Lincoln Electric K2803 Operator's Manual

IM2064

04/2017

REV01

POWER WAVE® AC/DC 1000 SD CE

OPERATOR’S MANUAL

ENGLISH

22801 St. Clair Ave., Cleveland Ohio 44117-1199 USA

THE LINCOLN ELECTRIC COMPANY

www.lincolnelectric.eu

THE LINCOLN ELECTRIC COMPANY

EC DECLARATION OF CONFORMITY

Manufacturer and technical documentation

holder:

Address:

EC Company:

Address:

Hereby declare that equipment:

The Lincoln Electric Company

22801 St. Clair Ave.

Cleveland Ohio 44117-1199 USA

Lincoln Electric Europe S.L.

c/o Balmes, 89 - 8

0 2a

08008 Barcelona

SPAIN

K2803, Power Wave AC/DC 1000 SD

K2444, CE Filter

K2814, MAXsa 10 Controller

K2626, MAXsa 19 Controller

K2370, MAXsa 22 Feed Head

K2312, MAXsa 29 Feed Head

(Sales codes may contain suffixes and prefixes.)

Is in conformity with Council Directives

and amendments:

Electromagnetic Compatibility (EMC) Directive 2014/30/EU

Low Voltage Directive (LVD) 2014/35/EU

Standards: EN 60974-1: 2012, Arc Welding Equipment – Part 1: Welding Power

Sources;

EN 60974-5: 2013, Arc Welding Equipment-Part 5: Wire Feeders;

EN 60974-10: 2014, Arc Welding Equipment-Part 10: Electromagnetic

compatibility (EMC) requirements;

CE marking affixed in 09

SamirFarah,Manufacturer DarioGatti,EuropeanCommunityRepresentative

ComplianceEngineeringManager EuropeanEngineeringManager

19January2017

MCD240f

20January2017

English English

I

THANKS! For having chosen the QUALITY of the Lincoln Electric products.

Please Examine Package and Equipment for Damage. Claims for material damaged in shipment must be notified

immediately to the dealer.

For future reference record in the table below your equipment identification information. Model Name, Code &

Serial Number can be found on the machine rating plate.

Model Name:

………………...…………………………….…………………………………………………………………………………………..

Code & Serial number:

………………….……………………………………………….. …………………………………………………….……………..

Date & Where Purchased:

…………………………………………………………………... ……………………….…………………………………………..

ENGLISH INDEX

Technical Specifications ...................................................................................................................................................... 1

Safety .................................................................................................................................................................................. 3

Installation and Operator Instructions ................................................................................................................................. 4

WEEE ................................................................................................................................................................................ 28

Spare Parts ....................................................................................................................................................................... 28

Authorized Service Shops Location .................................................................................................................................. 28

Electrical Schematic .......................................................................................................................................................... 29

Suggested Accessories ..................................................................................................................................................... 31

