Page 1

24-42

VAC

60

50

Hz

SEMIAUTOMATIC WIRE FEEDERS

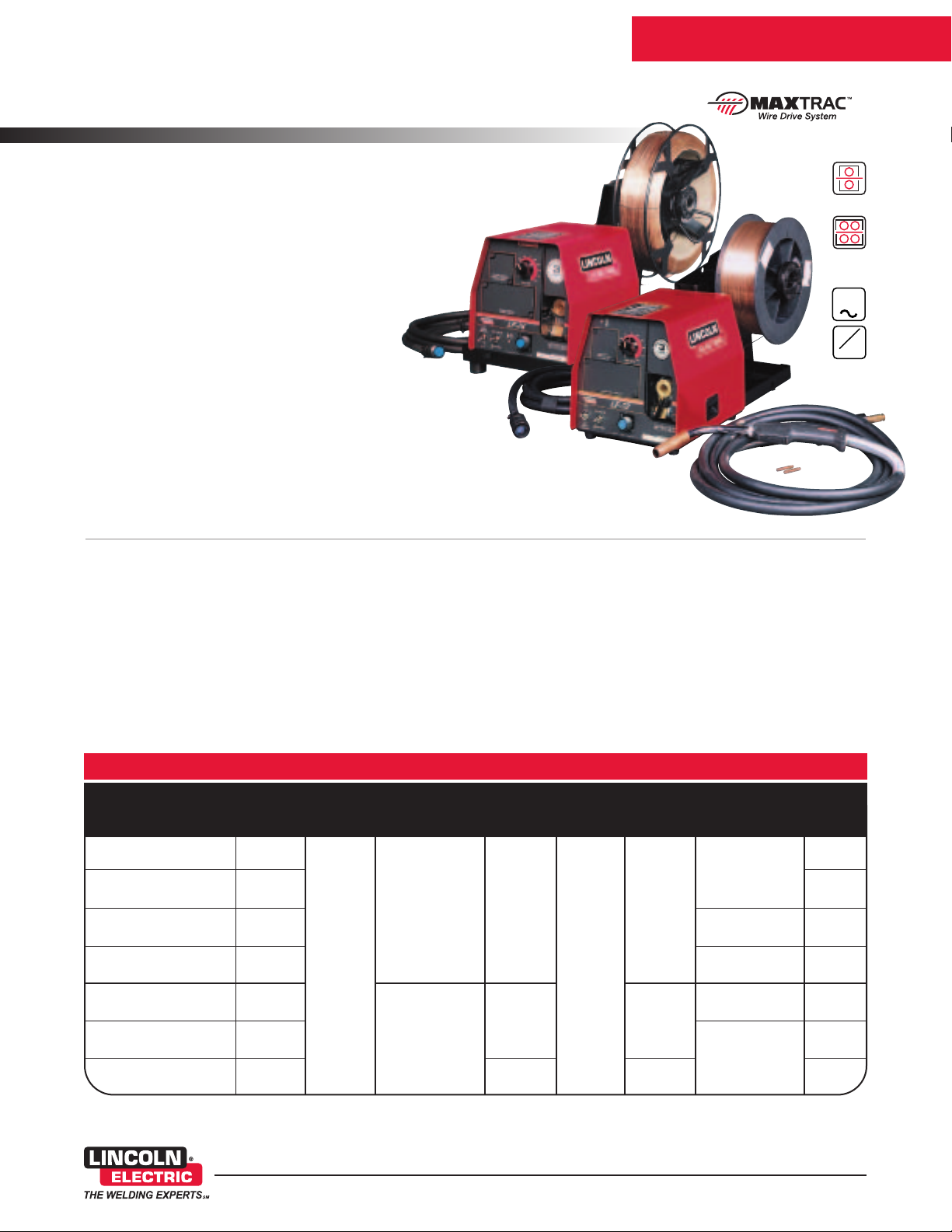

LF-72 and LF-74 Wire Feeders

2-Roll or 4-Roll Heavy Duty Industrial Feeders

Output

Designed for MIG and cored wire welding in job shop and manufacturing

environments, the rugged LF-72 and LF-74 wire feeders are built to

deliver reliable performance day after day. The heart of these feeders

is the highly engineered 2-roll or 4-roll MAXTRAC™ wire drive

system, delivering strong and consistent feeding force for tough

applications.

