip.’’)

5. The upward motion of the arc is caused by a very slight wrist

motion. The arm must NOT move in and out, as this makes the

entire process very complicated and difficult to learn.

6. If the upward motion of the arc is done with a correct wrist

motion, the arc will automatically become a long arc that

deposits little or no metal. (See drawing.)

7. During this entire process the ONLY thing to watch is the molten

5

Page 9

LEARNING TO STICK WELD

BACK-STEPPING

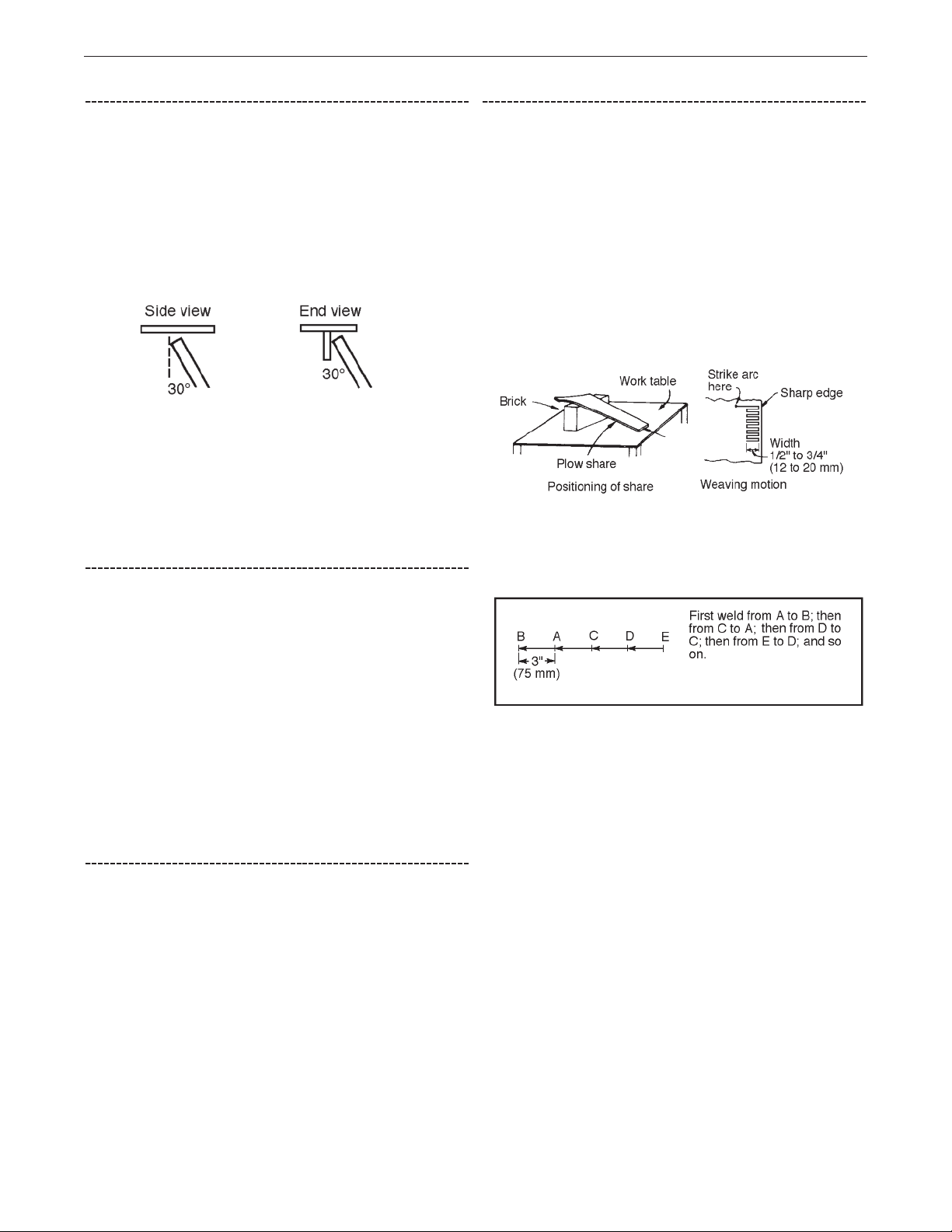

Overhead Welding

Various techniques are used for overhead welding. However, in the

interest of simplicity for the inexperienced welder the following

technique will probably take care of most needs for overhead welding:

1. Use 1/8" (3.2mm) at 90-105 amps or 3/32" (2.4mm) at 60 amps

Fleetweld®180 electrode.

2. Put the electrode in the holder so it sticks straight out.

3. Hold the electrode at an angle approximately 30° off vertical,

both seen from the side and seen from the end.

The most important thing is to hold a VERY SHORT arc. (A long

arc will result in falling molten metal; a short arc will make the

metal stay.)

If necessary — and that is dictated by the looks of the molten

puddle — a slight back and forth motion along the seam with the

electrode will help prevent “dripping.”

Welding Sheet Metal

Welding sheet metal presents an additional problem. The thinness of

the metal makes it very easy to burn through. Follow these few

simple rules:

1. Hold a very short arc. (This prevents burn through, since

beginners seem to hold too long an arc.)

2. Use 1/8” (3.2mm) or 3/32" (2.4mm) Fleetweld® 180 electrode.

3. Use low amperage. 75 amps for 1/8" (3.2mm) electrode, 40-60

amps for 3/32" (2.4mm) electrode.

4. Move fast. Don’t keep the heat on any given point too long. Keep

going. Whip the electrode.

5. Use lap welds whenever possible. This doubles the thickness of

the metal.

How to Hardface the Sharp Edge (Metal to Ground Wear)

1. Grind the share, approximately one inch (25mm) wide along the

edge, so the metal is bright.

2. Place the share on an incline of approximately 20-30°. The

easiest way to do this is to put one end of the share on a brick.

(See drawing.)

Most users will want to hardface the underside of the share, but

some might find that the wear is on the top side. The important

thing is to hardface the side that wears.

3. Use 1/8" (3.2mm) Wearshield™ ABR electrode at 90-105 amps.

Strike the arc about one inch (25mm) from the sharp edge.

4. The bead should be put on with a weaving motion, and it should

be 1/2” to 3/4" (12.5 to 19mm) wide. Do not let the arc blow

over the edge, as that will dull the edge. (See drawing.)

5. Use the back-stepping method. Begin to weld 3" (75mm) from

the heel of the share and weld to the heel. The second weld will

begin 6" (150mm) from the heel, the third weld 9" (225mm) from

the heel, etc.

Back-stepping greatly reduces the chances for cracking of the share,

and it also greatly reduces possible warpage.

NOTE: The entire process is rather fast. Many beginners go much too slowly

when hardfacing plow shares, running the risk of burning through the thin

metal.

Hardfacing

There are several kinds of wear. The two most often encountered are

as follows:

1. Metal to Ground Wear

(Plowshares, bulldozer blades, buckets, cultivator shares, and

other metal parts moving in the soil.)

2. Metal to Metal Wear

(Trunnions, shafts, rollers and idlers, crane and

mine car wheels, etc.)

Each of these types of wear demands a different kind of

hardsurfacing electrode.

