Page 1

IM3056

11/2017

REV01

LGA Interface

OPERATOR’S MANUAL

ENGLISH

Lincoln Electric Bester Sp. z o.o.

ul. Jana III Sobieskiego 19A, 58-263 Bielawa, Poland

www.lincolnelectric.eu

Page 2

English English

1

Declaration of conformity

Lincoln Electric Bester Sp. z o.o.

Declares that the device:

K14140-1 LGA Interface – PROFINET

K14140-2 LGA Interface – DEVICENET

K14140-3 LGA Interface – PROFIBUS

conforms to the following directives:

2014/30/CE

and has been designed in compliance with the

following standards:

EN 60974-10:2014

15.11.2017

Piotr Spytek

Operations Director

Lincoln Electric Bester Sp. z o.o., ul. Jana III Sobieskiego 19A, 58-263 Bielawa, Poland

07/11

Page 3

English English

2

12/05

THANKS! For having chosen the QUALITY of the Lincoln Electric products.

Please Examine Package and Equipment for Damage. Claims for material damaged in shipment must be notified

immediately to the dealer.

For future reference record in the table below your equipment identification information. Model Name, Code &

Serial Number can be found on the machine rating plate.

Model Name:

………………...…………………………….…………………………………………………………………………………………..

Code & Serial number:

………………….……………………………………………….. …………………………………………………….……………..

Date & Where Purchased:

…………………………………………………………………... ……………………….…………………………………………..

ENGLISH INDEX

Technical Specifications .................................................................................................................................................. 3

Electromagnetic Compatibility (EMC) .............................................................................................................................. 3

Safety .............................................................................................................................................................................. 4

Introduction ...................................................................................................................................................................... 5

Installation and Operator Instructions .............................................................................................................................. 5

Appendix ........................................................................................................................................................................ 18

WEEE ............................................................................................................................................................................ 21

Spare Parts .................................................................................................................................................................... 21

Authorized Service Shops Location ............................................................................................................................... 21

Electrical Schematic ...................................................................................................................................................... 21

Page 4

English English

3

Technical Specifications

NAME INDEX

LGA Interface – PROFINET

LGA Interface – DEVICENET

LGA Interface – PROFIBUS

K14140-1

K14140-2

K14140-3

INPUT

Input Voltage U1 Input Amperes I1 EMC Class

40 Vdc 0.2 A A

DIMENSION

Weight Height Width Length

0.5 kg 170 mm 140 mm 50 mm

Protection Rating Operating Temperature Storage Temperature

IP20 from -10°C to +40°C from -25°C to 55°C

Electromagnetic Compatibility (EMC)

01/11

This machine has been designed in accordance with all relevant directives and standards. However, it may still generate

electromagnetic disturbances that can affect other systems like telecommunications (telephone, radio, and television) or

other safety systems. These disturbances can cause safety problems in the affected systems. Read and understand

this section to eliminate or reduce the amount of electromagnetic disturbance generated by this machine.

This machine has been designed to operate in an industrial area. To operate in a domestic area it is

necessary to observe particular precautions to eliminate possible electromagnetic disturbances. The

operator must install and operate this equipment as described in this manual. If any electromagnetic

disturbances are detected the operator must put in place corrective actions to eliminate these disturbances

with, if necessary, assistance from Lincoln Electric.

Before installing the machine, the operator must check the work area for any devices that may malfunction because of

electromagnetic disturbances. Consider the following.

Input and output cables, control cables, and telephone cables that are in or adjacent to the work area and the

machine.

Radio and/or television transmitters and receivers. Computers or computer controlled equipment.

Safety and control equipment for industrial processes. Equipment for calibration and measurement.

Personal medical devices like pacemakers and hearing aids.

Check the electromagnetic immunity for equipment operating in or near the work area. The operator must be sure

that all equipment in the area is compatible. This may require additional protection measures.

The dimensions of the work area to consider will depend on the construction of the area and other activities that are

taking place.

Consider the following guidelines to reduce electromagnetic emissions from the machine.

Connect the machine to the input supply according to this manual. If disturbances occur if may be necessary to take

additional precautions such as filtering the input supply.

The output cables should be kept as short as possible and should be positioned together. If possible connect the

work piece to ground in order to reduce the electromagnetic emissions. The operator must check that connecting

the work piece to ground does not cause problems or unsafe operating conditions for personnel and equipment.

Shielding of cables in the work area can reduce electromagnetic emissions. This may be necessary for special

applications.

WARNING

EMC classification of this product is class A in accordance with electromagnetic compatibility standard EN 60974-10 and

therefore the product is designed to be used in an industrial environment only.

WARNING

The Class A equipment is not intended for use in residential locations where the electrical power is provided by the public

low-voltage supply system. There can be potential difficulties in ensuring electromagnetic compatibility in those locations,

due to conducted as well as radio-frequency disturbances.

Page 5

English English

4

Safety

01/11

WARNING

This equipment must be used by qualified personnel. Be sure that all installation, operation, maintenance and repair

procedures are performed only by qualified person. Read and understand this manual before operating this equipment.

Failure to follow the instructions in this manual could cause serious personal injury, loss of life, or damage to this

equipment. Read and understand the following explanations of the warning symbols. Lincoln Electric is not responsible

for damages caused by improper installation, improper care or abnormal operation.

WARNING: This symbol indicates that instructions must be followed to avoid serious personal injury,

loss of life, or damage to this equipment. Protect yourself and others from possible serious injury or

death.

READ AND UNDERSTAND INSTRUCTIONS: Read and understand this manual before operating

this equipment. Arc welding can be hazardous. Failure to follow the instructions in this manual could

cause serious personal injury, loss of life, or damage to this equipment.

ELECTRIC SHOCK CAN KILL: Welding equipment generates high voltages. Do not touch the

electrode, work clamp, or connected work pieces when this equipment is on. Insulate yourself from

the electrode, work clamp, and connected work pieces.

ELECTRICALLY POWERED EQUIPMENT: Turn off input power using the disconnect switch at the

fuse box before working on this equipment. Ground this equipment in accordance with local electrical

regulations.

ELECTRICALLY POWERED EQUIPMENT: Regularly inspect the input, electrode, and work clamp

cables. If any insulation damage exists replace the cable immediately. Do not place the electrode

holder directly on the welding table or any other surface in contact with the work clamp to avoid the

risk of accidental arc ignition.

ELECTRIC AND MAGNETIC FIELDS MAY BE DANGEROUS: Electric current flowing through any

conductor creates electric and magnetic fields (EMF). EMF fields may interfere with some

pacemakers, and welders having a pacemaker shall consult their physician before operating this

equipment.

CE COMPLIANCE: This equipment complies with the European Community Directives.

ARTIFICIAL OPTICAL RADIATION: According with the requirements in 2006/25/EC Directive and

EN 12198 Standard, the equipment is a category 2. It makes mandatory the adoption of Personal

Protective Equipments (PPE) having filter with a protection degree up to a maximum of 15, as

required by EN169 Standard.

