Lincoln Electric LECS-5100-400-W0, LECS-5100-125-W0, LECS-5100-200-W0, LECS-5100-275-W0, LECS-5100-125-D0 User Manual

...Page 1

USER GUIDE

June 5, 2019

Copyright 2019

Lincoln Electric Cutting Systems

Page 2

Table of contents

Unpacking the machine iii

Technical Support | On-site Service xi

Statement of Warranty xii

Safety Information 1

Table Specications 5

Site Preparation 6

Grounding the Machine 8

Power/Air/Water Requirements 9

Slats and Waterbed 10

Powering up the 5100 11

Water table operation 12

Filling the water table 13

Downdraft Operation 16

FlexCut 125 Plasma Controls and Settings (See FlexCut 125 manual) 18

FlexCut 200 Plasma Controls and Settings (See FlexCut 200 manual) 20

Performing First Cut (straight torch) 22

Performing First Cut (bevel) 23

Overview of the Visual Machine Designer 24

Using the Shape Library in VMD 37

Running a Job 39

Cut Quality 41

Build Your Own Cut Chart 42

Nesting 43

Bevel 48

Red Dot Accessory 59

Basic Maintenance 60

Basic Troubleshooting 66

Torchmate 5100

ii

Page 3

C

B

DETAIL C

DETAIL B

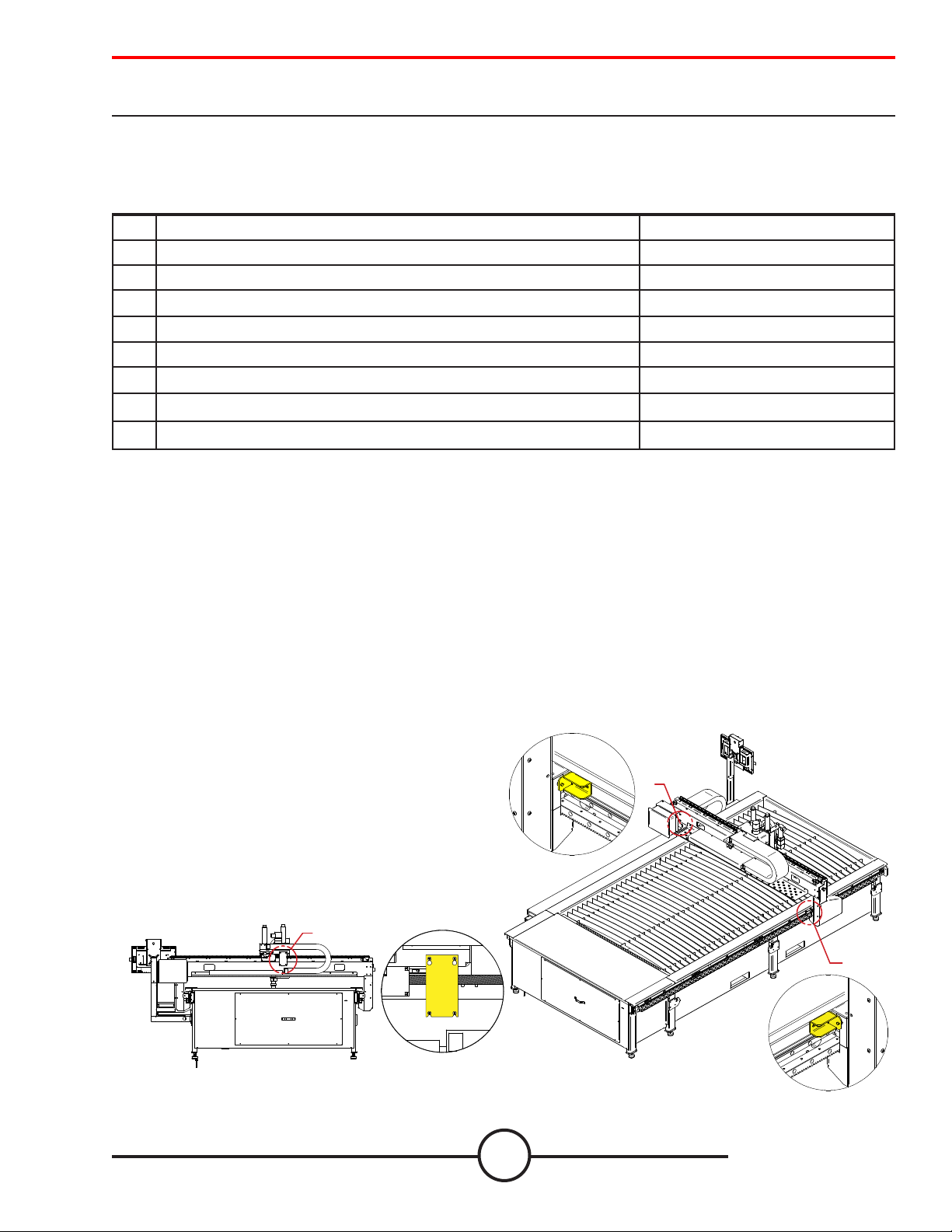

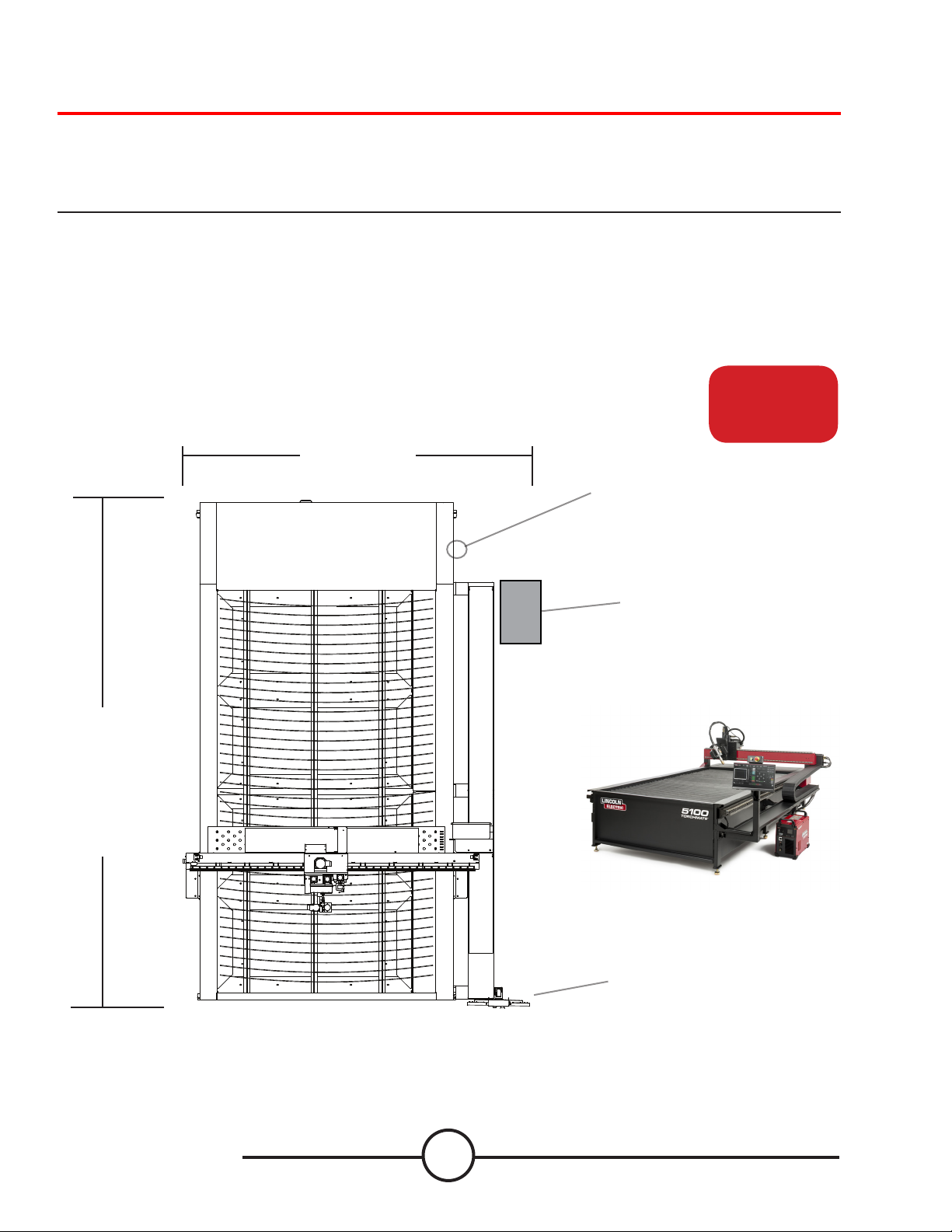

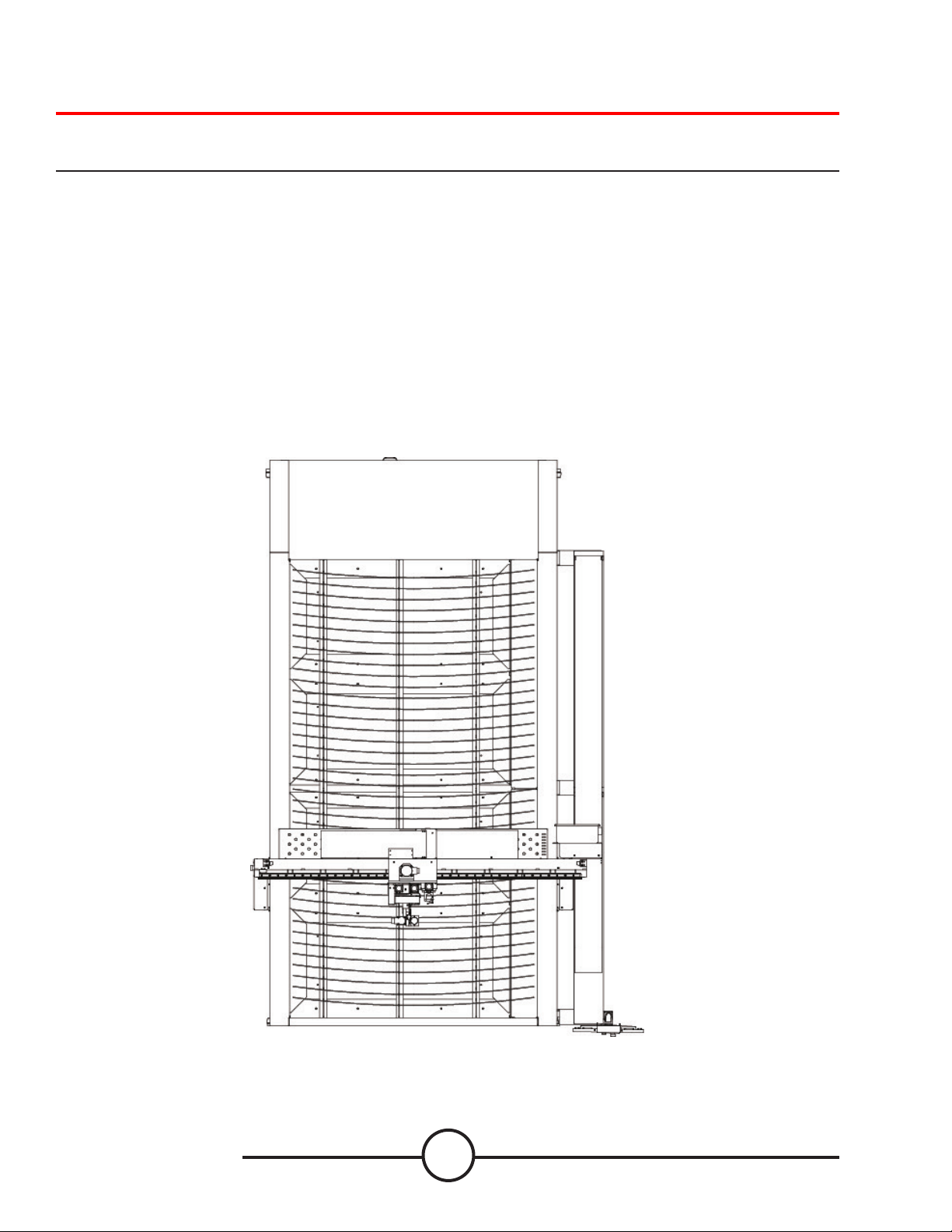

Unpacking your new machine

Your new Torchmate 5100 CNC machine is delivered assembled, but you will need to remove the shipping

material and gantry locks before operation. Verify all items have been shipped without damage before you accept the

order from the shipping company. Notify Lincoln Electric® 775-673-2200 to report any shipping damages. Your machine

was fully tested at the factory, a metal cut sample can be found in the bed of the machine.

Qty. Description Part Number

1 Lincoln Electric Torchmate

1 Lincoln Electric Torchmate

1

Lincoln Electric Torchmate

1

Lincoln Electric Torchmate

1 Lincoln Electric Torchmate

1 Lincoln Electric Torchmate

1

Lincoln Electric Torchmate

1

Lincoln Electric Torchmate

To unpackage your new Torchmate 5100 is simple. Your machine will arrive on a atbed truck and wrapped in plastic.

Use a razor knife to remove the wrap from the machine. Inspect the contents and verify that there is no damage to the

machine or its contents in the bed. If damaged, do not accept the shipment and contact Lincoln Electric Cutting

Systems.

TM

5100 Water Table with FlexCutTM 125 Plasma Unit LECS-5100-125-W0

TM

5100 Water Table with FlexCutTM 200 Plasma Unit LECS-5100-200-W0

TM

5100 Water Table with Spirit® II 275 Plasma Unit

TM

5100 Water Table with Spirit® II 400 Plasma Unit

TM

5100 Down draft with FlexCutTM 125 Plasma Unit LECS-5100-125-D0

TM

5100 Down draft with FlexCutTM 200 Plasma Unit LECS-5100-200-D0

TM

5100 Down draft with Spirit® II 275 Plasma Unit

TM

5100 Down draft with Spirit® II 400 Plasma Unit

LECS-5100-275-W0

LECS-5100-400-W0

LECS-5100-275-D0

LECS-5100-400-D0

The plasma unit, along with all the connection cables will be secured to a separate pallet. To remove the plasma power

supply from the pallet, team lift or forklift the plasma power supply and set aside until the machine is placed in its nal

operational location. The plasma unit will sit on the oor near the cable carrier exit on the monitor side.

A 6,600lb + forklift with 8’+ long forks is required to place the machine in its operational position. Use the forklift access

ports on the machine. Do not lift the machine from the cable carrier side.