Select the 2-roll LF-72 for most .035-.045 wire applications.

Select the 4-roll LF-74 for large diameter wires, longer

gun cables or long boom conduit or hard automation

applications.

Processes

MIG, Pulsed, Flux-Cored

LF-74 Bench Model, Heavy Duty, Extra Torque, K2426-3

LF-72 Bench Model, Standard Duty, K2327-2

(Shown with optional wire.)

Advantage Lincoln

• Patented MAXTRAC™ heavy-duty cast aluminum wire drive system

provides reliable feeding and durability.

• Brass-to-brass gun connections for better electrical conductivity that

results in better arc performance.

• Totally tool-less drive rolls and wire guide installation. Two or four

gear-driven wire drive rolls slide on and off easily!

• Calibrated wire feed speed dial for precise and accurate settings.

• Rugged, industrial-grade wire feeder motor.

or

Input

• In addition to great mild steel performance, these feeders deliver

positive arc starting and feeding with stainless steel, aluminum and

flux-cored wires!

• Control cable connector with a Spin-Nut™ makes connecting the

control cable a simple twist-of-the-wrist.

• Totally enclosed wire drive.

• Manufactured under a quality system certified ISO 9001

requirements and ISO 14001 environmental standards.

• Three-year warranty on parts and labor.

Product Product Input Output Capacity Speed Range Range H x W x D Weight

(1)

Name

LF-72 Base Model K2327-1 24-42 VAC 500 Amps @ 60% 50-800 Solid Cored 11.1 x 10.2 x 12.9 44

(with gun) 50/60 Hz 400 Amps@ 100% (1.3-20.3) .023-1/16 .030-5/64 (282 x 259 x 328) (20)

•

LF-72 Base Model, K2327-4 27

(no gun, no cable) (12)

LF-72 Bench Model, K2327-2 12.6 x 10.9 x 22.5 53

Standard Duty (320 x 277x 572) (24)

LF-72 Bench Model, K2327-3 15.3 x 13.0 x 27.7 68

Heavy Duty (389 x 330 x 704) (31)

LF-74 Base Model K2426-1 600 Amps @ 60% 100-800 .030-5/64 11.1 x 10.2 x 12.9 46

LF-74 Bench Model, K2426-2 15.3 x 13.0 x 27.7 71

Heavy Duty (389 x 330 x 704) (32)

LF-74 Bench Model, K2426-3 50-400 .030-3/32 71

Heavy Duty, Extra Torque (1.3-10.1) (0.8-2.4) (32)

(1)

See selection guide on page 4.

TECHNICAL SPECIFICATIONS

Wire Feed Wire Size Dimensions Net

Number Power Current / Duty Cycle ipm (m/min) in (mm) in (mm) lbs (kg)

9 Amps (0.6-1.6) (0.8-2.0)

500 Amps@ 100% (2.5-20.3) (0.8-2.0) (282 x 259 x 328) (21)

Publication E8.11 8/06

www.lincolnelectric.com

Page 2

A CLOSER LOOK

PERFORMANCE

F

F

D

E

A

B

C

LF-74 Four Roll Drive

Rigid Cast Aluminum Frame

A

• Enhances precise drive roll

alignment

Brass to Brass Interchangeable

B

Gun Bushings

• More reliable electrical

conductivity – no oxide

build-up

• More efficient energy transfer –

lower voltage drops

• Easily adapt any number

of Lincoln Magnum or

competitive guns

G

New Patent-Pending Drive Rolls

C

• For steel - new design delivers

20% more feeding force

• For aluminum - chrome plated

to resist build-up

Twist-Lock Drive Roll Hubs

D

• Two or four gear driven rolls

• Fast, tool-less changeovers

Patented Split Wire Guides

E

• Full support for wire throughout

the drive path

• Removable outer wire guide for

easy access

• No tools required

• No birdnesting

LF-72 Two Roll Drive

Patent-Pending Dual Spring

F

Pressure Arm

• Easy turn numeric tension

indicator

• Set heavy tension for steel

and stainless

• Set moderate tension for cored

wires

• Set soft tension for aluminum

• Wide idler arm hinge delivers

improved drive roll clamping

pressure

Separate Drive Gear

G

• Reduces pressure on motor for

extended service life

[2]

