Page 1

IMT913-A

RETURN TO MAIN MENU

MAGNUM®100SG SPOOL GUN

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However,

your overall safety can be

increased by proper installation ...

and thoughtful operation on your

part. DO NOT INSTALL, OPER-

ATE OR REPAIR THIS EQUIPMENT WITHOUT READING

THIS MANUAL AND THE

SAFETY PRECAUTIONS CONTAINED THROUGHOUT. And,

most importantly, think before you

act and be careful.

August, 2010

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

OPERATOR’S MANUAL

Copyright © Lincoln Global Inc.

• World's Leader in Welding and Cutting Products •

• Sales and Service through Subsidiaries and Distributors Worldwide •

Page 2

magnetowireasappropriate.

work,disconnectthesparkplugwires,distributorcapor

turningtheengineorweldinggeneratorduringmaintenance

2.d.5.Donotworknexttoweldingpowersource.

1.g.Topreventaccidentallystartinggasolineengineswhile

___________________________________________________

possibletotheareabeingwelded.

2.d.4.Connecttheworkcabletotheworkpieceascloseas

side,theworkcableshouldalsobeonyourrightside.

whiletheengineisrunning.

workcables.Iftheelectrodecableisonyourright

idlerbypushingonthethrottlecontrolrods

Donotattempttooverridethegovernoror

2.d.3.Donotplaceyourbodybetweentheelectrodeand

1.f.Donotputyourhandsneartheenginefan.

___________________________________________________

2.d.2.Nevercoiltheelectrodeleadaroundyourbody.

parts.

Alwaysusethegreatestcarewhenworkingnearmoving

themwithtapewhenpossible.

maintenancerequiringtheirremovaliscomplete.

2.d.1.

Routetheelectrodeandworkcablestogether-Secure

guardsonlywhennecessaryandreplacethemwhenthe

guardstoperformrequiredmaintenance.Remove

minimizeexposuretoEMFfieldsfromtheweldingcircuit:

1.e.Insomecasesitmaybenecessarytoremovesafety

2.d.Allweldersshouldusethefollowingproceduresinorderto

____________________________________________________

effectswhicharenownotknown.

whenstarting,operatingorrepairingequipment.

2.c.ExposuretoEMFfieldsinweldingmayhaveotherhealth

awayfromV-belts,gears,fansandallothermovingparts

tionandingoodrepair.Keephands,hair,clothingandtools

beforewelding.

1.d.Keepallequipmentsafetyguards,coversanddevicesinposiweldershavingapacemakershouldconsulttheirphysician

____________________________________________________

2.b.EMFfieldsmayinterferewithsomepacemakers,and

havebeeneliminated.

wipeitupanddonotstartengineuntilfumes

weldingmachines

notspillfuelwhenfillingtank.Iffuelisspilled,

currentcreatesEMFfieldsaroundweldingcablesand

contactwithhotenginepartsandigniting.Do

localizedElectricandMagneticFields(EMF).Welding

ingtopreventspilledfuelfromvaporizingon

2.a.Electriccurrentflowingthroughanyconductorcauses

theengineandallowittocoolbeforerefuelingarcorwhentheengineisrunning.Stop

1.c.Donotaddthefuelnearanopenflameweld-

maybedangerous

____________________________________________________

MAGNETICFIELDS

ELECTRICAND

outdoors.

areasorventtheengineexhaustfumes

1.b.Operateenginesinopen,well-ventilated

____________________________________________________

workunlessthemaintenanceworkrequiresittoberunning.

1.a.Turntheengineoffbeforetroubleshootingandmaintenance

hot.

poweredequipment.

radiatorpressurecapwhentheengineis

FORENGINE

1.h.Toavoidscalding,donotremovethe

PERFORMEDONLYBYQUALIFIEDINDIVIDUALS.

BESURETHATALLINSTALLATION,OPERATION,MAINTENANCEANDREPAIRPROCEDURESARE

LincolnElectricCompany,22801St.ClairAvenue,Cleveland,Ohio44117-1199.

Miami,Florida33135orCSAStandardW117.2-1974.AFreecopyof“ArcWeldingSafety”bookletE205isavailablefromthe

purchaseacopyof“SafetyinWelding&Cutting-ANSIStandardZ49.1”fromtheAmericanWeldingSociety,P.O.Box351040,

Readandunderstandthefollowingsafetyhighlights.Foradditionalsafetyinformation,itisstronglyrecommendedthatyou

KEEPCHILDRENAWAY.PACEMAKERWEARERSSHOULDCONSULTWITHTHEIRDOCTORBEFOREOPERATING.

ARCWELDINGCANBEHAZARDOUS.PROTECTYOURSELFANDOTHERSFROMPOSSIBLESERIOUSINJURYORDEATH.

otherreproductiveharm.

orotherreproductiveharm.

ofCaliforniatocausecancer,birthdefects,and

StateofCaliforniatocausecancer,birthdefects,

someofitsconstituentsareknowntotheState

thisproductcontainschemicalsknowntothe

ForDieselEngines:Dieselengineexhaustand

ForGasolineEngines:Theengineexhaustfrom

CALIFORNIAPROPOSITION65WARNINGS

WARNING

SAFETY

i

i

i

SAFETY

WARNING

CALIFORNIA PROPOSITION 65 WARNINGS

For Diesel Engines: Diesel engine exhaust and

some of its constituents are known to the State

of California to cause cancer, birth defects, and

other reproductive harm.

ARC WELDING CAN BE HAZARDOUS. PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH.

KEEP CHILDREN AWAY. PACEMAKER WEARERS SHOULD CONSULT WITH THEIR DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For additional safety information, it is strongly recommended that you

purchase a copy of “Safety in Welding & Cutting - ANSI Standard Z49.1” from the American Welding Society, P.O. Box 351040,

Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the

Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

FOR ENGINE

powered equipment.

1.a. Turn the engine off before troubleshooting and maintenance

work unless the maintenance work requires it to be running.

____________________________________________________

____________________________________________________

____________________________________________________

1.d. Keep all equipment safety guards,covers and devices in posi-

____________________________________________________

1.e. In some cases it may be necessary to remove safety

___________________________________________________

___________________________________________________

1.g. To prevent accidentally starting gasoline engines while

1.b.Operate engines in open, well-ventilated

areas or vent the engine exhaust fumes

outdoors.

1.c. Do not add the fuel near an open flame weld-

ing arc or when the engine is running. Stop

the engine and allow it to cool before refueling to prevent spilled fuel from vaporizing on

contact with hot engine parts and igniting. Do

not spill fuel when filling tank. If fuel is spilled,

wipe it up and do not start engine until fumes

have been eliminated.

tion and in good repair.Keep hands, hair, clothing and tools

away from V-belts, gears, fans and all other moving parts

when starting, operating or repairing equipment.

guards to perform required maintenance. Remove

guards only when necessary and replace them when the

maintenance requiring their removal is complete.

Always use the greatest care when working near moving

parts.

1.f. Do not put your hands near the engine fan.

Do not attempt to override the governor or

idler by pushing on the throttle control rods

while the engine is running.

turning the engine or welding generator during maintenance

work, disconnect the spark plug wires, distributor cap or

magneto wire as appropriate.

For Gasoline Engines: The engine exhaust from

this product contains chemicals known to the

State of California to cause cancer, birth defects,

or other reproductive harm.

1.h. To avoid scalding, do not remove the

radiator pressure cap when the engine is

hot.

ELECTRIC AND

MAGNETIC FIELDS

may be dangerous

2.a. Electric current flowing through any conductor causes

localized Electric and Magnetic Fields (EMF). Welding

current creates EMF fields around welding cables and

welding machines

2.b. EMF fields may interfere with some pacemakers, and

welders having a pacemaker should consult their physician

before welding.

2.c. Exposure to EMF fields in welding may have other health

effects which are now not known.

2.d. All welders should use the following procedures in order to

minimize exposure to EMF fields from the welding circuit:

Route the electrode and work cables together - Secure

2.d.1.

them with tape when possible.

2.d.2. Never coil the electrode lead around your body.

2.d.3. Do not place your body between the electrode and

work cables. If the electrode cable is on your right

side, the work cable should also be on your right side.

2.d.4. Connect the work cable to the workpiece as close as

possible to the area being welded.

2.d.5. Do not work next to welding power source.

i

Page 3

Page 4

Page 5

zonesoùlʼonpiquelelaitier.

soudage.Utiliserdeslunettesavecécranslaterauxdansles

5.Toujoursporterdeslunettesdesécuritédanslazonede

sdesûretéàleurplace.

4.Gardertouslescouverclesetdispositif

onssansrevers,etchaussuresmontantes.

tal

delʼhuile,telsquelesgantsencuir,chemiseépaisse,paneràlʼinterrupteuràlaboitedefusibles.

soudage.Seprotégeravecdesvêtementsdeprotectionlibres

3.Avantdefairesdestravauxàlʼinterieurdeposte,ladebranch-

4.Desgouttesdelaitierenfusionsontémisesdelʼarcde

effectuésparunélectricienqualifié.

soudageàlʼaidedʼécransappropriésetnon-inflammables.

2.Autantquepossible,Iʼinstallationetlʼentretienduposteseront

c.Protégerlʼautrepersonneltravaillantàproximitéau

desoudeuretdesaidescontrelerayonnementdelʻarc.

bonnemiseàlaterre.

b.Porterdesvêtementsconvenablesafindeprotégerlapeau

demontageoulapieceàsouderdoitêtrebranchéàune

quandonregardelʼarc.

lʼélectricitéetauxrecommendationsdufabricant.Ledispositif

projectionsquandonsoudeou

nementdelʼarcetdes

1.Relieràlaterrelechassisduposteconformementaucodede

quʼunverreblancafindeseprotégerlesyeuxdurayon-

a.Utiliserunbonmasqueavecunverrefiltrantappropriéainsi

REDRESSEUR

3.Uncoupdʼarcpeutêtreplussévèrequʼuncoupdesoliel,donc:

TRANSFORMATEURETÀ

corps.

LESMACHINESÀSOUDERÀ

enroulerlecâble-électrodeautourdenʼimportequellepartiedu

contreleschutesdanslecasouonrecoitunchoc.Nejamais

PRÉCAUTIONSDESÛRETÉPOUR

rotéger

2.Danslecasdetravailaudessusduniveaudusol,sep

soudage.

pourleporte-électrodesʼapplicuentaussiaupistoletde

courantpoursoudagesemi-automatique,cesprecautions

W117.2-1974.

f.Sionutiliselamachineàsoudercommeunesourcede

lecode“Codeforsafetyinweldingandcutting”CSAStandard

delatensionàvidedesdeuxmachines.

ûreté,voir

11.Pourobtenirdeplusamplesrenseignementssurlas

parcequelatensionentrelesdeuxpincespeutêtreletotal

desporte-électrodesconnectésàdeuxmachinesàsouder

ouautresproduitsirritants.

e.Nejamaistouchersimultanémentlespartiessoustension

dusolvantpourproduireduphosgéne(gasfortementtoxique)

refroidir.

chaleuroulesrayonsdelʼarcpeuventréagiraveclesvapeurs

électrodedanslʼeaupourle

d.Nejamaisplongerleporte-

dʼopérationsdedégraissage,nettoyageoupistolage.La

tionnement.

10.Nepassouderenprésencedevapeursdechloreprovenant

soudageetlamachineàsouderenbonetsûrétatdefonc-

c.Maintenirleporte-électrode,lapincedemasse,lecâblede

produitdesfumeéstoxiques.

partieducorpspeutêtreencontactaveclamasse.

galvaniséesplombées,oucadmiéesoutoutautremétalqui

lespositionsassisoucouchépourlesquellesunegrande

es

Ceciestparticuliérementimportantpourlesoudagedetôl

alliqueoudesgrillesmetalliques,principalementdans

9.Assureruneventilationsuffisantedanslazonedesoudage.

soudedansdesendroitshumides,ousurunplanchermet-

b.Fairetrésattentiondebiensʼisolerdelamassequandon

câblesjusquʼàcequʼilsserompent.

pourisolerlesmains.

trous

risquesdʼincendieoudʼechauffementdeschainesetdes

oulesvétementsmouillés.Porterdesgantssecsetsans

câblesdegrue,ouautrescircuits.Celapeutprovoquerdes

toutcontactentrelespartiessoustensionetlapeaunue

passerlecourantdesoudageparleschainesdelevage,

quandlamachineàsouderestenmarche.Evitertoujours

éloignésdelazonedetravail,onaugmentelerisquedevoir

a.Lescircuitsàlʼélectrodeetàlapiécesontsoustension

massesurlacharpentedelaconstructionoudʼautresendroits

placela

lazonedetravailquʼilestpratiquedelefaire.Sion

1.Protegez-vouscontrelasecousseélectrique:

8.Sʼassurerquelamasseestconnectéelepluspréspossiblede

SûretéPourSoudageALArc

échauffementetunrisquedʼincendie.

antes:

lamasse.Uncourt-circuitaccidentalpeutprovoquerun

manuelaussibienquelesprécautionsdesûretégénéralessuiv-

7.Quandonnesoudepas,poserlapinceàuneendroitisoléde

etlesprécautionsdesûretéspecifiquesquiparraissentdansce

Pourvotrepropreprotectionlireetobservertouteslesinstructions

prévenirtoutrisquedʼincendiedûauxétincelles.

