Page 1

GMAW

C

®

Pyth

RETURN TO MAIN MENU

Push-Pull Gun

OPERATOR'S MANUAL

Model number K2447-1, K2447-2, K2447-3

IM875

MK 091-0564

September 2005

Rev A.

Safety Depends on You

Lincoln arc welding equipment

is designed and built with safety

in mind. However, your overall safety can be increased by

proper installation...and thoughtful

operation on your part. DO NOT

INSTALL, OPERATE OR REPAIR

THIS EQUIPMENT WITHOUT

READING THIS MANUAL AND

THE SAFETY PRECAUTIONS

CONTAINED THROUGHOUT.

And, most importantly, think before

you act and be careful.

OPERATOR’S MANUAL

on is a registered trademark of MK Products

World's Leader in Welding and Cutting Products

Sales and Service through Subsidiaries and Distibutors Worldwide

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

opyright © 2005 Lincoln Global Inc.

Page 2

Py

thon-Plus Owner's Manual Page i

Page 3

Py

n

-

i

tho

Plus Owner's Manual Page i

Page 4

Python-Plus Owner's Manual Page iii

Page 5

Page 6

Page 7

0LEASE %XAMINE #ARTON AND %QUIPMENT &OR $AMAGE )MMEDIATELY

7HEN THIS EQUIPMENT IS SHIPPED TITLE PASSES TO THE PURCHASER UPON RECEIPT BY THE

CARRIER #ONSEQUENTLY CLAIMS FOR MATERIAL DAMAGED IN SHIPMENT MUST BE MADE BY THE

PURCHASER AGAINST THE TRANSPORTATION COMPANY AT THE TIME THE SHIPMENT IS RECEIVED

0LEASE RECORD YOUR EQUIPMENT IDENTIFICATION INFORMATION BELOW FOR FUTURE REFERENCE 4HIS

INFORMATION CAN BE FOUND ON YOUR MACHINE NAMEPLATE

-ODEL .AME .UMBER ?????????????????????

#ODE 3ERIAL .UMBER ?????????????????????

$ATE OF 0URCHASE ?????????????????????

7HENEVER YOU REQUEST REPLACEMENTS

SUPPLY THE INFORMATION YOU HAVE RECORDED ABOVE

2EAD THIS /WNERS -ANUAL COMPLETELY BEFORE ATTEMPTING TO USE THIS EQUIPMENT 3AVE THIS MANUAL

AND KEEP IT HANDY FOR QUICK REFERENCE 0AY PARTICULAR ATTENTION TO THE SAFETY INSTRUCTIONS WE

HAVE PROVIDED FOR YOUR PROTECTION

PARTS FOR OR INFORMATION ON THIS EQUIPMENT ALWAYS

Page 8

Table of Contents

S

iii

.

.

.

.

Accessories

C

.

4

.

4

.

.

els

.

ce

iodic Maintenance

App

l

l

W

y

afety Considerations .......................................................................-

nstallation

echnical Specifi cations

Support Equipment Required

un Lead Connections

peration

eneral

ontrols and Settings

rigger Adjustment ............................................................................................

rive Roll and Idler Rolls................................................................................

ptional Kits

Snake Skins

ontact Tips

as Cups ..........................................................................................................

rr

...........................................................................................................

......................................................................................

....................................................................................................

....................................................................................................

....................................................................................................

.............................................................................................................

intenan

r

Recommended Spare Parts List

ection A

ection B

ection

ection D

roubleshooting

roubleshooting Guide

esting The Gun

ection E

endices.............................................................................ection F

iagrams / Parts List

echanica

ectrica

K Repair Stations

afety Warnings

arrant

Page 9

THIS PAGE INTENTIONALLY BLANK

Page 10

1

ection A

n

s

y

d

)

2

s

A

)

)

)

g)

)

g)

T

)

Air/

)

d

ead Connections

e

A #

t

p

t

The Pyth

comes standard with a poly-lined conduit, for feeding

f

Adap

ose

T

t

ectric Cable

A

t

lly

/

.

nstallatio

Technical Specifi cation

Wire Capacit

.030" - .045" (0.6mm - 1.2mm) solid and hard wire

.030" - 1/16" (0.8mm - 1.6mm) aluminum and cored wire

Wire Spee

00 IPM (20.3 mpm) Max. at rated feeder Input Voltage (120VAC / 42VAC

Duty Cycle - 100% (All ratings are using Argon Gas)

00 Amps/25 Volt

hipping Weight (approximate) - Air Cooled

15ft. (4.5m

25ft. (7.6m

0ft. (15.2m

orch weight (less leads

Water cooled - 2.5 lbs. (1.13 kilogram

ir cooled standard

29.9 lbs.

.09 lbs.

.29 lbs.

5.94 Kg

8.29 K

13.19 K

upport Equipment Require

.V. or C.C. Power Source of suffi cient capacity for your needs.

egulated gas supply and hoses.

roperly sized power leads from power source to wire feeder and

round.

n L

Power Cabl

2 AWG power cable is used on the Python-

cable has a fi tting crimped to the copper cable strands. This fi tting is

hen threaded into the gun body. The cabinet end of the power cable is

incor

orated into the Power/Gas Adaptor.

ndui

onaluminum wire. The longer fi tting with a shallow groove is used on the gun

end. A set screw located on top o

lace. The cabinet end of the conduit is incorporated into the Power/Gas

tor.

H

he gas hose is pushed over a barbed fi tting on the gun body and secured

with a plastic tie wrap. The cabinet end of the gas hose is incorporated into

he Power/Gas Adaptor.

El

multi-conductor control cable is used on the Python-

he cable is secured with a cable clamp and the wires are connected to the

potentiometer, the micro switch, the motor and the gun body mechanica

lack is left in the electric cable as it exits the back of the gun to prevent

cable and

7-Pin, Amphenol connector

or wire breakage. The cabinet end of the control cable uses a

the gun handle secures the conduit in

us. The gun end of the

us. The gun end of

.

thon-

lus Owner's Manual -

age

Page 11

2

ection B

n

T

t

y

gs

r

T

h

T

T

f

A

tri

Adj

itch l

T

t

t

f

t

liki

Idl

lls

al

The Pyth

idl

y

S

eratio

eneral

he Python gun maintains a constant, steady, uniform wire feed speed,

regardless of curved or looped wire conduit. The constant push exerted by

he slave motor in the cabinet, combined with the pull of the torch motor,

causes the wire to literally fl oat friction-free through the wire conduit. The

24VDC torch motor is controlled b

potentiometer in the torch handle.

ontrols and Settin

Potentiomete

he laterally-positioned potentiometer is located in the lower end of the

handle, providing up to 800 ipm with 3 3/4 turns.

icro Switc

he micro switch assembly consists of the micro switch, and leads.