12/05

English English

II

3

W

Technical Specifications

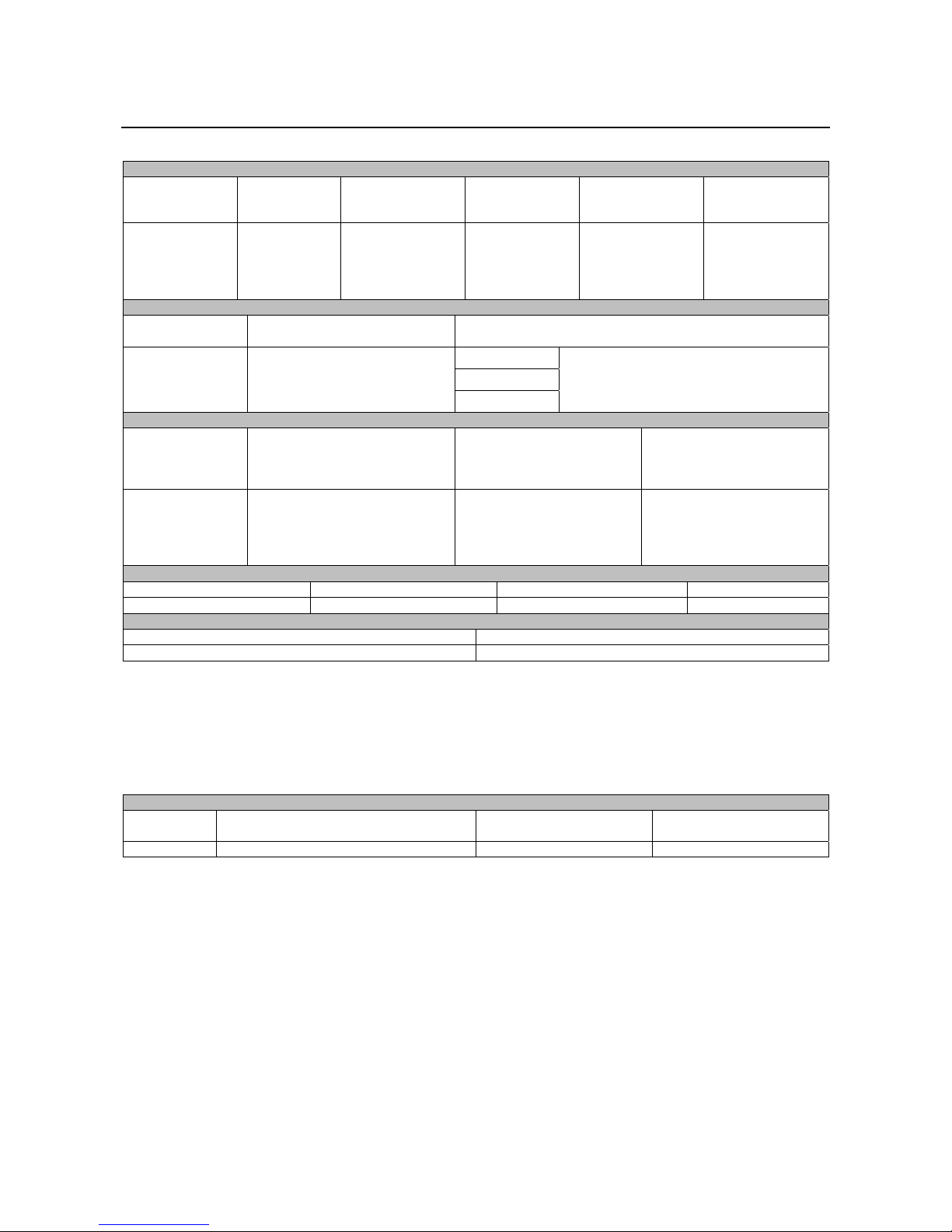

POWER WAVE® AC/DC 1000 SD CE (K2803-1*)

INPUT AT RATED OUTPUT – THREE PHASE ONLY

INPUT VOLTS 3

PHASE 50/60Hz

380

400

460

500

575

INPUT

CURRENT

AMPS

82

79

69

62

55

OUTPUT

CONDITIONS

1000A@44V.

100% Duty Cycle

IDLE POWER

WATTS

225 .95 86%

OUTPUT

OPEN CIRCUIT

VOLTAGE

71V

70VACpk.

AUXILIARY POWER (CIRCUIT

BREAKER PROTECTED)

40 VDC AT

10 AMPS

115 VAC AT

10 AMPS

PROCESS CURRENT RANGES (AC or DC)

SAW-DC+

SAW-DC-

SAW-AC

RECOMMENDED INPUT WIRE AND FUSES SIZES1

3 PAHESE INPUT

VOLTAGE

50/60Hz

380

400

460

500

575

TYPE 90°C COPPER WIRE

CONDUIT

AWG (mm

2

3 (25)

3 (25)

4 (25)

4 (25)

6 (16)

IN

COPPER GROUNDING

CONDUCTOR

)

AWG (mm2)

8 (10)

8 (10)

8 (10)

8 (10)

10 (6)

PHYSICAL DIMENSIONS

HEIGHT (mm) WIDTH (mm) DEPTH (mm)

1248 501 1184 363

TEMPERATURE RANGES

OPERATING TEMPERATURE RANGE (ºC) STORAGE TEMPERATURE RANGE (ºC)

-10 to +40 -40 to +85

1

Wire and Fuse Sizes based upon the U.S. National Electric Code and maximum output for 40°C ambient.

2

Also called “inverse time” or “thermal/magnetic” circuit breakers; circuit breakers that have a delay in tripping action that

decreases as the magnitude of current increases.

3

Fail to use proper type of copper wire will cause fire hazards.

*

An External filter will be required to meet CE or C-Tick/RCM conducted emission requirements. It will meet CE and C-

Tick/RCM requirements with the use of an optional external filter. (K2444-3 CE and C-Tick/RCM Filter Kit).

WELDING PROCESSES

PROCESS ELECTRODE DIAMETER RANGE

OUTPUR RANGE

(Amperes)

SAW 2 – 5.6mm 100 -1000 See Wire Drive Section

Insulation Class: Class F (155°C)

POWER FACTOR

@ RATED

OUTPUT

EFFICIENCY @

RATED OUTPUT

100amps@24Volts

1000Amps@44Volts

(Actual range may be limited by process)

TIME DELAY FUSER OR

BREAKER

AMPS

100

90

90

80

70

EIGHT (kg)

WIRE FEED SPEED

RANGE

2

English English

1

Electromagnetic Compatibility (EMC)

This machine has been designed in accordance with all relevant directives and standards. However, it may still generate

electromagnetic disturbances that can affect other systems like telecommunications (telephone, radio, and television) or

other safety systems. These disturbances can cause safety problems in the affected systems. Read and understand

this section to eliminate or reduce the amount of electromagnetic disturbance generated by this machine.

with, if necessary, assistance from Lincoln Electric.

Before installing the machine, the operator must check the work area for any devices that may malfunction because of

electromagnetic disturbances. Consider the following.

Input and output cables, control cables, and telephone cables that are in or adjacent to the work area and the

machine.

Radio and/or television transmitters and receivers. Computers or computer controlled equipment.

Safety and control equipment for industrial processes. Equipment for calibration and measurement.

Personal medical devices like pacemakers and hearing aids.

