Lincoln Electric LN-25, LN-25 PORTABLE CV, LN-25 PORTABLE CC Service Manual

LN-25 PORTABLE CV/CC

SEMIAUTOMATIC WIRE FEEDER

SVM114-A

June 1995

For use with machines having Code Numbers:

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However,

your overall safety can be

increased by proper installation

... and thoughtful operation on

your part. DO NOT INSTALL,

OPERATE OR REPAIR THIS

EQUIPMENT WITHOUT READING THIS MANUAL AND THE

SAFETY PRECAUTIONS CONTAINED THROUGHOUT. And,

most importantly, think before you

act and be careful.

9218

9219

9220

9383

9810

9811

9812

10148

10149

10150

SERVICE MANUAL

World's Leader in Welding and Cutting Products Premier Manufacturer of Industrial Motors

Sales and Service through Subsidiaries and Distributors Worldwide

22801 St. Clair Ave. Cleveland, Ohio 44117-1199 U.S.A. Tel. (216) 481-8100

SAFETY

ii

WARNING

ARC WELDING can be hazardous.

PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH. KEEP CHILDREN

AWAY. PACEMAKER WEARERS SHOULD CONSULT WITH THEIR DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For additional safety information, it is strongly recommended that you

purchase a copy of “Safety in Welding & Cutting - ANSI Standard Z49.1” from the American W elding Society, P .O. Box 351040,

Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the

Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

BE SURE THA T ALLINSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

ELECTRIC SHOCK can kill.

1.a. The electrode and work (or ground) circuits

are electrically “hot” when the welder is on.

Do not touch these “hot” parts with your bare

skin or wet clothing. Wear dry, hole-free

gloves to insulate hands.

1.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full

area of physical contact with work and ground.

In addition to the normal safety precautions, if welding

must be performed under electrically hazardous

conditions (in damp locations or while wearing wet

clothing; on metal structures such as floors, gratings or

scaffolds; when in cramped positions such as sitting,

kneeling or Iying, if there is a high risk of unavoidable or

accidental contact with the workpiece or ground) use

the following equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

1.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel, welding head, nozzle or semiautomatic

welding gun are also electrically “hot”.

1.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection

should be as close as possible to the area being welded.

1.e. Ground the work or metal to be welded to a good electrical

(earth) ground.

1.f.

Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

1.g. Never dip the electrode in water for cooling.

1.h. Never simultaneously touch electrically “hot” parts of

electrode holders connected to two welders because voltage

between the two can be the total of the open circuit voltage

of both welders.

1.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

1.j. Also see Items 4.c. and 6.

2.b. Use suitable clothing made from durable flame-resistant

material to protect your skin and that of your helpers from

the arc rays.

2.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

fumes and gases away from the breathing zone. When

welding with electrodes which require special

ventilation such as stainless or hard facing (see

instructions on container or MSDS) or on lead or

cadmium plated steel and other metals or coatings

which produce highly toxic fumes, keep exposure as

low as possible and below Threshold Limit Values (TLV)

using local exhaust or mechanical ventilation. In

confined spaces or in some circumstances, outdoors, a

respirator may be required. Additional precautions are

also required when welding on galvanized steel.

3.b.

Do not weld in locations near chlorinated hydrocarbon

coming from degreasing, cleaning or spraying

operations.The heat and rays of the arc can react with solvent vapors

irritating products.

3.c. Shielding gases used for arc welding can displace air and

cause injury or death. Always use enough ventilation,

especially in confined areas, to ensure breathing air is safe.

3.d. Read and understand the manufacturer’s instructions for this

equipment and the consumables to be used, including the

material safety data sheet (MSDS) and follow your

employer’s safety practices. MSDS forms are available from

your welding distributor or from the manufacturer.

ARC RAYS can burn.

2.a. Use a shield with the proper filter and cover

plates to protect your eyes from sparks and

the rays of the arc when welding or observing

open arc welding. Headshield and filter lens

should conform to ANSI Z87. I standards.

FUMES AND GASES

can be dangerous.

3.a.Welding may produce fumes and gases

hazardous to health. Avoid breathing these

fumes and gases. When welding, keep

your head out of the fume. Use enough

ventilation and/or exhaust at the arc to keep

vapors

to

form phosgene, a highly toxic gas, and other

3.e. Also see item 7b.

LN-25

Apr. ‘93

SAFETY

iiii

WELDING SPARKS can

cause fire or explosion.

4.a.

Remove fire hazards from the welding area.

If this is not possible, cover them to prevent

the welding sparks from starting a fire.

materials from welding can easily go through small cracks

and openings to adjacent areas. Avoid welding near

hydraulic lines. Have a fire extinguisher readily available.

4.b. Where compressed gases are to be used at the job site,

special precautions should be used to prevent hazardous

situations. Refer to “Safety in Welding and Cutting” (ANSI

Standard Z49.1) and the operating information for the

equipment being used.

4.c. When not welding, make certain no part of the electrode

circuit is touching the work or ground. Accidental contact can

cause overheating and create a fire hazard.

4.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to ensure that such procedures

will not cause flammable or toxic vapors from substances

inside. They can cause an explosion even

been “cleaned”. For information, purchase “Recommended

Safe Practices for the

Containers and Piping That Have Held Hazardous

Substances”, AWS F4.1 from the American Welding Society

(see address above).

4.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

4.f.

Sparks and spatter are thrown from the welding arc. Wear oil

free protective garments such as leather gloves, heavy shirt,

cuffless trousers, high shoes and a cap over your hair. Wear

ear plugs when welding out of position or in confined places.

Always wear safety glasses with side shields when in a

welding area.

4.g. Connect the work cable to the work as close to the welding

area as practical. Work cables connected to the building

framework or other locations away from the welding area

increase the possibility of the welding current passing

through lifting chains, crane cables or other alternate circuits.

This can create fire hazards or overheat lifting chains or

cables until they fail.

4.h. Also see item 7c.

Remember that welding sparks and hot

though

they have

Preparation

for Welding and Cutting of

CYLINDER may explode

if damaged.

5.a. Use only compressed gas cylinders

containing the correct shielding gas for the

process used and properly operating

regulators designed for the gas and

pressure used. All hoses, fittings, etc. should be suitable for

the application and maintained in good condition.

5.b. Always keep cylinders in an upright position securely

chained to an undercarriage or fixed support.

5.c. Cylinders should be located:

•Away from areas where they may be struck or subjected to

physical damage.

• A safe distance from arc welding or cutting operations and

any other source of heat, sparks, or flame.

5.d. Never allow the electrode, electrode holder or any other

electrically “hot” parts to touch a cylinder.

5.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

5.f. Valve protection caps should always be in place and hand

tight except when the cylinder is in use or connected for

use.

5.g. Read and follow the instructions on compressed gas

cylinders, associated equipment, and CGA publication P-l,

“Precautions for Safe Handling of Compressed Gases in

Cylinders,” available from the Compressed Gas Association

1235 Jefferson Davis Highway, Arlington, VA 22202.

FOR ELECTRICALLY

powered equipment.

6.a.Turn off input power using the disconnect

switch at the fuse box before working on

the equipment.

6.b. Install equipment in accordance with the U.S. National

Electrical Code, all local codes and the manufacturer’s

recommendations.

6.c. Ground the equipment in accordance with the U.S. National

Electrical Code and the manufacturer’s recommendations.

Mar. ‘93

LN-25

SAFETY

iiiiii

FOR ENGINE

powered equipment.

7.a. Turn the engine off before troubleshooting and maintenance

work unless the maintenance work requires it to be running.

____________________________________________________

7.b. Operate engines in open, well-ventilated

areas or vent the engine exhaust fumes

outdoors.

____________________________________________________

7.c. Do not add the fuel near an open flame

welding arc or when the engine is running. Stop the engine and allow it to cool

before refueling to prevent spilled fuel

from vaporizing on contact with hot

engine parts and igniting. Do not spill

fuel when filling tank. If fuel is spilled,

wipe it up and do not start engine until

fumes have been eliminated.

____________________________________________________

7.d. Keep all equipment safety guards, covers

and devices in position and in good repair.

Keep hands, hair, clothing and tools away

from V-belts, gears, fans and all other

moving parts when starting, operating or

repairing equipment.

ELECTRIC AND MAGNETIC FIELDS

may be dangerous

8.a. Electric current flowing through any conductor causes

localized Electric and Magnetic Fields (EMF). Welding

current creates EMF fields around welding cables and

welding machines

8.b. EMF fields may interfere with some pacemakers, and

welders having a pacemaker should consult their physician

before welding.

8.c. Exposure to EMF fields in welding may have other health

effects which are now not known.

8d. All welders should use the following procedures in order to

minimize exposure to EMF fields from the welding circuit:

8.d.1.

Route the electrode and work cables together - Secure

them with tape when possible.

8.d.2. Never coil the electrode lead around your body.

8.d.3. Do not place your body between the electrode and

work cables. If the electrode cable is on your right

side, the work cable should also be on your right side.

8.d.4. Connect the work cable to the workpiece as close as

possible to the area being welded.

8.d.5. Do not work next to welding power source.

____________________________________________________

7.e. In some cases it may be necessary to remove safety

guards to perform required maintenance. Remove

guards only when necessary and replace them when the

maintenance requiring their removal is complete.

Always use the greatest care when working near moving

parts.

7.f. Do not put your hands near the engine fan. Do not

attempt to override the governor or idler by pushing on

the throttle control rods while the engine is running.

7.g. To prevent accidentally starting gasoline engines while

turning the engine or welding generator during maintenance

work, disconnect the spark plug wires, distributor cap or

magneto wire as appropriate.

___________________________________________________

Mar. ‘93

LN-25

SAFETY

iviv

PRÉCAUTIONS DE SÛRETÉ

Pour

votre propre protection lire et observer toutes les instructions

et les précautions de sûreté specifiques qui parraissent dans ce

manuel aussi bien que les précautions de sûreté générales suivantes:

Sûreté Pour Soudage A L’Arc

1. Protegez-vous contre la secousse électrique:

a. Les circuits à l’électrode et à la piéce sont sous tension

quand la machine à souder est en marche. Eviter toujours

tout contact entre les parties sous tension et la peau nue

ou les vétements mouillés. Porter des gants secs et sans

trous pour isoler les mains.

b. Faire trés attention de bien s’isoler de la masse quand on

soude dans des endroits humides, ou sur un plancher metallique ou des grilles metalliques, principalement dans

les positions assis ou couché pour lesquelles une grande

partie du corps peut être en contact avec la masse.

c. Maintenir le porte-électrode, la pince de masse, le câble de

soudage et la machine à souder en bon et sûr état defonctionnement.

d.Ne jamais plonger le porte-électrode dans l’eau pour le

refroidir.

e. Ne jamais toucher simultanément les parties sous tension

des porte-électrodes connectés à deux machines à souder parce que la tension entre les deux pinces peut être le

total de la tension à vide des deux machines.

f. Si on utilise la machine à souder comme une source de

courant pour soudage semi-automatique, ces precautions

pour le porte-électrode s’applicuent aussi au pistolet de

soudage.