When the proper electrode is applied, hardsurfacing can more than

double the service life of the part. For instance, hardsurfacing of

plowshares results in 3-5 times more acreage plowed.

6

Page 10

LEARNING TO STICK WELD

Hardfacing of Idler and Roller (Metal to Metal Wear)

A very common application of hardfacing for metal to metal wear is

the hardfacing of idlers and rollers and the rails that ride on these

rollers and idlers.

The reason for hardfacing these parts is primarily monetary. A few

dollars worth of electrode will completely build up a roller or idler, and

the hard surface will outlast several times the normal life or such

rollers and idlers.

If the below procedure is followed, it is not even necessary to remove

the grease bearing while welding. This will save a lot of time.

1. The roller (or idler) is inserted on a piece of pipe that is resting on

two sawbucks. This enables the operator to turn it while welding.

2. Use Wearshield™ BU electrodes, 5/32" (4.0mm) at 175 amps or

3/16" (4.8mm) at 200 amps.

3. Weld across the wearing surface. Do not weld around.

4. Keep the roller (or idler) cool by quenching with water, and by

stopping the welding periodically. This will prevent shrinking of

the roller (or idler) on the grease bearing.

5. Build up to dimension. The weld metal deposited by

Wearshield™ BU electrode is often so smooth that machining or

grinding is not necessary.

NOTE: The quenching of the roller (or idler) has another purpose: it increases

the hardness — and thus the service life — of the deposit.

The hardfacing of the rails is a lot easier:

1. Place the rails with the side that rides on the rollers and idlers

upwards.

2. Use Wearshield™ BU electrodes, 5/32" (4.0mm) at 175 amps or

3/16" (4.8mm) at 200 amps.

3. Build up to size.

4. Do not quench. This will make the deposit slightly softer than the

deposit on the idlers and rollers. That means that the wear will

primarily be on the rails, which are a lot easier and less timeconsuming and cheaper to build up.

NOTE: The same electrode — Wearshield™ BU — will give the operator two

desired hardnesses, just by a difference in cooling rate, making it possible

to put the hardest deposit on the most expensive parts.

NOTE: The outside of the rails (the side that comes in contact with the ground)

should be surfaced with Wearshield™ ABR, since this side has Metal to

Ground wear.

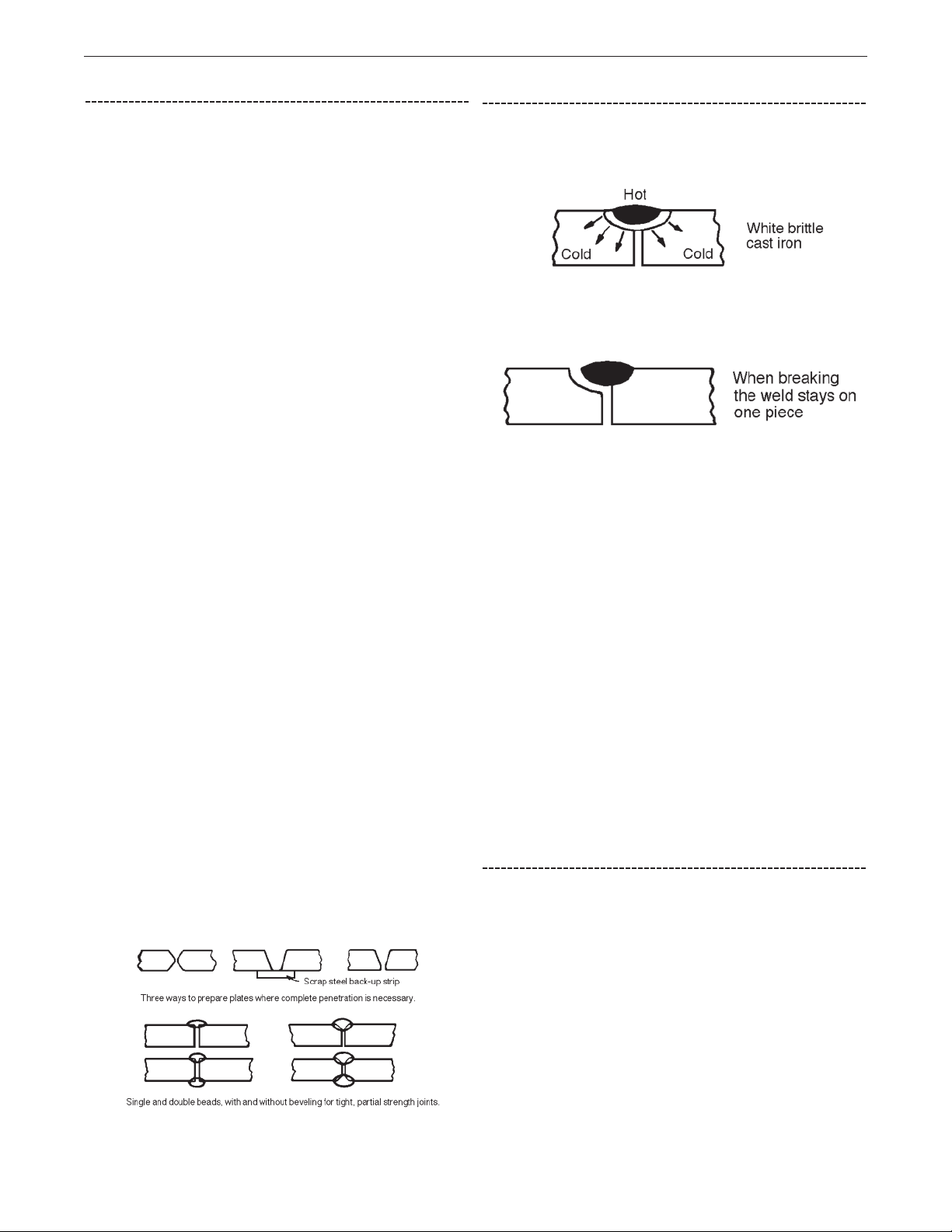

Welding Cast Iron

When welding on a piece of cold cast iron, the tremendous heat from

the arc will be absorbed and distributed rapidly into the cold mass.

This heating and sudden cooling creates WHITE, BRITTLE cast iron in

the fusion zone.

This is the reason why welds in cast iron break. Actually, one piece of

the broken cast iron has the entire weld on it, and the other piece has

no weld on it.

In order to overcome this, the welding operator has two choices:

1. Preheat the entire casting to 500-1200°F. (260-649°C). If the

cast iron is hot before welding, there will be no sudden chilling

which creates brittle white cast iron. The entire casting will cool

slowly.

2. Weld 1/2" (12.5mm) at a time, and not weld at that spot again

until the weld is completely cool to the touch.

In this way, no large amount of heat is put into the mass.

If you have no way of preheating large castings, you’ll probably find it

easier to use the second of the two methods discussed above.

However, smaller castings can easily be preheated before welding by

using a forge, stove, fire, or Arc Torch.

When using the 1/2" (12.5mm) at a time method, it is recommended

to start 1/2" (12.5mm) away from the previous bead and weld into the

previous bead (backstepping).

After welding Cast Iron, protect the casting against fast cooling. Put it

in a sand (or lime) box.

If sand or lime is not available, cover it with sheet metal or any other

non-flammable material that will exclude drafts and retain heat.

