Page 1

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

• World's Leader in Welding and Cutting Products •

“LEARNING TO WELD”

“APRENDIENDO A SOLDAR”

“APPRENEZ À SOUDER”

WORKPIECE

ARC

ARCO

ARC

WORK CLAMP

PINZA DE TRABAJO

BRIDE DE TRAVAIL

GUN AND CABLE

ANTORCHA Y CABLE

PISTOLET ET C BLE

PIEZA DE TRABAJO

MORCEAU DE TRAVAIL

May, 2006

LTW1

Copyright © 2006 Lincoln Global Inc.

Safety Depends on You

Lincoln arc welding and cutting equipment

is designed and built with safety in mind.

However, your overall safety can be

increased by proper installation ... and

thoughtful operation on your part. DO NOT

INSTALL, OPERATE OR REPAIR THIS

EQUIPMENT WITHOUT READING THE

OPERATORS MANUAL WHICH IS PROVIDED WITH YOUR MACHINE AND THE

SAFETY PRECAUTIONS CONTAINED

THROUGHOUT. And, most importantly,

think before you act and be careful.

La seguridad depende de usted

El equipo de soldadura por arco y corte de

Lincoln está diseñado y construido teniendo

en mente la seguridad. Sin embargo, la

seguridad general puede ser mejor si instala

y opera la máquina adecuadamente.

NO

INSTALE, NO PONGA EN FUNCIONAMIENTO NI REPARE ESTE EQUIPO

SIN LA LECTURA DEL MANUAL DE LOS

OPERADORES QUE SE PROPORCIONA

CON SU MÁQUINA Y LAS MEDIDAS DE

SEGURIDAD CONTENIDAS EN EL MISMO.

Lo más importante, piense antes de actuar

y tenga cuidado.

La sécurité dépend de vous

Le matériel de soudage et de coupage à

l'arc Lincoln est conçu et construit en tenant

compte de la sécurité. Toutefois, la sécurité

en général peut être accrue grâce à une

bonne installation... et à la plus grande prudence de votre part.

NE PAS INSTALLER,

N'ACTIONNEZ PAS OU NE RÉPARER PAS

CET EQUIPEMENT SANS LIRE LE MANUEL

D'OPÉRATEURS QUI EST EQUIPEMENT DE

VOTRE MACHINE ET DE MESURES DE

SÉCURITÉ CONTENUES PARTOUT.

Et, par

dessus tout, réfléchissez avant d'agir et

exercez la plus grande prudence.

RETURN TO MAIN MENU

Page 2

1

1

TABLE OF CONTENTS

Page

Learn to Weld.................................................................................................................2

Arc Welding Circuit....................................................................................................2

Self-Shielded FCAW (Flux Core Arc Welding)..........................................................3

GMAW (Gas Metal Arc Welding) ..............................................................................3

Process Selection......................................................................................................4

For GMAW (MIG) Process..................................................................................4

For FCAW (Innershield) Process........................................................................4

Common Metals..................................................................................................4

Joint Types and Positions .........................................................................................4

Butt Joints...........................................................................................................4

Penetration .........................................................................................................5

Fillet Joints..........................................................................................................5

Welding In The Vertical Position ...............................................................................5

Vertical-up And Overhead Welding ....................................................................5

Vertical-down Welding........................................................................................6

Machine Set Up For The Self-Shielded FCAW Process...........................................6

Welding Techniques For The Self-Shielded FCAW Process....................................6

1. The Correct Welding Position.........................................................................6

2. The Correct Way To Strike An Arc .................................................................7

3. The Correct Contact Tip To Work Distance....................................................7

4. The Correct Welding Speed (Travel Speed)...................................................7

Helpful Hints..............................................................................................................8

Practice .....................................................................................................................8

Machine Set Up For The GMAW (MIG) Process ......................................................9

Weld Techniques For The GMAW (MIG) Process....................................................9

1. The Correct Welding Position.........................................................................9

2. The Correct Way To Strike An Arc .................................................................9

3. The Correct (CTWD) Contact Tip To Work Distance....................................10

4. The Correct Welding Speed ........................................................................10

Helpful Hints............................................................................................................10

Practice ...................................................................................................................10

Troubleshooting Welds ..............................................................................................11

Page 3

2

LEARNING TO WELD

2

LEARNING TO WELD

Welding is a skill that can only be learned by practicing. No one can become an accomplished welder

simply by reading about it. The following pages will

help the inexperienced operator to understand the

basics about wire welding and provide guidance to

help develop this skill. For more detailed information,

order a copy of “New Lessons in Arc Welding”.

THE ARC-WELDING CIRCUIT

The operators knowledge of arc welding must go

beyond the arc itself. The operator must know how to

control the arc, and this requires a knowledge of the

welding circuit and the equipment that provides the

electric current used in the arc. Figure 1 illustrates the

welding circuit for a typical welding machine. The circuit begins where the gun cable is attached to the

welding machine. Current flows through the gun

cable, gun, and contact tip, to the wire and across the

arc. On the work side of the arc, current flows through

the base metal to the work cable and back to the

welding machine. This circuit must be complete for the

current to flow. Loose or poor connections anywhere

in the circuit will rob voltage from the arc and cause it

to become erratic.

This machine’s welding circuit has a voltage output of

32 volts DC maximum. This voltage is quite low and is

only present when the gun trigger is pressed.

FIGURE 1

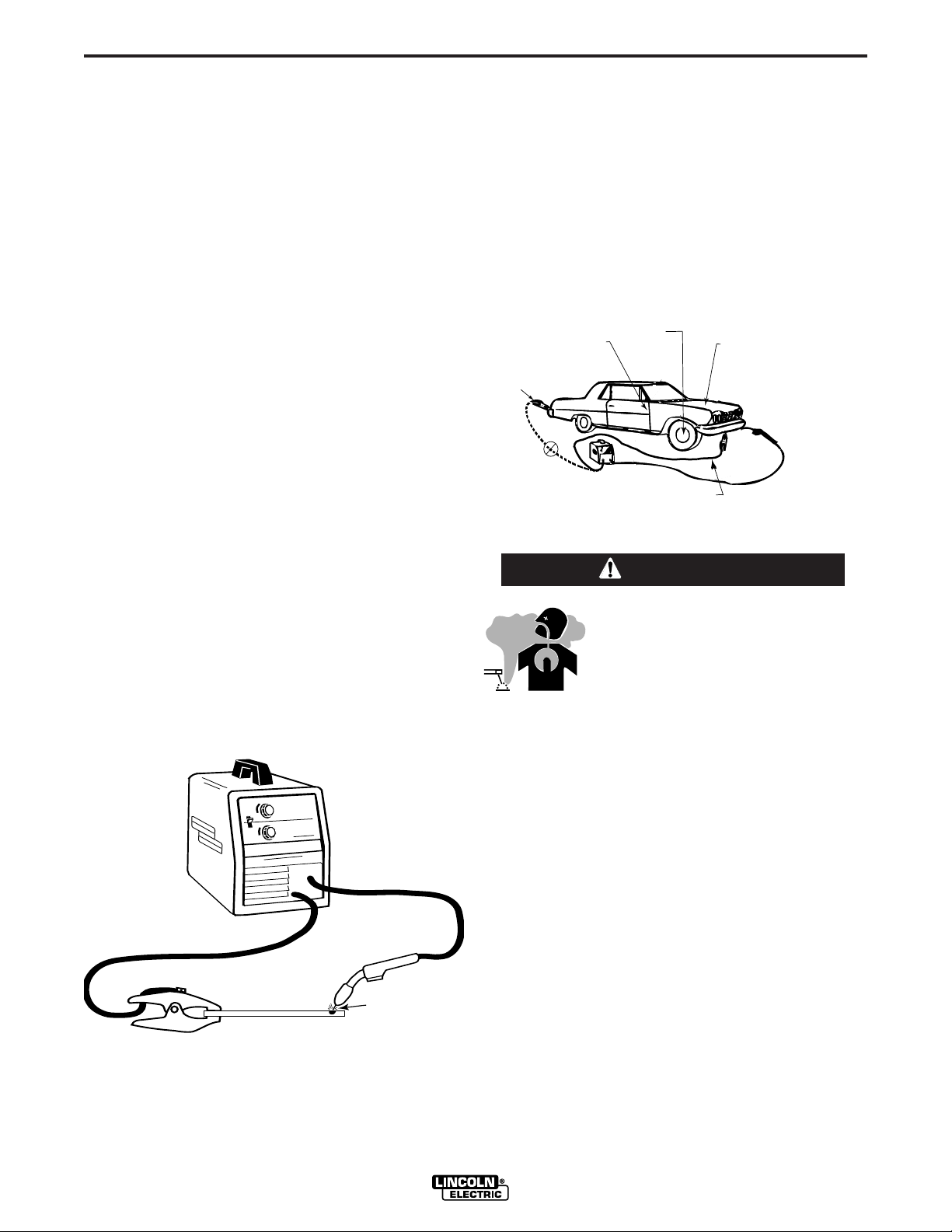

To weld, the work clamp must be tightly connected to

clean base metal. Clean the joints by removing

excessive scale, rust, moisture, paint, oil and grease

from the surface. As with all welding applications, joint

cleanliness is necessary to avoid porosity and to

attain the best weld quality. Connect the work clamp

“as close as possible” to the area you wish to weld.

This helps prevent current from going through an

unwanted path. Avoid allowing the welding circuit to

pass through hinges, bearings, electronic components, or similar devices that can be damaged. See

Figure 2. Always disconnect electrical devices before

welding upon them.

FIGURE 2

Fumes and slag generated from

Innershield type electrodes recommended for use with this welding

machine can produce fumes and

gases hazardous to your health.

• Avoid contact with eyes and skin.

• Do not take internally.

• Keep slag away from children.

• Keep out of reach of children.

• Follow all safety precautions found in your

operator’s manual.

-----------------------------------------------------------------------

The gun and cable assembly is held by the operator

who guides the automatically fed wire along the joint,

maintaining a contact tip to work distance of about 3/8

to 1/2 inch (10 – 12 mm) This is called Contact Tip to

Work Distance. The welding arc is established in the

gap between the work and the end of a small diameter wire. When the power source is properly set, the

length of the arc is maintained automatically.

Arc welding is a manual skill requiring a steady hand,

good physical condition, and good eyesight. The operator controls the welding arc, and, therefore, the quality of the weld made.

WRONG

WRONG

CURRENT

CURRENT

PATH

TH

Bearings

Hinges

Electrical Components

CORRECT

CORRECT

CURRENT

CURRENT

PATH

TH

*

* For best results position work clamp approximantely

12 inches(294mm) from the welded area.

WARNING

WORKPIECE

ARC

GUN and CABLE

WORK CLAMP

Page 4

3

LEARNING TO WELD

3

SELF-SHIELDED FCAW (FLUX CORE

ARC WELDING)

Figure 3 illustrates the action taking place in the selfshielded FCAW (Innershield) welding arc. It closely

resembles what is actually seen while welding.

FIGURE 3

The “arc stream” is seen in the middle of the picture.

This is the electric arc created by the electric current

flowing through the space between the end of the wire

electrode and the base metal. The temperature of this

arc is about 6000°F, which is more than enough to

melt metal.

The arc is very bright, as well as hot, and cannot be

looked at with the naked eye without risking painful

injury. A very dark lens, specifically designed for arc

welding, must be used with the hand or face shield

whenever viewing the arc .(ANSI Z49.1-88)

The arc melts the base metal and actually digs into it

much as water through a nozzle on a garden hose

digs into the earth. The molten metal forms a molten

pool or crater and tends to flow away from the arc. As

it moves away from the arc, it cools and solidifies.