FUMES AND GASES CAN BE DANGEROUS: Welding may produce fumes and gases hazardous to

health. Avoid breathing these fumes and gases. To avoid these dangers the operator must use

enough ventilation or exhaust to keep fumes and gases away from the breathing zone.

ARC RAYS CAN BURN: Use a shield with the proper filter and cover plates to protect your eyes from

sparks and the rays of the arc when welding or observing. Use suitable clothing made from durable

flame-resistant material to protect you skin and that of your helpers. Protect other nearby personnel

with suitable, non-flammable screening and warn them not to watch the arc nor expose themselves to

the arc.

WELDING SPARKS CAN CAUSE FIRE OR EXPLOSION: Remove fire hazards from the welding

area and have a fire extinguisher readily available. Welding sparks and hot materials from the welding

process can easily go through small cracks and openings to adjacent areas. Do not weld on any

tanks, drums, containers, or material until the proper steps have been taken to insure that no

flammable or toxic vapors will be present. Never operate this equipment when flammable gases,

vapors or liquid combustibles are present.

WELDED MATERIALS CAN BURN: Welding generates a large amount of heat. Hot surfaces and

materials in work area can cause serious burns. Use gloves and pliers when touching or moving

materials in the work area.

SAFETY MARK: This equipment is suitable for supplying power for welding operations carried out in

an environment with increased hazard of electric shock.

Page 6

English English

5

CYLINDER MAY EXPLODE IF DAMAGED: Use only compressed gas cylinders containing the

correct shielding gas for the process used and properly operating regulators designed for the gas and

pressure used. Always keep cylinders in an upright position securely chained to a fixed support. Do

not move or transport gas cylinders with the protection cap removed. Do not allow the electrode,

electrode holder, work clamp or any other electrically live part to touch a gas cylinder. Gas cylinders

must be located away from areas where they may be subjected to physical damage or the welding

process including sparks and heat sources.

The manufacturer reserves the right to make changes and/or improvements in design without upgrade at the same time

the operator’s manual.

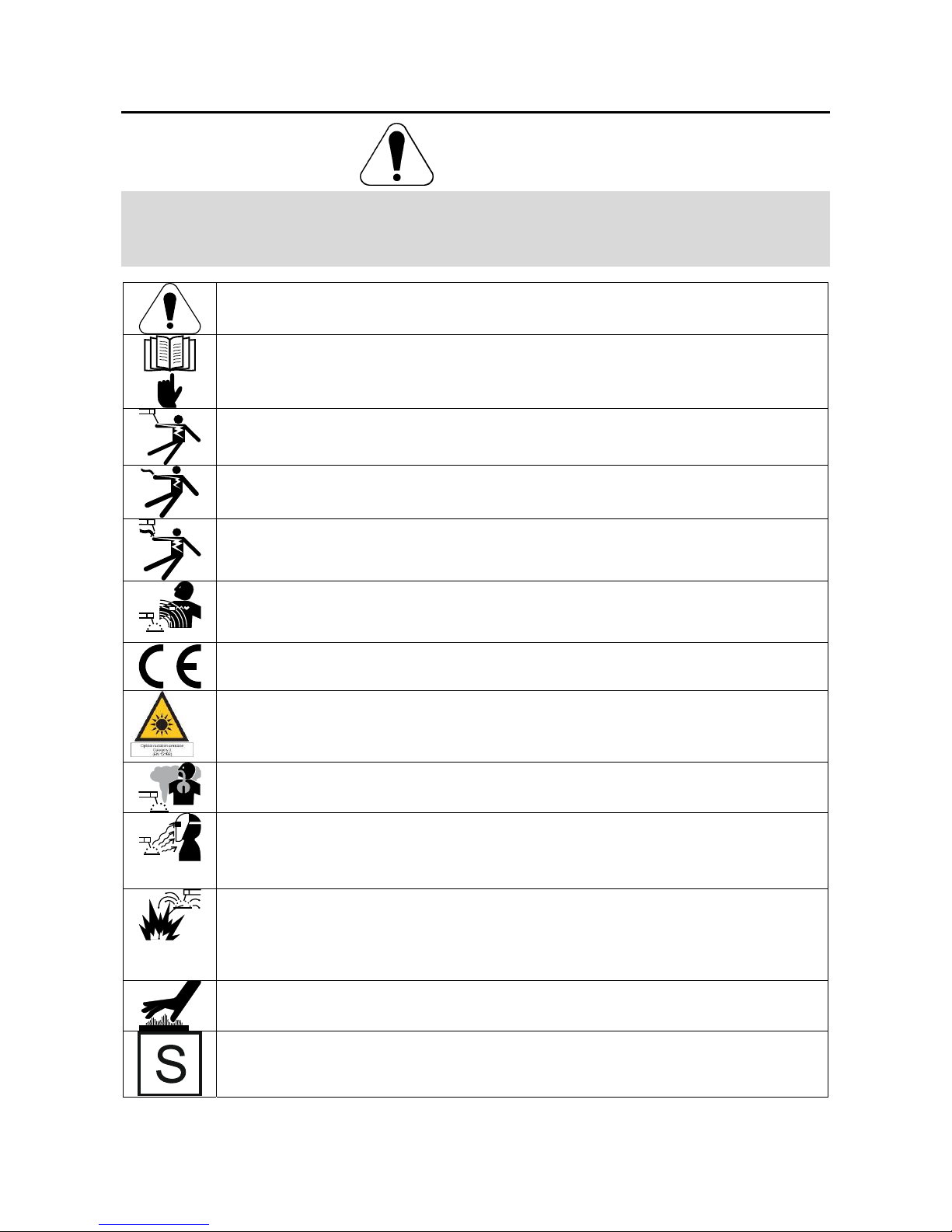

Introduction

LGA Interface is an add-on module intended to be used

with Lincoln Electric Arclink welders such as Power

Wave R450 and S500,. The module attaches to the

front of a machine in place of a User Interface. The

LGA Interface add-on contains a Lincoln Electric

L16616 Anybus board with an HMS Anybus

CompactCom M30 module.. LGA works as a gate

between an industrial network and the welder’s internal

Arclink network. It also works as the welding sequencer

for the welder and is capable of storing up to 1000

welding jobs. A welding job contains all necessary

welding parameters: from PostFlow, to Striking,

Ramping up, Welding, Ramping down, Crater fill,

Burnback operation, and Post Flow.

Configuration of the job can be done in one of two

different ways, using the LGA Control Panel or through

the Power Wave Manager software. The jobs are saved

on the L16616 board in the LGA Interface module.

When replacing a LGA Interface module or this board,

the Jobs should be backed up first, and then restored

when the new module/board is installed.

