Page 1

Description

Output

MIG Flux-Cored

LN-25 Wire Feeder

Portable, Construction Wire Feeder

The LN-25 semiautomatic wire feeder is ideal for field or construction use. Since it is

powered across the arc, no control cables are needed! Simply connect the weld cable,

attach the arc sensing clip, and you’re ready to go. This portable MIG and flux-cored wire

feeder comes in a fully enclosed case to protect against damage on the job site. The

LN-25 features a tool-less quick release mechanism for easy wire changing, and it

accepts 10-44 lbs. (4.5-19.9 kg) wire packages for plenty of welding versatility.

Processes

Advantage Lincoln

Required Options

Order

TECHNICAL SPECIFICATIONS

Recommended General Options

• For MIG and flux-cored arc welding processes using up to

44 lb. (19.9 kg) spools.

• Designed for .023-1/16" (0.6-1.6mm) solid, .035-5/64"

(0.9-2.0mm) cored and .035-1/16" (0.9-1.6mm) aluminum wire

sizes.

• Selectable dial for setting low range, 50-350 ipm (1.3-8.9m/min)

wire feed speed or high range, 50-700 ipm (1.3-17.8m/min) wire

feed speed.

• Includes DC voltmeter, voltmeter polarity switch and 15 ft.

(4.6m) arc sensing lead and clip and 20" (508mm) weld power

cable.

• For use with Magnum® flux-cored and MIG guns.

• Automatic overvoltage and motor overload shutdown

protection.

• Double-latched case features an insulated gun holder and easy

access to wire.

• Entire unit is compact and portable and will pass through a

16" (400mm) diameter manway.

• Manufactured under a quality system certified to ISO 9001

requirements.

• Three-year warranty on parts and labor.

Recommended Power Source Options

SEMIAUTOMATIC WIRE FEEDERS

Gun and Cable Assembly, Drive Roll Kit, Weld Power Cable, Cable

Lug, Twist-Mate Cable Plug

Base Unit Includes

Arc Sensing Lead & Clip,15 ft. (4.5m), Weld Power Cable, 20" (508mm)

K428 LN-25 Wire Feeder

K449 LN-25 Wire Feeder with Internal Contactor

and Gas Solenoid

Jumper Plug Kit, Remote Voltage and Output Control Kits, Gas

Solenoid Kit, Internal Contactor Kit, Gas Flow Timer Kit, 30 lb.

Adapter, Spindle Adapter

All Lincoln Engine Driven or Electric Welders with CV Capability

Wire Feed Wire Size Range Dimensions Net

Product Product Input Rated Output Speed Range in. (mm) H x W x D Weight

Name Number Power Current / Duty Cycle ipm (m/min.) Solid Aluminum Cored in. (mm) lbs. (kg)

K428 15-40V DC Up to 500A / 60%

28

LN-25 (110V DC 50 - 700 .023 - 1/16" .035 - 1/16" .035 - 5/64" 14 x 7.4 x 21

(12.7)

Across-The-Arc Max. OCV) (1.2 - 17.7) .(0.6 - 1.6) (0.9 - 1.6) (0.9 - 2.0) (356 x 188 x 533)

K449 Up to 300A / 60% 35

(15.4)

Publication E8.100 11/03

www.lincolnelectric.com

Page 2

[2]

A CLOSER LOOK

LN-25 Wire Feeder

www.lincolnelectric.com

PERFORMANCE

• 2-roll wire drive system for easy wire feeding.

• The LN-25 provides constant wire feed speed for use with

constant voltage (CV) power sources, and arc sensing wire

feed speed for use with constant current (CC) power sources

(1)

.

• Dynamic braking system stops wire feed motor quickly to

minimize crater sticking problems.

(1) Most semiautomatic wire welding processes perform better using CV power sources.

Be sure the proper power source is used for your application. Contactor life may be

shortened in applications using CC power sources with high OCV.

QUALITY AND RELIABILITY

• Fully enclosed molded case meets UL94-VO flammability

resistance and is heat, spatter, and impact resistant.

• Automatic overvoltage and motor overload shutdown protection.

• Three-year warranty on parts and labor.

• Manufactured under a quality system certified to ISO 9001

requirements.

• CSA approved.

FEATURES

• Tool-less quick release wire drive tension system and gun cable

connections for easy wire or gun changes.