The function of the Innershield cored wire electrode is

much more than simply to carry current to the arc. The

wire core is composed of fluxes and/or alloying ingredients around which a steel sheath has been formed.

It is simply a stick electrode turned inside out in a continuous wire form.

The cored wire melts in the arc and tiny droplets of

molten metal shoot across the arc into the molten

pool. The wire sheath provides additional filler metal

for the joint to fill the groove or gap between the two

pieces of base metal.

The core materials also melt or burn in the arc and

perform several functions. They make the arc steadier, provide a shield of smoke-like gas around the arc

to keep oxygen and nitrogen in the air away from the

molten metal, and provide a flux for the molten pool.

The flux picks up impurities and forms the protective

slag on top of the weld during cooling.

After running a weld bead, the slag may be removed

with a chipping hammer and wire brush. This

improves appearance and allows for inspection of the

finished weld.

Since machine size and output characteristics limit the

size and type of wire electrode which can be used, check

your Instruction Manual “Application Chart” or see the

Application Guide on the inside door of the Machine. This

will give you the proper electrode size and control settings to be used.

GMAW (GAS METALARC WELDING)

Figure 4 illustrates the GMAW (Also referred to as MIG)

welding arc. Solid wire does not contain fluxes or ingredients to form its own shielding and no slag forms to protect the molten weld metal. For this reason, a continuous

even flow of shielding gas is needed to protect the

molten weld metal from atmospheric contaminant’s such

as oxygen and nitrogen. Shielding gas is supplied

through the gun and cable assembly, through the gas

nozzle and into the welding zone.

Important!

The MIG welding process requires that the welder has a

gas solenoid valve installed in order to control the flow of

the shielding gas. Read your Operators Manual to see if

your machine requires additional items to MIG weld.

When comparing the GMAW and FCAW processes, you

can see that the principal difference between the two lies

in the type of shielding used. GMAW uses gas for shielding, thus we have Gas Metal Arc Welding. FCAW uses

the melting or burning of the core ingredients for shielding, and is thus termed Self-Shielded Flux-Cored Arc

Welding.

The recommended LINCOLN Super Arc L-56 solid wire

and gas for Gas Metal Arc Welding (MIG)Metal Inert Gas

is also located in the Instruction Manual “Application

Chart” or see the Application Guide on the inside door of

the Machine. This machine is capable of welding a wide

range of mild steels in all positions, however, more skill

IS required for out-of-position welding with the GMAW

process.

FIGURE 4

Gas nozzle

Shielding gasSolid wire

electrode

Contact Tip

Base metal

Weld metal

Burning of core materials

inside the wire electrode

provides a gas to shield

the molten metal as it

solidifies.

Arc Stream

Weld Puddle

Cored Wire

Protective Slag

Weld Metal

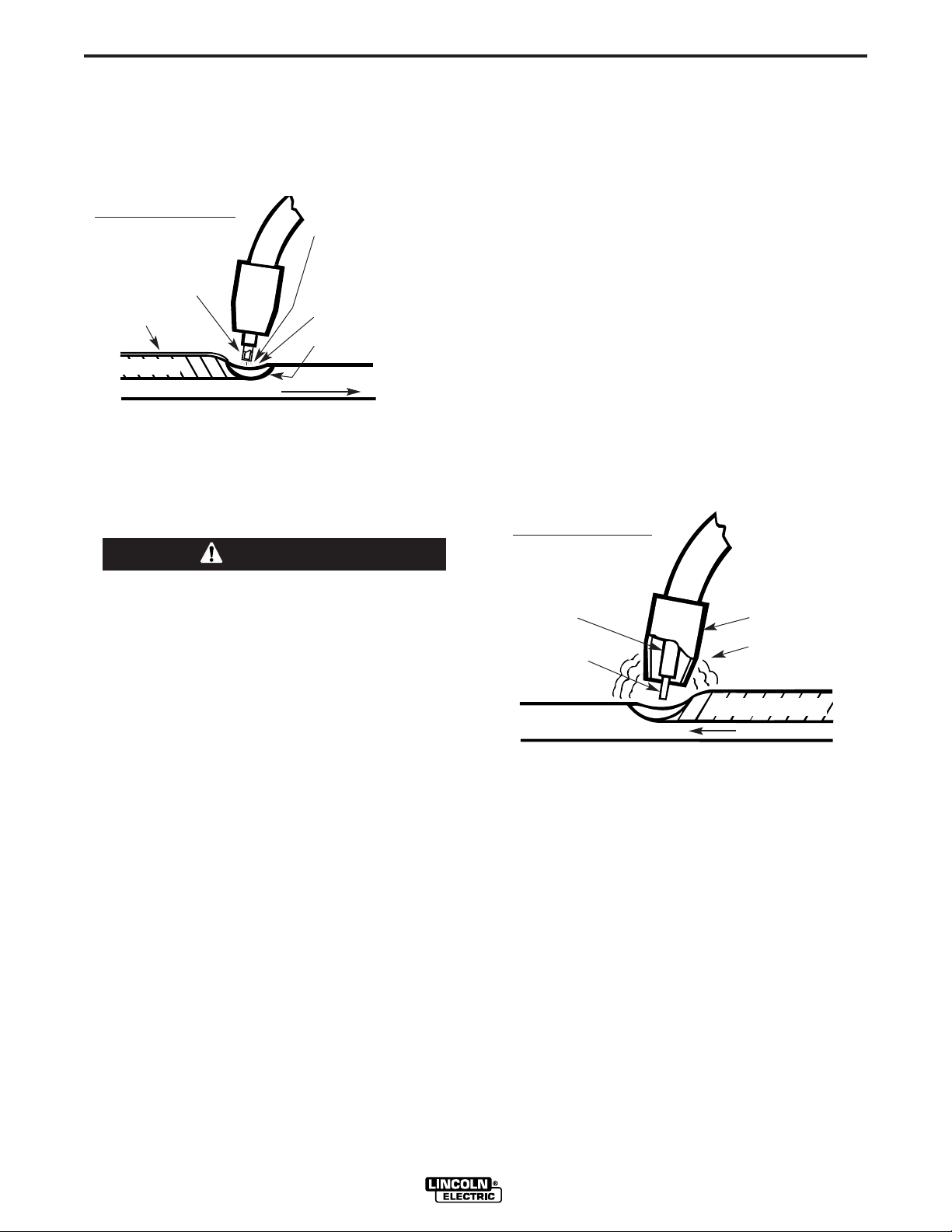

DRAG TECHNIQUE

PUSH TECHNIQUE

DIRECTION OF TRAVEL

DIRECTION OF TRAVEL

WARNING

Page 5

4

LEARNING TO WELD

4

PROCESS SELECTION

By gaining knowledge of the differences between the

two processes, you will be able to select the best

process for the job you have at hand. In selecting a

process, you should consider:

For GMAW (MIG) Process

1. Is most of my welding performed on 16 gauge and

lighter materials?

2. Can I afford the extra expense, space, and lack of

portability required for gas cylinders and gas supply?

3. Do I require clean, finished-looking welds?

4. Base metal must be clean.

If you have answered yes to all the above questions

GMAW may be the process for you. If you have

answered no to any of the above questions, then you

should consider using the FCAW process.

For FCAW (Innershield) Process

1. Do I want simplicity and portability?

2. Will welding be performed outdoors or under windy

conditions?

3. Do I require good all position welding capability?

4. Will most welding be performed on 16 gauge and

heavier, somewhat rusty or dirty materials?

5. Weld must be cleaned prior to painting.

6. Please note that your machine may or may not be

set up to handle both FCAW and GMAW welding

processes. Refer to your “Operators Manual” to

determine Option Accessories are required to adapt

to your machine.

COMMON METALS

Most metals found around the farm, small shop or

home are low carbon steel, sometimes referred to as

mild steel. Typical items made with this type of steel

include most sheet metal, plate, pipe and rolled

shapes such as channels and angle irons. This type of

steel can usually be easily welded without special precautions. Some steels, however, contain higher carbon levels or other alloys and are more difficult to

weld. Basically, if a magnet sticks to the metal and

you can easily cut the metal with a file, chances are

good that the metal is mild steel and that you will be

able to weld the material. If you plan to weld on aluminum, special drive rolls or aluminum Welding Kits

may be required or highly recommended. Consult

your machines Operators Manual. Pure Argon shielding gas and a spool of aluminum welding wire will also

be required. For further information on identifying various types of steels and other metals, and for proper

procedures for welding them, we again suggest you

purchase a copy of “Metals and How to Weld Them”.

Regardless of the type of metal being welded, in order

to get a quality weld, it is important that the metal is

free of oil, paint, rust or other contaminant’s.

JOINT TYPES AND POSITIONS

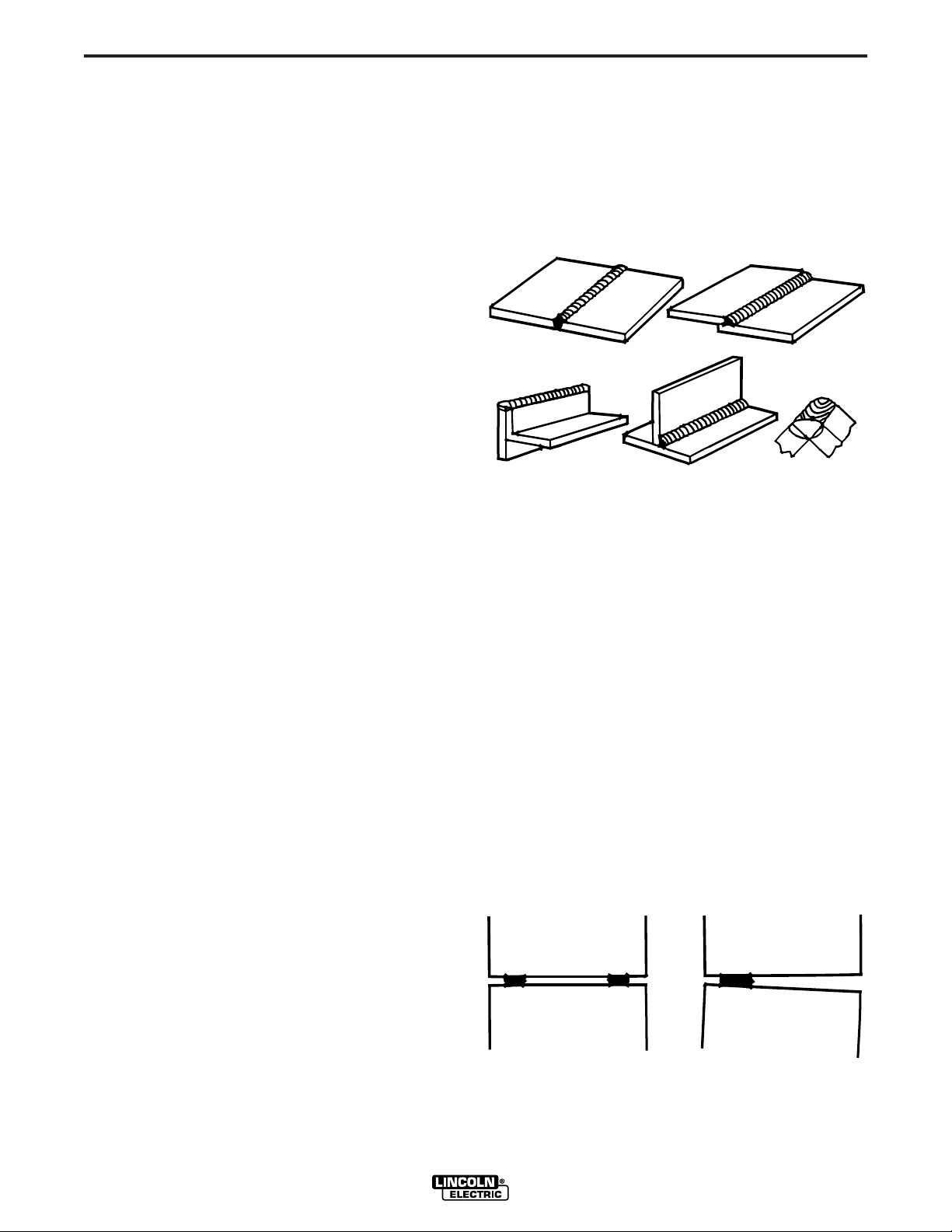

Five types of welding joints are: Butt joint, Fillet joint,

Lap joint, Edge joint and Corner joint. See Figure 5.

