Lincoln Electric K2613-5, K2613-7, LN-25 PRO Operator's Manual

LN-25™ PRO

OPERATOR’S MANUAL

IM2071

10/2017

REV01

ENGLISH

22801 St. Clair Ave., Cleveland Ohio 44117-1199 USA

THE LINCOLN ELECTRIC COMPANY

www.lincolnelectric.eu

THE LINCOLN ELECTRIC COMPANY

EC DECLARATION OF CONFORMITY

Manufacturer and technical documentation

holder:

Address:

EC Company:

Address:

Hereby declare that welding equipment:

Product Numbers:

Is in conformity with Council Directives and

amendments:

Low Voltage Directive 2014/35/EU

Standards: EN 60974-5: 2013, Arc Welding Equipment – Part 5: Wire Feeders,

CE marking affixed in 08

Samir Farah, Manufacturer Dario Gatti, European Community Representative

Compliance Engineering Manager European Engineering Director Machines

17 May 2016 19 May 2016

MCD143e

The Lincoln Electric Company

22801 St. Clair Ave.

Cleveland Ohio 44117-1199 USA

Lincoln Electric Europe S.L.

c/o Balmes, 89 - 80 2a

08008 Barcelona

SPAIN

LN-25 PRO & LN-25 PRO Dual, Wire Feeders

K2613 & K2614

(Product numbers may also contain prefixes and suffixes)

Electromagnetic Compatibility (EMC) Directive 2014/30/EU

EN 60974-10: 2007 Arc Welding Equipment – Part 10:

Electromagnetic compatibility (EMC) requirements;

English English

I

THANKS! For having chosen the QUALITY of the Lincoln Electric products.

Please Examine Package and Equipment for Damage. Claims for material damaged in shipment must be notified

immediately to the dealer.

For future reference record in the table below your equipment identification information. Model Name, Code &

Serial Number can be found on the machine rating plate.

Model Name:

………………...…………………………….…………………………………………………………………………………………..

Code & Serial number:

………………….……………………………………………….. …………………………………………………….……………..

Date & Where Purchased:

…………………………………………………………………... ……………………….…………………………………………..

ENGLISH INDEX

Technical specifications ...................................................................................................................................................... 1

Electromagnetic Compatibility (EMC) ................................................................................................................................. 2

Safety .................................................................................................................................................................................. 3

Installation and Operator Instructions ................................................................................................................................. 4

WEEE ................................................................................................................................................................................ 18

Spare Parts ....................................................................................................................................................................... 18

Authorized Service Shops Location .................................................................................................................................. 18

Electrical Schematic .......................................................................................................................................................... 19

Suggested Accessories ..................................................................................................................................................... 20