• Optional gas solenoid, timer kit for preflow and postflow of gas,

internal contactor, and remote voltage control kits are available.

• Standard Voltmeter

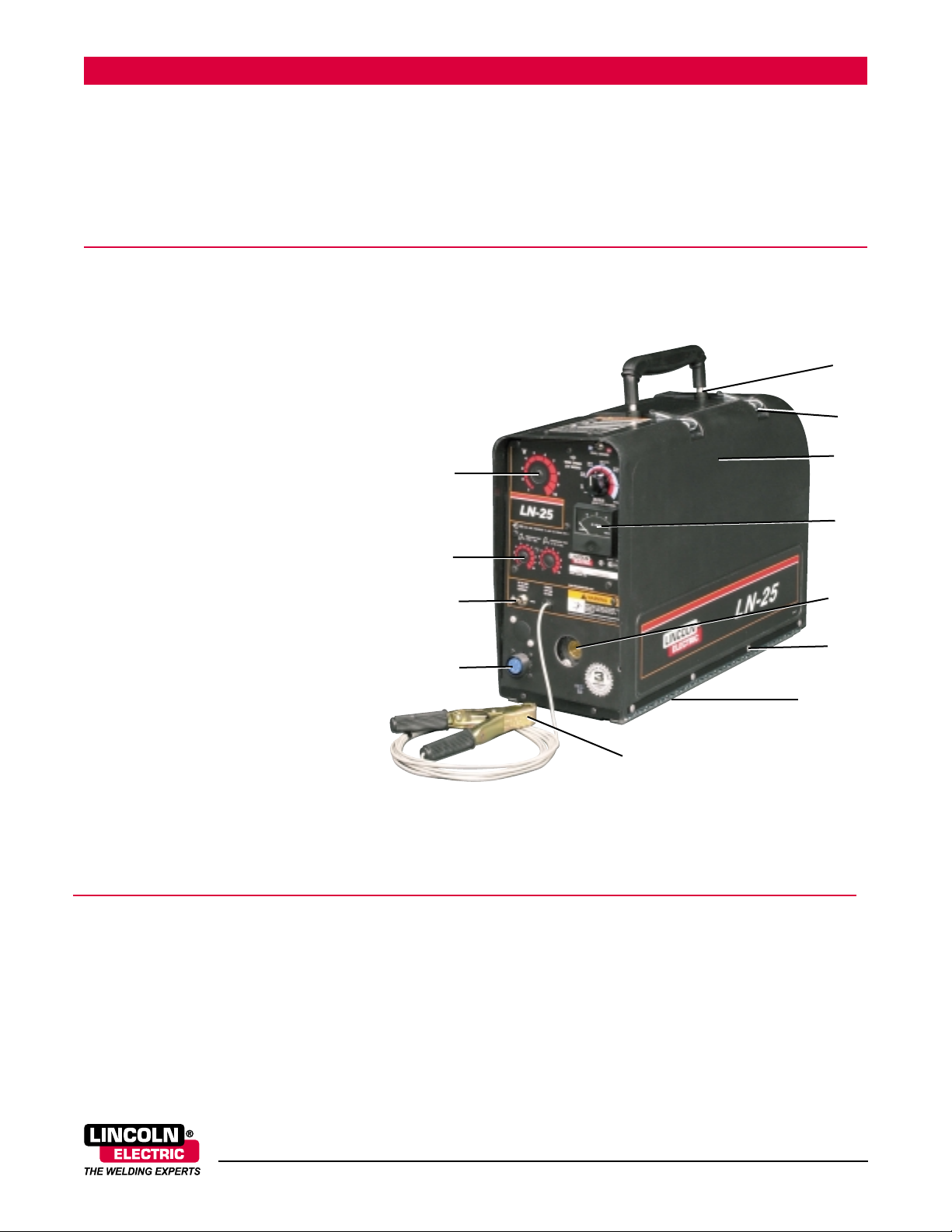

1

12

10

2

3

4

11

9

7

8

5

Key Controls

1. Optional Remote Voltage Control

2. Optional Gas Timer Flow Kit

3. Voltmeter Polarity Switch

4. Trigger Connection

5. Arc Sensing Lead and Clip

6. Skid Plate

7. Riveted Door and Hinge Assembly

8. Gun and Cable Connection

9. Voltmeter

10. Molded Case Door

11. Case Latches

12. Fold Down Carrying Handle

6

Page 3

[3]