LF-72/LF-74 Wire Feeders

www.lincolnelectric.com

Page 3

A CLOSER LOOK

FEATURES

Heavy Duty hinged door opens upward to

provide generous access to wire drive.

Convenient storage tray on top for

contact tips and drive rolls.

Calibrated Wire Feed Speed Dial for precise setting.

Convenient 2 Step/Trigger Interlock Switch

for operator comfort during long welds.

Cold Feed for safety/Gas Purge clears

shielding gas line.

Front View

LF-74 Four Roll Bench Model Shown

H

(optional)

G

(optional)

Rugged MAXTRAC™ wire drive system.

Gas Hose Connection Inlet.

Control Cable Connector with Spin-Nut™

for fast, easy, tool-less connection.

Patented Ball Bearing Inlet

Guide for accurate feeding.

A

B

Back View

Key Controls (LF-72 and LF-74)

A ) Calibrated Wire Feed Speed Dial

B ) Gun Connection (K1500-2)

C ) 5-Pin Gun Connection

D ) Motor Thermal Protection Light

E ) Cold Feed/Gas Purge Switch

F ) 2-Step/Trigger Interlock Switch

G) Burnback/Postflow Timer Kit (optional)

H ) Remote Voltage Control Kit (optional)

F

E

D

C

[3]

LF-72 shown with optional K2330-1 Postflow and Burnback Timer Kit

and K2329-1 Remote Voltage Control Kit.

LF-72/LF-74 Wire Feeders

www.lincolnelectric.com

Page 4

SYSTEM SELECTION

•

WIRE FEEDER SELECTION GUIDE

Number of Rolls:

LF-72

LF-74 LF-74 Extra Torque

Inches Per Minute

(m/min):

Wire Size, in. (mm):

BASE MODEL

no gun, no cable

For boom mounting

or for use with

bulk consumables.

BASE MODEL

For boom mounting

or for use with

bulk consumables.

BENCH MODEL

STANDARD DUTY

For most welding

needs that require a

rugged and

dependable wire

feed system.

BENCH MODEL

HEAVY DUTY

For applications

requiring up to 60 lb.

wire packages.

50-800

(1.3-20.3)

Solid

Cored

Unit Includes:

• Drive Roll and

Wire Guide Kit

Unit Includes:

• Drive Roll and

Wire Guide Kit

• Gun and Cable

Assembly

• Control Cable

10' (3m)

Unit Includes:

• Drive Roll and

Wire Guide Kit

• Gun and Cable

Assembly

• Control Cable

10' (3m)

LF-72 Bench Model, Standard Duty (K2327-2)

Unit Includes:

• Drive Roll and

Wire Guide Kit

• Gun and Cable

Assembly

• Control Cable

10' (3m)

.023-1/16 (0.6-1.6)

.030-5/64 (0.8-2.0)

LF-72 Base Model (no gun, no cable)

10-44 lb. (4.5-19.9 kg) wire spool.

(K2327-4)

LF-72 Base Model with gun

(K2327-1)

Shown with optional

Solid

Cored

Unit Includes:

• Drive Roll and

Wire Guide Kit

• Control Cable

10' (3m)

Unit Includes:

• Drive Roll and

Wire Guide Kit

• Control Cable

10' (3m)

.023-1/16 (0.6-1.6) .023-1/16 (0.6-1.6)

.030-5/64 (0.8-2.0) .030-3/32 (0.8-2.4)

100-800

(2.5-20.3)

LF-74 Base Model (K2426-1)

Solid

Cored

Unit Includes:

• Drive Roll and

Wire Guide Kit

• Control Cable

10' (3m)

50-400

(1.3-10.1)

Recommended for

Flux-Cored

Wire Feeding

LF-72 Bench Model, Heavy Duty (K2327-3)

Shown with optional 50-60 lb.