12/05

English English

II

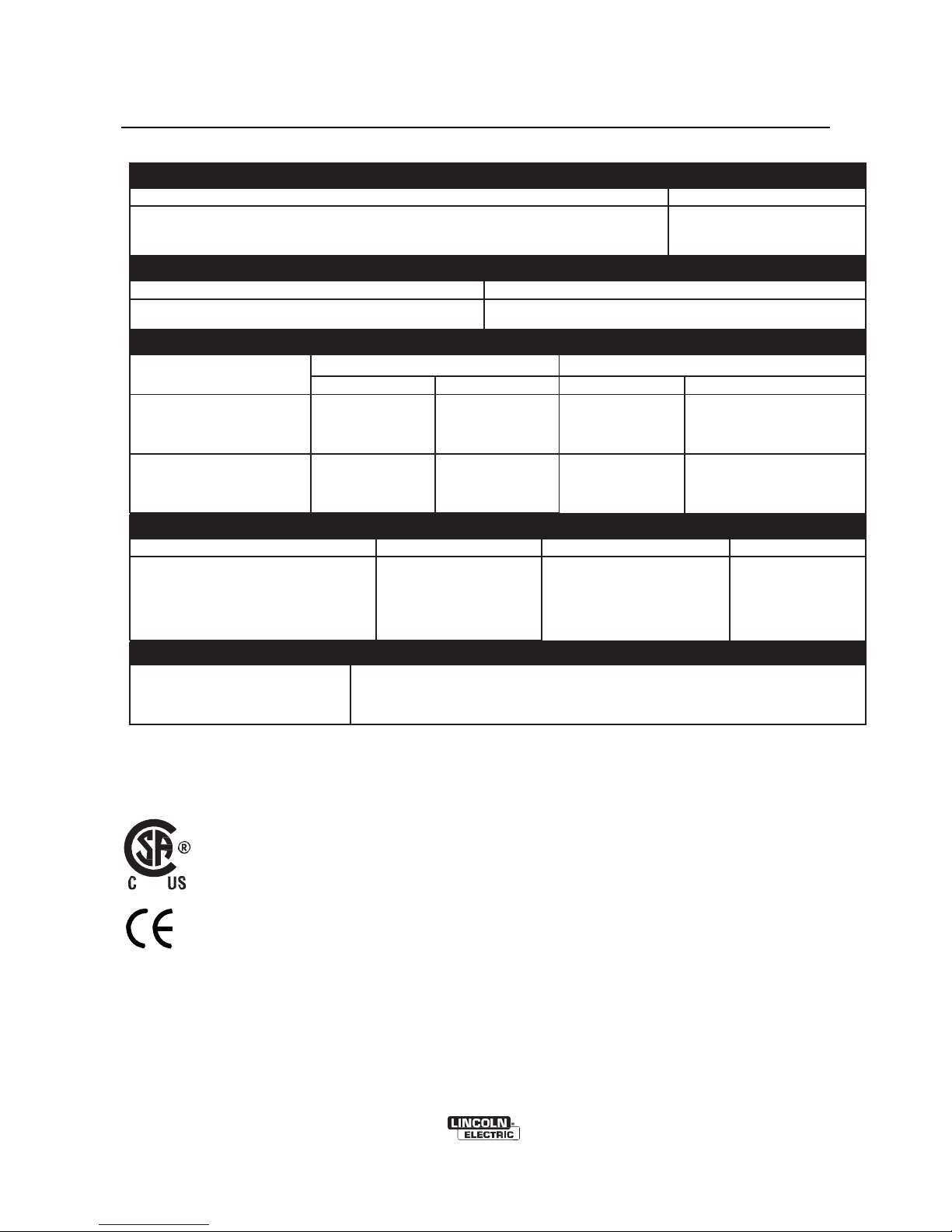

Technical specifications

LN-25™ PRO (K2613-5, K2613-7) (CODE NUMBER: 11746, 11747).

INPUT VOLTAGE AND CURRENT

INPUT VOLTAGE ± 10% INPUT AMPERES

DUTY CYCLE INPUT AMPERES

60% RATING 450

GEARING - WIRE FEED SPEED RANGE-WIRE SIZE

GEARING

EXTRA TORQUE K2613-7

STANDARD SPEED

K2613-5

HEIGHT WIDTH DEPTH WEIGHT

14.8 INCHES

(376 MM)

HANDLE FOLDED DOWN

15-110 VDC

4A

RATED OUTPUT @ 104°F (40°C)

GMAW FCAW

WFS RANGE WIRE SIZES WFS RANGE WIRE SIZES

50 – 400 IPM

(1.3 – 10.1M/MIN)

50 – 700 IPM

(1.3 – 17.7M/MIN)

.023 – 1/16"

(0.6 – 1.6MM)

.023 – 1/16"

(0.6 – 1.6MM)

50 – 400 IPM

(1.3 – 10.1M/MIN)

50 – 700 IPM

(1.3 – 17.7M/MIN)

.030 - 3/32”

(0.8 – 2.4MM)

.030 - 5/64

(0.8 - 2.0MM)

PHYSICAL DIMENSIONS

8.7 INCHES

( 221 MM)

23.2 INCHES

(589 MM)

38 LBS

(17 KG)

TEMPERATURE RANGE

OPERATION: STORAGE:

Thermal tests have been performed at ambient temperature. The duty cycle (duty factor) at 40°C has been

determined by simulation.

Duty cycle is based upon the amount of welding performed in a 10 minute period.