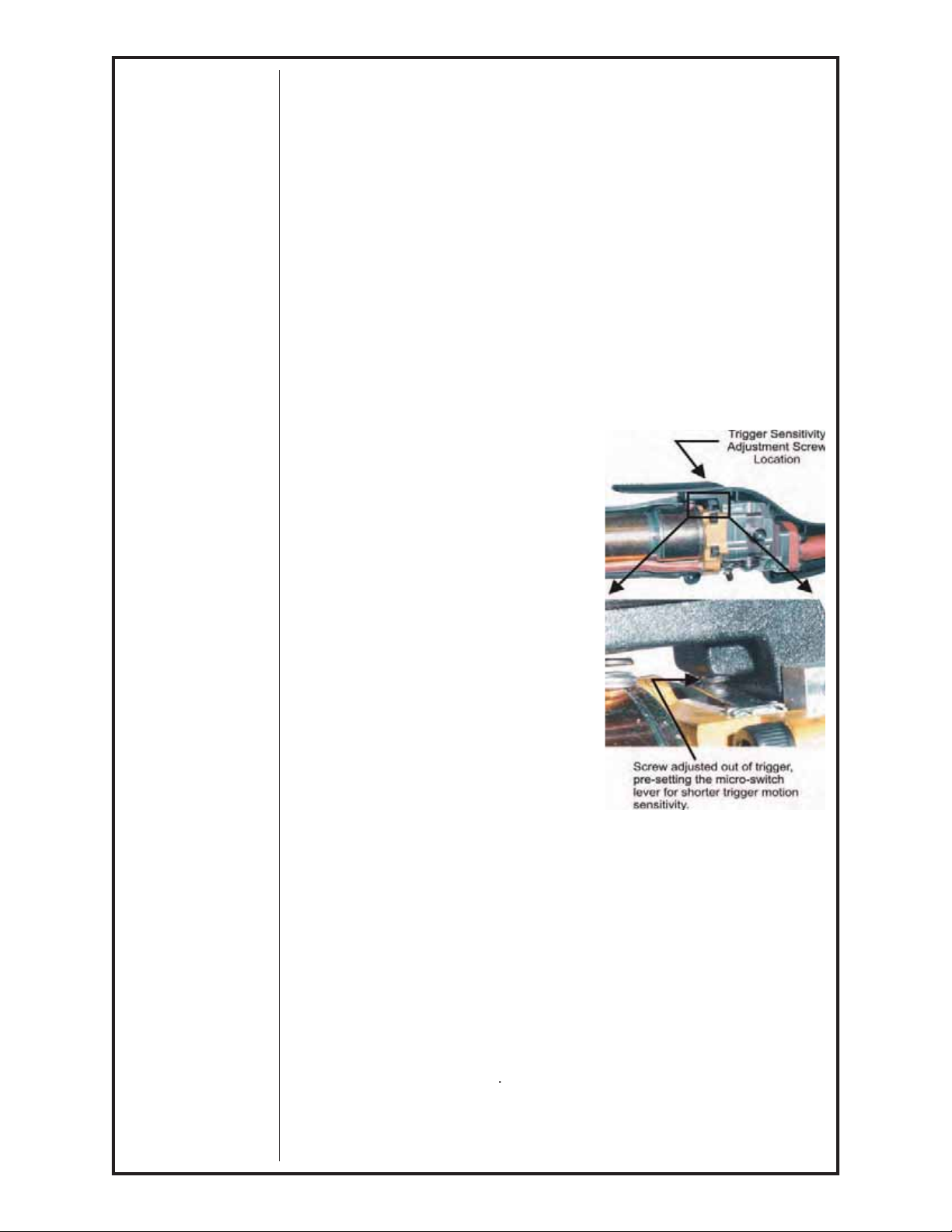

Trigger Sensitivity

he amount of trigger level travel can

be shortened

responsive" action.

more sensitive trigger lever is produced

by reducing the gap between the

gger lever and the micro-switch lever.

By turning-in the Trigger Sensitivity

ustment Screw, it closed the gap

etween the trigger lever and the microsw

he sensitivity of the trigger lever.

ever.

his well enable the operator to increase

or a "quicker" or "more

a three and three-quarter (3 3/4) turn

ensitivity Adjustmen

With the wire feeder turned on (with or

without welding wire loaded), turn the

rew in until the micro-switch is activated.

Once activated, the gun and wire feeder

motors will begin

he screw accordingly until the system is

eactivated and adjusted to the operators'

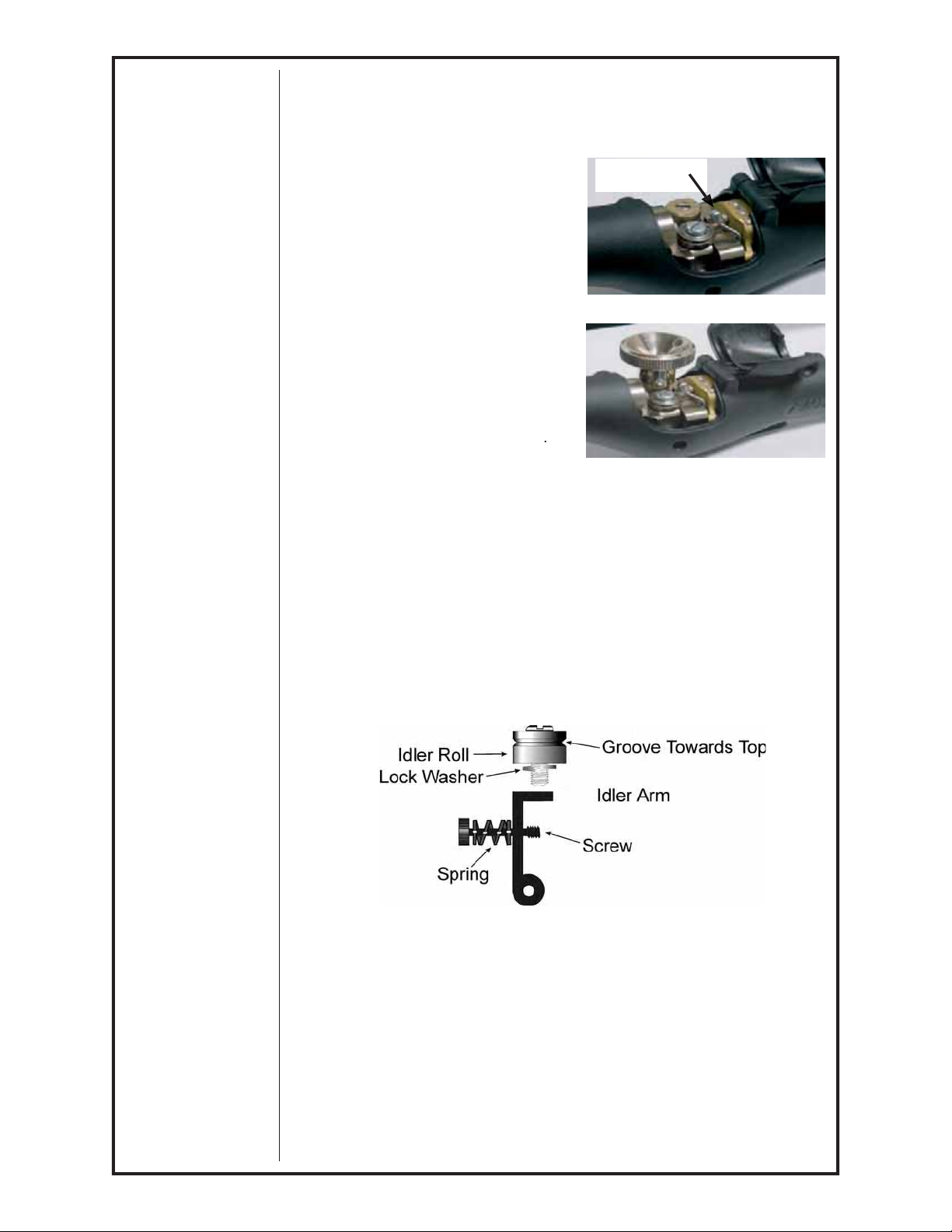

rive Roll and

ner

on gun comes standard with a knurled drive roll and a grooved

roll, which will handle both steel and aluminum wire with diameters from

.030-1/16 inch. Optional insulated V-groove drive rolls are also available for

aluminum wire if desired (see Optional Kits).

rive roll tension is accomplished with a unique spring-loaded pressure

screw. The P

screw preset.

eeding wire. Retract

ng.

er Ro

er

thon comes from the factory with the pressure adjustment

O ADJUSTMENT IS REQUIRED FOR ALL SIZES

AND TYPES OF WIRE

thon-

lus Owner's Manual -

age

Page 12

3

Drive Roll In

stallatio

al

eeds to be removed to access the

e

the idle

Ali

t

N

4

eaded shaf

stallation and Removal

)

idl

idl

idl

2

1

3

n/Remov

NOTE: Neither of the handles n

Driv

r Idler Rolls.

am Lever

.

ull the Cam Lever away from

r roll. This will relieve the

pressure against the drive roll (as

shown in Figure 1).

igure

gn the Drive Roll Removal Tool

P/N 931-0100) over the fl ats of the

rive roll (as shown in Figure 2).

the torch with one hand or on

a table top, with the other hand give

he Removal Tool a quick snap-turn

n the CLOCKWISE DIRECTIO

Figure

3. Once the drive roll is loose, continue to spin drive roll in the clockwise

irection to remove the drive roll from the torch.