Check the electromagnetic immunity for equipment operating in or near the work area. The operator must be sure

that all equipment in the area is compatible. This may require additional protection measures.

The dimensions of the work area to consider will depend on the construction of the area and other activities that are

taking place.

Consider the following guidelines to reduce electromagnetic emissions from the machine.

Connect the machine to the input supply according to this manual. If disturbances occur if may be necessary to take

additional precautions such as filtering the input supply.

The output cables should be kept as short as possible and should be positioned together. If possible connect the

work piece to ground in order to reduce the electromagnetic emissions. The operator must check that connecting

the work piece to ground does not cause problems or unsafe operating conditions for personnel and equipment.

Shielding of cables in the work area can reduce electromagnetic emissions. This may be necessary for special

applications.

EMC classification of this product is class A in accordance with electromagnetic compatibility standard EN 60974-10 and

therefore the product is designed to be used in an industrial environment only.

The Class A equipment is not intended for use in residential locations where the electrical power is provided by the public

low-voltage supply system. There can be potential difficulties in ensuring electromagnetic compatibility in those locations,

due to conducted as well as radio-frequency disturbances.

This machine has been designed to operate in an industrial area. To operate in a domestic area it is

necessary to observe particular precautions to eliminate possible electromagnetic disturbances. The

operator must install and operate this equipment as described in this manual. If any electromagnetic

disturbances are detected the operator must put in place corrective actions to eliminate these disturbances

WARNING

WARNING

01/11

English English

2

Safety

11/04

WARNING

This equipment must be used by qualified personnel. Be sure that all installation, operation, maintenance and repair

procedures are performed only by qualified person. Read and understand this manual before operating this equipment.

Failure to follow the instructions in this manual could cause serious personal injury, loss of life, or damage to this

equipment. Read and understand the following explanations of the warning symbols. Lincoln Electric is not responsible

for damages caused by improper installation, improper care or abnormal operation.

WARNING: This symbol indicates that instructions must be followed to avoid serious personal injury,

loss of life, or damage to this equipment. Protect yourself and others from possible serious injury or

death.

READ AND UNDERSTAND INSTRUCTIONS: Read and understand this manual before operating

this equipment. Arc welding can be hazardous. Failure to follow the instructions in this manual could

cause serious personal injury, loss of life, or damage to this equipment.

ELECTRIC SHOCK CAN KILL: Welding equipment generates high voltages. Do not touch the

electrode, work clamp, or connected work pieces when this equipment is on. Insulate yourself from

the electrode, work clamp, and connected work pieces.

ELECTRICALLY POWERED EQUIPMENT: Turn off input power using the disconnect switch at the

fuse box before working on this equipment. Ground this equipment in accordance with local electrical

regulations.

ELECTRICALLY POWERED EQUIPMENT: Regularly inspect the input, electrode, and work clamp

cables. If any insulation damage exists replace the cable immediately. Do not place the electrode

holder directly on the welding table or any other surface in contact with the work clamp to avoid the

risk of accidental arc ignition.

ELECTRIC AND MAGNETIC FIELDS MAY BE DANGEROUS: Electric current flowing through any

conductor creates electric and magnetic fields (EMF). EMF fields may interfere with some

pacemakers, and welders having a pacemaker shall consult their physician before operating this

equipment.

CE COMPLIANCE: This equipment complies with the European Community Directives.

FUMES AND GASES CAN BE DANGEROUS: Welding may produce fumes and gases hazardous to

health. Avoid breathing these fumes and gases. To avoid these dangers the operator must use

enough ventilation or exhaust to keep fumes and gases away from the breathing zone.

ARC RAYS CAN BURN: Use a shield with the proper filter and cover plates to protect your eyes from

sparks and the rays of the arc when welding or observing. Use suitable clothing made from durable

flame-resistant material to protect you skin and that of your helpers. Protect other nearby personnel

with suitable, non-flammable screening and warn them not to watch the arc nor expose themselves to

the arc.

WELDING SPARKS CAN CAUSE FIRE OR EXPLOSION: Remove fire hazards from the welding

area and have a fire extinguisher readily available. Welding sparks and hot materials from the welding

process can easily go through small cracks and openings to adjacent areas. Do not weld on any

tanks, drums, containers, or material until the proper steps have been taken to insure that no

flammable or toxic vapors will be present. Never operate this equipment when flammable gases,

vapors or liquid combustibles are present.

WELDED MATERIALS CAN BURN: Welding generates a large amount of heat. Hot surfaces and

materials in work area can cause serious burns. Use gloves and pliers when touching or moving

materials in the work area.

SAFETY MARK: This equipment is suitable for supplying power for welding operations carried out in

an environment with increased hazard of electric shock.

English English

3

CYLINDER MAY EXPLODE IF DAMAGED: Use only compressed gas cylinders containing the

correct shielding gas for the process used and properly operating regulators designed for the gas and

pressure used. Always keep cylinders in an upright position securely chained to a fixed support. Do

not move or transport gas cylinders with the protection cap removed. Do not allow the electrode,

electrode holder, work clamp or any other electrically live part to touch a gas cylinder. Gas cylinders

must be located away from areas where they may be subjected to physical damage or the welding

process including sparks and heat sources.