Cast Iron Plate Preparation

Wherever practical, the joint to be welded should be “veed” out by

grinding or filing to give complete penetration. This is especially

important on thick castings where maximum strength is required. In

some instances, a back-up strip may be used and plates may be

gapped 1/8" (3.2mm) or more.

On sections where only a sealed joint is required and strength is not

important, the joint may be welded after slightly veeing out the seam

as shown.

7

Page 11

LEARNING TO STICK WELD

8

Page 12

The business of The Lincoln Electric Company is manufacturing and

selling high quality welding equipment, consumables, and cutting

equipment. Our challenge is to meet the needs of our customers and

to exceed their expectations. On occasion, purchasers may ask

Lincoln Electric for advice or information about their use of our

products. We respond to our customers based on the best information

in our possession at that time. Lincoln Electric is not in a position to

warrant or guarantee such advice, and assumes no liability, with

respect to such information or advice. We expressly disclaim any

warranty of any kind, including any warranty of fitness for any

customer’s particular purpose, with respect to such information or

advice. As a matter of practical consideration, we also cannot assume

any responsibility for updating or correcting any such information or

advice once it has been given, nor does the provision of information

or advice create, expand or alter any warranty with respect to the sale

of our products.

Lincoln Electric is a responsive manufacturer, but the selection and

use of specific products sold by Lincoln Electric is solely within the

control of, and remains the sole responsibility of the customer. Many

variables beyond the control of Lincoln Electric affect the results

obtained in applying these types of fabrication methods and service

requirements.

Subject to Change – This information is accurate to the best of our

knowledge at the time of printing. Please refer to

www.lincolnelectric.com for any updated information.

Page 13

Guía de soldadura

APRENDIENDO PALILLO SOLDAR

,+/1)0%

'00-333)(+#,)+%)%#0.(##,*/!&%04

-!.!,"0%+%.(+&,.*!#(9+!$(#(,+!)

Welding Safety

Interactive Web Guide

for mobile devices

LTW2 | Issue D ate 07/13

© Lincoln Global, Inc. All Rights Reserved.

Page 14

El equipo de soldadura por arco y corte de Lincoln está diseñado y

construido teniendo en mente la seguridad. Sin embargo, la

seguridad general puede ser mejor si instala y opera la máquina

adecuadamente. NO INSTALE, NO PONGA EN FUNCIONAMIENTO NI

REPARE ESTE EQUIPO SIN LA LECTURA DEL MANUAL DE LOS

OPERADORES QUE SE PROPORCIONA CON SU MÁQUINA Y LAS

MEDIDAS DE SEGURIDAD CONTENIDAS EN EL MISMO. Lo más

importante, piense antes de actuar y tenga cuidado.

WARNING

Esta declaración aparece donde la información debe seguirse

exactamente para evitar lesiones personales serias o pérdida de la

vida.

CAUTION

Esta declaración aparece donde la información debe seguirse para

evitar lesiones personales menores o daños a este equipo.

NO se acerque demasiado al arco.

Utilice lentes correctivos si es

necesario para permanecer a una

distancia razonable del arco.

LEA y obedezca la Ficha de Datos

de Seguridad de Material (MSDS) y

la etiqueta de advertencia que

aparece en todos los contenedores

de los materiales de soldadura.

UTILICE SUFICIENTE VENTILACIÓN

o escape en el arco, o ambos, para mantener los humos y gases

alejados de su zona de respiración y área en general.

EN UN CUARTO GRANDE O EN EXTERIORES, la ventilación natural es

adecuada si mantiene su cabeza alejada de los humos (vea a

continuación).

UTILICE LAS CORRIENTES DE AIRE NATURALES o ventiladores para

mantener los humos alejados de su cara.

Si desarrolla síntomas inusuales, vea a su supervisor. Tal vez deban

revisarse la atmósfera de soldadura y sistema de ventilación.

>

=

PROTEJA sus ojos y cara con la careta de soldadura

ajustada adecuadamente, y una placa de filtro de

grado adecuado (Vea ANSI Z49.1).

PROTEJA su cuerpo de la salpicadura de soldadura y

destellos del arco con ropa de seguridad incluyendo

ropa de lana, mandil y guantes a prueba de fuego,

pantalones de cuero y botas altas.

PROTEJA a otros de las salpicaduras, destellos y

deslumbramientos con pantalla o barreras de

protección.

EN ALGUNAS ÁREAS, la protección contra el ruido

resulta adecuada.

ASEGÚRESE de que el equipo protector esté en buenas condiciones.

Asimismo, utilice SIEMPRE lentes de seguridad en el área de trabajo.

NO SUELDE O CORTE contenedores o materiales que han estado

previamente en contacto con sustancias peligrosas a menos que

estén propiamente limpios. Esto es extremadamente peligroso.

NO SUELDE O CORTE partes pintadas o enchapadas a menos que

haya tomado precauciones especiales con la ventilación. Pueden

liberar humos o gases altamente tóxicos.

Medidas de precaución adicionales

PROTEJA los cilindros de gas comprimido del calor excesivo,

impactos mecánicos y arcos; sujete los cilindros para que no se

puedan caer.

ASEGÚRESE de que los cilindros nunca estén aterrizados ni sean

parte de un circuito eléctrico.

REMUEVA todos los riesgos de incendio potenciales del área de

soldadura.

SIEMPRE TENGA EQUIPO CONTRA INCENDIOS LISTO PARA USO

INMEDIATO Y APRENDA A USARLO.

Page 15

APRENDIENDO PALILLO SOLDAR

Aprendiendo Palillo Soldar...........................................................................................1

Circuito de la Soldadura al Arco................................................................................2

Qué Sucede en el Arco

Posición Correcta para Soldar

Forma correcta para iniciar un arco

Longitud correcta del arco

CONTENIDO

Page

.................................................................................................2

........................................................................................3

...............................................................................3

.............................................................................................3

Práctica

.......................................................................................................................4

Metales Comunes

Tipos de soldadura ...........................................................................................5

Soldadura a tope ..............................................................................................5

Penetración.......................................................................................................5

Soldadura de filete............................................................................................5

Soldadura de Pasadas Multiples ........................................................................6

Soldadura en posición vertical

Soldadura en dirección vertical ascendente

Soldadura vertical descendente

Soldadura sobre Cabeza

Soldadura de hojas metálicas

Recubrimiento duro

Como realizar el recubrimiento duro en extremos filosos

Recubrimiento duro deruedas y rodillo

Como soldar hierro vaciado ......................................................................................................8

Preparación de una placa de hierro vaciado ......................................................8

..................................................................................................4

.................................................................................6

..............................................................6

..........................................................................6

........................................................................................7

.................................................................................7

................................................................................................7

............................................7

.....................................................................8

1

Page 16

APRENDIENDO PALILLO SOLDAR

To electrical

(earth) ground.

APRENDIENDO A PALILLO

SOLDAR

Nadie puede aprender a soldar simplemente leyendo cómo

hacerlo. La destreza sólo se obtiene con la práctica. Las

páginas a continuación ayudarán al soldador sin experiencia

a aprender y a desarrollar sus habilidades de soldadura.

Para una información más detallada pida una copia de (las

“nuevas lecciones en la soldadura al arco” availiable de la

fundación de la soldadura al arco de James F. Lincoln).