6. Eloigner les matériaux inflammables ou les recouvrir afin de

prévenir tout risque d’incendie dû aux étincelles.

7. Quand on ne soude pas, poser la pince à une endroit isolé de

la masse. Un court-circuit accidental peut provoquer un

échauffement et un risque d’incendie.

8. S’assurer que la masse est connectée le plus prés possible de

la zone de travail qu’il est pratique de le faire. Si on place la

masse sur la charpente de la construction ou d’autres endroits

éloignés de la zone de travail, on augmente le risque de voir

passer le courant de soudage par les chaines de levage,

câbles de grue, ou autres circuits. Cela peut provoquer des

risques d’incendie ou d’echauffement des chaines et des

câbles jusqu’à ce qu’ils se rompent.

9. Assurer une ventilation suffisante dans la zone de soudage.

Ceci est particuliérement important pour le soudage de tôles

galvanisées plombées, ou cadmiées ou tout autre métal qui

produit des fumeés toxiques.

10. Ne pas souder en présence de vapeurs de chlore provenant

d’opérations de dégraissage, nettoyage ou pistolage. La

chaleur ou les rayons de l’arc peuvent réagir avec les vapeurs

du solvant pour produire du phosgéne (gas fortement toxique)

ou autres produits irritants.

11. Pour obtenir de plus amples renseignements sur la sûreté, voir

le code “Code for safety in welding and cutting” CSAStandard

W 117.2-1974.

2. Dans le cas de travail au dessus du niveau du sol, se protéger

contre les chutes dans le cas ou on recoit un choc. Ne jamais

enrouler le câble-électrode autour de n’importe quelle partie

du corps.

3. Un coup d’arc peut être plus sévère qu’un coup de soliel,

donc:

a. Utiliser un bon masque avec un verre filtrant approprié

ainsi qu’un verre blanc afin de se protéger les yeux du rayonnement de l’arc et des projections quand on soude ou

quand on regarde l’arc.

b. Porter des vêtements convenables afin de protéger la

peau de soudeur et des aides contre le rayonnement de

l‘arc.

c. Protéger l’autre personnel travaillant à proximité au

soudage à l’aide d’écrans appropriés et non-inflammables.

4. Des gouttes de laitier en fusion sont émises de l’arc de

soudage. Se protéger avec des vêtements de protection libres

de l’huile, tels que les gants en cuir, chemise épaisse, pantalons sans revers, et chaussures montantes.

5. Toujours porter des lunettes de sécurité dans la zone de

soudage. Utiliser des lunettes avec écrans lateraux dans les

zones où l’on pique le laitier.

PRÉCAUTIONS DE SÛRETÉ POUR

LES MACHINES À SOUDER À

TRANSFORMATEUR ET À

REDRESSEUR

1. Relier à la terre le chassis du poste conformement au code de

l’électricité et aux recommendations du fabricant. Le dispositif

de montage ou la piece à souder doit être branché à une

bonne mise à la terre.

2. Autant que possible, I’installation et l’entretien du poste seront

effectués par un électricien qualifié.

3. Avant de faires des travaux à l’interieur de poste, la debrancher à l’interrupteur à la boite de fusibles.

4. Garder tous les couvercles et dispositifs de sûreté à leur

place.

LN-25

MASTER TABLE OF CONTENTS FOR ALL SECTIONS

Page

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i-iv

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section A

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Power Source Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Gun Cable Connection to Feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Weld Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Wire Feed Drive Roll and Guide Tube Kits . . . . . . . . . . . . . . . . . . . . . . A-5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section B

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Recommended Processes and Equipment . . . . . . . . . . . . . . . . . . . . . . B-2

Welding Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

LN-25 Instruments and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Welding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

Procedure at End of Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

Open Arc Welding with a Constant Current Power Source . . . . . . . . . . B-9

Automatic Protection Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

vv

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section C

LN-25 Option Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Remote Output Control Options and Control Cable Assemblies . . . . . . C-4

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section D

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Circuit Protection and Automatic Shutdown . . . . . . . . . . . . . . . . . . . . . . D-2

Adjusting Speed Sensor Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Calibration of LN-25 Wire Speed Dial . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section E

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Control Circuit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Auxiliary Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4

Troubleshooting and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section F

How to Use Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . F-2

PC Board Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . F-3

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-4

Test Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-7

Component Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . F-20

Retest After Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-38

Electrical Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section G

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-3

Operating Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-5

Control PC Board Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-7

Contactor PC Board Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-11

Parts Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-175

LN-25

NOTES

vi

TABLE OF CONTENTS

- INSTALLATION SECTION -

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section A

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Power Source Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

DC-250 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

DC-400 and CV-400 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

DC-600 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

R3S-325 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

SAM-400, -650 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

SA-200, -250 or SAE-300, -400 . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Invertec, CV300 and other newer Lincoln Power Sources . . . . . . . . A-4

Gun Cable Connection to Feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Weld Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Electrode Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Work Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Wire Feed Drive Roll and Guide Tube Kits . . . . . . . . . . . . . . . . . . . . . . A-5