MOVING PARTS ARE DANGEROUS: There are moving mechanical parts in this machine, which

can cause serious injury. Keep your hands, body and clothing away from those parts during machine

starting, operating and servicing.

EQUIPMENT WEIGHT OVER 30kg: Move this equipment with care and with the help of another

person. Lifting may be dangerous for your physical health.

The manufacturer reserves the right to make changes and/or improvements in design without upgrade at the same time

the operator’s manual.

Installation and Operator Instructions

Read this entire section before installation or operation

of the machine.

General Description

The Power Wave® AC/DC 1000 SD CE is a high

performance, digitally controlled inverter welding power

source. It is capable of producing a variable frequency

and amplitude AC output, DC positive output, or DC

negative output without the need for external

reconnection. It utilizes complex, high-speed waveform

control to support a variety of constant current and

constant voltage welding modes in each of its output

configurations.

The Power Wave

designed to be a part of a modular welding system. Each

welding arc may be driven by a single machine, or by a

number of machines in parallel. In multiple arc

applications the phase angle and frequency of different

machines can be synchronized by interconnecting the

units with a control cable to improve performance and

reduce the effects of arc blow.

The Power Wave

designed to interface with compatible ArcLink

equipment. However, it can also communicate with other

industrial machines and monitoring equipment via

DeviceNet, or Ethernet. The result is a highly integrated

and flexible welding cell.

®

AC/DC 1000 SD CE power source is

®

AC/DC 1000 SD CE is primarily

Recommended Process

The Power Wave® AC/DC 1000 SD CE is designed for

submerged arc welding (SAW). Due to its modular

design the Power Wave AC/DC can operate on either

single arc or in multi-arc applications with up to six arcs.

Each machine is factory preprogrammed with multiple

welding procedures to support all types of submerged

arc welding. The Power Wave

carries an output rating of 1000 amps, 44 volts (at 100%

duty cycle). If higher currents are required machines can

be easily paralleled for up to 3000 amps on each arc

(see Duty Cycle section)

®

AC/DC 1000 SD CE

Process Limitations

The Power Wave® AC/DC 1000 SD CE is suitable only

for the Submerged Arc Process (SAW).

Equipment Limitations

The Power Wave® AC/DC 1000 SD can be used in

outdoor environments. The Operating Temperature

Range is 14°F to 104°F(0°C to +40°C).

Only the MAXsa™ 22 or MAXsa™ 29 Wire Drives and

MAXsa™ 10 or MAXsa™ 19 Controllers may be used

with a K2803-1 PowerWave

Multi Arc system. Other Lincoln or non-Lincoln Wire

Drives can only be used with custom interfaces.

The Power Wave

maximum average output current of 1000 Amps at 100%

Duty Cycle.