El conocimiento del operador sobre la soldadura de arco debe ser

más amplio que simplemente conocer el arco mismo. Usted debe

saber controlar el arco, y ?e requiere un conocimiento del circuito de

la soldadura y del equipo que proporciona la corriente el?rica usada

en el arco. La figura 1 es un diagrama del circuito de soldadura. El

circuito empieza en donde el cable del electrodo está conectado a la

soldadora y termina en donde el cable de trabajo está conectado a la

máquina soldadora. La corriente fluye por el cable del electrodo al

portaelectrodo, a través del mismo hacia el arco. En el lado de

trabajo del arco, la corriente fluye a través del metal base hacia el

cable de trabajo y de regreso a la máquina soldadora. El circuito

debe completarse para que haya flujo de corriente. Para soldar, la

pinza de trabajo debe conectarse firmemente al metal base limpio.

Elimine pintura, óxido, etc. según sea necesario para obtener una

conexión adecuada. Conecte la pinza de trabajo tan cerca como sea

posible del área que desea soldar. No permita que el circuito de

soldadura pase a través de bisagras, rodamientos, componentes

electrónicos o dispositivos similares que pudieran dañarse.

El circuito de soldadura por arco tiene un voltaje de salida de hasta 79

voltios que puede provocar una descarga eléctrica.

El arco voltaico se hace entre el trabajo y el extremo de la extremidad

de un pequeño alambre de metal, el electrodo, que se afianza con

abrazadera en un sostenedor y el sostenedor es sostenido por el

soldador.

WARNING

UNA DESCARGA ELECTRICA PUEDE SER

MORTAL.

REVISE CUIDADOSAMENTE LAS PRECAUCIONES DE SEGURIDAD DE LA SOLDADURA

DE ARCO AL PRINCIPIO DE ESTE MANUAL.

FIGURA 1 - Circuito para la soldadura de arco con

electrodo revestido(SMAW).

¿Qué sucede en el arco?

La figura 2 ilustra la acción que tiene lugar en el arco eléctrico. Se

asemeja mucho a lo que se ve en realidad durante la soldadura.

Revestimiento

Electrodo

Gases protectores

Escoria solidificada

Metal soldado

Arco

Con base metálica

FIGURE 2—The welding arc

El "flujo del arco" se puede ver en el centro de la figura. Este es el

arco eléctrico creado por la corriente eléctrica que fluye a través del

espacio que existe entre la punta del electrodo y el trabajo. La

temperatura de este arco es de aproximadamente 3315°C (6000°F),

lo que es más que suficiente para derretir el metal. El arco es muy

brillante y de una temperatura muy alta por lo que no se debe ver sin

protección en los ojos, ya que podría causar lesiones muy dolorosas.

Los lentes obscuros, específicamente diseñados para la soldadura por

arco, deben utilizarse manualmente o integrados en la careta siempre

que vea el arco.

El arco derrite el metal base y lo que realmente hace es excavar en él,

de la misma forma en que el agua que pasa a través de la boquilla de

una manguera excava en la tierra cuando cae. El metal derretido

forma un charco de soldadura o cráter que tiende a fluir alejándose

del arco. A medida que fluye del arco se enfría y solidifica. En la

parte superior de la soldadura se forma una escoria para proteger la

soldadura mientras se enfría.

El arco eléctrico se crea entre el trabajo y la punta de un alambre de

metal pequeño, el electrodo, el cual se inserta en un portaelectrodo y

éste a su vez es sostenido por la soldadora. Se crea un espacio en el

circuito de soldadura (véase la figura 1) sosteniendo la punta del

electrodo a 1.6 mm - 3.2 mm (1/16" - 1/8") del trabajo o metal base

que se está soldando. El arco eléctrico se establece en este espacio,

se mantiene y desliza a lo largo de la unión que se va a soldar,

derritiendo el metal a medida que se mueve.

La soldadura por arco es una habilidad manual que requiere pulso

estable, óptima condición física y buena vista. El operador controla el

arco de soldadura y, por lo tanto, es responsable de la calidad del

trabajo de la misma.

2

Page 17

APRENDIENDO PALILLO SOLDAR

El electrodo revestido tiene otras funciones además de llevar la

corriente al arco. El electrodo se compone de un núcleo de alambre

de metal alrededor del cual se colocó un revestimiento químico. El

alambre del núcleo se derrite en el arco y gotas diminutas de metal

derretido caen pasando a través del arco hacia el charco de metal

fundido. El electrodo proporciona un metal de relleno adicional para

la junta, el cual rellena la ranura o el espacio entre las dos piezas del

metal base. El revestimiento también se derrite o se quema en el

arco. Este tiene diversas funciones. Se encarga de que el arco sea

más estable, proporciona una protección de gas similar al humo,

alrededor del arco para alejar al oxígeno y nitrógeno (que se

encuentran en el aire) del metal derretido y proporciona un fundente

para el charco de soldadura. El fundente elimina las impurezas y

forma la escoria protectora. Las diferencias principales entre los

diversos tipos de electrodos se encuentran en sus revestimientos. Si

varia el revestimiento, es posible cambiar considerablemente las

características de operación de los electrodos. Conociendo las

diferencias entre los diversos revestimientos, usted sabrá cómo

seleccionar el mejor electrodo para realizar un trabajo de soldadura.

Cuando seleccione un electrodo debe considerar:

1. El tipo de depósito que desea, por ejemplo acero

suave, acero inoxidable, acero con baja aleación o

acero para recubrimientos duros.

2. El grosor de la placa que desea soldar.

3. La posición en que debe soldarse (en forma

descendente, fuera de posición)

4. La condición de las superficies del metal que va a

soldar.

5. Su habilidad para manejar y obtener el electrodo

deseado.

Cuatro tipos simples de manejo son de vital importancia. Si no se

tiene un dominio total de éstos cuatro, la soldadura será ineficaz.

Con un dominio total de estos cuatro tipos, soldar será muy fácil.

Si está utilizando un protector para ojos de mano, sostenga

el portaelectrodo con su mano derecha y el protector de

ojos con la izquierda. Las personas zurdas deberán realizan

lo mismo, pero con la otra mano. Cuando sea posible,

suelde de izquierda a derecha (si es diestro). Esto le

permite ver claramente lo que está haciendo. Sostenga el

electrodo con una leve inclinación como se muestra.

2. La forma correcta de iniciar un arco

Asegúrese de que la pinza de trabajo haga buen contatco

eléctrico con el trabajo. Baje su careta o mantenga la

careta de mano en frente de su cara. Frote el electrodo

lentamente sobre el metal y verá chispas volando. Mientras

frota, levante el electrodo 3.2mm (1/8") y se establecerá el

arco.

NOTA: Si deja de mover el electrodo mientras frota, éste se adherirá.

NOTA: La mayoría de los principiantes intentan iniciar el arco con un

movimiento descendente, rápido y punzante sobre la placa. Resultado: el

electrodo se adhiere o su movimiento es tan rápido que rompen el arco

inmediatamente.