. Install a new drive roll on the left-hand thr

t. The drive roll will

self-tighten when it is feeding wire.

ler Roll In

Reference Figure 3

.

sing a slot type screwdriver, loosen

er screw, taking care not to lose

lock washer under idler roll.

nsert new

er roll and lock washer onto screw, insuring that

er groove

s toward top and lock washer is beneath.

igure

.Tighten.

OTE: Lock washer must be under idler roll or it will not turn freely.

thon-

lus Owner's Manual -

age

Page 13

ection C Accessories/Options

/N

t

r

030

t

r

035

t

t

t

062

y

005-0699

cludes

gg

0694

Trigg

guns.

005-0701

otentiomete

005-0695

s

®

®

protective covers are now standard on all guns. You may order

f

©

0

.

0122

)

0123

Insulated Drive Roll Kits are used to prevent preheating of the wire which

may soften it and clog the liner. This picking up of current at the drive rolls

rather than at the contact tip is usually not a problem unless using too large

f a contact tip or excessively oxidized aluminum wire.

nsulated Groove Drive Roll Ki

.

Fo

nd i

nsulated Groove Drive Roll Ki

Fo

nd i

nsulated Groove Drive Roll Ki

For .040"(1.0mm) dia. aluminum wire. Includes insulated g

nd i

nsulated Groove Drive Roll Ki

For .045"(1.2mm) dia. aluminum wire. Includes insulated g

nd i

nsulated Groove Drive Roll Ki

For .

and insulated idler roll ass

Handle Kit.........................................................................................

n

Tri

replacement for all Python

eplacement micro switch assembly for all Python guns.

P

eplacement potentiometer assembly for all Python guns.

"(0.8mm) dia. aluminum wire. Includes insulated g

latedidler roll assy.

.

"(0.9mm) dia. aluminum wire. Includes insulated g

lated idler roll assy.

lated idler roll assy.

lated idler roll assy.

"

1.6mm) dia. aluminum wire. Includes insulated g

.

left and right handles, screws and drive roll door.

er Kit.........................................................................................005-

er adjustment kit includes a spring and sensitivity adjustment screw

icro Switch Kit...............................................................................

r Kit.............................................................................

E P/N

P1594-030

P1594-035

/a

KP1594-3/64

P1594-1/16

K P

005-0640

vedrive roll

005-0641

vedrive roll

005-0642

vedrive roll

005-0643

vedrive roll

005-0644

vedrive roll

nake Skin

nake Skin

spare replacement covers to protect the lead assy of the torch when the

actory one becomes damaged or worn. It can easily be replaced in the fi eld

by means of Velcro

Snake Skin Cover 13ft (for 15ft leads)

nake Skin Cover 23ft (for 25ft leads).....................................

Snake Skin Cover 48ft (for 50ft leads

931-011

-

-

thon-

lus Owner's Manual -

age 4

Page 14

y

y

y

y

y

y

*

(

used.

Contact Tip

s

s

6

)

8

2213-1

8

)

0*

)

50

10

)

0251

2216-1

12

)

2

*

h

1

8

2226-1

931-013

Contact Tip - 3/8" Diameter

LE P/N MK P/N Wire Size Tip ID Arc Tip Length

-

-

-

P2217-5B1 621-0394

Standard - furnished with torch.

To Remove contact tip when using full water cooled gas cup

621-0390

621-0396

621-0391

621-0397

621-0392

621-0398

621-0393*

621-0399

621-0400

621-0395

030"(0.8mm) .040"(1.0mm) Spra

030"(0.8mm) .040"(1.0mm) Short

035"(0.9mm) .045"(1.1mm) Spra

035"(0.9mm) .045"(1.1mm) Short

047"(1.2mm)

047"(1.2mm)

047"(1.2mm) .060"(1.5mm) Spra

045" or .052" .060"(1.5mm) Short

/16"(1.6mm) .074"(1.9mm) Spra

/16"(1.6mm) .074"(1.9mm) Short

/16"(1.6mm)

054"(1.37mm) Spra

054"(1.37mm) Short

085"(2.16mm) Spra

P/N 621-0065), contact tip removal tool (P/N 931-0002) must

.57"(39.9mm)

-7/8"(47.6mm)

.57"(39.9mm)

.82"(46.2mm)

.57"(39.9mm)

.82"(46.2mm)

.57"(39.9mm)

-7/8"(47.6mm)

.57"(39.9mm)

-7/8"(47.6mm)

-5/8"(41.3mm)

Finned Copper Cup

Finned Copper Gas Cups

Cup Size Cup I.D. MK P/N LE P/N

No.

No.

No. 1

8" (9.25mm

1/2" (12.7mm

/8" (15.8mm

-024

21-0249

21-02

P

P2215-1

-

Heavy Duty Finned Copper Gas Cups

Cup Size Cup I.D. MK P/N LE P/N

No.

No.

Standard - furnished with torc

5/8" (15.8mm

3/4" (19.0mm

-

-025

P

Torch Barrel Liners

Part Number Description

LE KP2244-

K 621-0424

-017

LE KP

K

7

Tip Extender (Air/Water cooled barrel only)

Bulk Tefl on Liner

ner Package, 5 pieces

thon-

lus Owner's Manual -

age 5

Page 15

6

arrel Assem

bli

A

s

The Pyth

s

guns come standard with a 60˚ curved barrel. The barrel

®

body using the patented EZ Lock™ system.

stallation

T

T

idl

n

T

fi

y

s

.

ce

®

System is designed to provide years of reliable

T

®

system that are subject to normal wear

T

p

t

y

0100

ll barrels are rated at 100% duty cycle

es

Barrel

Air Cooled

on

u

assembly locks to the Python

Barrel Removal and In

o remove the barrel assembly, loosen the patented EZ Lock™ Taper lock

nut until it is clear of the threads. Pull barrel out of the gun body.

o replace a barrel assembly, open the drive and idler roll door and seat the

arrel assembly until the inlet guide is almost touching the drive and

and the rear face of the barrel is fl ush with the aluminum body block. Take

care not to damage the “O” rings when inserting into the body. Tighten taper

lock nut assembly fi rmly so that barrel cannot rotate.

arrel Rotatio

o rotate a barrel assembly, loosen the patented EZ Lock™ Taper lock nut

assembly no more than 1 turn. Rotate barrel to the position of your choice

and retighten taper lock nut assembly

WARNING: Do not attempt to weld without the barrel being tightl

ecured in the torch body, or damage to the barrel or body may result

rmly so that the barrel cannot rotate.

er roll

Periodic Maintenan

Your Cobramatic

service.Maintenance of the torch will normally consist of a general cleaning

the wire guide system, including barrels, drive rolls, and conduits at regular

intervals.

emove spatter build-up from inside of nozzles with a hardwood stick.

he only parts on the Cobramatic

are the conduit, contact tips, gas cups, front body liners, wire guides, drive

and idler rolls. A supply of these parts should be maintained on hand.

he number of units in operation and the importance of minimal “down time”

will determine to what extent s

he “Recommended Spare Parts List” for the most commonly replaced parts.