®

AC/DC 1000 SD CE will support a

®

AC/DC 1000 SD CE in a

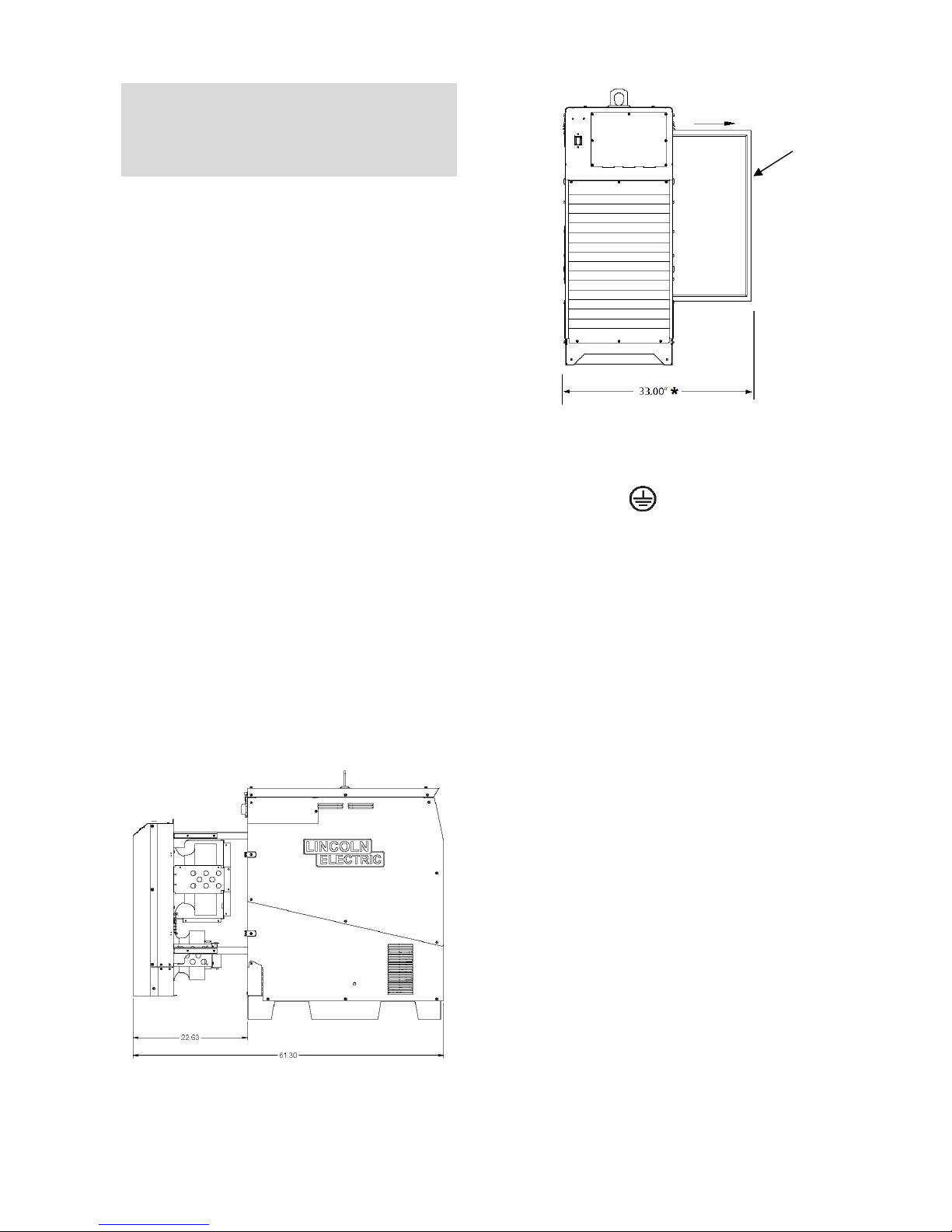

Location and Mounting

Place the welder where clean cooling air can freely

circulate in through the rear louvers and out through the

case sides and front. Dirt, dust, or any foreign material

that can be drawn into the welder should be kept at a

minimum. Failure to observe these precautions can

result in excessive operating temperatures and nuisance

shutdowns. See the Clearance Requirements and Figure

#1 below.

Stacking

DO NOT MOUNT OVER COMBUSTIBLE SURFACES.

Where there is a combustible surface directly under

stationary or fixed electrical equipment, the surface shall

be covered with a steel plate at least 1.6mm thick, which

shall extend not more than 150mm beyond the

equipment on all sides.

The Power Wave

be stacked.

WARNING

®

AC/DC 1000 SD CE machine cannot

Lifting

FALLING EQUIPMENT can cause injury.

Lift only with equipment of adequate lifting capacity.

Be sure machine is stable when lifting.

WARNING

English English

4

Do not lift this machine using lift bail if it is equipped

with a heavy accessory such as trailer or gas

cylinder.

Do not lift machine if lift bail is damaged.

Do not operate machine while suspended from lift

bail

Lift the machine by the lift bail only. The lift bail is

designed to lift the power source only . Do not attempt to

lift the Power Wave

accessories attached to it.

®

AC/DC 1000 SD CE with

Duty Cycle

The Power Wave® AC/DC 1000 SD CE is capable of

welding 1000Amps,. @44V, at a 100% Duty cycle.

Environmentasl Limitations

The Power Wave® AC/DC 1000 SD CE can be used in

an outdoor environment with an IP 23 rating. It should

not be subjected to falling water, nor should any parts of

it be submerged in water. Doing so may cause improper

operation as well as pose a safety hazard. The best

practice is to keep the machine in a dry, sheltered area.

Clearence Requirements

The maintenance requirements of the Power Wave®

AC/DC 1000 SD CE demands that enough clearance

behind the machine be maintained. This is especially

important where more than one machine is to be used or

if the machines are going to be rack mounted.

The rear portion of the machine that contains the filter

and the cooling fans slides out for easy access to clean

the heat sink fins.

Removing the four clips and pulling back on the rear

portion of the machine will provide access for cleaning

the machine and checking the filter. The filter is removed

from the right side of the machine.

Where machines are mounted side by side, the machine

that is furthest to the right will need to have the indicated

clearance to the right side for filter removal. See Figure

#1

FILTER REMOVAL

FROM SIDE OF

MACHINE

*: 33.00” width needed for filter maintenance access.

Figure #1: Clearance Requirements

Input and Ground Connections

Machine Grounding

The frame of the welder must be grounded. A ground

terminal marked with a ground symbol shown is located

inside the reconnect/input access door for this purpose.

See your local and national electrical codes for proper

grounding methods.

English English

5

Input Connection

WARNING

ELECTRIC SHOCK can kill

Only a qualified electrician should connect the input

leads to the Power Wave. Connections should be made

in accordance with all local and national electrical codes

and the connection diagrams located on the inside of the

reconnect/input access door of the machine. Failure to

do so may result in bodily injury or death.

Use a three-phrase supply line. A 45mm diameter

access hole for the input supply is located on the case

back. Connect L1, L2, L3 and ground according to the

Input Supply Connection Diagram.

Input Fuse and Supply Wire

Considerations

Refer to Specifications page for recommended fuse and

wire sizes. Fuse the input circuit with the recommended

super lag fuse or delay type breakers (also called

"inverse time" or "thermal/magnetic" circuit breakers).

