Page 1

Description

Output Input

Submerged Arc

LT-7 Tractor

Submerged Arc DC Wire Feeder

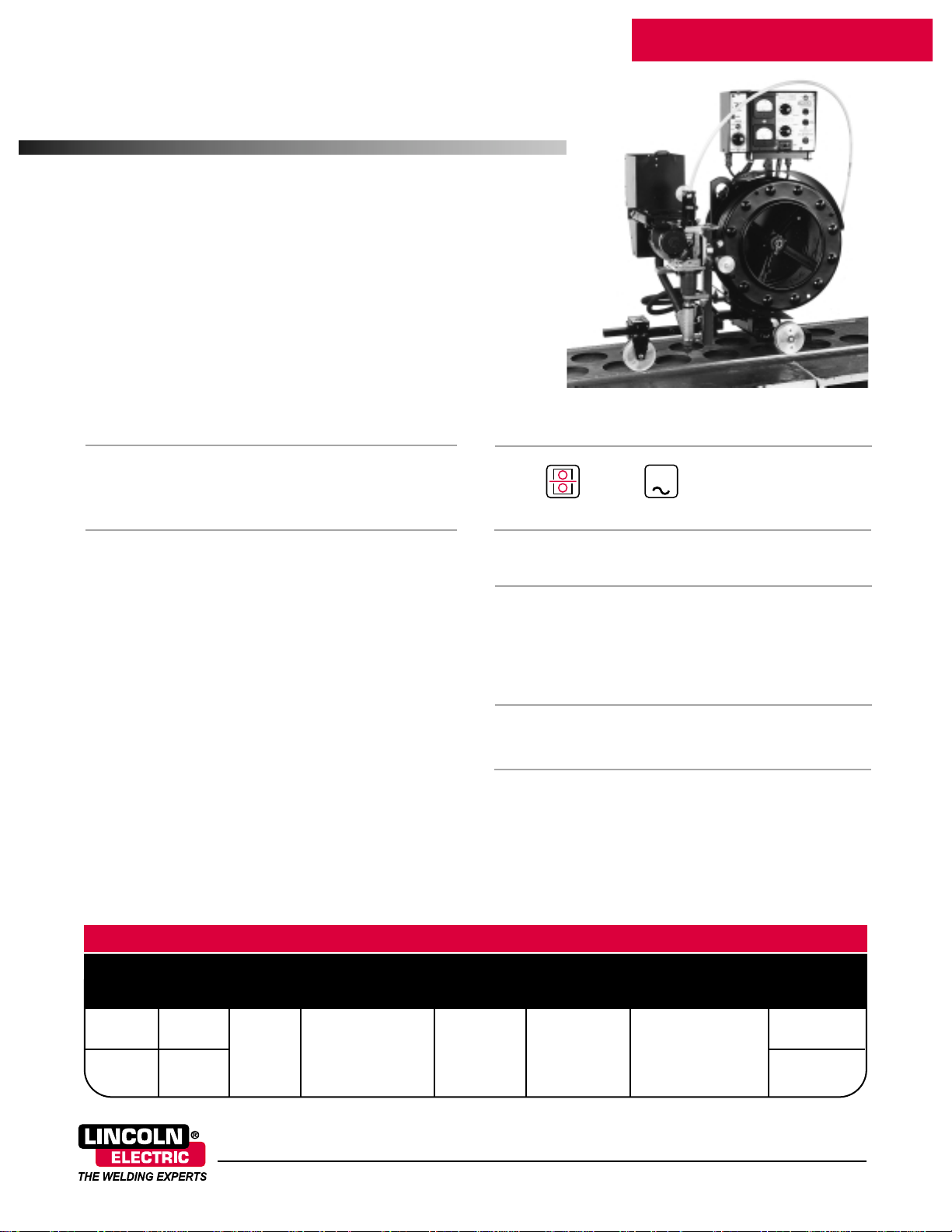

The LT-7 Tractor is a self-propelled mechanized wire feeder, designed for the

submerged arc process with track system capabilities. It is self-guiding and

easy to operate – only one operator is usually required. It is designed to be

used with a variety of Lincoln DC constant voltage and constant current power

sources. The rugged, lightweight unit permits quick movement to the next joint.

Its compact size fits through small openings and confined spaces. Butt and

fillet welds can be made on heavy plate or steel as light as 12 gauge (2.5mm).

The LT-7 Tractor is ideal for the following applications: ship and barge building,

storage tank erection, bridge deck installation, beam, girder or column

fabrication, and long seams on heavy weldments.

