Page 1

LN-25™ PRO

OPERATOR’S MANUAL

IM2071

10/2017

REV01

ENGLISH

22801 St. Clair Ave., Cleveland Ohio 44117-1199 USA

THE LINCOLN ELECTRIC COMPANY

www.lincolnelectric.eu

Page 2

THE LINCOLN ELECTRIC COMPANY

EC DECLARATION OF CONFORMITY

Manufacturer and technical documentation

holder:

Address:

EC Company:

Address:

Hereby declare that welding equipment:

Product Numbers:

Is in conformity with Council Directives and

amendments:

Low Voltage Directive 2014/35/EU

Standards: EN 60974-5: 2013, Arc Welding Equipment – Part 5: Wire Feeders,

CE marking affixed in 08

Samir Farah, Manufacturer Dario Gatti, European Community Representative

Compliance Engineering Manager European Engineering Director Machines

17 May 2016 19 May 2016

MCD143e

The Lincoln Electric Company

22801 St. Clair Ave.

Cleveland Ohio 44117-1199 USA

Lincoln Electric Europe S.L.

c/o Balmes, 89 - 80 2a

08008 Barcelona

SPAIN

LN-25 PRO & LN-25 PRO Dual, Wire Feeders

K2613 & K2614

(Product numbers may also contain prefixes and suffixes)

Electromagnetic Compatibility (EMC) Directive 2014/30/EU

EN 60974-10: 2007 Arc Welding Equipment – Part 10:

Electromagnetic compatibility (EMC) requirements;

English English

I

Page 3

THANKS! For having chosen the QUALITY of the Lincoln Electric products.

Please Examine Package and Equipment for Damage. Claims for material damaged in shipment must be notified

immediately to the dealer.

For future reference record in the table below your equipment identification information. Model Name, Code &

Serial Number can be found on the machine rating plate.

Model Name:

………………...…………………………….…………………………………………………………………………………………..

Code & Serial number:

………………….……………………………………………….. …………………………………………………….……………..

Date & Where Purchased:

…………………………………………………………………... ……………………….…………………………………………..

ENGLISH INDEX

Technical specifications ...................................................................................................................................................... 1

Electromagnetic Compatibility (EMC) ................................................................................................................................. 2

Safety .................................................................................................................................................................................. 3

Installation and Operator Instructions ................................................................................................................................. 4

WEEE ................................................................................................................................................................................ 18

Spare Parts ....................................................................................................................................................................... 18

Authorized Service Shops Location .................................................................................................................................. 18

Electrical Schematic .......................................................................................................................................................... 19

Suggested Accessories ..................................................................................................................................................... 20