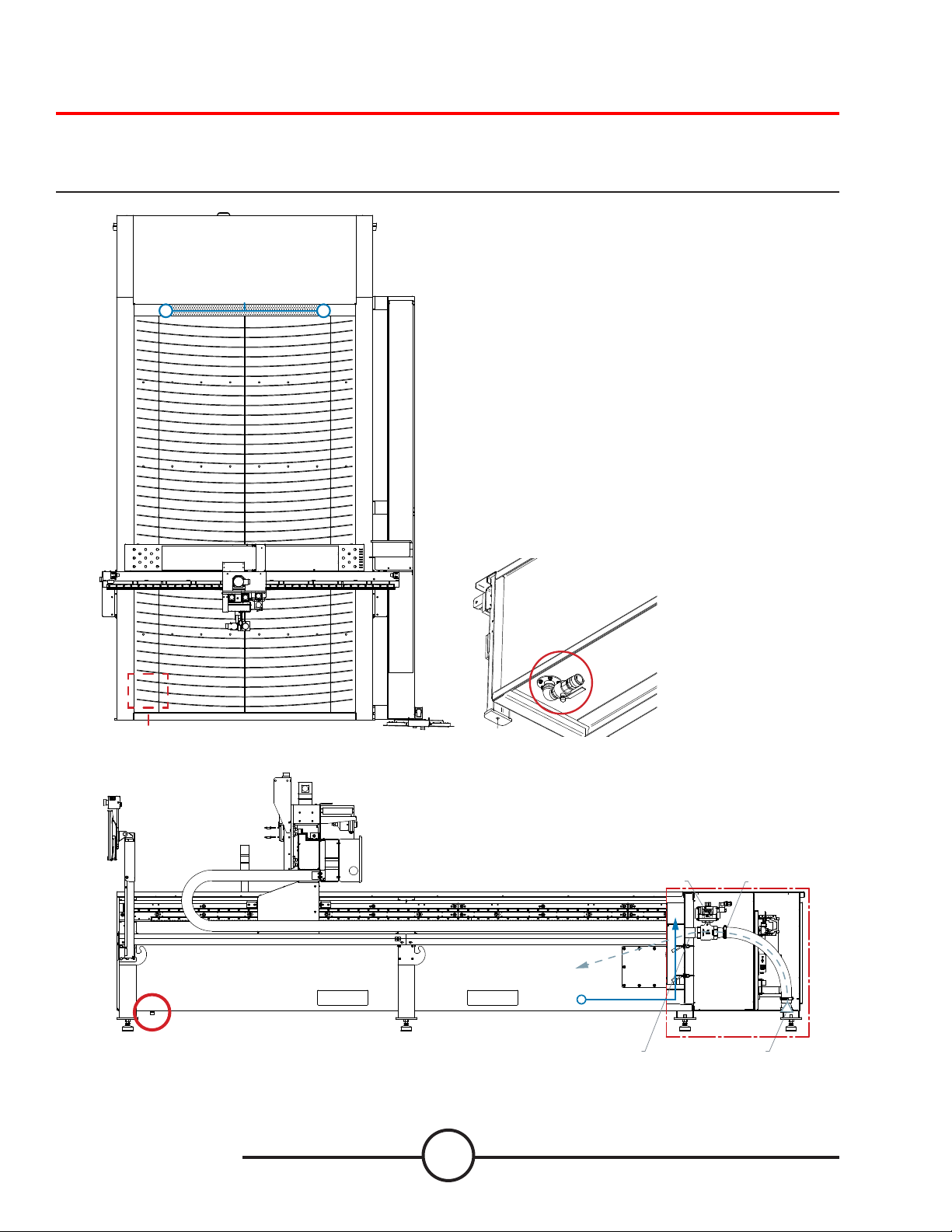

Torchmate 5100 models ship with factory installed gantry

locks. The yellow locking devices MUST BE removed before

the machine can be made operational.

DO NOT REPLACE THE BOLTS FROM THE GANTRY LOCKS

AS THIS WILL CAUSE DIRECT DAMAGE TO THE MACHINE.

Do Not Fork Lift From

Cable Carrier Side Of

Machine!

A

DETAIL A

iii

User Guide

Page 4

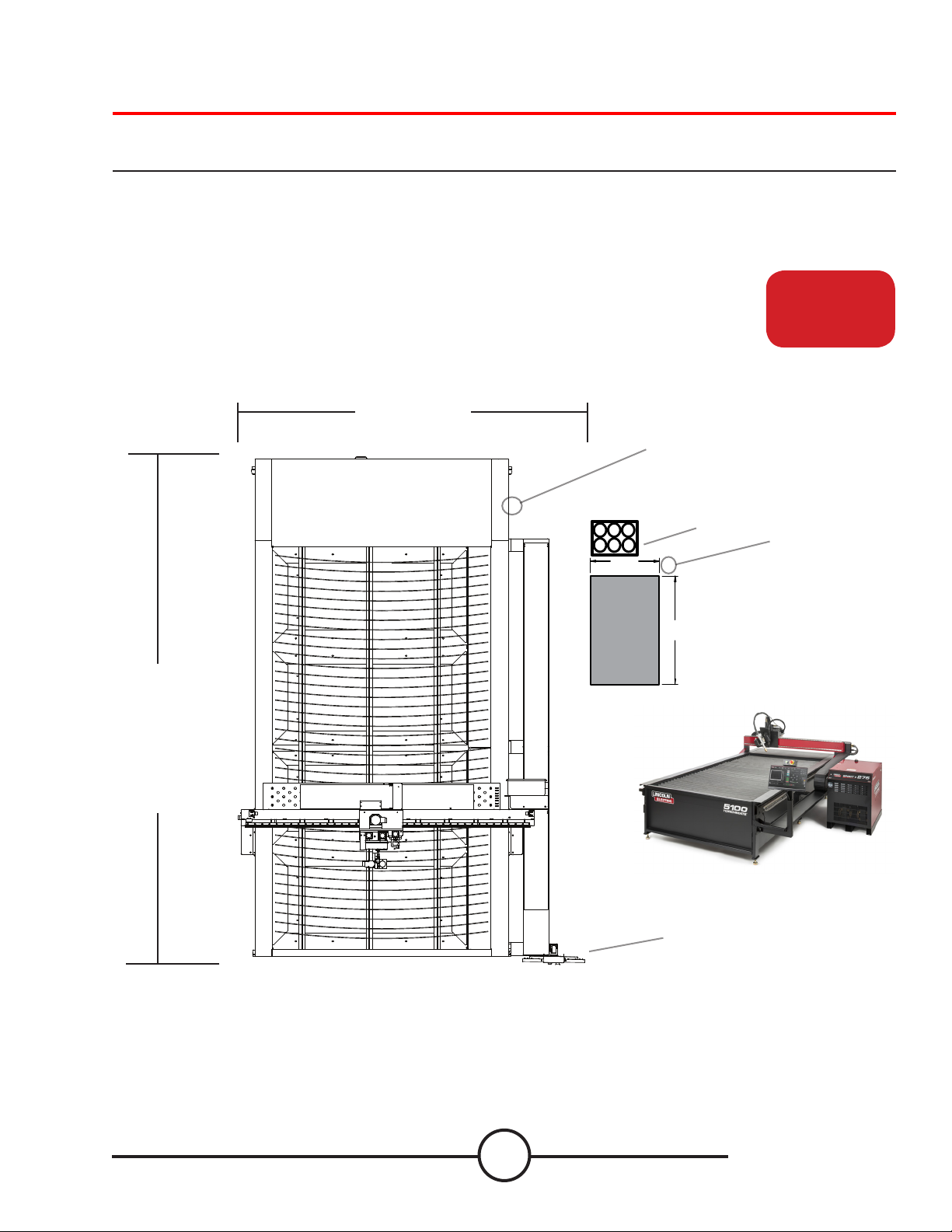

Unpacking your new machine (Leveling Feet)

When placing the machine, you will need to install the adjustable feet into the pads prior to leveling the machine. With

the machine lifted and secured, screw in all of the adjustable feet into each of the pads. DO NOT USE a hydraulic lift to

secure the machine when installing the leveling feet. Screw them halfway into the pads to get the most movement for

leveling. Once the machine is placed, then level the table. When the machine is level, then follow the WATER FILL

process.

Use ALL of the leveling feet to secure and level the table.

Make sure the table does not rock or have any movement once level.

Then the table is ready to be lled with water. (if water table)

Torchmate 5100

iv

Page 5

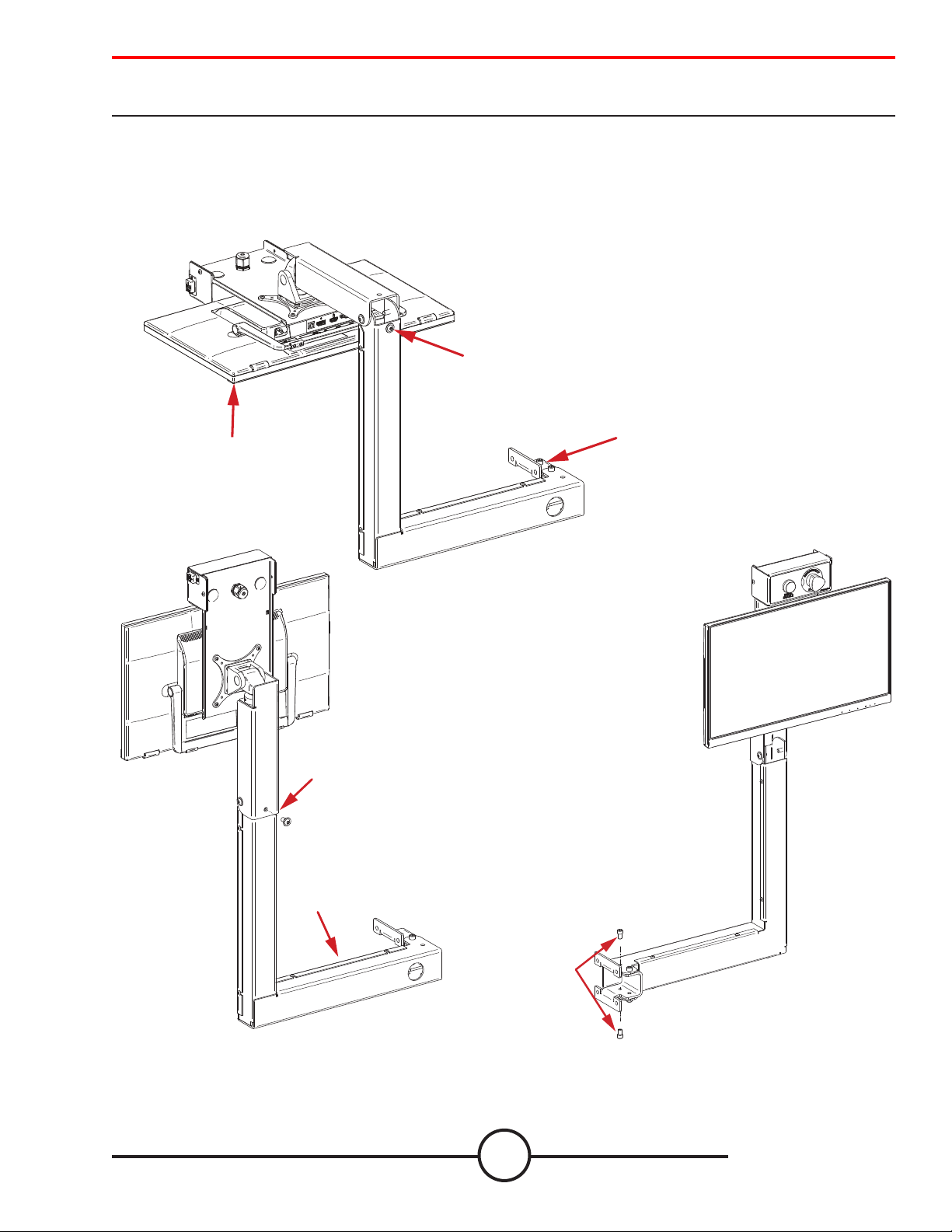

Unpacking your new machine (Monitor Arm Assembly)

4. REINSERT BOLTS

AND SECURE IN PLACE

Unfolding and securing the Monitor Arm Assembly requires a few bolts to be removed and reused to secure the arm in

place.

Remove the bolts that are indicated in the drawing and reuse them to secure the arm

1. Remove the bolt from behind the monitor and

two bolts on the swing bracket.

2. Lift the monitor up and secure with the removed bolt.

3. Grab the arm and swivel it 180 degrees into

place.