Publication E9.70 12/03

www.lincolnelectric.com

Processes

Advantage Lincoln

Order

TECHNICAL SPECIFICATIONS

Recommended General Options

• LT-7 Tractor feeds 3/32 to 3/16” (2.4 to 4.8 mm) solid wires,

from 100 - 400 inches per minute (2.5 - 10.2 m/min) wire feed

speed.

• Calibrated tractor drive adjusts travel speeds from 6 to 70

inches per minute (0.12 to 1.8 m/min).

• Vertical head lift adjuster for adjusting electrical stickout from

1/2 in. to 5 in. (12.7 to 127.0 mm).

• Weld angle is up to 50° from vertical on either side; drag

angle is up to 30° from vertical.

• Control box is conveniently located on the tractor (can be

mounted either left or right), eliminating the need to return to

the power source for routine procedure changes.

• Exceptional tracking control and self-steering in most

applications leave the operator free for quality control, joint

cleaning and flux handling.

• Welds butts, horizontal fillet and lap joints to the left or right

side of the tractor frame for convenience.

• Close mechanical alignment between wire and joint maximizes

weld quality with no fixturing costs.

• Three-year warranty on parts and labor.

Recommended Power Sources

AUTOMATIC WIRE FEEDERS

11 5

VAC

K227-1 LT-7 Standard Model

K395-1 LT-7 Track Model

Wire Feeder Control Cable Extensions, Adapter Cable, Linc-Fill™

Attachments, Horizontal Fillet and Lap Adapter Kit, Flat Fillet Adapter

Kit, Butt Seam Guide Kit, Track Conversion Kit, Tiny Twinarc

®

Adapter Kit, Track Section, Flux Screen, Magnetic Flux Screen

Separator, Concentric Flux Cone Assembly

Required Options

Control Cable, Weld Power Cable, Contact Nozzle Assembly

CV-655, DC-600, DC-655, DC-1000, DC-1500

Wire Feed Wire Size Range Dimensions Net

Product Product Input Rated Output Speed Range Solid H x W x D Weight

Name Number Power Current/Duty Cycle ipm (m/min) in. (mm) in. (mm) lbs. (kg)

LT-7 K227-1 115 VAC 600A/100% 100 - 400 3/32 - 3/16” 27.5 x 33 x 14 120

Standard 50/60 Hz 1100A/100% (with (2.5 - 10.2) (2.4 - 4.8) (698 x 838 x 356) (54)

LT-7 K395-1

water cooling)

130

Track (59)

Track Model Shown

Page 2

LT-7 Tractor

www.lincolnelectric.com

[2]

A CLOSER LOOK

REQUIRED OPTIONS

PERFORMANCE

• Solid-state control system precisely regulates procedures for

reliable starting and economical welding.

• Automatic compensation for input voltage and tractor loading

variations.

• Function lights built into the solid-state printed circuit boards aid

troubleshooting to minimize down time.

• Cross seam adjuster speeds setup and lets operator track

irregular joints while welding. Adjustment range is 3-1/8 in.

(79 mm) with clamp and 2-1/2 in. (63 mm) with handwheel.

• To perform a curved weld, the minimum diameter can be as small

as 10 ft. (3.0m) for an inside weld and 13 ft. (3.9m) for an outside

weld.

• To perform an inside circumferential weld, the minimum inside

diameter that can be welded is approximately 5 ft. (1.5m).

QUALITY AND RELIABILITY

• Three-year warranty on parts and labor.

• Manufactured under a quality system certified to ISO 9001

requirements.

• Rugged and durable design recognized throughout the industry

for its long life and years of trouble-free wire feeding.

FEATURES

• Quick, easy installation of optional guides for different joints.

• Reel holds 60 lb. (27.2 kg) solid wire coils.

• Flux hopper capacity of 15 lbs. (6.8 kg). Includes a manual flux

flow rate control valve and can be mounted at four locations to

the left or right.

• Continuous Vertical Adjustment: 1-1/2” (38 mm) handweel

variation for ESO (electrical stickout).

• Travel clutch operates from either side of the tractor.

456

WELD POWER CABLES

CONTROL CABLES

Description Order No.

Wire Feeder Control Cable K1822-25 - 25 ft. (7.6m)

Wire Feeder Control Cable Extensions K1797-25 - 25 ft. (7.6m)

K1797-50 - 50 ft. (15.2m)

Adapter Cable for Control Cable K1798

to Terminal Strip Power Sources

Order No. Description

K1842-10 Lug to Lug, 3/0, 600A, 60% duty cycle, 10 ft. (3.0m)

K1842-35 Lug to Lug, 3/0, 600A, 60% duty cycle, 35 ft. (10.6m)

K1842-60 Lug to Lug, 3/0, 600A, 60% duty cycle, 60 ft. (18.2m)

K1842-110 Lug to Lug, 4/0, 600A, 60% duty cycle, 110 ft. (33.5m)

456

CONTACT NOZZLE ASSEMBLIES

Description/Diameter Wire Order No.