-40°F TO 104°F (-40°C TO 40°C)

-40°F TO 122°F (-40°C TO 50°C)

IP23

IEC 60974-5

English English

1

Electromagnetic Compatibility (EMC)

This machine has been designed in accordance with all relevant directives and standards. However, it may still generate

electromagnetic disturbances that can affect other systems like telecommunications (telephone, radio, and television) or

other safety systems. These disturbances can cause safety problems in the affected systems. Read and understand

this section to eliminate or reduce the amount of electromagnetic disturbance generated by this machine.

with, if necessary, assistance from Lincoln Electric.

Before installing the machine, the operator must check the work area for any devices that may malfunction because of

electromagnetic disturbances. Consider the following.

Input and output cables, control cables, and telephone cables that are in or adjacent to the work area and the

machine.

Radio and/or television transmitters and receivers. Computers or computer controlled equipment.

Safety and control equipment for industrial processes. Equipment for calibration and measurement.

Personal medical devices like pacemakers and hearing aids.

Check the electromagnetic immunity for equipment operating in or near the work area. The operator must be sure

that all equipment in the area is compatible. This may require additional protection measures.

The dimensions of the work area to consider will depend on the construction of the area and other activities that are

taking place.

Consider the following guidelines to reduce electromagnetic emissions from the machine.

Connect the machine to the input supply according to this manual. If disturbances occur if may be necessary to take

additional precautions such as filtering the input supply.

The output cables should be kept as short as possible and should be positioned together. If possible connect the

work piece to ground in order to reduce the electromagnetic emissions. The operator must check that connecting

the work piece to ground does not cause problems or unsafe operating conditions for personnel and equipment.

Shielding of cables in the work area can reduce electromagnetic emissions. This may be necessary for special

applications.

EMC classification of this product is class A in accordance with electromagnetic compatibility standard EN 60974-10 and

therefore the product is designed to be used in an industrial environment only.

The Class A equipment is not intended for use in residential locations where the electrical power is provided by the public

low-voltage supply system. There can be potential difficulties in ensuring electromagnetic compatibility in those locations,

due to conducted as well as radio-frequency disturbances.

This machine has been designed to operate in an industrial area. To operate in a domestic area it is

necessary to observe particular precautions to eliminate possible electromagnetic disturbances. The

operator must install and operate this equipment as described in this manual. If any electromagnetic

disturbances are detected the operator must put in place corrective actions to eliminate these disturbances