6.Eloignerlesmatériauxinflammablesoulesrecouvrirafinde

PRÉCAUTIONSDESÛRETÉ

SAFETY

iv

iv

iv

SAFETY

iv

PRÉCAUTIONS DE SÛRETÉ

Pour votre propre protection lire et observer toutes les instructions

et les précautions de sûreté specifiques qui parraissent dans ce

manuel aussi bien que les précautions de sûreté générales suiv-

antes:

Sûreté Pour Soudage A LArc

1. Protegez-vous contre la secousse électrique:

a. Les circuits à lʼélectrode et àla piéce sont sous tension

quand la machine à souder est en marche. Eviter toujours

tout contact entre les parties sous tension et la peau nue

ou les vétements mouillés. Porter des gants secs et sans

trous

pour isoler les mains.

b. Faire trés attention de bien sʼisoler de la masse quand on

soude dans des endroits humides, ou sur un plancher metallique ou des grilles metalliques, principalement dans

les positions assis ou couchépour lesquelles une grande

partie du corps peut être en contact avec la masse.

c. Maintenir le porte-électrode, la pincedemasse,lecâblede

soudage et la machine à souder en bon et sûr état defonc-

tionnement.

d.Ne jamais plonger le porte-

refroidir.

e. Ne jamais toucher simultanément les parties sous tension

des porte-électrodes connectés à deux machines à souder

parce que la tension entre les deuxpinces peut être letotal

de la tension à vide des deux machines.

f.Sionutilise la machine à souder comme une source de

courant pour soudage semi-automatique, ces precautions

pour le porte-électrode sʼapplicuent aussi au pistolet de

soudage.

2. Dans le cas de travail au dessus du niveau du sol,sep

contre les chutes dans le cas ou on recoit un choc. Ne jamais

enrouler lecâble-électrode autour de nʼimporte quelle partie du

corps.

3. Un coup dʼarc peut être plus sévère quʼun coup de soliel, donc:

a. Utiliser un bon masque avec un verre filtrant approprié ainsi

quʼun verre blanc afin de se protéger les yeux du rayonnement de lʼarc et des

quand on regarde lʼarc.

b. Porter des vêtements convenables afin de protéger la peau

de soudeur et des aides contre lerayonnement de lʻarc.

c. Protéger lʼautre personnel travaillant àproximité au

soudage àlʼaide dʼécrans appropriés et non-inflammables.

4. Des gouttes de laitier en fusion sont émises de lʼarc de

soudage. Se protéger avec des vêtements de protection libres

de lʼhuile, tels que les gants en cuir, chemise épaisse, pantal

ons sans revers, et chaussures montantes.

5. Toujours porter des lunettes de sécurité dans la zone de

soudage. Utiliser des lunettes avec écrans lateraux dans les

zones oùlʼon pique le laitier.

électrode dans lʼeau pour le

rotéger

projections quand on soude ou

6. Eloigner les matériaux inflammables ou les recouvrir afin de

prévenir tout risque dʼincendie dû auxétincelles.

7. Quand on ne soude pas, poser la pince à une endroit isolé de

la masse. Un court-circuit accidentalpeut provoquer un

échauffement et un risque dʼincendie.

8. Sʼassurer que la masse est connectée le plus prés possiblede

la zone de travailquʼil est pratique de le faire. Si on

masse sur la charpente de la construction ou dʼautres endroits

éloignésdela zone de travail, on augmente lerisque de voir

passer le courant de soudage par les chaines de levage,

câbles de grue, ou autres circuits. Cela peut provoquer des

risques dʼincendie ou dʼechauffement des chaines et des

câbles jusquʼà ce quʼilsserompent.

9. Assurer une ventilation suffisante dans la zone de soudage.

Ceci est particuliérement important pour le soudage de tôl

galvanisées plombées, ou cadmiées ou tout autre métalqui

produit des fumeéstoxiques.

10. Ne pas souder en présence de vapeurs de chlore provenant

dʼopérations de dégraissage, nettoyage ou pistolage. La

chaleur ou les rayons de lʼarc peuvent réagir avec les vapeurs

du solvant pour produire du phosgéne (gas fortement toxique)

ou autres produits irritants.

11. Pour obtenir de plus amples renseignements sur las

le code “Code for safety in welding and cutting” CSA Standard

W 117.2-1974.

place la

ûreté, voir

PRÉCAUTIONS DE SÛRETÉ POUR

LES MACHINES À SOUDER À

TRANSFORMATEUR ET À

REDRESSEUR

1. Relier àla terre le chassis du poste conformement au code de

lʼélectricité et aux recommendations du fabricant. Le dispositif

de montage ou la piece à souder doit être branchéàune

bonne mise àla terre.

2. Autant que possible, Iʼinstallation et lʼentretien du poste seront

effectués par un électricien qualifié.

3. Avant de faires des travauxàlʼinterieur de poste, la debranch-

er àlʼinterrupteur àla boite de fusibles.

4. Garder tous les couvercles et dispositif

sdesûretéàleur place.

es

Page 6

Thank

You

for selecting a QUALITY product by Lincoln Electric. We want you

Y

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the needs of our customers and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric

for advice or information about their use of our products. We respond to our customers based on the best information in our possession at that

time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or

advice. We expressly disclaim any warranty of any kind, including any warranty of fitness for any customers particular purpose, with respect

to such information or advice. As a matter of practical consideration, we also cannot assume any responsibility for updating or correcting any

such information or advice once it has been given, nor does the provision of information or advice create, expand or alter any warranty with

respect to the sale of our products.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control

of, and remains the sole responsibility of the customer. Many variables beyond the control of Lincoln Electric affect the results obtained in

applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com

for any updated information.

to take pride in operating this Lincoln Electric Company product •••

as much pride as we have in bringing this product to you!

CUSTOMER ASSISTANCE POLICY

vv

When this equipment is shipped, title passes to the purchaser upon receipt by the carrier. Consequently, Claims

for material damaged in shipment must be made by the purchaser against the transportation company at the

time the shipment is received.

Please record your equipment identification information below for future reference. This information can be found

on your equipment nameplate.

Model Name and Sales Spec Number (K-xxx) _____________________________________

Date of Purchase __________________________________

Whenever you request replacement parts for or information on this equipment always supply the information you

have recorded above.

On-Line Product Registration

Please Examine Carton and Equipment For Damage Immediately

- Register your machine with Lincoln Electric either via fax or over the Internet.

• For faxing: Complete the form on the back of the warranty statement included in the literature packet

• For On-Line Registration: Go to our

Read this Operators Manual completely before attempting to use this equipment. Save this manual and keep it

handy for quick reference. Pay particular attention to the safety instructions we have provided for your protection.

The level of seriousness to be applied to each is explained below:

accompanying this machine and fax the form per the instructions printed on it.

WEB SITE at www.lincolnelectric.com. Choose “Quick Links” and then

“Product Registration”. Please complete the form and submit your registration.

WARNING

This statement appears where the information must be followed exactly to avoid serious personal injury or loss of life.

CAUTION

This statement appears where the information must be followed to avoid minor personal injury or damage to this equipment.

Page 7

TABLE OF CONTENTS

Page

Installation Section--------------------------------------------------------------------------------A

Technical Specification---------------------------------------------------------------------------A-1

Unpacking the Spool Gun-----------------------------------------------------------------------A-1

Safety Precautions--------------------------------------------------------------------------------A-2

Locating Spool Gun Components And Features------------------------------------------A-2

Assembly of Items Inside the Magnum Spool Gun---------------------------------------A-3

Welding Machines--------------------------------------------------------------------------------A-4

Recommended Welding Machines-----------------------------------------------------------A-5

Spool Gun / Wire Drive Selector Switch Installation--------------------------A-6 thru A-9

Routine Welding Machine Preparation------------------------------------------------------A-10

Preparing the Spool Gun-----------------------------------------------------------------------A-10

Loading Aluminum-----------------------------------------------------------------A-10 thru A-13

Connecting the Gun to the Welding Machine--------------------------------------------A-13

__________________________________________________________________

PERATION Section----------------------------------------------------------------------------------B

O

Safety Precaution---------------------------------------------------------------------------------B-1

Product Description-------------------------------------------------------------------------------B-1

Machine Speed and Voltage tap Settings--------------------------------------------B-1, B-2

Welding Procedures------------------------------------------------------------------------------B-3

__________________________________________________________________

Maintenance Section------------------------------------------------------------------------------ D

Safety Precautions--------------------------------------------------------------------------------D-1

Routine and Periodic Maintenance-----------------------------------------------------------D-1

Recommended Tools-----------------------------------------------------------------------------D-1

Cleaning and Inspections-----------------------------------------------------------------------D-1

P6 Connector Pin-Out----------------------------------------------------------------------------D-1

Gas Diffuser Replacement----------------------------------------------------------------------D-1

Liner Assembly Replacement or Cleaning--------------------------------------------------D-2

Drive Roll Replacement--------------------------------------------------------------------------D-2

Idle Roll Assembly Replacement--------------------------------------------------------------D-3

Gun Tube Assembly Replacement------------------------------------------------------------D-3

Wire Drive Assembly Removal And Installation--------------------------------------------D-4

Trigger Assembly Replacement----------------------------------------------------------------D-4

Welding Cable Assembly Replacement-----------------------------------------------D-4, D-5

Correcting Wire Shaving issues--------------------------------------------------------------D-5

__________________________________________________________________

Page 8

TABLE OF CONTENTS

Page

Troubleshooting Section -------------------------------------------------------------------------E

Safety Precautions--------------------------------------------------------------------------------E-1

How To Use Trouble Shooting Guide---------------------------------------------------------E-1

Troubleshooting----------------------------------------------------------------------------E-2 to E-4

____________________________________________________________________

Diagrams Section -----------------------------------------------------------------------------------F

Wiring Diagrams------------------------------------------------------------------------------------F-1

____________________________________________________________________

Parts List--------------------------------------------------------------------------------P-554 Series

____________________________________________________________________

Page 9

INSTALLATION

TECHNICAL SPECIFICATIONS - MAGNUM®100SG SPOOL GUN K2532-1

MODEL

WELDING PROCESS

WIRE ALLOYS

WIRE SIZES (DIAMETERS)

SPOOL SIZE

RATED WELDING CURRENT

AND DUTY CYCLE

OVERALL WEIGHT

CABLE LENGTH

OVERALL SIZE (BOUNDING BOX)

METHOD OF GUIDANCE

METHOD OF COOLING

K2532-1 Magnum®100SG Spool Gun

Aluminum GMAW (MIG), DC electrode positive

polarity with 100% argon welding shielding gas.

Aluminum only: alloys 4043 or 5356

Solid wire 0.030 or 0.035 inches (0.8 or 0.9 mm)

1 lb. weight, nominal 4 inch diameter spool

130 amps at 30% for 10-minute basis

3.5 lbs. with cable but without case or spool

10.0±0.2 feet

In inches: 15.75 long x 10.50 high x 4.25 thick max.,

without case or gun cable.