(22.6-27.2 kg) coil adapter and wire.

LF-72 includes FREE:

(1)

LF-74 Bench Model, Heavy Duty (K2426-2)

.035"-.045" (0.9-1.2mm) Drive Roll and

Wire Guide Kit (KP1696-1)

Male 14-pin to Female 14-pin Control Cable

10 ft. (3.0m) (K1797-10)

Magnum 400 Gun and 15 ft. (4.5m) Cable

Assembly with .035"- .045" (0.9mm-1.2mm)

liner (K471-21). LF-72 Base Model without

gun also available (K2327-4).

(1)

K2327-4 includes Drive Roll & Wire Guide Kit Only

Shown with optional 50-60 lb.

(22.6-27.2 kg) coil adapter and wire.

[4]

LF-74 Bench Model, Heavy Duty,

Extra Torque (K2426-3)

Shown with optional 50-60 lb.

(22.6-27.2 kg) coil adapter and wire.

LF-74 includes FREE:

.035"/.045" (0.9mm/1.2mm) Drive Rolls

and Wire Guides

Male 14-pin to Female 14-pin

Control Cable 10 ft. (3.0m) (K1797-10)

LF-72/LF-74 Wire Feeders

www.lincolnelectric.com

Page 5

OPTIONS

DRIVE ROLL & WIRE GUIDE KITS

Description LF-72 Two-Roll LF-74 Four-Roll

Steel Wire Sizes (includes stainless steel):

.023-.030" (0.6-0.8mm) KP1696-030S KP1505-030S

.035" (0.9mm) KP1696-035S KP1505-035S

.045" (1.2mm) KP1696-045S KP1505-045S

.052" (1.4mm) KP1696-052S KP1505-052S

.035", .045" (0.9, 1.2mm) KP1696-1

.040" (1.0mm) KP1696-2 –

1/16" (1.6mm) KP1696-1/16S KP1505-1/16S

Cored Wire Sizes:

.030-.035" (0.8-0.9mm) KP1697-035C KP1505-035C

.040-.045" (1.0-1.2mm) KP1697-045C KP1505-045C

.052" (1.4mm) KP1697-052C KP1505-052C

1/16" (1.6mm) KP1697-1/16C KP1505-1/16C

Steel or Cored Wire Sizes:

.068-.072" (1.8mm) KP1697-068 KP1505-068

5/64" (2.0mm) KP1697-5/64 KP1505-5/64

3/32" (2.4mm) – KP1505-3/32

Aluminum Wire Sizes:

.035" (0.9mm) KP1695-035A KP1507-035A

.040" (1.0mm) KP1695-040A KP1507-040A

3/64" (1.2mm) KP1695-3/64A KP1507-3/64A

1/16" (1.6mm) KP1695-1/16A KP1507-1/16A

(1)

Standard on LF-72.

(1)

–

CONTROL EXTENSION CABLES

Cable Type Description

Wire Feeder Control Extension Cables

K1797-10 - 10 ft

K1797-25 - 25 ft.

K1797-50 - 50 ft.

K1797-100 - 100 ft.

(1)

Standard with all LF-72 (except K2327-4) and LF-74 models.

(1)

.

Male 14-pin to female 14-pin

WELD POWER CABLE REQUIRED

WELD POWER CABLES

Order No. Description

K1840-10 Twist-Mate™ to Lug, 1/0, 350A, 60% duty cycle, 10 ft.

K1842-10 Lug to Lug, 3/0, 600A, 60% duty cycle, 10 ft.

K1842-35 Lug to Lug, 3/0, 600A, 60% duty cycle, 35 ft.

K1842-60 Lug to Lug, 3/0, 600A, 60% duty cycle, 60 ft.

K1842-110 Lug to Lug, 4/0, 600A, 60% duty cycle, 110 ft.