WARNING

WARNING

01/11

English English

2

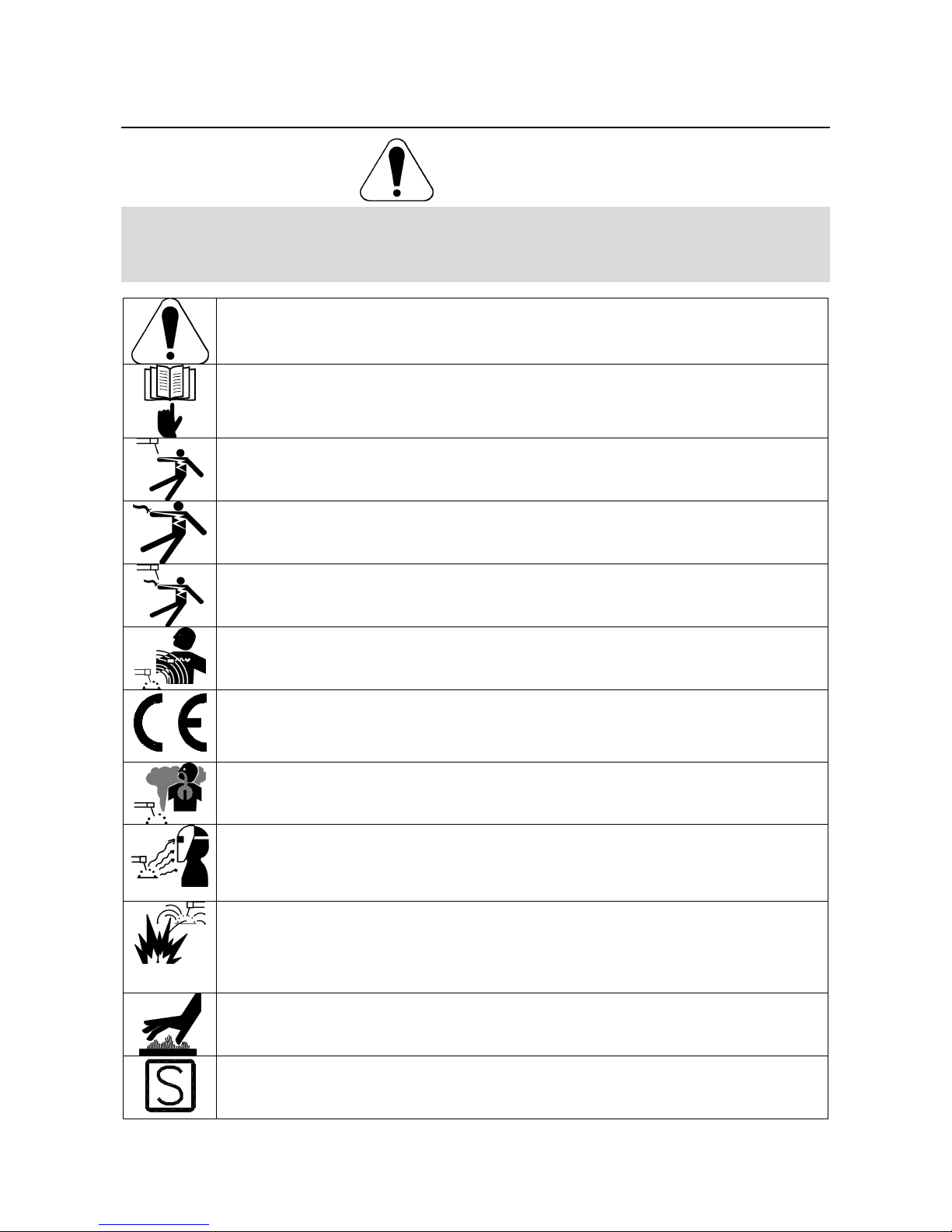

Safety

11/04

WARNING

This equipment must be used by qualified personnel. Be sure that all installation, operation, maintenance and repair

procedures are performed only by qualified person. Read and understand this manual before operating this equipment.

Failure to follow the instructions in this manual could cause serious personal injury, loss of life, or damage to this

equipment. Read and understand the following explanations of the warning symbols. Lincoln Electric is not responsible

for damages caused by improper installation, improper care or abnormal operation.

WARNING: This symbol indicates that instructions must be followed to avoid serious personal injury,

loss of life, or damage to this equipment. Protect yourself and others from possible serious injury or

death.

READ AND UNDERSTAND INSTRUCTIONS: Read and understand this manual before operating this

equipment. Arc welding can be hazardous. Failure to follow the instructions in this manual could cause

serious personal injury, loss of life, or damage to this equipment.

ELECTRIC SHOCK CAN KILL: Welding equipment generates high voltages. Do not touch the

electrode, work clamp, or connected work pieces when this equipment is on. Insulate yourself from the

electrode, work clamp, and connected work pieces.

ELECTRICALLY POWERED EQUIPMENT: Turn off input power using the disconnect switch at the

fuse box before working on this equipment. Ground this equipment in accordance with local electrical

regulations.

ELECTRICALLY POWERED EQUIPMENT: Regularly inspect the input, electrode, and work clamp

cables. If any insulation damage exists replace the cable immediately. Do not place the electrode

holder directly on the welding table or any other surface in contact with the work clamp to avoid the

risk of accidental arc ignition.

ELECTRIC AND MAGNETIC FIELDS MAY BE DANGEROUS: Electric current flowing through any

conductor creates electric and magnetic fields (EMF). EMF fields may interfere with some

pacemakers, and welders having a pacemaker shall consult their physician before operating this

equipment.

CE COMPLIANCE: This equipment complies with the European Community Directives.