4. Re-insert the bolts to secure the arm in place.

2. LIFT MONITOR

1. REMOVE BOLT

1. REMOVE BOLTS 2x,

ONE TOP AND ONE ON BOTTOM

2. REINSTALL BOLT

3. ROTATE ENTIRE MONITOR

ARM 180 DEGREES

v

User Guide

Page 6

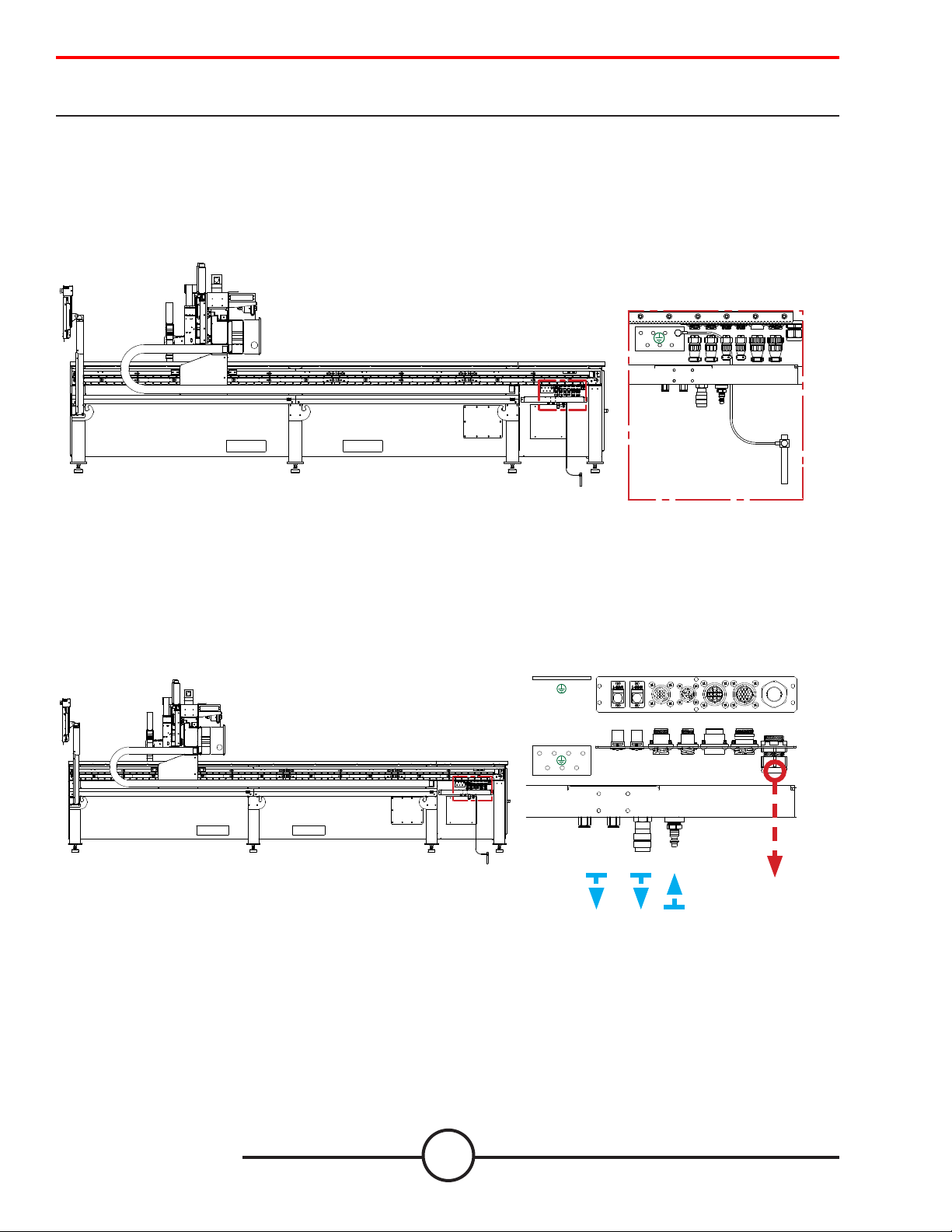

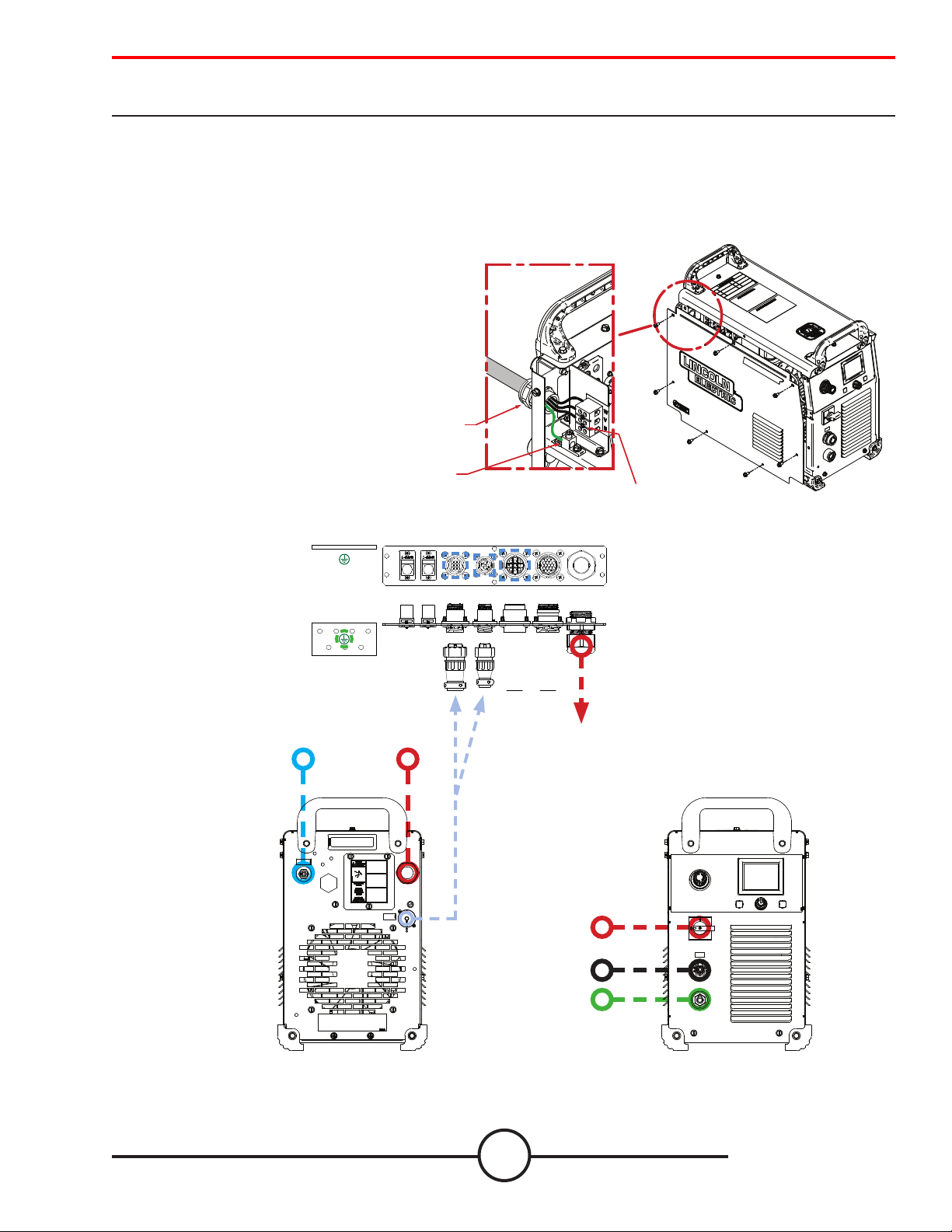

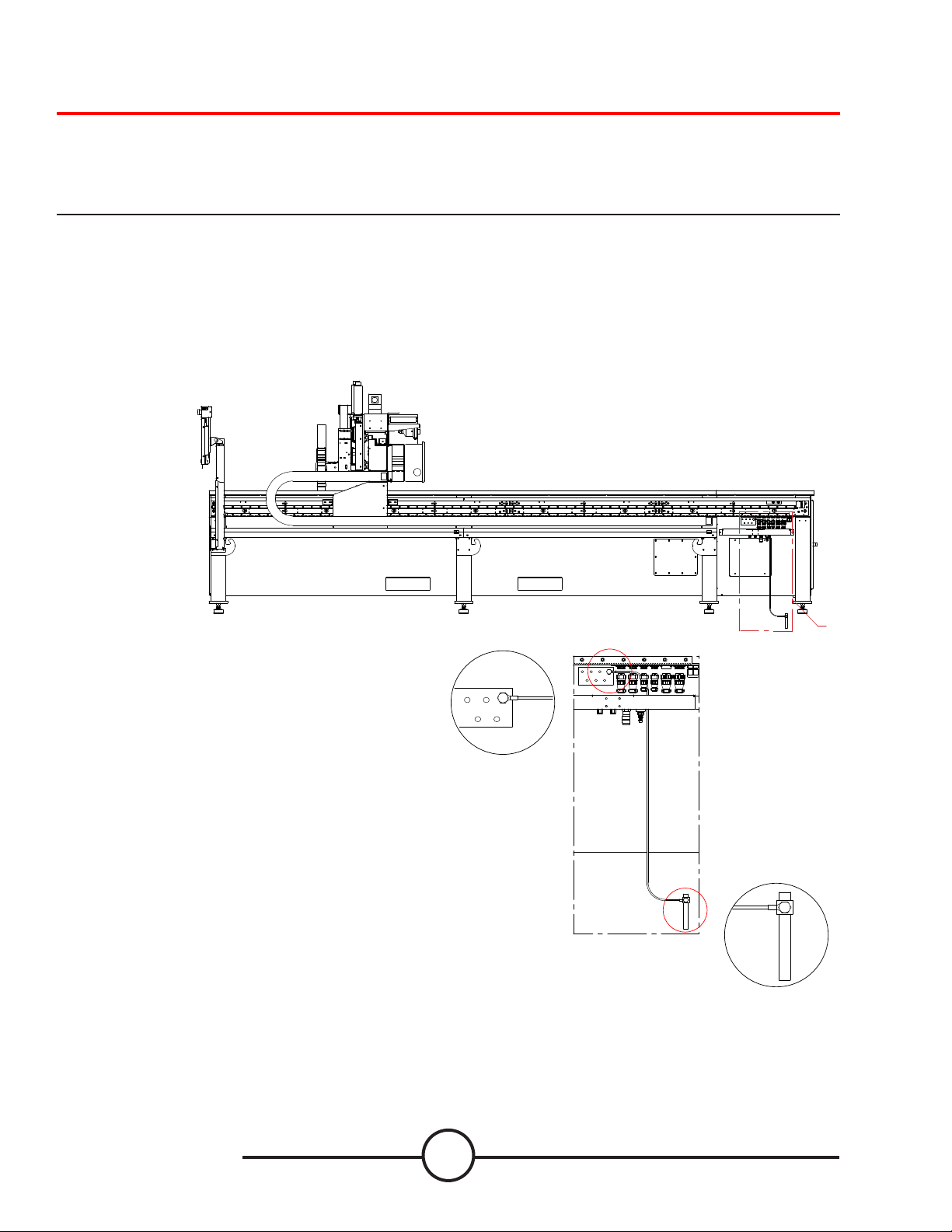

Unpacking your new machine (Electrical Connections)

INPUT

To Plasma

(for accessories)

Internally the 5100 comes pre-wired and ready to run. All systems are test red and disconnected at the facility before

packaging and shipping. For shipping purposes, the plasma power supply is disconnected from the system and will

require a connection to the machine. The table has a single 120v NEMA 5-15P plug that powers the table and computer/

monitor. The plasma power supply chosen requires 3-phase electrical connections along with numerous other connections that are required by your specic power supply to interface with the machine.

All electrical, air, and interface connections

to the machine will be o of the BULKHEAD

Electrical Bulkhead

5100 - Table Power and Air connections:

Attach the supplied 120v 15A plug into a wall outlet. This will power the electronics and table functions.

Star Ground

Star Ground

1/4” OD TUBING

PUSH

CONNECT

ETH 0

EXT. NETWORK

ETH 1

FLEX NET

1/4” QUICK

CONNECT

PLASMA

INTERFACE

P1

1/4” QUICK

CONNECT

P2

PLASMA

ARC VOLATGE

P3

P4

CAN

AUXILARY

INTERFACE

I/O

120v Power Cord

15’, NEMA 5-15p

5100 - Pneumatic Connection:

The 1/4” Industrial Quick Disconnect input on the bulkhead will distribute the air to the plasma power supply along

with table operations. Any accessories or collision sensors will also be provided shop air by tapping into the two

provided output 1/4” Tubing Push-Connects.

POWER

ENTRY

BOTTOM

VIEW

FRONT

VIEW

Torchmate 5100

vi

Page 7

Unpacking your new machine (FlexCut™ 125)

GROUND CONNECTION

CONNECT GROUND LEAD PER LOCAL

AND NATIONAL ELECTRIC CODE

INPUT CORD STRAIN RELIEF

ROUTE INPUT CORD THROUGH RELIEF

AND TWIST NUT TO TIGHTEN

POWER CONNECTION BLOCK

CONNECT EACH PHASE OF A

THREE PHASE CONDUCTOR HERE

FlexCut 125:

FlexCut 125 will have two barrel connectors to attach to the bulkhead. When moving your FlexCut 125, use

team lift or hoist. A 10 ft.(3m) power cord is provided with the FLEXCUT 125. Three Phase Input Only. Connect green lead

to ground per National Electric Code.

Connect black, red and white leads to power.

In all cases, the green or green/yellow grounding wire

must be connected to the grounding pin of the plug,

usually identied by a green screw. Attachment plugs

must comply with the Standard for Attachment Plugs

and Receptacles, UL498.The product is considered

acceptable for use only when an attachment plug as

specied is properly attached to the supply cord.

Air or Gas Inlet (1/4”

Female Quick Connect)

from bulkhead:

Star Ground

Star Ground

3-ph

Main Power

ETH 0

EXT. NETWORK

ETH 1

FLEX NET

P1

PLASMA

INTERFACE

PLASMA

ARC VOLATGE

P3

P2

CAN

INTERFACE

AUXILARY

P4

I/O

120v Connection

CNC Interface

Cable

Main Power

Switch

Torch Lead

Work (ground)

Connection to

Star

POWER

ENTRY

BOTTOM

VIEW

FRONT

VIEW

FlexCut 125

Back

vii

FlexCut 125

Front

User Guide

Page 8

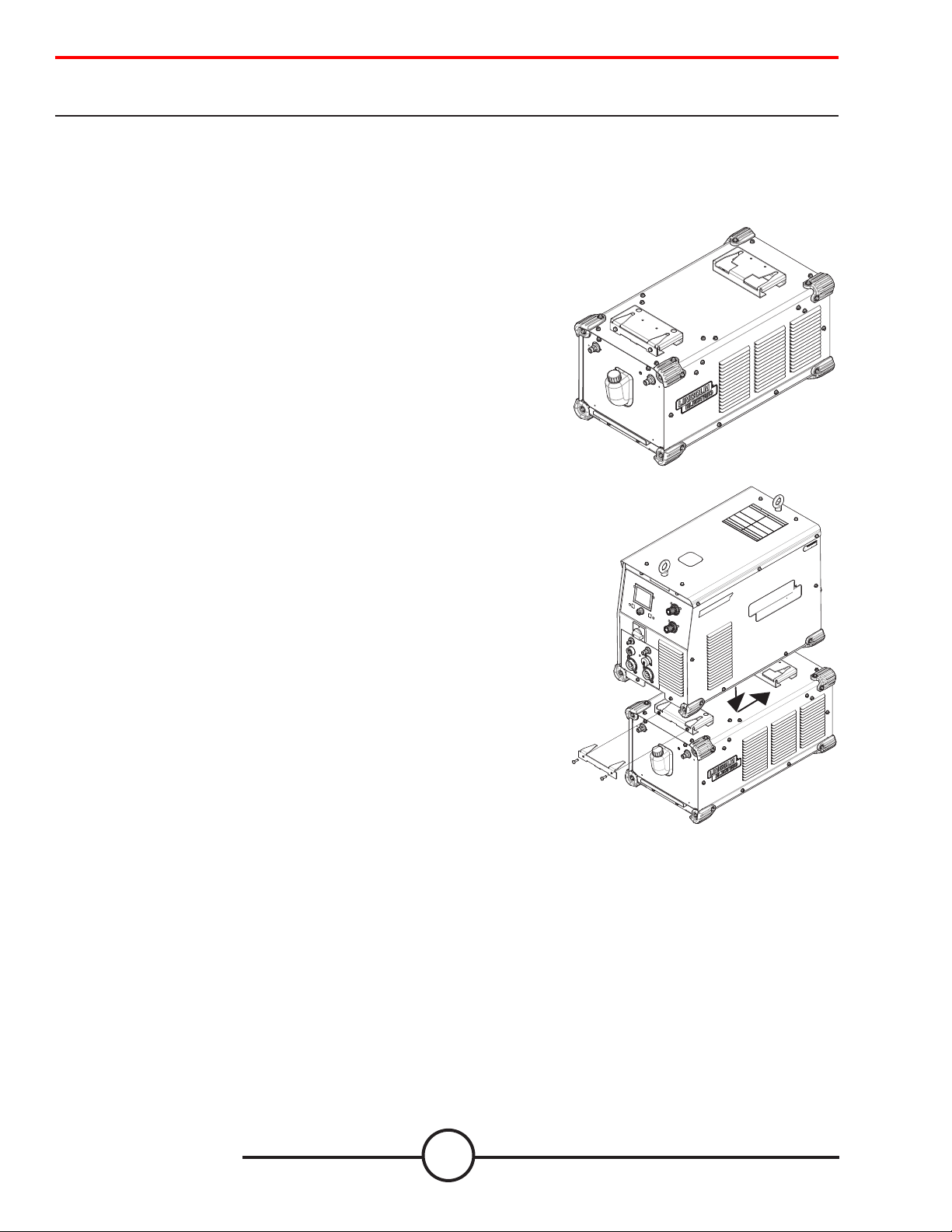

Unpacking your new machine (FlexCut™ 200/FlexCool™ 35)

FlexCut 200 and FlexCool 35:

FlexCut 200 is liquid cooled and is supplied with the FlexCool 35. For complete instructions on the FlexCut 200

and the FlexCool 35 see their corresponding user guides.

Unpacking the FlexCool 35:

The packaging of the cooler is designed to withstand shipping abuse. If any

shipping damage has occurred, contact your certied Lincoln distributor

or service center. When unpacking the unit, avoid thrusting sharp objects

through the carton, which may damage the machine. Below is the recommended procedure for unpacking the cooler:

• Cut and remove banding straps around skid and carton

• Remove carton

• Cut and remove banding straps around skid and cooler

• Remove cooler, literature, and other items

Save the instruction manual and service directory supplied with the

FlexCool 35 for parts orders and future maintenance service.

Mounting the FlexCool 35 underneath the FlexCut 200:

The FlexCool 35 can be mounted underneath the FlexCut 200 machine or by

itself on a at surface.

No power source should ever be installed underneath the FlexCool 35.

Securing the FlexCut 200 to the FlexCool 35:

1. Begin by setting the FlexCool 35 on a hard at surface.

2. Remove the two 7/16” bolts and the locking bracket from the

front mounting bracket

3. Lift the FlexCut 200 and place on top and slightly forward of the

FlexCool 35

4. Carefully guide the FlexCut 200 so that the quick lock feet on the

bottom of the power source slide into the channels of the mount

ing brackets on top of the FlexCool 35. Be sure all 4 feet are within

the channels.

5. Slide the FlexCut 200 all the way back so that it is sitting exactly

overtop of the FlexCool 35. The feet should be all the way at the

back of the channels.

6. Replace the locking bracket into the front mounting bracket of the

FlexCool 35. Torque both 7/16” bolts to 50 in-lbs.

Filling the Coolant Reservoir:

USE ONLY LINCOLN ELECTRIC TORCH COOLANT - BK500695

1.5 gallons of coolant are preloaded into the machine at the facility for live re testing.

Pour .75 gallons (2.84 liters) of coolant into the coolant reservoir ll hole through a funnel.

Use the coolant purge command in the machine UI menus to help prime the system.

While priming, add additional coolant to keep the reservoir full. The cooler is “FULL” when the coolant lies just below the

coolant reservoir opening.

Be certain to replace the reservoir ll cap when the reservoir is full. Operation of the FlexCool 35 without the reservoir

cap can cause unnecessary contamination and could be hazardous to others. See the FlexCool 35 manual for complete

instructions and safety precautions.

