Page 1

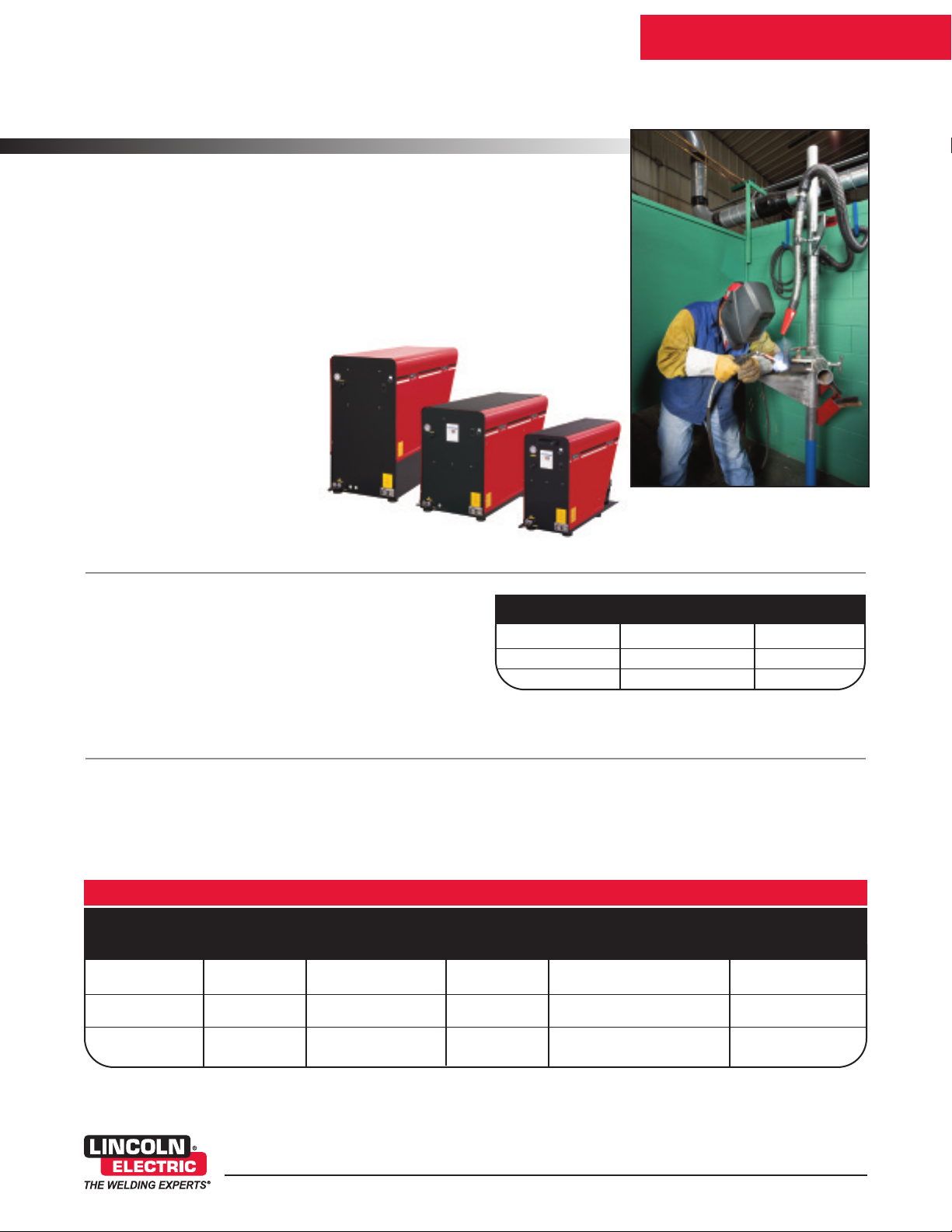

X-Tractor 3A, 5A & 8A

Welding Fume Extractor

Lincoln’s self contained X-Tractor units are specifically designed for the removal and

filtration of welding fume. They feature a high vacuum, low volume system with an

automatic self-cleaning filter system. They are suitable for heavy duty welding

applications and continuous use, powered by three phase AC motors.

These units are designed to supply suction for up to 8 fume guns or 5 suction heads.

Air enters the system through a connection on the rear side of the machine. It then

passes through the filter and the fume particles are captured in the filter media. The

air then passes through the blower and exits through an internal silencer. A timer

signals a pulse of compressed air that

loosens the particulate from the

outside surface of the filter so that

it falls to the bottom of the particulate

bin canister.

ENVIRONMENTAL SYSTEMS

Processes

Stick, TIG, MIG, Flux-Cored

Advantage Lincoln

• Integrated automatic filter cleaning

• Automatic operation capability using wire feeder trigger signal

• For 1 to 8 operators simultaneously

• Used as a stationary or mobile installation

• Rugged design for industrial use and impact resistance

• Large range of accessories available

• Compact design for easy installation in narrow spaces

Welding Fume Extractor Suction Nozzle Capacity Fume Gun Capacity

X-Tractor 3A 13

X-Tractor 5A 35

X-Tractor 8A 58

Note: Number of extraction nozzles/fume guns that can be connected to each system

is directly related to the overall lengths of duct and flex hose used for connection.