The LGA Interface is designed for ease of configure

and use with a PLC. There are two modes of operation,

Job Mode and Job Mode with Parameter Inputs. Each

of these modes of operation requires that 12 bytes of

data be sent to and from the Master to the welder. In its

simplest implementation, Job Mode, all that is required

to initiate welding is to send over a valid Job Number

and then to set the Trigger input bit to true. All the

welding parameters are contained from the Job setup

parameters. With Job Mode with Parameters Inputs, the

weld state inputs are obtained from IO inputs from the

PLC interface to the welder. In this mode of operation,

the Master has direct control of the weld state welding

parameters and these inputs parameters can be

changed during the weld.

LGA is designed to work in different welding

configurations. The LGA will control turn on and off the

Wire Drive motor and Gas output automatically during

the welding sequence.

Installation and Operator Instructions

Read this entire section before installation or operation

of the machine.

Connection Digram

Figure 1

Note: All welding parameters are stored in the LGA

Interface and it can work without LGA Control Panel

connected. It is recommended to connect/disconnect

LGA Control Panel when Power Source is switched off.

Connecting/disconnecting LGA Control Panel during

operation will stop welding process and restart the

system.

Requirements

A Robotic Wire Drive must be present or the Module

will go fatal with a 0x5211 (Required Object Not

Found), with an instance code of 1. A semiautomatic wire drive will not work.

A Power Wave Control board (“G4800”, “G6683”, or

“L11088”) must be present or the Module will go

fatal with a 0x5211 (Required Object Not Found),

with an instance code of 2.

If an Autodrive SA or S is found, the Module will go

fatal with a 0x5611 (Arclink Bad Object).

Page 7

English English

6

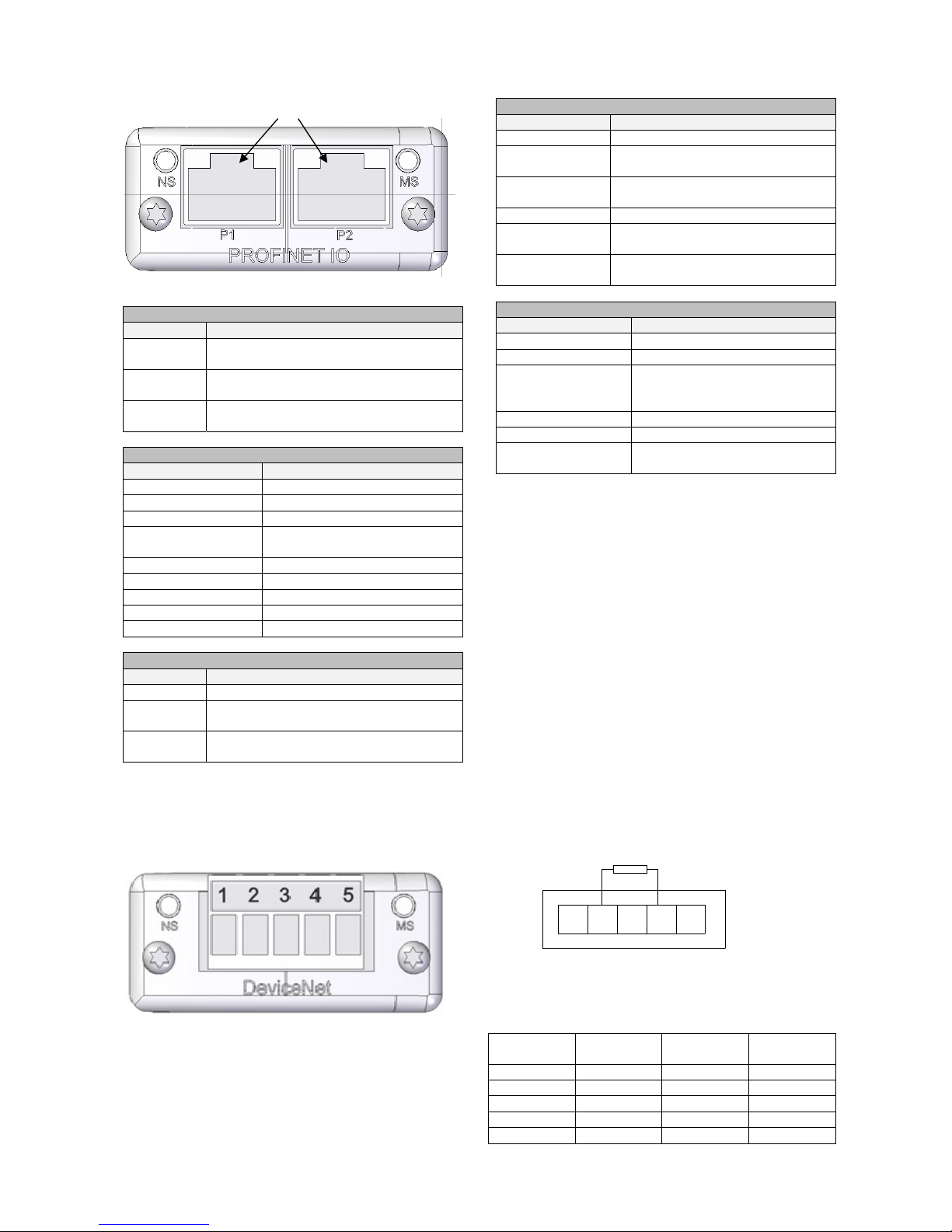

Anybus Module LEDs - PROFINET

Figure 2

NS – Network Status

State Indication

Off No Power/No connection with IO

Controller

Green Online. Connection with IO Controller

Established, in Run State

Green,

Flashing

Online. Connection with IO Controller

Established, in Stop State

MS – Module Status

State Indication

Off Not Initialized

Green Operating in Normal Condition

Green (1 flash) Diagnostic Event Present

Green (2 flashes) Blink, Used by tools to Identify

the node on network

Red Exception Error

Red, (1 flash) Configuration Error

Red, (2 flashes) IP Address Error (Not Set)

Red, (3 flashes) Station Name Error (Not Set)

Red, (4 flashes) Internal Error.

Link/Activity

State Indication

Off No Link, No Communication Present

Green Link, Ethernet link Established, No

Communication Present

Green,

flickering

Activity, Ethernet link Established,

Communication Present

Cable

Use PROFINET cable 4x22AWG PVC GREEN.

AnyBus Modules LEDs & Connector

IO - DeviceNet

Figure 3

IO Connector:

Pin 1 = V Pin 2 = CAN L

Pin 3 = Drain

Pin 4 = CAN H

Pin 5 = V+

NS – Network Status

State Indication

Off Not On-Line/ No Power

Green On-Line, one or more connections

are Established

Flashing Green

(1Hz)

On-Line, no connections

established

Red Critical link failure

Flashing Red

(1Hz)

One or more connections timed-out

Alternating

Red/Green

Self Test

MS – Module Status

State Indication

Off No Power

Green Operating in Normal Condition

Flashing Green

(1Hz)

Missing or incomplete

configuration, device needs

commissioning

Red Unrecoverable Fault(s)

Flashing Red (1Hz) Recoverable Fault(s)

Alternating

Red/Green

Self Test

Power Supply

The total number of units that can be connected to the

DeviceNet bus is limited by the maximum current that

the power supply can deliver to the bus. Maximum

current consumption per unit is specified in the

DeviceNet specification to 750mA. If e.g. the supply can

deliver 9A and all units consume maximum current, the

maximum numbers of units allowed on the bus are 12

(12x750mA=9A).

