Page 1

AUTOMATED SOLUTIONS

24

VDC

Power REAM

™

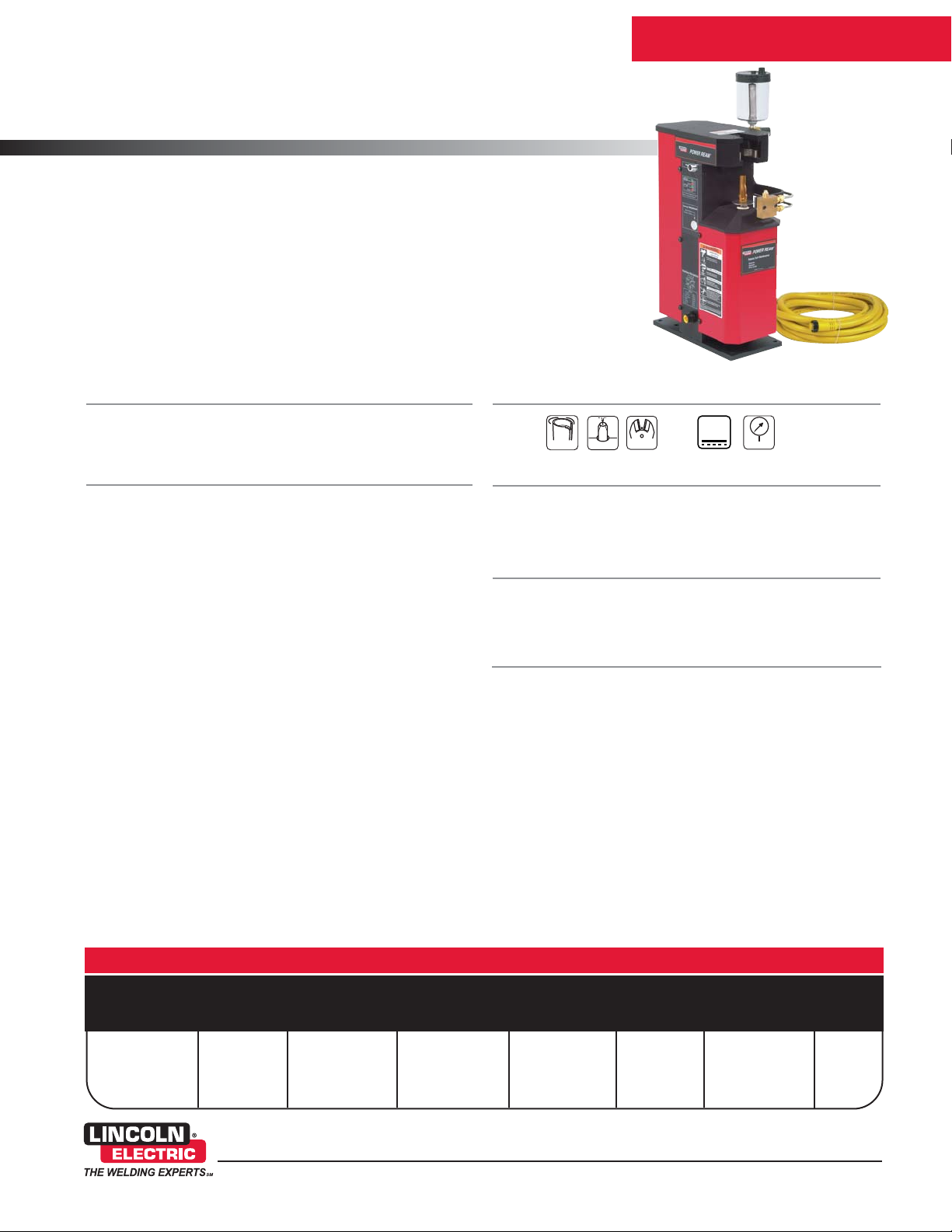

Robotic Torch Maintenance Center

Maintain high quality and productivity in your MIG robotic welding cell with the

Power REAM from Lincoln Electric. This automatic nozzle cleaning station removes

and reduces spatter accumulation for improved performance. The Power REAM

clamps the torch nozzle firmly in place while a constant torque air-motor drives a

high-speed reamer, cutting away spatter from the nozzle, contact tip, and gas

diffuser. A vortex action anti-spatter sprayer provides a radial spray pattern to

uniformly coat the inside of the nozzle for superior protection against weld spatter

buildup.

Processes

Reamer Sprayer Wire Clipper

Advantage Lincoln

• The Power REAM delivers features unmatched in current competitive

models. The design of the Power REAM offers a simple pushbutton

“No Error” programming technique, with the added advantage of

interactive process monitoring.

• The Power REAM is the only reamer to offer an automatic retry

feature. It detects when excessive spatter builds up, preventing the

reamer from fully extending into the nozzle. When this occurs, the

reamer retracts and automatically retries.

• Diamond-shaped clamp design provides a positive, self-centering

grip on all nozzle sizes.

• Input and output signals are easily configured, allowing easy

integration for all makes and models of robot systems.

• Maintenance features such as on-board diagnostic indicator lights

and error codes allow trouble-free setup, fast maintenance, and easy

replacement of standard components.

• One year warranty on parts and labor.

• Standard integrated wire clipper provides consistent wire stickout

and removes the ball end of the welding wire to provide superior arc

starting performance for .030”- 1/16” (0.8-1.6mm) solid wires.