K1500-1 Gun

Receiver Bushing

(Optional)

• Magnum 200, 300

and 400 gun and

cable assemblies

with K466-1

connector kit.

• Lincoln Innershield

gun and cable

assembly.

• Magnum 550 gun

and cable assembly

with K613-1

connector kit.

K1500-2 Gun

Receiver Bushing

(Standard)

• Magnum 200 and

400 fully assembled

guns (K497-2x and

K471-2x).

• Magnum 200, 300

and 400 gun and

cable assemblies

with K466-10

connector kit.

• Guns with Tweco #2,

#3, and #4

connectors.

FEED PLATE GUN RECEIVER BUSHINGS

K1500-3 Gun

Receiver Bushing

(Optional)

• Magnum 550 gun

and cable assembly

with K613-7

connection.

• Guns with Tweco

#5 connectors.

K1500-4 Gun

Receiver Bushing

(Optional)

• Magnum 200, 300

and 400 gun and

cable assemblies

with K466-3

connector kit.

K1500-5 Gun

Receiver Bushing

(Optional)

• To adapt to OXO

guns.

K489-7 Fast-Mate

Gun Receiver

Bushing (Optional)

• Magnum gun and

cable assemblies

with Fast-Mate

connections.

• Handles both

single and dual

procedure guns.

[5]

LF-72/LF-74 Wire Feeders

www.lincolnelectric.com

Page 6

OPTIONS

GENERAL OPTIONS

Magnum Gas-Shielded Gun and

Cable Assemblies

Available 200-550 amps, aircooled, gas-shielded welding guns.

See publication E12.10

Magnum Self-Shielded Gun and

Cable Assemblies

Available 250-600 amps.

See publication E12.110

Postflow and Burnback

Timer Kit

Provides adjustable delay of power

source output shut off to prevent

electrode sticking in crater when

using high wire feed speeds.

Order K2330-1

Remote Voltage Control Kit

Allows arc voltage to be changed

at the feeder.

Order K2329-1

Incoming Bushing for Lincoln

Conduit

Feed Plate Incoming Bushings

connect directly to wire conduit (not

included), for use in boom system,

long distances, or large payoff

packages. Bushings can be used

with any wire conduit (K515 or

K565).

Order K1546-1 for .025-1/16" wire

Order K1546-2 for 1/16-1/8" wire

Spindle Adapter

for Readi-Reels® and Spools

For fixture and other custom

installations. Features 2" (51mm)

O.D. spindle for mounting ReadiReels and 2" (51mm) I.D. spools up

to 60 lb. (27.2 kg) capacity.

Order K162-1

Deluxe Adjustable Gas Regulator

& Hose Kit

Accommodates CO2, Argon, or

Argon-blend gas cylinders. Includes

a cylinder pressure gauge, dual

scale flow gauge and 4.3 ft. (1.3m)

gas hose.

Order K586-1

Gas Guard Regulator

For CO2and Argon blend gases.

Reduces surge caused by excess

pressure in supply hose. Includes

adjustable flow regulator with

removable adjuster key.

Order K659-1

Adapter for Competitive Power

Sources

Allows wire feeder to connect to

select Miller Electric® power

sources.

Order K2335-1

Control Cable to Terminal Strip

Adapter

Connects 14-pin control cable to

power sources with terminal strip.

Order K1798

115V/42V Transformer Kit

Provides a way to use the wire

feeder on power sources that have

115V AC available on the terminal

strip.

Order K1520-1

Welding Fume Extractors

Lincoln offers a wide variety of

welding fume extraction

environmental system solutions,

ranging from portable systems

easily wheeled around the shop to

shop-wide central systems

servicing many dedicated welding

stations.

Request Publication E13.40

ADDITIONAL OPTIONS FOR

BASE MODEL (Does not

include Wire Reel Stand)

Standard Duty Wire Reel Stand

For use with Lincoln 10-44 lb.

(4.5-20 kg) wire packages that use

a 2" (51mm) spindle.