Section A

LN-25

A-2

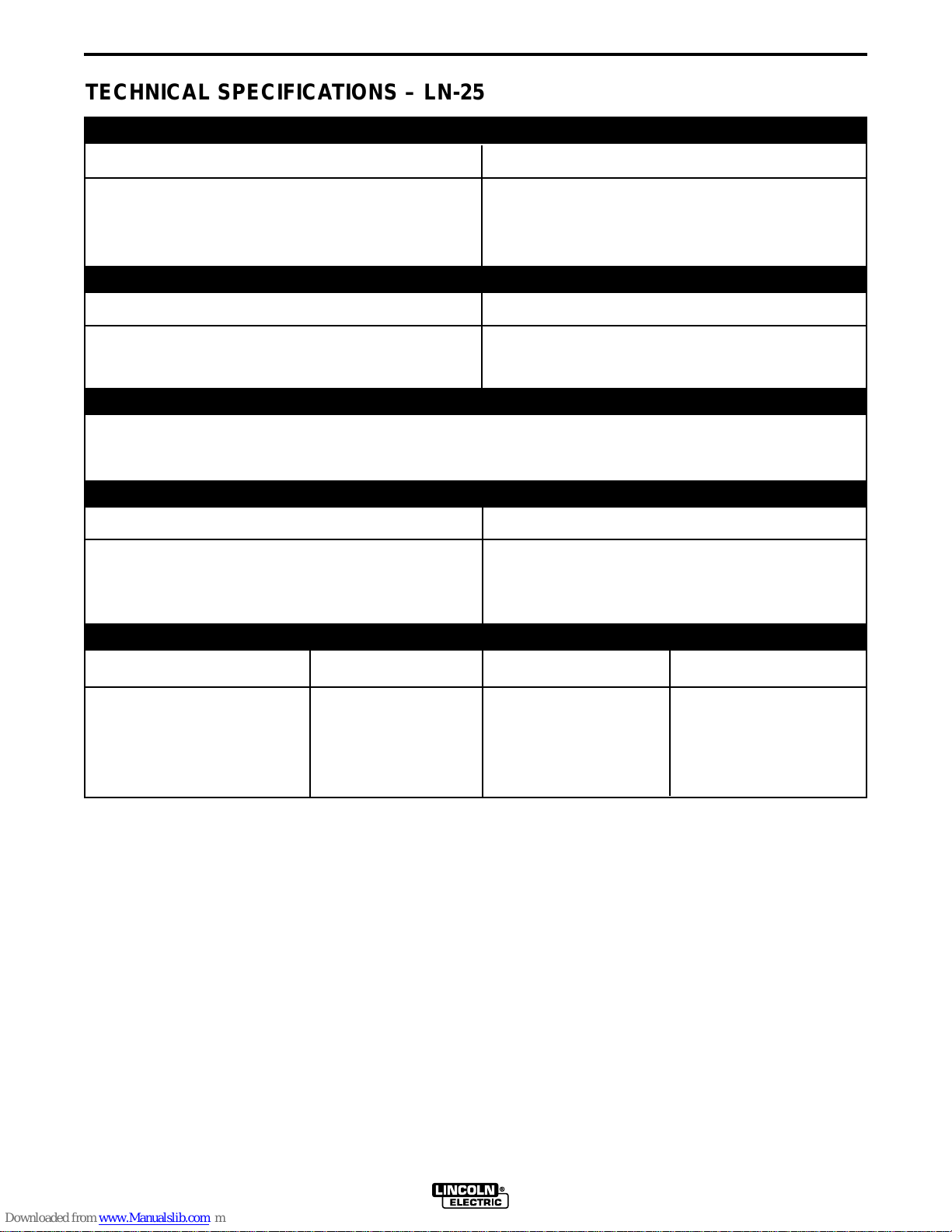

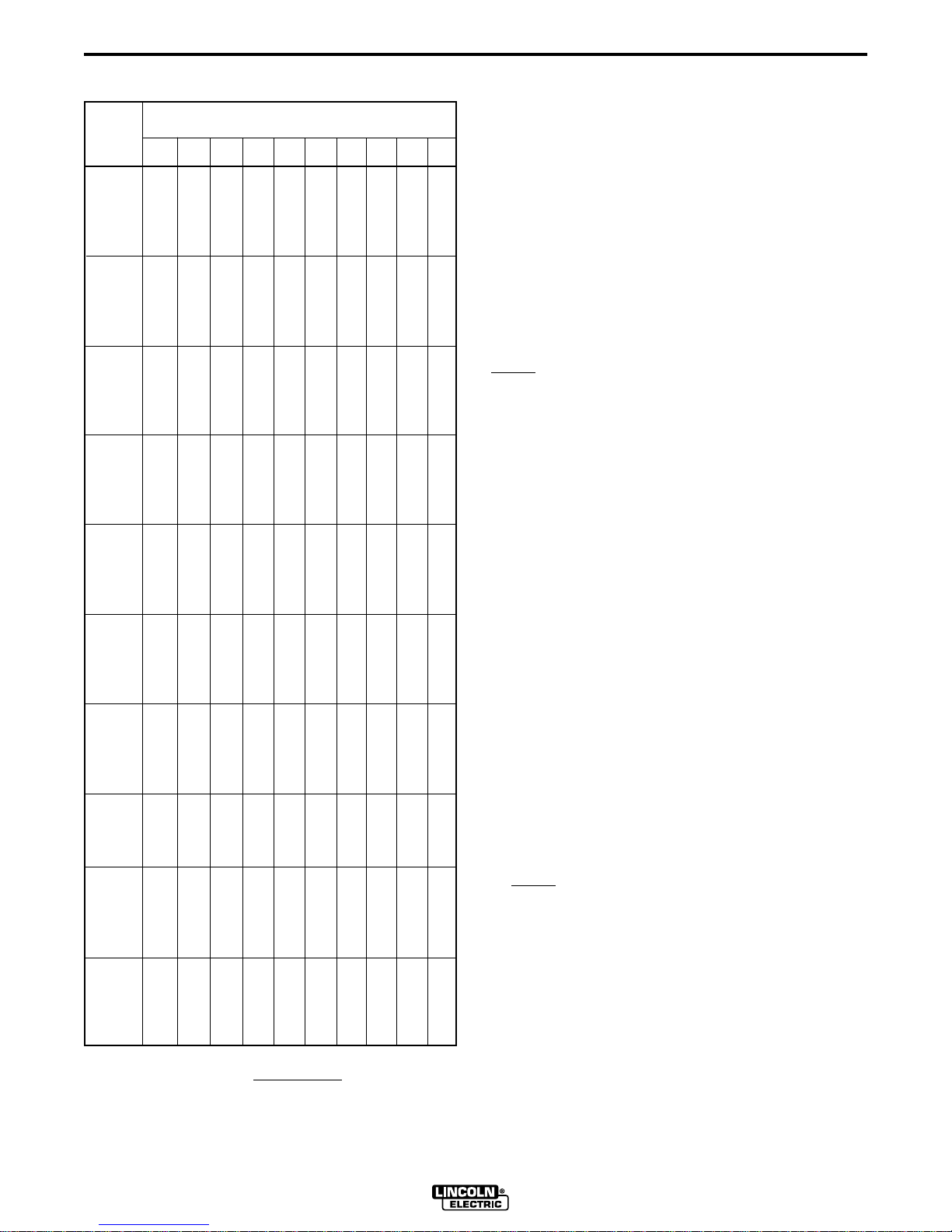

RATED CURRENT

WIRE FEED SPEED

PHYSICAL DIMENSIONS

WIRE DIAMETERS

VOLTAGE

INSTALLATION

TECHNICAL SPECIFICATIONS – LN-25

VOLTAGE

Modes Range

Constant Voltage (CV)

or 15-40 VDC (110VDC Maximum OCV)

Constant Current (CC)

RATED CURRENT

Without Contactor With Contactor

500 Amps 60% Duty Cycle 300 Amps 60% Duty Cycle

WIRE SPEED RANGE

50 – 700 Inches Per Minute (IPM)

A-2

RECOMMENDED ELECTRODE WIRE SIZES

Diameter Wire Type

.023" to 1⁄16" SOLID STEEL WIRE

.035" to 5⁄64" CORED WIRE

.035" to 1⁄16" ALUMINUM WIRE

HEIGHT WIDTH DEPTH WEIGHT

(Handle Down) w/o Options

14 Inches 7.4 Inches 21 Inches 28 lbs

(354 mm) (187 mm) (531 mm) (13 kg)

PHYSICAL DIMENSIONS

LN-25

A-3

INSTALLATION

A-3

SAFETY PRECAUTIONS

WARNING

Unless an optional output control or contactor is used

with the LN-25, the electrode circuit (including welding

wire, wire drive and welding gun) is electrically hot

when the welding power source is on. The gun trigger

controls wire feed only.

Disconnect or shut off welding power source before

making connections or installations to the LN-25.

Welding gun should be stored in the insulated

gun holder, located near the rear on the top of the

LN-25 case, to avoid accidental arcing.

WARNING

ELECTRIC SHOCK can kill.

• Do not touch metal portions

of the LN-25 lead clip when

welding power source is on.

WARNING

ELECTRIC SHOCK can kill.

• Do not operate with covers

removed.

• Turn off power source before

installing or servicing.

• Do not touch electrically

hot parts.

• Turn the input power to the

welding power source off at the

fuse box before working in the

terminal strip.

• Only qualified personnel should

install, use or service this

equipment.

DC-250

POWER SOURCE CONNECTION

The LN-25 can be used with any DC welding power

source. A constant voltage power source is

recommended; however, the LN-25 can also be used

with a constant current power source as long as the

open circuit voltage is less than 110V DC.

CAUTION

Do not use LN-25 models below Code 9200 with any

TIG or Square Wave welding power sources. Do not

use LN-25 models equipped with internal contactors

with non- Lincoln TIG or Square Wave welding power

sources. Damage to the LN-25 circuit can occur as a

result of the high output inductance typically

associated with these power sources. TIG high

frequency power should never be applied to the LN-25.

If not using an LN-25 Remote Output Control option

(See Remote Output Control Options and Cable

Assemblies Section), the power source output must

be electrically “hot” at all times when the power

source is turned on.

a. Connect a jumper from 2 to 4 on the power source

terminal strip so the output will be energized when

the DC-250 is turned on.

b. Connect electrode cable to the “Innershield/

GMAW” output terminal of polarity required by

electrode. Connect work lead to other

“Innershield/GMAW” output terminal.

c. Place “Set to CV Electrode Cable Polarity” switch

at appropriate position.

d. Place power source toggle switch in “Output

Control at DC-250” position, unless a Remote

Control is connected to 75, 76 and 77 on the DC250 terminal strip.

e. Place mode switch in “Innershield GMAW (CV)”

position. Set CV arc control to “2” (or “NORMAL”

on some machines). Initially set the output

control on “7”.

DC-400 AND CV-400

a. Connect a jumper from 2 to 4 on the power

source terminal strip so the output will be

energized when the power source is turned on.

NOTE: DC-400 machines above Code 9200 have

an output toggle switch to perform this function.

See the power source instruction manual for proper

power source connections and setting required.

b.Connect the electrode cable to the output

terminal of polarity required by electrode.

Connect work lead to other output terminal.

LN-25

A-5

INSTALLATION

A-5

Install the barbed fitting and union nut to the 5⁄8-18

female inert gas fitting on the front panel of the LN25 case. Connect the 3⁄16" I.D. gas hose from the gun

cable to the barbed fitting.

When the gun is to be removed, this fitting can be

easily detached by loosening the union nut.

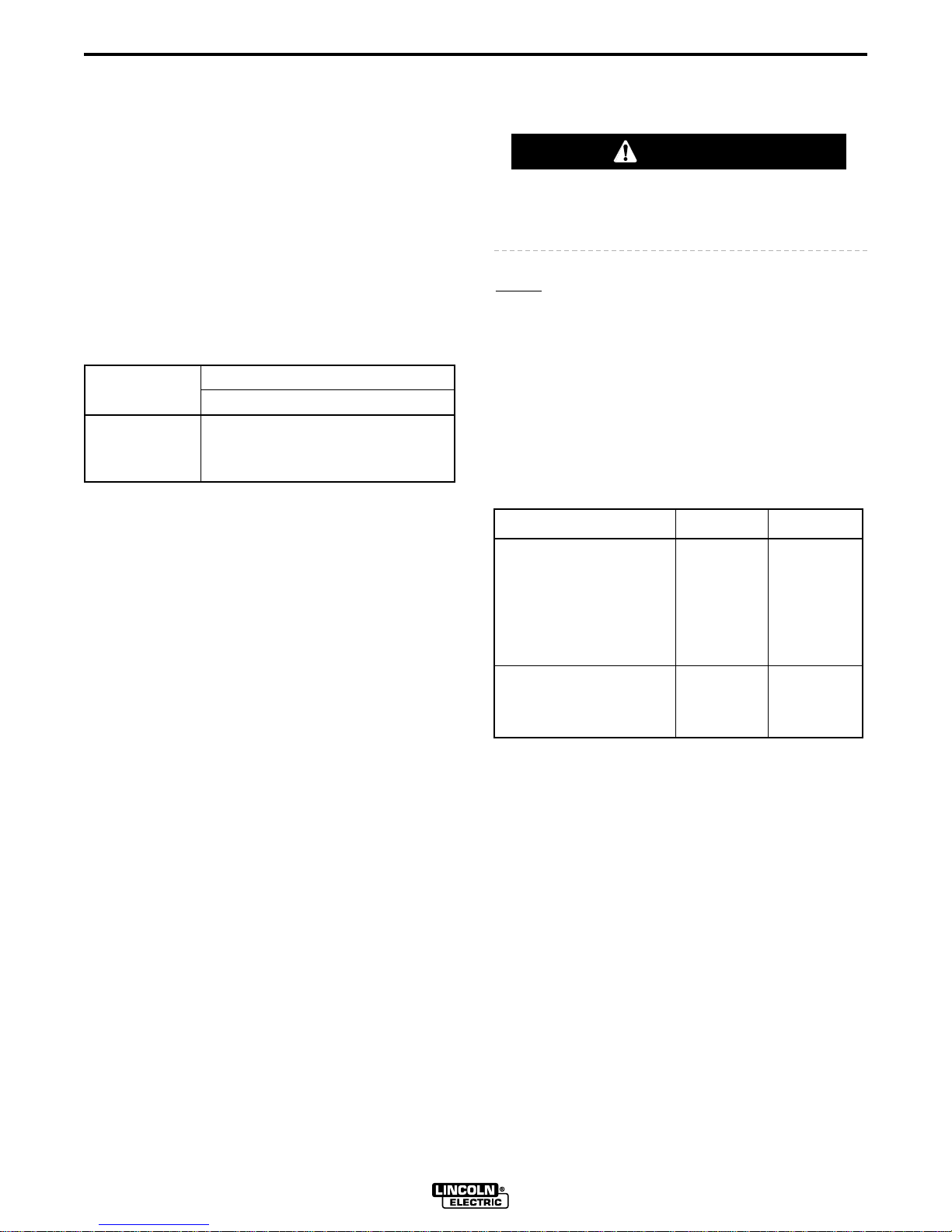

WELD CABLE CONNECTION

The size of the electrode cable and work cable must

be sufficient for the maximum weld current and total

cable length to be used. Refer to table A.1.

TABLE A.1

Weld Current

60% Duty Cycle 50'-100' 100'-150' 150'-200' 200'-250'

200Amps 2 AWG 2 AWG 1 AWG 1/0

300Amps 1 AWG 1 AWG 1/0 2/0

400Amps 2/0 2/0 3/0 3/0

500Amps 2/0 3/0 3/0 4/0

ELECTRODE CABLE CONNECTION

On units without an internal contactor route the

electrode cable through the oval hole in the LN-25 rear

panel, then along the case floor behind the reel

support and around the door side of the wire drive.