FUMES AND GASES CAN BE DANGEROUS: Welding may produce fumes and gases hazardous to

health. Avoid breathing these fumes and gases. To avoid these dangers the operator must use

enough ventilation or exhaust to keep fumes and gases away from the breathing zone.

ARC RAYS CAN BURN: Use a shield with the proper filter and cover plates to protect your eyes from

sparks and the rays of the arc when welding or observing. Use suitable clothing made from durable

flame-resistant material to protect you skin and that of your helpers. Protect other nearby personnel

with suitable, non-flammable screening and warn them not to watch the arc nor expose themselves to

the arc.

WELDING SPARKS CAN CAUSE FIRE OR EXPLOSION: Remove fire hazards from the welding area

and have a fire extinguisher readily available. Welding sparks and hot materials from the welding

process can easily go through small cracks and openings to adjacent areas. Do not weld on any

tanks, drums, containers, or material until the proper steps have been taken to insure that no

flammable or toxic vapors will be present. Never operate this equipment when flammable gases,

vapors or liquid combustibles are present.

WELDED MATERIALS CAN BURN: Welding generates a large amount of heat. Hot surfaces and

materials in work area can cause serious burns. Use gloves and pliers when touching or moving

materials in the work area.

SAFETY MARK: This equipment is suitable for supplying power for welding operations carried out in

an environment with increased hazard of electric shock.

English English

3

CYLINDER MAY EXPLODE IF DAMAGED: Use only compressed gas cylinders containing the correct

shielding gas for the process used and properly operating regulators designed for the gas and

pressure used. Always keep cylinders in an upright position securely chained to a fixed support. Do

not move or transport gas cylinders with the protection cap removed. Do not allow the electrode,

electrode holder, work clamp or any other electrically live part to touch a gas cylinder. Gas cylinders

must be located away from areas where they may be subjected to physical damage or the welding

process including sparks and heat sources.

NOISE APPEARES DURING WELDING CAN BE HARMFUL: Welding arc can cause noise with high

level of 85dB for 8-hour week day. Welders operating welding machines are obligated to wear the

proper ear protectors /appendix No. 2 for the Decree of the Secretary of Labor and Social Policy from

17.06 1998 – Dz.U. No. 79 pos. 513/. According to the Decree the Secretary of Health and Social

Welfare from 09.07.1996 /Dz.U. No. 68 pos. 194/, employers are obligated to carry examinations and

measurements of health harmful factors.

MOVING PARTS ARE DANGEROUS: There are moving mechanical parts in this machine, which can

cause serious injury. Keep your hands, body and clothing away from those parts during machine

starting, operating and servicing.

Installation and Operator Instructions

Read this entire section before installation or operation

of the machine.

WARNING

ELECTRIC SHOCK CAN KILL.

• Turn the input power OFF at the disconnect switch or

fuse box before attempting to connect or disconnect

input power lines, output cables or control cables.

• Only qualified personnel should perform this

installation.

• Do not touch metal portions of the LN-25™ PRO

work clip when the welding power source is on.

• Do not attach the work clip to the wire feeder.

• Connect the work clip directly to the work, as close

as possible to the welding arc.

• Turn power off at the welding power source before

disconnecting the work clip from the work.

• Only use on power sources with open circuit voltages

less than 110 VDC.

Location

For best wire feeding performance, place the LN- 25™

Pro on a stable and dry surface. Keep the wire feeder in

a vertical position. Do not operate the wire feeder on an

angled surface of more than 15 degrees.

Do not submerge the LN-25™ Pro.

The LN-25™ Pro is rated IP23 and is suitable for

outdoor use.

The handle of the LN-25™ Pro is intended for moving

the wire feeder about the work place only.

When suspending a wire feeder, insulate the hanging

device from the wire feeder enclosure.

High Frequency Protection

Locate the LN-25™ PRO away from radio controlled

machinery. The normal operation of the LN-25™ PRO

may adversely affect the operation of RF controlled

equipment, which may result in bodily injury or damage

to the equipment.