12/05

English English

II

Page 4

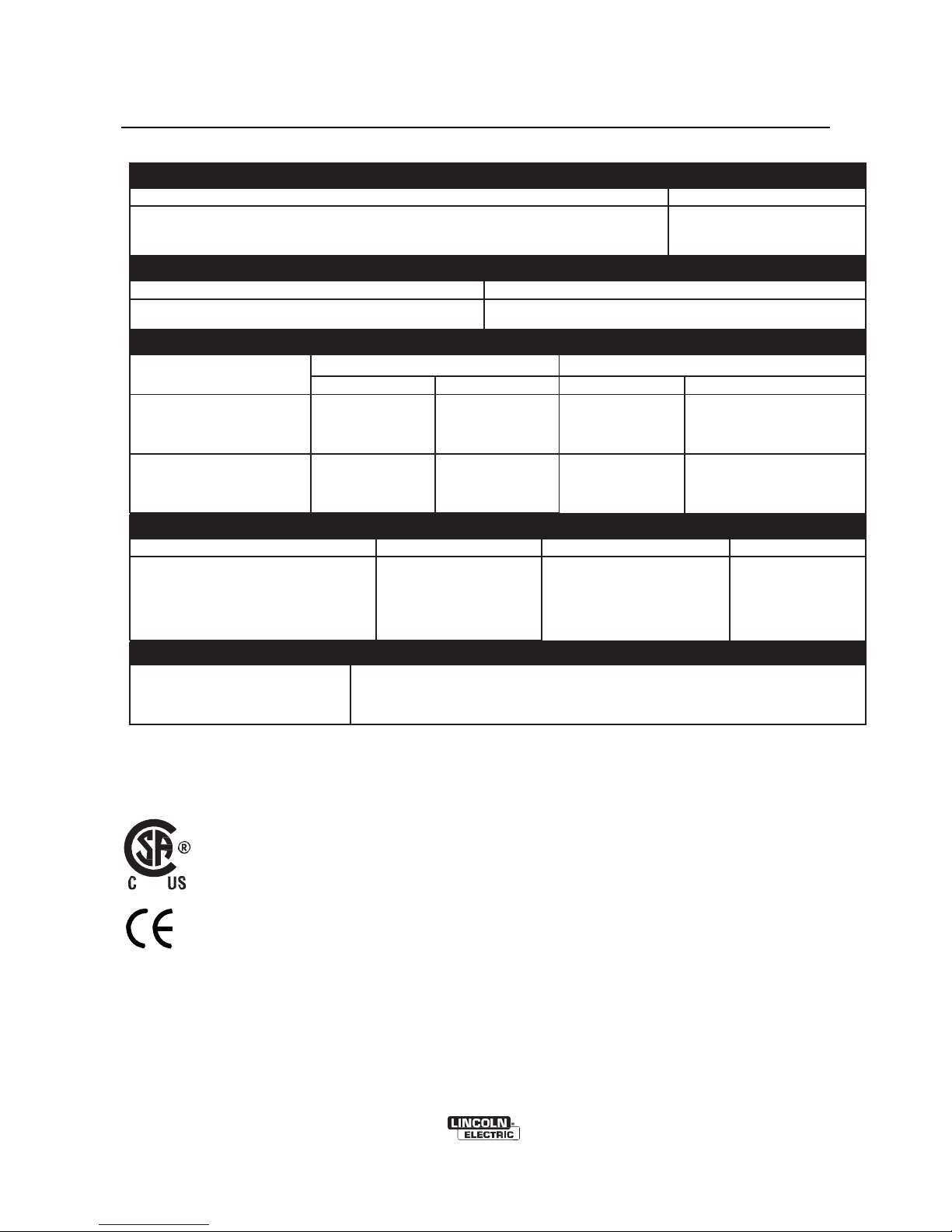

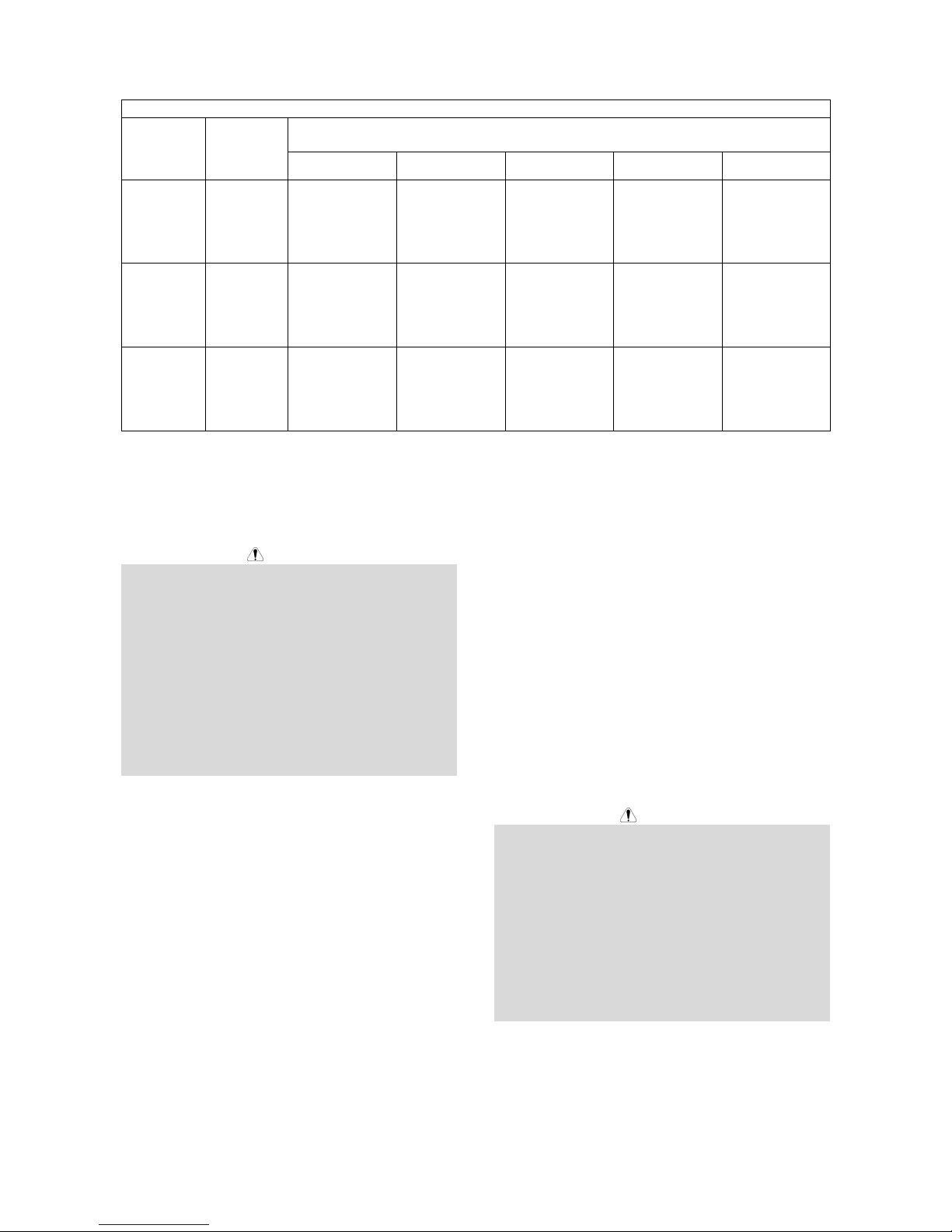

Technical specifications

LN-25™ PRO (K2613-5, K2613-7) (CODE NUMBER: 11746, 11747).

INPUT VOLTAGE AND CURRENT

INPUT VOLTAGE ± 10% INPUT AMPERES

DUTY CYCLE INPUT AMPERES

60% RATING 450

GEARING - WIRE FEED SPEED RANGE-WIRE SIZE

GEARING

EXTRA TORQUE K2613-7

STANDARD SPEED

K2613-5

HEIGHT WIDTH DEPTH WEIGHT

14.8 INCHES

(376 MM)

HANDLE FOLDED DOWN

15-110 VDC

4A

RATED OUTPUT @ 104°F (40°C)

GMAW FCAW

WFS RANGE WIRE SIZES WFS RANGE WIRE SIZES

50 – 400 IPM

(1.3 – 10.1M/MIN)

50 – 700 IPM

(1.3 – 17.7M/MIN)

.023 – 1/16"

(0.6 – 1.6MM)

.023 – 1/16"

(0.6 – 1.6MM)

50 – 400 IPM

(1.3 – 10.1M/MIN)

50 – 700 IPM

(1.3 – 17.7M/MIN)

.030 - 3/32”

(0.8 – 2.4MM)

.030 - 5/64

(0.8 - 2.0MM)

PHYSICAL DIMENSIONS

8.7 INCHES

( 221 MM)

23.2 INCHES

(589 MM)

38 LBS

(17 KG)

TEMPERATURE RANGE

OPERATION: STORAGE:

Thermal tests have been performed at ambient temperature. The duty cycle (duty factor) at 40°C has been

determined by simulation.

Duty cycle is based upon the amount of welding performed in a 10 minute period.

-40°F TO 104°F (-40°C TO 40°C)

-40°F TO 122°F (-40°C TO 50°C)

IP23

IEC 60974-5

English English

1

Page 5

Electromagnetic Compatibility (EMC)

This machine has been designed in accordance with all relevant directives and standards. However, it may still generate

electromagnetic disturbances that can affect other systems like telecommunications (telephone, radio, and television) or

other safety systems. These disturbances can cause safety problems in the affected systems. Read and understand

this section to eliminate or reduce the amount of electromagnetic disturbance generated by this machine.

with, if necessary, assistance from Lincoln Electric.

Before installing the machine, the operator must check the work area for any devices that may malfunction because of

electromagnetic disturbances. Consider the following.

Input and output cables, control cables, and telephone cables that are in or adjacent to the work area and the

machine.

Radio and/or television transmitters and receivers. Computers or computer controlled equipment.

Safety and control equipment for industrial processes. Equipment for calibration and measurement.

Personal medical devices like pacemakers and hearing aids.

Check the electromagnetic immunity for equipment operating in or near the work area. The operator must be sure

that all equipment in the area is compatible. This may require additional protection measures.

The dimensions of the work area to consider will depend on the construction of the area and other activities that are

taking place.

Consider the following guidelines to reduce electromagnetic emissions from the machine.

Connect the machine to the input supply according to this manual. If disturbances occur if may be necessary to take

additional precautions such as filtering the input supply.

The output cables should be kept as short as possible and should be positioned together. If possible connect the

work piece to ground in order to reduce the electromagnetic emissions. The operator must check that connecting

the work piece to ground does not cause problems or unsafe operating conditions for personnel and equipment.

Shielding of cables in the work area can reduce electromagnetic emissions. This may be necessary for special

applications.

EMC classification of this product is class A in accordance with electromagnetic compatibility standard EN 60974-10 and

therefore the product is designed to be used in an industrial environment only.

The Class A equipment is not intended for use in residential locations where the electrical power is provided by the public

low-voltage supply system. There can be potential difficulties in ensuring electromagnetic compatibility in those locations,

due to conducted as well as radio-frequency disturbances.

This machine has been designed to operate in an industrial area. To operate in a domestic area it is

necessary to observe particular precautions to eliminate possible electromagnetic disturbances. The

operator must install and operate this equipment as described in this manual. If any electromagnetic

disturbances are detected the operator must put in place corrective actions to eliminate these disturbances