3. La longitud de arco correcta

La longitud del arco es la distancia de la punta del alambre

tubular del electrodo al metal base. Una vez que se ha

establecido el arco, mantener la longitud correcta del arco

se vuelve extremadamente importante. El arco deberá ser

corto, aproximadamente de 1.6 a 3.2mm (1/16 a 1/8") de

largo. A medida que el electrodo se quema, éste debe

alimentarse al trabajo para mantener una longitud correcta

del arco. La manera más fácil de indicar si el arco tiene una

longitud correcta es escuchando su sonido. Un arco bueno

y corto tiene un sonido distintivo de “chisporroteo”, muy

parecido al de unos huevos friendose en la sartén. Un arco

largo e incorrecto tiene un sonido cavernoso, de soplo o

siseante.

4. Velocidad correcta de avance

1. Posición correcta para soldar

A los principiantes se les facilitará aprender a controlar el

arco de soldadura utilizando las dos técnicas que se

proporcionan a continuación. Para esto es necesario

utilizar una careta.

a. Sostenga el portaelectrodo con la mano derecha

b. Coloque la mano izquierda debajo de la derecha.

c. Apoye el codo izquierdo en la parte izquierda de su

cuerpo. (para las personas zurdas, se hace lo

contrario)

Vista lateral

Vista de frente

Posición correcta para la soldadura

Es importante observar mientras suelda el charco de metal

derretido justo detrás del arco. NO observe al arco. La

apariencia del charco y el reborde donde el charco

derretido se solidifica es lo que indica la velocidad correcta

de avance. El reborde debe ser de aproximadamente 9.5

mm (3/8") atrás del electrodo.

Reborde donde el charco

se solidifica

Charco derretido

La mayoría de los principiantes tiende a soldar muy rápido,

dando como resultado un cordón con apariencia de

"oruga", delgada y dispareja. Cuando esto sucede, no están

observando el metal derretido.

IMPORTANTE: En general, para soldar no es necesario mover el arco ni hacia

adelante ni hacia atrás, ni tampoco hacia los lados. Suelde a un ritmo

estable; será más fácil de esta forma.

NOTA: Cuando suelde sobre una placa delgada, se dará cuenta de que tiene

que aumentar la velocidad de soldadura, mientras que al soldar sobre una

placa gruesa, es necesario llevar un ritmo más lento a fin de lograr una

penetración adecuada.

3

Page 18

APRENDIENDO PALILLO SOLDAR

PRÁCTICA

La mejor forma de practicar las cuatro actividades que le permitirán

mantener:

1. La posición correcta de soldadura

2. La forma correcta para iniciar un arco

3. La longitud correcta del arco

4. La velocidad correcta de avance

es invertir un poco de tiempo en el siguiente ejercicio.

Utilice lo siguiente:

Placa de acero suave, 4.8 mm (3/16") o más grueso

Electrodo, 3.2 mm (1/8"), Lincoln E6013

Programación de corriente, ...AC de 105 amperes o

CD(+) de 95 amperes

Realice lo siguiente:

1. Aprenda cómo iniciar el arco frotando el electrodo

sobre la placa. Asegúrese de que el ángulo del

electrodo sea el correcto. Si cuenta con una careta

utilice ambas manos.

2. Cuando pueda iniciar un arco sin pegar el electrodo,

practique la longitud correcta del arco. Aprenda a

distinguirla escuchando su sonido.

3. Cuando esté seguro de que puede mantener un arco

corto con el sonido correcto, empiece a deslizar el

electrodo. Observe el charco derretido constantemente y también el reborde en donde se solidifica

el metal.

4. Practique los cordones sobre una placa plana.

Hágalos paralelos a la orilla superior (la orilla que se

encuentra más lejos de usted). Esto le ayuda a

practicar soldaduras derechas y también le ofrece

una forma fácil para verificar su progreso. La décima

soldadura que haga, tendrá una mejor apariencia que

la primera. Al revisar constantemente sus errores y

su progreso, en poco tiempo, el proceso de

soldadura se convertirá en algo rutinario.

Metales comunes

La mayoría de los metales que se encuentran en los establecimientos

o ferreterías son aceros con bajo contenido de carbono, algunas

veces denominados aceros suaves. Los trabajos comunes que se

realizan con este tipo de acero incluyen generalmente hojas

metálicas, placas, tubería y formas laminadas como canales, ángulos

de hierro y vigas "I". Este tipo de acero puede soldarse normalmente

sin dificultades y sin necesidad de tomar precauciones especiales.

Sin embargo, algunos tipos de acero contienen cantidades mayores

de carbono. Las aplicaciones comunes incluyen placas desgastadas,

ejes, varillas de conexión, rejillas de arado y cuchillas de corte.

Estos aceros con cantidades mayores de carbono pueden soldarse

con éxito en la mayoría de los casos. Sin embargo, deben seguirse

cuidadosamente los procedimientos adecuados, incluyendo el precalentamiento del metal que se va a soldar y, en algunos casos, el

control cuidadoso de la temperatura durante y después del proceso

de soldadura.

A fin de obtener una soldadura de calidad, sin importar el tipo de

metal que se está soldando, es importante que éste esté libre de

aceite, pintura, óxido u otros contaminantes.

4

Page 19

APRENDIENDO PALILLO SOLDAR

TIPOS DE SOLDADURA

Los cinco tipos de uniones de soldadura son: soldadura a tope,

soldadura de filete, soldadura de empalme, soldadura de extremos y

soldadura de esquinas. See Figura 3

De estas, la soldadura a tope y la soldadura de filete son los dos tipos

de soldadura más comunes.

FIGURA 3

Soldadura a tope

Soldadura de empalme

Penetración

A menos que una soldadura penetre casi al 100%, una soldadura a

tope será más débil que el material que se soldó.

12.5 m m

Deficiente

(1/2")

En este ejemplo, la soldadura total únicamente es de 12.5 mm (1/2")

del grosor del material; por lo tanto, la soldadura es aproximadamente la mitad de fuerte que el metal.

Adecuada

Soldadura de extremos

Soldadura a tope

Soldadura de filete

Soldadura de esquinas

Las soldaduras a tope son las soldaduras que más se utilizan.

Coloque dos placas una al lado de la otra, dejando un espacio de 1.6

mm (1/16") (para metal delgado) y de 3.2 mm (1/8") (para metal

grueso) entre ellas, a fin de lograr una penetración profunda.

Suelde provisionalmente las dos placas en ambos extremos, de otra

forma el calor provocará que se separen. (Véase la figura 4):

FIGURA 4

Ahora, suelde las dos placas. Suelde de izquierda a derecha (si es

diestro). Coloque el electrodo sobre la hendidura entre las dos

placas, manteniendo el electrodo ligeramente inclinado hacia la

dirección de avance.

En este ejemplo, la unión se ha biselado con soplete o esmerilado

antes de soldarse para lograr una penetración del 100%. La

soldadura, si se realiza adecuadamente, es tan fuerte o más fuerte

que el metal original.

Soldadura de filete

Cuando se realizan soldaduras de filete, es muy importante sostener

el electrodo en un ángulo de 45° entre ambos lados o el metal no se

distribuirá equitativamente.

Para lograr mantener un ángulo de 45°, es mejor colocar el electrodo

en el portaelectrodos en un ángulo de 45°, como se muestra a

continuación:

Observe el metal derretido para asegurarse de que se distribuya

equitativamente a ambos lados y entre las placas. Se refiere esto

como la “técnica del tirón”. En el metal de hoja fino del calibrador,

utilice la “técnica del empuje”.