Torchmate 5100

viii

Page 9

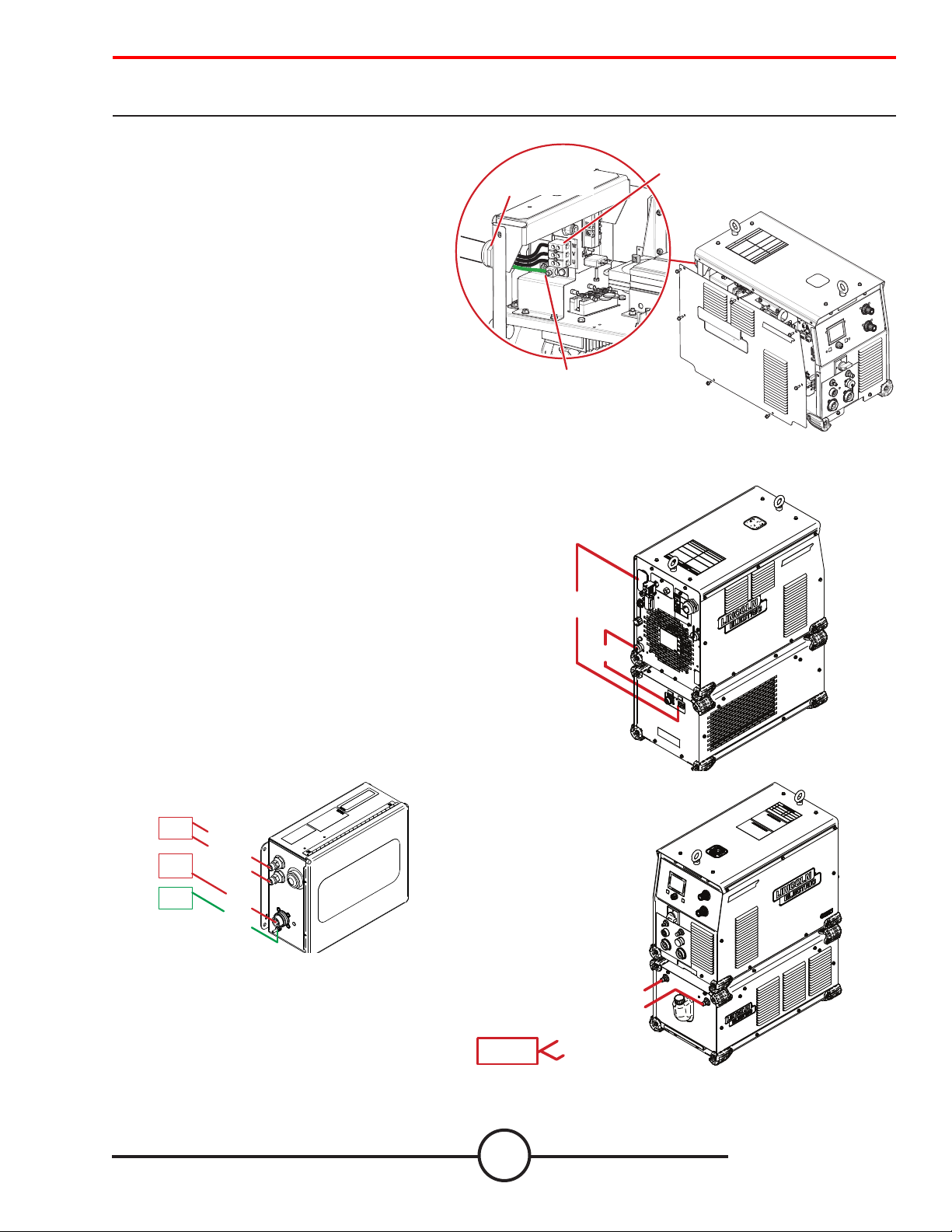

Unpacking your new machine (FlexCut™ 200/FlexCool™ 35)

The FlexCut 200 does not come with an SO

cord installed for the main power connection.

Use a three-phase supply line. A 1.75 inch (45

Input Cord Strain Relief:

Route input cord through

relief and twist nut to tighten.

mm) diameter access hole for the input supply

is located on the case back.

Connect L1, L2,L3 and ground per connection

diagrams and National Electric Code.

To access the input power connection block,

remove the seven screws and the left case side

of the machine as shown.

Connections between the FlexCut 200 and FlexCool 35:

1. Connect the 115v from the FlexCool 35 to the 115v connection on the back of the FlexCut 200.

2. Connect the ARCLINK cable into the FlexCut 200 to the

FlexCool 35.

3. The two coolant supply lines from the FLEXSTART box will

be coming out the cable carrier. Attach the supply lines to

the FLEXCOOL 35.

4. On the gantry by the FLEXSTART box, remove the zip tie

and connect the two hoses and ARCLINK barrel connector to

the FLEXSTART.

Ground Connection:

Connect Ground Lead per local

and national electrical codes

115 V

AC**

ARC LINK

Power Connection Block:

Connect each phase of a three

phase connector here

FROM

COOLER

COOLANT RETURN

COOLANT SUPPLY

FROM

POWER

SOURCE

TO

STAR

GROUND

ARCLINK

GROUND

FLEXSTART box mounted to gantry on the

5100. Hoses and cables are run into the

cable carrier.

TO

FLEXSTART

ix

COOLANT RETURN

COOLANT SUPPLY

User Guide

Page 10

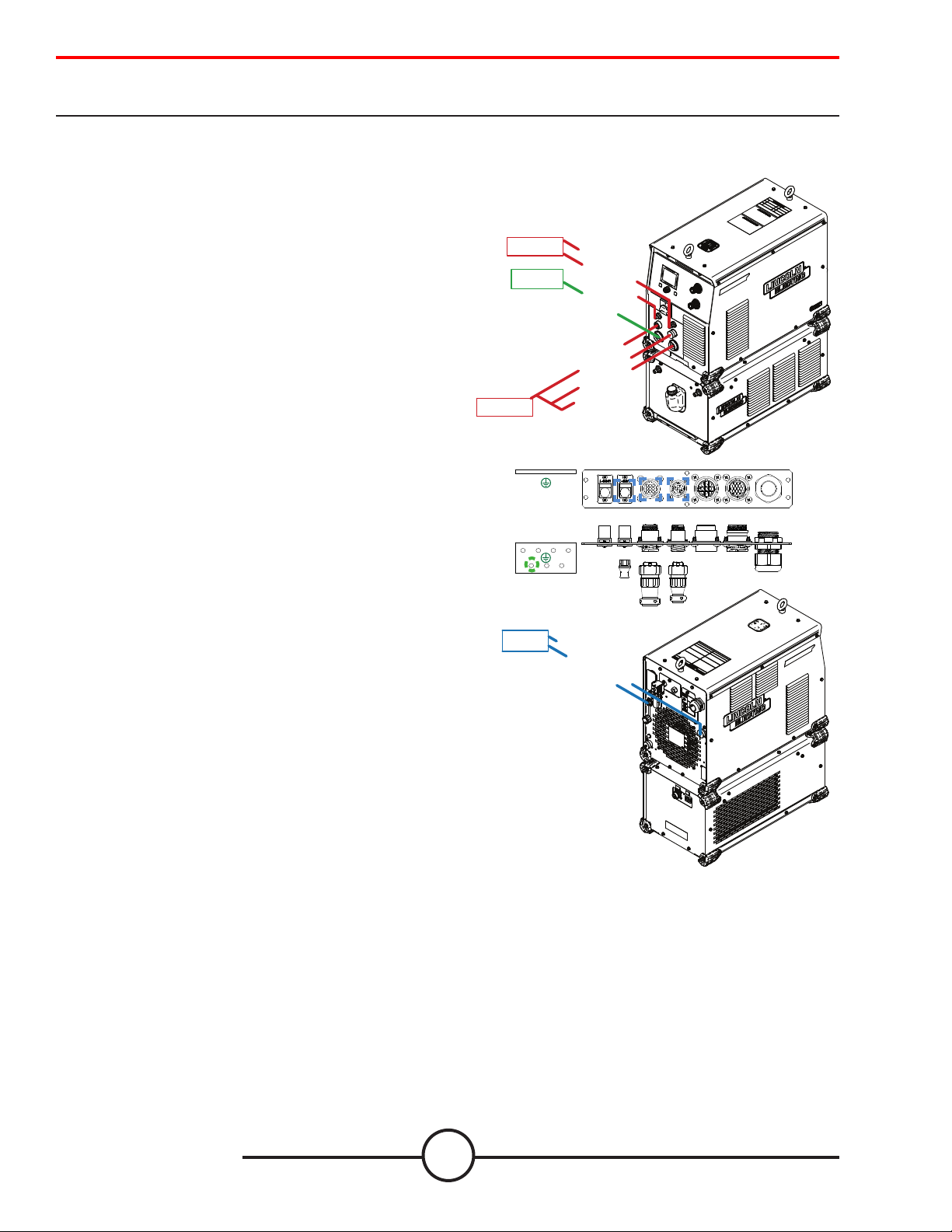

Unpacking your new machine (FlexCut™ 200/FlexCool™ 35)

Connections between the FlexCut 200 and 5100:

5. From the cable carrier, connect the PLASMA GAS

and SHIELD GAS to the FlexCut 200.

6. Attach the PLASMA connections from the cable

carrier to the NOZZLE, ARC LINK, ELECTRODE.

7. Connect the WORK to the STAR GROUND BLOCK on

the machine.

CABLE CARRIER

STAR GROUND

FROM

CABLE CARRIER

FROM

TO

Star Ground

PLASMA GAS

SHIELD GAS

WORK

NOZZLE

ARC LINK

ELECTRODE

ETH 1

ETH 0

FLEX NET

EXT. NETWORK

PLASMA

INTERFACE

P1

PLASMA

ARC VOLATGE

CAN

INTERFACE

AUXILARY

P4

POWER

ENTRY

I/O

P3

P2

8. Connect the CNC interface cable to the BULKHEAD

P1 and P2.

9. Connect the ETHERNET connector to the back of

the FLEXCUT 200. Attach the other end to the ETH1

port to the Fiber Optic box. Attach the ber optic and

power cable to the converter box.

For full wiring instructions, see the corresponding

manuals for the FlexCut 200 and FlexCool 35.

Star Ground

TO

5100 BULKHEAD

CNC INTERFACE

ETHERNET

Torchmate 5100

x

Page 11

Technical Support | On-Site Service

Lincoln Electric Cutting Systems provides numerous technical support opportunities with the purchase of your new

Torchmate 5100 CNC cutting machine. The following is a brief outline of available options. On-site visits are available at

an additional cost call 775-673-2200 for additional information.

• Phone Support

Phone support is available Monday – Friday 7:00 am-4:00 pm PST. Lincoln Electric will make every eort to handle phone calls promply. Due to the nature of machine diagnoses and the varied

capabilities of machine operators we cannot guarantee hold wait times for phone-in technical

support.

Technical support includes, machine assembly/set-up, troubleshooting, conguration, and quality

related issues. Operational or CAD training is not included in phone technical support.

• Email

Lincoln Electric will return emails to the support@Torchmate.com email address within 24 hours

Monday-Friday

• Webinars and LiveStream

Lincoln Electric provides live webinars from time to time to assist customers in the optimization and

operation of CNC systems. Please subscribe to our newsletter for dates and times.

http://torchmate.com/webinars

• Torchmate Training Seminars

Lincoln Electric provides a number of training opportunities at our Reno, Nevada campus and at

select Regional locations. Please call 775-673-2200 for details or visit

http://torchmate.com/seminars

• Torchmate Online Training

Lincoln Electric maintains a number of operational training resources at

http://torchmate.com/training

• Torchmate YouTube Channel:

Lincoln Electric provides a wide selection of how to tutorials on our YouTube page.

https://www.youtube.com/user/torchmatedotcom

xi

User Guide

Page 12

Statement of Warranty

30 Day guarantee

Warranty

If Buyer is not satised with the performance of the Goods within 30 days from the

date the Goods were shipped from the Seller, Buyer may return the Goods in the

original carton(s) for a full refund less Shipping, Handling, Damages and Freight

Charges. All sales become nal after this 30 day period. Buyer should determine the

satisfactory performance of the Goods by using the software, and inspecting and

bench running the motors and/or accessory items. Any items to be returned for full

refund must be in new, unused (except for bench testing), and saleable condition at

the sole determination of the Seller. Items that, in the Seller’s judgment, have been

used or modied in any way, or kits that have been partially or fully completed will

be subject to a restocking fee to be determined by the Seller. A return merchandise

authorization number (RMA) must be obtained by the customer prior to any return.

Shipments of returned items not marked with a valid RMA will be refused.

Electronics and motors are warranted by their manufacturer to the original purchaser

for 12 months from the date of Torchmate, Inc.’s sale invoice. Mechanical components

are standard industrial parts and are not warranted except by their respective

manufacturers. If any of the warranted items are found by Seller to be defective, such

Goods will, at Seller’s option, be replaced or repaired at Seller’s cost. No defective

goods are to be returned without written authorization of seller. The sole purpose

of the stipulated exclusive remedy shall be to provide the Buyer with free repair and

replacement of defective Goods in the manner provided herein. This exclusive remedy

shall not be deemed to have failed of its essential purpose so long as the Seller is

willing and able to repair or replace defective Goods in the prescribed manner. The

foregoing warranty is in lieu of all other warranties, express or implied, including

those of merchantability or tness for any purpose not expressly set forth herein. No

armation of Seller, by words or action, other than as set forth in this Section shall

constitute a warranty. Seller’s warranty does not apply to any Goods which have been

subjected to misuse, mishandling, misapplication, neglect (including but not limited

to improper maintenance), accident, improper installation, modication (including

by not limited to use of unauthorized parts or attachments), or adjustment or repair

performed by anyone other than Seller or one of Seller’s authorized agents. When

returning products to Seller packaging must be adequate or all warranty is null and

void. Buyer will pay for the cost of Shipping to and from the Seller for all warranty

repairs.

Any claim by Buyer with reference to the Goods sold hereunder shall be deemed waived

by the Buyer unless submitted in writing to seller within the earlier of (i) thirty (30)

days following the date Buyer discovered or by reasonable inspection should have

discovered, any claimed breach of foregoing warranty, or (ii) 12 months following the

date of shipment. Any cause of action for breach of the foregoing warranty shall be

brought within one year from the date the alleged breach was discovered or should

have been discovered, whichever occurs rst.

Torchmate 5100

xii

Page 13

Statement of Warranty (cont.)

Seller’s liability (whether under the theories of breach of contract or warranty,

negligence, or strict liability) for its Goods shall be limited to repairing or replacing

Goods found by Seller to be defective, or at Seller’s option, to refunding the purchase

price of such Goods or parts thereof.

In no event shall seller be liable for consequential damages arising out of or in

connection with this agreement, including without limitation, breach of any obligation

imposed on seller hereunder. Consequential damages shall include without limitation,

loss of use, income or prot, or loss sustained as the result of injury (including death)

to any person, or loss of or damage to property (including without limitation property

handled or processed by the use of the goods). Buyer shall indemnify seller against all

liability, cost or expense which may be sustained by seller on account of any such loss,

damage, or injury.

Upon buyer’s receipt of shipment, Buyer shall immediately inspect the Goods. Unless

Buyer provides Seller with written notice of any claim for shortage, overcharge, or

damage of Goods within ten (10) days from invoice date, such Goods shall be deemed

nally inspected, checked and accepted by Buyer and no allowances shall be made

thereafter. In absence of shipping and packaging instructions, Seller shall use its own

discretion in the choice of carrier and method of packing. Seller shall not be responsible

for insuring shipments unless specically requested by Buyer and any insurance or

special packaging so requested shall be at Buyer’s expense and valuation.

Title to any Goods sold and risk of loss of such Goods passes to Buyer upon delivery by

Seller to carrier and any claims for losses or damages shall be made by Buyer directly

with carrier.

A. In addition to the rights and remedies conferred upon Seller by law, Seller shall not

be required to proceed with the performance of any order or contract if the Buyer

is in default in the performance of any order or contract with Seller, and in case

of doubt as to Buyer’s nancial responsibility, shipments under this order may be

suspended.