Choose input and grounding wire size according to local

or national electrical codes. Using fuses or circuit

breakers smaller than recommended may result in

"nuisance" shut-offs from welder inrush currents, even if

the machine is not being used at high currents.

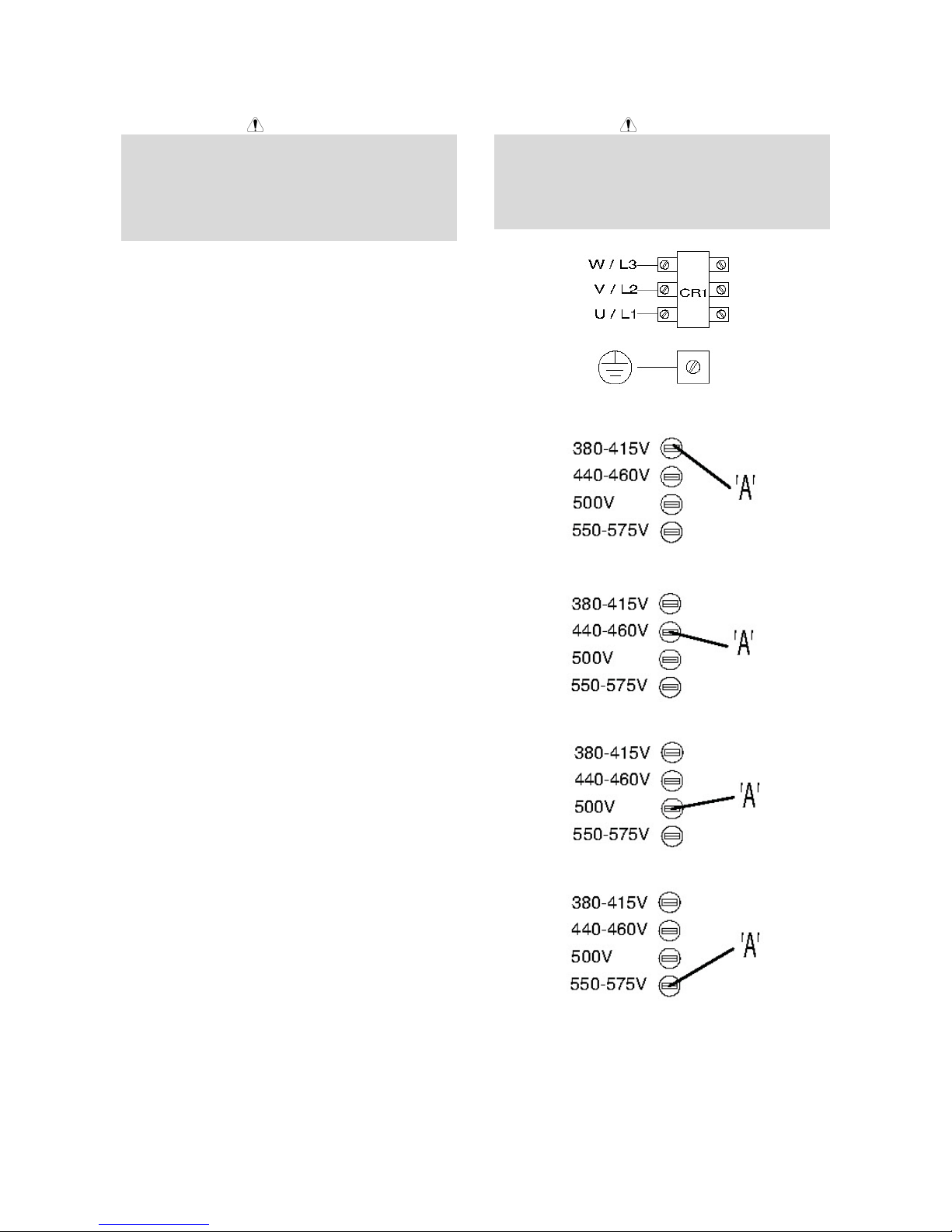

Input Voltage Selection

Welders are shipped connected for the highest input

voltage listed on the rating plate. To move this

connection to a different input voltage, see the diagram

located on the inside of the input access door, or the

Input Supply Connection Diagram below. If the Auxiliary

lead (indicated as ‘A’) is placed in the wrong position,

there are two possible results.

a) If the lead is placed in a position higher than the

applied line voltage, the welder may not come on at

all.

b) If the Auxiliary lead is placed in a position lower than

the applied line voltage, the welder will not come on,

and the two circuit breakers in the reconnect area

will open. If this occurs, turn off the input voltage,

properly connect the auxiliary lead, reset the

breakers, and try again.

Input Supply Connection for K2803-1

ELECTRIC SHOCK CAN KILL:

Do not operate with covers removed

Disconnect input power before servicing

Do not touch electrically live parts

Only qualified persons should install, use or service

this equipment

Voltage=380-415V

Voltage=440-460V

Voltage=500V

WARNING

English English

Voltage=550-575V

6

System Connection

System Overview

The Power Wave® AC/DC 1000 SD CE power source is

designed to be a part of a modular welding system

typically controlled by a MAXsa™ 10 Controller or a

customer supplied Programmable Logic Controller

(PLC). Each welding arc may be driven by a single

power source or by a number of power sources

connected in parallel. The actual number of power

sources per arc will vary depending on the application.