Weld Direction

5

Page 20

APRENDIENDO PALILLO SOLDAR

Soldaduras de pasadas múltiples

Realice soldaduras de filete en forma horizontal de pasadas múltiples

como se muestra en la figura. Ponga el primer cordón en la esquina,

utilizando una corriente verdaderamente alta. Mantenga el ángulo del

electrodo que se necesita para depositar los cordones de relleno

como se muestra, colocando el cordón final contra la placa vertical.

Soldadura en posición vertical

La soldadura en posición vertical puede realizarse, ya sea en forma

ascendente o descendente. La soldadura vertical ascendente se

utiliza cuando se desea una soldadura resistente y grande. La

soldadura vertical descendente se utiliza principalmente en hojas

metálicas para soldaduras rápidas y de baja penetración.

Soldadura en dirección vertical ascendente

El problema, cuando se suelda en forma vertical y ascendente, es

colocar el metal derretido donde se desea y lograr que permanezca

en esa posición. Si se deposita demasiado metal derretido, la

gravedad lo atraerá hacia abajo y hará que "gotee". Por lo tanto,

deben seguirse ciertas técnicas:

Arco largo

Arco corto

NOTA: El extremo del portaelectrodo donde se encuentra el electrodo

está más abajo que el arco

1. Utilice un electrodo Fleetweld‚180 (E6011) de 3.2 mm (1/8") a 90105 amperes o de 2.4 mm (3/32") a 60 amperes.

2. Cuando suelde, el electrodo debe mantenerse en una posición

horizontal o apuntando ligeramente hacia arriba. (Véase la figura).

3. Inicie el arco y deposite el metal en la parte inferior de las dos

piezas que se están soldando.

4. Antes de que se deposite demasiado metal derretido, mueva el

arco LENTAMENTE 12.5-19 mm (1/2- 3/4") hacia arriba. Esto

elimina el calor del charco derretido, que se solidifica. Si el arco no

se retira lo suficientemente rápido, se depositará un exceso de

metal y comenzará a gotear.

5. El movimiento hacia arriba del arco se logra con un movimiento

suave de la muñeca. De manera más clara, el brazo no debe

moverse hacia adentro o hacia afuera, ya que esto complica todo el

proceso y lo hace difícil de aprender.

6. Si el movimiento hacia arriba del arco se realiza correctamente con

un movimiento de la muñeca, el arco se convertirá automáticamente en un arco largo que deposite poco o nada de metal.

(Véase la figura).

7. Durante todo este proceso, el UNICO elemento a observar es el

metal derretido. Tan pronto como se solidifica, el arco se retira

LENTAMENTE y se depositan otras cuantas gotas. NO SIGA EL

MOVIMIENTO HACIA ARRIBA Y HACIA ABAJO DEL ARCO CON LOS

OJOS. MANTENGA SU VISTA SOBRE EL METAL DERRETIDO.

8. Cuando el arco se coloca nuevamente sobre el charco ya solidificado, DEBE SER CORTO, de otra forma no se depositará metal, el

charco se derretirá otra vez y comenzará a gotear.

9. Es importante darse cuenta que todo el proceso implica

movimientos LENTOS Y DELIBERADOS. No deben realizarse

movimientos rápidos.

Soldadura vertical descendente

Las soldaduras verticales descendentes se hacen a un ritmo rápido.

Por lo tanto, estas soldaduras son poco profundas y estrechas, lo que

las hace excelentes para las hojas metálicas. No utilice la técnica

vertical descendente en metales gruesos. Las soldaduras no serán lo

suficientemente fuertes.

1. Utilice un electrodo Fleetweld 180 (E6011) de

3.2 mm (1/8") o de 2.4 mm (3/32").

Arco muy

corto

2. En metal delgado utilice de 60 a 75 amperes

(14 ga 75 amperes - 16 ga 60 amperes).

3. Mantenga el electrodo a un ángulo de 30-45°

con la punta del electrodo hacia arriba.

4. Mantenga un arco MUY CORTO, mas no permita que el electrodo

toque el metal.

5. Un movimiento rápido hacia arriba y hacia abajo ayudará a evitar

que se perforen placas muy delgadas.

6. Observe cuidadosamente el metal derretido.

Lo importante es continuar bajando todo el brazo a medida que se

realiza la soldadura a fin de no modificar el ángulo del electrodo.

Mueva el electrodo tan rápido que la escoria no alcance el arco. Con

la soldadura vertical descendente se realizan soldaduras delgadas y

poco profundas. No debe utilizarse esta técnica en materiales

gruesos donde se necesitan soldaduras grandes.

6

Page 21

APRENDIENDO PALILLO SOLDAR

Soldadura sobre cabeza

Se utilizan diversas técnicas para la soldadura sobre cabeza. Sin

embargo, a fin de que el soldador sin experiencia aprenda en una

forma simple, se ha elegido la técnica que se muestra a continuación

y que probablemente satisfacerá la mayoría de sus necesidades para

la soldadura sobre cabeza:

1. Utilice un electrodo Fleetweld ‚180 (E6011) de 3.2mm (1/8") a 90105 amperes o 2.4 mm (3/32") a 60 amperes.

2. Coloque el electrodo en el portaelectrodo de tal forma que

sobresalga y se mantenga en una posición recta.

3. Mantenga el electrodo en un ángulo de aproximadamente 30°,

visto en forma lateral y frontal.

Vista lateral

Vista frontal

Lo más importante es mantener un arco MUY CORTO (un arco largo

dará como resultado material fundido que gotee; un arco corto evitará

que el metal gotee).

Si es necesario y, si así lo indica la apariencia del metal fundido, un

movimiento ligero del electrodo hacia adelante y hacia atrás, a lo

largo del cordón de soldadura, ayudará a evitar el "goteo".

Soldadura de hojas metálicas

Soldar hojas metálicas presenta un problema adicional. Lo delgado

del metal hace que sea muy fácil perforarlo. Siga estas reglas

simples:

1. Mantenga un arco muy corto. Esto evita la perforación, ya que los

principiantes tienden a mantener el arco durante mucho tiempo.

2. Utilice un electrodo Fleetweld 180 de 3.2 mm (1/8") o 2.4 mm

(3/32").

3. Utilice un amperaje bajo. 75 amperes para el electrodo de 3.2 mm

(1/8"), 40-60 amperes para el electrodo de 2.4 mm (3/32").

4. Realice movimientos rápidos. No mantenga el calor en un punto

dado por demasiado tiempo. Continúe. Avance el electrodo con un

movimiento corto.

5. Utilice soldaduras de empalme cuando sea posible. Esto duplica el

grosor del metal.

Recubrimiento duro

Existen diversas clases de desgaste. Los dos tipos que se encuentran

con más frecuencia son:

1. Desgaste del metal por la tierra.

Rejas de arado, cuchillas de tractor nivelador, cucharones, rejas de

agricultura y otras partes metálicas que se utilizan en la tierra.

2. Desgaste de metal por metal.

Muñones, ejes, rodillos y gobernadores, grúas, ruedas de vagones

mineros y grúas, etc.