WARNING

WARNING

01/11

English English

2

Page 6

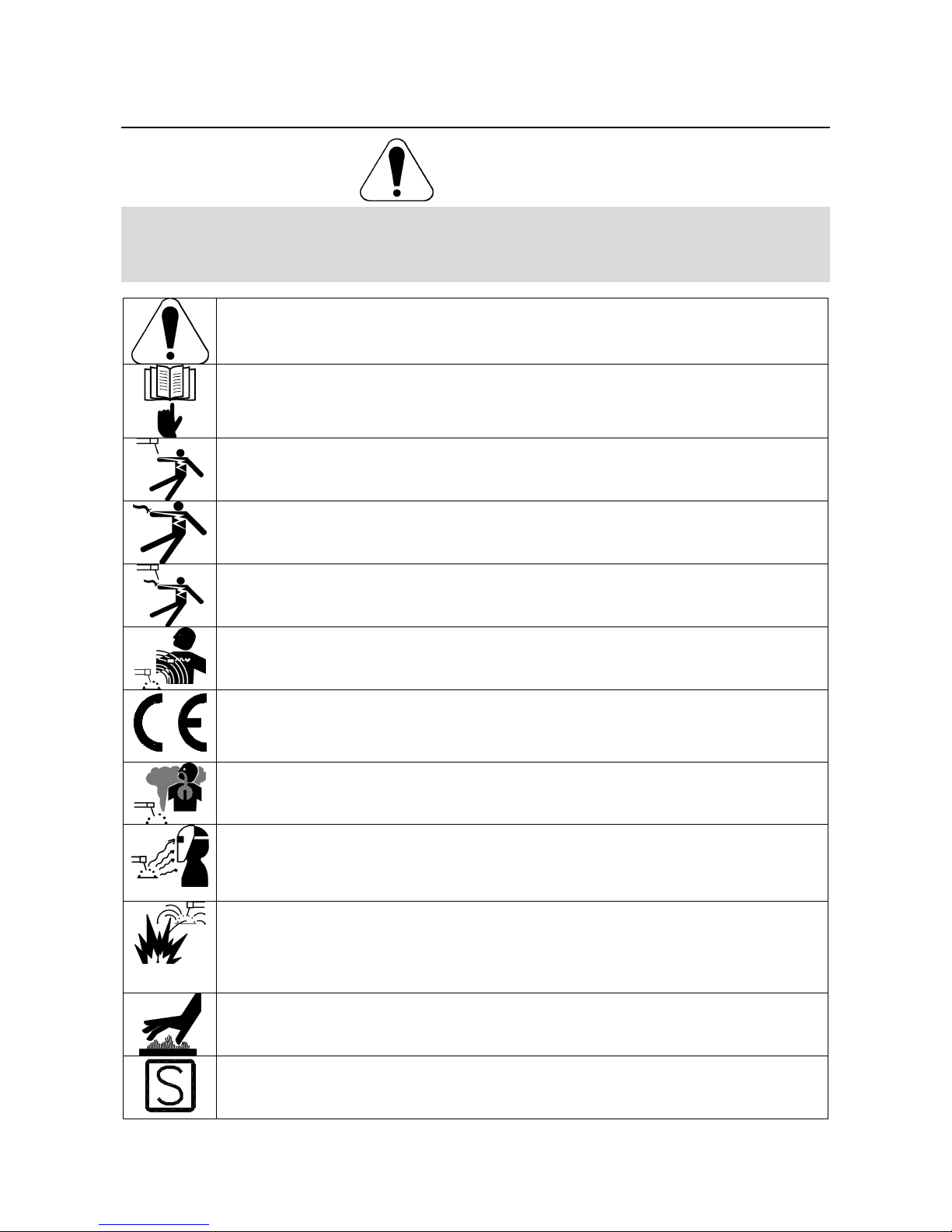

Safety

11/04

WARNING

This equipment must be used by qualified personnel. Be sure that all installation, operation, maintenance and repair

procedures are performed only by qualified person. Read and understand this manual before operating this equipment.

Failure to follow the instructions in this manual could cause serious personal injury, loss of life, or damage to this

equipment. Read and understand the following explanations of the warning symbols. Lincoln Electric is not responsible

for damages caused by improper installation, improper care or abnormal operation.

WARNING: This symbol indicates that instructions must be followed to avoid serious personal injury,

loss of life, or damage to this equipment. Protect yourself and others from possible serious injury or

death.

READ AND UNDERSTAND INSTRUCTIONS: Read and understand this manual before operating this

equipment. Arc welding can be hazardous. Failure to follow the instructions in this manual could cause

serious personal injury, loss of life, or damage to this equipment.

ELECTRIC SHOCK CAN KILL: Welding equipment generates high voltages. Do not touch the

electrode, work clamp, or connected work pieces when this equipment is on. Insulate yourself from the

electrode, work clamp, and connected work pieces.

ELECTRICALLY POWERED EQUIPMENT: Turn off input power using the disconnect switch at the

fuse box before working on this equipment. Ground this equipment in accordance with local electrical

regulations.

ELECTRICALLY POWERED EQUIPMENT: Regularly inspect the input, electrode, and work clamp

cables. If any insulation damage exists replace the cable immediately. Do not place the electrode

holder directly on the welding table or any other surface in contact with the work clamp to avoid the

risk of accidental arc ignition.

ELECTRIC AND MAGNETIC FIELDS MAY BE DANGEROUS: Electric current flowing through any

conductor creates electric and magnetic fields (EMF). EMF fields may interfere with some

pacemakers, and welders having a pacemaker shall consult their physician before operating this

equipment.

CE COMPLIANCE: This equipment complies with the European Community Directives.

FUMES AND GASES CAN BE DANGEROUS: Welding may produce fumes and gases hazardous to

health. Avoid breathing these fumes and gases. To avoid these dangers the operator must use

enough ventilation or exhaust to keep fumes and gases away from the breathing zone.

ARC RAYS CAN BURN: Use a shield with the proper filter and cover plates to protect your eyes from

sparks and the rays of the arc when welding or observing. Use suitable clothing made from durable

flame-resistant material to protect you skin and that of your helpers. Protect other nearby personnel

with suitable, non-flammable screening and warn them not to watch the arc nor expose themselves to

the arc.

WELDING SPARKS CAN CAUSE FIRE OR EXPLOSION: Remove fire hazards from the welding area

and have a fire extinguisher readily available. Welding sparks and hot materials from the welding

process can easily go through small cracks and openings to adjacent areas. Do not weld on any

tanks, drums, containers, or material until the proper steps have been taken to insure that no

flammable or toxic vapors will be present. Never operate this equipment when flammable gases,

vapors or liquid combustibles are present.

WELDED MATERIALS CAN BURN: Welding generates a large amount of heat. Hot surfaces and

materials in work area can cause serious burns. Use gloves and pliers when touching or moving

materials in the work area.

SAFETY MARK: This equipment is suitable for supplying power for welding operations carried out in

an environment with increased hazard of electric shock.

English English

3

Page 7

CYLINDER MAY EXPLODE IF DAMAGED: Use only compressed gas cylinders containing the correct

shielding gas for the process used and properly operating regulators designed for the gas and

pressure used. Always keep cylinders in an upright position securely chained to a fixed support. Do

not move or transport gas cylinders with the protection cap removed. Do not allow the electrode,

electrode holder, work clamp or any other electrically live part to touch a gas cylinder. Gas cylinders

must be located away from areas where they may be subjected to physical damage or the welding

process including sparks and heat sources.

NOISE APPEARES DURING WELDING CAN BE HARMFUL: Welding arc can cause noise with high

level of 85dB for 8-hour week day. Welders operating welding machines are obligated to wear the

proper ear protectors /appendix No. 2 for the Decree of the Secretary of Labor and Social Policy from

17.06 1998 – Dz.U. No. 79 pos. 513/. According to the Decree the Secretary of Health and Social

Welfare from 09.07.1996 /Dz.U. No. 68 pos. 194/, employers are obligated to carry examinations and

measurements of health harmful factors.

MOVING PARTS ARE DANGEROUS: There are moving mechanical parts in this machine, which can

cause serious injury. Keep your hands, body and clothing away from those parts during machine

starting, operating and servicing.

Installation and Operator Instructions

Read this entire section before installation or operation

of the machine.

WARNING

ELECTRIC SHOCK CAN KILL.

• Turn the input power OFF at the disconnect switch or

fuse box before attempting to connect or disconnect

input power lines, output cables or control cables.