Description

Output Input

Base Unit Includes

• Reaming Station (5/8” reamer bit included)

• Spray System

• Wire Cutter

• 20 ft. (6.0m) Input Cable

Recommended General Options

Power Ream Robot Cable, Remote Power Ream Reservoir Kit,

Reaming Bit, Anti-Spatter Fluid, Power Ream Utility Stand

Order

K2391-1 Power REAM

REAMER

SPRAYER

CUTTER

Pressure

TECHNICAL SPECIFICATIONS

Input Air Dimensions

Product Product Pressure and H x W x D Net Weight

Name Number Input Power Flow Rated Output Input Current inches (mm) lbs (kg)

with reservoir attached

Power REAM K2391-1 24V DC 80 PSI 1100 rpm, 0.65 HP 0.50A DC 24.9 x 8.9 x 13.2 62

15 SCFM (633 x 228 x 337) (28)

without reservoir

19.5 x 8.9 x 13.2

(495 x 228 x 337)

Publication E10.110 11/04

www.lincolnelectric.com

Page 2

WIRING

1. OV DC (WHT)

2. +24V DC (RED)

3. Complete (GRN)

4. Start (ORG)

5. Spray (BLK)

6. Error (BLU)

A CLOSER LOOK

Setup Sequencer

Press to Clamp

Hold to Raise

RESET

Clamp

Open

Closed

Lift

To p

Bottom

For flashing diagnostic codes,

refer to operator manual.

PERFORMANCE

The Power REAM controls the entire reaming process with its internal

microcontroller. Every aspect of the reaming cycle is commanded,

monitored and checked by the controller. The feedback signal to the

robot is a true “complete” signal indicating that the entire sequence has

been executed without error.

KEY CONTROLS

1 Fail-safe reset pushbutton overrides the

microcontroller’s commands to the cylinders

and sends them back to their home position.

2 Diagnostic LEDs are visible to an operator

and provide an indication of the position of

the air cylinders. If an error occurs, corresponding flash error codes make troubleshooting much easier.

3 “No Error” programming: The setup push-

button is used to sequence the reamer solenoids for easy programming of the correct

position the very first time. Subsequent

pressing of the button will raise the reaming

head (without spinning the ream bit), then

grip and release the nozzle.

4 Easy configuration of sinking vs. sourcing

inputs and outputs. No need to open the

case to set internal dip-switches during

installation!

-Error signal feedback to the robot: If an

error occurs in the process, then the

Power REAM returns to its home

position and sends an error signal to

the robot.

1

2

4

3

QUALITY AND RELIABILITY

• Powerful constant torque drive system provides non-stall capability.

The motor travels with the reaming bit, a design feature that aids

reliability and extends motor service life, up to 2.4 million cycles.

• Reaming bits are precision manufactured from tool steel with

titanium nitride coating.

• Dry-run feature helps prevent accidental damage to the unit.

• Synchronous timing belt does not allow slippage, avoiding excessive

belt wear.

• Wire cutter jaws designed for up to 90,000 cycles.

• One-year warranty on parts and labor.

Power REAM

[2]

www.lincolnelectric.com

Page 3

RECOMMENDED OPTIONS

GENERAL OPTIONS

Power Ream Robot Cable

20 feet (6.0m) replacement control cable.

Reamer side has a thread on connector.

Controller side has stripped wires for

connection to a terminal strip.

Order K2433-1

Remote Power Ream Reservoir Kit

Includes mounting bracket and fittings to

remount the anti-spatter spray reservoir

from the top of the reamer to another

location within the robotic cell.

Order K2434-1

Reaming Bit 1/2" (12mm)

Spatter reaming bit for a 1/2" I.D.

gun nozzle.

Order KP2435-1

Anti Spatter Fluid

1 Gallon

Order KP2457-1

Power Ream Utility Stand

Lifts Power Ream to convenient

work height.

Order L10412-51

Reaming Bit, 5/8" (15.5mm)

Spatter reaming bit for a 5/8" (15.5mm)

I.D. gun nozzle.

Order KP2435-3

Reaming Bit, 3/4" (19mm)

Spatter reaming bit for a 3/4" (19mm)

I.D. gun nozzle.

Order KP2435-5

[3]

Power REAM

www.lincolnelectric.com

Page 4

POWER REAM ORDER FORM

PRODUCT DESCRIPTION ORDER NUMBER QUANTITY PRICE

POWER REAM K2391-1

RECOMMENDED GENERAL OPTIONS

Power Ream Robot Cable, 20 ft. (6.1m) K2433-1

Remote Power Ream Reservoir Kit K2434-1

Reaming Bit, 1/2" (12mm), w/ Washer KP2435-1

Reaming Bit, 5/8" (15.5mm), w/ Washer KP2435-3

Reaming Bit, 3/4" (19mm), w/ Washer KP2435-5

Anti Spatter Fluid, 1 Gallon KP2457-1

Power Ream Utility Stand L10412-51

TOTAL:

CUSTOMER ASSISTANCE POLICY

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the needs of our

customers and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric for advice or information about their use of our products. We respond to our customers based

on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or

advice. We expressly disclaim any warranty of any kind, including any warranty of fitness for any customer’s particular purpose, with respect to such information or advice. As a matter of

practical consideration, we also cannot assume any responsibility for updating or correcting any such information or advice once it has been given, nor does the provision of information or

advice create, expand or alter any warranty with respect to the sale of our products.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility of the

customer. Many variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change — This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

THE LINCOLN ELECTRIC COMPANY

22801 St. Clair Ave., Cleveland, OH 44117-1199 • 216.481.8100 • www.lincolnelectric.com

Loading...

Loading...