Cada uno de estos tipos de desgaste requieren una clase diferente de

electrodo de recubrimiento duro.

Cuando utilice el electrodo adecuado, la duración de la pieza, en la

mayoría de los casos será más del doble. Por ejemplo, el

recubrimiento duro de rejas de arado aumentan por 3 - 5 veces el

número de hectáreas aradas.

Como realizar el recubrimiento duro en extremos filosos

(desgaste del metal por la tierra)

1. Pula la reja, aproximadamente 25 mm (una pulgada) a lo largo del

borde, hasta que el metal brille.

2. Coloque la reja en un ángulo de aproximadamente 20-30°. La

forma más fácil de hacer esto es colocando un extremo de la reja

sobre un ladrillo. (Véase la figura).

La mayoría de los usuarios querrán realizar un recubrimiento duro

en la parte inferior de la reja, pero otros pueden encontrar que el

desgaste se presenta en el lado superior. Lo importante es recubrir

el lado que se desgasta.

3. Utilice un electrodo WearshieldTM ABR de 3.2 mm (1/8") a 90-105

amperes. Inicie el arco aproximadamente a 25 mm (1 pulgada) del

borde afilado.

4. El cordón debe colocarse con un movimiento de lado a lado y debe

tener de 12.5 a 19 mm (de 1/2 a 3/4 ") de ancho. No permita que

el arco quede sobre el borde, ya que le quitaría el filo. (Véase el

dibujo).

Mesa de trabajo

Ladrillo

Reja de arado

Posición de la reja

In icie al

arco aquí

Borde filoso

Ancho de 12

a 20 mm (de

1/2 a 3/4")

Movimiento de lado a lado

5. Utilice el método regresivo. Inicie soldando 75 mm (3") a partir de

la base de la reja y continúe hacia la base. Inicie la segunda

soldadura a 150 mm (6") de la base de la reja y la tercera a 225

mm (9") de la base de la reja y así sucesivamente.

Primero suelde de A a B;

después, de C a A; continúe de D a C y de E a D y

así sucesivamente.

METODO REGRESIVO

El método regresivo realmente reduce las posibilidades de que la reja

se agriete y también disminuye en gran medida la posibilidad de que

ésta se distorsione.

NOTA: El proceso completo es un tanto rápido. Muchos principiantes van más

lento cuando realizan el recubrimiento duro en rejas de arado, arriesgándose a sufrir una quemadura a través del metal delgado.

7

Page 22

APRENDIENDO PALILLO SOLDAR

Recubrimiento duro deruedas y rodillo (desgaste de metal

por metal)

Una aplicación muy común de recubrimiento duro para el desgaste de

metal por metal es el recubrimiento duro de ruedas, rodillos y de los

rieles que se utilizan en los mismos.

La razón de un recubrimiento duro para estas partes es básicamente

económica. La inversión en electrodos vale la pena, ya que se

reconstruye completamente una rueda o rodillo y la superficie dura

mucho más que un rodillo o rueda normal.

Si se sigue el procedimiento que se muestra a continuación, no es

necesario eliminar el rodamiento de grasa mientras se suelda. Esto

le ahorrará mucho tiempo:

1. El rodillo (o gobernador) se inserta en un tubo que descanse sobre

dos caballetes. Esto permite que el operador lo gire mientras

suelda.

2. Utilice electrodos Wearshield™ BU, 4.0 mm (5/32") a 175

amperes o 4.8 mm (3/16") a 200 amperes.

3. Suelde a lo largo de la superficie que se desgasta. No suelde

alrededor.

4. Mantenga el rodillo (o rueda) frío sumergiéndolo en agua y

deteniendo el trabajo de soldadura periódicamente. Esto evitará

que el rodillo (o rueda) se contraiga en el rodamiento de grasa.

5. Recúbralo hasta darle la dimensión deseada. El metal de

soldadura depositado por el electrodo Wearshield™ BU a menudo

es tan suave que no es necesario esmerilarlo o pulirlo.

NOTA: Enfriar el rodillo (o rueda) tiene otro propósito: aumentar la dureza y

por lo tanto, la vida útil del depósito.

El recubrimiento duro de los rieles es mucho más fácil:

1. Coloque los rieles con la parte donde se deslizan los rodillos y

gobernadores hacia arriba.

2. Utilice electrodos Wearshield™ BU. Se utiliza el mismo amperaje

que en los gobernadores y rodillos.

3. Recubra hasta obtener el tamaño deseado.

4. No enfríe. Esto hará que el depósito sea un poco más suave que el

depósito en los rodillos y ruedas. Esto significa que el área de

desgaste estará básicamente en los rieles, que requieren menos

tiempo, dinero y esfuerzo para recubrirlos.

NOTA: El mismo electrodo, Wearshield™ BU, ofrecerá al operador dos

opciones de dureza por una diferencia en la velocidad de enfriamiento,

haciendo posible colocar el depósito más duro en las partes más cos-

tosas.

NOTA: La parte exterior de los rieles (que tiene contacto con la tierra) debe

recubrirse con Wearshield™ BU, ya que este lado presenta un desgaste

del metal por la tierra.

Como soldar hierro vaciado

Cuando se suelda una pieza de hierro vaciado frío, la enorme

cantidad de calor que despide el arco será absorbida y distribuida

rápidamente en la masa fría. Esta calor y enfriamiento repentino crea

hierro vaciado BLANCO y QUEBRADIZO en la zona de fusión.

Caliente

Hierro vaciado blan-

Frío

Frío

co y quebradizo

Esta es la razón por la que las soldaduras en hierro vaciado se

rompen. En realidad, una pieza de fierro vaciado rota se queda con la

soldadura completa en ella y la otra pieza sin soldadura.

Cuando se rompe, la

soldadura queda en

una de las piezas.

Para contrarrestar esto, el soldador tiene dos opciones:

1. Puede precalentar toda la pieza de 260 a 649°C (500 -1200°F). Si

el hierro vaciado se calienta antes de soldar, no habrá enfriamiento

repentino que produzca un hierro vaciado blanco y quebradizo.

Toda la pieza fundida se enfriará lentamente.

2. Puede soldar 12.5 mm (1/2") a la vez y no soldar en esa área otra

vez hasta que la soldadura esté completamente fría al tacto.

De esta forma, no se aplica una gran cantidad de calor a la masa.

La mayoría de los soldadores sin experiencia probablemente

utilizarán el segundo método, porque no cuentan con una forma de

precalentamiento para piezas fundidas grandes. Las piezas fundidas

más pequeñas pueden (y deben) precalentarse fácilmente antes de

soldarse. Una fragua, horno, soplete o la misma antorcha de arco son

medios excelentes de precalentamiento.

Cuando se utiliza el método en el que se suelda 12.5 mm (1/2") a la

vez, se recomienda comenzar a 12.5 mm (1/2") del cordón anterior y

soldar hacia el mismo (método regresivo).

Después de soldar hierro vaciado, proteja la pieza fundida contra un

enfriamiento rápido. Póngala en una caja con arena (o cal).

Si no cuenta con arena o cal, cubra la pieza con hojas metálicas o

cualquier otro material no inflamable que eviten las corrientes de aire

y conserve el calor.