Of these, the Butt Joint and Fillet Joint are the two

most common welds.

FIGURE 5

Butt Joints

Place two plates side by side with a tight Fit-up to prevent burn thru when welding.

Securely clamp or tack weld the plates at both ends,

otherwise the heat will cause the plates to move apart.

See Figure 6.

Now weld the two plates together. Weld from left to

right (if right handed). Point the wire electrode

between the two plates, keeping the gun slightly tilted

in the direction of travel. Watch the molten metal to be

sure it distributes itself evenly on both edges and in

between the plates. This is referred to as the “pull

technique”. On thin gauge sheet metal, use the “push

technique”. See “Welding Techniques for GMAW

(MIG) Process”.

FIGURE 6

Butt joint Lap joint

Edge joint Fillet joint Corner joint

Page 6

5

LEARNING TO WELD

5

Penetration

Unless a weld penetrates close to 100% of the metal

thickness, a butt joint will be weaker than the material

welded together. In the example shown in Figure 7,

the total weld is only half the thickness of the material

thus the weld is only approximately half as strong as

the metal.

FIGURE 7

FIGURE 8

In the example shown in Figure 8, the joint has been

welded so that 100% penetration could be achieved.

The weld, if properly made, is as strong as or stronger

than the original metal.

Fillet Joints

When welding fillet joints, it is very important to hold

the wire electrode at a 45° angle between the two

sides or the metal will not distribute itself evenly. The

gun nozzle is generally formed at an angle to facilitate

this. See Figure 9.

FIGURE 9

Welding In The Vertical Position

Welding in the vertical position can be done either vertical-up or vertical-down. Vertical-up is used whenever

a larger, stronger weld is desired 1/4”(6.4mm) and

thicker material. Vertical-down is used primarily on

sheet metal 3/16”(4.8mm)and thinner materials cause

for fast, low penetrating welds.

Use of this unit on thicker materials than recommended may result in welds of poor quality. The

welds may appear to be fine, but may lack the

fusion or bonding necessary to give a strong

weld. This is called "Cold Casting" or "cold lapping" and is some what similar to a cold solder

joint. Weld failure may result.

------------------------------------------------------------------------

Vertical-up And Overhead Welding

The problem, when welding vertical-up 1/4”(6.4mm)

and thicker material, is to put the molten metal where

it is wanted and make it stay there. If too much molten

metal is deposited, gravity will pull it down wards and

make it “drip”. Therefore, a certain technique has to

be followed.

When welding out-of-position, run stringer beads.

Don’t whip, break the arc, move out of the puddle, or

move too fast in any direction. Use Wire Feed Speed

(WFS) in the low portion of the range. The general

technique and proper gun angle is illustrated in Figure

10.

Generally, keep the electrode nearly perpendicular to

the joint as illustrated. The maximum angle above perpendicular may be required if porosity becomes a

problem.

FIGURE 10

45¡ CENTER LINE

TO HORIZONTAL PLATE

WARNING

PROPER GUN ANGLE

FOR GMAW PROCESS

WELDING IN THE VERTICAL DOWN POSITION

3/16 INCH AND THINNER

1/4 INCH AND THICKER

PROPER GUN ANGLE

FOR FCAW PROCESS

WELDING IN THE VERTICAL UP POSITION

45° CENTERLINE OF GUN TO

HORIZONTAL PLATE

Page 7

6

LEARNING TO WELD

6

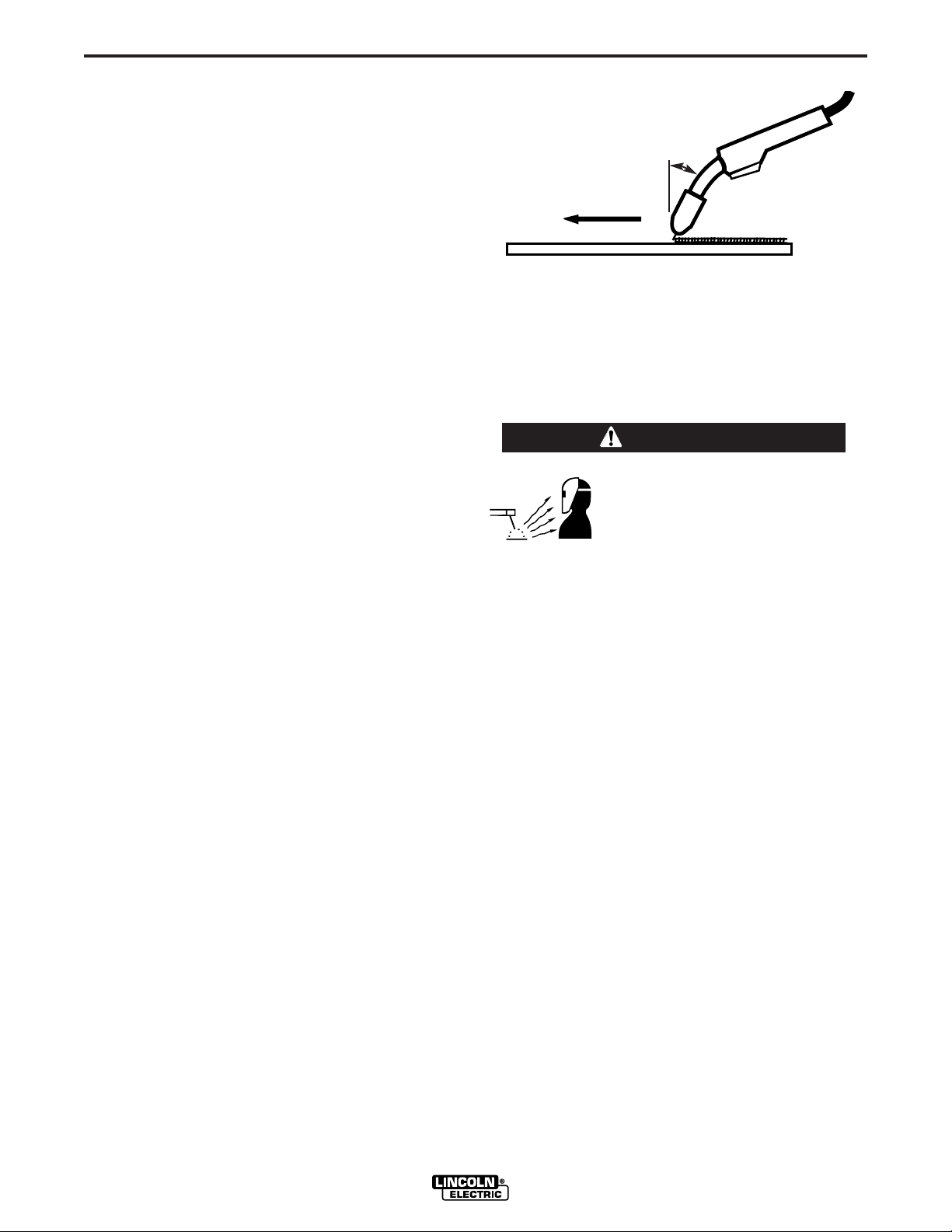

Vertical-down Welding

Refer to Figure 11 Vertical-down welds are applied at

a fast pace. These welds are therefore shallow and

narrow and, as such, are excellent for sheet metal.

Vertical-down welds may be applied by a table which

is found in the Instruction Manual for lighter material.

Use stringer beads and tip the gun in the direction of

travel so the arc force helps hold the molten metal in

the joint. Move as fast as possible consistent with

desired bead shape.

The important thing is to continue lowering the entire

arm as the weld is made so the angle of the gun does

not change. Move the electrode wire fast enough that

the slag does not catch up with the arc. Vertical-down

welding gives thin, shallow welds. It should not be

used on heavy material where large welds are

required. Use the vertical up technique for where large

welds are required.

FIGURE 11

MACHINE SET UP FOR THE

SELF-SHIELDED FCAW PROCESS

1. See PROCESS GUIDELINES in the OPERATION

section for selection of welding wire and voltage,

and for range of metal thicknesses that can be

welded.

2. See the Application Guide on the inside of wire

feed section door for information on setting the

controls.

3. Set the “Voltage” and “Wire Speed” controls to the

settings suggested on the Application Guide for the

welding wire and base metal thickness being used.

The voltage control is marked “V” and the wire feed

speed is marked “olo.”

4. Check that the polarity is correct for the welding

wire being used. Set the polarity for DC(–) when

welding with Innershield NR-211-MP electrode.

See Work Cable Installation in the INSTALLATION

section for instructions on changing polarity.

5. When using Innershield electrode, the gasless nozzle may be used instead of a gas nozzle to improve

visibility of the arc.

6. Connect work clamp to metal to be welded. Work

clamp must make good electrical contact to the

work piece. The work piece must also be grounded

as stated in the “Arc Welding Safety Precautions”

at the beginning of the Instruction Manual which is

supplied with each welder.

WELDING TECHNIQUES FOR THE SELFSHIELDED FCAW PROCESS

Four simple manipulations are of prime importance

when welding. With complete mastery of the four,

welding will be easy. They are as follows:

1. The Correct Welding Position

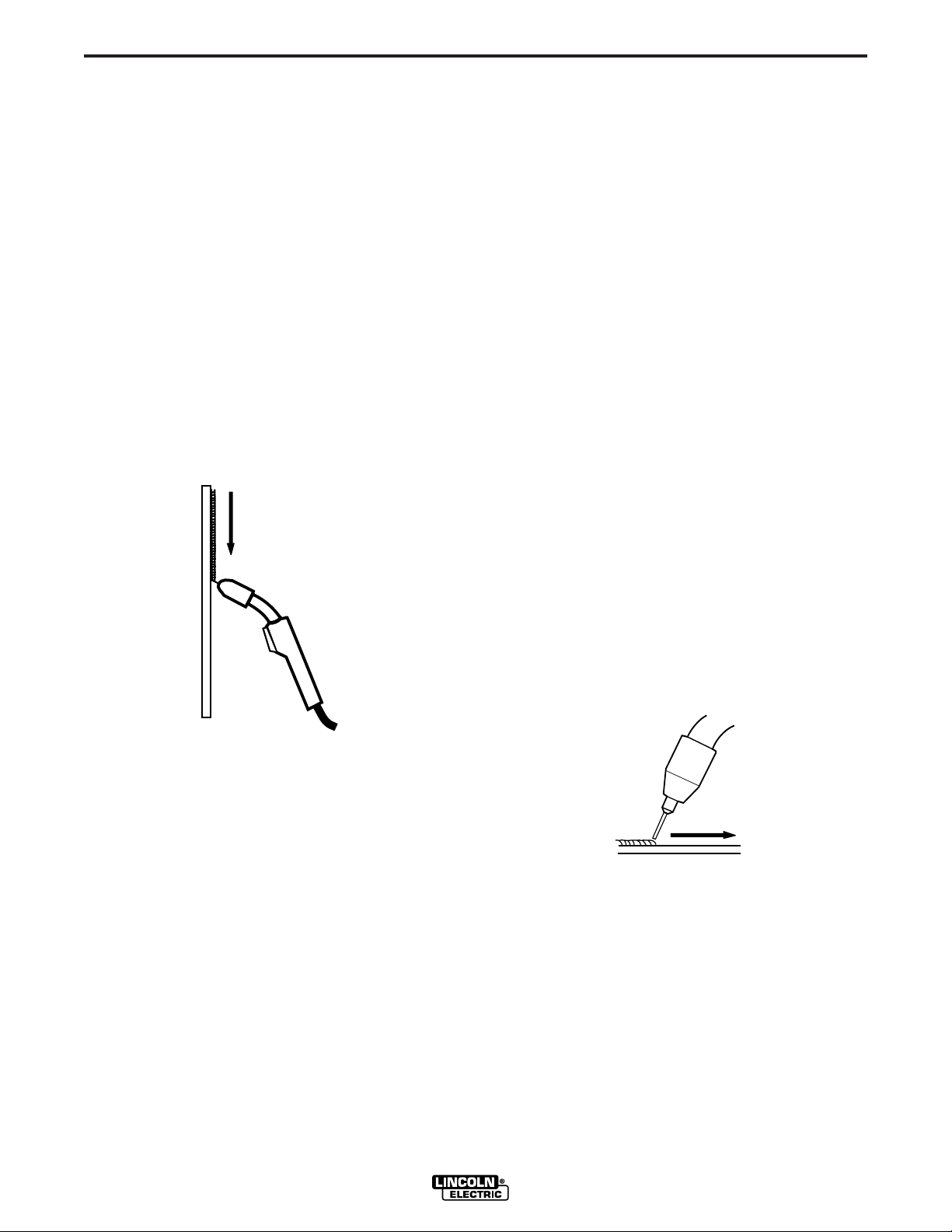

Figure 12 illustrates the correct welding position for

right handed people. (For left handed people, it is

the opposite.)

Hold the gun (of the gun and cable assembly) in

your right hand and hold the shield with your left

hand. (Left handers simply do the opposite.)

When using the FCAW Process, weld from left to

right (if you are right handed). This enables you to

clearly see what you are doing. (Left handers do

the opposite.) Tilt the gun toward the direction of

travel holding the electrode at an angle as shown

in Figure 12.

FIGURE 12

Page 8

7

LEARNING TO WELD

7

ARC RAYS can burn eyes and skin.

When using an open arc process, it

Is necessary to use correct eye,

head and body protection.

Protect yourself and others, read

“ARC RAYS can burn” at the front

of the Instruction Manual supplied

with welder.

-----------------------------------------------------------------------

2. The Correct Way To Strike An Arc

1. Be sure the work clamp makes good electrical

contact to the work.

2. Position gun over joint. End of wire may be

lightly touching the work.

3. Position face shield to protect face and eyes,

close gun trigger, and begin welding. Hold the

gun so that the contact tip to work distance is

about 3/8 to 1/2 inch (10 – 12 mm).

4. To stop welding, release the gun trigger and

the pull the gun away from the work after the

arc goes out.

5. A ball may form at the tip end of the wire after

welding. For easier restrikes (with Innershield

wire) the ball may be removed by feeding out a

few inches of wire and simply bending the wire

back and forth until it breaks off.

6. When no more welding is to be done, turn off

the machine.

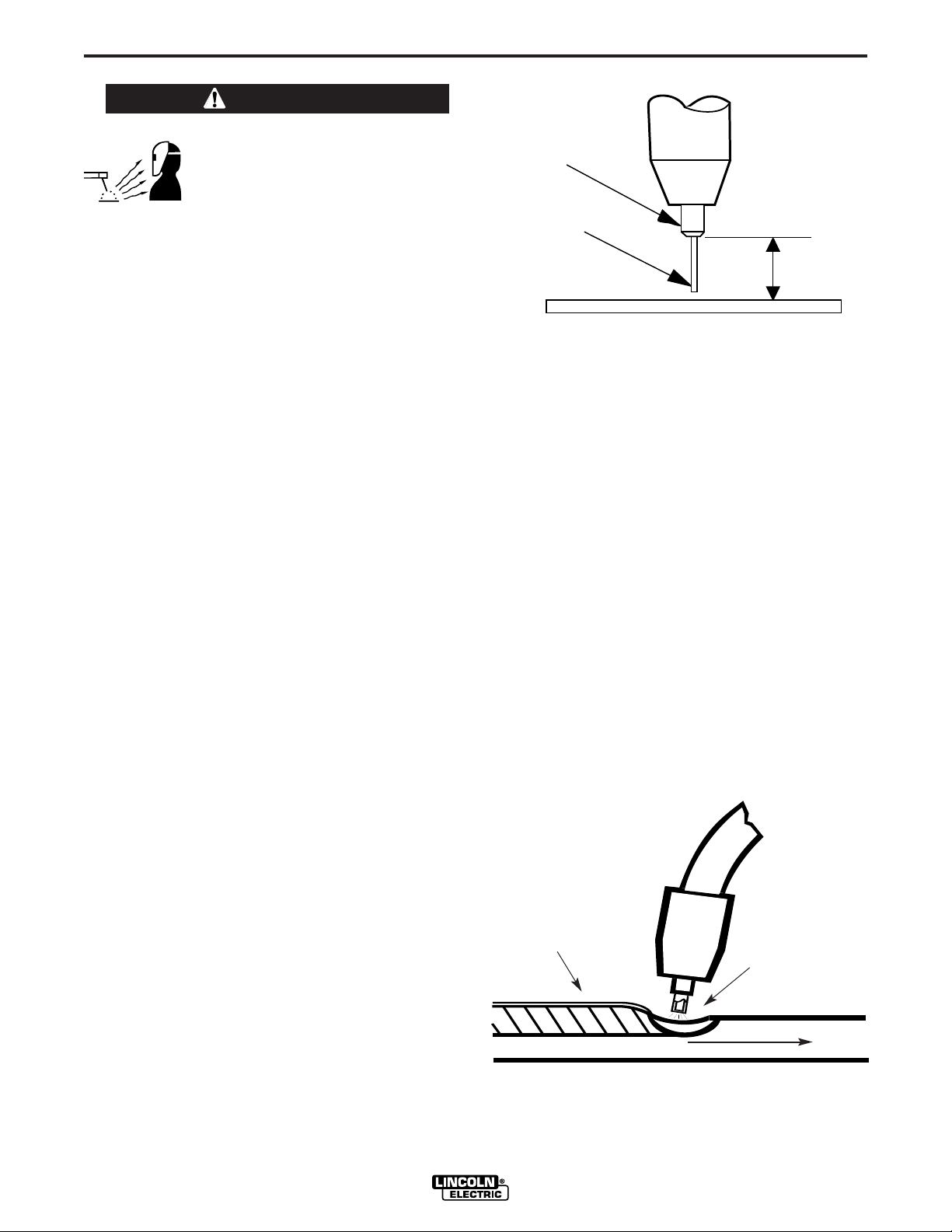

3. The Correct Contact Tip to Work Distance

(CTWD)

The Contact Tip to Work Distance (CTWD) is the

distance from the end of the contact tip to the work.

See Figure 13.

Once the arc has been established, maintaining

the correct CTWD becomes extremely important.

The CTWD should be approximately 3/8 to 1/2 inch

(10 to 12 mm) long.

FIGURE 13

The easiest way to tell whether the CTWD is the

correct length is by listening to its sound. The correct CTWD has a distinctive “crackling” sound, very

much like eggs frying in a pan. A long CTWD has a

hollow, blowing or hissing sound. If the CTWD is

too short, you may stick the contact tip or nozzle to

the weld puddle and/or fuse the wire to the contact

tip.

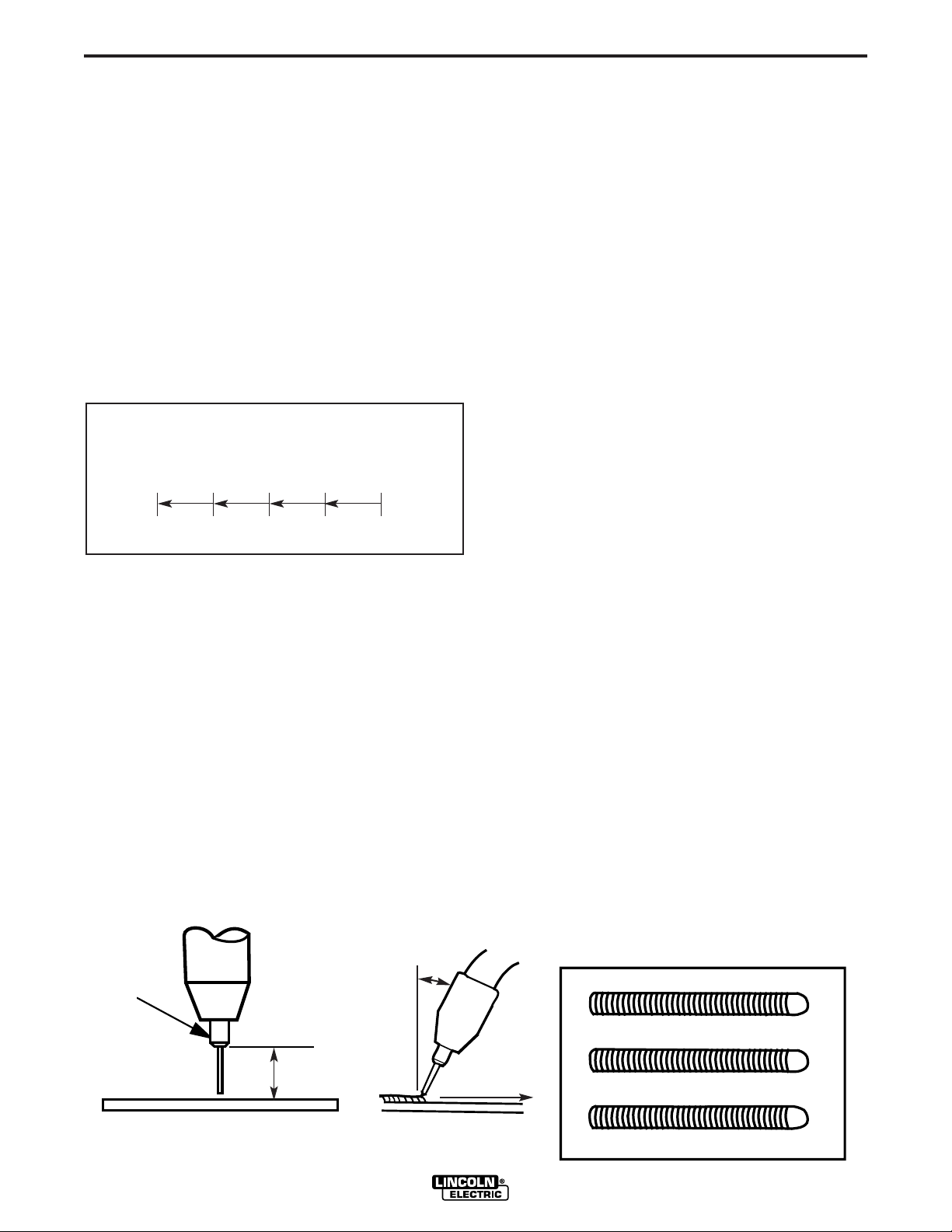

4. The Correct Welding Speed (Travel Speed)

The important thing to watch while welding is the

puddle of molten metal right behind the arc. See

Figure 14. Do not watch the arc itself. It is the

appearance of the puddle and the ridge where the

molten puddle solidifies that indicates correct welding speed. The ridge should be approximately 3/8”

(10 mm) behind the wire electrode.