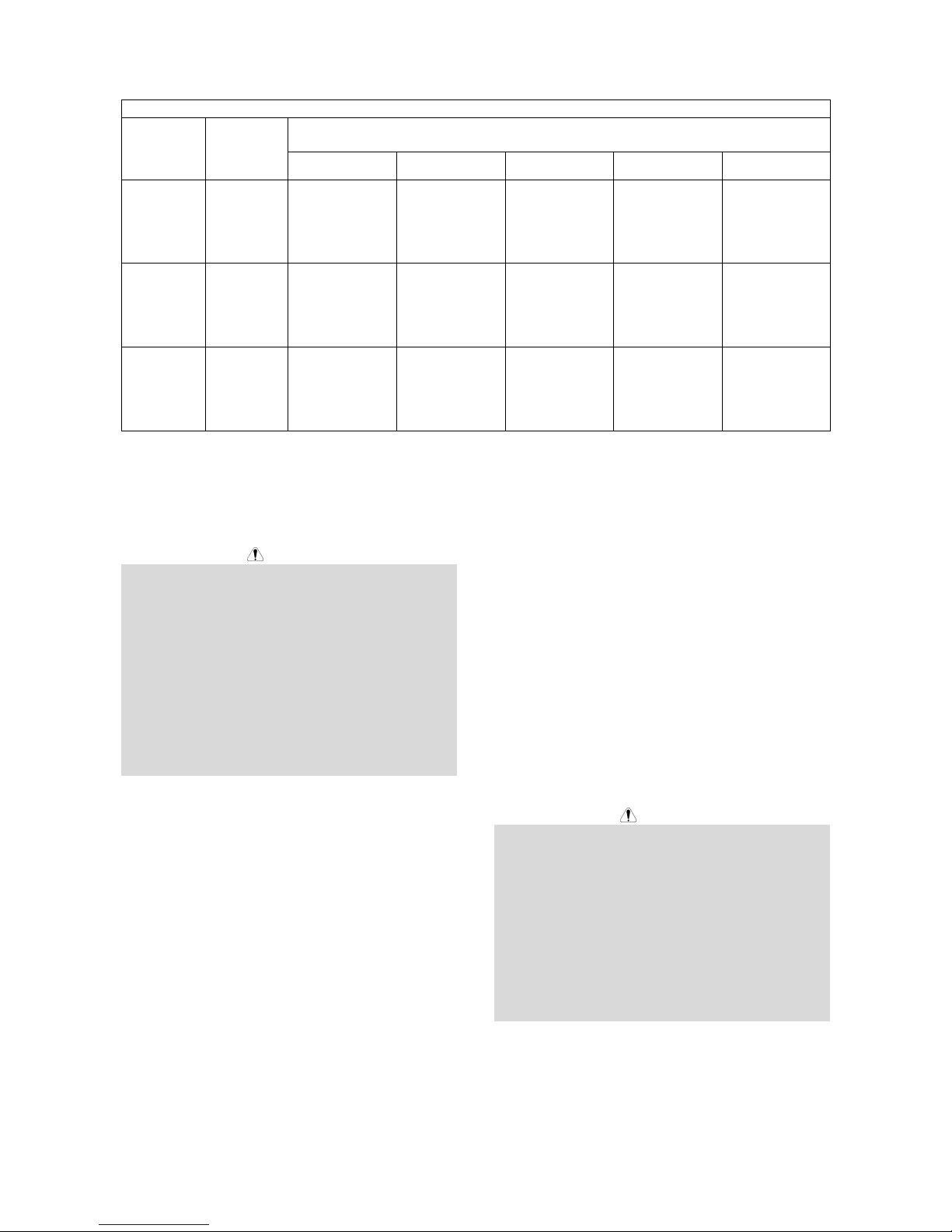

Weld cable size

Table 1 located below are copper cable sizes

recommended for different currents and duty cycles.

Lengths stipulated are the distance from the welder to

work and back to the welder again. Cable sizes are

increased for greater lengths primarily for the purpose of

minimizing cable drop.

Electrode lead

The electrode lead is a 4/0 cable.