Connect the electrode cable to the LN-25 using the

1

⁄2" bolt on the front of the wire drive.

Total Cable Length

WIRE FEED DRIVE ROLL AND

GUIDE TUBE KITS

WARNING

Turn off power source before installing or changing

drive roll and/or guide tubes.

NOTE: The maximum wire sizes the LN-25 will

satisfactorily feed are 5⁄64" cored and 1⁄16" solid

electrodes.

The electrode sizes that can be fed with each roll and

guide tube are stencilled

for proper components. See the instructions, included

with the drive roll kit, to install these parts on new

machines or replace them on used machines. Refer

to table A.2.

Steel Wire Sizes:

.068-5⁄64 Cored KP450-3⁄32 S17984

1

⁄16 (.062) Cored or Solid -1⁄16

Steel

(Can also be used for .052)

.045 and .052 Solid Steel -.052

.045 and .052 Cored -.052C

.023-.035 Solid Steel KP451-.035S S17831

(1)

on each part. Check the kit

TABLE A.2

Kit Instructions

On units with an internal contactor connect the

electrode cable to the LN-25 electrode input cable with

the nut and bolt provided. Tape the bolted connection.

WORK CABLE CONNECTION

Connect a work lead of sufficient size between the

proper output stud on the power source and the

work. Be sure the connection to the work makes

tight metal-to-metal electrical contact. Poor

work lead connections can result in poor welding

performance.

Aluminum Wire Sizes:

1

⁄16 KP452-

3

⁄64 -3⁄64A

.035 -.035A

(1)

Drive rolls for .045-.052 cored electrode sizes are stencilled with

a “C” suffix to the wire sizes. Drive rolls for aluminum wire sizes

are stencilled with an “A” suffix to the wire sizes.

1

⁄16A S17083

LN-25

NOTES

A-6A-6

LN-25

TABLE OF CONTENTS

- OPERATION SECTION -

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section B

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Recommended Processes and Equipment . . . . . . . . . . . . . . . . . . . . . . B-2

Welding Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

LN-25 Instruments and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Loading Electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Mounting 22 to 30 lb Readi-Reel Coils . . . . . . . . . . . . . . . . . . . B-5

Mounting 10 to 30 lb Spools . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Mounting 13 or 14 lb Innershield Coils . . . . . . . . . . . . . . . . . . . B-5

Loading Wire Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Idle Roll Pressure Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Presetting Wire Feed Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Setting Constant Wire Feed Speed (CV Mode) . . . . . . . . . . . . . B-7

Setting Arc Sensing Wire Feed Speed (VV [CC] Mode) . . . . . . B-7

Making a Weld . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Welding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

Procedure at End of Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

Open Arc Welding with a Constant Current Power Source . . . . . . . . . . B-9

Automatic Protection Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

Overvoltage Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

Motor Overload Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

Section B

LN-25

OPERATION

B-2B-2

SAFETY PRECAUTIONS

READ AND UNDERSTAND ENTIRE SECTION

BEFORE OPERATING MACHINE

WARNING

ELECTRIC SHOCK can kill.

¥Do not touch electrically live

part or electrode with skin or

wet clothing.

¥Insulate yourself from work

and ground.

¥Always wear dry insulating

gloves.

FUMES AND GASSES can

be dangerous.

¥Keep your head out of

fumes.

¥Use ventilation or exhaust to

remove fumes from breath-

WELDING SPARKS can

cause fire or explosion.

¥Keep flammable material

away.

ARC RAYS can burn.

¥Wear eye, ear and body pro-

tection.

GENERAL DESCRIPTION

The LN-25 is a lightweight portable semiautomatic

wire feeder designed for Òacross-the-arcÓ operation

without a control cable on most any DC welding power

source. Simply connect the LN-25 to the electrode

cable, clip it to W ork and it is ready to weld, using up

to 30 lb. coils or spools.

The wire drive, controls and wire reel are fully

enclosed in a rugged molded plastic case providing a

compact and versatile welding package ideally suited

to Òon-the-goÓ field welding applications in virtually any

environment.

RECOMMENDED PROCESSES

AND EQUIPMENT

When combined with the quality drive roll kits and

accessories available for use with the LN-25, a

versatile portable welding system can be provided to

meet the specific needs of Innershield, submerged arc

or gas metal arc welding applications within the wire

feed capabilities of the LN-25.

The LN-25 provides constant wire feed speed for use

with constant voltage (CV) power sources, and arcsensing wire feed speed for use with constant current

(CC) (formerly variable voltage) power sources. W ire

speed is presettable on a dual-range calibrated dial.

The power sources recommended for use with the LN25 include the DC-250, -400, -600, CV -400 and R3S

type transformer machines, and the SAM-400, -650

engine welders, as well as the SA-200, -250 or SAE300, -400 with CV Adapter and Pulse Power 500 with

K460-1 LN-25 Kit.

WELDING CAPABILITY

The LN-25 will handle up to 500 Amp 60% duty cycle

welding currents. However , when equipped with a

K443-1 Contactor , the LN-25 will handle up to 300

Amp 60% duty cycle.

LN-25

OPERATION

B-3B-3

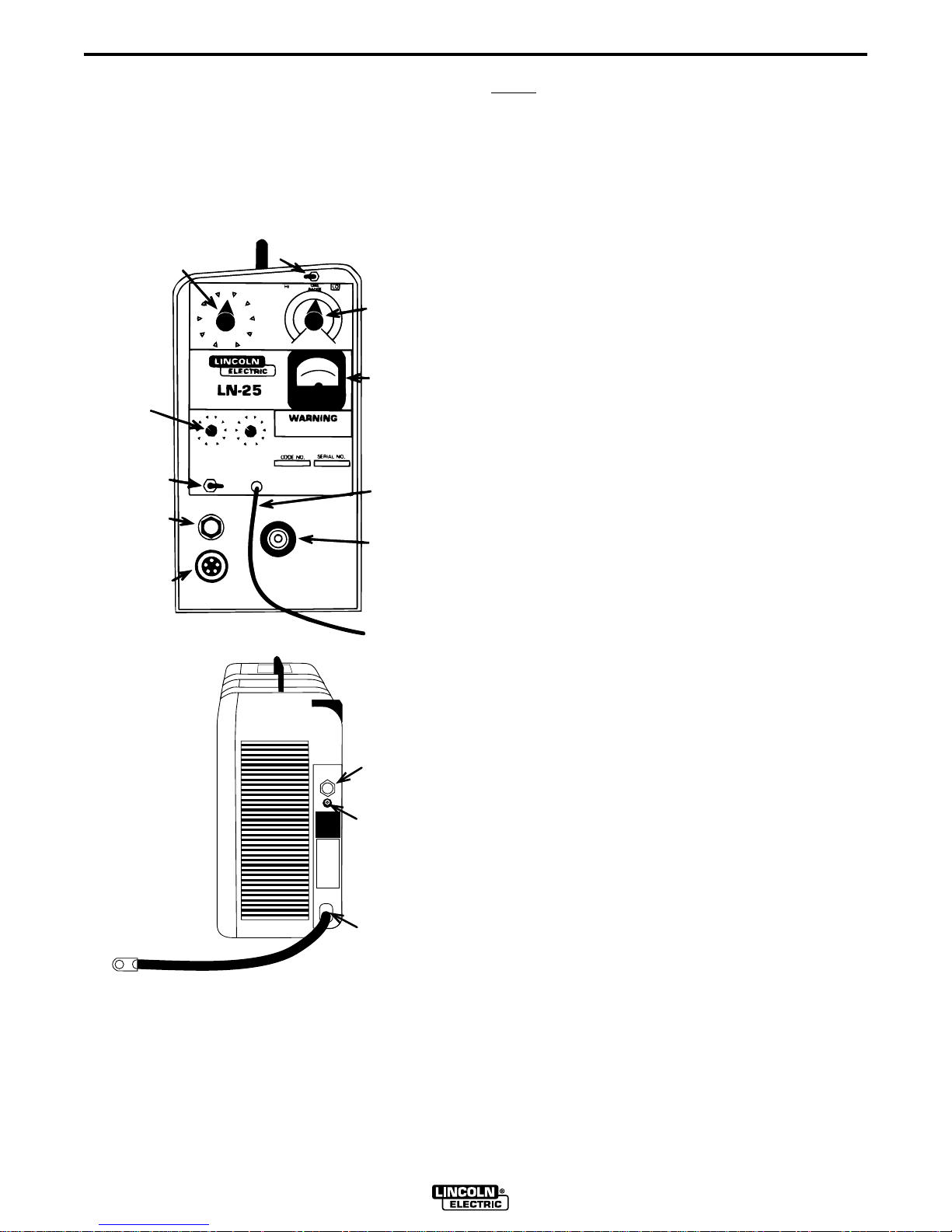

LN-25 INSTRUMENTS AND

CONTROLS

Refer to Figure B.1 for control locations.

FIGURE B.1 Ð CONTROL LOCATIONS.

REMOTE

ARC VOLTAGE

CONTROL

(OPTIONAL)

GAS POST/

PRE FLOW

TIMERS

(OPTIONAL)

ELECTRODE

POLARITY

SWITCH

GAS

FITTING

(OPTIONAL)

GUN

TRIGGER

AMPHENOL

CONNECTOR

WIRE SPEED

DIAL RANGE

SWITCH

WIRE

SPEED

DIAL

VOLT

METER

WORK CLIP

LEAD

GUN

CONNECTION

BLOCK

NOTE:

1. The Voltmeter will read zero if the LN-25 work clip

lead is not connected to work, even if the elec trode is electrically ÒhotÓ to work.

2. The Voltmeter will read below zero if the LN-25

polarity switch is not set to the same polarity as

the electrode.

3. The Voltmeter will read power source open circuit

voltage when the gun trigger is open, even if the

LN-25 is equipped with the internal contactor .

ÒELECTRODE POLARITYÓ SWITCH

The polarity switch is located on the front panel of the

LN-25 case.

Set the switch to the same polarity as the electrode

lead connection to the power source. If the switch is

not set for the correct polarity , the wire feeder will not

operate.

WIRE FEED MODE SWITCH

The CV-VV (CC) Wire Feed Mode switch is located

inside the LN-25 case. The toggle switch extends from

beneath the control box just above the wire drive.

The forward ÒCVÓ position provides constant wire feed

speed mode for use with constant voltage (CV)

welding power sources.