If repairs do become necessary, qualifi ed shop maintenance personnel can

easil

replace any part.

are parts should be stocked on hand. See

Maintenance Tools

Tool Part Number

rive Roll Removal Tool

-

thon-

lus Owner's Manual -

age

Page 16

led Drive Roll

e Ro

ool

00

y

dle

t

Recommended Spare Parts List

0603-15

3

0603-50

3

069

Tri

Kit

069

Kit

0699

01

t

005-0686

Qty. Part No. Description

E KP2463-1

K 615-

1

E KP2463-2

K 615-0603-25

E KP2463-

K 615-

437-025

5-

4

5-

5

55-07

E KP2219-1

K 511-0101

E KP2220-1

MK

onduit - 15 ft

Conduit - 25 ft

Conduit - 50 ft

rive Roll Door

gger Assy.

otentiometer Assy.

andle Kit

Micro-Switch Assy. Ki

Drive Roll

Idler Roll Kit

Driv

ll Removal T

1-01

nur

E P/N KP2219-1

K P/N 511-0101

r Roll Ki

I

LE P/N KP2220-1

K P/N 005-0686

Micro Switch Assembl

-0701

thon-

lus Owner's Manual -

age 7

Page 17

8

t

/

f

g

oken elec

cable

t

C C

f

.

.

C

p

/

f

g

oose o

cable

Welding

e feeds

.

W

oll stuck

idl

ll,

e feeds one

.

.

f

.

/

idl

Trouble Cause Remedy

o wire feed at

orch, feeder not

perating, i.e. no

lave motor or brake

lenoid.

o wire feed at

orch, feeder

perating properly.

Wire

eeds, but

weldin

energized.

Wir

erratically

Wir

Wire walks out of

wire is not

peed only

rive rolls.

42 VAC Control fuse in

115

feeder/Control box blown.

Micro-switch de

activated.

bein

Br

trical

ective/not

.

eplace fuse.

eplace switch. Check

witch for operation.

heck micro-switch

wires for continuity.

24 VA

ontrol fuse in

feeder/Control box blown.

heck motor leads for

orts; then replace

use

ad potentiometer

heck potentiometer

with meter.

heck motor and

Broken Electrical

able.

potentiometer wires for

ontinuity.

See specifi c cabinet

Bad S

eed control/PCB

ontrol box owners

manual for speed

ontrol operation.

L

nnections.

r no

heck all power

nnections.

heck power supply

ontactor control cable

oose or in wrong position.

wners manual for

location and type

f contactor signal

required.

power source.

irty or worn conduit.

heck power source.

Blow out or replace

onduit.

rong size contact tip. See Contact tip table.

heck for lock washer

r r

.

under

er ro

or

replace if damaged.

ad potentiometer

heck with meter.

heck potentiometer

roken electrical cable.

wires

or continuity or

hort

ee specifi c cabinet

Bad speed control.

ntrol owners manual

for speed control

peration.

er roll upside-down.

ear wire guide missing.

ace groove in

roll toward top.

eplace wire guide.

er

thon-

lus Owner's Manual -

age

Page 18

9

Troubleshooting Guid

e

f

t

g

th

t

T

y

t

g

n

he Pyth

®

Electrical Diagram for information

k

d

he p

h

egardless of which torch or feeder used, all MK Products’ push-pull guns

erate on the same principle. The slave motor in the feeder runs at a fast,

constant speed, but has very low torque. It is always trying to

han the torch motor wants, and when the motor gets all it wants, it slows the

slave motor, preventin

a bird’s nest. Because of the low torque produced by

e slave motor, a brake system is used to prevent wire overrun rather than

ension. The drag adjustment in the feeder is used simply to keep the wire

slightly taut, so it will not pull off the spool while feeding wire.

he high torque 24VDC torch motor is controlled by a solid state speed

control located in the feeder, and a pot located in the torch. The torch motor,

otentiometer, and micro switch are connected to the cabinet/control box via

a control cable and Amphenol connector. If this cable becomes damaged, a

variet

of symptoms can occur, depending on which wire(s) break. To test,

check each wire for continuity and shorts.

emember, the micro switch in the torch activates both the slave motor and

orch motor circuits in the cabinet. Therefore, if the slave motor and brake

solenoid operate, but the torch does not, look more toward the torch motor’s

24V circuits, speed control, control cable, or the torch motor. If nothin

erates, look more toward the slave motor’s input, micro switch leads, or

micro switch.

eed more wire

Testing The Gu

eference the "W" clocked torch wiring diagram on

t

otor Chec

emove the torch connector from the cabinet.

sing the torch Amphenol connector, check the resistance across pins

and

” (motor leads). The resistance across the motor should be between

- 10 ohms as the potentiometer is turned.

If an open circuit or short exist, check the motor leads and motor

ndependently.

Testing the Potentiometer - “W” Clocke

sing the torch Amphenol connector, check the resistance across pin

wiper) and pin “C”. The resistance should vary from

potentiometer is turned.

heck the resistance across pin D (wiper) and pin “G”. The resistance

should vary from 5K - 0 ohms as t

Testing the Micro Switc

sing the torch Amphenol connector, check for continuity across pins

nd F when the trigger is pressed.

on

about pin-outs and locations.

- 5K ohmsas the

otentiometer is turned.

A”

D”

E”

thon-

lus Owner's Manual -

age

Page 19

THIS PAGE INTENTIONALLY BLANK

Page 20

11

ection

F

Appendices

us

Exploded View

Bill of Material

3

A/

y

Electrical

6

Diagrams / Parts List

Python-

ython Front Body Assembly

W Barrel Assembl

l

thon-

thon-

1

1

thon-

lus Owner's Manual -

age

Page 21

thon-us Exploded View

80

0123

2

0226

5

63

3

6

5

0603

50

6

3

06

0

3

06

N 001-14

-

47

21

5

LE KP24

-2

5

1

K

-2

-

-

4

4

4

2

-

No. Description 15' 25' 50'

thonPlus Owner's Manual - page 12

Page 22

y

d

R

B

d

069

igg

Ki

0

53

S

C

3/8

08

B

dy

A

y

0

3

l

Ti

W

p

5

y

00

8

3/3

/8

SS

0

01

S

1622

S

/8

0

21

°

/

y

163

S

3/8

0

3/8

00

1

8

53

h

B

A

y

0699

2

,

30,

35

06

/G

C

06

8

/G

02

3

M

ld

d

069

A

Kit

026

C

pp

7

H

dl

Ad

p

8

Tail

Piece

9

0096

g

y

05

6

g

K

30

00

8

9

G

C

r

9

0

5

8

0

3/8

SS

00

0

g

0258

8

0

5/8

SS

E

C

y

008

0

3/

6

ST

E

y

0518

/

0

3/8

009

S

C

2209

G

y

1

0021

y

G

110

S

#

0268

0012

S

C

/

4

T

x 4-4

x

2 x 7

ra

1-72 x

e

H

et

pring Lock Washer #6

crew PH Phil 4-40 x 5/16 SST

333-0005

336-0020

5

crew

1

-

e

in Dowel

1

24

11-

21-

-2

crew 1

crew

houlder

7 Hex

-

-

tor

e

o

trap Motor

Handle Kit: includes line items

5

5

5-

and

-

oor

5

7-

4

5

a

e

able Handle

an

olded

ut

7

7-

37-0272

37-0273

lea

AW

onduit Ass

Gas Hose

ube Insulation

4

7-

FT

.