• Only qualified personnel should perform this

installation.

• Do not touch metal portions of the LN-25™ PRO

work clip when the welding power source is on.

• Do not attach the work clip to the wire feeder.

• Connect the work clip directly to the work, as close

as possible to the welding arc.

• Turn power off at the welding power source before

disconnecting the work clip from the work.

• Only use on power sources with open circuit voltages

less than 110 VDC.

Location

For best wire feeding performance, place the LN- 25™

Pro on a stable and dry surface. Keep the wire feeder in

a vertical position. Do not operate the wire feeder on an

angled surface of more than 15 degrees.

Do not submerge the LN-25™ Pro.

The LN-25™ Pro is rated IP23 and is suitable for

outdoor use.

The handle of the LN-25™ Pro is intended for moving

the wire feeder about the work place only.

When suspending a wire feeder, insulate the hanging

device from the wire feeder enclosure.

High Frequency Protection

Locate the LN-25™ PRO away from radio controlled

machinery. The normal operation of the LN-25™ PRO

may adversely affect the operation of RF controlled

equipment, which may result in bodily injury or damage

to the equipment.

Weld cable size

Table 1 located below are copper cable sizes

recommended for different currents and duty cycles.

Lengths stipulated are the distance from the welder to

work and back to the welder again. Cable sizes are

increased for greater lengths primarily for the purpose of

minimizing cable drop.

Electrode lead

The electrode lead is a 4/0 cable.

WARNING

English English

4

Page 8

RECOMMENDED CABLE SIZES (RUBBER COVERED COPPER - RATED 167°F OR 75°C)**

CABLE SIZES FOR COMBINED LENGTHS OF ELECTRODE AND WORK

CABLES

0 to 50 Ft.

(0 to15m)

2

2

4 or 5

3

3

50 to 100 Ft.

(15 to 30m)

2

2

3

3

3

100 to 150 Ft.

(30 to 46m)

2

2

2

2

2

150 to 200 Ft.

(46 to 61m)

1

1

1

1

1

AMPERES

200

200

225

225

250

PERCENT

DUTY

CYCLE

60

100

20

40 & 30

30

200 to 250 Ft.

(61 to 76m)

1/0

1/0

1/0

1/0

1/0

250

250

250

300

325

350

400

400

500

** Tabled values are for operation at ambient temperatures of 104°F(40°C) and below. Applications above 104°F(40°C) may require

cables larger than recommended, or cables rated higher than 167°F(75°C).

40

60

100

60

100

60

60

100

60

2

1

1

1

2/0

1/0

2/0

3/0

2/0

2

1

1

1

2/0

1/0

2/0

3/0

2/0

1

1

1

1

2/0

2/0

2/0

3/0

3/0

1

1

1

1/0

2/0

2/0

3/0

3/0

3/0

1/0

1/0

1/0

2/0

3/0

3/0

4/0

4/0

4/0

Table 1

Shielding gas connection

WARNING

CYLINDER MAY EXPLODE IF DAMAGED.

• Keep cylinder upright and chained to support.

• Keep cylinder away from areas where it may be

damaged.

• Never lift welder with cylinder attached.

• Never allow welding electrode to touch cylinder.

• Keep cylinder away from welding or other live

electrical circuits.

• BUILD UP OF SHIELDING GAS MAY HARM

HEALTH OR KILL.

• Shut off shielding gas supply when not in use.

• See American National Standard z-49.1, "Safety in

Welding and Cutting” Published by the American

Welding Society.

Maximum inlet pressure is 100 psi. (6.9 bar.)

Install the shielding gas supply as follows:

1. Secure the cylinder to prevent it from falling.

2. Remove the cylinder cap. Inspect the cylinder valves

and regulator for damaged threads, dirt, dust, oil or

grease. Remove dust and dirt with a clean cloth. DO

NOT ATTACH THE REGULATOR IF OIL, GREASE

OR DAMAGE IS PRESENT! Inform your gas

supplier of this condition. Oil or grease in the

presence of high pressure oxygen is explosive.

3. Stand to one side away from the outlet and open the

cylinder valve for an instant. This blows away any

dust or dirt which may have accumulated in the valve

outlet.

4. Attach the flow regulator to the cylinder valve and

tighten the union nut(s) securely with a wrench. Note:

if connecting to 100% CO2 cylinder, insert regulator

adapter between regulator and cylinder valve. If

adapter is equipped with a plastic washer, be sure it

is seated for connection to the CO2 cylinder.

5. Attach one end of the inlet hose to the outlet fitting of

the flow regulator. Attach the other end to the

welding system shielding gas inlet. Tighten the union

nuts with a wrench.

6. Before opening the cylinder valve, turn the regulator

adjusting knob counterclockwise until the adjusting

spring pressure is released.

7. Standing to one side, open the cylinder valve slowly

a fraction of a turn. When the cylinder pressure gage

stops moving, open the valve fully.

8. The flow regulator is adjustable. Adjust it to the flow

rate recommended for the procedure and process

being used before making a weld.

Wire drive configuration

(See Figure 1)

Gun bushing, thumb screw and socket head

cap screw

WARNING

ELECTRIC SHOCK CAN KILL.

• Turn the input power OFF at the welding power

source before installation or changing drive rolls

and/or guides.

• Do not touch electrically live parts.

• When inching with the gun trigger, electrode and

drive mechanism are "hot" to work and ground and

could remain energized several seconds after the

gun trigger is released.

• Do not operate with covers, panels or guards

removed or open.

• Only qualified personnel should perform

maintenance work.

English English

5

Page 9

A

A

Tools required:

• 1/4" hex key wrench.

Note: Some gun bushings do not require the use of

the thumb screw.

1. Turn power off at the welding power source.

2. Remove the welding wire from the wire drive.

3. Remove the thumb screw from the wire drive.

4. Remove the welding gun from the wire drive.

5. Loosen the socket head cap screw that holds the

connector bar against the gun bushing. Important:

Do not attempt to completely remove the socket

head cap screw.

6. Remove the outer wire guide, and push the gun

bushing out of the wire drive. Because of the

precision fit, light tapping may be required to remove

the gun bushing.

7. Disconnect the shielding gas hose from the gun

bushing, if required.

8. Connect the shielding gas hose to the new gun

bushing, if required.

9. Rotate the gun bushing until the thumb screw hole

aligns with the thumb screw hole in the feed plate.

Slide the gun receiver bushing into the wire drive and

verify the thumb screw holes are aligned.

10. Tighten the socket head cap screw 10 to 14 ft-lbs

(13.5 to 19.0 Nm).

11. Insert the welding gun into the gun bushing and

tighten the thumb screw.

Procedure to install drive rolls and wire

guides

WARNING

• Turn the input power OFF at the welding power

source before installation or changing drive rolls

and/or guides.

• Do not touch electrically live parts.

• When inching with the gun trigger, electrode and

drive mechanism are "hot" to work and ground and

could remain energized several seconds after the

gun trigger is released.

• Do not operate with covers, panels or guards

removed or open.

• Only qualified personnel should perform

maintenance work.

1. Turn power off at the welding power source.

2. Release the idle roll pressure arm.

3. Remove the outer wire guide by turning the knurled

thumbscrews counter-clockwise to unscrew them

from the feed plate.

4. Rotate the triangular lock and remove the drive rolls.

B

C

D

A. THUMB SCREW

B. GUN RECEIVER BUSHING

C. CONNECTOR BLOCK

D. SOCKET HEAD CAP SCREW

E. OUTER WIRE GUIDE

F. LOOSEN

G. TIGHTEN

Figure 1

A. UNLOCKED POSITION

B. LOCKED POSITION

5. Remove the inner wire guide.

E

F

G

6. Insert the new inner wire guide, groove side out, over

the two locating pins in the feed plate.