The anybus CompactCom 30 DeviceNet module accepts

11 – 25V on the industrial network side of the module.

Maximum current consumption at 11 – 25V is 36 – 38

mA/module.

PE Connection

Terminating Resistors

The termonating resistor reduces reflections of the

communication signals on the network.

You must attach a terminating resistor equal to 121

ohms, 1%, 1/4W or greater wattage, to each end of the

trunk cable. You must connect these resistors directly

across the blue and white wires of the DeviceNet™

cable.

1

23

4

5

V-

CAN L

Drain

CAN H

V-

Parameters of the Cable

Use only Devicenet™ media that meet or exceed ODVA

specifications.

Wire Colo

r

Wire

Identity

Usage

Round

Usage Flat

White CAN_H Signal Signal

Blue CAN_L Signal Signal

Bare Drain Shield n/a

Black V- Power Power

red V+ Power Power

Link Activity

Page 8

English English

7

You can connect components using three cable options:

Use this cable Fo

r

Round (thick) The trunk line on the DeviceNet™

network with a nominal outside

diameter of 12.2mm. You can also

use this cable for drop lines.

Round (mid) The trunk line on the DeviceNet™

network where smaller cable

diameters and smaller bend radii are

required. Its outside diameter is

specified by the vendor. This cable

can also be used for drop lines.

Round (thin) The drop line connecting devices to

the main line with an outside

diameter of 6.9mm. This cable has a

smaller diameter and is more flexible

than thick cable. You can also use

this cable for the trunk line.

Note: these generic cable types are available in a variety

of different offerings such as FLEX, HAZ-DUTY, CLASS

I (600V), UV RESISTANT, etc.

All deviceet™ cabling components selected shall be

suitable for the environment in which they are

installed and in particular, corrosion resistance, IP

rating and Ultra Violet stabilization.

NOTE: DeviceNet™ cables are available in a variety

of different types including: High Flexibility,

Hazardous duty, Class I – 600 Volt, UV resistant.

Consideration must be also given to environmental

protection of the cable components when individual

nodes are removed for maintenance and for testing.

Excessive bending of DeviceNet™ cables can

reduce their ability to meet the

DeviceNet™specification. Standard thick cables

have a bending radius of greter than 75mm.

standard thin cables have a bending radius of

greater than 50mm.

Round shielded cable (thick, mid and thin) contains

five wires: one twisted pair (red and black) for 24V

dc power, one twisted pair (blue and white) for

signal, and a drain wire (bare).

Network Topology

Understand the Topoly.

The DeviceNet™ cable system uses a trunk/drop line

topology.

Trunk line

Drop Line

Device or node

Terminating resistor

You must terminate the trunk line at ends with 121

Ohms, 1%, 1/4 W terminating resistors.

Determine the Maximum Trunk Line

Distance

The maximum cable distance is not necessary the trunk

length only. It is the maximum distance between any two

devices.

The distance between any two points must not exceed

the maximum cable distance allowed for the data rate

used.

Data rate Maximum

distance

(thick cable)

Maximum

distance

(mid cable)

Maximum

distance

(thin cable)

125k bit/s 500m 300m 100m

250k bit/s 250m 250m 100m

500k bit/s 100m 100m 100m

Determine the Cumulative Drop Line

Lenght

The data rate you choose determines the maximum

trunk line and the cumulative drop line lengths.

The maximum cable distance from any device on a

branching drop line to the trunk line is 6m.

The cumulative drop line length refers to the sum of all

drop lines, thick, thin, or mid cable, in the cable system.

This sum cannot exceed the maximum cumulative length

allowed for the data rate used.

Data rate Cumulative drop line length

125k bit/s 156m

250k bit/s 78m

500k bit/s 39m

AnyBus Module LEDs - Profibus

Figure 4

Re

f

Item

1 Operation Mode

2 Status

3 Profibus Connector, 9-pin

female D-Sub

Page 9

English English

8

OP – Operation Mode

OP – Operation Mode

State Indication Comments

Off Not on line/ no

power

-

Green Online, data

exchange

-

Flashing

Green

Online, clear -

Flashing

Red (1flash)

Parameterization

error

See

"Parameterization

Data Handing"

Flashing

Red (2

flashes)

PROFIBUS

Configuration error

See

"Configuration

Data Handing"

OP – Operation Mode

State Indication

Off Not On-Line/ No Power

Green Data Exchange

Flashing Green Clear

Red Critical link failure

Flashing Red (1

flash)

Parameterization Data Handling

Flashing Red (2

flashes)

Configuration Data Handling

ST - Status

ST - Status

State Indication Comments

Off Not initialized Anybus

state="SETUP" or

"NW_INIT"

Green Initialized Anybus module has

left the "NW_INIT"

state

Flashing

Green

Initialized,

diagnostic

event(s)

present

Extended diagnostic

bit is set

Red Exception error Anybus

state="EXCEPTION"

ST –Status

State Indication

Off Not Initialized

Green Initialized

Flashing

Green

Initialized, Diagnostic Event

Present

Red Exception Error

Profibus Connector (DB9F)

Pin Signal Description

1 - 2 - 3 B Line Positive RxD/TxD,

RS485 level

4 RTS Request to send

5 GND Bus Ground (isolated)

6 +5V Bus Output +5V termination power

(isolated, short-circuit

protected)

7 - 8 A Line Negative RxD/TxD,

RS485 level

9 - Housing Cable Shield Internally connected to

the Anybus protective

earth via cable shield

filters according to the

PROFIBUS standard.

Cable specification

it is recommended to use cable Type A

Type A Technical specification:

Impedance: 35 up to 165 Ohm at frequencies from 3

to 20 Mhz.

Cable capacity: < 30 pF per meter.

Core diameter: > 0,34 mm², corresponds to AWG

22.

Cable type: twisted pair cable. 1x2 or 2x2 or 1x4

lines.

Resistance: < 110 Ohm per km.

Signal attenuation: max. 9 dB over total length of

line section.

Shielding: CU shielding braid or shielding braid and

shielding foil.

Max. Bus length: 200 m at 1500 kbit/s, up to 1,2 km

at 93,75 kbit/s.

Terminators

Terminators at both ends of the cable must be enabled.

Termination of the bus prevents signal reflections on the

PROFIBUS cable. Wrong or missing termination results

in transmission errors when the worst case result is that

the communication link is lost.