Preparación de una placa de hierro vaciado

Si es posible, la junta que se soldará debe prepararse limándola en

forma de "V" para lograr una penetración completa. Esto es

especialmente importante en piezas fundidas gruesas donde se

requiere máxima resistencia. En algunos casos, puede utilizarse una

pieza de respaldo y las placas pueden separarse 3.2 mm (1/8") o

más.

Las secciones que únicamente se requieran unir y la dureza no es

importante, la junta puede soldarse después de esmerilar ligeramente

las partes en forma de "V" como se muestra a continuación.

8

Page 23

APRENDIENDO PALILLO SOLDAR

Pieza de respaldo de acero

Tres formas para preparar placas donde se necesita una penetración completa

Cordones sencillos y dobles con y sin biselado en forma de V para uniones

firmes y parcialmente resistentes.

9

Page 24

The business of The Lincoln Electric Company is manufacturing and

selling high quality welding equipment, consumables, and cutting

equipment. Our challenge is to meet the needs of our customers and

to exceed their expectations. On occasion, purchasers may ask

Lincoln Electric for advice or information about their use of our

products. We respond to our customers based on the best information

in our possession at that time. Lincoln Electric is not in a position to

warrant or guarantee such advice, and assumes no liability, with

respect to such information or advice. We expressly disclaim any

warranty of any kind, including any warranty of fitness for any

customer’s particular purpose, with respect to such information or

advice. As a matter of practical consideration, we also cannot assume

any responsibility for updating or correcting any such information or

advice once it has been given, nor does the provision of information

or advice create, expand or alter any warranty with respect to the sale

of our products.

Lincoln Electric is a responsive manufacturer, but the selection and

use of specific products sold by Lincoln Electric is solely within the

control of, and remains the sole responsibility of the customer. Many

variables beyond the control of Lincoln Electric affect the results

obtained in applying these types of fabrication methods and service

requirements.

Subject to Change – This information is accurate to the best of our

knowledge at the time of printing. Please refer to

www.lincolnelectric.com for any updated information.

Page 25

Guide de soudage

APPRENTISSAGE DE BÂTON SOUDURE

%-,.0%52,1/7

'00-333)(+#,)+%)%#0.(##,*/!&%04-,1.

,"0%+(.$%/(+&,.*!0(,+//1.)!/8#1.(08

Welding Safety

Interactive Web Guide

pour les appareils

mobiles

LTW2 | Issue D ate 07/13

© Lincoln Global, Inc. All Rights Reserved.

Page 26

666

Le matériel de soudage et de coupage à l'arc Lincoln est conçu et

construit en tenant compte de la sécurité. Toutefois, la sécurité en

général peut être accrue grâce à une bonne installation... et à la plus

grande prudence de votre part. NE PAS INSTALLER, N'ACTIONNEZ

PAS OU NE RÉPARER PAS CET EQUIPEMENT SANS LIRE LE MANUEL

D'OPÉRATEURS QUI EST EQUIPEMENT DE VOTRE MACHINE ET DE

MESURES DE SÉCURITÉ CONTENUES PARTOUT. Et, par dessus tout,

réfléchissez avant d'agir et exercez la plus grande prudence.

WARNING

Cette déclaration apparaît lorsque les indications doivent être suivies

avec exactitude afin d’éviter des blessures graves ou un décès.

CAUTION

Cette déclaration apparaît lorsque les indications doivent être suivies

avec exactitude afin d’éviter des blessures légères ou des dommages

à l’appareil.

;

NE PAS s’approcher trop près de

l’arc. Utiliser des verres de

correction si besoin est pour

rester à une distance raisonnable

de l’arc.

LIRE et respecter la Fiche

Technique Santé - Sécurité (MSDS) et l’étiquette d’avertissement qui

figure sur tous les conteneurs de matériel de soudage.

UTILISER SUFFISAMMENT DE VENTILATION ou d’échappement au

niveau de l’arc, ou les deux, pour maintenir les vapeurs et les gaz

hors de la zone de respiration et de la zone générale de travail.

DANS UNE GRANDE PIÈCE OU EN EXTÉRIEUR, la ventilation

naturelle peut s’avérer appropriée si on maintient sa tête en dehors

des vapeurs (voir ci-dessous).

UTILISER DES APPELS D’AIR NATURELS ou des ventilateurs pour

éloigner les vapeurs du visage.

Si des symptômes inhabituels apparaissent, prévenir le superviseur.

L’atmosphère de soudage et le système de ventilation ont peut-être

besoin d’une révision.

.

SE PROTÉGER les yeux et le visage avec un casque

de soudage adapté comportant une plaque filtre d’un

degré approprié (Voir ANSI Z49.1).

SE PROTÉGER le corps contre les projections de

soudure et les coups d’arc au moyen de vêtements

de protection comprenant des vêtements en laine, un

tablier et des gants ignifuges, des leggings en cuir et

des bottes montantes.

PROTÉGER les autres contre les projections, les

coups d’arc et l’éblouissement à l’aide d’écrans ou

de barrières de protection.

DANS CERTAINS ENDROITS, une

protection sonore peut s’avérer appropriée.

VÉRIFIER que l’équipement de protection soit en bon

état.

Porter également EN PERMANENCE des lunettes de sécurité dans la

zone de travail.

<

NE PAS SOUDER NI COUPER des conteneurs ou des matériaux ayant

préalablement été en contact avec des substances dangereuses à

moins qu’ils n’aient été parfaitement nettoyés. Ceci est extrêmement

dangereux.

NE PAS SOUDER NI COUPER des pièces peintes ou plaquées à moins

de prendre des précautions spéciales en matière de ventilation. Elles

peuvent émettre des vapeurs ou des gaz fortement toxiques.

Mesures de sécurité supplémentaires

PROTÉGER les bouteilles de gaz comprimé de la chaleur

excessive, des chocs mécaniques et des arcs ; attacher

les bouteilles afin qu’elles ne puissent pas tomber.

VÉRIFIER que les bouteilles ne soient jamais mises à la

terre et qu’elles ne fassent pas partie d’un circuit

électrique.

ÉLIMINER tous les risques d’incendie potentiels de la zone de

soudage.

L’ÉQUIPEMENT DE LUTTE CONTRE LES INCENDIES DOIT

TOUJOURS ÊTRE PRÊT POUR UN USAGE IMMÉDIAT ET LES

USAGERS DOIVENT SAVOIR COMMENT S’EN SERVIR.

Page 27

APPRENTISSAGE DE BÂTON SOUDURE

Apprenez DE BÂTON SOUDURE..................................................................................2

TABLE DES MATIÈRES

Page

Le circuit de soudage à l'arc

Que se passe-t-il dans l'arc?.....................................................................................2

La bonne position de soudage ..................................................................................3

La bonne façon d'amorcer l'arc .................................................................................3

La bonne longueur d'arc............................................................................................3

Pratique.....................................................................................................................4

Métaux communs ...............................................................................................4

Types de soudures ...........................................................................................5

Soudures bout à bout .......................................................................................5

Pénétration .......................................................................................................5

Soudures d'angle..............................................................................................5

Soudures multipasses ........................................................................................6

Soudage en position verticale.............................................................................6

Soudage à la verticale en montant .....................................................................6

Soudage à la verticale en descendant

Soudage au plafond

Soudage de tôles

Rechargement dur