Most beginners tend to weld too fast, resulting in a

thin uneven, “wormy” looking bead. If this occurs

slow down your travel speed.

FIGURE 14

WARNING

Contact Tip

Wire Electrode

3/8 - 1/2" (10 - 12 mm)

(CTWD)

Solidifying ridge

Molten puddle

Direction of Travel

Page 9

8

LEARNING TO WELD

8

Helpful Hints

• For general welding, it is not necessary to weave

the arc, neither forward or backward nor sideways.

Weld along at a steady pace. You will find it easier.

• When welding on thin plate, you will find that you

will have to increase the welding speed, whereas

when welding on heavy plate, it is necessary to go

more slowly in order to get good penetration.

• When welding sheet metal 16 gauge (1.5 mm) and

lighter, heat buildup may cause part warpage and

burn through. One way to eliminate these problems

is to use the back-stepping method illustrated in

Figure 15.

FIGURE 15

Practice

The best way of getting practice in the four skills that

enable you to maintain:

1. Correct welding position.

2. Correct way to strike an arc.

3. Correct Contact Tip to Work Distance.

4. Correct welding speed is to perform the following

exercise. Refer to Figure 16. Use PROCESS

GUIDELINES in the Instruction Manual and

Application Guide on the inside of wire feed section

door for selection of welding wire, wire feed speed,

voltage, and for range of metal thicknesses that

can be welded.

1. Position face shield to protect face and eyes.

2. Learn to strike an arc by positioning the gun over

the joint and touching the wire to the work.

3. Depress gun trigger, hold gun so contact tip to

work distance is about 3/8 to 1/2 inch (10 to 12

mm) and the gun is at proper angle.

4. After you strike the arc, practice the correct CTWD.

Learn to distinguish it by its sound.

5. When you are sure that you can hold the CTWD,

with a smooth “crackling” arc start moving. Look at

the molten puddle constantly, and look at the

“ridge” where the metal solidifies.

6. Run beads on a flat plate. Run them parallel to the

top edge (the edge farthest away from you). This

gives you practice in running straight welds, and

also gives you an easy way to check your

progress. The 10th weld will look considerably better than the first weld. By constantly checking on

your mistakes and your progress, welding will soon

be a matter of routine.

First weld from A to B; then from C to A; then

from D to C; then from E to D, and so on.

BACDE

Back-Stepping

Contact

Tip

Gun Angle

CTWD

15°-20°

Direction of Travel

FIGURE 16

Example of good consistent welding beads

after practicing.

Page 10

9

LEARNING TO WELD

9

MACHINE SET UP FOR THE GMAW (MIG)

PROCESS

1. See APPLICATION CHART in the OPERATION

section or Application Chart on the inside of wire

feed section door for selection of welding wire and

shielding gas, and for range of metal thicknesses

that can be welded. Also setting the proper controls, Drive Roll Orientation and Output Polarity.

2 Set the “Voltage” and “Wire Speed” controls to the

settings suggested on the Application Guide for the

welding wire and base metal thickness being used.

The voltage control is marked “V” and the wire feed

speed is marked with the icon “olo.’’

3 Check that the polarity is correct for the welding

wire being used. Set the polarity for DC(+) when

welding with the GMAW (MIG) process. See

INSTALLATION section of the Operators Manual

for instructions for changing polarity.

4. Check that the gas nozzle and proper size liner

and contact tip are being used and that the gas

supply is turned on. If adjustable, set for 30 to 40

cubic feet per hour (7 to 10 l/min..) under normal

conditions, increase to as high as 45 CFH (17

I/min.) under drafty (slightly windy) conditions.

5. Connect work clamp to metal to be welded. Work

clamp MUST make good electrical contact to the

work piece. The work piece must also be grounded

as stated in the “Arc Welding Safety Precautions”

at the beginning of the Instruction Manual which is

supplied with each welder.

WELDING TECHNIQUES FOR THE GMAW

(MIG) PROCESS

Four simple manipulations are of prime importance

when welding. With complete mastery of the four,

welding will be easy. They are as follows:

1. The Correct Welding Position

Figure 17 illustrates the correct welding position for

right handed people. (For left handed people, it is

the opposite.)

When GMAW (MIG) welding on sheet metal, it is

important to use the “forehand” push technique.

Hold the gun (of the gun and cable assembly) in

your right hand and hold the shield with your left

hand. (Left handers simply do the opposite.)

FIGURE 17

When using the GMAW process on light gauge material, weld from right to left (if you are right handed).

This results in a colder weld and has less tendency for

burn through.

2. The Correct Way To Strike An Arc

ARC RAYS can burn eyes and skin.

When using an open arc process, it

Is necessary to use correct eye,

head and body protection.

Protect yourself and others, read

“ARC RAYS can burn” at the front

of the Instruction Manual supplied

with welder.(ANSI Z.49.1-88)

-----------------------------------------------------------------------

1. Be sure the work clamp makes good electrical contact to the work.

2. Position gun over joint. End of wire may be lightly

touching the work.

3. Position face shield to protect face and eyes, close

gun trigger, and begin welding. Hold the gun so

that the contact tip to work distance is about 3/8 to

1/2 inch (10 – 12 mm).

4. To stop welding, release the gun trigger and pull

the gun away from the work after the arc goes out.

5. A ball may form at the tip end of the wire after

welding. For easier restrikes, the ball may be

removed by feeding out a few inches of wire and

cutting off the end of the wire with wire cutters.

6. When no more welding is to be done, close the

valve on the gas cylinder, momentarily operate the

gun trigger to release gas pressure, then turn off

the machine.

WARNING

15°-20°

Push

Page 11

10

LEARNING TO WELD

10

3. The Contact Tip to Work Distance (CTWD)

The Contact Tip to Work Distance (CTWD) is the

distance from the end of the contact tip to the work.

See Figure 18.

Once the arc has been established, maintaining

the correct CTWD becomes extremely important.

The CTWD should be approximately 3/8 to 1/2 inch

(10 to 12 mm) long.

The easiest way to tell whether the CTWD is the

correct length is by listening to its sound. The correct CTWD has a distinctive “crackling” sound, very

much like eggs frying in a pan. A long CTWD has a

hollow, blowing or hissing sound. If the CTWD is

too short, you may stick the contact tip or nozzle to

the weld puddle and/or fuse the wire to the contact

tip.

FIGURE 18

4. The Correct Welding Speed

The important thing to watch while welding is the

puddle of molten metal right behind the arc. See

Figure 19. Do not watch the arc itself. It is the

appearance of the puddle and the ridge where the

molten Puddle solidifies that indicates correct welding speed. The ridge should be approximately 3/8”

(10 mm) behind the wire electrode.

Most beginners tend to weld too fast, resulting in a

thin, uneven, “wormy” looking bead. They are not

watching the molten metal.

FIGURE 19

Helpful Hints

1. For general welding, it is not necessary to weave

the arc, neither forward or backward nor sideways.

Weld along at a steady pace. You will find it easier.

2. When welding on thin plate, you will find that you

will have to increase the welding speed or else

burn through, whereas when welding on heavy

plate, it is necessary to go more slowly in order to

get good penetration.

3. When welding sheet metal 16 gauge (1.5 mm) and

lighter, heat buildup may cause part warpage and

burn through. One way to eliminate these problems

is to use the back-stepping method illustrated in

Figure 15.

Practice

The best way of getting practice in the four skills that

enable you to maintain:

1. Correct welding position.

2. Correct way to strike an arc.

3. Correct Contact Tip to Work Distance.

4. Correct welding speed is to perform the following

exercise. Refer to Figure 16. Use PROCESS

GUIDELINES in the Instruction Manual and

Application Guide on the inside of wire feed section

door for selection of welding wire, shielding gas,

wire feed speed, voltage, and for range of metal

thicknesses that can be welded.

1. Position face shield to protect face and eyes.

2. Learn to strike an arc by positioning the gun over

the joint and touching the wire to the work.

3. Press gun trigger, hold gun so contact tip to work

distance Is about 3/8 to 1/2 inch (10 to 12 mm) and

the gun is at proper angle.

Contact Tip

Wire Electrode

CTWD

Molten puddle

Base metal

Push Technique

Weld metal ridge

Page 12

11

LEARNING TO WELD

11

TROUBLESHOOTING WELDS

Good welds have excellent appearance.

To Eliminate Porosity

(In order of priority):

1. Check for proper gas flow and reset WFS & Volts

on chart inside door.

2. Clean joints from moisture, paint, rust etc.

3. Decrease CTWD with GMAW.

4. Decrease drag angle.

5. Decrease travel speed.

NOTE: Always be sure the joint is free from moisture,

oil, rust, paint or other contaminant’s.

To Eliminate a Ropy Convex Bead

(In order of priority):

1. Check or reset WFS & Volts on chart inside door.

2. Decrease CTWD.

3. Decrease travel speed.

4. Decrease drag angle.

To Reduce Spatter (in order of importance):

1. Check or reset WFS & Volts on chart inside door.

2. Increase drag angle.

3. Decrease CTWD.

4. Decrease travel speed.

To Correct Poor Penetration (In order of priority):

1. Check or reset WFS & Volts on chart inside door.

2. Decrease CTWD.

3. Decrease speed.

4. Decrease drag angle.

If Arc Blow Occurs* (In order of priority):

NOTE: Try different work connection locations before

adjusting procedures.

1. Check or reset WFS & Volts on chart inside door.

2. Decrease drag angle.

3. Increase CTWD or weld in opposite direction.

4. Decrease travel speed.

*Arc blow is the effect of a magnetic field which forces

the arc from its normal path visual results are concave

face uneven leg lengths heavy spatter and porosity.

To Eliminate Stubbing** (In order of priority):

1. Check or reset WFS & Volts on chart inside door.

2. Decrease CTWD.

3. Increase drag angle.

** Stubbing occurs when the electrode drives through

the molten puddle and hits the bottom plate tending

to push the gun up.

Proper Gun Handling

Most feeding problems are caused by improper handling of the gun cable or electrodes.

1. Do not kink or pull the gun around sharp corners.

2. Keep the gun cable as straight as practical when

welding.

3. Do not allow dolly wheels or trucks to run over the

cables.

4. Keep the cable clean.

5. Innershield electrode has proper surface lubrication. Use only clean, rust-free electrode.

6. Replace contact tip when it becomes worn or the

end is fused or deformed.