Base Unit Includes

• Extraction Unit

• Filter Cartridge

• Automatic Filter Cleaning System

TECHNICAL SPECIFICATIONS

Product Product Input H x W x D Net Weight

Name Number Power CFM mm (in.) kg (lbs.)

X-Tractor 3A L12810-1 230/3/60 165 1118 x 711 x 762 75

L12810-2 460/3/60 (44 x 28 x 30) (165)

X-Tractor 5A L12810-3 230/3/60 285 1397 x 711 x 838 129

L12810-4 460/3/60 (55 x 28 x 33) (285)

X-Tractor 8A L12810-5 230/3/60 475 1397 x 711 x 1118 215

L12810-6 460/3/60 (55 x 28 x 44) (475)

• Internal Compressed Air Regulator

• Automatic Operation Connection

• Starter/Overload Switch

Dimensions

Publication E13.19 3/08

www.lincolnelectric.com

Page 2

A CLOSER LOOK

Automatic Filter Cleaning

The cleaning timer system is factory preset, but can be adjusted

based on the welding application and usage amounts.

The system consists of a holding tank with compressed air, a solenoid

value and a timer mounted directly on the solenoid valve. The tank is

filled with compressed air, the solenoid value opens at intervals set by

the timer, and compressed air is blown into the filter from the clean side.

Particulate stuck on the outside of the filter, drops off and into a dustbin.

The tank is then again filled with compressed air, awaiting the next cycle.

This cycle can be turned off by placing the filter cleaning switch on the

front panel in the OFF position.

Automatic Operation

The extraction unit can be operated in an automatic mode, where

the extraction system will operate based on the welding machine

status. Using an electromechanical relay circuit (provided by the

customer) the welding machine trigger voltage can be used to

operate a relay circuit which would be connected to the automatic

operation circuit of the extraction system. This provides extraction

demand only when welding is taking place.

Off-Line Filter Cleaning

In addition to the automatic cleaning function, there is also a built

in off-line cleaning function that operates the cleaning system when

the machine is shut down. When the unit is shut off, the signal to

the cleaning system solenoid is delayed by an additional timer placed

inside the cabinet. The timer extends the cleaning signal in order to

operate more cleaning cycles after the extraction is shut down. Inside

the filter container there is a backflow damper that closes the inlet in

order to avoid particulate re-entrance in the duct/hose system.

Shown: Front view

Shown: Back view

Easy-Duct System

The Easy-Duct system is specially designed for a leak-proof, simple

installation for up to 8 connection points. The duct system is designed

specifically to the layout of the welding facility. The engineering behind

the design takes into account welding facility layout, the number of

welding stations, welding processes, physical obstacles and overall duct

lengths to maintain specific airflow characteristics and provide an efficient

and effective solution. A requirement is a facility layout that will show

workplace locations, obstacles and extraction equipment location. The

duct system consists of a metal duct and related accessories to build an

extraction system for all types of welding environments.

High Vacuum/Low Volume System

High vacuum welding fume extraction systems utilize higher pressure of

70-90” WG and low volume of 50-100 CFM with an air speed of 40005000 ft/min. The air handling configuration of high vacuum equipment

allows the use of small diameter rigid duct and small diameter flexhose to

easily reach extraction points. It is perfect for applications such as short

welds when using fume suction nozzles or larger fixture welding using

integrated fume extraction guns. This process is designed for close

proximity source extraction from 2-4” to the welding source.

Since the hoses and suction nozzles are smaller than those of low

vacuum systems, it is much easier to carry the fume gun, extraction

nozzle and/or flex hose into confined spaces depending on the type of

welding, base material, consumable used, and length of time. The

mobility of the suction devices allows the main filter unit to be kept at a

central location. Due to the low air volume (CFM) extracted, make-up air

and negative room air pressures are kept to a minimum when exhausting

outside the facility.

Shown: Distribution & Shutoff Valves

Shown: Easy-Duct System

[2]

X-Tractor 3A, 5A & 8A

www.lincolnelectric.com

Page 3

RECOMMENDED OPTIONS

GENERAL OPTIONS

Aluminum Suction Nozzles with

Magnetic Mounting

Includes S20591-7 adapter for 1-3/4"

(45 mm) hose. Best capture distance:

~1-1/2" (38 mm).

Order K639-1 for

SHM-300 Nozzle - 300 mm (12")

Order K639-2 for

SHM-400 Nozzle - 400 mm (16")

Order K639-3 for

SHM-500 Nozzle - 500 mm (20")

SHMS-400 Low Noise Nozzle

400 mm (16") aluminum suction nozzle with

magnetic mounting. Includes S20591-7

adapter for 1-3/4" (45 mm) hose. Best

capture distance: ~1-1/2" (38 mm).

Order K639-4

SHFA Flat Suction Nozzle

150 mm (6") Aluminum suction nozzle with

20" (500 mm) flexible steel hose and

magnetic mounting. Includes adapter for

1-3/4" (45 mm) hose. Best capture distance:

< 4" (100 mm).