7. Install a drive roll on each hub assembly secure with

the triangular lock.

8. Install the outer wire guide by aligning it with the pins

and tightening the knurled thumbscrews.

9. Close the idle arm and engage the idle roll pressure

arm. Adjust the pressure appropriately.

LOADING SPOOLS OF WIRE

• Keep hands, hair, clothing and tools away from

rotating equipment.

• Do not wear gloves when threading wire or changing

wire spool.

• Only qualified personnel should install, use or service

this equipment.

Loading 10 to 15 lb. (4.5 – 6.8kg) Spools.

A K468 spindle adapter is required for loading 2"

(51mm) wide spools on 2" (51mm) spindles. Use a K468

spindle adapter for loading 2-1/2" (64mm) wide spools.

1. Squeeze the release bar on the retaining collar and

remove it from the spindle.

2. Place the spindle adapter on the spindle, aligning the

spindle brake pin with the hole in the adapter.

WARNING

B

English English

6

Page 10

A

A

3. Place the spool on the spindle and align the adapter

brake tab with one of the holes in the back side of

the spool. An indicator mark on the end of the

spindle shows the orientation of the brake tab. Be

certain the wire feeds off of the spool in the proper

direction.

4. Re-install the retaining collar. Make sure that the

release bar snaps out and that the retaining collar

fully engages the groove on the spindle.

Pressure arm and adjustment

WARNING

ELECTRIC SHOCK CAN KILL.

• Turn the input power OFF at the welding power

source before installation or changing drive rolls

and/or guides.

• Do not touch electrically live parts.

• When inching with the gun trigger, electrode and

drive mechanism are "hot" to work and ground and

could remain energized several seconds after the

gun trigger is released.

• Do not operate with covers, panels or guards

removed or open.

• Only qualified personnel should perform

maintenance work.

The pressure arm controls the amount of force the drive

rolls exert on the wire. Proper adjustment of the pressure

arm gives the best welding performance. Many welding

problems can be attributed to setting the pressure arm

too high and causing wire deformation. Set the pressure

arm to minimum amount that provides reliable feeding.

Set the pressure arm as follows: (See Figure 2)

Aluminum wires between 1 and 2

Cored wires between 1 and 3

Steel, Stainless wires between 3 and 5

Gun connection

WARNING

ELECTRIC SHOCK CAN KILL.

• Turn the input power OFF at the welding power

source before installation or changing drive rolls

and/or guides.

• Do not touch electrically live parts.

• When inching with the gun trigger, electrode and

drive mechanism are "hot" to work and ground and

could remain energized several seconds after the

gun trigger is released.

• Do not operate with covers, panels or guards

removed or open.

• Only qualified personnel should perform

maintenance work.

The LN-25™ PRO comes with a K1500-2 gun adapter

installed. (See Figure 3)

To install a gun,

1. Turn power OFF.

2. Remove the thumb screw.

3. Push the gun the completely into the gun bushing.

4. Secure the gun in place with the thumb screw.

5. Connect the trigger cable from the gun to the trigger

connector on the front of the feeder.

Note: Not all gun bushings require the use of the thumb

screw.

B

A. THUMB SCREW

B. GUN

B

C

A. AL - ALUMINUM WIRES

B. FCAW - CORED WIRES

C. GMAW - STEEL, STAINLESS WIRES

English English

Figure 2

7

Figure 3

Page 11

k

k

Power source to LN-25™ PRO cable

connection diagrams

Across the arc set-ups

CC power sources with output terminals

always hot (see figure 4)

CC Power Source

Classics

Big Red’s

Eagle 10,000 Plus

Pipeliner 200D Without Wire Feed module

SAE’s Without CV Adapter

SAE 400 with CV adapter

Engine Driven welder with

Wire Feed Module

If the power source has a Remote/Local switch, place

the switch in the Local position.

Place the CV/CC switch in the feeder in the "CC"

position.

CV power sources with stud connectors and

remote/local switch (see figure 5)

Electrode

Figure 4

LN-25™ PRO

(Across the Arc)

Wor

Work clip

K# Description

K2613-5 LN-25™ PRO Wire Feeder

K2613-7 LN-25™ PRO Extra Torque

KP1695-xx

KP1696-xx

Drive Roll Kit

KP1697-xx

See Magnum Literature Welding Gun

CC power source

K1803-xx Welding Cables

CV-400

CV-655

DC-400

DC-600

DC-655

V450-Pro

SAE 400 with CV adapter

Engine Driven welder with

Wire Feed Module Ranger

250 GXT

Electrode

Wor

Place the power source Remote/Local switch in the

Local position.

Place CV/CC switch in the feeder in the "CV" position.

Figure 5

LN-25™ PRO

(Across the Arc)

Work clip

K# Description

K2613-5 LN-25™ PRO

K2613-7 LN-25™ PRO Extra Torque

KP1695-XX

KP1696-XX

Drive Roll Kit

KP1697-XX

See magnum Literature Welding Gun

CV power Source

K1803-XX Welding Cables

K484 Jumper Plug Kit

English English

8

Page 12

A

k

k

CV power sources with stud connectors and no

remote/local switch. (see figure 6)

Ranger 250, 250 LPG

Ranger 305G, 305D

Ranger 10,000

Ranger 3 Phase

Ranger 225, 225GXT

Commander 300

Vantage 300, 400, 500

ir Vantage 500

Electrode

Wor

Place CV/CC switch in the feeder in the "CV" position.

CV power source with twist-mate connectors

and remote/local switch. (see figure 7)

Figure 6

LN-25™ PRO

(Across the Arc)

Work clip

K# Description

K2613-5 LN-25™ PRO

K2613-7 LN-25™ PRO Extra Torque

KP1695-XX

KP1696-XX

KP1697-XX

See Magnum Literature Welding Gun

CC power Source

K1803-XX Welding Cables

Drive Roll Kit

V350-Pro

CV 305

Electrode

Wor

Place the power source Remote/Local switch in the

Local position.

Place CV/CC switch in the feeder in the “CV” position.

CV Power Source with Twist-Mate Connectors and no

Remote/Local Switch. (See Figure 8)

Figure 7

LN-25™ PRO

(Across the Arc)

Work clip

K# Description

K2613-5 LN-25™ PRO

K2613-7 LN-25™ PRO Extra Torque

KP1695-XX

KP1696-XX

Drive Roll Kit

KP1697-XX

See Magnum Literature Welding Gun

CV power Source

K1841-XX Welding Cables

K852-95 Twist-Mate Cable Plug

English English

9

Page 13

k

CV power source with twist-mate connectors

and no remote/local switch. (see figure 8)

Jumper

CV-250

CV-300

Place CV/CC switch in the feeder in the "CV" position.

Electrode

Wor

Figure 8

LN-25™ PRO

(Across the Arc)

Work clip

K# Description

K2613-5 LN-25™ PRO

K2613-7 LN-25™ PRO Extra Torque

KP1695-XX

KP1696-XX

Drive Roll Kit

KP1697-XX

See Magnum Literature Welding Gun

CV power Source

K1841-XX Welding Cables

K852-95 Twist-Mate Cable Plug

K484 Jumper Plug kit

English English

10

Page 14

Graphic symbols that appear on this

machine or in this manual

INPUT POWER

ON

OFF

WIRE FEEDER

POSITIVE OUTPUT

NEGATIVE OUTPUT

INPUT POWER

DIRECT CURRENT

OPEN CIRCUIT VOLTAGE

INPUT VOLTAGE

OUTPUT VOLTAGE

INPUT CURRENT

OUTPUT CURRENT

PROTECTIVE GROUND

Definition of welding terms

WFS

• Wire Feed Speed

CC

• Constant Current

CV

• Constant Voltage

GMAW

• Gas Metal Arc welding

SMAW

• Shielded Metal Arc welding

FCAW

• Flux Core Arc Welding

General description

General physical description

The LN-25™ PRO is specially engineered to be the most

rugged portable wire feeder available.