When only one power source is required for an arc

group, it must be configured as a Master. When parallel

machines are required, one is designated as the Master

and the rest as Slaves. The synchronizing connectors for

paralleled machines are on the back of the power

source. The Master controls the AC switching for the arc

group, and the Slaves respond accordingly. See Figure

#3 below.

When employed in a multi-arc AC system the arcs must

be synchronized to each other. The Master for each arc

can be configured to follow a dedicated external

synchronization signal to determine its frequency and

balance. The Synchronizing Connectors on the back of

the Power Wave

means to synchronize the AC wave shapes of up to six

different arcs to a common carrier frequency. (See

Figure #3). This frequency can range from 20 hertz to

100 hertz. It can also control the phase angle between

arcs to reduce the effects of welding related issues such

as "Arc Blow".

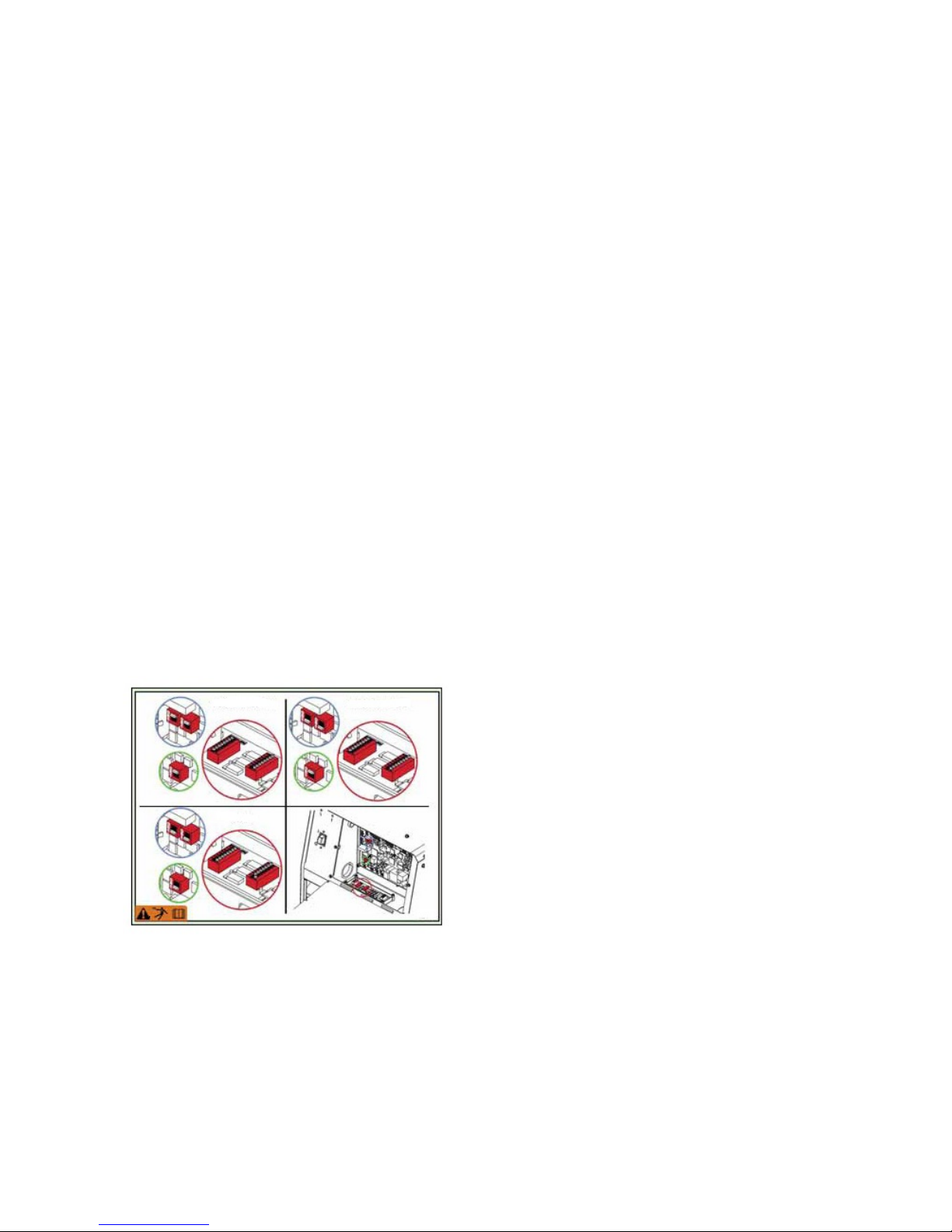

The arc to arc phase relationship is determined by the

timing of each arc’s "sync" signal relative to the "sync"

signal of ARC 1. DIP Switches on the Control PC Board

of each machine must be set to identify it as a Master

Lead, Master Trail or Slave. See Figure #2.