Order K639-5

KT

N

K2389-3

KC

N

K2389-4

EN 40 Extraction Nozzle

The EN 40 nozzle is designed for stick

electrode applications. With its L-shaped

tube and an elongated slotted opening, the

EN 40 nozzle is designed to coincide with

the time it takes the welder to use one stick

electrode. This design alleviates the welder

from having to continuously reposition the

nozzle. Magnetic mounting stand included.

Order K2389-6

Gun Mounted Nozzle Kit

Nickel plated brass nozzle slips over the

gun’s gas nozzle and secures with screw.

Includes a total of 16 ft. (5 m) of hose and all

necessary adapters including SS-3245 for

connection to 1-3/4" (45 mm) hose.

Order K639-20

Nozzle Kits

The NKT and NKC nozzle kits provide

extraction capacity to standard welding

torches. The NKT kit is for mounting the

extraction hose on top of gun. The NKC kit

is for circular extraction. Note: guns not

included.

Order K2389-3 for NKT

Order K2389-4 for NKC

UNM Suction Nozzle for Heavy Smoke

200 mm (8") Aluminum suction nozzle with

magnetic mounting. Includes S20591-7

adapter for 1-3/4" (45 mm) hose. Best

capture distance: < 4" (100 mm).

Order K639-6

SHMT Round Suction Nozzle

90 mm (3.6") Suction nozzle with 13"

(330 mm) flexible steel hose and magnetic

mounting. Includes S20591-8 adapter for

Hoses

Flexible hoses in PVC with internal steel

spiral spring. Fits directly on adaptors and

available in different lengths.

Contact Lincoln Electric Sales Office

Adapters

Connects easily and prevent leakages in

extraction system and damaged hoses.

Contact Lincoln Electric Sales Office

1-3/4" (45 mm) hose. Best capture distance:

< 4" (125 mm).

Order K639-14

Fume Guns

To extract welding fumes, Lincoln Electric's

X-Tractor 250FG, 340FG, and 500FG fume

EN 20 Extraction Nozzle

The EN 20 nozzle is designed for a wide

array of welding applications. With its funnel

extraction opening and magnetic mounting

guns, can be connected to the X-Tractor

1GC and its extraction hose.

For X-Tractor 250FG, 340FG, 500FG

Contact Lincoln Electric Sales Office

stand, it gives the welder a greater amount

of versatility.

Order K2389-5

The operation of welding fume control equipment is affected by various factors including proper use and positioning of the equipment, maintenance of the

equipment and the specific welding procedure and application involved. Worker exposure level should be checked upon installation and periodically

thereafter to be certain it is within applicable OSHA PEL and ACGIH TLV limits.

[3]

X-Tractor 3A, 5A & 8A

www.lincolnelectric.com

Page 4

X-TRACTOR 3A, 5A & 8A ORDER FORM

PRODUCT DESCRIPTION ORDER NUMBER QUANTITY PRICE

tractor 3A: L12810-1: 230/3/60

X

tractor 5A: L12810-3: 230/3/60

X

Xtractor 8A: L12810-5: 230/3/60

ENERAL OPTIONS

G

SHM-300 Nozzle K639-1

SHM-400 Nozzle K639-2

HM-500 Nozzle K639-3

S

SHMS-400 Low Noise Nozzle K639-4

SHFA Flat Suction Nozzle K639-5

NM Suction Nozzle for Heavy Smoke K639-6

U

HMT Round Suction Nozzle K639-14

S

EN 20 Extraction Nozzle K2389-5

EN 40 Extraction Nozzle K2389-6

Gun Mounted Nozzle Kit K639-20

KT Nozzle Kits K2389-3

N

KC Nozzle Kit K2389-4

N

Hoses Contact Lincoln Electric Sales Office

Hose Adaptors Contact Lincoln Electric Sales Office

ume Guns

F

L12810-2: 460/3/60

12810-4: 460/3/60

L

L12810-6: 460/3/60

Contact Lincoln Electric Sales Office

TOTAL:

Environmental Systems Family

High & Low

Vacuum Solutions

For further information, contact Lincoln Electric’s Automation team at:

automation@lincolnelectric.com or call 888.935.3878

The business of The Lincoln Electric Company®is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the needs of

our customers and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric for information or advice about their use of our products. Our employees respond to

inquiries to the best of their ability based on information provided to them by the customers and the knowledge they may have concerning the application. Our employees, however, are not

in a position to verify the information provided or to evaluate the engineering requirements for the particular weldment. Accordingly, Lincoln Electric does not warrant or guarantee or assume

any liability with respect to such information or advice. Moreover, the provision of such information or advice does not create, expand, or alter any warranty on our products. Any express or

implied warranty that might arise from the information or advice, including any implied warranty of merchantability or any warranty of fitness for any customers’ particular purpose is

specifically disclaimed.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility of the

customer. Many variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

C U S T O M E R A S S I S T A N C E P O L I C Y

THE LINCOL N E L E C T R I C COMPA NY

22801 St. Clair Ave., Cleveland, OH 44117-1199 • 216.481.8100 • www.lincolnelectric.com

Loading...

Loading...