Page 13

1

1

CONTENIDO

Page

Aprendiendo a Soldar ...................................................................................................2

Circuito de Soldadura por Arco.................................................................................2

Soldadura de Arco Tubular (FCAW) .........................................................................3

Soldadura de Arco Metálico con Gas (GMAW).........................................................3

Selección del Proceso...............................................................................................4

Para el Proceso GMAW (MIG) ...........................................................................4

Para el Proceso FCAW (Innershield)..................................................................4

Metales Comunes...............................................................................................4

Tipos de Unión y Posiciones.....................................................................................4

Soldadura a Tope...............................................................................................4

Penetración.........................................................................................................5

Soldadura de Filete.............................................................................................5

Soldadura en Posición Vertical .................................................................................5

Soldadura Vertical Ascendente y Aérea.............................................................5

Soldadura Vertical Descendente........................................................................6

Configuración del Proceso FCAW Auto-Revestido...................................................6

Técnicas de Soldadura para el Proceso FCAW de Soldadura de

Arco Tubular..............................................................................................................6

1. Posición Correcta para Soldar........................................................................6

2. Forma Correcta de Iniciar un Arco..................................................................7

3. La Punta de Contacto Correcta para la Distancia de Trabajo (CTWD)..........7

4. Velocidad Correcta de Soldadura (Velocidad de Desplazamiento)................7

Consejos Útiles .........................................................................................................8

Práctica .....................................................................................................................8

Configuración de la Máquina para el Proceso GMAW (MIG)....................................9

Técnicas de Soldadura para el Proceso GMAW (MIG).............................................9

1. Posición Correcta para Soldar........................................................................9

2. Forma Correcta de Iniciar un Arco..................................................................9

3.La Punta de Contacto Correcta para la Distancia de Trabajo (CTWD).........10

4. Velocidad Correcta de Soldadura.................................................................10

Consejos Útiles .......................................................................................................10

Práctica ...................................................................................................................10

Localización de Averías en Soldaduras ...................................................................11

Page 14

2

APRENDIENDO A SOLDAR

2

APRENDIENDO A SOLDAR

La soldadura es una habilidad que sólo puede aprenderse mediante la práctica. Nadie puede convertirse

en un soldador experimentado simplemente

leyendo acerca de soldadura. Las siguientes pági-

nas ayudarán al operador sin experiencia a entender

los aspectos básicos de la soldadura de alambre y

proporcionarán una guía para ayudarle a desarrollar

esta habilidad. Para obtener información específica,

ordene una copia de “Nuevas Lecciones de

Soldaduras por Arco”.

CIRCUITO DE SOLDADURA POR ARCO

El operador debe saber más de la soldadura por arco

que simplemente conocer el arco. Debe saber cómo

controlarlo y esto requiere cierto conocimiento del circuito de soldadura, así como del equipo que proporciona la corriente eléctrica utilizada en el arco. La

Figura 1 ilustra el circuito de soldadura para una soldadora normal. El circuito se inicia cuando el cable

de la antorcha se conecta a la máquina de soldar. La

corriente fluye por el cable de la antorcha, la antorcha

misma y la punta de contacto hacia el alambre y a

través del arco. En el área de trabajo del arco, la corriente fluye a través del metal base hacia el cable de

trabajo y de regreso a la máquina de soldar. Para

que la corriente fluya, este circuito debe estar completo. Las conexiones flojas o incorrectas en cualquier

parte del circuito eliminarán voltaje del arco y ocasionarán que sea inestable.

El circuito de soldadura de esta máquina tiene una

salida máxima de voltaje de 32 voltios de CD. Este

voltaje es particularmente bajo y sólo se presenta

cuando se presiona el gatillo de la antorcha.

FIGURA 1

Para soldar, la pinza de trabajo debe estar bien

conectada al metal base limpio. Limpie las uniones

eliminando los residuos, escoria, humedad, pintura,

aceite y grasa excesiva de la superficie. Al igual que

con todas las aplicaciones de soldadura, la limpieza

de las uniones es necesaria para evitar la porosidad

y para lograr una soldadura con la mejor calidad.

Conecte la pinza de trabajo “lo más cerca posible”

del área que desea soldar. Esto ayuda a evitar que la

corriente se desvíe. Evite que el circuito de soldadura

pase a través de bisagras, rodamientos, componentes

electrónicos o dispositivos similares que puedan

dañarse. Vea la Figura 2. Siempre desconecte los

dispositivos eléctricos antes de soldar en ellos.

FIGURA 2

Los electrodos tipo Innershield

que se recomiendan para esta

soldadora pueden generar

humos y gases peligrosos para su

salud.

• Evite el contacto con los ojos y la piel.

• No toque las partes internas.

• Mantenga la escoria alejada de

los niños.

• Mantenga el equipo alejado del

alcance de los niños.

• Siga todas las precauciones de seguridad que

se encuentran en este manual de operación.

-----------------------------------------------------------------------

El operador sostiene la antorcha, y guía la alimentación de alambre automática a lo largo de la

unión, manteniendo una distancia aproximada de 10 –

12 mm (3/8 a 1/2 pulgadas) entre la punta de contacto

y el trabajo. Esto se llama Punta de Contacto para

Distancia de Trabajo. El arco de soldadura se

establece en el espacio que hay entre el trabajo y el

extremo de un alambre de diámetro pequeño.

Cuando la fuente de poder se establece adecuadamente, la abertura del arco se mantiene automáticamente.

La soldadura de arco es una habilidad manual que

requiere estabilidad en la mano, buena condición física y buena vista. El operador controla el arco de soldadura, y, por lo tanto, la calidad de la soldadura realizada.

RUTA DE

CORRIENTE

EQUIVOCADA

Rodamientos

Bisagras

Componentes eléctricos

RUTA DE CORRIENTE

CORRECTA

*

* Para mejores resultados coloque la pinza de trabajo aproximadamente

12 pulgadas (294 mm) del rea de soldadura.

ADVERTENCIA

PIEZA DE TRABAJO

ARCO

ANTORCHA Y CABLE

PINZA DE TRABAJO

Page 15

3

APRENDIENDO A SOLDAR

3

SOLDADURA DE ARCO TUBULAR

(FCAW)

La Figura 3 ilustra la acción que se lleva a cabo en el

arco de soldadura (Innershield) FCAW autoprotegido.

Es muy similar a lo que se observa en una soldadura

real.

FIGURA 3

En la mitad de la figura se observa el “flujo de arco”. Este

es el arco eléctrico creado a través de la corriente

eléctrica que fluye por el espacio existente entre el

extremo del electrodo tubular y el metal base. La

temperatura de este arco es de 3,300˚C (6,000˚F)

aproximadamente, que es más que suficiente para

fundir el metal.

El arco es muy brillante y caliente, por lo que no

puede observarse sin proteger los ojos ya que

existe riesgo de lesión. Cuando sea necesario

observarlo, deberán utilizarse con la careta unos

lentes obscuros diseñados específicamente para

la soldadura por arco. (ANSI Z49.1-88)

El arco funde el metal base y penetra en él, como el

agua entra en la tierra cuando sale de una manguera

para jardín. El metal fundido forma un charco de soldadura o cráter, y tiende a alejarse del arco. A medida que lo hace, se enfría y solidifica.

La función del electrodo tubular Innershield es mucho

más que simplemente llevar corriente al arco. El

alambre está compuesto de fundentes y/o ingredientes de aleación alrededor de los cuales se ha formado la vaina de acero. Es simplemente un electrodo de varilla revestida invertido con forma de alambre

continuo.

El alambre tubular se funde en el arco y brotan

pequeñas gotas de metal fundido que forman un charco de soldadura. La vaina de alambre proporciona

metal adicional de relleno para la unión, a fin de llenar

el hueco entre las dos piezas de metal base.

Los materiales tubulares también se funden o queman en el arco y tienen diversas funciones. Hacen

que el arco sea más estable, proporcionan alrededor

del mismo un revestimiento de gas similar al humo

para alejar del material fundido el oxígeno y nitrógeno

del aire, y brindan un fundente para el charco de soldadura. El fundente recoge las impurezas y forma

una capa protectora en la parte superior de la soldadura durante el enfriamiento.

Después de correr un cordón de soldadura, la capa

puede removerse con un cincel y un cepillo de alambre. Esto mejora la apariencia y permite revisar la

soldadura terminada.

Ya que el tamaño de la máquina y las características

de salida limitan la dimensión y el tipo de electrodo

tubular que puede utilizarse,verifique su “Diagrama de

Aplicación” del Manual de Instrucción o consulte la

Guía de Aplicación en el interior de la máquina. Esto le

permitirá conocer el tamaño de electrodo adecuado y

las configuraciones de control que deberán utilizarse

SOLDADURA DE ARCO METÁLICO CON

GAS (GMAW)

La Figura 4 ilustra el arco de soldadura GMAW

(También conocida como MIG). El alambre sólido no

contiene fundentes o ingredientes que formen su propio revestimiento ni tampoco se forma ninguna capa

que proteja al metal de soldadura fundido. Por esta

razón, se necesita un flujo continuo de gas protector

para proteger el metal de soldadura fundido de los

contaminantes atmosféricos, como el oxígeno y el

nitrógeno. El gas protector se suministra a través del

ensamble de la antorcha y del cable, y pasa por la

tobera de gas hacia la zona de soldadura

FIGURA 4

¡Importante!

El proceso de soldadura MIG requiere que el soldador

tenga una válvula de gas selenoide instalada a fin de

controlar el flujo del gas protector. Lea su Manual del

Operador para ver si su máquina requiere elementos

adicionales para soldadura MIG.

Al comparar los procesos GMAW y FCAW puede

observarse que la diferencia principal entre los mismos es el tipo de protección que se utiliza. El proceso GMAW utiliza el gas como protección, por lo que

se origina una Soldadura de Arco Metálico de Gas. El

proceso FCAW utiliza la fundición y el quemado de

los ingredientes tubulares como protección, y es por

eso que se obtiene una Soldadura de Arco Tubular

Autorevestido.

El alambre tubular recomendado LINCOLN Super ARC L-56

y gas para MIG de soldadura de arco metálico con gas se

localiza en el “Diagrama de Aplicación” del Manual de

Instrucción o consulte la Guía de Aplicación en el interior de

la máquina. Esta máquina tiene capacidad para soldar una

amplia gama de aceros suaves en todas las posiciones, sin

embargo, se requiere más habilidad para la soldadura fuera

de posición con el proceso GMAW.

Tobera de gas

Gas protector

Electrodo

sólido

Punta de Contacto

Metal base

Metal soldado

El quemado de los

materiales centrales

dentro del electrodo

tubular proporciona gas

para revestir el metal

fundido a medida que se

solidifica.

Flujo del arco

Charco de soldadura

Alambre tubular

Escoria de protección

Metal soldado

TÉCNICA DE ARRASTRE

TÉCNICA DE APORTE

DIRECCIÓN DE DESPLAZAMIENTO

DIRECCIÓN DE DESPLAZAMIENTO

ADVERTENCIA

Page 16

4

APRENDIENDO A SOLDAR

4

SELECCIÓN DEL PROCESO

Al aprender más sobre las diferencias existentes

entre los dos procesos, usted podrá elegir el mejor

para el trabajo que va a realizar. Al seleccionar el

proceso, deberá considerar lo siguiente:

Para el Proceso GMAW (MIG)

1. ¿La mayoría de mi trabajo de soldadura se realiza

con calibre 16 y materiales más ligeros?

2. ¿Puedo afrontar los gastos, el espacio adicional y

la falta de portabilidad de los cilindros y del suministro de gas?

3. ¿Necesito soldaduras limpias y con buen acabado?

4. ¿El metal base debe estar limpio?

Si usted ha contestado sí a todas las preguntas anteriores, el proceso que le conviene es el GMAW. Si ha

contestado no a alguna de las preguntas anteriores,

entonces deberá considerar utilizar el proceso FCAW.

Para el Proceso FCAW (Innershield)

1. ¿Necesito que sea sencilloy fácil de transportar?

2. ¿La soldadura se va a realizar en exteriores o bajo

condiciones de viento?

3. ¿Requiero una capacidad de soldadura adecuada

en todas las posiciones?

4. ¿La mayoría de la soldadura se realizará en calibre 16 o mayor, así como en materiales oxidados o

sucios?

5. La soldadura debe limpiarse antes de pintar.

6. Por favor observe que su máquina puede o no

estar configurada para manejar ambos procesos

de soldadura FCAW y GMAW. Consulte su

Manual del Operador para determinar los

Accesorios Opcionales que deberá adaptar a su

máquina.

METALES COMUNES

La mayoría de los metales que se encuentran en las

granjas, talleres pequeños u hogares son de acero

bajo en carbón, también conocido como acero dúctil.