Semiautomatic (manually-guided)

Air-cooled

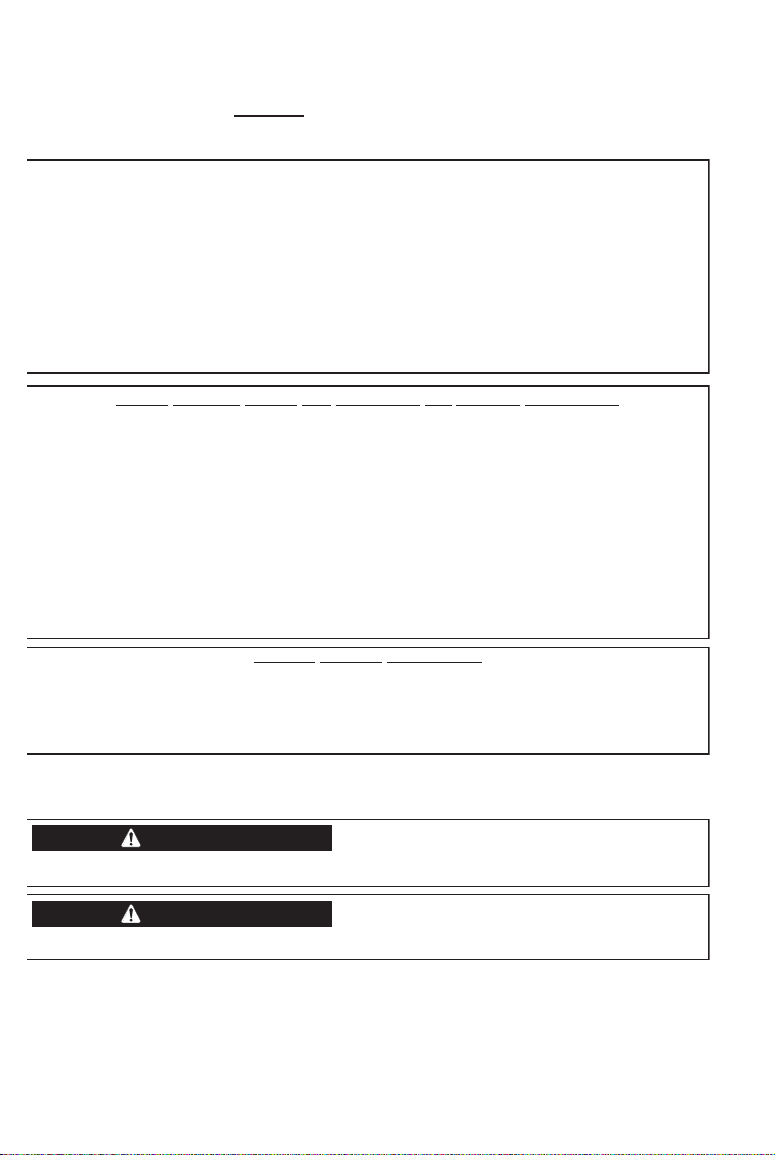

UNPACKING THE SPOOL GUN

The spool gun is factory-assembled and tested, and then packed in its own cushioned carrying case. It is shipped fully-equipped to weld with 0.035 inch diameter aluminum wire. After opening the case, check that it contains the following items:

1. One fully assembled K2532-1 spool gun.

2. One T11862-65 Conical Compression Spring for use with alloy 5356 wire (spool

not included).

3. One spool of 0.035 aluminum alloy 4043 wire

4. Three S19726-3 contact tips

5. One instruction manual (IM913)

6. One M21182 electrical harness with toggle switch.

3

5

4

1

2

Plastic Bag

A-1

6

Page 10

INSTALLATION

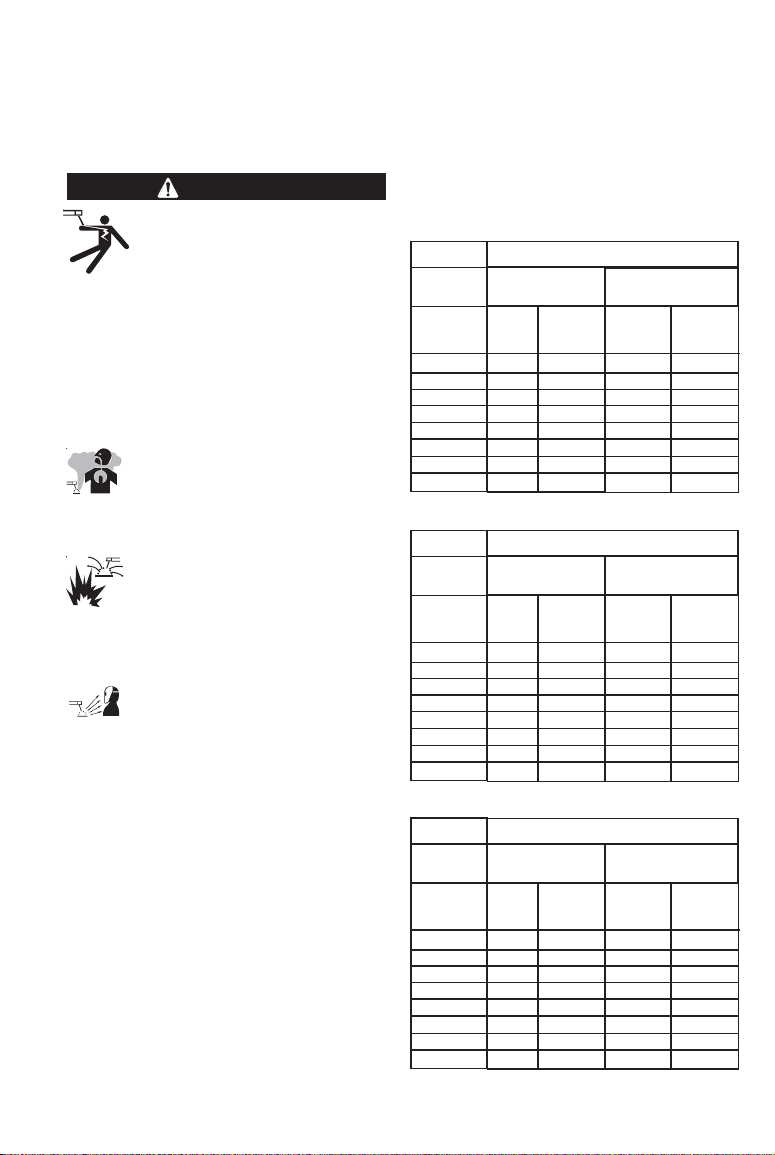

SAFETY PRECAUTIONS

WARNING

ELECTRIC SHOCK CAN KILL.

• Turn the input power OFF at the welding power source before

installation or changing drive rolls and/or guides.

• Do not touch electrically live parts.

• When inching with the gun trigger, electrode and drive mechanism

are "hot" to work and ground and could remain energized several

seconds after the gun trigger is released.

-----------------------------------------------------------------------------------------------------

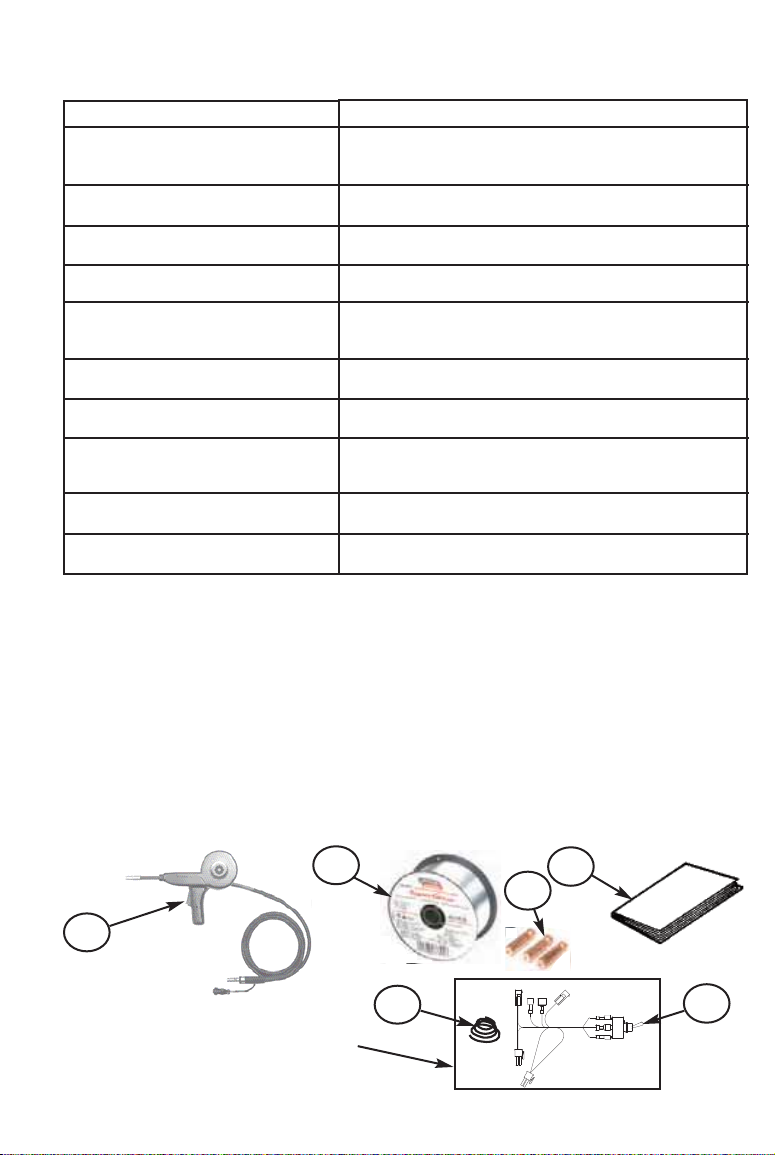

LOCATING SPOOL GUN COMPONENTS AND FEATURES

(See Figure 1.A for Items 1 thru 6)

1. Gas Cone Assembly and Contact Tip.

2. Straightened Gun Tube Assembly.

3. 1/4-Turn Locking Collar.

4. Trigger Assembly.

5. Spool Cover: Provides easy, wide-

open access to spool and wire

drive.

6. Locking Knob: Captive in spool

cover.

1

3

2

FIGURE A.1

5

5

4

(See Figure A.2 for these following items)

7. Integrated Single-Piece Cable:

The Magnum

neat and clean appearance; simplifies cable management and

reduces entanglements.

8. Standard Durable Strain Relief

Clamp.

9. Three Captive Hex Nuts.

®

design provides

A-2

Left Side View

FIGURE A.2

8

7

9

Right Side View

Page 11

INSTALLATION

1

2

4

3

P6 CONNECTOR PINOUT

MASTER KEY

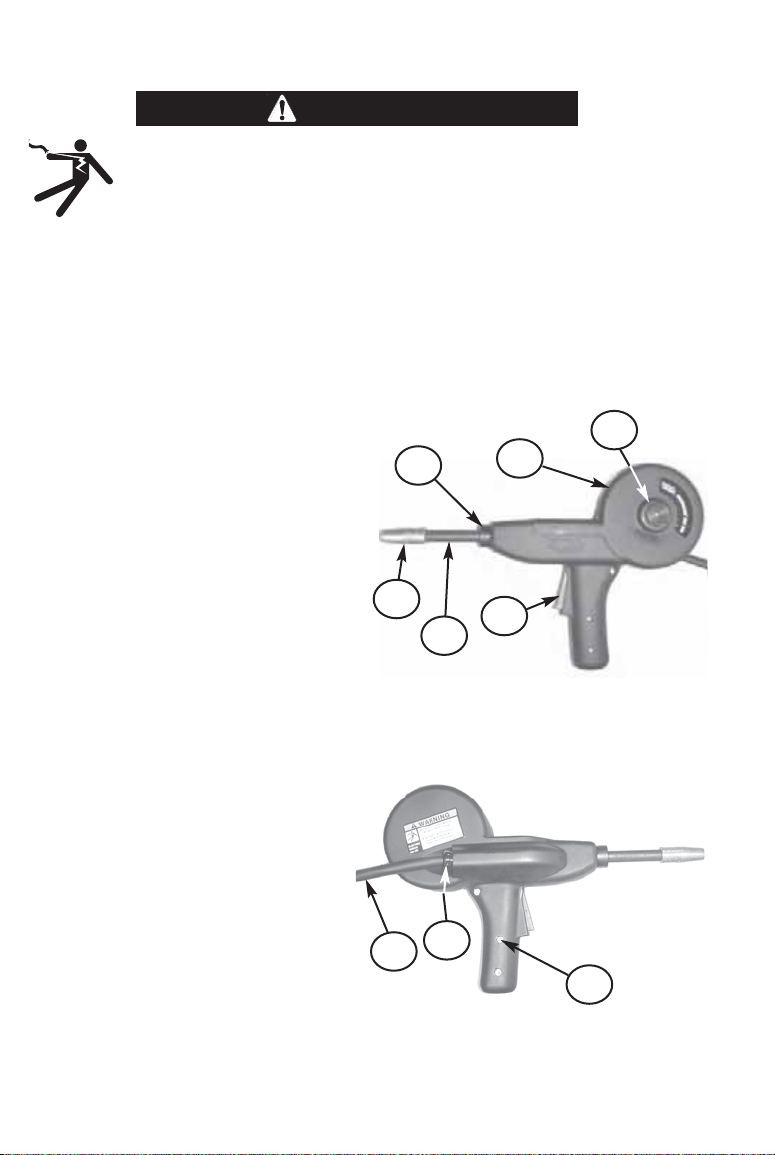

ASSEMBLY OF ITEMS INSIDE THE MAGNUM®SPOOL GUN

FIGURE A,3

2

Machine Connections

6

1. Liner Assembly feeds all specified

wire.

2. Drive Roll: This Drive Roll feeds all

specified wires.

3. Idle Roll Assembly: Non-adjustable

tension setting for all specified wires

4. Incoming Wire Guide: Highly wearresistant.

5. P6 Connector Control Leads: Motor

Power and Trigger. (See

Maintenance Section for more

details)

6. Welding Power and Shielding Gas

Machine connection (Sealed with 2

o-rings).

TOP VIEW

4

7

3

8

1

9

Spool Cover and left

handle removed

7. Locking Knob: Independently retains

the wire spool on the spindle.

8. Liner Assembly: Includes a gas seal

with the cable connector and is the

outgoing wire guide.