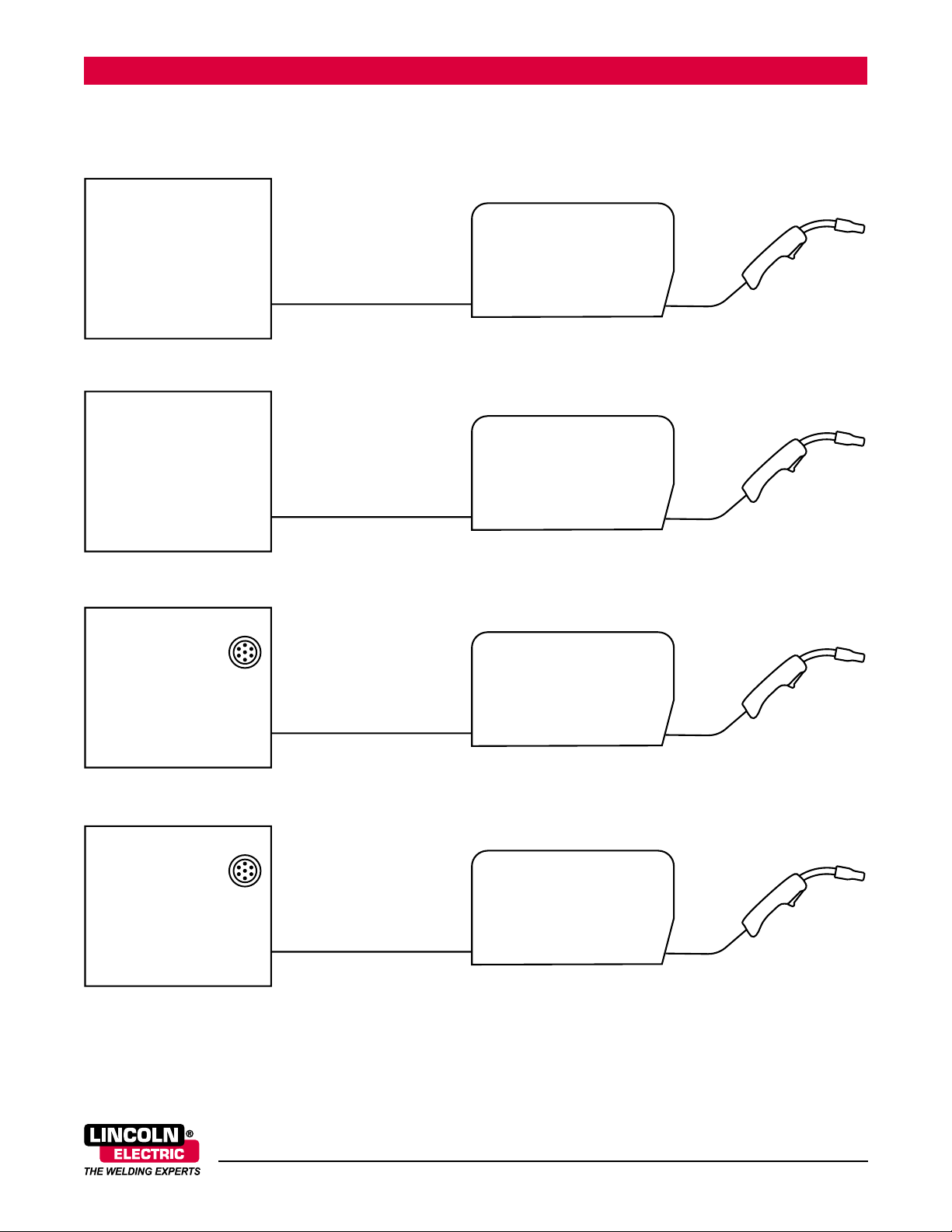

SYSTEM SELECTION

LN-25 Wire Feeder

www.lincolnelectric.com

Electrode cold operation is available with K449 or K428 (with optional K443-2 Internal Contactor Kit installed).

(Connections are for current equipment design. Subject to change without notice.)

ACROSS THE ARC SET-UP (with Electrode Cold Operation)

Power source contactor

switch must be in the

“ON” position or use

K484 Jumper Plug Kit.

Order K484 Jumper

Plug Kit.