OPTIONAL

GAS INPUT

FITTING

GAS PURGE

BUTTON

ELECTRODE

CABLE

VOLTMETER

(Factory installed on model Codes above 9218)

The 40V DC analog voltmeter is mounted to the front

control panel of the LN-25 and is connected to read

the arc voltage between the LN-25 electrode cable

connection and the work clip lead.

The backward ÒVV (CC)Ó position provides arc-sensing

wire feed speed mode for use with constant current

(formerly variable voltage) welding power sources.

WIRE SPEED DIAL AND RANGE SWITCH

The Wire Speed control dial on the front panel of the

LN-25 has two calibrated dial ranges selected by the

HI-LO Dial Range switch.

When switched to the LO range position, the constant

wire feed speed (CV Wire Feed Mode) is set on the

inside (white) dial range calibrated for 50 to

350 in/min.

When switched to the HI range position, the constant

wire feed speed (CV Wire Feed Mode) is set on the

outside (black) dial range calibrated for 50 to

700 in/min.

The volts marks around the HI range calibrated dial

indicate the minimum arc volts required to obtain the

indicated HI range wire feed speeds. For example; if

wire speed is set to 400 in/min., a welding procedure

LN-25

OPERATION

B-4B-4

arc voltage of at least 17V would be required to obtain

the 400 in/min. wire feed speed.

WORK CLIP LEAD

WARNING

ELECTRIC SHOCK can kill.

• Do not touch metal portions

of the LN-25 lead clip when

welding power source is on.

WARNING

IMPORTANT SAFETY NOTE: To avoid possible

electrical shock, do not touch the metal portions of

the LN-25 work lead clip if the power source output is

on. The clip will be electrically “HOT” to work if the

input electrode cable to the LN-25 is electrically “HOT”

even if the gun trigger is off and even if an internal

contactor is used. Care should be taken to only handle

the LN-25 work clip by its non-metal insulated portions

and/or the welding power source should be turned off

before handling the work clip.

AWG Maximum Length

#14 25 Ft

#12 50 Ft

#10 100 Ft

#6 200 Ft

REMOTE ARC VOLTAGE CONTROL (OPTIONAL)

This rheostat control allows you to control the power

source output arc voltage level. Refer to K444, K444-1

and K444-2 Remote Voltage Kits in the Accessories

section.

GAS FITTING (OPTIONAL)

Provides gas output connection to the welding gun for

the GMAW process. Refer to K430-1 Gas Solenoid Kit

in the Accessories Section.

GAS POST PRE-FLOW TIMERS (OPTIONAL)

Allows for variable adjustment of gas pre-flow & postflow at the start and end of the weld. Refer to K4341 Gas Flow Timer Kit in Accessories Section.

The 15 ft work clip lead attached to the front panel of

the LN-25 case must be connected directly to the work

using the spring clip on the end of the lead.

If not connected, the LN-25 will not operate even if a

K431-1 or K624-1 (42V) Remote Output Control

option (refer to Accessories Section) is used.

However, the electrode will still be electrically “HOT”

when the clip lead is disconnected, if K431-1 or K6241 (42V) Remote Output Control Option, or Internal

Contactor (K443-1), is not used.

NOTE: The clip lead also serves as a work sensing

lead for the LN-25 Voltmeter. If the clip lead is

extended by the user beyond the standard 15 ft.

length, the voltmeter reading will be lower than the

actual arc volts due to the LN-25 motor control current flowing through the resistance of the extended

lead. To minimize this voltmeter error, the following

minimum lead size is recommended for the maximum

extended lengths shown:

LN-25

OPERATION

B-5B-5

SEQUENCE OF OPERATION

LOADING ELECTRODE

WARNING

ELECTRIC SHOCK can kill.

•Unless an optional output

control or internal contactor is

used with the LN-25, the

electrode circuit is electrically

“Hot” when the power source

is on.

• Turn off the power source

while mounting electrode

coils.

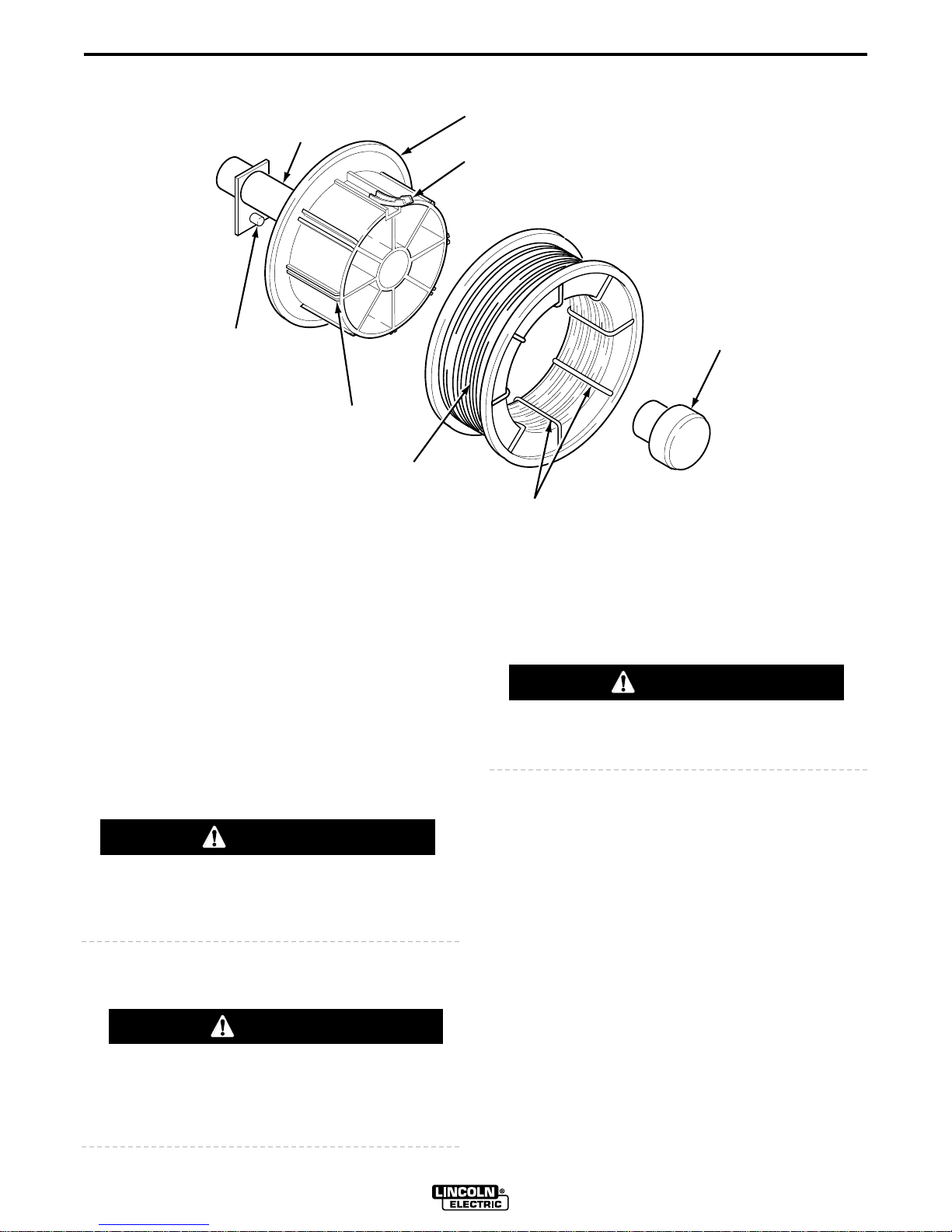

MOUNTING 22 TO 30 LB READI-REEL®COILS

The LN-25 is factory equipped with a K363-P ReadiReel®Adapter which is required to load Lincoln 22 to

30 lb Readi-Reel coils.

a. Make certain that the threaded locking collar is

tight and securely locks the adapter on the

spindle (see figure B.2).

b. Rotate the spindle and adapter so the retaining

spring is at the 12 o’clock position.

c. Position the Readi-Reel so that it will rotate in a

clockwise direction when feeding (wire is to be

dereeled from bottom of the coil).

d. Set one of the Readi-Reel inside cage wires on

the slot in the retaining spring tab.

e. Lower the Readi-Reel to depress the retaining

spring and align the other inside cage wires with

the grooves in the molded adapter.

f. Slide cage all the way onto the adapter until the

retaining spring “pops up” fully.

g. To remove Readi-Reel from Adapter, depress re-

taining spring tab with thumb while pulling the

Readi-Reel cage from the molded adapter with

both hands. It is not necessary to remove adapter

from spindle.

h. Load wire into wire drive per Loading Wire Drive

Section.

MOUNTING 10 TO 30 LB SPOOLS

For 12" Diameter Spools:

a. Remove the locking collar and the Readi-Reel

adapter shipped on the 2" diameter spindle

(adapter is not required).

b. Place the spool on the spindle so the brake

holding pin enters one of the holes in the back

side of the spool. Be sure the wire comes off the

spool in a clockwise direction when dereeled from

the bottom of the coil.

c. Replace and tighten the locking collar.

d. See Loading Wire Drive section for loading

instructions.

For 8" Diameter Spools (Requires optional K468

Spindle Adapter for 8" Spools):

a. Remove the locking collar and the Readi-Reel

adapter shipped on the 2" diameter spindle

(adapter is not required).

b. Slide S18221 Spindle Adapter onto the 2" spindle

so the brake holding pin enters the adapter pin

hole.

c. Place the spool on the spindle so the adapter tab

enters one of the holes in the back side of the

spool. Be sure the wire comes off the spool in a

clockwise direction when dereeled from the

bottom of the coil.

d. Replace and tighten the Locking Collar.

WARNING

Check to be sure the retaining spring has fully

returned to the locking position and has securely

locked the Readi-Reel cage in place. Retaining spring

must rest on the cage, not the welding electrode.

e. Load wire into wire drive per Loading Wire Drive

Section.

MOUNTING 13 OR 14 LB INNERSHIELD COILS

(Requires Optional K435 Spindle Adapter for 14 lb

Coils.)

a. Remove the locking collar and the Readi-Reel

adapter shipped on the 2" diameter spindle

(adapter is not required).

b. Mount K435 Spindle Adapter and Innershield coil

per the Instructions (S18256) included with the

K435.

LN-25

OPERATION

FIGURE B.2 Ð READI-REEL INSTALLATION.

B-6B-6

2" O.D.