1

0.218 ID x 0.50 LG

trl Ass

ap Plu

able

2

1-

REF TABL

able Power Ass

REF TABL

4

ord

l 0.625 ID x 2.00 L

piral

rap

ap, Vin

4

-

5

over Knob

7-

Python-Plus Parts List

02-0629 Cam Idler Arm Ass

No. Qty Part No. Description No. Qty Part No. Description

y

o

t

ear

er

raze

r

4

-

02-0631

ss

o

ront

-21

nob Pot Ass

-212

W Ass

A

wx Kit

arrel 60

Micro

47

7

-

77 Motor Pittman

-

-

thonPlus Owner's Manual - page 13

onnector Assy

as

ss

oot

orc

-21

as Adaptor Assy

razed Power

razed Power

57

5

-

-

ort 3

ssy

ot

oot Cable Su

nake Skin 3

5

5-

01-0108

2-007 Buna N

2-010 0.239 ID x 0.07 TH

O-Rin

O-Rin

1

-

-

03-0010 O-Ring 2-014 0.489 ID x 0.629 OD 3

53

7

T

T

x

2 4-4

crew FH Phil

4

2

-

1

1

x

x

2 4-4

crew FH Phil

-

x

4 - 2

R FP 1

crew Button 4-4

4

-

-

8-32

uide Ass

crew Mod

et

Wire

4

-

-

8

6-32 x 3

H

crew

-

Page 23

thon Front Body Assem

bly

003

08

0686

w

w

0686

419-0092

2219-1

511-0101

ll

P/N

-21

NOTE: Items #3, 4 and

can be ordered together

in Kit P/N LE KP2220-1,

MK 005-

Python Front Body Assembly

No. Qty P/N Description No. Qty P/N Description

03-2083

03-2106

25-0206 10-24 x 3/8 PH Scre

33-0082 # 10 Lock Washer

utput Shaft Assembly 6

ody Assembly

ompression Spring

thonPlus Owner's Manual - page 14

421-0525 1/8 x 7/8 SST Dowel Pin

431-1663 Idler Adjusting Scre

431-1598

LE KP2220-1

MK 005LE KP

MK

er Wire Feed Assembly

rive Ro

r Arm

Page 24

A

/W Barrel Assembly

0696

0091

/N LE KP2225-1, MK 003-2147

A/W 60º Curved Barrel Assembly

No. Qty. Part Number Description

-

431-1774

-

thonPlus Owner's Manual - page 15

nsulator Replacement Kit

up Insulator

Retaining Ring 5/8 Shaft

-

. x 0.070 Width

. x 0.070 Width

pieces

inned #10

60

Page 25

Python Electrica

l

$

#

!

2ED

"LACK

7HITE

'REEN

%

&

'

4ORCH ,EAD

!

"LUE

"ROWN

9ELLOW

"

2ED

!

"LACK

"

7HITE

'

'REEN

$

"LUE

#

"ROWN

%

9ELLOW

&

thonPlus Owner's Manual - page 16

Page 26

MK WARRANTY REPAIR STATIONS

.

05/251-6835

, AL

56/538-615

S

L

05/6

58

.

T

/653-46

W

.

AL

868

W

AL

/832-9353

S

S

,

Anch

AK

A

.

0500

Y

8/539-0003

.

V

SAS

R

SAS

Y

O

Y

AR

SCO

AR

A

CA

383

.

CA

0/523-9355

G

6/331-0595

9/628-10

R

CA

0

CA

CA

H

CA

R

N

CA

668

CA

800

R

6/96

for most up-to-date list, please visit www.mkproducts.com

for MK Products as of 9/14/05

ALABAMA

AIRGAS - SOUTH, INC

Birmingham, AL

2

IXIE WELDING SUPPLY

Attalla

2

NDUSTRIAL WELDING SERVICE

uinton, A

2

KIBRO, INC

heodore, AL

4

ELDING ENGINEERING SUPPLY CO

richard,

4/457-

ELDING MACHINE HOSPITAL

ontgomery,

4

ALA

FAIRBANKS AERO SERVICE

Fairbanks, AK

907/479-6666

RNR

INC. dba

Rubey Engine & Electric

orage,

907/336-5152

7

74-32

72

1

KA

RIZONA

ALLSTATE ELECTRIC MOTOR CO

hoenix, AZ

2/233-

ARC DYNAMICS

uma, AZ

2

RAXAIR DISTRIBUTION, INC

hoenix, AZ

2/269-2151

ERN LEWIS WLDG. SUPPLY

hoenix, AZ

2/252-0341

ARKAN

APPLIED SERVICES, INC.

Benton, A

501/860-6464

ARKAN

ot Springs, AR

501/321-9922

EL D

PPL

Dorado,

870/863-4088

WEL

ttle Rock,

501/372-2252

WELDING IND’L SUPPL

RADO WELDING & INDUSTRIAL

ALIFORNI

ADVANCED WELDER REPAIR

ommerce,

23/263-7

AIRGAS - WEST, INC

ardena,

1

ALL PHASE WELDER REPAIR & CONSULTIN

acramento, CA

1

ARC PRODUCTS

an Diego, CA

1

ARCO WELDER REPAI

anta Fe Springs,

2/921-524

resno,

292-4714

CAL-WELD SUPPLY

resno,

445-0131

DELTA-TEC

un Valley,

18/767-4234

EMCO-EAST WELD’R REPAI

oncord, CA

25/798-4411

RESNO OXYGE

resno,

233-

INDUSTRIAL ELECTRICAL CO

Modesto,

27-2

INDUSTRIAL WELDER REPAI

aPuente, CA

2

1-7643

22

4

thon-Plus Owner's Manual -

age 17

Page 27

18

MK WARRANTY REPAIR STATIONS

SCO

ON

)

.

S

A

A

A

R

O

C

R

O

A

CO

G

CO

R

CO

6

ABCO

CO.

CT

TEC

R

S

CE

S

/

.

/

O

S

L

/368

35

P

FL

/33

36

Y

ille, FL

N

L

8

/999-5

.

Wi

FL

/681-606

L

/35

Y

859

E

3

E

W

FL

S

80

/397-3340

for most up-to-date list, please visit www.mkproducts.com

for MK Products as of 9/14/05

NE

Fontana, CA

09/427-9670

ARC RENTS

Signal Hill, CA

62/989-3212

Bakersfi eld, CA

661/321-9922

San Diego, C

619/565-6960

10/233-3327

Santa Ana, C

714/549-9393

Fontana, CA

09/357-1661

VERN

626/858-4750

WESTEC WELDING EQUIPMENT REPAI

Sacramento, CA

16/924-5370

WELDING SUPPLY

RAXAIR DISTRIBUTI

RAXAIR DISTRIBUTION, INC

. J. KATE

ED-D-ARC, INC.

arson, C

IMS-ORANGE WELDING SUPPLY

THWEST WELDER REPAI

N ELECTRI

ovina, CA

OLORAD

IRGAS - INTERMOUNTAIN, INC.

olorado Springs,

719/473-1947

WELDERS & EQUIP. SVC. & TESTIN

Littleton,

2-8755

WESTERN SLOPE WELDER REPAI

rand Junction,

70/243-961

ONNETICUT

WELDING & INDUSTRIAL SUPPLY

Waterford,

00/962-0285

H AI

Milford, CT

203/783-1834

WELDER REPAIR AND RENTAL

Durham, CT

860-349-0864

ERVI

ELAWARE

EEN COMPRESSED GA

New Castle, DE

302

594-4555

WARREN ELECTRIC CO., INC

eaford, DE

302

629-9134

FL

RIDA

A & I SPECIALTIE

ehigh Acres, F

41

AAA GENERATOR & PUM

t. Myers,

41

ACTION WELDING SUPPL

acksonv

AMVEL CORPORATIO

Miami, F

ELECTRICAL WELDERS SERVICE

407

407

.K. CIRCUIT TECHNOLOG

ROPER ELECTRIC MOTOR SERVIC

Panama City, FL

TRI-GA

TRI-STATE SALES & LEASING

ake City, FL

-74

2-11

4/786-2254

2-567

rlando, FL

214

AUN SYSTEMS REPAIR, INC

nter Park,

4

OLOX

cala, F

2

1-4417

oynton Beach, FL

1/733-7

769-664

MITTY’S WELDER SERVIC

est Palm Beach,

1/845-1224

ami, FL

2-31

4

thon-Plus Owner's Manual -

age

Page 28

19

MK WARRANTY REPAIR STATIONS

T

CH

L

C

CT CORPO

ON

A

S

A

A

CULLOUG

C.

A

A

I

Aiea, HI

8900

O

CO

C

S

C.

R

L

US

S

Alsip, IL

R

IL

.

9/989-9030

.

8905

560

5990

Y

IN

888

.

ille, IN

903

N

9/879-0

.

9353

.