WARNING

English English

4

RECOMMENDED CABLE SIZES (RUBBER COVERED COPPER - RATED 167°F OR 75°C)**

CABLE SIZES FOR COMBINED LENGTHS OF ELECTRODE AND WORK

CABLES

0 to 50 Ft.

(0 to15m)

2

2

4 or 5

3

3

50 to 100 Ft.

(15 to 30m)

2

2

3

3

3

100 to 150 Ft.

(30 to 46m)

2

2

2

2

2

150 to 200 Ft.

(46 to 61m)

1

1

1

1

1

AMPERES

200

200

225

225

250

PERCENT

DUTY

CYCLE

60

100

20

40 & 30

30

200 to 250 Ft.

(61 to 76m)

1/0

1/0

1/0

1/0

1/0

250

250

250

300

325

350

400

400

500

** Tabled values are for operation at ambient temperatures of 104°F(40°C) and below. Applications above 104°F(40°C) may require

cables larger than recommended, or cables rated higher than 167°F(75°C).

40

60

100

60

100

60

60

100

60

2

1

1

1

2/0

1/0

2/0

3/0

2/0

2

1

1

1

2/0

1/0

2/0

3/0

2/0

1

1

1

1

2/0

2/0

2/0

3/0

3/0

1

1

1

1/0

2/0

2/0

3/0

3/0

3/0

1/0

1/0

1/0

2/0

3/0

3/0

4/0

4/0

4/0

Table 1

Shielding gas connection

WARNING

CYLINDER MAY EXPLODE IF DAMAGED.

• Keep cylinder upright and chained to support.

• Keep cylinder away from areas where it may be

damaged.

• Never lift welder with cylinder attached.

• Never allow welding electrode to touch cylinder.

• Keep cylinder away from welding or other live

electrical circuits.

• BUILD UP OF SHIELDING GAS MAY HARM

HEALTH OR KILL.

• Shut off shielding gas supply when not in use.

• See American National Standard z-49.1, "Safety in

Welding and Cutting” Published by the American

Welding Society.

Maximum inlet pressure is 100 psi. (6.9 bar.)

Install the shielding gas supply as follows:

1. Secure the cylinder to prevent it from falling.

2. Remove the cylinder cap. Inspect the cylinder valves

and regulator for damaged threads, dirt, dust, oil or

grease. Remove dust and dirt with a clean cloth. DO

NOT ATTACH THE REGULATOR IF OIL, GREASE

OR DAMAGE IS PRESENT! Inform your gas

supplier of this condition. Oil or grease in the

presence of high pressure oxygen is explosive.

3. Stand to one side away from the outlet and open the

cylinder valve for an instant. This blows away any

dust or dirt which may have accumulated in the valve

outlet.

4. Attach the flow regulator to the cylinder valve and

tighten the union nut(s) securely with a wrench. Note:

if connecting to 100% CO2 cylinder, insert regulator

adapter between regulator and cylinder valve. If

adapter is equipped with a plastic washer, be sure it

is seated for connection to the CO2 cylinder.

5. Attach one end of the inlet hose to the outlet fitting of

the flow regulator. Attach the other end to the

welding system shielding gas inlet. Tighten the union

nuts with a wrench.

6. Before opening the cylinder valve, turn the regulator

adjusting knob counterclockwise until the adjusting

spring pressure is released.

7. Standing to one side, open the cylinder valve slowly

a fraction of a turn. When the cylinder pressure gage

stops moving, open the valve fully.

8. The flow regulator is adjustable. Adjust it to the flow

rate recommended for the procedure and process

being used before making a weld.

Wire drive configuration

(See Figure 1)

Gun bushing, thumb screw and socket head

cap screw

WARNING

ELECTRIC SHOCK CAN KILL.

• Turn the input power OFF at the welding power

source before installation or changing drive rolls

and/or guides.

• Do not touch electrically live parts.

• When inching with the gun trigger, electrode and

drive mechanism are "hot" to work and ground and

could remain energized several seconds after the

gun trigger is released.

• Do not operate with covers, panels or guards

removed or open.

• Only qualified personnel should perform

maintenance work.

English English

5

Loading...

Loading...