CC Power Source,

RangerTM10,000,

Ranger 3 Phase,

SAE 400 with CV Adapter

Magnum gun and

cable assembly

Weld Power Cable

LN-25 Wire Feeder

K449 or K428 (with K443-2)

LN-25 Wire Feeder

K449 or K428 (with K443-2)

LN-25 Wire Feeder

K449 or K428 (with K443-2)

LN-25 Wire Feeder

K449 or K428 (with K443-2)

Output Terminals

Always Hot.

Ranger 250, Ranger 250 LPG,

Ranger 305G, Ranger 305D,

Commander® 300,

Vantage® 500,

Air Vantage® 500,

Engine Driven Welders

with Wire Feed Module

(local/remote switch in local position)

Power source contactor

switch must be in the

“ON” position.

Magnum gun and

cable assembly

Weld Power Cable

Output Terminals

Always Hot.

Output Terminals

Always Hot.

Output Terminals

Always Hot.

CV-250,

CV-300,

CV-400,

CV400-I,

CV500-I

Magnum gun and

cable assembly

Weld Power Cable

14 Pin

CV-655,

DC-400,

DC-600,

DC-655,

V350-PRO

Magnum gun and

cable assembly

Weld Power Cable

14 Pin

Page 4

[4]

SYSTEM SELECTION

LN-25 Wire Feeder

www.lincolnelectric.com

ACROSS THE ARC SET-UP (with Electrode Cold Operation and Remote Voltage Control at LN-25)

Magnum gun and

cable assembly

Output Terminals Always Hot.

Output Terminals Always Hot.

Electrode cold operation is available with K449 or K428 (with optional K443-2 Internal Contactor Kit installed).

(Connections are for current equipment design. Subject to change without notice.)

RangerTM250,

Ranger 250 LPG,

Ranger 305G,

Ranger 305D,

Commander®300,

Vantage®500,

Air Vantage®500

Magnum gun and

cable assembly

Ranger 250, Ranger 250 LPG,

Ranger 305G,

Ranger 305D,

Commander 300,

Vantage 500,

Air Vantage 500,

CV-250, CV-300,

CV-400, CV-655,

DC-400, DC-600 (Above

Code 10500), CV400-I,

CV500-I, V350-PRO,

Engine Driven Welders

with Wire Feed Module

(local/remote switch in remote position)

K444-1 Remote

Voltage Control Kit

K444-2 Remote Voltage Control Kit

K444-2 has built-in jumper to keep contactor in

power source closed all the time.

6 Pin

14 Pin

LN-25 Wire Feeder

K449 or K428 (with K443-2)

LN-25 Wire Feeder

K449 or K428 (with K443-2)

Weld Power Cable

Weld Power Cable

Power Source Contactor Switch must

be in the “ON” position.

Page 5

LN-25 Wire Feeder

www.lincolnelectric.com

[5]

SYSTEM SELECTION

ACROSS THE ARC SET-UP (with Electrode Cold Operation and Remote Voltage Control at LN-25)

WELD POWER CABLE SET-UP

CV-250, CV-300,

CV400-I, CV500-I,

CV-655, V350-PRO,

DC-400, DC-600,

DC-655, Ranger 250,

Ranger 250 LPG,

Ranger 305G,

Ranger 305D,

Commander 300,

Vantage 500,

Air Vantage 500

K624-1

Remote Output

Control Module

Magnum gun and

cable assembly

LN-25 Wire Feeder

K428 model only

14 Pin

For LN-25 K428 Model without Internal Contactor.

(Connections are for current equipment design. Subject to change without notice.)

42 Volt Remote Output Control Systems

Control Cable and Extensions

K1819-10 Wire Feeder Control Cable, 10 ft. (3.0m)

K1797-25 14-pin Extension Control Cable, 25 ft. (7.6m)

K1797-50 14-pin Extension Control Cable, 50 ft. (15.2m)

Weld Power Cables

K1841-25 Twist-Mate to Twist-Mate, 1/0, 350A, 60% duty cycle, 25 ft. (7.6m)

K1841-50 Twist-Mate to Twist-Mate, 2/0, 350A, 60% duty cycle, 50 ft. (15.2m)

Twist-Mate Cable Plugs

K852-70 for 1/0-2/0 cable

K852-95 for 2/0-3/0 cable

Weld Power Cables

K1842-10 Lug to Lug, 3/0, 600A, 60% duty cycle, 10 ft. (3.0m)