Submerged Arc:

3/32” (2.4 mm) K231-3/32

1/8” (3.2 mm) K231-1/8

5/32” (4.0 mm) K231-5/32

3/16” (4.8 mm) K231-3/16

Positive:

3/32 - 1/8” (2.4 - 3.2 mm) K148A

3/32 - 3/16” (2.4 - 4.8 mm) K148B

Linc-Fill™ Attachments for Positive Contact Nozzle Asbly

Extension for K148

3/32” (2.4 mm) K149-3/32

1/8” (3.2 mm) K149-1/8

5/32” (4.0 mm) K149-5/32

Page 3

LT-7 T r actor

www.lincolnelectric.com

[3]

RECOMMENDED OPTIONS

GENERAL OPTIONS

Horizontal Fillet and Lap

Adapter Kit

Includes a rear guide wheel, head

tension spring and front guide

wheel assembly on an adjustable

arm which rides in the joint to

maintain alignment and electrode

angle. Kit includes separate front

guide wheel assemblies for fillet

and lap joints. Welds to the left

or right of the tractor’s center line.

Order K232

Flat Fillet Adapter Kit

Includes front and rear guide

wheels for operating the tractor in

30° or 45° flat fillet joints.

Order K229

Butt Seam Guide Kit

Mount in place of the standard

front wheel to ride in a V-groove

or open 1/8 - 3/8” (3.2 - 9.5 mm)

butt joint, keeping the wire in

required alignment.

Order K230

Track Conversion Kit

Converts the LT-7 standard model

for track guidance. Shown with

K396 track section.

Order K400

GENERAL OPTIONS

Tiny Twinarc Adapter Kit

Converts the LT-7 standard model

to Tiny Twinarc using 5/64” (2.0

mm) electrode. These kits may

also be used for horizontal fillets

with the addition of the K232

Adapter Kit.

Order K277-1 for Butt Seams

Order K277-2 for Flat Fillets

Track Section

Each provides 70 in. (1.8m) of

travel. To be used with the

K395-1, LT-7 Track Model.

Order K396

Flux Screen

For submerged arc welding.

Removes large particles from

reused flux. Includes air-driven

vibrator.

Order K310

Magnetic Flux Screen Separator

For submerged arc welding.

Removes foreign magnetic

particles from reused flux.

Order K58

Concentric Flux Cone Assembly

For use with the K148B, Positive

Contact Nozzle Assembly. Gives

concentric flux coverage around

the electrode.

Order K285

K396

Page 4

LT-7 STANDARD MODEL K227-1

LT-7 TRACK MODEL K395-1

REQUIRED OPTIONS

Control Cable See Page 2

Weld Power Cable See Page 2

Contact Nozzle Assembly See Page 2

RECOMMENDED GENERAL OPTIONS

Wire Feeder Control Cable Extensions See Page 2

Adapter Cable See Page 2

Linc-Fill™ Attachments See Page 2

Horizontal Fillet and Lap Adapter Kit K232

Flat Fillet Adapter Kit K229

Butt Seam Guide Kit K230

Track Conversion Kit K400

Tiny Twinarc Adapter Kit, for Butt Seams K277-1

Tiny Twinarc Adapter Kit, for Flat Fillets K277-2

Track Section K396

Flux Screen K310

Magnetic Flux Screen Separator K58

Concentric Flux Cone Assembly K285

RECOMMENDED POWER SOURCES

CV-655 see publication E4.40

DC-600 see publication E5.40

DC-655 see publication E5.46

DC-1000 see publication E5.50

DC-1500 see publication E5.60

TOTAL:

THE LINCOLN ELECTRIC COMPANY

22801 St. Clair Ave., Cleveland, OH 44117-1199 • 216.481.8100 • www.lincolnelectric.com

LT-7 TRACTOR ORDER FORM

PRODUCT DESCRIPTION ORDER NUMBER QUANTITY PRICE

CUSTOMER ASSISTANCE POLICY

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the

needs of our customers and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric for advice or information about their use of our products. We respond

to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability,

with respect to such information or advice. We expressly disclaim any warranty of any kind, including any warranty of fitness for any customer’s particular purpose, with respect to

such information or advice. As a matter of practical consideration, we also cannot assume any responsibility for updating or correcting any such information or advice once it has

been given, nor does the provision of information or advice create, expand or alter any warranty with respect to the sale of our products.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility

of the customer. Many variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

Loading...

Loading...