B. No delay or omission by Seller in exercising any right or remedy provided for herein

shall constitute a waiver of such right or remedy and shall not be constituted as a

bar to or a waiver of any such right or remedy on any future occasion.

C. The sale of Goods shall be governed by the laws of the State of Maryland. Seller

agrees to comply with all applicable laws of the United States.

D. The purchasers of products from Lincoln Electric Cutting Systems are responsible

to dispose of consumables, uids and machinery at the end of the life cycle in

accordance with federal and local regulations.

The invalidity or unenforceability of any one or more phrases, sentences, or sections

shall not aect the validity or enforceability of the remaining portions of this

Agreement.

Limitation of

liability

Disclaimer of

consequential

damages

Acceptance and transportation

Title and

risk of loss

General

conditions

Severability

xiii

User Guide

Page 14

Safety First

Torchmate and Lincoln Electric Cutting Systems equipment is designed and built with safety in mind. Safe

operation requires that the user follow proper installation, training, and safe operating procedures.

THIS MACHINE CREATES ELECTRO-MAGNETIC FIELDS DURING OPERATION

WARNING

PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH.

DO NOT INSTALL,

OPERATE, OR REPAIR

THIS EQUIPMENT

WITHOUT READING

THE SAFETY WARNINGS

CONTAINED THROUGHOUT THIS MANUAL.

Think before you act—

and be careful.

While Operating the machine.

• WEAR CORRECT EYE, EAR & BODY PROTECTION

• PROTECT your eyes and face with welding helmet properly tted and with proper hade rating of lter plate (See

ANSI Z49.1).

• PROTECT your body from welding spatter and arc ash with protective clothing including woolen clothing, ameproof apron and gloves, leather leggings, and high boots.

• PROTECT others from splatter, ash, and glare with protective screens or barriers.

• WHEN OPERATING THIS EQUIPMENT, wear hearing protection.

• BE SURE protective equipment is in good condition.

• Provide adequate lighting to the area around the machine appriopriate for all the tasks being completed.

• Wear safety glasses in work area AT ALL TIMES.

• Do not climb on machine. It is not intended as a ladder or to support anything but the intended use of metal cutting. Climbing onto the machine could result in a fall that can result in injury or death.

KEEP CHILDREN AWAY.

IF YOU WEAR A PACEMAKER, YOU SHOULD CONSULT WITH YOUR

DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For additional safety information it

is strongly recommended that you acquire a copy of “Lincoln Electric E205 ‘Arc Welding

Safety’”as well as “Safety in Welding & Cutting - ANSI Standard Z49.1” from the American

Welding Society, P.O. Box 351040, Miami, Florida 33135 or CSA Standard W117.2.

BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE, AND REPAIR

PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS

ELECTRIC SHOCK can kill.

• The electrode and work (or ground) circuits are electrically “hot” when the power source is on. Do not touch these

“hot” parts with your bare skin or wet clothing. Wear dry, hole-free gloves to insulate hands.

• Disconnect the power source before performing any service or repairs. When the power source is operating,

voltages in excess of 250 volts are produced. This creates the potential for serious electrical shock - possibly even

fatal.

• Insulate yourself from work and ground using dry insulation. Wear dry gloves and clothing. Take extra care when

the work place is moist or damp.

• Always be sure the work cable makes a good electrical connection with the metal being cut or gouged. The

connection should be as close as possible to the area being cut or gouged.

• Ground the work or metal to be cut or gouged to a good electrical (earth) ground.

• Maintain the plasma torch, cable and work clamp in good, safe operating condition. Repair or replace all worn or

damaged parts. Replace damaged insulation.

• Never dip the torch in water for cooling or plasma cut or gouge in or under water.

• When working above oor level, protect yourself from a fall should you get a shock.

• Operate the pilot arc with caution. The pilot arc is capable of burning the operator, others or even piercing safety

clothing.

1

User Guide

Page 15

FUMES AND GASES can be dangerous.

• Plasma cutting or gouging may produce fumes and gases hazardous to your health. Avoid breathing these fumes

and gases. When cutting or gouging, keep your head out of the fumes. Use enough ventilation and/or exhaust at the

arc to keep fumes and gases away from the breathing zone and general area.

• Use an air-supplied respirator if ventilation is not adequate to remove all fumes and gases.

• When plasma cutting or gouging on lead or cadmium plated steel and other metals or coatings which produce toxic

fumes, keep exposure as low as possible and within applicable limits such as the OSHA PEL and ACGIH TLV limits,

using local exhaust or mechanical ventilation. In conned spaces or in some circumstances a respirator will be

required.

• Additional precautions are also required when cutting (zinc) galvanized steel or materials containing or coated with

any of the following:

Antimony Beryllium Cobalt Manganese Selenium

Arsenic Cadmium Copper Mercury Silver

Barium Chromium Lead Nickel Vanadium

• The operation of plasma cutting or gouging fume control equipment is aected by various factors including proper

use and positioning of the equipment, maintenance of the equipment, and the specic procedure and application

involved. Worker exposure levels should be assessed by a qualied individual, such as an industrial hygienist, upon

installation and periodically thereafter to be certain levels are within applicable exposure limits, such as the OSHA

PEL and ACGIH TLV. For information on how to test for fumes and gases in your work place, refer to publications

section of this manual.

• Do not use plasma cutting or gouging equipment in locations near chlorinated hydrocarbon vapors coming from

degreasing, cleaning or spraying operations. The ultraviolet rays from the arc can react with solvent vapors to form

phosgene, a highly toxic gas, and other irritating products. Remove all sources of these vapors.

• Materials containing chromium may release hexavalent chromium compounds during plasma cutting and other hot

work.

• Hexavalent chromium compounds are on the IARC list as posing a lung cancer risk to humans. Use adequate ventilation to avoid overexposures.

• Gases used for plasma cutting and gouging can displace air and cause injury or death. Always use enough

ventilation, especially in conned areas, to insure breathing air is safe.

• Read and understand the manufacturer’s instructions for this equipment and follow your employer’s safety

practices.

• This product, when used for cutting, produces fumes or gases which contain chemicals known to the State of

California to cause birth defects

• Fumes and gases from hot work and dust created by routing, sawing, grinding, drilling, and other construction

activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Avoid prolonged contact with this dust. Wear protective clothing and wash exposed areas with soap and water. Avoid dust to get into

your mouth, eyes, or lay on the skin as this may promote or result in the absorption of harmful chemicals.

Some examples of these chemicals are:

• Lead from lead-based paint.

• Crystalline silica from bricks and cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on the nature and frequency of this type of work. To revent your exposure to these chemicals: Use local exhaust ventilation and/or work in a well ventilated area, and work with approved

safety equipment, including respiratory protection that is properly selected in accordance with the contaminants, and

their concentrations present in the work environment.

Torchmate 5100

2

Page 16

ARC RAYS can burn.

• Plasma Arc Rays can injure your eyes and/or burn your skin. The plasma arc process produces very bright ultraviolet

and infrared rays. These will damage your eyes and burn your skin if you are not properly protected.

• Use safety glasses and a shield with the proper lter and cover plates to protect your eyes from sparks and the rays

of the arc when performing or observing plasma arc cutting or gouging. Glasses, head-shield, and lter lens should

conform to ANSI Z87. I standards.

Use suitable clothing including gloves made from durable ame-resistant material to protect your skin and that of

your helpers from the arc rays.

• Protect other nearby personnel with suitable non-ammable screening and warn them about the hazards of the

activity taking place, and the precautions they must take.

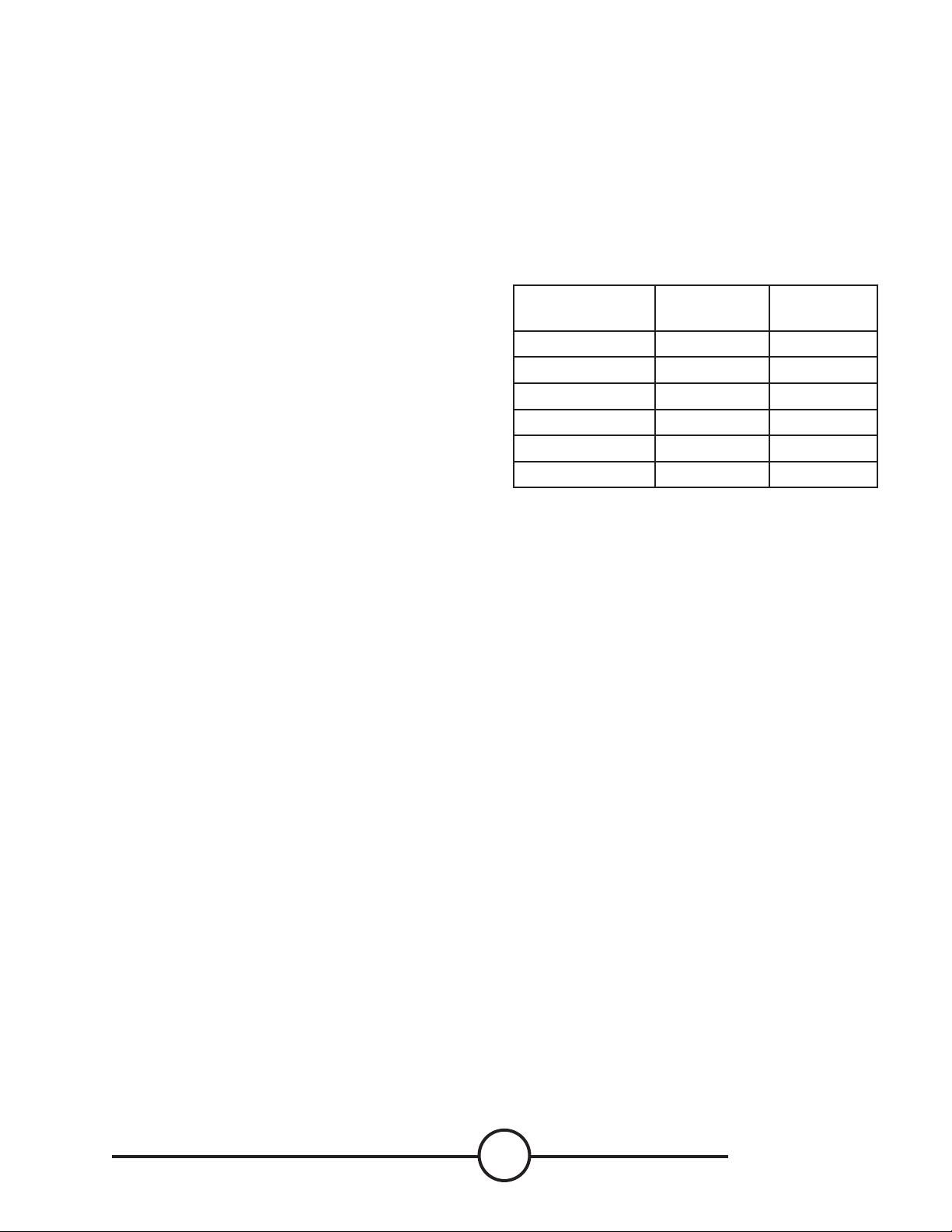

• According to IARC, ultraviolet radiation from

welding causes ocular melanoma. IARC identies

gouging, brazing, carbon arc or plasma arc cutting, and

soldering as processes closely related to welding

Cutting ame and sparks can cause FIRE OR EXPLOSION.

Arc Current Minimum

Shade No.

Less than 20A 4 4

20A-40A 5 5

40A-60A 6 6

60A-300A 8 9

300A-400A 9 12

400A-800A 10 14

Suggested

Shade No.

• Read and follow NFPA 51B “ Standard for Prevention During Welding, Cutting and Other Hot Work”, available from

NFPA, 1 Batterymarch Park,PO box 9101, Quincy, Ma 022690-9101.

• Fire and explosion can be caused by hot slag, sparks, oxygen fueled cutting ame, or the plasma arc.

• Have a re extinguisher readily available. Provide a re watch when working in an area where re hazards may

exist.

• When not cutting or gouging, make certain no part of the electrode circuit is touching the work or ground.

Accidental contact can cause overheating and create a re hazard.

• Be sure there are no combustible or ammable materials in the workplace. Any material that cannot be removed

must be adequately protected as to avoid any potential for contact with ames, sparks or spatter.

• Sparks and hot materials from cutting or gouging can easily go through small cracks and openings to adjacent

areas.

• Avoid cutting or gouging near hydraulic lines.

• Do not cut or gouge tanks, drums or containers until the proper steps have been taken to insure that such

procedures will not cause ammable or toxic vapors from substances inside. They can cause an explosion even

though they have been “cleaned.” For information purchase “Recommended Safe Practices for the Preparation for

Welding and Cutting of Containers and Piping That Have Held Hazardous Substances”, AWS F4.1 from the American

Welding Society (see address above).

• Vent hollow castings or containers before heating, cutting or gouging. They may explode.

• Do not add fuel to engine driven equipment near an area where plasma cutting or gouging is being done.

• Connect the work cable to the work as close to the cutting or gouging area as practical. Work cables connected

to the building framework or other locations away from the cutting or gouging area increase the possibility of

the current passing through lifting chains, crane cables or other alternate circuits. This can create re hazards or

overheat lifting chains or cables until they fail.

• Hydrogen gas may be formed and trapped under aluminum work pieces when they are cut underwater or while

using a water table. DO NOT cut aluminum alloys underwater or on a water table unless the hydrogen gas can be

eliminated or dissipated. Trapped hydrogen gas that is ignited will cause an explosion.

3

User Guide

Page 17

CYLINDER may EXPLODE if damaged.

• Use only compressed gas cylinders containing the correct gas for the process used and properly operating

regulators designed for the gas and pressure used. All hoses, ttings, etc. should be suitable for the application and

maintained in good condition.

• Always keep cylinders in an upright position securely chained to an undercarriage or xed support.

• Cylinders should be located: • Away from areas where they may be struck or subjected to physical damage. • A safe

distance from plasma cutting or gouging, arc welding operations and any other source of heat, sparks, or ame.

• Never allow any part of the electrode, torch or any other electrically “hot” parts to touch a cylinder.

• Keep your head and face away from the cylinder valve outlet when opening the cylinder valve.

• Valve protection caps should always be in place and hand tight except when the cylinder is in use or connected for

use.

• Read and follow the instructions on compressed gas cylinders, associated equipment, and CGA publication P-l,

“Precautions for Safe Handling of Compressed Gases in Cylinders,”available from the Compressed Gas Association

1235 Jeerson Davis Highway, Arlington, VA 22202.

FOR ELECTRICALLY powered equipment.

• Turn o input power using the disconnect switch at the fuse box before working on the equipment.

• Install equipment in accordance with the U.S. National Electrical Code, all local codes and the manufacturer’s recommendations.

• Ground the equipment in accordance with the U.S. National Electrical Code and the manufacturer’s

recommendations.

PLASMA ARC can injure.

• Keep your body away from nozzle and plasma arc.

• Operate the pilot arc with caution. The pilot arc is capable of burning the operator, others or even piercing safety

clothing.

ELECTRIC AND MAGNETIC FIELDS may be dangerous

• Electric current owing through any conductor causes localized Electric and Magnetic Fields (EMF). Cutting or gouging current creates EMF elds around torch cables and cutting machines.

• EMF elds may interfere with some pacemakers or other medical implant devices, so operators who have such a

device should consult their physician and the device manufacturor before cutting or gouging.

• Exposure to EMF elds during cutting or gouging may have other health eects which are now not known.

• All operators should use the following procedures in order to minimize exposure to EMF elds from the cutting or

gouging circuit:

• Route the torch and work cables together - Secure them with tape when possible.

• Never coil the torch cable around your body.

• Do not place your body between the torch and work cables. If the torch cable is on your right side, the work

cable should also be on your right side.

• Connect the work cable to the workpiece as close as possible to the area being cut or gouged.

• Do not work next to cutting power source.