Page 10

English English

10

I/O Format

I/O from Welder to Master

Cyclic I/O From Welder to Master

Byte B7 B6 B5 B4 B3 B2 B1 B0

0 Misc

Module

Fault

Wire Stick WC Fault Water

Fault

WD Fault Gas Fault Touch

Sense

Arc

Detect

1 Anybus

Fault

PM Limit PM Fault Weld

Complete

Limit Error

2 Weld Sequencer Current State

3

4 Voltage Feedback, Low Byte (In Volts with 1 implied decimal places)

5 Voltage Feedback, High Byte

6 Current Feedback, Low Byte (In Amps with 1 implied decimal places)

7 Current Feedback, High Byte

8 Wire Drive Motor Current, Low Byte (Signed value In Amps with 2 implied decimal places)

9 Wire Drive Motor Current, High Byte

10 Wire Feed Speed Feedback, Low Byte

11 Wire Feed Speed Feedback, High Byte

I/O Bit Description to Master

Item Description

Arc Detect A True value indicates sufficient arc voltage and arc current have been detected. Arc voltage and

arc current levels are addicted to mode. When there is no longer sufficient Arc current and Arc

voltage then go to False.

Touch Sensed A True value indicates that the Touch Sense detected a short between the work piece and the

electrode.

Gas Fault A True value indicates there is a failure in the gas controller. If a fault occurs the weld Power Wave

will turn the output off and welding will not be possible until the problem is corrected and the fault

is cleared.

WD Fault Asserted when there is a fault in the Wire Drive. This fault occurs also when Shutdown input is

open on the external I/O connector Ref. Power Wave / Power Feed Wire Feeder Interconnections

section describing External I/O Connector in the Operator’s Manual. If a fault occurs the weld

Power Wave will turn the output off and welding will not be possible until the problem is corrected

and the fault is cleared.

Water Fault True when Arclink Water Cooler reports an error. If a fault occurs the weld Power Wave will turn

the output off and welding will not be possible until the problem is corrected and the fault is

cleared.

WC Fault True when there is a Weld Controller fault. Refer to “Troubleshooting” in the Operator’s Manual

for a list of possible errors. If a fault occurs the weld Power Wave will turn the output off and

welding will not be possible until the problem is corrected and the fault is cleared.

Wire Stick True value indicates that after the welding output is turned off there is a short between the

electrode and the workpiece. This will stay true until the welding output is turned on and the error

is cleared or if a Touch Sense Command is asserted and the short has been cleared. This check

is disabled by default and be enabled using the option “Enable Wire Stick Check”.

Misc Module

Fault

True value indicates that a module, like the Advance Module, STT Switch, High Frequency Switch

has a fault.

Limit Error Indicates that one of the Welding Job Parameters is out of limits. This will not stop welding

process.

Weld

Complete

Indicates that the weld has completed (subsequent to the trigger going false) including any

downslope, crater, burnback and postflow times. Goes false when the next weld begins (trigger

going true).

PM Fault This bit is used to indicate that the Production Monitoring object is faulty, a common cause is that

the Production Monitoring object detected a limit error while welding and the Out of limit action

was set to Alarm Latch. This faulty condition must be cleared before welding; toggling the PM Flt

Reset bit to the welder should clear this condition.

PM Limit This bit is used to indicate that the Production Monitoring (PM) object detected a limit error. This

bit is clear automatically when the trigger input goes on or when the PM Flt Reset bit to the welder

goes on.

This bit is basically just a status item indicating a PM limit fault occurred, but depending on how

PM is configured, other behavior can occur when this bit goes on. If PM is set to Fault System,

then PM will shut the Power Source output off automatically when a limit error occurs, this will

cause the LGA sequencer to fault and stop welding. If PM is set to Alarm Latch and a limit error

occurs, then the PM object will fault after the weld is over and welding can not resume until the PM

fault is cleared (see the PM Fault bit).

Anybus Fault This bit is used to indicate that the Anybus module has a fault. This includes selecting a job with

invalid Workpoint or Trim units, or selecting an invalid Job number.

Page 11

English English

11

Weld

Sequencer

Current State

This 4-bit field returns the state that the welding sequencer is currently in, where 0=Idle (Not

welding), 2=Preflow, 3=Strike, 4=Start, 5=Upslope, 6=Weld, 8=Downslope, 9=Crater,

10=Burnback, 11=Postflow, 12=Restrike.

Voltage

Feedback

Returns the Voltage feedback value. This value is in Volts with an implied decimal place.

Current

Feedback

Returns the Current feedback value. This value is in Amps with an implied decimal place.

WD Motor

Current

Feedback

Returns the Wire Drive Motor Current feedback value. This is a signed value In Amps with 2

implied decimal places. A negative value means that the motor is in reverse.

WFS

Feedback

Returns the Wire Feed Speed feedback value. The units depend on the setting of the option WFS

Feedback Units. This can be either in English (Inches per Minute) or in Metric (CM per Minute).

The default settings is Metric.

I/O from Master to Welder

I/O Format while in Job Mode

Cyclic I/O To Welder From Master

Byte B7 B6 B5 B4 B3 B2 B1 B0

0 Control Bit 1 Control Bit 0 Trigger

1 PM Flt

Reset

Weld

Disable

Touch

Sense

CI Rev CI Fwd Gas

Purge

2 Job Number (low byte)

3 Job Number (high byte)

4

5

6

7

8 Production Monitoring Profile Number (1 to 200)

9

10

11

Format while using I/O Parameter Inputs

Cyclic I/O To Welder From Master

Byte B7 B6 B5 B4 B3 B2 B1 B0

0 Control Bit 1 Control Bit 0 Trigger

1 PM Flt

Reset

Weld

Disable

Touch

Sense

CI Reverse CI Forward Gas

Purge

2 Job Number (low byte) 1 to 1000

3 Job Number (high byte)

4 WorkPoint, Low Byte 0 to 32767 (Low Limit to High Limit)

5 WorkPoint, High Byte

6 Trim, Low Byte 0 to 32767 (Low Limit to High Limit)

7 Trim, High Byte

8 Production Monitoring Profile Number (1 to 200)

9

10 Non-Synergic Welding Speed. Low Byte (0 – 3048 cm/min or 0 – 1200 IPM)

11 Non-Synergic Welding Speed, High Byte

Page 12

English English

12

I/O Bit Description to Welder

I/O Control Bits

Cyclic I/O to Welder Control Bits

Control Bit # Mode Description

1 0

0 0 Job Mode Uses Job Mode and all parameters from the stored settings.

0 1 Job Mode using

I/O Parameter

Inputs

Uses Job Mode, but welding parameters are from the inputs from the Cyclic I/O to

the welder. Note that the Trim might not be relevant for all weld modes.

1 0 N/A Reserved for future use.

1 1 N/A Reserved for future use.

Item Description

Trigger The trigger is used to enable/disable welding.

Can not trigger on when a cold inching input or when the Touch Sense Input is on. Trigger will only

come On when these inputs are off. If set Trigger to On when one of these are On, then when

these go off, must set Trigger to Off, then set Trigger back On. Before trigger on, make sure a valid

Job No is set.