Order K2328-1

Heavy Duty Wire Reel Stand

For use with Lincoln 10-60 lb.

(4.5-27.2 kg) wire packages that

use a 2" (51mm) spindle. Hole in

stand fits over lift bail.

Order K1524-3

6000 Series Welding Arm

Create a safe, uncluttered work

environment where floor space is

used effectively with a Lincoln

Series 6000 Welding Arm. Glide

the arm effortlessly into position

when in use or swing it

conveniently against a wall or

beam for safe, out-of-the-way

storage. An 18" x 18" (457 x

457mm) footprint ties up very little

floor space.

Order K1778-1

•

•

Harris Argon Flowmeter/

Regulator and Hose Kit

Order 3100211

LF-72/LF-74 Wire Feeders

[6]

www.lincolnelectric.com

Page 7

OPTIONS

ADDITIONAL OPTIONS FOR

FEEDERS EQUIPPED WITH

STANDARD DUTY WIRE

REEL STAND

Lift Bail Kit

Allows the entire wire feeder to be

hung from a crane or hook. Use

with Standard Duty Wire Reel

Stand.

Order K2331-1

Lightweight Swivel Kit

Allows wire feeder to freely turn. For

use with Standard Duty Wire Reel

Stand.

Order K2332-1

Undercarriage

Includes mounting frame, front

casters, rear wheels and handle for

hand towing. For use with Wire Reel

Stands.

Order K163

14 lb. Innershield® Coil Adapter

Permits 14 lb. (6 kg) Innershield

electrode coils to be mounted on 2"

(51mm) O.D. spindles.

Order K435

8" O.D. Spool Adapter

Permits 8" (200mm) O.D. spools to

be mounted on 2" (51mm) O.D.

spindles.

Order K468

Wire Reel Cover Kit

Plastic enclosure for up to 44 lb.

(20 kg) wire packages.

Order K1634-1

ADDITIONAL OPTIONS FOR

FEEDERS EQUIPPED WITH

HEAVY DUTY WIRE REEL

STAND

Insulated Lift Bail

Allows the entire wire feeder to be

hung from a crane or hook. Use

with Heavy Duty Wire Reel Stand.

Order K1555-1

Swivel Platform

Mounts to the lift bail on the power

source and bottom of the Heavy

Duty Wire Reel stand. Wire feeder

may be lifted off if needed.

Compatible with Light Duty Caster

Kit. Includes “lazy susan” parts tray.

Order K1557-1

Undercarriage

Includes mounting frame, front

casters, rear wheels and handle for

hand towing. For use with Wire Reel

Stands.

Order K163

14 lb. Innershield® Coil Adapter

Permits 14 lb. (6 kg) Innershield

electrode coils to be mounted on 2"

(51mm) O.D. spindles.

Order K435

8" O.D. Spool Adapter

Permits 8" (200mm) O.D. spools to

be mounted on 2" (51mm) O.D.

spindles.

Order K468

Wire Reel Cover Kit

Plastic enclosure for up to 44 lb.

(20 kg) wire packages.

Order K1634-1

50-60 lb. Readi-Reel® Adapter

Adapts 60 lb. (27.2 kg) coils of

Lincoln electrode to 2" (51mm)

spindle.

Order K438

50-60 lb. Coil Adapter

Adapts 50-60 lb. (22.6-27.2 kg) coils

of Lincoln electrode to

2" (51mm) spindle.

Order K1504-1

Plastic Wire Cover Kit

Plastic enclosure for up to 60 lb.

(27.2 kg) wire packages.

Order K1634-2

Caster Kit — Light Duty

Mounts to the Heavy Duty Wire

Reel Stand. Allows for easy

movement of wire feeder.

Order K1556-1

[7]

NOTE:

Miller Electric® is not a trademark

of The Lincoln Electric Company.