For more information on electromagnetic interference please visit

Torchmate 5100

http://torchmate.com/white-papers/EMI-Reduction

4

Page 18

Table Specications

Input Power

• 120V / 1Ph / 15A / 60Hz (table and computer)

• 380-600V / 3Ph / 50-60Hz (Plasma Power Supply specic)

Machine Size

• 60˝ x 120” (1524mm x 3048mm) Cutting Area

• 113.5˝ x 167” (2895.6mm x 4241.8mm) Footprint

Traverse Speed

• 1,500 ipm (0.635 mps)

Cut Speed

• Up to 1500 ipm

Plate Capacity

• Holds Up To 4” (102mm) 5’x10’ (1524mm x 3048mm) Mild Steel

Weight

• 6,600 lbs (

Operating Temperature

• 32-104° Farenheit (0-40° Celcius)

Motors

• Servo Motors Fitted with Rotary Glass Encoders

Drive System

• Helical Gear Rack and Hardened Pinion with Lubrication

System

Linear Guidance

• Prole Linear Rail

Height Control

• Ohmic Sensing

• Automatic Torch Height Control

• 6.75” Z-axis Travel

Bevel Capabilities

• +/-45° Rotation (dependent on material thickness and power

supply conguration)

Software

• Easy-To-Use Lincoln Electric User Interface

• CAM with Irregular Part Nesting

• Popular Shape Library

Fume Extraction (Optional Accessory)

• 61,801 ft3/hr or 1,750 m3/hr minimum

• Automatic Filter Cleaning, Pressure Controlled

Downdraft Conguration

• Multiple Zones Controlled By Motion Controller

Safety

• Dual-Channel Safety System Supporting Emergency Stop

Switch

• Safety System Extended To External Peripherals

• External Drive Power On Switch

Machine Construction

• Fabricated Steel Frame with Powder Coated Finish

Acceleration Rate

• 0.08g (0.06g Bevel)

Warranty

• *1 Year Warranty

Deceleration Rate

• 0.08g (0.06g Bevel)

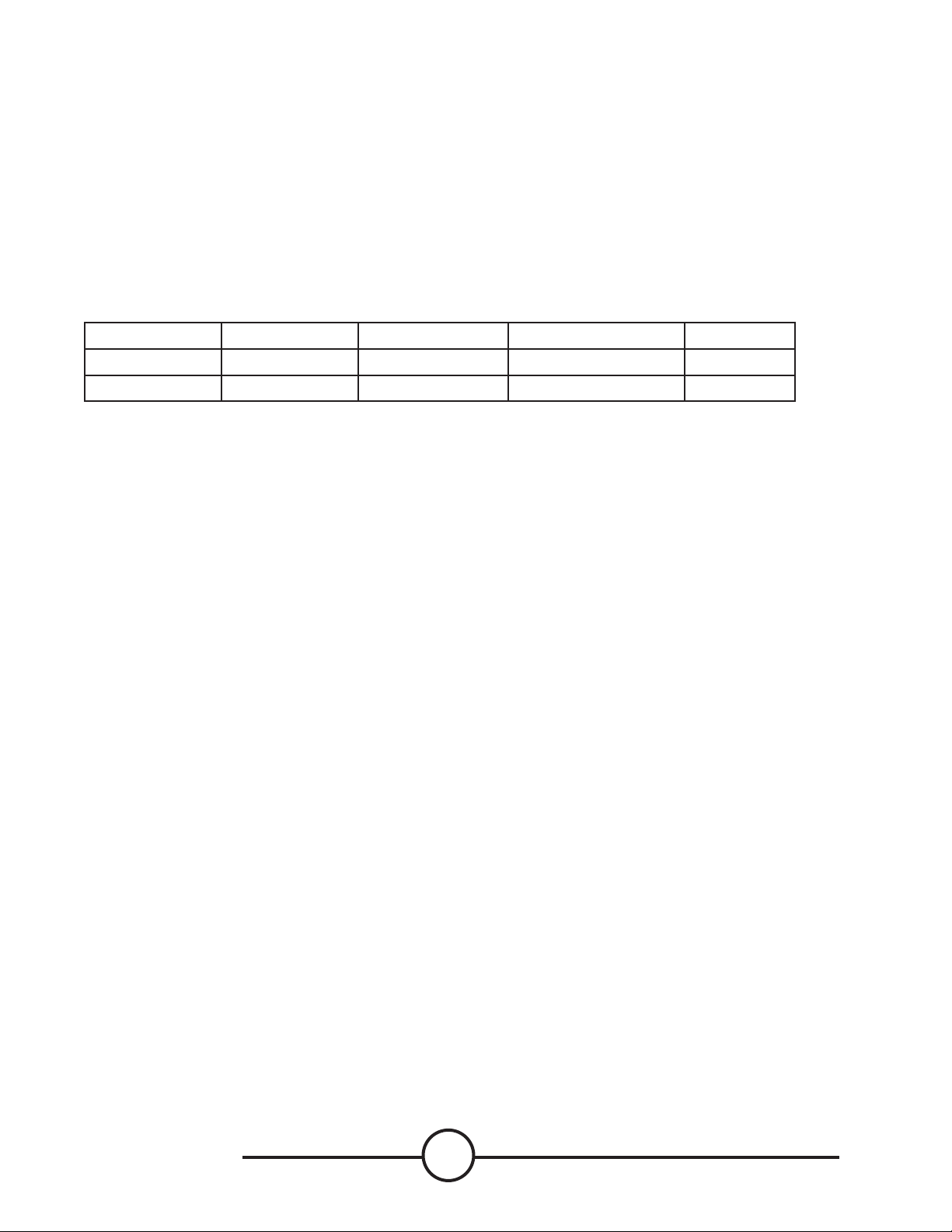

TORCHMATE 5100 CNC PLASMA SYSTEMS FC 125 FC 200 SP 275 SP 400

PRODUCTION CUTTING CAPACITY

Mild Steel 1” (25mm) 1.25” 1.5” (38mm) 2” (50mm)

Stainless Steel 3/4”(20mm) 3/4”(20mm) 1” (25mm) 1.5” (38mm)

Aluminum 5/8”(16mm) 3/4”(20mm) 3/4” (20mm) 1.5” (38mm)

CUTTING SPEED @ RATED OUTPUT CURRENT

1/4” MS 210 ipm @125A 200 ipm @200A 230 ipm @200A 230 ipm @ 200A

1/2” MS 88 ipm @125A 110 ipm @200A 125 ipm @ 275A 160 ipm @ 400A

1” MS 32 ipm @125A 40 ipm @200A 65 ipm @275A 85 ipm @ 400A

PROCESS AMPS 20A - 125A 15A - 200A 30A - 275A 30A - 400A

CUTTING GAS

Mild Steel Air / Air Air / Air Oxygen / Air Oxygen / Air Oxygen / Oxygen

Stainless Steel Air / Air Nitrogen Air / Air Nitrogen Air / Air - Nitrogen H17 / Nitrogen Nitrogen / Air

Aluminum Air / Air Air / Air Air / Nitrogen Nitrogen Air

INPUT VOLTAGE 380/400/415V3Ph50/60Hz 380/460/575V3Ph50/60Hz 380V 3Ph 50/60Hz | 400V 3Ph 50/60 Hz

460V 3Ph 50/60Hz 400V3Ph 50Hz (CE) 415V 3Ph 50/60Hz | 440V 3Ph 50/60Hz

575V 3Ph 50/60Hz 480V 3Ph 50/60Hz | 600V 3Ph 50/60 Hz

5

User Guide

Page 19

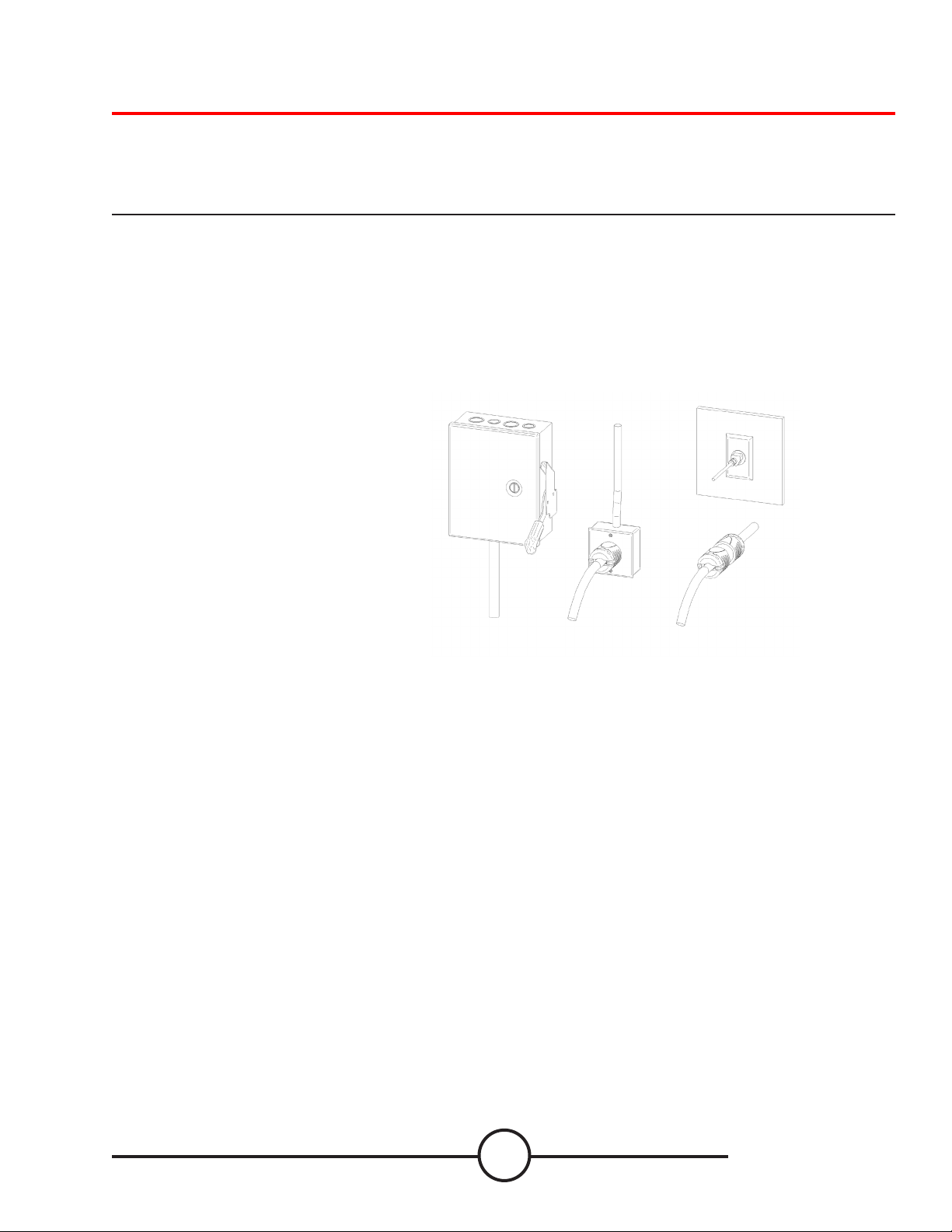

Site Preparation

When installing a Lincoln Electric CNC Cutting System in your shop, there are many factors that will inuence the

tential productivity, ease of use of the machine and the safety of the operator. The main factors to prepare for include

the physical layout and placement of the machine in the shop, the availability of power, an EMI ground, compressed air

and other gases, and ventilation.

• When preparing to install the Lincoln Electric CNC Cutting System, provide sucient space. Three feet of work

space should be maintained at the front of machine

• Forklift load material opposite the cable carrier only. Utilize the back of the machine to park the gantry while

loading material.

• A dedicated earth ground must be provided and should be installed in a manner to reduce trip hazard.

po-

5100

5100

113.25”

15’ Power Cord, NEMA 5-15P

Air Supply

Earth Ground

Provided by Other

FlexCut 125/200

Plasma

Machine

within 10’ of cable

carrier

167”

Load From

This Side

Torchmate 5100

Operator

Console

MAINTAIN WORK AREA

6

Page 20

Site Preparation (HD)

Burny Kaliburn Spirit II power supplies have a larger power box and a gas box. The placement of these products need to

be moved to the cable carrier side within 6’ of the end of the cable chain.

5100 HD

167”

Load From

This Side

113.25”

15’ Power Cord, NEMA 5-15P

Air Supply

Earth Ground

Provided by Other

Gases

30.0

Burny

Spirit 2

Power

Supply

Locate power supply

within 6’ of table cable

chain. Automatic Gas

43.0

Console should be kept

within 2’ of power

supply.

3-phase

Power Supply

Air Supply

Provided by Customer

MAINTAIN WORK AREA

Operator

Console

7

User Guide

Page 21

Grounding Your Machine

Proper grounding must be provided to ensure personnel safety and to suppress high frequency noise. The foundation of

good grounding is an eective earth ground rod. A star ground point connects to the rod with a short, heavy conductor.

A simple copper clad steel rod can be driven into the ground to create a Grounding Rod. A ground rod must be installed.

Consult with a qualied electrical technician to verify your system grounding.

Use 6 AWG Stranded Wire to connect the Star Ground on the table to the customer supplied dedicated earth ground.

For proper operation of your CNC cutting tables you are required to run a 6 AWG cable from the “star” ground to a

dedicated earth-ground rod

Ground rod installations are covered by NEC Section 250.

Place the plasma unit on the appropriate location.

Re-install the power lead and the table ground into

the plasma power supply.

The FlexCut plasma unit is shipped with a factory

ground attached to the star ground. In addition, a

work ground is attached to the star ground to connect

to your material to be cut. If the work piece is painted

or dirty it may be necessary to expose the bare metal

to make a good electrical connection.

Earth Ground Rod is not included with machine

A

STAR GROUND

DETAIL A

GROUND ROD

Torchmate 5100

8

Page 22

Power/Air/Water Requirements and Installation (non-HD)

Please refer to the FlexCut/Spirit II operators manual for a complete installation and operation guidelines. Only a qualied electrician should connect the input leads to the Torchmate 5100 CNC unit and FlexCut/Spirit II Plasma unit. Connections should be made in accordance with all local and national electrical codes. Failure to do so may result in bodily

injury or death.

The FlexCut 125/200 is rated for 380 VAC through 575 VAC input voltage, three phase only and 50 or 60 Hz. Before

connecting the machine to power, be sure the input supply voltage, phase and frequency all match those listed on the

machine rating plate.

The Burny Kaliburn Spirit II plasma cutters are manufactured to the customer’s power availability.

The power supply cord is supplied on the FlexCut 125 without an attachment plug to accommodate three phase installations of being hard wired to a disconnect or for a wall plug. FC200/Spirit II do not include SO cord for connection to

customers power and will need to have the appropriate cable connected per electrical requirements.

Warning:

The FlexCut on/o switch is not

intended as a service disconnect

for this equipment. Only a

qualied electrician should

connect the input leads to the

Torchmate 5100.

120v to Machine

To Plasma Power Supply

The Torchmate 5100 CNC machine requires a clean, dry, oil-free compressed air. A high pressure regulator MUST be used

with a compressor or high pressure cylinder.

Supply pressure must be between 87-110 psi (6-7.6 bar) with ow rated rates of at least 300 SCFH or 140 SLPM.

AIR SUPPLY PRESSURE SHOULD NEVER EXCEED 130 PSI OR DAMAGE TO THE MACHINE MAY OCCUR!

A standard nominal 5 micron in-line lter is recommended, but for optimal performance, select a pre-lter with

a 3 micron absolute rating. Air must be supplied to the plasma with 3/8” inside diameter tubing and 1/4 NPT quick

disconnect coupler. Air lines should be run as to not create a trip hazard.

Water should be installed in the table before operation. Operators are encouraged to use a readily available

anti-corrosive water additive designed for use in CNC plasma water tables.

Water Capacity: 428 gallons (1620 liters)

9

User Guide

Page 23

Slats inside the cutting bed.