®

AC/DC 1000 SD CE provide the

NOTE: The K2803-1 Power Wave® AC/DC 1000® SD

is backwards compatible with the K2344-2 Power

Wave® AC/DC 1000 in tandem or multi-arc systems.

The K2803- 1 and K2344-2 machines cannot be

connected in parallel. Paralleled machines must be of

the same type. A K1805- 1 (14 to 22 pin adapter cable)

is required to interface to the K2282-1 Systems Interface

in these setups A PLC interface is an alternate method

of control for larger systems. The PLC is typically

connected via DeviceNet directly to the Master power

source of each arc group in the system. MAXsa™ 19

Controller is still required to power the Wire Drive.

Contact your Local Lincoln Electric Representative for

more information.

The connection diagrams describe the layout of several

typical systems including Multi-Arc and Paralleled

machine set-ups. Each system also has a step by step

“Installation Checklist”.

MASTER-LEAD MASTER-TRAIL

SLAVE

Figure #2: Dip Switch Settings

In a typical multi-arc system, each arc is controlled by its

own MAXsa™10 Controller. The basic characteristics of

the individual arcs such as WFS, amplitude, and offset

are set locally by each arc’s dedicated controller. The

frequency, balance, and phase shift parameters of each

arc are controlled by the MAXsa™ 10 Controller for ARC

1 (Master Lead).

English English

7

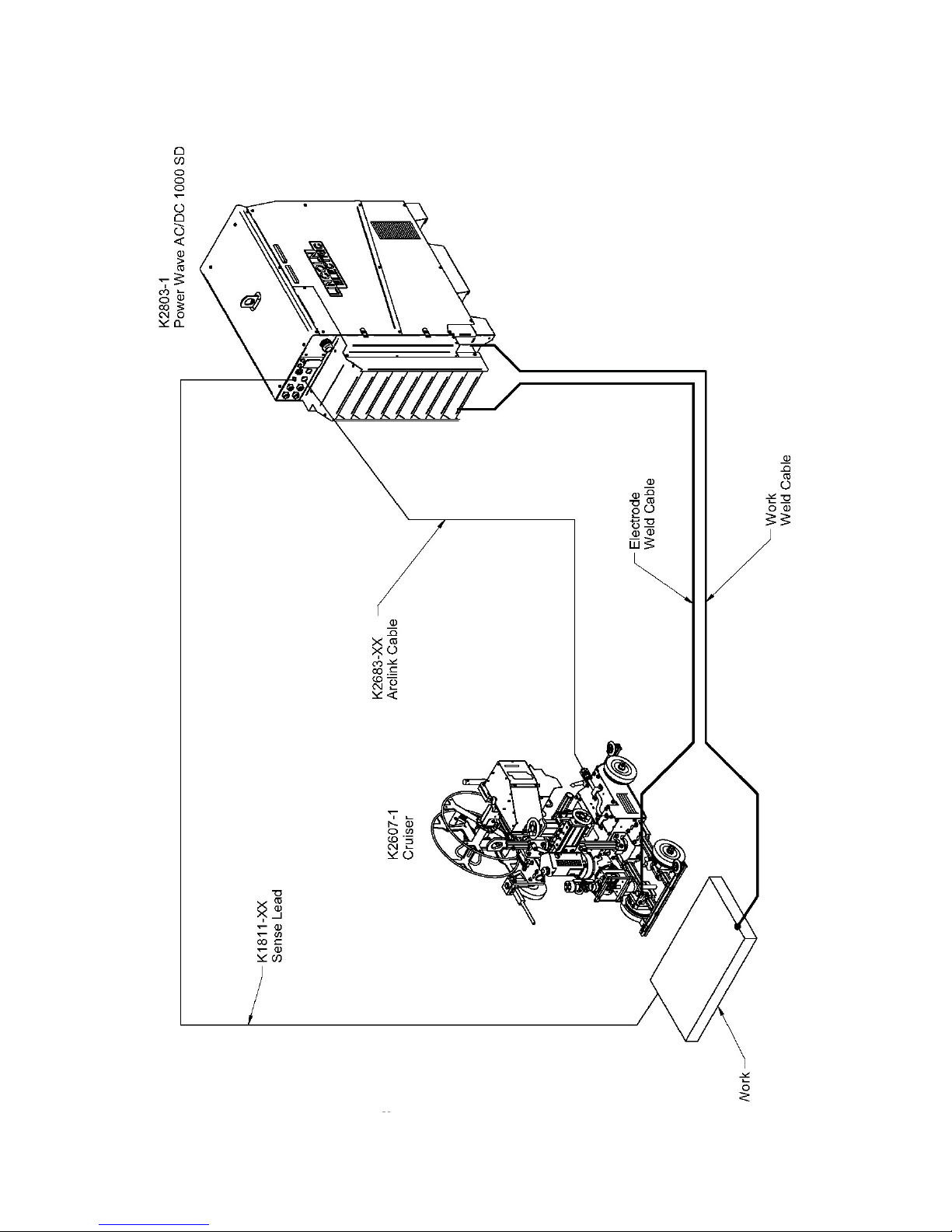

Cruiser Connection Diagram

English English

8

Loading...

Loading...