9. Only 4 sub-assemblies: gun tube;

cable; wire drive; trigger.

10. Conical spring (not shown) serves

as the spool brake (use only with

aluminum alloy 5356).

A-3

Page 12

INSTALLATION

SAFETY PRECAUTIONS

WELDING MACHINES

CAUTION

• Read and understand the welding machineʼs instruction manual and all hazard warnings on equipment and in the manual.

• Wear the proper personal protective equipment for welding,

including but not limited to, safety glasses, hearing protection,

welding helmet, welding gloves, and welding leathers.

-----------------------------------------------------------------------------------------------------

SPOOL GUN

WARNING

ELECTRIC SHOCK CAN KILL.

• The spool of wire may fall out of the gun if the locking knob is

not installed.

• Metal parts may be at welding voltage (electrically "hot").

• Metal parts remain at welding voltage for several seconds after trigger is

released. Read warning label on gun.

• This product shall not be used in precipitation, or in wet or damp locations.

------------------------------------------------------------------------------------------------------

A-4

Page 13

INSTALLATION

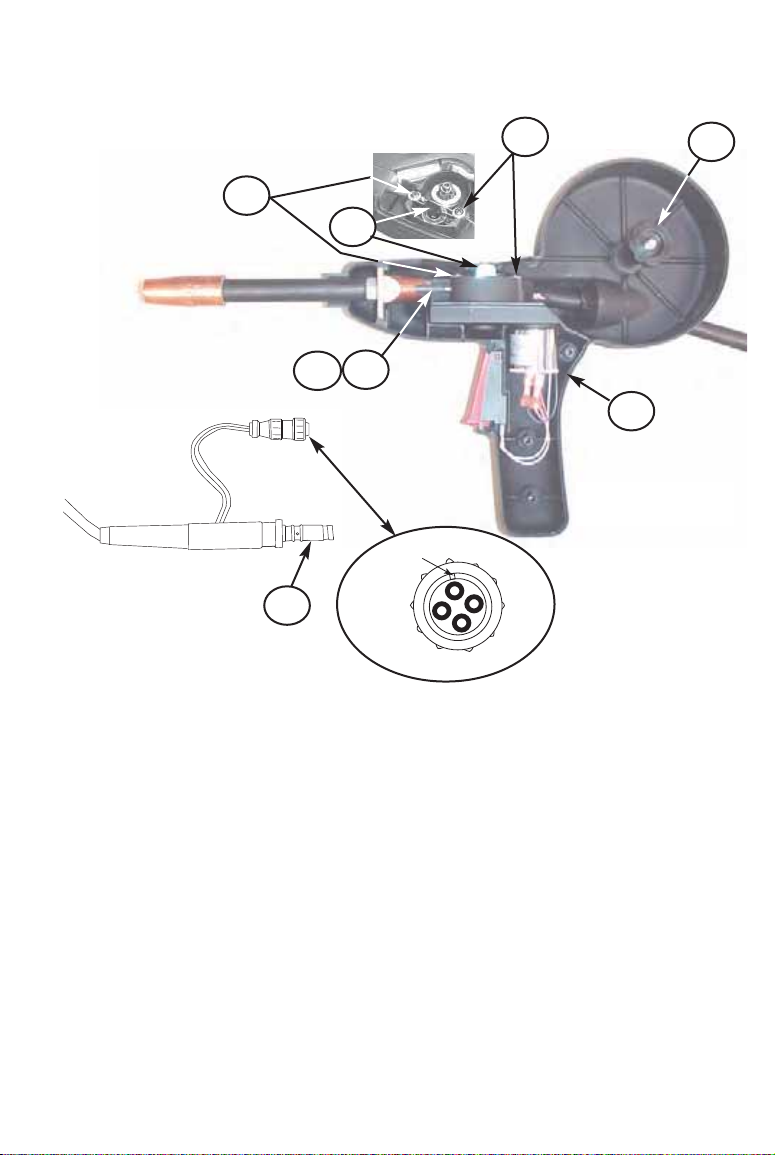

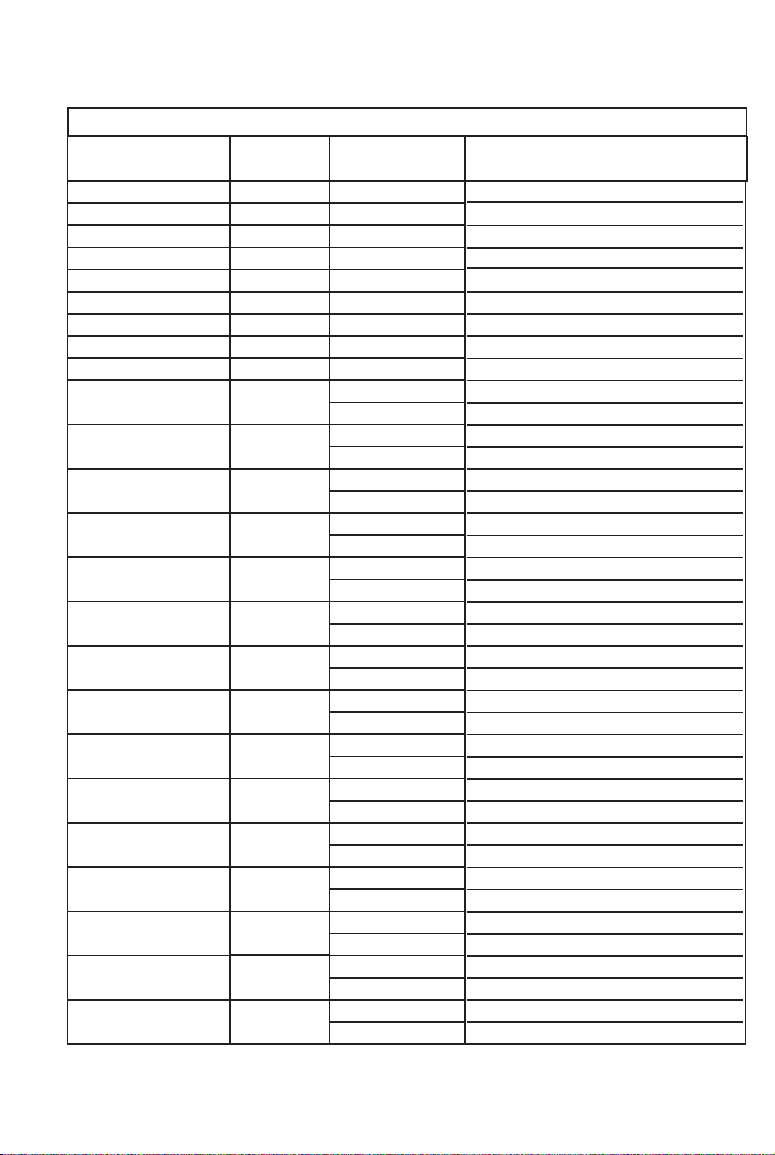

RECOMMENDED WELDING MACHINES

MACHINE NAME

POWER MIG 216

POWER MIG 215XT

POWER MIG 180C

POWER MIG 140C

POWER MIG 180 DUAL

POWER MIG 180C AU

POWER MIG 180C CE

POWER MIG 140T

POWER MIG 180T

PRO CORE 125

PRO MIG 140

WELD PAK 125 HD

WELD PAK 140 HD

MIG PAK 140

EASY CORE 125

EASY MIG 140

WORK PAK 125

CORE PACK 125

PRO MIG 180

WELD PAK 180HD

MIG PAK 180

SP-140T

SP-180T

EASY MIG 180

NOTE: THE MACHINE CODE NUMBER IS LISTED ON THE BACK OF THE MACHINE.

K-NUMBER

K2816-1

K2700-1

K2473-1

K2471-1

K3018-1

K2668-1

K2661-1

K2470-1

K2472-1

K2479-1

K2480-1

K2513-1

K2514-1

K2658-1

K2696-1

K2697-1

K2699-1

K2785-1

K2481-1

K2515-1

K2659-1

K2688-1

K2689-1

K2698-1

CODE NUMBER

11588

11521

11257

11255

11659

11444

11442

11254

11256

11631

11300

11634

11173

11632

11302

11635

11303

11636

11440

11633

11503

11637

11504

11638

11506

11639

11550

11646

11175

11647

11304

11648

11441

11658

11501

11649

11502

11650

11505

INSTALLATION OF M21182 HARNESS

AND SELECTOR SWITCH

NOT REQUIRED

NOT REQUIRED

REQUIRED

REQUIRED

NOT REQUIRED

REQUIRED

REQUIRED

REQUIRED

REQUIRED

SPOOL GUN USE NOT AVAILABLE

REQUIRED

NOT REQUIRED

REQUIRED

SPOOL GUN USE NOT AVAILABLE

REQUIRED

NOT REQUIRED

REQUIRED

NOT REQUIRED

REQUIRED

SPOOL GUN USE NOT AVAILABLE

REQUIRED

NOT REQUIRED

REQUIRED

SPOOL GUN USE NOT AVAILABLE

REQUIRED

SPOOL GUN USE NOT AVAILABLE

REQUIRED

REQUIRED

REQUIRED

REQUIRED

REQUIRED

REQUIRED

REQUIRED

REQUIRED

REQUIRED

REQUIRED

REQUIRED

REQUIRED

REQUIRED

A-5

Page 14

INSTALLATION

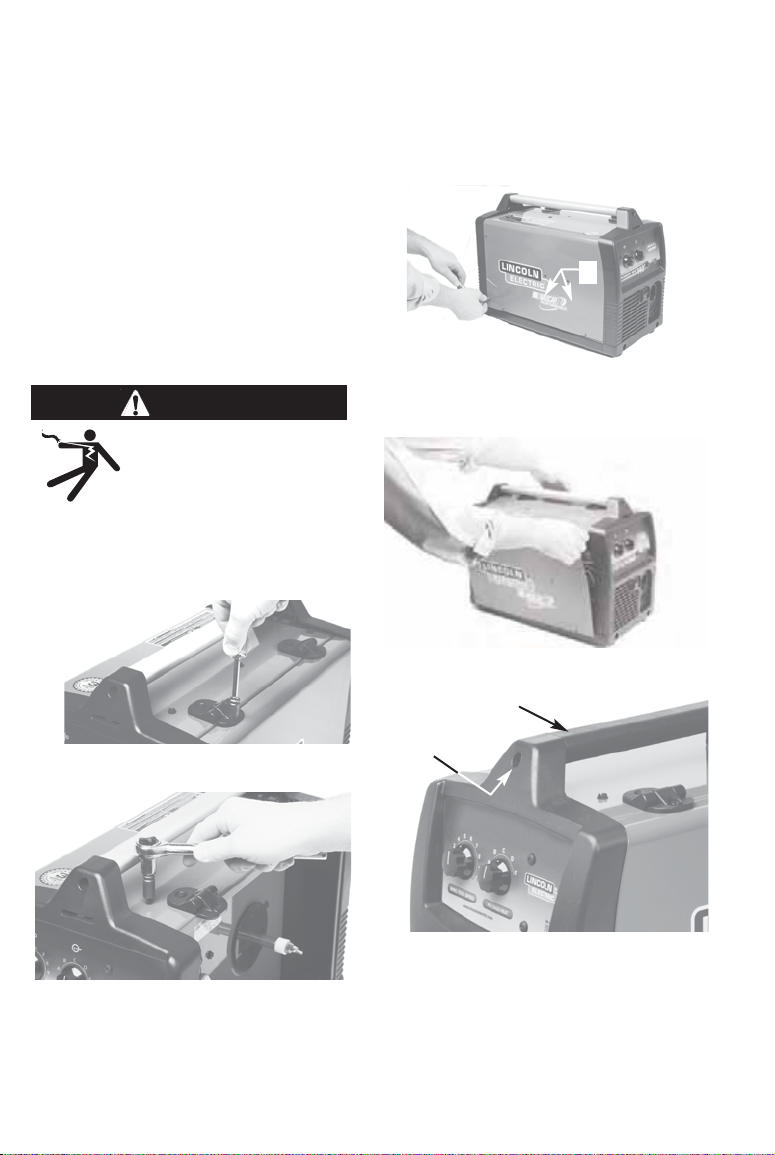

NOTE: Installation of the M21182 harness and spool gun selector switch is

not required for all machines. If a spool gun switch is pre-installed in the

machineʼs wire drive compartment, then the SPOOL GUN / WIRE DRIVE

SLECTOR SWITCH INSTALLATION SECTION can be disregarded.

SPOOL GUN / WIRE DRIVE

SELECTOR SWITCH

INSTALLATION

A

. Install the M21182 electrical adapter

1

harness that came with the spool gun

per the following instructions.

ELECTRIC SHOCK CAN KILL.

WARNING

2. Disconnect input

power from the

machine.

5. Remove screws from cover.

(A) is the location of two 3/4” long

screws.

------------------------------------------------

OPEN THE MACHINE

3. Remove two 5/16“ hex hinge screws

from door.