The 5100 WT/DD has an array of slats inside the cutting area. These slats hold your material level for cutting. They are

considered a “consumable” item and will need to get replaced on a regular schedule.

• Inside the table sit an array of 69.625” x 3” x 3/16” (4.7625mm) thickness slats that support the material

being cut. After repeated cutting, generally after a year or so of normal cutting time, you will need to

replace the slats. Perform the replacement when the slats can no longer support the material properly or

the build up is hindering the plate from being at.

• The center slat support is oset, to create an ARC of the slats. This makes the slats less prone to getting

damaged in straight cuts, along with keeping the material from moving during cutting.

• The slats can be used on one side and ipped over to increase usage time on one set of slats.

Torchmate 5100

10

Page 24

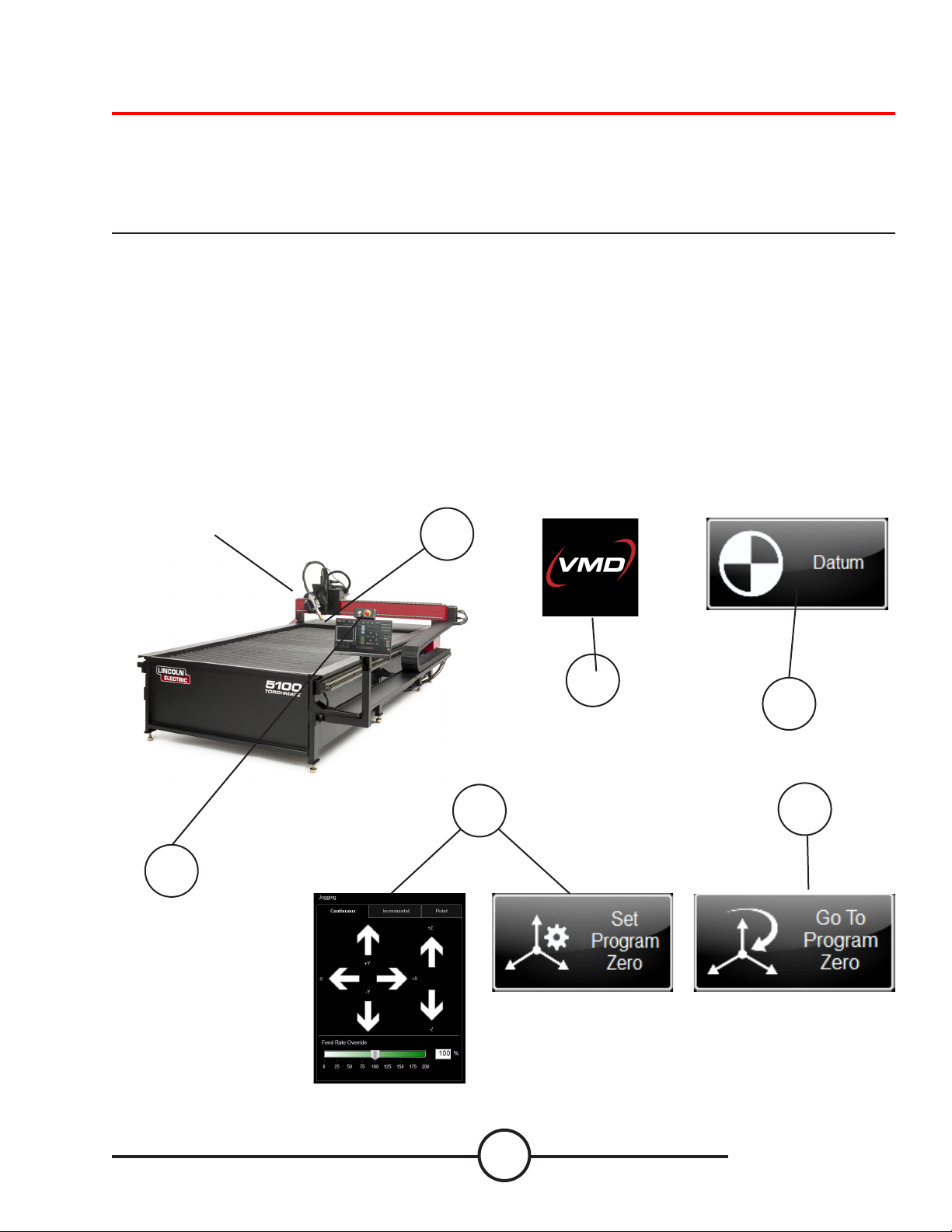

Powering up the Torchmate 5100

To power up your Torchmate 5100 CNC machine, the following items need to be powered up; Machine and Plasma Unit.

The machine will power the controller, computer, and touchscreen. The switch is located on the backside of the machine.

Once switched on, the computer and all the electronics will power up. The power switch for the plasma power supply

is located on the front of the unit. The complete user guide is available as an embedded le in the VMD. Use the button

with the question mark to access this le.

1. Power up the machine by using the toggle switch. (back left of the machine)

2. The VMD Application will auto start with the computer, wait for control panel to load (run.wap)

3. Verify the EMERGENCY STOP(s) are disengaged by turning the RED EMERGENCY STOP button clockwise. One on the

non-cable carrier side of the gantry and one above the monitor.

4. Press the GREEN BUTTON above the Operators Console. (This will power the motors)

5. Press DATUM. (Machine will seek back left corner)

6. Go to the plasma torch head to check and evaluate the consumables. Turn the plasma power supply on and set

the appropriate amperage for the consumables and the material you will be cutting. Cut charts are available in the FlexCut manual. Verify air pressure is correct per manual.

7. Jog the torch to the lower left corner of the material you are going to cut. Press SET PROGRAM ZERO.

8. Press GO TO PROGRAM ZERO. The head should return to the top of the lifter.

Back

Left

Corner

1

3, 4

To JOG machine press

and swipe your nger in

the direction you wish

to JOG.

2

5

7 8

11

User Guide

Page 25

Water Table Operation

Table Drain

The 5100 in Water Table conguration, the water level is controlled by the HMI to raise and lower the machine. The

button RAISE switches a valve to use compressed air to “push” the water to the cutting bed. While pressing LOWER

releases the air from the lower chamber.

The water table is controlled by the HMI.

When you press RAISE WATER, compressed air is

FILL / DRAIN

pushed into the lower chamber.

This “pushes” the water up into the cutting table.

When you press LOWER WATER, the ball valve will

OPEN, releasing the compressed air from the bottom

chamber. This allows the upper chamber to drain the

water into the lower chamber.

• To completely DRAIN your table, use the 2”

QC ball valve in the FRONT LEFT of the table.

Table Drain

Torchmate 5100

12

Table Drain

Air IN

Water UP

WATER TABLE

LOWER CHAMBER

BALL VALVE

OVER FLOW DRAIN

(DRAINS TO FLOOR)

OVERFLOW TUBE

Page 26

Filling the Water Table

The 5100 has an automated water level feature that is controlled on the RUN panel. There is a process that needs to be

followed to properly ll the table to allow proper operation. Connect your air supply to the air inlet on the machine to

proceed.

1. Press LOG ON. Select ADMIN (password 1234). Press OK

2. MACHINE SETTINGS will open. Press the WATER FILL tab.

2.a] If the MACHINE SETTINGS window does not open, in the upper left corner press MAIN

MENU. In the SELECT A PANEL window left click on CONFIGURATION.wap. Press OK, and

MACHINE SETTINGS panel will open.

13

User Guide

Page 27

Filling the Water Table

3. Press the EXHAUST button. This opens the external exhaust vent to allow the air to transfer out of the

empty water tank while the water lls up.

4. Start to ll the table with water. Once the internal tank lls past 2” in the tank, the LOW

WATER indicator will no longer display.

Torchmate 5100

14

Page 28

Filling the Water Table

5. Once the WATER FULL indicator turns on, turn the input water o to the table.

Close the EXHAUST by pressing the EXHAUST button.

6. Raise the water into the main chamber by pressing and holding the RAISE WATER button. Once the

water reaches the top of the slat, then release the RAISE WATER button. If the water does not reach the

top of the slats, then directly add water to the table to get the water level to the top of the slats. Now to

control the water level function you will now use the WATER LEVEL controls on the RUN HMI.

15

User Guide

Page 29

Downdraft Operation

The 5100 in Downdraft conguration, there are 4 zones that are controlled by the program. The “zone” that is active

(open) is dependent on where the job is located in the cutting bed when PROGRAM ZERO is established.

Each zone is controlled by pneumatic actuators to

open/close the dampers inside the table to allow for

OUTPUT

proper air ow. The zones will open/close based on

where the parts are established on the cutting bed

and SET PROGRAM ZERO.

ZONE 4

ZONE 3

ZONE 2

ZONE 1

If a part or nest covers more than one zone, then

multiple zones will open to allow proper ventilation

Output diameter connector ring is 14” diameter.

Output air ow required Fume Extraction (Optional

Accessory)

• 61,801 ft3/hr or 1,750 m3/hr minimum

• Automatic Filter Cleaning, Pressure Controlled.

ZONE 1 ZONE 2 ZONE 3 ZONE 4

Torchmate 5100

OUTPUT

16

Page 30

17

User Guide

Page 31

FlexCut 125 Plasma Controls and Settings

Please refer to the complete operation and user manual for your FlexCut 125 located with the plasma unit. When the

machine is turned on, an auto-test executes; during this test the Control Panel light up.

Controls »

FRONT

1. LCD DISPLAY

2. PRIMARY AIR, GAS PRESSURE GAUGE

AND REGULATOR KNOB

3. HOME BUTTON

4. ONOFF SWITCH

5. TORCH CONNECTION

6. WORK LEAD CONNECTION

7. MENU CONTROL KNOBBUTTON

8. PURGE

BACK

9. AIR OR GAS INLET 14”IN. NPT QUICK

CONNECT

10. RECONNECT PANEL ACCESS

11. INPUT CORD STRAIN RELIEF

12. 14PIN CNC INTERFACE

13. FAN

1

2

3

4

5

6

9

10

7

8

11

Torchmate 5100

12

13

18

Page 32

FlexCut 125 Plasma Cutter Consumable Use

Please refer to the FlexCut operators manual for a complete installation and operation guidelines. Do not over tighten

the consumables. Only tighten until the parts are seated properly.

Product

Name

FlexCut 125 K4811-1 380/400/415/460

Product

Number

Input Power

Voltage/Phase/Hertz

/575/3/50/60

Rated Output:

Current/

Voltage/Duty Cycle

125A/175V/100% 3PH/100%

Input Current @

Rated Output

40/40//40/33/28

Output

Range

3PH

20-125A

Gas Pressure

Required

90-120 PSI

(6.21-8.27 Bar)

MECHANIZED CUT CAPACITY MATERIAL THICKNESS MILD STEEL

Recommended cut capacity at 32ipm 1 in. (25.4 mm)

PIERCE CAPACITY MATERIAL THICKNESS MILD STEEL

Pierce capacity with programmable torch height control

3/4 in. (19 mm)

MAXIMUM CUT SPEEDS MILD STEEL

1/4 in. (6.35 mm) 180 ipm

1/2 in. (12.7 mm) 72 ipm

3/4 in. (19 mm) 40 ipm

1 in. (25.4 mm) 23 ipm

CONSUMABLES STARTER KIT FOR LC125M MACHINE TORCH K43022

Electrode (LC125M) BK14300-1 2 Qty

Shield Cap 45 A - 65 A (LC125M) BK14300-3 1 Qty

Shield Cap 85 A - 125 A (LC125M) BK14300-4 1 Qty

Nozzle 45A (LC125M) BK14300-7 1 Qty

Nozzle 65A (LC125M) BK14300-8 1 Qty

Nozzle 85A (LC125M) BK14300-9 1 Qty

Nozzle 105A (LC125M) BK14300-10 2 Qty

Nozzle 125A (LC125M) BK14300-11 2 Qty

Swirl Ring 45 A - 125 A (LC125M) BK14300-13 1 Qty

Retaining Cap-CTP (LC125M) BK14300-15 1 Qty

Gas Flow

Rate

550 SCFH @90 PSI

260 SLPM @6.21 Bar

H x W x D

in (mm)

20.72 x 12.25 x 25.53

(526 x 311 x 648)

Net Wt.

lb (kg)

118 (53.5)

19

User Guide

Page 33

FlexCut 200 Plasma Controls and Settings

Please refer to the complete operation and user manual for your FlexCut 200 located with the plasma unit. When the

machine is turned on, and auto-test is executed; during this test the screen will change.

Controls »

FRONT

1. LCD DISPLAY

2. HOME BUTTON

3. MENU CONTROL KNOBBUTTON

4. ONOFF SWITCH

5. SHIELD GAS OUTLET

6. NOZZLE LEAD CONNECTION

7. WORK LEAD CONNECTION

8. ELECTRODE LEAD CONNECTION

9. ARCLINK CONNECTOR 5PIN

10. PLASMA GAS OUTLET

11. PURGE

12. SHIELD GAS REGULATOR

13. PLASMA GAS REGULATOR

BACK

14. AIR OR GAS INLET 14”IN. NPT QUICK

CONNECT

1

2

3

4

5

6

14

15

13

12

11

10

9

7

8

20

15. 115V15A AUXILIARY POWER RECEPTACLE

16. 15 AMP CIRCUIT BREAKER

1 7. ETHERNET CONNECTOR

18. 10 AMP CIRCUIT BREAKER

19. FLEXCOOL CONNECTOR

20. INPUT CORD STRAIN RELIEF

21. CNC INTERFACE CONNECTOR

22. FAN

Torchmate 5100

16

17

18

19

21

22

20

Page 34

FlexCut 200 Plasma Cutter Consumable Use

Please refer to the FlexCut operators manual for a complete installation and operation guidelines. Do not over tighten

the consumables. Only tighten until the parts are seated properly.

Product

Name

FlexCut 200 K4812-1 380/400/415/460

Product

Number

Input Power

Voltage/Phase/Hertz

/575/3/50/60

Rated Output:

Current/

Voltage/Duty Cycle

200A/300V/100% 3PH/100%

Input Current @

Rated Output

71/63/55

Output

Range

3PH

20-200A

Gas Pressure

Required

90-120 PSI

(6.21-8.27 Bar)

MECHANIZED CUT CAPACITY MATERIAL THICKNESS MILD STEEL

Recommended cut capacity at 32ipm 1 in. (25.4 mm)

PIERCE CAPACITY MATERIAL THICKNESS MILD STEEL

Pierce capacity with programmable torch height control

3/4 in. (19 mm)

MAXIMUM CUT SPEEDS MILD STEEL

1/4 in. (6.35 mm) 180 ipm

1/2 in. (12.7 mm) 72 ipm

3/4 in. (19 mm) 40 ipm

1 in. (25.4 mm) 23 ipm

CONSUMABLES STARTER KIT FOR LC125M MACHINE TORCH BK244100SK

Removal Tool, Nozzle BK277056 1 Qty

Removal Tool, Swirl Ring BK260105 1 Qty

O-Ring Lubricant BK716012 1 Qty

Internal Retaining Cap 50 A BK244453 1 Qty

Internal Retaining Cap 100 A BK244452 1 Qty

Internal Retaining Cap 150-200 A BK244466 1 Qty

Outer Retaining Cap 50-200 A BK244454 1 Qty

Shield Cap 50 A BK244450 1 Qty

Shield Cap 100 A BK244417 1 Qty

Shield Cap 150 A BK244474 1 Qty

Shield Cap 200 A BK244463 1 Qty

Electrode 50 A BK244431 1 Qty

Electrode 100 A BK244492 1 Qty

Electrode 150 A BK244491 1 Qty

Electrode 200 A BK244470 1 Qty

Swirl Ring 50 A BK244442 1 Qty

Swirl Ring 100 A BK244439 1 Qty

Swirl Ring 150 A BK244443 1 Qty

Swirl Ring 200 A BK244458 1 Qty

Nozzle 50 A BK244425 1 Qty

Nozzle 100 A BK244493 1 Qty

Nozzle 150 A BK244489 1 Qty

Nozzle 200 A BK244469 1 Qty

Gas Flow

Rate

550 SCFH @90 PSI

260 SLPM @6.21 Bar

H x W x D

in (mm)

23.66. x 15.97 x 32.19

(601 x 406 x 818)

Net Wt.

lb (kg)

190 (86.2)

21

User Guide

Page 35

Performing Your First Test Cut (straight torch NON BEVEL)

The LINE SPEED TEST.gm and 5100 Test Cut.gm is provided to determine the proper feed rate in IPMs to cut the

material thickness to the amperage you have set on the plasma power supply. These have been included in your

pre-loaded rst cut on the Torchmate 5100 models. The plasma torch body is pre-loaded with 65 amp consumables

(FlexCut 125) or 100 amp (FlexCut 200) for a 3/16” material cut from the factory. We highly suggest your rst cut is our

pre-loaded, *FC125/200 INLINE TEST CUT 65A/100A.gm to ensure your machine has transported in the same condition it

has left the factory. Please locate the factory test sample located in the waterbed and load a piece of 3/16” mild steel for

the comparison cut test.