K1842-35 Lug to Lug, 3/0, 600A, 60% duty cycle, 35 ft. (10.6m)

K1842-60 Lug to Lug, 3/0, 600A, 60% duty cycle, 60 ft. (18.2m)

K1842-110 Lug to Lug, 4/0, 600A, 60% duty cycle, 110 ft. (33.5m)

Cable Lug

S1119-14 for 1/0-2/0 cable

Weld Power Cable

K1819-10 Wire Feeder

Control Cable

CV-250,

CV-300,

CV400-I,

CV500-I,

V350-PRO

CV-400, CV-655,

DC-400, DC-600,

DC-655, Ranger 250,

Ranger 250 LPG,

Ranger 305G,

Ranger 305D,

Commander 300,

Vantage 500,

Air Vantage 500

Engine Driven Welders

w/Wire Feed Module

Magnum gun and

cable assembly

LN-25 Wire Feeder

K428 model only

Weld Power Cable

Magnum gun and

cable assembly

LN-25 Wire Feeder

K428 model only

Weld Power Cable

Twist-Mate Cable Plug

Cable Lug

Page 6

[6]

RECOMMENDED OPTIONS

LN-25 Wire Feeder

www.lincolnelectric.com

REQUIRED OPTIONS

Magnum Gas-Shielded Gun and

Cable Assemblies

Available 200-550 amps, air-cooled,

gas-shielded welding guns.

See publication E12.10

Magnum Self-Shielded Gun and

Cable Assemblies

Available 250-600 amps.

See publication E12.110

REQUIRED OPTIONS, CON'T

Twist-Mate Cable Plug

For connecting welding cable to

output terminal receptacles. For

1/0 – 2/0 (50 – 70 mm

2

) cable.

Order K852-70

Twist-Mate Cable Plug

For connecting welding cable to

output terminal receptacles. For

2/0 – 3/0 (70 – 95 mm

2

) cable.

Order K852-95

Cable Lug

For #1 1/0-2/0 cable.

Order S1119-14

GENERAL OPTIONS

Jumper Plug Kit

For use with CV only power sources

with 14 pin MS-type wire feeder

connections and no contactor control switch. Jumper plug kit closes

contactor for always hot welding

output.

Order K484

Terminal Strip Remote Voltage

Control Kit

Provides 25 ft. (7.6m) of remote

output voltage control with power

sources having a terminal strip.

Order K444

6 Pin Remote Voltage Control Kit

Provides 25 ft. (7.6m) of remote

voltage control when used with

power sources having a 6 pin

MS-type connector.

Order K444-1

14 Pin Remote Voltage Control Kit

Provides 25 ft. (7.6m) of remote

output voltage control and output

jumper (2 and 4) for power sources

having a 14 pin MS-type connector.

Order K444-2

42 Volt Remote Output Control

Module

Provides remote voltage control and

power source output control.

Requires 42 volt auxiliary power.

Mounts inside LN-25 control box.

Requires K1819-10 Wire Feeder

Control Cable.

Order K624-1

DRIVE ROLL AND GUIDE TUBE KITS

45 6

WELD POWER CABLES

Wire Type Order

and Sizes Number

Solid Wire:

.023 - .025" (0.6 mm) KP653-025S

.030" (0.8 mm) KP653-030S

.035" (0.9 mm) KP653-035S

.045 - .052" (1.2 - 1.4 mm) KP653-052S

Cored Wire:

.035" (0.9 mm) KP653-035C

.045 - .052" (1.2 - 1.4 mm) KP653-052C

Solid or Cored Wire:

.052 - 1/16" (1.3 - 1.6 mm) KP653-1/16

.068 - 5/64" (1.7 - 2.0 mm) KP653-3/32

Aluminum Wire:

.035" (0.9 mm) KP654-035A

3/64" (1.2 mm) KP654-3/64A

1/16” (1.6 mm) KP654-1/16A

Aluminum Wire (Clutched Drive Roll):

.035" (0.9 mm) KP1682-035A

1.0 mm KP1682-1.0A

3/64" (1.2 mm) KP1682-3/64A

1/16” (1.6 mm) KP1682-1/16A

Order No. Description

K1841-25 Twist-Mate to Twist-Mate, 1/0, 350A, 60% duty cycle, 25 ft. (7.6m)

K1841-50 Twist-Mate to Twist-Mate, 2/0, 350A, 60% duty cycle, 50 ft. (15.2m)