Gas Purge Gas can be controlled directly by this bit if a preflow and postflow is desired. But Gas will come on

and go off according to the sequencer’s machine state; regardless of this bit if the Job is set to use

a Preflow/Postflow if the selected mode requires Gas.

Touch Sense This input will cause the power supply emit only a low current low voltage output used to detect a

short or zero voltage condition indicating that the wire has touched the workpiece. The Touch

Sense output bit is true when touching; false otherwise. This bit should not be set while the Trigger

input is true.

Weld Disable When bit is true in the idle state, this will prevent any welding. If this is turned on during welding and

“Enable Burnback on a Fault” is true, then weld sequencer will transition to the Burnback state and

then disable the weld controller preventing any welding. If this is turned on during welding and

“Enable Burnback on a Fault” is set to false, then the welding will be stopped immediately and the

weld controller will be disabled preventing any welding.

CI Fwd

CI Rev

Cold Inch Forward or Cold Inch in Reverse.

These inputs will cause the wire to “cold inch”. The direction is determined by the true bit (the

second bit set true is ignored). The wire feed speed is determined by the value of the Cold Inch

Speed on the Wire drive.

Note that these inch command inputs are ignored during welding (Trigger = true).

PM Flt Reset Production Monitoring Fault Reset. This bit is used when using Production Monitoring, to clear a

production monitoring fault or alarm.

Job Number This input to the welder is used to select the desired Job Number to weld with. The valid range is

from 1 to 1000. Note that there must be a valid job “programmed” for the inputted job number and

the programmed Job WorkPoint and Trim units must match the present units for these items in

order to weld.

Job Number can be changed many times during the weld. If a job numbers changes during

upsloping, upsloping will stop and the sequencer will go to the weld state. If a Job number changes

during downsloping, downsloping will stop, and the sequener will proceed to the next enabled end

state.

If a Job number is actually updated, any new welding settings will not take effect during the

welding. After the welding is complete, the job parameters will be updated with any new settings.

Page 13

English English

13

Operation of Module

There are two modes of operation for the module : Job

Mode and Job Mode with Parameter Inputs. The I/O

Control Bits on the Cyclic I/O to the welder controls

which of these modes are operational. The two modes of

operation assume that a “Job” or “Jobs” have been

preconfigured using a pendant or perhaps by the Power

Wave Manager.

A Job is basically the welding sequence that will

preformed when the trigger input is activated on the

Cyclic I/O. The selected job will select the welding wave

form (the weld mode), the welding parameters for the

wave form, and the welding sequence. The welding

sequence refers to things like ramping up or down,

performing a crater fill, burnback, etc (see the section on

LGA Weld Sequencer). During welding, the actual job

number can be changed at any time, however there are

some limitations of this, see the LGA Weld Sequencer,

Sequencer Notes.

Modes of Operation

Job Mode

This is the most basic mode of operation for the

interface. All what is required for a welding, provide that

the jobs have been setup already, is to set a valid Job

number, then assert the trigger bit. Then during welding

monitor the digital feedback bits for any faults or possible

issues like the Arc Detect bit not coming on. The

interface will automatically turn on the gas controller if a

weld mode “requires” gas and turn on the Wire Drive if

the weld mode uses wire and a wire drive is present.

Job Mode with Parameter Inputs

This mode of operation is similar to the Job Mode,

except for while in the Weld sequencer state (see LGA

Weld Sequencer). When in the Weld sequencer state,

the state wave form parameters will be set using I/O

coming from the interface instead of the parameters from

the Job setup. These I/O parameters can be changed as

many times as desired. If the Job is setup to perform

something like ramping or crater, it will still do it. If it is

desired for the interface to perform these functions, then

make sure that selected Job is not setup to perform

them. Note that the Trim and Non-Synergic WFS input

might not be relevant for all welding modes. The NonSynergic WFS is active for Non-Synergic wave forms

only. Note the actual internal units, limits, and decimal

places of the parameters can vary depending on the

welding mode. For example for Synergic pulse modes,

Trim controls “Trim” with engineer units from 0.50 to 1.50

with a midpoint of 1.00, but for Synergic CV modes, Trim

typically controls voltage that does not have a “midpoint”.

The parameters inputs for the Workpoint and Trim do not

use engineering units. These values range from 0 to

32767 where 0 will select the parameter low limit and

32767 will select the parameter high limit.

Weld Sequencer

The LGA Interface has a built in welding sequencer that

controls time and event related sequences of the

welding process and operation of standard peripherals

objects. For standardization purposes of application

descriptions, communicating case and effects

relationships, a generalized model (shown below) was

chosen for the sequencer. Sequencer states are shown

on Figure 5.

Figure 5

Not all these sequencer states need to be used for a

Job. For the Preflow, Up Slope, Down Slope, Crater,

Burnback, and Post Flow states, these states are

entered only if a state time is set for them. If their state

time is 0, then the state will be bypassed. For the most

basic welding, the only necessary states are Idle, Strike,

and Weld; these states are always enabled. For the

“welding” states (Strike, Upslope, Weld, Downslope,

Crater, and Burnback), each of these states has their

own parameters that control the wave form. For every

welding state that is used, the state’s control parameters

must be initialized before the welding. The only

exception to this rule is if Job mode with Parameter

Inputs is being used, then the welding state parameters

are obtained from the I/O parameters inputs.

Page 14

English English

14

Sequencer State Description

State Purpose Exit

Conditions

Equipment

State

IDLE

Ready to weld. 1) Trigger On Output: Off

Wire: Off

Gas: Off

PREFLOW

Gas purge before welding. 1) Preflow Timer

2) Trigger Off

Output: Off

Wire: Off

Gas: On

STRIKE

Allow arc to establish. This is a Non-synergic state where

Strike Speed is set independently of strike workpoint.

1) Arc Established

2) Strike Timer

3) Trigger Off

Output: On

Wire: On

Gas: On

START

Allow process to stabilize following initial arc

establishment and prior to steady state.

1) Start Timer

2) Trigger Off

3) Arc Out

Output: On

Wire: On

Gas: On

UPSLOPE

Welding parameters are ramped (linearly) to their steady

state welding (WELD) values.

1) Upslope Timer

2) Trigger Off

3) Arc Out

Output: On

Wire: On

Gas: On

WELD

Steady welding state. 1) Trigger Off

2) Arc Out

Output: On

Wire: On

Gas: On

DOWNSLOPE

Welding parameters are ramped (linearly) from their

steady state welding values to arc ending values.

1) Downslope Timer

2) Trigger On

3) Arc Out

Output: On

Wire: On

Gas: On

CRATER

Allows the welding crater to be “filled”. 1) Crater Timer

2) Trigger On

3) Arc Out

Output: On

Wire: On

Gas: On

BURNBACK

Allows for proper wire stick out following a weld. 1) Burnback Timer

2) Trigger On

3) Arc Out

Output: On

Wire: Off

Gas: On

POSTFLOW

Gas purge after welding. 1) Postflow Timer

2) Trigger On

Output: Off

Wire: Off

Gas: On

RESTRIKE

Allows the arc to re-establish if extinguished

unexpectedly during the weld. This is a Non-synergic

state where “Restrike Speed” is set independently of

strike workpoint.