Algunos de los artículos más comunes que se fabrican con este tipo de acero son las hojas de metal,

placas, tubos y formas laminadas, como canales y

hierro angular. Este tipo de acero se puede soldar

fácilmente sin tener precauciones especiales. Sin

embargo, algunos aceros contienen niveles más altos

de carbón u otras aleaciones y son más difíciles de

soldar. Básicamente, si un imán se adhiere al metal y

éste puede cortarse fácilmente con una lima,

entonces es probable que el metal sea acero dúctil y

que usted pueda soldarlo. Si planea soldar aluminio,

rodillos impulsores especiales o aluminio pueden

requerirse o ser altamente recomendables los Juegos

de Soldadura. Consulte el Manual del Operador de

su máquina. Asimismo, se requiere el gas protector

de argón puro y una bobina de alambre de aluminio.

Para más información sobre cómo identificar los

diversos tipos de aceros y otros metales, y para conocer los procedimientos adecuados para la soldadura

de los mismos, nuevamente le sugerimos comprar

una copia de “Metales y Cómo Soldarlos”.

A pesar del tipo de metal que se esté soldando, con el

fin de obtener una soldadura óptima, es importante

que el metal esté libre de aceite, pintura, polvo u otros

contaminantes.

TIPOS DE UNIÓN Y POSICIONES

Los cinco tipos de unión de soldadura son: Soldadura

a tope, Soldadura de filete, Soldadura de empalme,

Soldadura de extremos y Soldadura de esquinas.

Vea la Figura 5.

De todas estas soldaduras, las más comunes son la

Soldadura a tope y la Soldadura de filete

FIGURA 5

Soldadura a Tope

Coloque las dos placas una al lado de la otra, con un

ajuste firme para evitar quemaduras durante la soldadura.

Asegure las placas en ambos extremos con una pinza

o con un punto de soldadura, ya que de otra manera

el calor haría que las placas se separaran. Vea la

Figura 6.

Ahora, suelde las dos placas. Trabaje de izquierda a

derecha (si es diestro). Coloque el electrodo tubular

entre las dos placas, manteniendo la antorcha ligeramente inclinada en dirección de la trayectoria.

Observe el metal fundido para asegurarse de que se

distribuya equitativamente en ambos bordes y entre

las placas. A esto se le conoce como “técnica de

arrastre”. En hojas de metal delgadas utilice la “técnica de alimentación”. Vea “Técnicas de Soldadura

para el Proceso GMAW (MIG)”.

FIGURA 6

Soldadura a Tope

Soldadura de Empalme

Soldadura de Extremos

Soldadura de Filete

Soldadura de Esquinas

Page 17

5

APRENDIENDO A SOLDAR

5

Penetración

Si la soldadura no penetra casi el 100% del grosor

del metal, entonces una soldadura a tope será más

débil que el material soldado. En el ejemplo que se

muestra en la Figura 7, la soldadura total penetró

sólo la mitad del grosor del material, por lo que será

aproximadamente la mitad de resistente que el metal.

FIGURA 7

FIGURA 8

En el ejemplo que se muestra en la Figura 8, la unión

ha sido soldada para que pueda obtenerse un 100%

de penetración. Si la soldadura se realiza adecuadamente, entonces será tan o más resistente que el

metal original.

Soldadura de Filete

Cuando se realizan soldaduras de filete, es muy

importante sostener el electrodo en un ángulo de 45°

entre ambos lados, o el metal no se distribuirá equitativamente. Por lo general, la tobera de la antorcha

tiene un ángulo que facilita este proceso. Vea la

Figura 9.

FIGURA 9

Soldadura en Posición Vertical

La soldadura en posición vertical puede realizarse en

forma ascendente o descendente. La soldadura vertical ascendente se utiliza cuando se desea una soldadura más resistente y grande y material de 1/4”

(6.4 mm) y más grueso. La soldadura vertical

descendente se utiliza principalmente en hojas de

metal de 3/16” (4.8 mm) y materiales más delgados

que originan soldaduras más rápidas y de menor

penetración/

Utilizar esta unidad en materiales más gruesos

que los recomendados puede resultar en soldaduras de baja calidad. Las soldaduras pueden

parecer finas pero puede existir falta de fusión o

unión necesaria para dar una soldadura sólida.

Esto se denomina “Vaciado en Frío” o “empalme

en frío” y es similar a la soldadura en frío. Puede

resultar una falla en la soldadura.

-----------------------------------------------------------------------

Soldadura Vertical Ascendente y Aérea

Cuando se suelda en forma vertical y ascendente en

material de 1/4” (6.4 mm) y más grueso, el problema

es colocar el metal derretido donde se desea y lograr

que permanezca en esa posición. Si se sedimenta

demasiado metal derretido, la gravedad lo atraerá

hacia la tierra y hará que “gotee”. Por lo tanto, deben

seguirse ciertas técnicas.

Cuando sue lda fuera de posición, corra cordones

extendidos. No opere el gatillo, interrumpa el arco,

salga del charco de soldadura ni mueva demasiado

rápido en cualquier dirección. Utilice la Velocidad de

Alimentación de Alambre (WFS) en la parte más baja

del rango. En la Figura 10 se muestra la técnica general y el ángulo de antorcha adecuado.

Generalmente, mantenga el electrodo en posición

casi perpendicular a la unión, según se muestra en la

figura. Si la porosidad se convierte en un problema,

tal vez sea necesario un ángulo máximo que

sobrepase al perpendicular.

FIGURA 10

ADVERTENCIA

ÁNGULO ADECUADO DE LA ANTORCHA PARA

EL PROCESO DE SOLDADURA GMAW

EN LA POSICIÓN VERTICAL DESCENDENTE

3/16 PULGADAS Y MÁS DELGADO

1/4 PULGADAS Y MÁS GRUESO

ÁNGULO ADECUADO DE LA ANTORCHA PARA

EL PROCESO DE SOLDADURA FCAW

EN LA POSICIÓN VERTICAL ASCENDENTE

Page 18

6

APRENDIENDO A SOLDAR

6

Soldadura Vertical Descendente

Consulte la Figura 11. Las soldaduras verticales

descendentes se aplican rápidamente. Por lo tanto,

son estrechas y poco profundas, lo que las hace

excelentes para las hojas metálicas. Las soldaduras

verticales descendentes pueden ser aplicadas por

una tabla la cual se encuentra en el Manual de

Instrucción para material más ligero.

Utilice cordones extendidos e incline la punta de la

antorcha en dirección de la trayectoria, para que la

fuerza del arco ayude a mantener el metal fundido en

la unión. Mueva lo más rápido posible y de manera

congruente con la forma de cordón deseada.

Lo importante es seguir moviendo todo el brazo conforme se realiza la soldadura, para que el ángulo de

la antorcha no cambie. Mueva el alambre tubular lo

suficientemente rápido para que la escoria no haga

contacto con el arco. La soldadura vertical descendente da como resultado soldaduras delgadas y uniformes. No deberá utilizarse este tipo de soldadura

en materiales pesados, donde se requieren soldaduras mayores. Utilice la técnica vertical ascendente donde se requieren soldaduras grandes.

FIGURA 11

CONFIGURACION DEL PROCESO FCAW AUTOREVESTIDO

1. Consulte los LINEAMIENTOS DEL PROCESO en

la sección de OPERACION para la selección del

alambre de soldadura y voltaje, y para el nivel de

grosor de metal que puede soldarse.

2. Consulte la Guía de Aplicación en la parte interna

de la puerta del alimentador de alambre para conocer la información acerca de la configuración de los

controles.

3. Establezca los controles de “Voltaje” y “Velocidad

de Alambre” para las configuraciones sugeridas en

la Guía de Aplicación para el alambre de soldadura

y grosor de metal base que está siendo utilizado.

El control de voltaje está marcado con una “V” y la

velocidad de alambre con “olo”.

4. Verifique que la polaridad sea la correcta para el

alambre de soldadura que se está utilizando.

Establezca la polaridad para CD(–) al soldar con el

electrodo Innershield NR-211-MP. Consulte

Instalación del Cable de Trabajo en la sección

INSTALACIÓN para conocer las instrucciones para

el cambio de polaridad.

5. Al utilizar el electrodo Innershield, la tobera sin gas

puede ser utilizada en lugar de la tobera de gas a

fin de mejorar la visibilidad del arco.

6. Conecte la pinza de trabajo al metal que va a soldar. La pinza de trabajo debe hacer un buen contacto eléctrico con la pieza de trabajo. Asimismo,

la pieza de trabajo debe aterrizarse como se

establece en “Precauciones de Seguridad de

Soldadura de Arco” al principio del Manual de

Instrucción el cual se proporciona con la soldadora.

TÉCNICAS DE SOLDADURA PARA EL

PROCESO FCAW DE SOLDADURADE

ARCO TUBULAR

Existen cuatro aspectos simples de vital importancia

para soldar. Si se dominan completamente, soldar

será muy fácil. Son los siguientes:

1. Posición Correcta para Soldar

La Figura 12 ilustra la posición correcta de soldadura para los diestros. (Para las personas zurdas, se hace lo contrario).

Sujete la antorcha (del ensamble de la antorcha y

del cable) con su mano derecha, y con la izquierda

sujete la careta. (Las personas zurdas simplemente hagan lo contrario).

Cuando se utilice el Proceso FCAW, suelde de

izquierda a derecha (si es diestro). Esto le permite

ver claramente lo que está haciendo. Incline la

antorcha hacia la trayectoria, sujetando el electrodo en ángulo, según se muestra en la Figura 12.

FIGURA 12

Page 19

7

APRENDIENDO A SOLDAR

7

Los RAYOS del ARCO pueden quemar los ojos y la piel.

Al utilizar un proceso de arco

abierto, es necesario usar protección para ojos, cabeza y cuerpo.

Protéjase usted y a los demás, lea

“Los RAYOS del ARCO pueden

quemar” al frente del Manual de

Instrucción proporcionado a cada

soldador.

-----------------------------------------------------------------------

2. Forma Correcta de Iniciar un Arco

1. Asegúrese de que la pinza de trabajo haga

buen contacto eléctrico con la pieza de trabajo.

2. Coloque la antorcha sobre la unión. El extremo

del alambre puede tocar ligeramente el trabajo.

3. Use la careta para proteger su cara y los ojos,

presione el gatillo de la antorcha y comience a

soldar. Sujete la antorcha de tal forma que la

distancia entre la punta de contacto y el trabajo

sea de 10 – 12 mm (3/8 a 1/2 pulgada) aproximadamente.

4. Para dejar de soldar, libere el gatillo y separe

la antorcha del trabajo después de que se haya

apagado el arco.

5. Después de soldar, tal vez se forme una

pequeña bola en la punta del alambre. Para

inicios de arco más sencillos (con alambre

Innershield), la bola puede eliminarse

desplazando un tramo de alambre y doblándolo hacia atrás y hacia adelante hasta que se

rompa.

6. Cuando no vaya a soldar más, apague la

máquina.

3. La Punta de Contacto Correcta para la

Distancia de Trabajo (CTWD)

La Punta de Contacto de Trabajo para la Distancia

de Trabajo (CTWD) es la distancia desde el

extremo de la punta de contacto hasta el trabajo

Vea la Figura 13.

Una vez que el arco se ha establecido, es muy

importante mantener una CTWD correcta. La

CTWD debe ser de 3/8 a 1/2 pulgada de largo (10

a 12 mm) aproximadamente .

FIGURA 13

La forma más fácil para saber si la CTWD tiene la

longitud correcta, es escuchando su sonido. Una

CTWD correcta tiene un sonido distintivo de “chisporroteo”, muy similar al que se produce cuando

se fríen alimentos en una sartén. Una CTWD larga

tiene un sonido hueco, de fritura o de soplo. Si la

CTWD es muy corta, usted podría colocar la punta

de contacto o la tobera en el charco de soldadura

y/o fusionar el alambre con la punta de contacto.