4. Remove ten 5/16“ hex screws from

cover.

6. Remove cover.

A

B

7. If machine has a plastic handle (A),

then remove screw (B).

A-6

Page 15

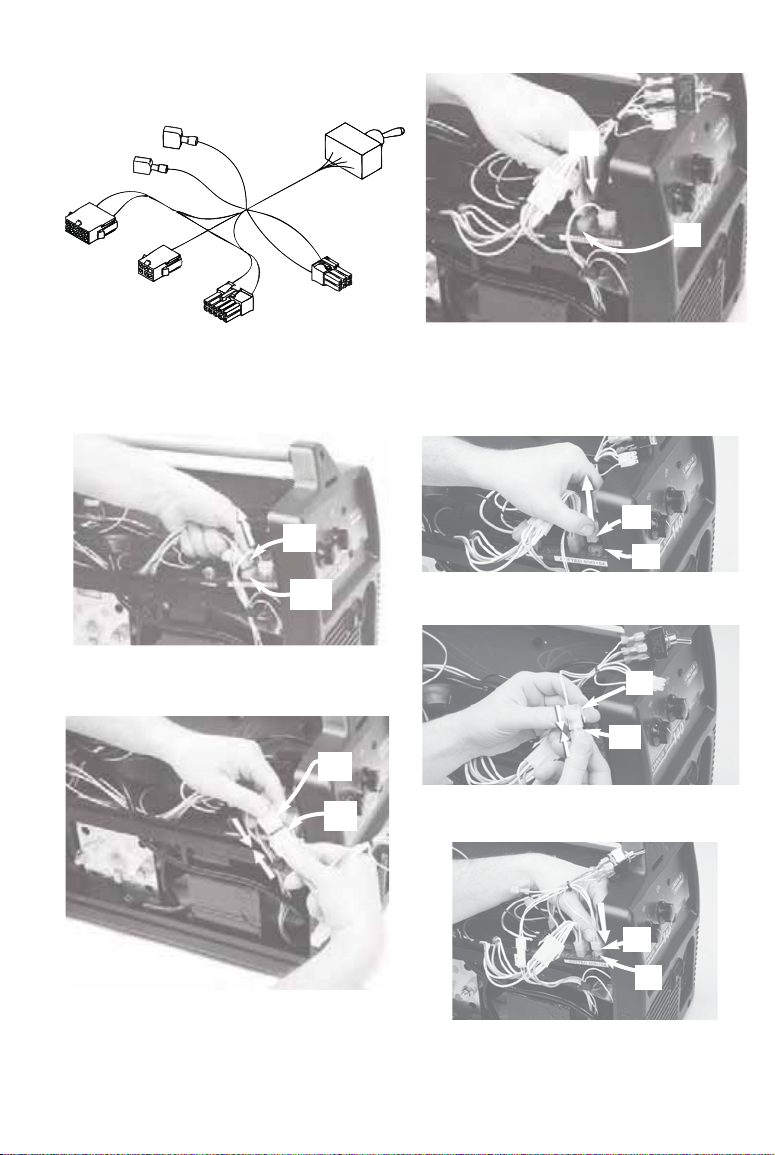

ELECTRICAL CONNECTIONS

544A

(Male)

543A

(Female)

INSTALLATION

P7

Toggle Switch

7 (10-pin)

J8 (6-pin)

P7 (10-pin)

P8 (6-pin)

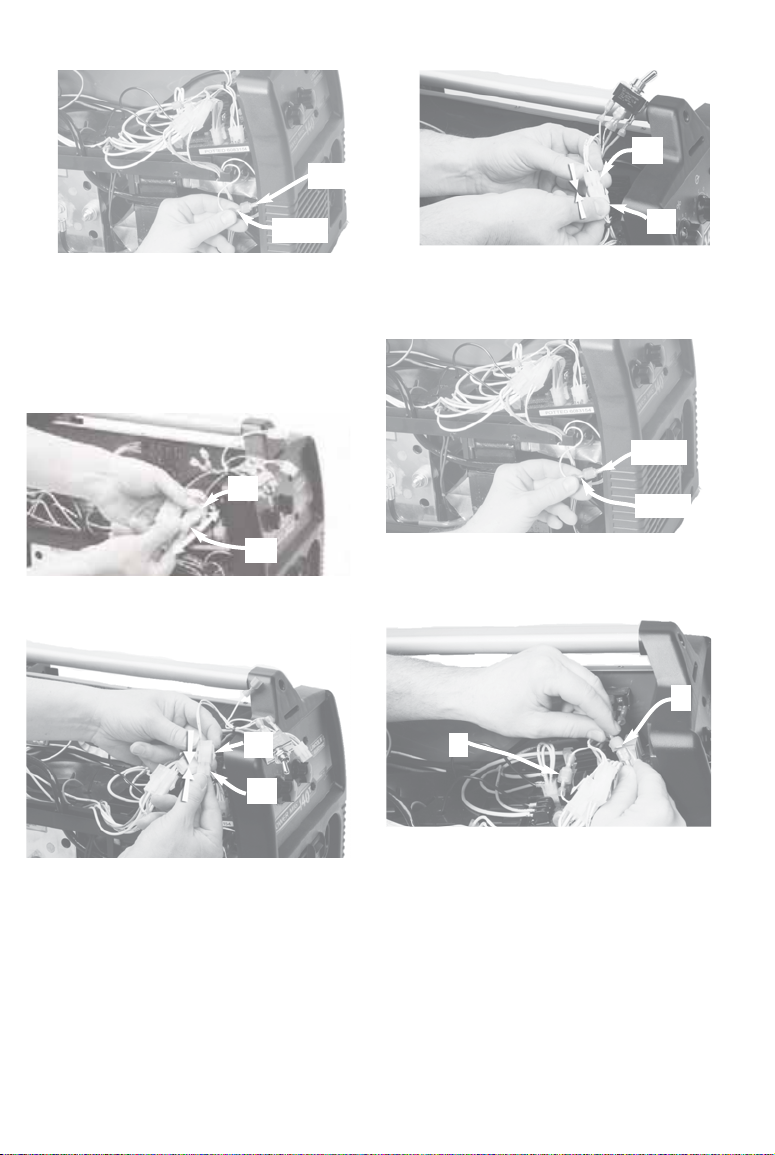

8. Adapter harness. All 6 connections

shown are used, and each one is

unique.

(Proceed as follows)

P3

J3

9. A. Remove P3 (10-pin) from board

J3 (10-pin).

P3

J7

J3

10. Connect harness P7 (10-pin) to

board J3 (10-pin).

IF MACHINE DOES NOT HAVE OPTIONAL

SPOT TIMER.

(11.A. thru 11.D.)

P5

J5

11.A. Remove P5 (6-pin) from

board J5 (6-pin).

J8

P5

11.B. Connect P5 (6-pin) to har-

ness J8 (6-pin).

9.B. Connect P3 (10-pin) to har-

ness J7 (10-pin).

P8

J5

11.C. Connect harness P8 (6-pin)

to board J5 (6-pin).

A-7

Page 16

INSTALLATION

544A

P8

543A

11.D. Find assembled pair of machine

terminals (leads 543A & 544A)

and disconnect. Go to step 13.

IF MACHINE DOES HAVE OPTIONAL SPOT

TIMER.

(12.A. thru 12.D.)

J9

P5

12.A. Remove P5 (6-pin) from spot

timer harness J9 (6-pin).

J8

P5

J9

12.C. Connect adapter harness P8 (6pin) to spot timer harness J9 (6-

pin).

544A

543A

12.D. Find assembled pair of machine

terminals (leads 543A & 544A)

and disconnect.

B

A

12.B. Connect P5 (6-pin) to adapter

harness J8 (6-pin).

13. Connect terminals:

(A) connect machine male (lead

543A) to adapter harness female

(lead 543A).

(B) connect machine female (lead

544A) to adapter harness male

(lead 544A).

14. Ensure that the locking tabs on all

connectors are latched closed.

A-8

Page 17

INSTALLATION

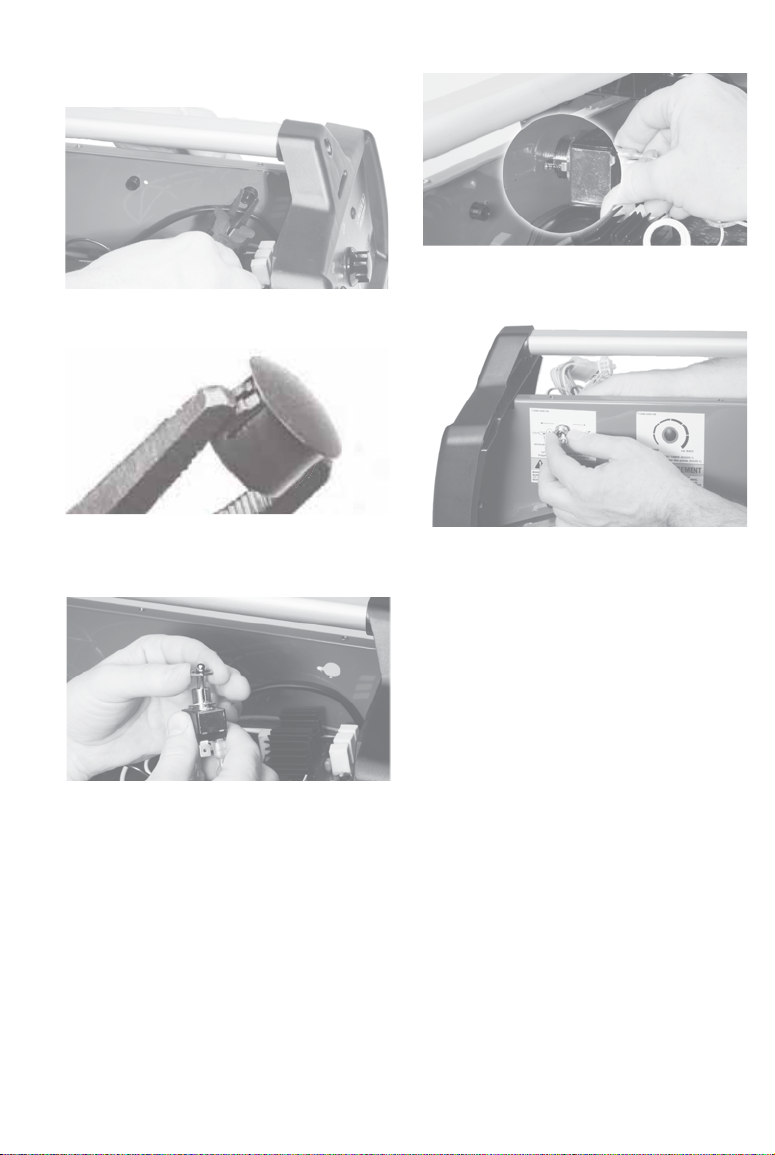

MOUNTING THE SWITCH

15. Remove the plug button from the

panel hole.

18. Install switch into panel hole.

Ensure washer tab is fully seated

into smaller hole.

16. Plug button is no longer needed.

Discard.

17. Remove mounting nut from switch.

Keep mounting nut for installation.

19. Reinstall mounting nut onto switch.

Wrench tighten.

RE-ASSEMBLE MACHINE AS

FOLLOWS:

20. Reinstall screw into plastic handle (if

so equipped).

21. Reinstall cover.

22. Reinstall door.

23. Reconnect input power to the

machine.

A-9

Page 18

INSTALLATION

ROUTINE WELDING MACHINE PREPARATION

WARNING

ELECTRIC SHOCK CAN KILL.

1. Disconnect input power to the machine.

------------------------------------------------------------------------

2. Machine polarity setting: Set to DC electrode positive

polarity per the machineʼs Instruction Manual.

3. Gas selection and flow rate: Connect 100% welding

grade argon gas supply to the machineʼs gas solenoid

valve. Set the supply regulator to deliver a gas flow rate

of 20 to 50 SCFH thru the spool gun.]

4. Flip the machineʼs wire drive selector switch (behind the

access door) to "Magnum® 100SG". (See Figure A.4)

FIGURE A.4

PREPARING THE SPOOL GUN

WARNING

ELECTRIC SHOCK CAN KILL.

1. Disconnect input power to the machine.

------------------------------------------------------------------------

2. The Conical Spring is used as the spool brake only when

feeding the stronger and harder aluminum alloy 5356.

The Conical Spring must be removed from the spool gun

whenever using the softer aluminum alloy 4043.