1) Arc Established

2) Restrike Timer

3) Trigger Off

Output: On

Wire: On

Gas: On

Page 15

English English

15

Sequencer State Transitions

LGA Weld Sequencer State Transitions

Current State Trigger On Trigger Off Arc On Arc Off Time Expires

(0) Idle If Preflow time goes

to Preflow, else go

to Strike.

- - - -

(2) Preflow

-

Go to Idle -

-

When time expires,

go to Strike

(3) Strike

-

Go to Idle If Start time go to

Start, else if

Upslope time go

to Upslope , else

go to Weld

-

If Strike fault timer

set, go to Idle

(4) Start

-

if Burnback

time go to BB,

else if

Postflow time

go to

Postflow, else

go to Idle

-

Go to

ReStike

if Upslope time go

to Upslope , else go

to Weld

(5) UpSlope

-

if Burnback

time go to BB,

else if

Postflow time

go to

Postflow, else

go to Idle

-

Go to

ReStike

Go to Weld

(6) Weld

-

If Downslope

time go to

D.S., else if

Crater time go

to Crater,

else if

Burnback time

go to BB, else

if Postflow

time go to

Postflow, else

go to Idle

-

Go to

ReStike

-

(8) DownSlope Go to Weld

- -

if Postflow

time go to

Postflow ,

else go to

Idle

if Crater time go to

Crater, else if

Burnback time go to

BB, else if Postflow

time go to Postflow,

else go to Idle

(9) Crater Go to Weld

- -

if Postflow

time go to

Postflow ,

else go to

Idle

if Burnback time go

to BB, else if

Postflow time go to

Postflow, else go to

Idle

(10) Burnback Go to Weld

- -

if Postflow

time go to

Postflow ,

else go to

Idle

if Postflow time go

to Postflow , else go

to Idle

(11)PostFlow Go to Strike

- - -

Go to Idle

(12) ReStrike

-

if Postflow

time go to

Postflow, else

go to Idle

Go back to

previous state

for the Start &

Weld states, for

the Upslope

state go to Weld

-

Go to Idle

Page 16

English English

16

Sequencer Notes

Item Description

States The LGA Weld Sequencer supports the Idle, Preflow, Strike, Start, Upslope, Weld,

Downslope, Crater, Burnback, Postflow, and Restrike states.

State Numbers The state numbers follow the standard Weld Sequencer state numbering – Idle (0),

Preflow (2), Strike (3), Start (4), Upslope (5), Weld (6), Downslope (8), Crater (9),

Burnback (10), Postflow (11), and Restrike (12) states. This number is used only for

certain events which might be logged when there is an issue.

Have a Downslope time,

but no Crater time.

If have a Downslope Time, but no Crater time, then the Downslope time will be divided

between the Downslope and Crater states.

Switching Jobs If change Jobs numbers during a state with a State timer, then the new settings will be

switched too, but the interface will continue using the old state timer from the last Job

# for the current weld.

Upslope/Downslope The time between slope updates is fixed at 100ms and the total slope time will always

be rounded off to a 100ms. Always one step will be done, even if the slope time is less

than 100ms.

The number of slope steps that are done is equal to the slope time divide by 100, with

the reminder dropped. For example if a time of 240 ms is inputted, then 2 steps will be

done.

WorkPoint, Trim, and WFS will be sloped.

Sloping can go in a positive or negative direction for both Upslope and Downslope.

Upslope goes from the Start settings to the Upslope settings.

Downslope goes from the Downslope Settings to the Crater settings.

If Job numbers will be change during upsloping, upsloping will stop and it will go to the

welding state.

If Job numbers will be change during downsloping, downsloping will stop, and it will

proceed to the next enabled end state.

Page 17

English English

17

Miscellanous Notes

Item Description

WorkPoint in Amps, Trim

in Volts

These settings should be set to the desired values in the weld control before any jobs

are setup. Once a job(s) is setup, these values must not be changed, else the job will

be considered invalid. If these values are changed, then the welder must be reset in

order to welding with the LGA Interface.

Sending an Invalid Job If an invalid job is sent to the board, it will be accepted and saved, but you can not

weld with it. An invalid job is a job that has a non-existent welding mode or a

WorkPoint or Trim value with the wrong units.

Updating the current Job

Number in use.

If an updated Job is download to the board, any new setting will not take effect if that

Job is currently in use and welding. When the welding goes to idle, it will be updated.

If weld mode uses gas If the welding mode has the Gas as a required, the gas will be turned on when the

Preflow or Strike is entered first. So the user does not have to turn on the Gas Purge

bit on the I/O.

Using GTAW processes When a GTAW process is currently selected and a Tig Gas object is detected in the

system, then this Gas solenoid will be enabled when the Sequencer turns on gas or

when the I/O Gas Purge bit is enabled. When a non-GTAW process is used, the gas

solenoid found on the Wire Drive will be enabled. If a gas solenoid is on and a new job

is selected and the process type is changed, the previous turned gas solenoid will

stay on. After this solenoid is turned off, then the correct solenoid type will be turned

on when commanded.

Setting Feedback Rate Used to set the feedback rate in the Weld Controller for the Current and Voltage and

the WFS feedback rate in the Wire Drive. This takes effect only after reset. If this

value is greater than the present setting, then no update will be done.

Enable Wire Stick Check After change this setting the system must be reset in order to take effect.

Enable Burnback on a

Fault

If Enable Burnback on a Fault is false, then if welding and a fault occurs, the

sequencer should turn everything off and go to the Idle state immediately. If the

Enable Burnback on a Fault is True, then if welding and a fault occurs, the sequencer

will transition to the Burnback state if a Burnback state time is set. If it was the Weld

controller that actually faulted, it stil will transition to the Burnback state, but the weld

output will be off so no actual burnback will be done.

Production Monitoring

Profile

The LGA Interface can be setup to select the Production Monitoring Profile number

when a job is selected. The valid profiles numbers range from 1 to 200. If an invalid

profile number is set in the job setup, then the LGA Interface will not write any profile

number out and Production Monitoring should remain using the last valid profile

number.

Job Mode with Parameter

Inputs

The I/O control bit to put the interface into this mode must be set to True before the

welding state is entered. If this not done the welder will use the values defined in the

Job setup when the weld state is first entered.

If the input is set to False when in the weld state, the welder will keep using the last

inputted values that were sent over the I/O interface.

Page 18

English English

18

Trace Function in Power Wave Manager Software

Items displayed by Trace Function

Item Description

Time (in seconds) This is just a running counter that gets incremented approximately every millisecond. This can

be used to see the relative time when the events happened. Note: It is possible that this

counter can roll over and new events have an older time stamp. Also since this is just a

counter that gets updated, this might not actually reflect the true timing of some events.

I/O Out Shows the I/O bytes (in Hex) from the welder. See the section, for the meaning of this data.