N

550

Y

36

A

A

A

1

p

T

A

A

for most up-to-date list, please visit www.mkproducts.com

for MK Products as of 9/14/05

RI-TE

Sarasota, F

41/758-3825

V.A. ELE

Hialeah, FL

05/825-3327

WELD DIRE

Jacksonville, FL

04/387-5664

TRICAL MOTORS CENTER, INC.

RATI

EORGI

B&W INDUSTRIAL SERVICE

ugusta, G

706/738-8722

Mc

tlanta, G

404/688-5251

H ELEC. MOTOR SV

AWAI

C ELECTRIC, INC.

483-

DAH

NOR

Boise, ID

208/336-1643

ITER ELECTRI

Idaho Falls, ID

208/529-3665

LLINOI

MS ELECTROMECHANICAL SERVICES, IN

alesburg, IL

09/342-4125 – 888/964-3526

FRED ARMS ELECTRIC MOTOR REPAI

Stone Park, I

708/343-6262

IND

708/371-5688

618/633-5000

TRIAL WELDER REBUILDER

ELIABLE EQUIPMENT REPAI

amel,

KFORD INDUSTRIAL WELDING SUPPLY

ockford, IL

15/226-1900

NDIANA

AGA GAS, INC

ammond, IN

1

AIRGAS - MID AMERICA, INC

Evansville, IN

424-

& H ELECTRIC

eymour, IN

12/522-

RETT DIEHM HOAGLAND ELECTRIC, INC.

ort Wayne, IN

-489-

COX EQUIPMENT COMPAN

ndianapolis,

17/241-

EVANSVILLE ARMATURE, INC

vansv

12/428-

ARRISON ELECTRIC, INC.

Michigan City, I

1

MODERN SUPPLY CO., INC

Evansville, IN

12/425-

PRAXAIR DISTRIBUTION, INC

peedway, I

17/481-4

UTTON-GARTEN COMPAN

Indianapolis, IN

17/264-32

7

1

4

444

W

ARC

rimes, I

515/986-4610

AIRGAS NORTH CENTRAL

Des Moines, I

515/266-111

EDAR RAPIDS WELDING SUPPLY

Cedar Ra

319/365-1466

ELECTRICAL ENGRG. & EQUIPMEN

Des Moines, I

515/266-8890

UPERIOR WELDING SUPPLY

Waterloo, I

319/236-9660

URCE MIDWEST

ids, IA

thon-Plus Owner's Manual -

age

Page 29

20

MK WARRANTY REPAIR STATIONS

WRIG

Y

A

ON

S

/

Y

S

655-9353

S

ille, KY

/635-5218

KY

3660

W

T

/636-0545

Y

A

CO.

A

1

C.

5

W

CO.

A

W

.

A

S

S

ME

GE GASES & TOOLS

O

Y

/

S

Y

A

5035

CO.

g

D

T

CO.

I

C.

I

C

CO.

I

C.

I

G

for most up-to-date list, please visit www.mkproducts.com

for MK Products as of 9/14/05

HT WELDING SUPPL

Ft. Dodge, I

515/576-0640

ANSAS

AEROFORM CORPORATI

offeyville, K

20/251-1430

KANOX

Hutchinson, KS

316

665-5551

ENTUCK

UPONT DYNAMIC

Bellevue, KY

-

GENERAL WELDING PRODUCT

ouisv

2

RED-D-ARC

exington,

245-

ELDING EQUIPMEN

Louisville, KY

2

ISIANA

T SVCS OF MORGAN CIT

organ City, L

985/385-4135

RED BALL OXYGEN

Shreveport, L

318/425-321

HAW OXYGEN CO., IN

onroe, LA

318/387-411

ELDERS EQUIPMENT

Broussard, L

337/837-5701

ELDERS SUPPLY & EQUIP

ort Allen, L

225/346-4712

AINE

ADVANTAGE GASES & TOOL

angor, ME

207/942-6393

ADVANTAGE GASES & TOOL

ortland,

207/797-2733

ADVANTA

ewiston, ME

07/784-4588

MAINE

Auburn, ME

07/784-5788

XY-ACETYLENE SUPPLY COMPAN

ARYLAND

M MECH/ELEC REPAIR SERVICE

wings, MD

301

855-7508

ASSACHUSETT

AIMTEK WELDING SUPPL

Auburn, M

2-

ICHIGAN

ANN ARBOR WELDING SUPPLY

Ypsilanti, MI

34/572-0444

APEX WELDING GASES & SUPPLY

Muske

AUTOMATIC WEL

Midland, MI

517/496-9245

517/386-4630

517/799-6291

PLYMOUTH WAYNE, IN

Wixom, M

PURITY

517/793-9696

Michigan Center, M

517/764-7766

Marysville, MI

810/364-6521

on Heights, MI

16/722-3185

REAT LAKES EQUIPMEN

lare, MI

AMILTON ELECTRIC

aginaw, M

48/735-7700

YLINDER GASES, INC.

rand Rapids, MI

16/532-2375

AGINAW WELDING SUPPLY

aginaw, M

IMPKINS ELECTRICAL SV

UTHPARK WELDIN

thon-Plus Owner's Manual -

age

Page 30

21

MK WARRANTY REPAIR STATIONS

W

WES

Y

T

WILSO

S

W

L

Alb

MN

1

Y

N

/

CO.

MN

CO.

C.

SSOURI

.

O

3500

O

417/86

5

.

O

6000

I

C.

S

Y

S

SO

Y

O

Y

Y

MT

.

V

5/359-05

S

C.

J

Y

NJ

YO

K

Y

Y

88

R

308

Y

Y

0

.

R

for most up-to-date list, please visit www.mkproducts.com

for MK Products as of 9/14/05

ELDING METALS, INC.

adison Heights, MI

248/585-0480

AR COMPAN

hree Rivers, MI

16/483-9125

N WELDING & MEDICAL GASE

arren, MI

586/751-7400

INNESOTA

AIRGAS – NORTH CENTRA

ert Lea,

507/373-241

APITOL CITY WELDING SUPPL

St. Paul, M

51/224-4843

ENTRAL McGOWAN

St. Cloud, MN

320

252-5292

INNEAPOLIS OXYGEN

nneapolis,

12/588-8855

XYGEN SERVICE

St. Paul, MN

12/644-7273

RAXAIR DISTRIBUTION, IN

St. Paul, MN

51/603-1996

I

EE-KAY SUPPLY, INC

t. Louis, M

24/644.G. WALKER

pringfi eld, M

2-174

ROD’S SERVICE, INC

t. Louis, M

14/721-

ISSISSIPP

3D SUPPLIES, IN

Jackson, M

01/353-3330

KOMP IND’L & WELD’G SUPPL

Hattiesburg, M

01/649-5889

MIDMeridian, MS

01/483-9331

N

01/545-1800

UTH WELDING SUPPL

RDAN SMITH WELDING SUPPL

attiesburg, MS

ONTANA

VALLEY WELDERS SUPPL

ngs,

406/256-3330

NEVADA

IERRA WELDING SUPPLY CO

parks, N

7

NEW HAMP

WELDING SYSTEMS SV

Raymond, NH

03/895-4700

EW

INDUSTRIAL ELECTRIC SERVICE CO.

awthorne,

973/423-1212

EW

DELO WELDING SUPPL

yracuse, N

15/478-21

DYNAMIC WELD’G & REPAI

ayshore, NY

1/643-1

AUN WELDING SUPPL

yracuse, NY

15/463-5241

ACKSON WELDING SUPPL

Rochester, NY

235-292

42

HIRE

ERSE

R

NORTH CAROLINA

ADAMS WELDER REPAIR & ELECTRICAL

ERVICE, INC.

Nashville, NC

52/459-1960

LOX LTD

Colfax, NC

336/996-1974

M & L WELDER REPAI

Asheville, NC

828/250-9353

thon-Plus Owner's Manual -

age

Page 31

22

MK WARRANTY REPAIR STATIONS

CO.

C

CO.

C

CO.

CO.

O

CO.

C

CO.

C

D

C.

/

O

A

.