A-10

Page 19

INSTALLATION

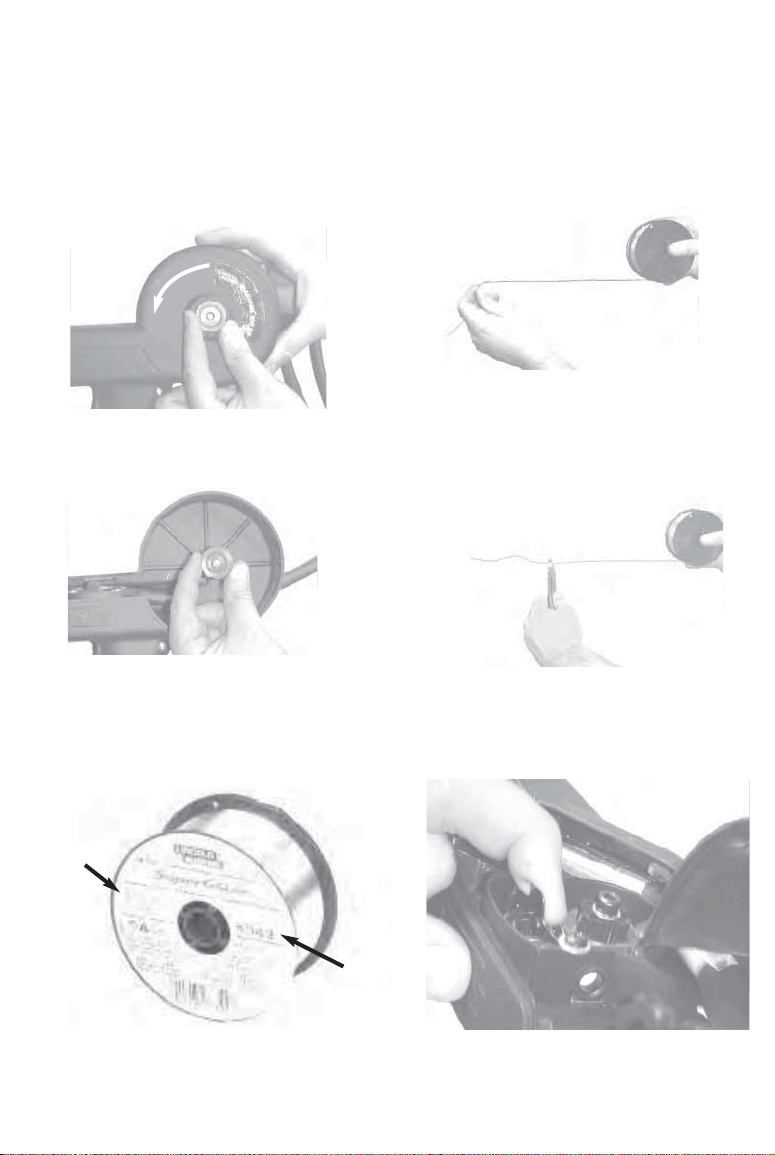

LOADING ALUMINUM WIRE

1. Remove gas cone and contact tip.

Remove spool cover by unscrewing

captive locking knob.

FIGURE A.5

2. Remove locking knob from spindle

bolt by unscrewing it.

FIGURE A.6

4. Extend approximately 12 inches

of wire from spool. Straighten it

out by back-bending it. Use care

to prevent the wire from dereeling.

FIGURE A.8

5. Cut off bent end of wire, leaving

straight section.

FIGURE A.9

3. Select wire alloy and diameter need-

ed. Alloy 4043 and 0.035 wire size

shown. Remove packaging and data

sheet from wire spool.

FIGURE A.7

Size

Alloy

6. Gently pull open the idle roll

assembly to expose the drive roll

groove.

FIGURE A.10

A-11

Page 20

INSTALLATION

7. Guide straightened wire through inlet

wire guide and toward drive roll

groove.

FIGURE A.11

8. While holding open the idle roll, slide

end of wire through drive rollʼs

groove and toward gun tube liner.

FIGURE A.12

10a. Alloy 4043: Roll up remaining wire

back onto spool and place spool

onto gun spindle. Install locking

knob and finger-tighten. Go to step

11.

FIGURE A.14

10b. Alloy 5356: Install Conical Spring,

small end first, onto gun spindle

(A). Roll up remaining wire back

onto spool and place spool onto

gun spindle. Install locking knob

and finger-tighten.

FIGURE A.15

A

9. Slide the wire into the liner until it

extends approximately 1 inch beyond

the end of the gas diffuser. Release

idle roll tab without snapping it.

FIGURE A.13

11. Grasp the

gas diffuser and slowly pull approximately 12 to 24 inches of wire

through the spool gun. There should

only be 1 to 2 lbs. of resistance. If

force is greater than 2 lbs. wire is

binding in the gun (also see

Troubleshooting guide).

free end of the wire at the

FIGURE A.16

A-12

Page 21

INSTALLATION

12. Cut off excess wire 1 to 2 inches

from gas diffuser. Install properly-

sized contact tip slightly past handtight. Install gas cone and handtighten.

FIGURE A.17

13. Reinstall spool cover. 1: tuck

coverʼs tab in place at arrow and

hold with thumb. 2: swing cover

closed. 3: finger-tighten locking

knob. 4: check for uniform fit all

around cover.

FIGURE A.18

4

CONNECTING THE GUN TO THE

WELDING MACHINE

1. Disconnect input power to the

machine.

2. Make sure that the gun locking knob

is loosened. (See Figure 20).

3. Fully insert gun cable connection

(welding power and gas supply) into

machine. Note that the master Key

way for P6 connector is located at

the arrow.

FIGURE A.19

P6

Connector

Key way

1

3

4. Check that the cable connectorʼs

2

end is flush with insulator at A.

Tighten gun locking knob (B) onto

cable connector.

FIGURE A.20

B

A

A-13

Page 22

NOTES

MAGNUM 100SG

Page 23

OPERATION

SAFETY PRECAUTIONS

• Uses reliable gun and feeder hardware from

Lincolnʼs Magnum® 100L Gun, Innershield

Read and understand this entire section before

guns, and small Power Mig products.

operating the machine.

WARNING

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts

or electrode with skin or wet

clothing.

• Insulate yourself from work and ground.

• Always wear dry insulating gloves.

• Read and follow “Electric Shock Warnings”

in the Safety section if welding must be performed under electrically hazardous conditions such as welding in wet areas or on or

in the workpiece.

FUMES AND GASES

can be dangerous.

• Keep your head out of fumes.

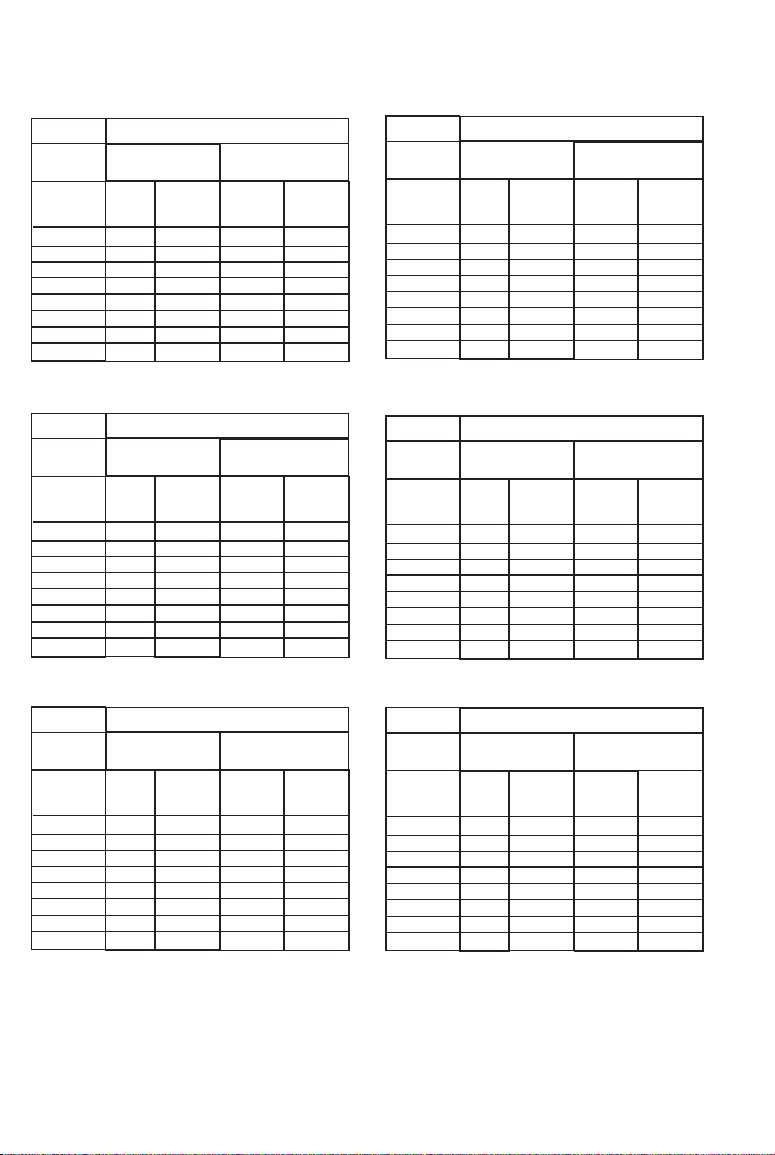

MACHINE SPEED AND VOLTAGE

TAP SETTINGS

5

MAX

5

MAX

3/16 in.

5

J

4

J

10 ga

4

I

3.5

J

12 ga

4.5

G

4

H

14 ga

4

F

3.5

F.5

16 ga

3

3

E

E

18 ga

1.5

2

D

D

20 ga

2

D

1.5

D

22 ga

Thickness

Tap

Tap

Weldment

Speed

Voltage

Speed

Voltage

0.0300.035

Wire Size:

Alloy:

4043

POWER MIG 180C MACHINE

6.5

8

E

E

3/16 in.

8

6.5

E

E

10 ga

7.5

6

E

E

12 ga

5.5

5

D

C

14 ga

5

4

B

B

16 ga

4

3

B

B

18 ga

3

2

A

A

20 ga

2

3

A

A

22 ga

Thickness

Tap

Tap

Weldment

Speed

Voltage

Speed

Voltage

0.030

0.035

Wire Size:

Alloy:

5356

POWER MIG 180T MACHINE

6.5

E

5

E

3/16 in.

5

E

4

E

10 ga

4.5

E

3.5

D

12 ga

4.5

D

3.5

D

14 ga

3

3.5

B

B

16 ga

2

3.5

A

A

18 ga

2.5

A

1.5

A

20 ga

2

A

1.5

A

22 ga

Thickness

Tap

Tap

Weldment

Speed

Voltage

Speed

Voltage

0.0300.035

Wire Size:

4043

Alloy:

POWER MIG 180T MACHINE

Alloy:

Wire Size:

Weldment

Thickness

22 ga

20 ga

18 ga

16 ga

14 ga

12 ga

10 ga

3/16 in.

• Use ventilation or exhaust to remove fumes

from breathing zone.

WELDING SPARKS

can cause fire or

explosion

• Keep flammable material away.

• Do not weld on containers that have held

combustibles.

ARC RAYS

can burn.

• Wear eye, ear and body protection.

Observe additional Safety Guidelines

detailed in the beginning of this manual.

Alloy:

Wire Size:

Weldment

Thickness

22 ga

20 ga

18 ga

16 ga

14 ga

12 ga

10 ga

3/16 in.

------------------------------------------------------------

PRODUCT DESCRIPTION

• Reliable, low-price aluminum welding accessory

for novice and experienced welders.

• Completely enclosed system.

• All combinations of specified aluminum alloys

and wire diameters can be fed with the same

drive roll and liner assembly.

• Gun cable compactly integrates welding current

and gas supplies with gun control functions.

Alloy:

Wire Size:

Weldment

Thickness

22 ga

20 ga

18 ga

16 ga

14 ga

12 ga

10 ga

3/16 in.

POWER MIG 180T MACHINE

4043

0.035

Speed

Speed

0.030

Voltage

Ta p

2

2.5

3.5

3.5

4.5

4.5

6.5

A

A

A

B

D

E

5

E

E

1.5

1.5

2

3

3.5

3.5

4

5

POWER MIG 180T MACHINE

5356

0.035

Speed

Speed

0.030

Voltage

Ta p

3

5.5

7.5

A

3

A

4

B

5

B

D

E

E

8

8

E

2

2

3

4

5

6

6.5

6.5

POWER MIG 180C MACHINE

4043

0.035

Speed

Speed

0.030

Voltage

Ta p

2

4.5

D

2

D

3

E

4

F

G

4

5

J

5

MAX

1.5

1.5

3

3.5

4

I

3.5

4

5

Voltage

Ta p

A

A

A

B

D

D

E

E

Voltage

Ta p

A

A

B

B

C

E

E

E

Voltage

Ta p

D

D

E

F. 5

H

J

J

MAX

B-1

Page 24

OPERATION

Alloy:

Wire Size:

Weldment

Thickness

22 ga

20 ga

18 ga

16 ga

14 ga

12 ga

10 ga

3/16 in.

Alloy:

Wire Size:

Weldment

Thickness

22 ga

20 ga

18 ga

16 ga

14 ga

12 ga

10 ga

3/16 in.