I/O In Shows the I/O bytes (in Hex) going to the welder. See the section to Welder, for the meaning

of this data.

A520 Rq Displays the welding parameters that were sent to the welder’s weld controller. The set mask

is a bit mask (in hex) that shows what items were sent, where 0x01=Weld Mode,

0x02=WorkPoint, 0x04=Trim, 0x08=Wave Control 1, 0x01=Wave Control 2, 0x02=Wave

Control 3, and 0x04=Wave Control 4.

A520 Rs Displays the response from the weld controller from receiving the welding parameters. The

Syn WFS displays the calculated Synergic Wire Feed Speed for the given Workpoint for

Synergic weld modes. If all parameters were in limit, the Error Mask will be 0, else it will be

non-zero if an item was out of limit.

Arc Status Displays the present status of the arc, where 0=No Voltage or Current, 1=Voltage Only (OCV

condition), 2=Current Only (Shorted Condition), 3=Both Voltage and Current present.

Weld State Displays the weld state that the machine went too.

Set WFS Displays the Wire Feed Speed that went to the wire drive.

Commands Displays when certain items were turned on or off, this includes: WC (Weld Controller) Output

On, WC Output Off, Gas On, Gas Off, WD (Wire Drive) Motor On, WD Motor Off.

Events Show when some type of event happened. Use Power Wave Manager and the Lookup Error

section to interpret what the return code means.

Trace Attributes

Attribute Description

Trace Logging Selects when the trace stops logging information. When “Stop when buffer full” is selected then

the trace will stop logging when the buffer can no longer store new logs. When “Continuous” is

selected, then the trace will always keep inputting new information. When the end of the buffer

is reached, it will roll-over and start to erase any old logs with new ones.

Filter Selects what is logged in the trace.

Using Trace

Step Description

1. Setup Select the desired Trace Logging method and what to log with the Filter.

2. Start Click on the Start trace button to start logging. Note that the trace function has a limited buffer

space, so after the trace is started, it is best to cause the event you want to capture and stop

the trace as quickly as possible.

3. Run Make a weld or cause the action you want to capture happen.

4. Stop Click on the Stop trace button to stop logging.

5. Read Click on the Read trace button to read in the trace data.

6. Save Click on the Save trace button if you want to save the trace to a file.

Appendix

PROFINET Configuration

Item

V

alue

PROFINET Vendor ID 733 (0x2DD)

Device ID 7

Lincoln Electric Bester Order Number K14140-1

GSD File GSDML-V2.31-LincolnElectric-K14140-1-

20141202.xml

Default Device Name lincoln0001

Page 19

English English

19

DeviceNet Configuration

Item

V

alue

Vendor ID 346 (0x15A)

Device ID/Product code 20

Lincoln Electric Bester Order

Number

K14140-2

EDS File LGA_DN_1-1.EDS

Default MAC ID 5

Default Baud Rate AUTO

DeviceNet requires to configure module parameters with

Power Wave Manager Software that You can

downloadfrom http://powerwavesoftware.com or with

LGA Control Panel (ref. IM3055).

Figure 6

MAC ID – unique node address (0 – 63),

Baud rate – three bit rates are available: 125 Kbit/s,

250 Kbit/s and 500 Kbit/s. There is also the AUTO

option – the bit rate is recognized and set

automatically.

PROFIBUS Configuration

Item

V

alue

Vendor Name HMS Industrial Networks

Ident Number 0x1811

Lincoln Electric Bester Order

Number

K14140-3

GSD File HMSB1811_LE.gsd

Default Node Address 5

PROFIBUS requires to configure module parameters

with Power Wave Manager Software that You can

download from http://powerwavesoftware.com or with

LGA Control Panel (ref. IM3055).

Figure 7

Node Address – unique node address (1 – 125),

Maintenance

WARNING

For any repair operations, modifications or maintenance,

it is recommended to contact the nearest Technical

Service Center or Lincoln Electric. Repair and

modification performed by unauthorized service or

personnel will cause the manufacturer’s warranty to

become null and void.

Any noticeable damage should be reported immediately

and repaired.

WARNING

Do not touch electrically live parts.

WARNING

Before the case of machine will be removed, the

machine has to be turned off and the power lead has to

be disconnected from mains socket.

WARNING

Mains supply network must be disconnected from the

machine before each maintenance and service. After

each repair, perform proper test to ensure safety.

Page 20

English English

20

Customer Assistance Policy

The business of The Lincoln Electric Company is

manufacturing and selling high quality welding

equipment, consumables, and cutting equipment. Our

challenge is to meet the needs of our customers and to

exceed their expectations. On occasion, purchasers may

ask Lincoln Electric for advice or information about their

use of our products. We respond to our customers

based on the best information in our possession at that

time. Lincoln Electric is not in a position to warrant or

guarantee such advice, and assumes no liability, with

respect to such information or advice. We expressly

disclaim any warranty of any kind, including any

warranty of fitness for any customer’s particular purpose,

with respect to such information or advice. As a matter of

practical consideration, we also cannot assume any

responsibility for updating or correcting any such

information or advice once it has been given, nor does

the provision of information or advice create, expand or

alter any warranty with respect to the sale of our

products.

Lincoln Electric is a responsive manufacturer, but the

selection and use of specific products sold by Lincoln

Electric is solely within the control of, and remains the

sole responsibility of the customer. Many variables

beyond the control of Lincoln Electric affect the results

obtained in applying these types of fabrication methods

and service requirements.

Subject to Change – This information is accurate to the

best of our knowledge at the time of printing. Please

refer to www.lincolnelectric.com for any updated

information.

Page 21

English English

21

WEEE

07/06

English

Do not dispose of electrical equipment together with normal waste!

In observance of European Directive 2012/19/EC on Waste Electrical and Electronic Equipment (WEEE)

and its implementation in accordance with national law, electrical equipment that has reached the end of its

life must be collected separately and returned to an environmentally compatible recycling facility. As the

owner of the equipment, you should get information on approved collection systems from our local

representative.

By applying this European Directive you will protect the environment and human health!

Spare Parts

12/05

Part List reading instructions

Do not use this part list for a machine if its code number is not listed. Contact the Lincoln Electric Service

Department for any code number not listed.

Use the illustration of assembly page and the table below to determine where the part is located for your particular

code machine.

Use only the parts marked "X" in the column under the heading number called for in the assembly page (# indicate

a change in this printing).

First, read the Part List reading instructions above, then refer to the "Spare Part" manual supplied with the machine, that

contains a picture-descriptive part number cross-reference.

Authorized Service Shops Location

09/16

The purchaser must contact a Lincoln Authorized Service Facility (LASF) about any defect claimed under Lincoln's

warranty period.

Contact your local Lincoln Sales Representative for assistance in locating a LASF or go to

www.lincolnelectric.com/en-gb/Support/Locator.

Electrical Schematic

Refer to the "Spare Part" manual supplied with the machine.

Loading...

Loading...