4. Velocidad Correcta de Soldadura (Velocidad de

Desplazamiento)

Mientras suelda, es importante observar el charco

de metal derretido justo detrás del arco. Vea la

Figura 14. No observe el arco directamente. La

apariencia del charco y el reborde donde se solidifica es lo que indica la velocidad correcta de soldadura. El reborde detrás del electrodo tubular

debe ser de 3/8” (10 mm) aproximadamente.

La mayoría de los principiantes tienden a soldar

muy rápido, dando como resultado un cordón delgado, disparejo y con apariencia “ondulada”. Si

esto ocurre disminuya la velocidad desplazamiento.

FIGURA 14

ADVERTENCIA

Contact Tip

Wire Electrode

3/8 - 1/2" (10 - 12 mm)

(CTWD)

3/8 – 1/2” (10 – 12 mm)

(CTWD)

Solidifying ridge

Molten puddle

Direction of Travel

Solidificación del reborde

Charco de soldadura

Dirección de Desplazamiento

Punta de Contacto

Electrodo de

Alambre

Page 20

8

APRENDIENDO A SOLDAR

8

Consejos Útiles

• Para soldaduras generales, no es necesario mover el

arco, ni hacia adelante ni hacia atrás o a los lados.

Suelde a un ritmo estable. Será más fácil en esta

forma.

• Cuando suelde sobre una placa delgada, se dará

cuenta de que tiene que aumentar la velocidad de

soldadura; por otro lado, al soldar sobre una placa

gruesa, será necesario llevar un ritmo más lento

para lograr una penetración adecuada.

• Al soldar una placa de metal de calibre 16 (1.5

mm) o más ligera, la acumulación de calor puede

ocasionar deformaciones y quemaduras. Una

manera de eliminar estos problemas es utilizar el

método de pasos en retroceso que se muestra en

la Figura 15.

FIGURA 15

Práctica

La mejor forma de obtener práctica en las cuatro

habilidades es permitirle mantener:

1. Posición de soldadura correcta.

2. Forma correcta de iniciar un arco.

3. Punta de Contacto Correcta para la Distancia de

Trabajo

4. La velocidad de soldadura correcta para realizar el

siguiente ejercicio. Consulte la Figura 16. Utilice

LINEAMIENTOS DE PROCESO en el Manual de

Instrucción y Guía de Aplicación en el interior de la

puerta de la sección de alimentación de alambre

para la selección del alambre de soldadura, velocidad de alimentación de alambre, voltaje y para el

nivel de grosor del metal que puede ser soldado.

1. Use la careta para proteger la cara y los ojos.

2. Aprenda a iniciar un arco colocando la antorcha

sobre la unión y tocando el trabajo con el alambre.

3. Suelte el gatillo de la antorcha, sujétela de tal

forma que la distancia entre la punta de contacto y

el trabajo sea de 3/8 a 1/2 pulgada (10 a 12 mm)

aproximadamente y la antorcha se encuentre en el

ángulo correcto.

4. Después de iniciar el arco, practique la CTWD

correcta. Aprenda a distinguirla por su sonido.

5. Cuando usted tenga la certeza de que puede mantener la CTWD correcta, inicie con un movimiento

de arco suave y de “chisporroteo”. Observe continuamente el charco de la soldadura y vigile el

“reborde” donde se solidifica el metal.

6. Corra los cordones en una placa plana. Córralos

paralelos al borde superior (el más alejado de

usted). Esto le permite practicar soldaduras rectas, y también es una manera fácil de verificar su

progreso. La décima soldadura se verá mucho

mejor que la primera. Al revisar constantemente

sus errores y su avance, la soldadura pronto será

cuestión de rutina.

La primera soldadura debe hacerde de A a B;

después de C a A; luego de D a C; después de

E a D y así sucesivamente.

BACDE

Método de Pasos en Retroceso

Punta de

Contacto

Ángulo de la Antorcha

15°-20°

Dirección de

Desplazamiento

FIGURA 16

Ejemplo de cordones de soldadura consistentes

adecuados después de practicar

CTWD

Page 21

9

APRENDIENDO A SOLDAR

9

CONFIGURACIÓN DE LA MÁQUINA PARA EL

PROCESO GMAW (MIG)

1. Consulte DIAGRAMA DE APLICACIÓN en la sección de OPERACIÓN o Diagrama de Aplicación en

el interior de la puerta de la sección de alimentación de alambre para la selección del alambre de soldadura y gas protector, y para el nivel de

grosor de metal que puede soldarse. Al tiempo

que configura los controles adecuados,

Orientación del Rodillo Impulsor y Polaridad de

Salida.

2 Establezca los controles de “Voltaje” y “Velocidad

de Alambre” para las configuraciones sugeridas en

la Guía de Aplicación para el alambre de soldadura

y grosor de metal base que está siendo utilizado.

El control de voltaje está marcado con una “V” y la

velocidad de alambre con “olo”.

3 Verifique que la polaridad sea la correcta para el

alambre de soldadura que se está utilizando.

Establezca la polaridad para CD (+) al soldar con el

proceso GMAW (MIG). Consulte la sección de

INSTALACIÓN del Manual del Operador para conocer las instrucciones para el cambio de polaridad.

4. Verifique que se utilice la tobera de gas y el

tamaño adecuados de la guía de alambre y punta

de contacto y que el suministro de gas esté encendido. Si se puede ajustar, establézcalo a 30 a 40

pies cúbicos por hora (7 a 10 l/min.) bajo condiciones normales, aumente a tan alto como 45 CFH

(17 I/min.) bajo condiciones con corrientes de aire

(ligeramente húmedas).

5. Conecte la pinza de trabajo al metal que va a soldar. La pinza de trabajo debe hacer un buen contacto eléctrico con la pieza de trabajo. Asimismo, la

pieza de trabajo debe aterrizarse como se

establece en “Precauciones de seguridad de

Soldadura de Arco” al principio del Manual de

Instrucción el cual se proporciona con la soldadora.

TÉCNICAS DE SOLDADURA PARA EL PROCESO

GMAW (MIG)

Existen cuatro aspectos simples de vital importancia

para soldar. Si se dominan completamente, soldar

será muy fácil. Son los siguientes:

1. Posición Correcta para Soldar

La Figura 17 ilustra la posición correcta de soldadura para los diestros. (Para las personas zurdas, se hace lo contrario).

Cuando se utiliza el proceso de soldadura GMAW

(MIG) en una hoja de metal, es importante aplicar

la técnica de empuje “hacia adelante”.

Sujete la antorcha (del ensamble de la antorcha y

del cable) con su mano derecha y con la izquierda

sujete la careta. (Las personas zurdas simplemente hagan lo contrario),

FIGURA 17

Cuando se utiliza el proceso GMAW en un material de

calibre ligero, suelde de derecha a izquierda (si es

diestro). Esto da como resultado una soldadura más

fría y disminuye las posibilidades de quemadura.

2. Forma Correcta de Iniciar un Arco

Los RAYOS del ARCO pueden quemar los ojos y la piel.

Al utilizar un proceso de arco

abierto, es necesario usar protección para ojos, cabeza y cuerpo.

Protéjase usted y a los demás, lea

“Los RAYOS del ARCO pueden

quemar” al frente del Manual de

Instrucción proporcionado a cada

soldador. (ANSI Z.49.1-88)

-----------------------------------------------------------------------

1. Asegúrese de que la pinza de trabajo haga buen

contacto eléctrico con la pieza de trabajo.

2. Coloque la antorcha sobre la unión. El extremo del

alambre puede tocar ligeramente el trabajo.

3. Use la careta para proteger su cara y los ojos, presione el gatillo de la antorcha y comience a soldar.

Sujete la antorcha de tal forma que la distancia

entre la punta de contacto y el trabajo sea de 3/8 a

1/2 pulgadas (10–12 mm ) aproximadamente.

4. Para dejar de soldar, libere el gatillo y separe la

antorcha del trabajo después de que se haya apagado el arco.

5. Después de soldar, tal vez se forme una pequeña

bola en la punta del alambre. Para reinicios de

arco más sencillos, la bola puede eliminarse

desplazando un tramo de alambre y extrayendo

algunas pulgadas de alambre y cortando el

extremo con unas pinzas de alambre

6. Cuando no vaya a soldar más, cierre la válvula del

cilindro de gas, opere momentáneamente el gatillo

de la antorcha para liberar la presión del gas, y

después apague la máquina.

ADVERTENCIA

15°-20°

Empuje

Page 22

10

APRENDIENDO A SOLDAR

10

3. La Punta de Contacto Correcta para la Distancia

de Trabajo (CTWD)

La Punta de Contacto de Trabajo para la Distancia

de Trabajo (CTWD) es la distancia desde el extremo

de la punta de contacto hasta el trabajo. Vea la

Figura 18.

Una vez que el arco se ha establecido, es muy

importante mantener una CTWD correcta. La

CTWD debe ser de 3/8 a 1/2 pulgada de largo (10 a

12 mm) aproximadamente .

La forma más fácil para saber si la CTWD tiene la

longitud correcta, es escuchando su sonido. Una

CTWD correcta tiene un sonido distintivo de “chisporroteo”, muy similar al que se produce cuando se

fríen alimentos en una sartén. Una CTWD larga

tiene un sonido hueco, de fritura o de soplo. Si la

CTWD es muy corta, usted podría colocar la punta

de contacto o la tobera en el charco de soldadura

y/o fusionar el alambre con la punta de contacto.

FIGURA 18

4. Velocidad Correcta de Soldadura

Mientras suelda, es importante observar el charco

de metal derretido justo detrás del arco. Vea la

Figura 19. No observe el arco directamente. La

apariencia del charco y el reborde donde se solidifica es lo que indica la velocidad correcta de soldadura. El reborde detrás del electrodo tubular debe ser

de 3/8” (10 mm) aproximadamente.

La mayoría de los principiantes tienden a soldar muy

rápido, dando como resultado un cordón delgado,

disparejo y con apariencia “ondulada”. Cuando esto

sucede significa que no están observando el metal

derretido.

FIGURA19

Consejos Útiles

1. Para soldaduras generales, no es necesario mover el

arco, ni hacia adelante ni hacia atrás o a los lados.

Suelde a un ritmo estable. Será más fácil en esta

forma.

• Cuando suelde sobre una placa delgada, se dará

cuenta de que tiene que aumentar la velocidad de

soldadura o hacer una soldadura más penetrante;

por otro lado, al soldar sobre una placa gruesa,

será necesario llevar un ritmo más lento para

lograr una penetración adecuada.

• Al soldar una placa de metal de calibre 16 (1.5

mm) o más ligera, la acumulación de calor puede

ocasionar deformaciones y quemaduras. Una

manera de eliminar estos problemas es utilizar el

método de pasos en retroceso que se muestra en

la Figura 15.

Práctica

La mejor forma de obtener práctica en las cuatro

habilidades es permitirle mantener:

1. Posición de soldadura correcta.

2. Forma correcta de iniciar un arco.

3. Punta de Contacto Correcta para la Distancia de

Trabajo

4. La velocidad de soldadura correcta para realizar el

siguiente ejercicio. Consulte la Figura 16. Utilice

LINEAMIENTOS DE PROCESO en el Manual de

Instrucción y Guía de Aplicación en el interior de la

puerta de la sección de alimentación de alambre

para la selección del alambre de soldadura, gas

protector, velocidad de alimentación de alambre,

voltaje y para el nivel de grosor del metal que

puede ser soldado.