OH

8

A

Y

OH

A

E

0/516-0303

A

Y

9353

A

T

A

OH

6

C

0/446-4360

1

R

C

R

CO.

S

CK’S

CE

OH

C.

R

S

S

S

O

S

C.

H

SOUTH

K

for most up-to-date list, please visit www.mkproducts.com

for MK Products as of 9/14/05

MACHINE & WELDING SUPPLY

unn, NC

10/892-4016

MA

HINE AND WELDING SUPPLY

reenville, NC

252/752-3089

MA

HINE AND WELDING SUPPLY

aleigh, NC

19/772-9500

MACHINE AND WELDING SUPPLY

Winston-Salem, NC

36/723-9651

NATI

High Point, N

NATIONAL WELDERS SUPPLY

704/392-7317

701

NAL WELDERS SUPPLY

10/882-1110

harlotte, N

ORTH

RAXAIR DISTRIBUTION, IN

argo, ND

237-5233

AKOTA

HI

GA GASES, INC

Lima,

419/228-282

LBRIGHT WELDING SUPPL

Wooster,

264-2021

LL ABOUT SERVIC

Wickliffe, OH

44

RC EQUIPMENT COMPAN

truthers, OH

750-

RC SERVICES, INC.

oledo, OH

419/478-6204

BELAIR PRODUCTS, INC.

kron,

253-311

BIG RIVER ELECTRI

allipolis, OH

74

nD MACHINE, INC.

anton, OH

478-881

ELECTRIC WELDER REPAI

Cuyahoga Heights, OH

16/271-5600

MAINTENAN

Cincinnati, OH

513/554-1313

.E. MEYER

andusky, OH

419/621-4201

HIO AIR PRODUCT

Canton, OH

330/821-2771

RI

Eastlake,

440/269-1204

330/424-3134

VALLEY NATIONAL GASE

513/241-5840

VALLEY NATIONAL GASE

419/228-1008

VALLEY NATIONAL GASE

VALLEY NATI

Toledo, OH

419/241-9114

VOLLMER ELECTRIC CO.

Columbus, OH

WEILER WELDING CO., IN

Dayton, O

937/222-8312

WELDINGHOUSE, INC.

Cleveland, OH

WELDER REPAIR SERVI

.D. NOLD, IN

isbon, OH

UTHERN OHIO WELDER REPAI

roveport, OH

14/-836-2069

incinnati, OH

ima, OH

illiard, OH

14/771-1311

14/476-8800

16/524-1955

E UNLTD. & TOOL REPAI

NAL GASE

KLAHOMA

AIRGAS MIDTulsa, O

918/582-0885

thon-Plus Owner's Manual -

age

Page 32

23

MK WARRANTY REPAIR STATIONS

R

K

S

K

Y

ARC SYS

S

R

1

OR

O

,

S

R

1

PA

60

N

A

/681-949

PA

.

PA

6650

.

PA

00

.

A

0/532-6460

S

A

C

SC

3/687-0413

S

S

O

R

N

T

N

CO

N

S

C.

Arli

.

A

TX

.

.

TX

.

.

W

for most up-to-date list, please visit www.mkproducts.com

for MK Products as of 9/14/05

BILL’S WELDER REPAI

Oklahoma City, O

405/232-4799

MUNN

nid, O

80/234-4120

KLAHOMA WELDERS SUPPL

Madill, OK

80/795-5561

UPPLY

REGON

TEMS SERVICE

entral Point, O

41/665-2676

C COMPANY

ba ELECTRICAL CONSTRUCTION

MPANY

ortland, OR

00/452-151

INDUSTRIAL SOURCE

ugene,

41/344-1438

IR

NTECH WELDING & INDUSTRIAL SUPPLY

INC.

ortland, OR

03/774-5145

WELDER

edmond, OR

41/548-871

ERVICE & REPAI

ENNSYLVANIA

EQUIPMENT

ttsburgh,

412/821-84

BY DESIG

olumbia, P

717

EOVIC WELDING SUPPLY

ton,

717/742-9377

J.A. CUNNINGHAM EQUIPMENT, INC

adelphia,

215/426JOSEPH PINTO, JR. EQUIPMENT CO

. Lansdowne,

10/259-41

OWER SOURCE REPAIR CO., INC

ollingdale, P

1

4

VALLEY NATIONAL GASE

Pittsburgh, P

412/281-1835

OUTH

CAROLINA WELDER SVC.

ake City,

4

AROLINA

ENNESSEE

ARC-ONE WELDER REPAIR, INC.

East Ridge, TN

423/894-9353

INDU

Rogersville, TN

423/272-8199

NATI

423/584-6390

Memphis, T

901/523-6821

Nashville, T

TRAM

423/968-4499

TRIAL MACHINE REPAIR

NAL RENTAL & REPAI

noxville, TN

UALITY WELD’G EQUIPMEN

15/726-5282

ristol, T

EXA

AIRGAS - SOUTHWEST, IN

ngton, TX

817/261-2967

AIRGAS-SOUTHWEST, INC

ustin,

512/835-0202

AIRGAS-SOUTHWEST, INC

Corpus Christi, TX

361/882-2531

AIRGAS-SOUTHWEST, INC

ouston,

13/462-8027

AIRGAS-SOUTHWEST, INC

an Antonio, TX

10/337-7255

AIRGAS-SOUTHWEST, INC

aco, TX

54/753-6443

thon-Plus Owner's Manual -

age

Page 33

MK WARRANTY REPAIR STATIONS

N

O

X

C.

S

C

T

X

V

,

TX

W

R

W

T

1

T

/531-8888

W

.

/334-0060

ONT

W

C.

V

Ashland, VA

CO.

VA

CO.

A

ORFO

Y

A

W

T

WA

.

V

WA

G

S

Tukwil

WA

S

WA

C.

A

S

C.

A

C

S

T

WA

A

W

S

G

.

V

590

V

0

W

.

for most up-to-date list, please visit www.mkproducts.com

for MK Products as of 9/14/05

ENISON OXYGE

enison, TX

903/465-3369

FT. W

Ft. Worth, T

San Angelo, TX

915/655-4545

LEKTROTECH, INC.

Greenville, TX

903/454-7146

RITE-WELD

Fort Worth, TX

Longview, T

903/238-9353

NC.

956/787-0469

San Antonio, TX

210/680-8390

RTH WELDERS SUPPLY, INC.

17/332-8696

PC SERVICES, IN

UPPLY, IN

17/626-8237

exAir WELDING SUPPLY

ALLEY OUTDOOR POWER EQUIPMENT

arr,

ELDING MACHINE & TORCH REPAI

TAH

ARC SERVICES, LLC

est Valley City, U

1/975-112

.W. SILVER INDUSTRIAL SERVICE

alt Lake City, U

1

OODLAND TECHNOLOGIES, INC

gden, UT 84401

1

VERM

.J. WELDING EQUIPMENT REPAIR, IN

. Clarendon, VT

02/775-7422

IRGINIA

ARC WELDERS, INC.

04/798-1818

ARCET EQUIPMENT

ampton,

57/728-9353

N.W. MARTIN

pringfi eld, V

03/644-0120

N

Norfolk, V

804/622-6571

LK WELDERS SUPPL

ASHINGTON

AIRGAS - NORPAC, INC.

acoma,

53/473-2282

AIRGAS – NORPAC, INC

ancouver,

360/574-5311

A-L WELDIN

a,

425/228-2218

AMERICAN EQUIPMENT SERVICE

ent,

53/395-9947

ARRIS ELECTRIC, IN

eattle, W

06/782-6668

& M ENTERPRISE

numclaw, WA

53/335-7817

XARC, IN

okane, W

509/535-7794

PA

IFIC WELDING SUPPLIE

acoma,

53/572-5302

PRECISION WELDER & ENGINE REPAIR

eattle, W

06/382-6227

E

T VIR

CARDINAL SALES & SERVICE, INC

larksburg, W

4/622-7

WILLARD C. STARCHER

pencer, W

4/927-252

PRODUCT

INIA

ISCONSIN

INTERSTATE WELDING SALES CORP

Appleton, WI

920/734-7173

thon-Plus Owner's Manual -

age 24

Page 34

MK WARRANTY REPAIR STATIONS

C

WI

C.