Several models of the LN-25™ PRO are offered to best

meet individual welder needs. The Extra Torque model

features additional torque gearing for reliable feeding of

large diameter FCAW wires. The Standard and Dual

Power models feature wire drive gearing for great

performance for both FCAW and GMAW wires of

common sizes. All of the models include a gas solenoid

for the flexibility to run most wire processes.

The plastic case is molded from a high impact, flame

retardant plastic for durability and low weight.

The heart of the LN-25™ PRO is the 2 roll MAX-TRAC™

drive. The patented features on the wire drive offer toolless changing of the drive rolls and wire guides for quick

spool changes. A tachometer controlled motor powers

the patented drive rolls for smooth, steady feeding

without slippage.

With a 450 amp, 60% duty cycle rating, these feeders

are ready for heavy duty welding.

General functional description

All LN-25™ PRO’s have adjustable WFS range for

improving the knob sensitivity. The low range is great for

critical welds with Innershield wires, and the upper range

is suitable for general purpose welding. Selection of the

WFS range is by a rocker switch or through the set-up

menu on meters with digital displays.

Recommended processes

• GMAW

• FCAW

WARNING OR CAUTION

English English

11

Page 15

A

Process limitations

• GMAW-P procedures must be qualified by the customer.

• Across-the-Arc models are not recommended for

stitch or spot welding.

(See Customer Assistance Policy in the front of this

Instruction Manual)

Case front controls

(See Figure 9)

Equipment limitations

• The duty cycle of the wire feeder is 450A, 60%. Duty

cycle is based upon the amount of welding

performed in a 10 minute period.

• The maximum spool size is 45 lb. (24 Kg), 12”

(305mm) diameter.

• Maximum FCAW gun length is 15 ft.

• Maximum GMAW gun length is 25 ft.

• K2330-1 Timer Kits do not work with the feeder. Use

K2330-2 kits.

• Push-pull guns do not work with the LN-25™ PRO.

• Not compatible with K489-7 Euro connector (except

K2614-7,-8)

B

C

Recommended power sources

• CV-305 • Ranger 3 Phase

• CV-400 • Ranger 225

• CV-655 • Ranger 225 GXT

• DC-400 • Ranger 250

• DC-600 • Ranger 305

• DC-655 • SAE-400

• Invertec V-350 • Pipeliner 200G

• FlexTec 450 • Classic 300

• Multi-Weld 350 • Vantage 300

• Ranger 10,000 • Vantage 400

• Vantage 500

D

E

A. ANALOG VOLTMETER

B. WIRE FEED SPEED KNOB

C. WIRE FEED SPEED RANGE SWITCH

D. 5-PIN GUN TRIGGER CONNECTOR

E. WORK SENSE LEAD

F. THERMAL LED, MOTOR OVERLOAD

G. POLARITY LED

Analog voltmeter

Reads 0 – 40 VDC and is polarity insensitive. Shows

OCV when not welding and arc voltage when

welding.

The serviceability of a product or structure utilizing the

LN-25™ PRO wire feeder is and must be the sole

responsibility of the builder/user. Many variables beyond

the control of The Lincoln Electric Company affect the

results obtained in using the LN-25™ PRO wire feeder.

These variables include, but are not limited to, welding

procedure, plate chemistry and temperature, weldment

design, fabrication methods and service requirements.

The available range of the LN-25™ PRO wire feeder

may not be suitable for all applications, and the

builder/user is and must be solely responsible for

welding settings.

F

G

Figure 9

English English

12

Page 16

CV OPERATION

Minimum Arc

Volts

Maximum WFS

(Standard

Torque)

Maximum WFS

(Extra Torque )

15 V 400 220

17 V 450 250

21 V 570 300

24 V 650 350

27 V 700 400

Wire Feed Speed, CC Operation

When Across the Arc models are operated with CC

power sources, the wire feed speed changes as the arc

voltage changes. When the arc voltage increases, the

wire feed speed will increase; and when the arc voltage

decreases, the wire feed speed will decrease.

To preset the wire feed speed on CC power sources:

1. Set the Wire Feed Mode switch inside the LN-25™

Pro to "CC".

2. Refer to the Figure 10 graph for the setting for the

wire feed speed knob setting. Select the horizontal

line representing the Desired Wire Feed Speed. (See

Figure 10 arrow for 375 in/min.)

3. Select the diagonal line representing the Arc Volts.

(See Figure 10 for 29 volts.)

4. Determine the vertical line representing the CC

representing the CC Wire Feed Speed setting where

the above two lines cross. (See Figure 10 arrow line

for 450.) Set the LN-25™ Pro wire feed speed knob

to this value.

CC WFS dial setting = desiredWFSx35

Arc Volts

Example:

= 375in/min.(HorizontalLine)x35

29 Arc Volts (Diagonal Line)

= 452.5 (Vertical Line) Use 450 setting

(See Figure 10)

A constant voltage (CV) power

source is recommended for

fluxcored arc welding. (FCAW) and

gas metal arc welding (GMAW) to

obtain code qual i ty resul ts.

However, this wire feeder may also

be used with a constant current (CC)

power source to obtain passable

results for noncritical quality

applications.

Figure 10

English English

13

Page 17

Constant current wire welding

(See Figure 11)

Most semiautomatic welding processes perform better

using constant voltage power sources.

Welding codes usually do not address the power source

selection or specifically, whether the welding process is

to be operated in the constant voltage or constant

current mode. Instead, codes typically specify limitations

on the current, voltage, heat input and preheat

temperature based on the material to be welded. The

intention is to assure that proper weld material properties

will develop.

Welding is sometimes performed using constant current

power sources. The operation can be more convenient

because it may allow the use of an existing stick

(SMAW) power source and the power source can be

placed at a distant location without any provision for

adjusting the output settings.

For constant current operation, the power source is set

to deliver the specified current. The power source

regulates this current regardless of changes in the

welding circuit, including cable length, electrode

diameter, wire feed speed, contact tip to work distance,

etc.

Changes in the wire feed speed (WFS) or contact tip to

work distance (CTWD) affect the arc voltage when

constant current power sources are used. Lowering the

wire feed speed raises the voltage, raising the wire feed

speed lowers the voltage. Lengthening the contact tip to

work distance raises the voltage, shortening the contact

tip to work distance lowers the voltage.

Current

Constant Current

Power Source

If the contact tip to work distance is properly maintained,

a satisfactory operating voltage range may be achieved,

and a sound weld may result. However, when a welder

uses a longer contact tip to work distance, an arcsensing wire feeder compensates by increasing the wire

feed speed to regulate the voltage. Even if the voltage

and current remain unchanged, the increased wire feed

speed may result in a deposition rate well beyond the

specified range of the electrode. Under these conditions,

the specified weld metal properties may not be achieved.

Constant voltage power sources deliver large current

surges to stabilize the arc when the electrode is shorted

or the arc length is very short. However, a constant

current power source does not provide such a response

to stabilize the arc. It may be difficult to achieve required

weld metal properties, or to achieve the required quality

of welds needed to pass nondestructive tests, when

such welds are made under constant current operation.