SPINDLE

BRAKE HOLDING PIN

(MUST ENGAGE HOLE

IN ADAPTER RIB)

LOADING WIRE DRIVE

MOLDED ADAPTER

RETAINING

SPRING

THREAD LOCKING

COLLAR

GROOVES

READI-REEL

INSIDE CAGE

WIRES

f. Inch the electrode through the gun.

a. Turn the reel or spool until the free end of the

electrode is accessible.

b. While tightly holding the electrode, cut of f the bent

end and straighten the first six inches. Cut of f the

first inch. (If the electrode is not properly

straightened, it may not feed or may not go into

the outgoing guide tube causing a ÒbirdnestÓ.)

c. Insert the free end through the incoming guide

tube to the drive roll.

d. Turn on the welding power source.

WARNING

Unless an optional output control or internal contactor

is used with the LN-25, the electrode circuit is

electrically ÒhotÓ when the power source is on.

e. Press the gun trigger and push the electrode until

it just enters the drive roll.

WARNING

When inching with gun trigger , the electrode and drive

mechanism are always ÒhotÓ to work and ground. Use

the ÒcoldÓ inch switch on models with internal

contactor .

g. Adjust the brake tension with the thumbscrew on

the spindle hub until the reel turns freely , but with

little or no overrun when wire feeding is stopped.

Do not overtighten.

CAUTION

Keep gun in LN-25 gun holder when not feeding wire

to prevent accidental arcing.

IDLE ROLL PRESSURE SETTING

The idle roll pressure is set at the factory backed out

two turns from full pressure. This is an approximate

setting. For small wire sizes and aluminum wire, the

optimum idle roll pressure varies with type of wire,

surface condition, lubrication and hardness. The optimum idle roll setting can be determined as follows:

1. Press end of gun against a solid object that is

electrically isolated from the welder output. Press

the gun trigger for several seconds.

2. If the wire Òbirdnests,Ó jams or breaks at the drive

roll, the idle roll pressure is too great. Back the

pressure setting out 1Ú2 turn, run new wire through

gun, and repeat above steps.

3. If the only result is drive roll slippage, shut of f the

power source, then loosen the gun cable clamping

LN-25

OPERATION

B-7B-7

screw in the gearbox conductor block and pull the

gun cable forward about six inches. There should

be a slight waviness in the exposed wire. If there

is no waviness, the pressure is too low . Increase

the pressure setting 1Ú4 turn, lock the gun cable in

place and repeat the above steps.

PRESETTING WIRE FEED SPEED

The LN-25 permits accurate presetting of the desired

wire feed speed, before welding, in both CV and CC

wire feed modes.

SETTING CONSTANT WIRE FEED SPEED (CV

MODE)

a. Set Wire Feed Mode switch to CV position.

b. Set Dial Range switch to LO position for wire feed

speeds up to 350 in/min., or HI position for wire

feed speeds over 350 in/min.

c. Set Wire Feed dial to the desired wire feed speed

on the selected calibrated dial range.

The wire speed will remain constant at the value set,

independent of arc voltage changes, as long as the

arc voltage does not drop below the value per the

chart below for the max. wire feed speed shown:

Maximum Speed Minimum Arc Volts

350 IPM 15V

400 IPM 17V

500 IPM 21V

600 IPM 24V

700 IPM 27V

SETTING ARC SENSING WIRE FEED SPEED

(CC MODE)

When using a constant current (formerly variable

voltage) power source, welding performance is im proved using arc sensing wire feed speed (CC [VV]

mode). In this wire feed mode the wire speed

increases if arc voltage increases, and decreases if

arc voltage decreases, but remains constant at any

specific voltage level.

The LN-25 permits accurate CC mode presetting of

the desired wire feed speed, for the desired arc

voltage to be used, by setting the Wire Speed dial in

the following manner before welding:

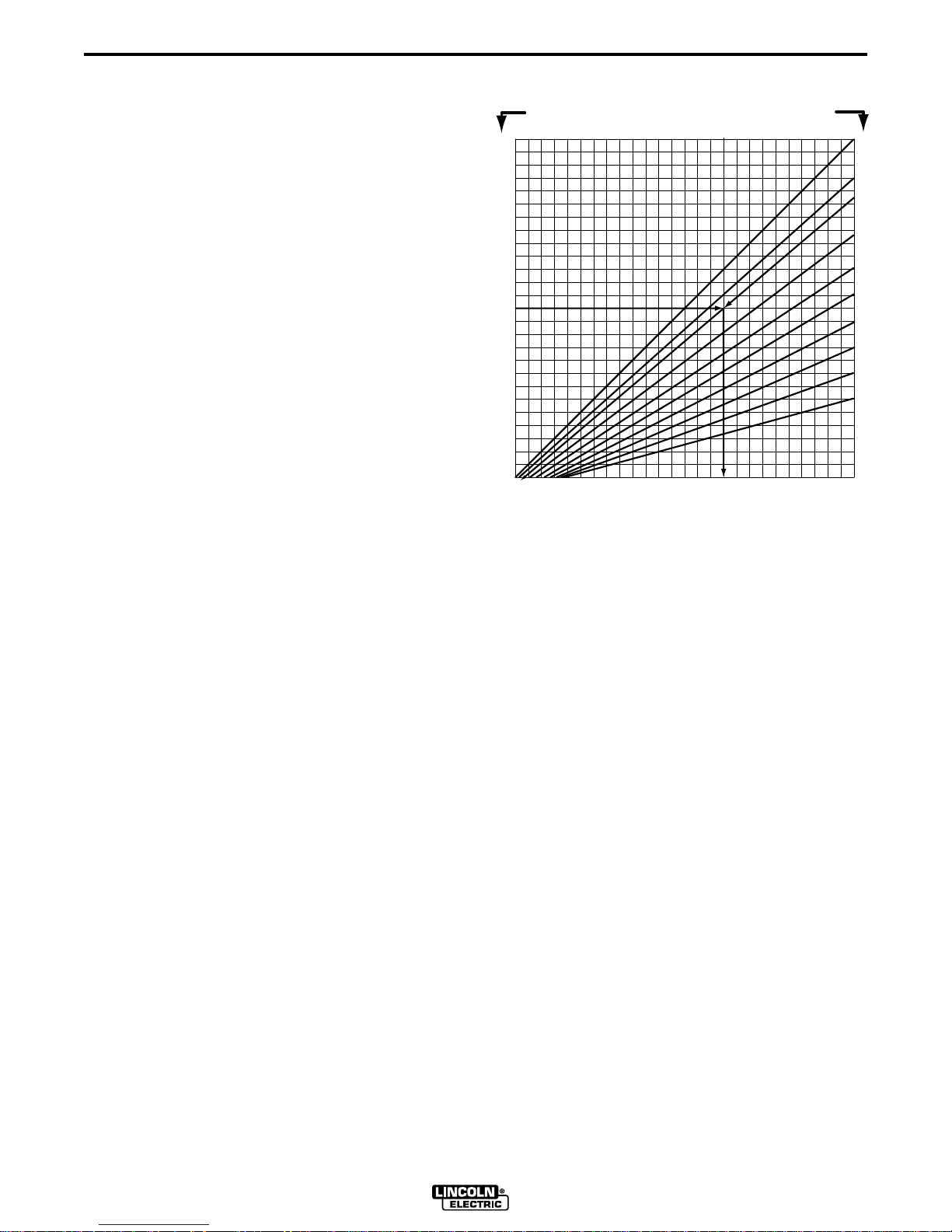

FIGURE B.3 Ð CC WIRE SPEED SETTING.

DESIRED IN/MIN ARC VOLTS USED

700

650

600

550

500

450

400

350

300

250

200

150

100

50

50 100 150 200 250 300 350 400 450 500 550 600 650 700

35

31

29

27

25

23

21

19

17

15

CC Wire Speed Setting

(Hl or LO Range)

b. Referring to the graph located above the Mode

switch (also shown in Figure B.3):

1. Select the horizontal line representing the DESIRED IN/MIN. for the welding procedure. (See

example arrow line for 375 in/min.)

2. Select the diagonal line representing the ARC

VOLTS to be used for the welding procedure.

(See example arrow line for 29 volts.)

3. Determine the vertical line representing the CC

WIRE SPEED SETTING where the above two

lines cross. (See example arrow line for 450.)

c. Set the Wire Speed dial to the value determined

in Step (3) above (450 for example used). Use HI

Dial Range if value to be set is over 350.

The wire will feed at the DESIRED IN/MIN speed

when the welding power source is set to the arc

voltage to be used for the weld procedure (375 in/min.

at 29V for example used).

A chart representation of the CC wire speed setting

graph is shown in Figure B.4, giving the Wire Speed

dial setting required for the DESIRED IN/MIN and ARC

VOLTS used for the welding procedures:

a. Set Wire Feed Mode switch to CC position.