K1842-10 Lug to Lug, 3/0, 600A, 60% duty cycle, 10 ft. (3.0m)

K1842-35 Lug to Lug, 3/0, 600A, 60% duty cycle, 35 ft. (10.6m)

K1842-60 Lug to Lug, 3/0, 600A, 60% duty cycle, 60 ft. (18.2m)

K1842-110 Lug to Lug, 4/0, 600A, 60% duty cycle, 110 ft. (33.5m)

Magnum 400 shown

K126 Innershield Gun

shown

Page 7

LN-25 Wire Feeder

www.lincolnelectric.com

[7]

RECOMMENDED OPTIONS

Wire Feeder Control Cable

10 ft. (3.0m) power source to wire

feeder cable. Male 9 pin to female

14 pin.

Order K1819-10

Wire Feeder Control Cable

Extension

Male 14 pin to female 14 pin.

(Requires K1819-10.)

Order K1797-25 for 25 ft.

Order K1797-50 for 50 ft.

Gas Solenoid Kit

Includes solenoid valve and mounting bracket. For K428 LN-25 model

only. (Standard on K449 LN-25

model.)

Order K430-2

Internal Contactor Kit

Provides cold electrode until gun

trigger is pressed and cold inch

switch for loading wire. For K428

LN-25 model only. (Standard on

K449 LN-25 model.)

Order K443-2

Gas Flow Timer Kit

For use with Gas Solenoid Kit.

Provides adjustable delays for preflow and postflow of shielding gas.

Order K434-1

22-30 lb. Readi-Reel Adapter

Adapts 22-30 lb. (10-14kg) Lincoln

Readi-Reels® of electrode to 2"

(51mm) spindle. Wire not included.

Order K363P

14 lb. Innershield Coil Adapter

Permits 14 lb. (6 kg) Innershield®

electrode coils to be mounted on

2" (51mm) O.D. spindles. Wire not

included.

Order K435

8” O.D. Spool Adapter

For small spools. Permits 8"

(203mm) O.D. spools to be mounted

on 2" (51mm) O.D. spindles.

Order K468

Page 8

LN-25 Wire Feeder K428

LN-25 Wire Feeder w/Internal Contactor and Gas Solenoid K449

Required Options

Magnum Gas-Shielded Gun and Cable Assemblies See publication E12.10

Magnum Self-Shielded Gun and Cable Assemblies See publication E12.110

Drive Roll and Guide Tube Kits See page 6

Weld Power Cables See page 6

Twist-Mate Cable Plug:

– for 1/0-2/0 cable K852-70

– for 2/0-3/0 cable K852-95

Cable Lug S1119-14

Recommended General Options

Jumper Plug Kit K484

Terminal Strip Remote Voltage Control Kit K444

6-Pin Remote Voltage Control Kit K444-1

14-Pin Remote Voltage Control Kit K444-2

42 Volt Remote Output Control Module K624-1

Wire Feeder Control Cable K1819-10

Wire Feeder Control Cable Extension:

25 ft.(7.6m), 50 ft.(15.2m) K1797-25, -50

Gas Solenoid Kit (standard on K449) K430-2

Internal Contactor Kit (standard on K449) K443-2

Gas Flow Timer Kit (K428 Requires K430-2) K434-1

22-30 lb. Readi-Reel Adapter K363P

14 lb. Innershield Coil Adapter K435

8” O.D. Spool Adapter K468

TOTAL:

CUSTOMER ASSISTANCE POLICY

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the needs of our customers and to exceed

their expectations. On occasion, purchasers may ask Lincoln Electric for advice or information about their use of our products. We respond to our customers based on the best information in our possession at that

time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or advice. We expressly disclaim any warranty of any kind, including any warranty

of fitness for any customer’s particular purpose, with respect to such information or advice. As a matter of practical consideration, we also cannot assume any responsibility for updating or correcting any such information or advice once it has been given, nor does the provision of information or advice create, expand or alter any warranty with respect to the sale of our products.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility of the customer. Many variables

beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

THE LINCOLN ELECTRIC COMPANY

22801 St. Clair Ave., Cleveland, OH 44117-1199 • 216.481.8100 • www.lincolnelectric.com

LN-25 ORDER FORM

PRODUCT DESCRIPTION ORDER NUMBER QUANTITY PRICE

Loading...

Loading...