For these reasons, Lincoln Electric does NOT

recommend constant current semiautomatic welding for

applications which need to meet specified weld metal

chemical or mechanical property requirements or weld

quality requirements.

Wire

Feeder

CTWD

WFS

2. Wire feed speed knob

Use the Wire Feed Speed Knob to adjust the rate of wire

feed speed.

WFS range for standard torque:

High = 50 to 700 ipm

Low = 50 to 200 ipm

WFS range for extra torque:

High = 50 to 400 ipm

Low = 50 to 200 ipm

English English

Current

Figure 11

Because the wire feeder is powered by the arc voltage,

the full range of wire feed speed may not be available at

low voltages.

3. Wire feed speed range switch

Use to select either the low range or high range for the

wire feed speed knob. Note – selecting the low range

does not increase the torque of the wire drive.

14

Page 18

4. 5-Pin gun trigger connector

There is one circular connector for the gun trigger on the

front of the LN-25™ PRO. Note – if the gun trigger is

already depressed when the feeder is powered up, the

feeder will not activate. Release and then press the gun

trigger to begin welding.

Function Pin Wiring

5-pin trigger

connector for

push-guns

only.

5. Work sense lead

Always turn power off at the welding power source

before moving the work sense lead.

The work sense lead attaches to the item being welded.

6. Thermal led, motor overload

The thermal light illuminates when the wire

drive motor draws too much current. If the

thermal light illuminates, the wire drive will

automatically shutdown for up to 30

seconds to allow the motor to cool. To start

welding again, release the gun trigger,

inspect the gun cable, liner (and conduit). Clean and

make repairs as necessary. Start welding again when

the problem has been safely resolved.

For best results, keep the gun cable and conduit as

straight as possible. Perform regular maintenance and

cleaning on the gun liner, conduit and gun. Always use

quality electrode, such as L-50 or L-56 from Lincoln

Electric.

7. Polarity LED

The Polari ty LED lights when the wire feeder is

connected for positive polarity. Use the polari ty LED to

verify if the wire feeder is connected for the proper

polarity.

+ POLARITY

POLARDAD

- POLARITÉ

A 5 volt supply

B Not used

C Trigger

D Not used

E Not used

Internal controls

D

C

B

A

G

I

H

A. 2 STEP TRIGGER INTERLOCK SWITCH

B. CV / CC SWITCH

C. PRESSURE ADJUSTMENT ARM

D. OPTIONAL TIMER KIT

E. SPOOL RETAINER

F. SPINDLE BRAKE

G. GUN BUSHING, THUMB SCREW AND SOCKET

HEAD CAP SCREW

H. DRIVE HUBS

I. COLD FEED PUSHBUTTON

Figure 12

Internal controls description

(See Figure 12)

1. 2 Step - Trigger interlock switch

The 2 Step - Trigger Interlock switch

changes the function of the gun trigger.

2 Step trigger operation turns welding

on and off in direct response to the

trigger. Trigger Interlock operation

allows welding to continue when the

trigger is released for comfort on long

welds.

Place the toggle switch in the DOWN

position for 2 Step operation or in the

UP position for Trigger Interlock operation.

2 Step Trigger

2 Step trigger operation is the most common. When the

gun trigger is pulled, the welding power source

energizes the electrode output and the wire feeder feeds

wire for welding. The power source and wire feeder

continue welding until the trigger is released.

Trigger Interlock

Trigger Interlock operation provides for operator comfort

when making long welds. When the gun trigger is first

pulled, the welding power source energizes the output

and the wire feeder feeds wire for welding. The gun

trigger is then released while the weld is made. To stop

welding, the gun trigger is pulled again, and when it is

released the welding power source output turns off and

the wire feeder stops feeding wire.

E

F

English English

15

Page 19

A

If the arc goes out while welding with trigger interlock

WARNING

operation, the electrode output from the welding power

source remains energized and the wire feeder will

continue to feed wire until the gun trigger is again pulled

and then released.

2. CV/CC switch

The CV/CC switch sets the wire feed

speed control method for the wire

feeder.

In the CV position, the wire feed speed

remains constant during welding. A

steady arc voltage is regulated by the

power source by adjusting the arc

current.

In the CC position, the wire feed speed varies during

welding. The arc length is maintained by changing the

wire feed speed.

3. Pressure arm and adjustment

(See installation section)

4. Optional timer kit

The optional Timer Kit provides control of preflow time,

burnback, and postflow time.

5. Spool retainer

To release the spool retainer, squeeze the metal bar

inwards. When securing the spool, verify the spool

retainer is fully seated in place in one of the three

grooves of the spindle.

6. Spool brake

Adjust the spool brake to provide enough friction to stop

wire overrun. Excessive brake force may cause motor

thermal overloads or welding problems.

7. Gun bushing, thumb screw and socket head cap

screw

(SEE INSTALLATION SECTION)

8. Drive rolls and wire guides

(See installation section)

9. Cold feed pushbutton

When cold feeding, the wire drive will feed electrode but

neither the power source nor the gas solenoid will be

energized. Adjust the speed of cold feeding by rotating

the WFS knob. Cold feeding, or "cold inching" the

electrode is useful for threading the electrode through

the gun.

Rear controls:

(See Figure 13)

1. Gas purge pushbutton

The gas solenoid valve will energize but neither the

power source output nor the drive motor will be turned

on. The Gas Purge switch is useful for setting the proper

flow rate of shielding gas. Flow meters should always be

adjusted while the shielding gas is flowing.

B

C

A. GAS PURGE PUSHBUTTON

B. SHIELDING GAS INLET

C. ELECTRODE LEAD

Figure 13

English English

16

Page 20

A

A

Maintenance

Safety precautions

WARNING

ELECTRIC SHOCK CAN KILL.

• Turn the input power OFF at the welding power

source before installation or changing drive rolls

and/or guides.

• Do not touch electrically live parts.

• When inching with the gun trigger, electrode and

drive mechanism are "hot" to work and ground and

could remain energized several seconds after the

gun trigger is released.

• Do not operate with covers, panels or guards

removed or open.

• Only qualified personnel should perform mainte

nance work.

Routine maintenance

• Check weld cables, control cables and gas hoses for

cuts.

• Clean and tighten all weld terminals.

Periodic maintenance

• Clean drive rolls and inner wire guide and replace if

worn.

• Blow out or vacuum the inside of the feeder.

• Inspect the motor brushes every 6 months. Replace

if shorter than 0.5” (12.7mm).

Calibration specification

Voltmeter validation

(See Figure 14)

To verify the analog voltmeter accuracy:

1. Turn power OFF.

2. Connect the LN-25™ PRO to the constant voltage

DC power supply capable of supply at least 4 amps.

Connect the electrode to the “+” positive terminal and

the work clip to the “-“ negative terminal.

3. Connect a reference voltmeter between the brass

block of the LN-25™ PRO and the work lead.

4. Turn power ON.

5. Energize the power supply. Adjust the power source

output to 20.0 VDC as measured on the reference

meter.

6. Verify that LN-25™ PRO voltmeter reads 20 volts.

Adjust the voltmeter as necessary by turning the

screw on the voltmeter.

Wire feed speed validation

Calibration of the LN-25™ PRO may be required when

the P.C. board, wire feed speed potentiometer or motor

is replaced or serviced. Calibration matches the scale on

the name plate to the actual wire feed speed.