LN-25

OPERATION

B-8B-8

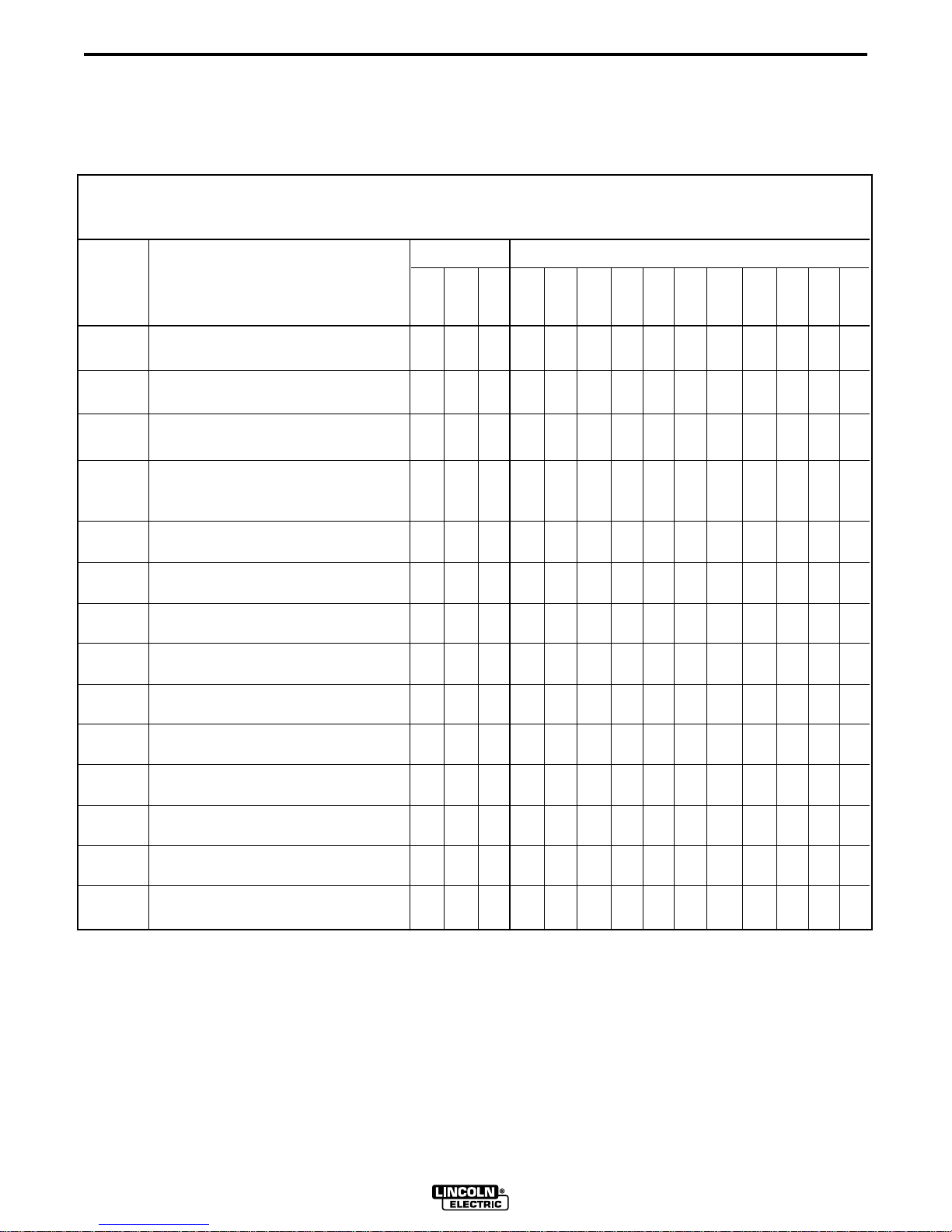

FIGURE B.4 Ð CC WIRESPEED SETTING.

Arc Volts Used

Desired

In/Min 16 18 20 22 24 26 28 30 32 34

50 109 97 88 80 73 67 63 58 55 51

60 131 117 105 95 88 81 75 70 66 62

70 153 136 123 111 102 94 88 82 77 72

80 175 156 140 127 117 108 100 93 88 82

90 197 175 158 143 131 121 113 105 98 93

100 219 194 175 159 146 135 125 117 109 103

110 241 214 193 175 160 148 138 128 120 113

120 263 233 210 191 175 162 150 140 131 124

130 284 253 228 207 190 175 163 152 142 134

140 306 272 245 223 204 188 175 163 153 144

150 328 292 263 239 219 202 188 175 164 154

160 350 311 280 255 233 215 200 187 175 165

170 372 331 298 270 248 229 213 198 186 175

180 394 350 315 286 263 242 225 210 197 185

190 416 369 333 302 277 256 238 222 208 196

200 438 389 350 318 292 269 250 233 219 206

210 459 408 368 334 306 283 263 245 230 216

220 481 428 385 350 321 296 275 257 241 226

230 503 447 403 366 335 310 288 268 252 237

240 525 467 420 382 350 323 300 280 263 247

250 547 486 438 398 365 337 313 292 273 257

260 569 506 455 414 379 350 325 303 284 268

270 591 525 473 430 394 365 338 315 295 278

280 613 544 490 445 408 377 350 327 306 288

290 634 564 508 461 423 390 363 338 317 299

MAKING A WELD

SETUP

a. Connect work cable to metal to be welded. W ork

cable must make good electrical contact to the

work. The work must also be grounded as stated

in ÒArc Welding Safety Precautions.Ó

b. Check that the LN-25 is properly connected to the

power source for the polarity and process to be

used, and appropriate power source settings are

made for the procedure to be used. (Refer to

power source operating and connection

instructions.)

NOTE

: If the K431-1 Remote Output Control Kit or

K624-1 42V Remote Control Module is installed but

the LN-25 is to be used without the Remote Control

Cable Assembly , then the Remote Board harness plug

must be removed from the 16-pin receptacle on the

Control Board and the jumper plug (T13498-21)

reinstalled.

c. Place the LN-25 conveniently near the work area

in a location to minimize exposure to weld spatter

and to avoid sharp bends in the gun cable.

d. Connect the LN-25 Clip Lead to work and set Po -

larity Switch to same polarity as electrode.

300 656 583 525 477 438 404 375 350 328 309

310 678 603 543 493 452 417 388 362 339 319

320 700 622 560 509 467 431 400 373 350 329

330 642 578 525 481 444 413 385 361 340

340 661 595 541 496 458 425 397 372 350

350 681 613 557 510 471 438 408 383 360

360 700 630 572 526 484 450 420 394 370

380 666 604 554 512 472 444 416 392

400 700 636 584 538 500 466 438 412

420 668 612 566 526 490 460 432

440 700 642 592 550 514 482 452

460 670 620 576 536 504 472

480 700 646 600 560 526 494

500 674 626 584 546 514

520 700 650 606 568 536

540 676 630 590 556

560 700 654 612 576

580 676 634 598

600 700 656 618

620 678 638

640 700 658

660 680

680 700

700

CC Speed Setting =

Desired IPM

X 35

Arc Volts

e. Set WIRE FEED MODE switch to CV or VV (CC),

as appropriate for the power source, then set the

proper DIAL RANGE and WIRE SPEED dial setting for the proper wire feed speed per the

welding procedure:

For CV: Set dial to the calibrated IN/MIN desired.

(Refer to Setting Constant Wire Feed Speed

Section.)

For CC: Set dial to value determined from the CC

Wire Speed Graph for the DESIRED IN/ MIN

and ARC VOLTS to be used. (Refer to Setting

Arc Sensing Wire Feed Speed Section.)

NOTE: If procedure permits a range of acceptable

arc voltage, use the middle of the range to

determine proper WIRE SPEED setting.

f. If using the optional Gas Flow Timer, set the de-

sired PREFLOW TIME and POSTFLOW TIME.

g. Be sure the proper contact tip for the wire size

being used is in the gun, and the gun is safe

from work contact. (Use the LN-25 insulated

gun holder .)

LN-25

OPERATION

B-9B-9

h. Turn on the welding power source, as well as the

shielding gas supply (if used).

WARNING

Unless an optional output control or internal contactor

is used, the electrode is electrically “hot” when the

power source is on. The gun trigger controls wire

feed only.

WARNING

CYLINDER may explode if

damaged.

•Keep cylinder upright and

chained to support.

•Keep cylinder away from

areas where it may be damaged.

•Never lift welder with cylinder

attached

•Never allow welding electrode to touch cylinder.

•Keep cylinder away from

welding or other live electrical

circuits.

WELDING

WARNING

ARC RAYS can burn.

c. Lower welding helmet, close gun trigger, and

begin welding. Hold the gun so the contact tip to

work distance gives the correct electrical stickout

as required for the procedure being used.

NOTE: If the arc voltage is not within the proper

procedure range adjust the power source output

control. (The CC mode WIRE SPEED setting should

not be changed from the preset procedure value for

the proper arc voltage.)

d. To stop welding, release the gun trigger and

then pull the gun away from the work. Store the

gun in the LN-25 insulated gun holder when

not welding.

PROCEDURE AT END OF COIL

When the wire on the reel is used up, the following

procedure is to be followed for removing the old wire

from the gun cable and loading a new reel.

a. Shut off power source if a Remote Output Control

Option or internal contactor is not used.

b. Cut the end of the electrode off at the gun end.

Do not break it off by hand since this puts a slight

bend in the wire and makes it difficult or

impossible to pull it back through the nozzle.

c. Uncouple the gun conductor cable from

the LN-25.

d. Lay the cable out straight.

e. Using pliers to grip the wire, pull it out of the

cable from the connector end. Do not pull it from

the gun end.

f. Put the conductor cable back on wire drive unit

after the electrode has been removed.

g. Load a new coil of wire and feed it through the

cable as described in Loading Electrode Section.

•Do not touch metal portions

of the LN-25 lead Clip when

welding power source is on.

a. Cut the electrode within approximately 3⁄8" of the

end of the contact tip for solid wire and within

approximately 3⁄4" of the extension guide for cored

wire.

b. Position electrode over joint. End of electrode

should be slightly off the work.

OPEN ARC WELDING WITH A

CONSTANT CURRENT (formerly

variable voltage) POWER

SOURCE

Although a constant voltage (CV) power source

is recommended for Innershield®and gas metal

arc (GMAW) open arc welding, satisfactory general

purpose welding may be obtained using the

LN-25 with a constant current (CC) power source

for noncritical commercial quality mild steel

welding applications.

LN-25

OPERATION

CAUTION

Do not use LN-25 models below Code 9200 with any

TIG or Square Wave welding power sources. Do not

use LN-25 models equipped with internal contactors

with non-Lincoln TIG or Square Wave welding power

sources. Damage to the LN-25 circuit can occur as

a result of the high output inductance typically

associated with these power sources. TIG high

frequency power should never be applied to the

LN-25.

While welding with a continuously fed electrode, weld

current variations are continuously taking place. There

are many causes for these variations, but

predominantly they occur due to changes in electrical

stickout (operator hand movements, nozzle tip contact

variations, etc.) and the dynamic metal transfer

characteristics of the process or procedure being

used (short arc, globular transfer, etc.).

When using a CV power source, these current

variations have essentially no effect on the welding

arc stability since CV power sources can provide a

wide range of weld current levels with virtually no

change in average arc voltage. These “flat slope” CV

power sources, therefore, provide the arc power

required to produce the best welding characteristics

and ease of operation for most open arc, constant

wire feed speed, welding processes.

CC (formerly VV) power sources, on the other hand,

permit the arc voltage to decrease with increases in

welding current. The output characteristics of these

power sources can range from a “drooping slope,”

which provide minor arc voltage changes with weld

current variations, to “steep slope” which provide

broad voltage changes with only minor current

variations. The steeper the slope the more difficult it

becomes to maintain arc voltage stability with a

constant wire speed open arc process.

B-10B-10

Arc shorting is more difficult to avoid when using

a CC power source, and requires a more refined

operator technique than when using a CV power

source. Improved performance can be obtained

on CC power source applications within the

following guidelines:

1. Flatter slope power sources with higher arc force

(short circuit current) will improve performance

over steep slope machines. The steeper the

slope, the more critical it is to hold proper

electrode stickout to maintain arc stability.

Welding techniques, such as weaving, will be

more difficult to control. Use the highest output

current tap or setting capable of providing the

voltage adjustment required for the procedure.

2. Use spray or non-shorting small ball type transfer

processes at higher procedure voltage levels.

Generally, open arc processes with procedure

voltage levels over 22 volts perform satisfactorily.