LF-72/LF-74 Wire Feeders

www.lincolnelectric.com

Page 8

LF-72 AND LF-74 WIRE FEEDERS ORDER FORM

PRODUCT DESCRIPTION ORDER NUMBER QUANTITY PRICE

LF-72 WIRE FEEDER, BASE MODEL, WITH GUN K2327-1

LF-72 WIRE FEEDER, BASE MODEL, NO GUN, NO CABLE K2327-4

LF-72 WIRE FEEDER, BENCH MODEL, STANDARD DUTY K2327-2

LF-72 WIRE FEEDER, BENCH MODEL, HEAVY DUTY K2327-3

LF-74 WIRE FEEDER, BASE MODEL K2426-1

LF-74 WIRE FEEDER, BENCH MODEL, HEAVY DUTY K2426-2

LF-74 WIRE FEEDER, BENCH MODEL, HEAVY DUTY, EXTRA TORQUE K2426-3

UNIT REQUIRES

Weld Power Cable See page 5

Magnum Gas-Shielded Gun and Cable Assemblies See publication E12.10

Magnum Self-Shielded Gun and Cable Assemblies See publication E12.110

GENERAL OPTIONS

Postflow and Burnback Timer Kit K2330-1

Remote Voltage Control Kit K2329-1

Incoming Bushing for Lincoln Conduit:

for .025-1/16" wire K1546-1

for 1/16-1/8" wire K1546-2

Spindle Adapter K162-1

Deluxe Adjustable Gas Regulator & Hose Kit K586-1

Gas Guard Regulator K659-1

Harris Argon Flowmeter/Regulator & Hose Kit 3100211

Adapter for Competitive Power Sources K2335-1

Control Cable to Terminal Strip Adapter K1798

115V/42V Transformer Kit K1520-1

Welding Fume Extractors See publication E13.40

ADDITIONAL OPTIONS FOR BASE MODEL

(Does Not Include Wire Reel Stand)

Standard Duty Wire Reel Stand K2328-1

Heavy Duty Wire Reel Stand K1524-3

6000 Series Welding Arm K1778-1

ADDITIONAL OPTIONS FOR FEEDERS EQUIPPED WITH

STANDARD DUTY WIRE REEL STAND

Lift Bail Kit K2331-1

Lightweight Swivel Kit K2332-1

Undercarriage K163

14 lb. Innershield® Coils Adapter K435

8" O.D. Spool Adapter K468

Wire Reel Cover Kit (for up to 44 lb. wire packages) K1634-1

ADDITIONAL OPTIONS FOR FEEDERS EQUIPPED WITH

UNIVERSAL WIRE REEL STAND

Insulated Lift Bail K1555-1

Caster Kit – Light Duty K1556-1

Swivel Platform K1557-1

Undercarriage K163

14 lb. Innershield® Coils Adapter K435

8" O.D. Spool Adapter K468

Wire Reel Cover Kit (for up to 44 lb. wire packages) K1634-1

50-60 lb. Readi-Reel® Adapter K438

50-60 lb.Coil Adapter K1504-1

Plastic Wire Cover Kit (for up to 60 lb. wire packages) K1634-2

POWER SOURCE OPTIONS

CV-305, CV400-I, CV-400, CV500-I, CV-655, Invertec® V350-PRO, See publications E4.22, E4.20.1,

Invertec® V450-PRO, DC-400, DC-600, DC-655 E4.30, E4.30.1,E4.40, E5.91,

E5.94, E5.20, E5.40, E5.46

TOTAL:

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the needs of our customers and to exceed

their expectations. On occasion, purchasers may ask Lincoln Electric for advice or information about their use of our products. We respond to our customers based on the best information in our possession at that time.

Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or advice. We expressly disclaim any warranty of any kind, including any warranty of

fitness for any customer’s particular purpose, with respect to such information or advice. As a matter of practical consideration, we also cannot assume any responsibility for updating or correcting any such information

or advice once it has been given, nor does the provision of information or advice create, expand or alter any warranty with respect to the sale of our products.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility of the customer. Many variables

beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

CUSTOMER ASSISTANCE POLICY

THE LINCOLN ELECTRIC COMPANY

22801 St. Clair Ave., Cleveland, OH 44117-1199 • 216.481.8100 • www.lincolnelectric.com

Loading...

Loading...