POWER MIG 180C MACHINE

5356

0.030

Speed

Voltage

3

3.5

5

6

7

8

8

9

MAX

POWER MIG 140T MACHINE

0.030

Speed

Voltage

2

2.5

3.5

4

4

4.5

N/A

N/A

Ta p

C

D

E

F

G

H

Ta p

A

A

B

D

E

E

N/A

N/A

Speed

2.5

3

3.5

4.5

5.5

I

6

6

7

4043

Speed

1.5

2

2.5

3

3

3

N/A

N/A

0.035

0.035

Voltage

Ta p

C

D

E

F

G

H

I

MAX

Voltage

Ta p

A

B

C

D

E

E

N/A

N/A

POWER MIG 140C MACHINE

Alloy:

Wire Size:

Weldment

Thickness

3/16 in.

Alloy:

Wire Size:

Weldment

Thickness

3/16 in.

Speed

22 ga

20 ga

18 ga

16 ga

14 ga

12 ga

10 ga

22 ga

20 ga

18 ga

16 ga

14 ga

12 ga

10 ga

3

3

5

6

6.5

7

N/A

N/A

POWER MIG 140C MACHINE

Speed

2

2

3

4

3

5

N/A

N/A

0.030

Voltage

0.030

Voltage

Ta p

E

E

F

G

I

MAX

/A

N

N/A

Ta p

E

E

E.5

G

I

MAX

N/A

N/A

4043

5356

Speed

2.5

2.5

4.5

5.5

5

5.5

N/A

N/A

Speed

1.5

1.5

3

3

3

4

N/A

N/A

0.035

Voltage

Ta p

E

E

F

G

J

MAX

N/A

N/A

0.035

Voltage

Ta p

E

E

F

G

J

MAX

N/A

N/A

Alloy:

Wire Size:

Weldment

Thickness

22 ga

20 ga

18 ga

16 ga

14 ga

12 ga

10 ga

3/16 in.

POWER MIG 140T MACHINE

5356

0.030

Speed

Voltage

3

3

5

5

6

6

N/A

N/A

Ta p

A

A

B

D

D

E

N/A

N/A

Speed

2.5

2.5

4

4.5

5

5

N/A

N/A

0.035

Voltage

Ta p

A

A

B

D

D

E

N/A

N/A

Wire Size:

Weldment

Thickness

3/16 in.

B-2

Alloy:

22 ga

20 ga

18 ga

16 ga

14 ga

12 ga

10 ga

Weld-Pak 125 MACHINE

4043

0.030

Speed

Voltage

2.5

2.5

3

3

3.5

3.5

N/A

N/A

Tap

N/A

N/A

Speed

B

B

C

D

E

E

2

2

2

2.5

3

3.5

N/A

N/A

0.035

Voltage

Tap

B

B

C

D

E

E

N/A

N/A

Page 25

N/A

N/A

N/A

N/A

3/16 in.

N/A

N/A

N/A

N/A

10 ga

5.5

7

E

E

12 ga

5

6

E

E

14 ga

4.5

5

D

D

16 ga

4

4.5

C

C

18 ga

2

2.5

B

B

20 ga

2

2.5

A

A

22 ga

Tap

Tap

Thickness

Voltage

Speed

Voltage

Weldment

Speed

0.030

0.035

Wire Size:

Alloy:

5356

Weld-Pak 125 MACHINE

Wire Size:

Weldment

Thickness

Weld-Pak 125 MACHINE

Alloy:

Speed

22 ga

20 ga

18 ga

16 ga

14 ga

12 ga

10 ga

3/16 in.

N/A

N/A

2.5

2.5

4.5

5356

Speed

2

2

4

4.5

5

5.5

N/A

N/A

0.035

Voltage

Tap

A

B

C

D

E

E

N/A

N/A

0.030

Voltage

Tap

A

B

C

5

D

6

E

7

E

N/A

N/A

After choosing the proper welding wire

for your application, load the aluminum

wire, connect the gun and cable to the

welding machine. (See Installation

Section).

WELDING PROCEDURES

1. Read and understand Arc Welding Safety

Precautions located throughout this manual

and the Welding Machineʼs Instruction Manual.

Also for helpful hints in welding see (LTW1) the

Learn to Weld manual which is supplied with

the welding machine.

2. Obtain and use the proper personal protective

equipment for welding. Connect the WORK

(welding ground) cable(-) to piece(s) being

welded. Make sure gas hose from cylinderʼs

regulator is connected to welderʼs gas INLET.

Open cylinderʼs gas valve.

OPERATION

6. Cut off the aluminum wire so that it extends

about 1/4 inches from the contact tip.

7. CTWD (Contact Tip to Work Distance): Position

the gun so that the contact tip is nominally 3/8

inches from the joint and tilted with a push

angle toward it. The aluminum wire should not

contact the workpiece. (See figure B.1)

FIGURE B.1

8. Protect the eyes and pull the trigger to begin

welding.

9. Adjust the hand travel speed of the gun to

achieve a proper weld. The emerging wire

should stay within the molten puddle and not

overrun it. This speed also should not be so

slow that either the workpiece excessively

melts, or the weld bead becomes excessively

large.

10. Release the trigger to stop welding.

3. Connect input power to the machine.

4. Turn the machineʼs power switch to "on". Set

wire speed and voltage tap settings to tables

which are provided in the beginning of this

section.

5. Flip toggle selector switch inside of machine to

"Magnum® 100SG" position. Press and hold

trigger for about 5 seconds to purge hose. Be

sure the Gas flow rate is set to 20 to 50 SCFH

thru the spool gun.

B-3

Page 26

MAINTENANCE

1

2

2

4

3

P6 CONNECTOR PINOUT

MASTER KEY

1

2

2

4

3

P6 CONNECTOR PINOUT

MASTER KEY

SAFETY PRECAUTIONS

WARNING

ELECTRIC SHOCK can kill.

• Only qualified personnel

should perform this maintenance.

• Turn the input power OFF at the disconnect switch or fuse box before

working on this equipment.

• Do not touch electrically hot parts.

-----------------------------------------------------

ROUTINE AND PERIODIC

MAINTENANCE

RECOMMENDED TOOLS

• #2 Phillips screw-driver

• Slotted screw-driver

• 5/16 inch nut driver

• Torque Wrench

• Adjustable-jaw pliers

• 7/16 inch open-end wrench (gas diffuser)

• 9/16 inch open-end wrench (gun tube nut)

• Welding pliers (optional)

• Wire cutter

• Wire stripper

• Needle nose pliers

• Terminal crimping tool

• Flashlight

• Hand-held electrical meter *

• 3.0 mm metric allen wrench (drive roll

screw)

• Tape measure or 6-inch scale

• Tachometer (optional)

*Note: Two meters are used for simultaneously

measuring drive motorʼs voltage and current.

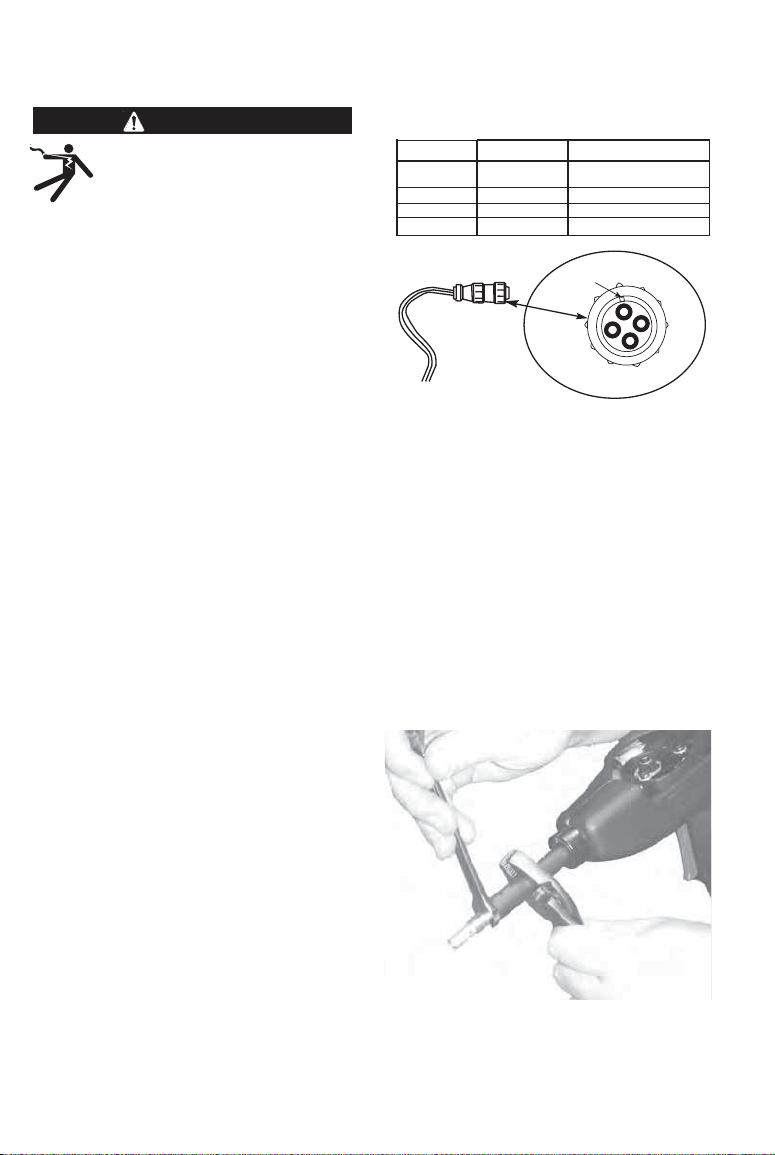

P6 CONNECTOR PIN-OUT

4

- Motor

Black

+ Motor

Red

3

Trigger

White

2

Trigger

White

1

Pin No.

Function

Gun Cable Lead Color

Pin No.

1

2

3

4

TABLE D.1

Function

Trigger

Trigger

+ Motor

- Motor

Gun Cable Lead Color

White

White

Red

Black

GAS DIFFUSER REPLACEMENT

This part may need to be replaced if it

has accumulated excessive spatter and

cannot be cleaned:

1. Remove gas cone and contact tip.

2. Carefully grasp gun tube with pliers

to prevent accidentally loosening gun

tube. Gas diffuser has right-hand

threads. Loosen gas diffuser with

wrench. (See Figure D.1)

FIGURE D.1

CLEANING AND INSPECTIONS

• Vacuum out any aluminum shavings that may

have accumulated inside of the gun. ( See

Correcting Wire Shaving Issues in this section).

• Wipe off dust and debris.

• Check that the gun tube and its lock nut are

properly tightened to the cable connector.

• Replace any warning or product identification

decals that have become illegible.

3. Install gas diffuser and thread into

place in gun tube. Tighten diffuser to

41 to 47 in.-lbs. with Torque Wrench.

D-1

Page 27

MAINTENANCE

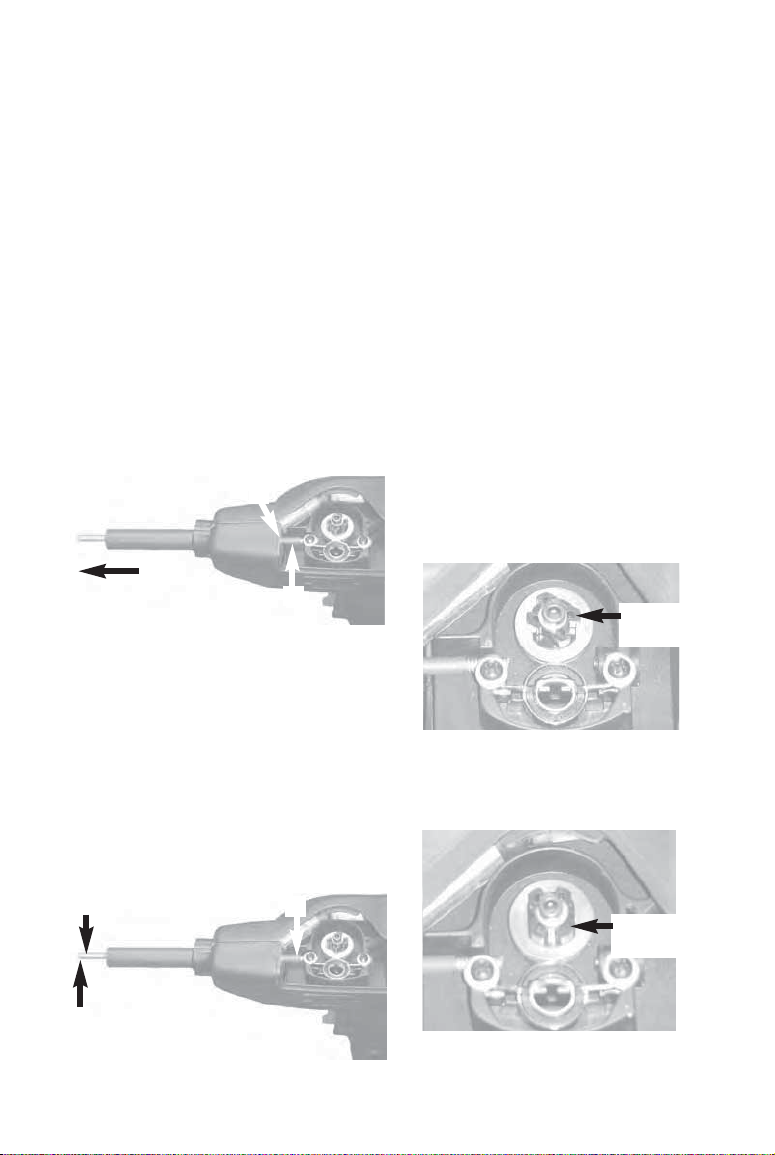

LINER ASSEMBLY REPLACEMENT

OR CLEANING

1. Replacement liner assemblies are factory-made to the correct length. No cutting is required. The same liner fits all

specified wire sizes and alloys:

2. Remove gas cone, contact tip, and gas

diffuser (see Gas Diffuser

Replacement in this Section). Remove

spool cover.