Arc stability at procedure voltage levels below 22

volts may be more difficult to control, with the

general exception of fine (.023–.035) solid steel

electrodes with Argon-rich shielding gas or NR-152

and NR-211 Innershield.

AUTOMATIC PROTECTION

SHUTDOWN

The LN-25 control provides automatic electronic

protection circuits which shut down the LN-25 for

excessively high power source open circuit voltage or

excessive motor overload.

OVERVOLTAGE SHUTDOWN

If the power source open circuit voltage exceeds about

110-120 volts, the LN-25 will not operate until the

power source voltage drops below about 102-110

volts.

To aid in stabilizing the arc voltage when welding on

CC power sources the LN-25 is provided with a CC

wire feed mode. This arc voltage sensing feed mode

decreases (or increases) the wire speed when the arc

voltage decreases (or increases). However, if the

electrode shorts to the work, the arc voltage will

essentially drop to zero and the short circuit current

supplied by the CC power source may not provide

enough power to re-establish the arc (especially with

steeper slope machines). Under this condition the

LN-25 feeder will stop, as if the trigger was released,

and not restart until the short has been opened.

MOTOR OVERLOAD SHUTDOWN

If excessive motor overload occurs (due to prolonged

excessive feeding force, jammed drive rolls or shorted

motor leads), the LN-25 will shut down within a few

seconds after the overload occurs.

The shutdown will reset automatically when the gun

trigger is released, but will reoccur if the overload

situation is not remedied.

LN-25

TABLE OF CONTENTS

- ACCESSORIES SECTION -

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section C

LN-25 Option Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

K430-1 Gas Solenoid Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

K434-1 Gas Flow Timer Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

K443-1 LN-25 Contactor Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Remote Output Control Options and Control Cable Assemblies . . . . . . C-4

K431-1 Remote Output Control Kit . . . . . . . . . . . . . . . . . . . . . . . . . C-4

K433 Power Source Remote Box . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

K432 Remote Control Cable Assembly . . . . . . . . . . . . . . . . . . . . . . C-4

K439 Remote Extension Cable Assembly . . . . . . . . . . . . . . . . . . . . C-5

K624-1 42V Remote Output Control Module . . . . . . . . . . . . . . . . . . C-5

K625, K626, K627 Remote Control Cable Assembly . . . . . . . . . . . . C-5

K444, K444-1 or K444-2 Remote V oltage Control Kit . . . . . . . . . . . C-5

K557-1 Rear Handle Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Section CSection C

LN-25

ACCESSORIES

C-2C-2

How to use Table C.1.

Determine which Kit No. is to be used. Locate that Kit No. in the left hand vertical column.

Scan horizontally to determine which LN-25 model is required and what additional kits may be required.

TABLE C.1

LN-25 OPTION CHART

O=CANNOT BE USED WITH X = REQUIRED ➀ = REQUIRES ONE OF THESE + = INCLUDED WITH

LN-25 MODELS LN-25 KITS

SEE TEXT

KIT NO.

K430-1

K431-1

K432

K433

K434-1

K439

K443-1

K444

K444-1

K444-2

K-624-1

K625

K626

K627

Solenoid

Kit

Remote Output

Control Module

Remote

Control Cable

115VAC

Power Source

Remote Box

Gas Flow

Timer Kit

50 Ft.

Ext. Cable

Contactor

Kit

Remote for Power

Source w/T erminal Strip

Remote for Power

Source w/6 Pin Amphenol

Remote for Power

Source w/14 Pin Amphenol

42VAC Remote

Output Control Module

500 Amp Cable /w Stud-

Type Output Terminals

350 Amp Cable /w Stud-

Type Output Terminals

400 Amp Cable /w Twist-

Mate Type Terminals

K428

LN-25

K446

LN-25

++

X

➀➀ OXXOOOOO

K431-1

K432

K433

K443-1

K444

K444-1

K449

LN-25

XX

XX

➀➀ ➀ ➀

X

K444-2

K624-1

K626

K625

+ OO

➀➀➀ OO

➀➀➀ OO

➀➀➀ OO

➀➀ OO OOOO ➀➀➀

X

X

X

K627

IMPORTANT SAFETY NOTE: This wire feeder provides ÒCOLDÓ electrode when gun trigger is released if

equipped with K431-1 or K624-1 remote output control system, or K443-1 internal contactor kit. This feature

and the use of a DC Constant V oltage welder provide an added margin of safety when welding must be

performed under electrically hazardous conditions such as:

¥ Damp locations ¥ While wearing wet clothing ¥ On metal structures, or , ¥ In cramped positions (sitting, kneeling

or lying) if there is a high risk of unavoidable or accidental contact with the workpiece or ground.

LN-25

OPTIONAL ACCESSORIES

ACCESSORIES

C-3C-3

WARNING

ELECTRIC SHOCK can kill.

•Do not operate with covers

removed.

• Turn off power source before

installing or servicing.

• Do not touch electrically hot

parts.

•Turn the input power to the

welding power source off at

the fuse box before working in

the terminal strip.

•Only qualified personnel

should install, use or service

this equipment.

K430-1 GAS SOLENOID KIT

(Factory Installed on K446 and K449 Models)

The kit permits the LN-25 to be used for Gas Metal

Arc Welding (GMAW) processes with a GMA gun

cable.

The kit can be used with or without a Remote Output

Control option installed in the LN-25 and provides flow

of shielding gas:

1. With wire feed, when the gun trigger is closed.

2. Without wire feed, when the kit’s Purge button

(located beneath the gas inlet fitting) is pressed.

WARNING

CYLINDER may explode if

damaged.

•Keep cylinder upright and

chained to support.

•Keep cylinder away from

areas where it may be damaged.

•Never lift welder with cylinder

attached.

•Never allow welding electrode

to touch cylinder.

•Keep cylinder away trom

welding or other live electrical

circuits.

See GMA Gun Cable Gas Connection.

Installation instructions (M17587) are included with the

kit.

K434-1 GAS FLOW TIMER KIT

(Requires either a K431-1 Remote Output Control Kit,

K624-1 42V Remote Output Control Kit, or internal

contactor K443-1 installed in LN-25).

The K434-1 Gas Flow Timer Kit is used with the

LN-25 Gas Solenoid when the LN-25 is equipped

with any of the Remote Output Control Options or

internal contactor.

NOTE: Always shut off the valve at the gas cylinder

before making any gas connections to the LN-25.

User must provide a supply of shielding gas, a pressure regulator, a flow control valve and a hose from

the flow valve to the gas inlet fitting of the LN-25.

Install by connecting a supply hose from the gas flow

valve outlet to the 5⁄8-18 female inert gas fitting on the

back panel of the LN-25 case.

WARNING

See American National Standard Z-49.1, “Safety in

Welding and Cutting” published by the American

Welding Society.

This kit provides the following gas flow

timer functions:

1. Preflow Control - Provides flow of shielding

gas to the work before the arc is established.

The solenoid valve is energized immediately

when the gun trigger is closed, but the time

delay before the wire feeder and welding output

are energized is adjustable between at least

0 to 1 second.

2. Postflow Control - Provides flow of shielding gas

to the work after welding is stopped. Delay of the

shut off of the solenoid valve after the gun trigger

is released is adjustable between at least 0.5 to

5 seconds.

Installation instructions (M17590) are included with

this kit.

LN-25

ACCESSORIES

C-4C-4

K443-1 LN-25 CONTACTOR KIT

(Factory installed in K449 Model.)

The internal contactor provides “cold” electrode until

the gun trigger is pressed, and a fixed burnback time

delay to prevent electrode from sticking in the weld

crater when the trigger is released. The contactor is

rated for use up to 300 amps. A cold inch switch

allows the wire to be loaded into the system without

being electrically “hot”.

Installation Instructions (L9676) are included with

the kit.

CAUTION

This kit can only be used with LN-25’s above Code

9200 or with LN-25’s equipped with a G1757-3 (or

higher part number) Control PC board. To prevent

possible damage to the LN-25 with internal contactor,

do not connect to non-Lincoln TIG or Square Wave

power sources. TIG high frequency power should

never be applied to the LN-25.

The Kit includes a Remote PC board and control

cable receptacle which mount and connect inside the

LN-25 control box per the Installation Instructions

(M17584) included with the kit.

NOTE: If the K431-1 Remote Output Control Kit is

installed but the LN-25 is to be used without the K432

Remote Control Cable Assembly, then the Remote

Board harness plug must be removed from the 12pin receptacle on the Control Board and the jumper

plug (T13498-21) reinstalled.

K433 POWER SOURCE REMOTE BOX

(Requires K431-1 Remote Output Control Kit installed

in LN-25 using K432 Remote Control Cable.)

The Remote Box is designed to mount and connect

to Lincoln Idealarc®semiautomatic power sources per

the Installation Instructions (M15324) and power

source connection diagrams included with the kit.

The Remote Box provides the proper welding power

source control interface and isolated 24V AC input

supply for the LN-25 equipped with the K431-1

Remote Output Control Kit.

NOTE: The K443-1 cannot be used with K431-1 or

K624-1 Remote Output Control Kit. If remote voltage

control is desired along with the internal contactor,

obtain a K444, K444-1 or K444-2 Remote Voltage

Control Kit.

REMOTE OUTPUT CONTROL

OPTIONS AND CONTROL CABLE

ASSEMBLIES

Remote Output Control Options are available to provide the LN-25 with the following additional features:

1. “Cold” electrode until the gun trigger is pressed,

and a fixed burnback time delay to prevent electrode from sticking in the weld crater when the

gun trigger is released.

2. Remote (10K ohm rheostat) control of power

source output arc voltage level.

K431-1 REMOTE OUTPUT CONTROL

KIT

(For use with K432 Remote Control Cable and K433

Power Source Remote Box.)

Remote Box requires 115V AC, 50/60 Hz input and a

welding power source using a contact closure output

pilot circuit, as available on appropriate Lincoln welding power sources.

K432 REMOTE CONTROL CABLE

ASSEMBLY

(Requires K431-1 Remote Output Control Kit installed

in LN-25 and K433 Remote Box mounted to power

source with 115V AC auxiliary power.)

The K432 control cable assemblies include an electrode cable, rated for up to 500 amps 60% duty cycle,

and a 6-conductor control cable with pin connectors

on both ends. Available in 25, 50, 75 and 100 ft.

lengths.

The cable assembly end with the socket pin connector

connects to the LN-25 per the Instructions (M17584)

included with the K431-1 kit.

The cable assembly end with the male pin connector

connects to the K433 and power source per the Instructions included with the K433 kit.

LN-25

Loading...

Loading...