1. Press SELECT JOB.

2. Locate FC125/200/400 (amperage of plasma) INLINE TEST CUT 65A/100A (plasma

machine).gm and press OK

3. Verify that your amperage on your plasma power supply is set to 65 amp (FC125) or

100 amp (FC200).

3. 5100 Inline test cut will now show in the display.

4. For the FC125, set the CUT PARAMETERS:

PIERCE HEIGHT to 0.16

CUT HEIGHT to 0.12

PIERCE DELAY to .5

For the FC200, set the CUT PARAMETERS:

PIERCE HEIGHT to .20

CUT HEIGHT to .11

PIERCE DELAY to .3

5. Set MODE to AUTO and SAMPLE VOLTAGE to ON.

IHS (ohmic detection) set to ON and IHS MODE to ALWAYS.

Complete AVHC settings for various material can be found in the plasma power

supply cut charts.

AVHC settings will change for dierent amperage and material thickness being cut.

See your FlexCut manual for further instruction after performing your rst cut.

6. Jog the head over to the Lower Left corner of the material you are going to cut and

press SET PROGRAM ZERO.

7. Assure that the FEED RATE OVERRIDE is set to 100%

8 PRESS RUN JOB (machine may throw sparks)

9. The cut will progress as follows.

Rapid travel to the rst inside feature.

Z Axis moves toward the material, touching the top of the material.

(IHS -ohmic detection)

Torch retracts to set PIERCE HEIGHT and will re.

Dwells until the PIERCE DELAY is expired.

Drops to set CUT HEIGHT and starts the program.

Will cut all inside features rst, then move to the outside geometry.

Torchmate 5100

Once cut is complete, compare the cut to the provided sample and verify that they

match. This will provide proof that the machine is functioning properly.

If you need to stop the

machine at any time

please hit the stop button

on the touch screen.

22

Page 36

Performing Your First Test Cut (BEVEL)

With the BEVEL head, the plasma torch body is pre-loaded with 125 amp consumables (FlexCut 125) or 150 amp (FlexCut

200) for a 1/2” MS material cut from the factory. We highly suggest your rst cut is our pre-loaded, *FC125/200 BEVEL

TEST CUT 105A/150A.gm to ensure your machine has transported in the same condition it has left the factory. Please

locate the factory test sample located in the waterbed and load a piece of 1/2” mild steel for the comparison cut test.

1. Press SELECT JOB.

2. Locate FC125/200/400 (amperage of plasma) BEVEL TEST CUT 105A/150A (plasma

machine).gm and press OK

3. Verify that your amperage on your plasma power supply is set to 105 amp (FC125) or

150 amp (FC200/SPII).

3. 5100 BEVEL test cut will now show in the display.

4. The CUT PARAMETERS along with the AVHC settings are pre-coded in the g-cod eof

the les. To have the system “see” these parameters, TOGGLE the CUT CHARTS to

CHARTS. This will tell the controller to look at the code to pre-populate the settings.

AVHC settings will change for dierent amperage and material thickness being cut.

See your FlexCut manual for further instruction after performing your rst cut.

5. Jog the head over to the Lower Left corner of the material you are going to cut and

press SET PROGRAM ZERO.

6. Assure that the FEED RATE OVERRIDE is set to 100%

7 PRESS RUN JOB (machine may throw sparks)

8 . The cut will progress as follows.

Rapid travel to the rst inside feature.

Z Axis moves toward the material, touching the top of the material.

(IHS -ohmic detection)

Torch retracts to set PIERCE HEIGHT and will re.

Dwells until the PIERCE DELAY is expired.

Drops to set CUT HEIGHT and starts the program.

The Torchbody will laydown inside the loops to accommodate the bevels in

the design.

Will cut all inside features rst, then move to the outside geometry.

60° ±4°

3.000 ±.0 32

1.000

30.0°

UNDERCUT, NOMINAL BEVEL TYPE

Once cut is complete, compare the cut to the provided sample and verify that they

match. This will provide proof that the machine is functioning properly.

If you need to stop the

machine at any time

please hit the stop button

5.000

.500

on the touch screen.

23

User Guide

Page 37

Overview of the Visual Machine Designer

Visual Machine Designer (VMD) is the driver software to all ACCUMOVE® CNC controllers. The majority of the control of

the table can be found on the main screen while hosting features that can create and manipulate les. This quick guide

will give you an overview of the features along with it’s operation.

Main Screen:

2

1

7

3 4 5 6

The main screen of the VMD is broken into sections for easy navigation and operation. Overview of all the buttons and

functions will be covered in sections.

1. Job group - Opens and controls all apects of the le being entered or creation of jobs

2. View Screen - Shows the graphic of the job, g-code of the job, or a graphic of the lifter station movements.

3. Datum/Program Zero - Establishes the machine zero through DATUM along with the program zero on the

machine.

4. Cut Parameters/AVHC - Settings for the height control and it’s functions.

5. Run group - These buttons control the start and stop of the job.

6. Jogging - Controls the torch movement on the machine along with program run speed

7. Dashboard - Displays the coordinates of the head along with all of the indicators being monitored on the

machine.

Torchmate 5100

24

Page 38

Job Group:

The JOB GROUP at the top, covers any “job” type functions. This group directly deals with selecting a job, creating a job

(Shape Library), or Alter job functions.

Select Job:

This is how to open jobs into the VMD.

In the SELECT JOB area shows the “HOT FOLDER” and the loaded jobs

in that folder. * C:\ControllerData\Jobs is the HOT FOLDER.

To select another source, then press BROWSE and that will open the

standard WINDOWS dialog.

In the PREVIEW window will display the selected job from the list.

Nesting:

This opens the VMD NESTING.

See the NESTING section to get an overview of the features.

Shape Library:

This allows you to create a user dened shape based on 27 of

the most common parts.

See the USING THE SHAPE LIBRARY section for details.

Job Setup:

JOB SETUP allows you to make alterations to the job itself.

ROW AND COLUMN: Allows you to add mulitples by adding

numbers to generate a GRID ARRAY of the job you have

selected.

TRANSFORMS: Allows you to MIRROR, ROTATE, or SCALE

your job.

MATERIAL SENSING: This works in conjuction with the CUT

PARAMETERS by setting a measurement for the TOP OF

MATERIAL and the MATERIAL THICKNESS of the plate you

are cutting.

25

User Guide

Page 39

Job Group: (cont)

Tool Library:

In TOOL LIBRARY congures and controls the tool outputs

on the machine.

KERF and DWELL times can be added along with

programming the oset to the plate marker acessory.

Log On:

LOG ON switches users of the VMD software.

OPERATOR is the standard user.

ADMIN opens the MACHINE SETTINGS. (password protected)

TECH SUPPORT is used only for Tech Support. (password

protected)

Shutdown:

SHUTDOWN will close the VMD and power down the

computer.

This should be used when shutting down the system.

Torchmate 5100

26

Page 40

View Screen:

The VIEW SCREEN in the VMD uses colors and will display the machine limits, head location, and job location. There are

four tabs along the top that will show a visual of the job, g-code of the job, or a graph of the lifter station. If you have a

FlexCut 200 attached to the machine, you can directly control the FlexCut 200 by using the Plasma Contol tab.

Plan View:

This displays the MACHINE LIMITS in blue. The head is represented with white crossed lines. Plasma assigned tool paths

are display in red. Plate Marker assigned tool paths are displayed in Magenta. Rapid travels will be a dashed grey line.

Zoom to Machine will zoom to the programmed machine

limits.

Zoom to Job will zoom to the job loaded.

Run From Torch position will start the job where the torch is

located on the job.

Maximize Viewport will display all views in one screen.

Job Program View:

This displays the g-code of the job that is loaded.

Edit Job will open the current g-code in a text editor.

Height Control View:

This displays in a moving graph the lifter station movements

while operating.

Trace Pause/Resume will pause the graph if tracing.

Trace o/on will toggle showing the lifter station being

monitored.

27

User Guide

Page 41

View Screen: (cont)

Plasma Console: (FlexCut 200/SPII)

The Plasma Console controls the settings of the plasma from

the HMI. This allows the operator to directly control the

plasma power supply without having to navigate away from

the HMI.

The settings that can be changed are:

• Current

• Plasma Process Mode (Cut, Plasma Mark, Expanded,

Gouge)

• Purge

• VMD in Control: Determines the HMI, or Plasma,

controlling the plasma settings.

Torchmate 5100

28

Page 42

Datum / Program Zero Group:

This group controls the startup of the machine along with setting jobs to start from a certain location on the table.

DATUM:

Datum has several features. When rst starting up your machine,

datum will power your motors and move the machine to establish

it’s MACHINE ZERO.

Once the torch has moved to the back left corner, the machine is

ready to operate.

Set Program Zero:

SET PROGRAM ZERO establishes the x0:y0 where the torch body is

positioned on the table. This is the origin where the job will start

from.

When running a job, you will move the torch body to the front left

corner of the material you are cutting. By pressing SET PROGRAM

ZERO, will establish the job’s absolute zero position.

Go To Program Zero:

Pressing this will move the torch body back to the established

PROGRAM ZERO

29

User Guide

Page 43

CUT PARAMETERS and AVHC:

Once you have your job ready to run, getting the settings correct and understanding their function is crucial to getting

quality cuts on your table. This covers go over the Cut Parameters and the AVHC settings.

Cut Parameters:

All the parameters in the Cut Parameters and AVHC tab set

the torch in proper position in relation to the material during

operation. Most of the parameters can be found in your FlexCut manual under CUT CHARTS.

• Transfer Height is the distance the Z-Axis will travel

down to transfer the PILOT ARC prior to Pierce height.

(used on Spirit II HD only) Enter 0 for conventional

plasma

• Pierce Height is the distance the head sits above the

material during piercing.

• Cut Height is the distance between the torch tip and top

of material during cutting.

• Pierce Delay is the time delay for the torch to pierce

through the material before executing movement.

• Retract Height is the distance the head will move up

during rapid travels when running a job.

• Arc Voltage is the voltage feedback comparison value. If

using SAMPLE VOLTAGE this will adjust during cutting.

AVHC (Automatic Voltage Height Control):

MODE is a toggle between MANUAL or AUTO.

• Manual - The torch will stay at the Cut Height

established at each material pierce. The torch will

not automatically adjust to the cut height during

cutting.

• Auto - The torch will maintain the distance entered

in CUT HEIGHT and prole the material based on

the SET VOLTAGE and the CURRENT VOLTAGE being

read from the plasma power supply.

Torchmate 5100

30

Page 44

CUT PARAMETERS and AVHC:(cont)

AVHC (Automatic Voltage Height Control):

Sample Voltage is a toggle On or OFF.

• On (with MODE: AUTO): At the beginning of the cut the

controller learns the proper Arc Voltage and maintains the

desired Cut Height value entered in CUT PARAMETERS.

• O (with MODE: AUTO): The AVHC will adjust based on

the SET VOLTAGE and CURRENT VOLTAGE only. If the SET

VOLTAGE is dierent than the CURRENT VOLTAGE then the

lifter will adjust to account for the dierence.

• On/O (with MODE: MANUAL): This feature is disabled.

IHS (Initial Height Sense) this setting turns OHMIC DETECTION on or o.

• ON: The head will detect material when the ohmic cap comes

into contact with the grounded, conductive material on the

table. Once detected the head will retract to PIERCE HEIGHT

setting.

• OFF: The head will move to TOP OF MATERIAL setting (Job

Setup) and retract to PIERCE HEIGHT.

IHS MODE is the process used to detect the material height and how it

reacts between pierces.

• Optimal: First pierce the head will detect the material via

OHMIC and will not detect the material for a set distance

away from the rst OHMIC detection.

• Always: The head will detect material via OHMIC at every

pierce.

CUT CHARTS this setting will allow the user to dene the cut parameters or have them prepopulate via g-code generated throught the

nesting process.

• Charts: Uses the predened cut settings generated through

the NESTING process and populates the settings in the CUT

PARAMETERS

• Custom: The operator enters the values into CUT

PARAMETERS from the cut charts.

RESET Z POSITION resets the Z lifter to its Zero Position by moving the

head to its upper stroke and re-establishing its zero position.

31

User Guide

Page 45

Oxy and Water Controls:

The VMD can control OXY cutting torches with the OXY tab. This allows to SET and CAPTURE time delays. The WATER

LEVEL tab, controls the water level in the table along with a LOW WATER indicator.

OXY:

LIFTER controls the lifter stations UP/DOWN position.

• Up will raise the lifter.

• Down wil lower the lifter.

PRE-HEAT sets and alters the PRE-HEAT time required for

the OXY cutting.

• OFF is a TOGGLE to ON or OFF. This will activate

the PREHEAT DELAY time that is entered in the

PREHEAT DELAY dialog.

• EXTEND is a toggle between EXTEND and

CAPTURE. When EXTEND is PRESSED, will extend

the time until released. It will then CAPTURE the

time

• CONTINUE is active or not. When pressed, will

turn on the HIGH PRESSURE REGULATOR to start

cutting.

WATER LEVEL:

WATER LEVEL allows the operator to control the level of

water in the water table. A LOW WATER indicator to show

when water needs to be added to the table. To properly ll

the table with water, follow the water ll instructions on

pg. 43

• RAISE WATER. When held down, will raise the

water. Release the button to stop raising the water.

• LOWER WATER. When held down, will drop the

water. Release the button to stop at the level

required.

• If the LOW WATER indicator is displayed, the water

level in the tank is low and will not allow to raise

the water past that level until the water level is

satised.

Torchmate 5100

NOTE: Hydrogen gas may be formed and be trapped under aluminum work pieces

when they are cut using a water table.

DO NOT cut aluminum alloys underwater or on a water table unless the hydrogen gas

can be eliminated or dissipated. Trapped hydrogen gas that is ignited will cause an

explosion.

32

Page 46

RUN Group and Jogging:

This group controls the start and stop of a job plus allows you to alter states of the plasma. Jogging allows the user to

move the head by pressing on the direction. Also, the jog is tabbed so being about to move the head to the proper location

anywhere on the table.

Active Run/Dry Run:

This button is a TOGGLE between ACTIVE RUN and DRY RUN.

ACTIVE RUN: This will activate your torch to re when you

RUN a job.

DRY RUN: This deactivates your torch from operation. If in

DRY RUN, the torch will simulate all movements without

ring the torch.

Laser:

This will activate the Laser pointer accessory.

RUN JOB:

RUN JOB will start the job that is loaded into the VMD.

STOP:

STOP button will stop the machine during any movement or

process.

RESET:

This will reset the job to start over. If the job has started and

not completed you will need to RESET to start the job over.

Jog:

The JOG keys are laid out in the manner as the table moves.

By pressing more towards the center of the jog key will move

the torch body slower and then on the outside it will move

faster. The JOG window is comprised of three seperate tabs:

Continuous, Incremental and Point.

On the bottom, is the FEED RATE OVERRIDE %. This will alter