To calibrate the LN-25™ PRO:

1. Turn power OFF at the welding source.

2. Remove the spool of wire and the cover from the

feeder. Remove the gun from the feeder plate,

leaving the gun trigger attached to the feeder.

Remove the plastic cover on the feed plate to reveal

the motor gear.

3. Place the WFS range switch in the “high” setting. Set

the WFS knob to

• 50 ipm for K2613-5

• 25 ipm for K2613-7

4. Trigger the LN-25™ PRO and measure the rpm of

the motor gear. Adjust the WFS knob as required

until the rpm measures 8.9 to 9.2 rpm.

5. Insert the shorting plug into the control board for 1

second and then remove the shorting plug. The

shorting plug shorts pins 4 and 7 of J3.

6. Set the WFS knob to

• 800 ipm for K2613-5

• 400 ipm for K2613-7

7. Trigger the LN-25™ PRO and measure the rpm of

the motor gear. Adjust the WFS knob as required

until the rpm measure 128.0 to 130.0 rpm.

8. Insert the shorting plug into the control board for 1

second and then remove the shorting plug. The

shorting plug shorts pins 4 and 7 of J3.

9. Turn power OFF and reassemble.

B

A. COVER

B. PC BOARD

Figure 15

A. CALIBRATION SCREW

English English

Figure 14

17

Page 21

WEEE

Do not dispose of electrical equipment together with normal waste!

In observance of European Directive 2012/19/EC on Waste Electrical and Electronic Equipment (WEEE)

and its implementation in accordance with national law, electrical equipment that has reached the end of its

life must be collected separately and returned to an environmentally compatible recycling facility. As the

English

owner of the equipment, you should get information on approved collection systems from our local

representative.

By applying this European Directive you will protect the environment and human health!

Spare Parts

For Spare Parts references visit the Web page: https://www.lincolnelectric.com/LEExtranet/EPC/

Authorized Service Shops Location

The purchaser must contact a Lincoln Authorized Service Facility (LASF) about any defect claimed under Lincoln's

warranty period.

Contact your local Lincoln Sales Representative for assistance in locating a LASF or go to

www.lincolnelectric.com/en-gb/Support/Locator.

07/06

12/05

09/16

English English

18

Page 22

Electrical Schematic

NOTE: this diagram is for reference only. It may not be accurate for all machines covered by this manual. The specific

diagram for a partiuclar code is pasted inside the machine on one of the enclosure panels. If the diagram is ellegible,

write to the Service Department for a raplacement. Give the equipment code number.

English English

19

Page 23

A

Suggested Accessories

Factory installed equipment

• K1500-2 Gun Receiver Bushing.

WIRE TYPE ELECTRODE SIZE KP KIT

Steel Wires: .023-.030 (0.6-0.8mm)

.035 (0.9mm)

.045 (1.2mm)

.052 (1.4mm)

1/16 (1.6mm)

.035,.045 (0.9, 1.2mm)

.040 (1.0mm)

KP1696-030S

KP1696-035S

KP1696-045S

KP1696-052S

KP1696-1/16S

KP1696-1

KP1696-2

Includes: 2 V groove

drive rolls and inner wire

guide.

Cored Wires: .030-.035" (0.8-0.9mm)

(Extra Torque Models

only)

luminum Wires: .035" (0.9 mm)

K2330-2 Timer Kit Includes: Panel and harness for adjusting

K2596-2 Plastic Case Includes: a complete engineered plastic

K1796-xx AWG 1/0 Co-Axial Power

K2593-xx AWG #1 Coaxial Power

.040-.045" (1.0-1.2mm)

.052" (1.4mm)

1/16" (1.6mm)

.068-.072" (1.7-1.8mm)

5/64" (2.0mm)

3/32” (2.4mm)

.040" (1.0mm)

3/64" (1.2mm)

1/16" (1.6mm)

Cable

Cable

KP1697-035C

KP1697-045C

KP1697-052C

KP1697-1/16C

KP1697-068

KP1697-5/64

KP1697-3/32

KP1695-035A

KP1695-040A

KP1695-3/64A

KP1695-1/16A

preflow, burnback and postflow times.

Includes: 1/0 Coaxial weld cable of length

"xx". Ends of the weld cable have lug con-

nections. Use for Pulse welding.

Includes: AWG #1 Coaxial weld cable of

length "xx". Ends of the weld cable have

lug connections. Use for Pulse or STT™

Includes: 2 Knurled drive

rolls and inner wire

Includes: 2 polished U

groove drive rolls, outer

wire guide and inner

wire guide.

case.

welding.

guide.

K1803-1 Work and Feeder Cables

K1840-xx Weld Power Cable, Twist-

K1842-xx Weld Power Cable, Lug to

K484 Jumper Plug Kit Includes: 14 pin circular connector with

English English

Package

Mate to Lug

Lug

Includes: Twist-Mate to Lug 2/0 cable 14'

(1.2m) long with Ground Clamp, and

Twist- Mate to Lug 2/0 Cable 9' (2.7m)

long.

Includes: Twist-Mate to Lug, 1/0 cable of

length "xx".

Includes: Lug to Lug, 3/0 Cable of length

"xx" for lengths up to 60' (18.3m). Lug to

Lug, 4/0 Cable of length "xx" for lengths

greater than 60' (18.3m).

jumper for leads 2-4. For use in power

sources for turning the weld terminals "ON"

at all times.

20

Page 24

K910-1 Ground Clamp Includes: One 300 Amp

Ground Clamp.

K910-2 Ground Clamp Includes: One 500 Amp

Ground Clamp.

K1500-1 Gun Receiver Bushing (for

guns with K466-1 Lincoln

Includes: Gun receiver bushing, set screw

and hex key wrench.

gun connectors; Innershield

and Subarc guns)

K1500-2 Gun Receiver Bushing (for

guns with K466-2, K466-10

Includes: Gun receiver bushing with hose

nipple, set screw and hex key wrench.

Lincoln gun connectors;

Magnum 200/300/400 guns

and compatible with

Tweco® #2-#4)

K1500-3 Gun Receiver Bushing (for

guns with K613-7 Lincoln

Includes: Gun receiver bushing with hose

nipple, set screw and hex key wrench.

gun connectors; Magnum

550 guns and compatible

with Tweco® #5)

K1500-4 Gun Receiver Bushing (for

gun with K466-3 Lincoln

Includes: Gun receiver bushing with hose

nipple, set screw and hex key wrench.

gun connectors; compatible

with Miller® guns.)

K1500-5 Gun Receiver Bushing

(compatible with Oxo®

Includes: Gun receiver bushing with hose

nipple, 4 guide tubes, set screw and hex

guns.)

K435 Spindle Adapter, for

mounting 14 lb. (6.4 kg)

Includes: Spindle Adapter made from 2

coil retainers. (Electrode not included.)

Innershield Coils on 2 in

(51 mm) spindles.

K468 Spindle Adapter, for

mounting 8in (203mm)

Includes: 2 Spindle Adapters, one for 2"

wide spools and the other for 3" wide

diameter spools on 2 in (51

mm) spindles.

K590-6 Water Connection Kit (for

Includes: 2 hoses with female quick

European and Control

cable models only)

connectors for 3/16" ID hose, 2 male

connectors for _" ID hose, and mounting

K586-1 Deluxe Adjustable Gas

Regulator

Includes: Deluxe Gas Regulator for Mixed

Gases, Adapter for CO2 and 10' (3.0m)

key wrench.

spools.

connectors at each end, 2 male

hardware.

Hose.

K283 Wire Feed Speed Meter Includes: A wire feed speed meter with

English English

digital display.

21

Loading...

Loading...