S

WI

CE

WI

A

.

A

R

o

05/525

55

.

3

.

8/594-885

9/8

9353

S

9353

.

8/683

80/532-5900

9938

S

C

1

.

SG)

D

/

C.

.

G

S

S

/

.

/

1

Winni

C

.

Y

6858 8395

for most up-to-date list, please visit www.mkproducts.com

for MK Products as of 9/14/05

MOSINEE MACHINE & ELECTRI

osinee,

715/693-0858

RAXAIR DISTRIBUTION, IN

Brookfi eld, WI

414/938-6365

ED-D-ARC APPLETON

Kaukauna, WI 54130

20/759-4700

VALLEY NATIONAL GASE

waukee,

414/281-9540

WELDER REPAIR & SERVI

redonia,

262/692-3068

ANADA

&A WELDER SERVICES LTD

askatoon, Saskatchewan

4-1601

RC & GENERATOR REPAI

arson, Ontari

7

B. HARRIS WELDING SVCS.

BARRY HAMEL EQUIPMENT LTD

BEAUCE TECHNOLOGIES, INC

41

1

41

7

HYPERDYNAMICS TECHNOLOGIES LTD.

-2141

artmouth, Nova Scotia

2/468-62

oquitlam, B.C.

4/945-931

t. Prosper, Quebec

2

HIPPINDALE ELECTRIC COMPANY

ambridge, Ontario

41-

-TECH WELD SERVICE

egina, Saskatchewan

-

LECTRO-MÉCANIK, INC

ainte-Foy, Quebec

-1724

PR INDUSTRIES 1994 LTD.

rande Prairie, Alberta

ickering, Ontario

-

INDUSTRIAL ELECTRONIC SERVICE

Calgary, Alberta

403/279-3432

HRISTIAN ELECTRI

Calgary, Alberta T2C 2CB

403/292-911

ADEL LTD

Quebec

819/376-6577

eBLANC ELECTRO-TECH, INC.

oucherville, Quebec

450/449-5244

INCOLN ELECTRIC COMPANY OF CANADA

A

Mississauga, Ontario

905/565-5600

MACTECH Distributors LT

Porterslake, Nova Scotia

902

827-3926

M.R.T. REPAIR CENTER, IN

Montreal, Quebec

514/648-0800

ZARK ELECTRICAL MARINE LTD

t. Johns, Newfoundland

09/726-4554

PEEL EN

Mississauga, Ontario

905/670-1535

T.F. DAB WELDER SERVICE

Ajax, Ontario

905

PROMOTECH ÉLECTRIQUE, INC

leurimont, Quebec

819

WELDERS SUPPLY

04/772-9476

WELDERTECH

Calgary, Alberta

403/279-3432

WELDTE

.C

04/545-3886

INE

424-8754

822-211

peg, Manitoba

HINA

PHT GROUP COMPAN

eijing, China

-10-

thon-Plus Owner's Manual -

age 25

Page 35

26

NDIA

S

A

JSK SYSTEM

ndheri (W), Mumbai

11-91-39-574-384

MK WARRANTY REPAIR STATIONS

for MK Products as of 9/14/05

for most up-to-date list, please visit www.mkproducts.com

thon-Plus Owner's Manual -

age

Page 36

Safety Warnings

thonPlus Owner's Manual - page 27

Page 37

thonPlus Owner's Manual - page 28

Page 38

THIS PAGE INTENTIONALLY BLANK

Page 39

2005

.

.

T

4

8

Copyrig

WARRANTY

quip

t

f

y

d

c

-

l.

f

ir

)

w

c

.

A

o

o

t

:

s

s

L

X

r

der

®

ys

4.

ys

t

g

g

g

O

T

O

U

.

-

TO,

.

GENUINE

MK PRODUCTS’

LIMITED WARRANTY

5

s

e

.

Effective May 1, 200

This warranty supersedes all previous MK Products warranties and i

xclusive, with no other guarantees or warranties expressed or implied

warrants that all new and unused e

roducts is free from defects in workmanship and material as of

he time and place of delivery by MK Products. No warranty is

items manufactured by others. Such trade accessories and other

items are sold subject to the warranties o

facturers, if an

K Products’ warranty does not apply to components having

ormal useful life of less than one (1) year, such as relay points,

wire con

with the welding wire, including gas cups, gas cup insulators, and

ontact tips where failure does not result from defect in workman

ship or materia

any duties with respect to the quality of goods, based upon the

ollowing options:

1) repa

2) replacement

3

ost of repair or replacement at our Irvine, California plant

s a matter of general policy only, MK Products may honor an

riginal user’s warranty claims on warranted equipment in the event

f failure resulting from a defect within the following periods from

he date of delivery of equipment to the original user

. Sidewin

ade by MK Products with respect to trade accessories or other

.

uit, tungsten, and welding gun parts that come in contact

Products shall, exclusively remedy the limited warranty or

here authorized in writing by MK Products, the reasonable

ower Supplies and Wire Feed Cabinet

Weldheads, Positioners, Prince XL and Prince X

Spool Guns, Python, CobraMAX, Cobra S

odules .......................................................80 da

epairs/Exchanges/Parts

- MK Products,Inc.,Irvine,California

ment furnished by MK

their respective manu-

year

1 yea

Spoolun, Prince SG Spool Guns,

0 da

Classifi cation of any item into the foregoing categories shall be at

he sole discretion of MK Products. Notifi cation of any failure must

be made in writin

A copy of the invoice showing the date of sale must accompany

products returned for warranty repair or replacement.

All equipment returned to MK Products for service must be properly

packa

ed to guard against damage from shipping. MK Products

will not be responsible for any damages resulting from shipping.

Normal surface transportation char

returned for warranty repair or replacement will be borne by MK

Products, except for products sold to foreign markets.

ANY EXPRESS WARRANTY NOT PROVIDED HEREIN AND ANY

MPLIED WARRANTY, GUARANTY, OR REPRESENTATION AS T

PERFORMANCE, AND ANY REMEDY FOR BREACH OF CONTRAC

WHICH, BUT FOR THIS PROVISION, MIGHT ARISE BY IMPLICATION,

PERATION OF LAW, CUSTOM OF TRADE, OR COURSE OF DEAL-

NG, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR OF FITNESS FOR PARTICULAR PURPOSE, WITH RESPECT TO

ANY AND ALL EQUIPMENT FURNISHED BY MK PRODUCTS, IS

EXCL

DED AND DISCLAIMED BY MK PRODUCTS

EXCEPT AS EXPRESSLY PROVIDED BY MK PRODUCTS IN WRIT-

NG, MK’s PRODUCTS ARE INTENDED FOR ULTIMATE PURCHASE

BY COMMERCIAL/INDUSTRIAL USERS AND FOR OPERATION BY

PERSONS TRAINED AND EXPERIENCED IN THE USE AND MAINTE

NANCE OF WELDING EQUIPMENT AND NOT FOR CONSUMERS OR

CONSUMER USE. MK PRODUCTS’ WARRANTIES DO NOT EXTEND

AND NO RE-SELLER IS AUTHORIZED TO EXTEND MK PROD-

CTS’ WARRANTIES TO ANY CONSUMER

USE OF OTHER THAN

CONSUMABLES, PARTS, AND ACCESSORIES MAY INVALIDATE

YOUR PRODUCT WARRANTY.

within 30 days of such failure.

es (one way) for products

Products, Inc

16882 Armstrong Ave

Irvine, CA 92606

el (949)863-123

Fax (949)474-142

ht © 2005 Lincoln Global Inc.

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

Sales and Service through Subsidiaries and Distibutors Worldwide

World's Leader in Welding and Cutting Products

ATE: May 1,

Loading...

Loading...