3. Liner removal: Grasp liner with Needle

nose pliers at point A. Gently work liner

toward cable connector until the liner is

loose in it. Be careful not to scrape

linerʼs gas-tight seal (point B) on connector. Withdraw liner out of gun tube

(arrow C). (See figure D.2)

FIGURE D.2

B

C

A

3a. Clean out old liner by blowing out with

shop air or obtain a new replacement

liner.

4. Slide liner, seal-end first, into gun tube.

Grasp liner with pliers at

A. Gently push liner into connector.

B. Check that liner passes through slot

in wire feeder.

C. Stop pushing when liner is 1.00 to

1.25 inches from end of gun tube.

(See figure D.3)

6. Reinstall gas diffuser (see Figure D.1)

and thread into place. Allow the diffuser

to push the liner into its final position.

Tighten to 41 to 47 in.-lbs. with a torque

wrench.

7. Reinstall contact tip and gas cone.

DRIVE ROLL REPLACEMENT

1. The same drive roll fits all specified wire

sizes and alloys (See Table D.1).

2. Replace the drive roll if its feeding

groove has become worn or cannot be

cleaned of galled aluminum.

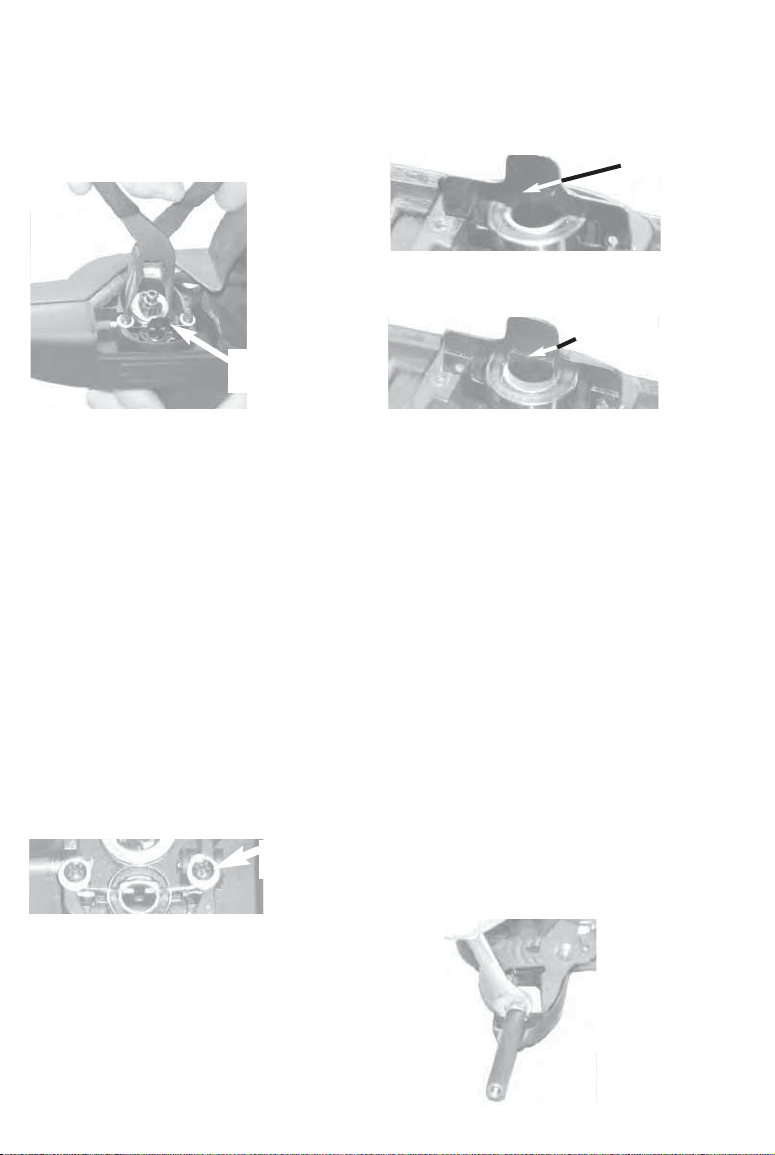

3. Drive roll removal: Remove wire from

the wire drive. Unlock drive roll by rotating twist-lock in either direction. (See

figure D.4 and figure D.5) .

4. Twist-lock is rotated to the locked posi-

tion, securing drive roll in place.

FIGURE D.4

Twist-lock

Locked position

5. Twist-lock is rotated to the unlocked

position, allowing drive roll removal.

FIGURE D.5

FIGURE D.3

A

B

C

5. Liner installation: See step 4 above.

Twist-lock

Unlocked position

D-2

Page 28

MAINTENANCE

6. Drive roll may be removed with pliers, as

shown in figure D.6. It may be helpful to

relieve the idle roll tension during this

step.

FIGURE D.6

Idle Roll

Tension

Correct orientation. Note that lower spring is

not visible in bore of idle roll bearing at

arrow.

FIGURE D.8

RIGHT

Incorrect orientation. Note that lower spring

is visible in bore of idle roll bearing at arrow.

FIGURE D.9

WRONG

7. Clean the drive rollʼs groove or obtain a

new replacement drive roll (if needed).

8. Install the drive roll by reversing the

above steps 1 thru 7. Either side of the

drive roll may be face-up.

IDLE ROLL ASSEMBLY

REPLACEMENT

1. Replace if it is degraded from use; for

example, it is becoming galled with aluminum deposits.

2. Remove drive roll. (See Maintenance

Section)

3. Remove both idle roll assembly retaining

screws and washers.(See figure D.7)

FIGURE D.7

Retaining screws

and washers

4. Using Needle nose pliers, slowly pull the

idle roll assembly out of the wire drive by

equally working both sides of the tabbed

idle roll spring.

6. Using Needle nose pliers, push the new

idle roll assembly into the wire drive until

it is fully seated.

7. Reinstall the retaining screws and washers. Do not use the screws to draw the

idle roll into place. Reinstall the drive roll

and wire into the wire drive.

GUN TUBE ASSEMBLY

REPLACEMENT

1. Replace if it is degraded from use; for

example, its insulating tube is breaking

down.

2. Remove liner assembly. (See

Maintenance Section)

3. Remove left side of handle. Loosen gun

tube nut with wrench. Nut has right-hand

threads. Use adjustable pliers on gun tube

mounting plate to prevent cable assembly

from rotating in gun handle. (See figure

D.10)

FIGURE D.10

5. Insert the new idle roll assembly into the

wire drive with the correct orientation,

(See figures D.8 and D.9).

D-3

Page 29

MAINTENANCE

4. Obtain a new replacement gun tube (if need-

ed). Remove locking nut from old gun tube and

install onto new gun tube. Nut should be fully

threaded finger-tight against the insulating

tube.

5. Slide gun tubeʼs external threads through gun

tube mounting plate and screw the gun tube by

hand into the cable connector until the nut pulls

the mounting plate snug against the connector.

6. Tighten the nut and mounting plate to the con-

nector with Torque Wrench 10 to 12 ft.-lbs.

7. Reassemble gun. Be careful not to pinch any

leads between gun handle halves.

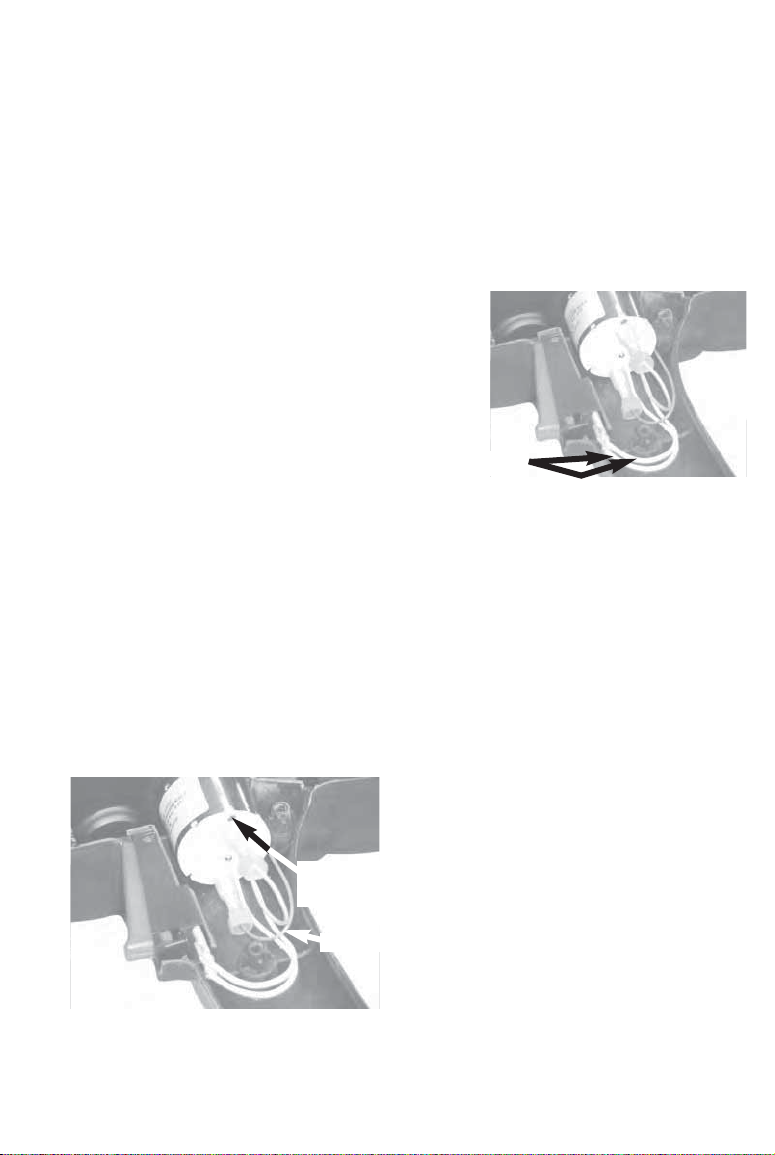

WIRE DRIVE ASSEMBLY REMOVAL AND

INSTALLATION

1. There are no serviceable or maintainable parts

inside of the wire drive.

2. Remove liner assembly (See Maintenance

Section figures D.2 and D.3).

3. Remove left side of handle.

4. Disconnect black and red leads from drive

motor. Use care to prevent damage to motorʼs

fast-on electrical tabs.

5. Slide wire drive out of right handle half.

6. When reinstalling wire drive, note the proper

motor lead connection in the figure. Reconnect

red motor lead to positive (+) terminal, marked

with red dot at arrow. Reconnect black lead to

other motor terminal. (See figure D.11)

“+” Terminal

Red Dot

Black Lead

FIGURE D.11

7. Reassemble gun. Be careful not to pinch any

leads between gun handle halves.

D-4

TRIGGER ASSEMBLY REPLACEMENT

1. There are no serviceable or maintainable parts

inside of the trigger.

2. Remove spool cover and left side of handle.

3. Slide trigger out of right handle half. Disconnect

both white leads from trigger. Use care to prevent damage to electrical leads and the terminals. (See Figure D.12)

FIGURE D.12

White Leads

4. Connect both white leads to the new trigger.

Either lead may be connected to either trigger

pin (non-polarized connections).

5. Slide new trigger into place and reassemble the

gun. Be careful not to pinch any leads between

gun handle halves.

WELDING CABLE ASSEMBLY

REPLACEMENT

1. Generally, there are no serviceable or maintain-

able parts, except for both o-rings on the

machineʼs power and gas connector; these

seals may be replaced. However, there are

options:

• Damage to the four #22 AWG control leads at

the gun cableʼs welding machine end (P6 plug)

may be repairable without

removing or

replacing the entire gun cable. The leads

can be spliced and soldered back together, and then reinsulated with heat-shrink

tubing. See Table D.1 in Maintenance

Section for a description of the connections.

• Otherwise, the damaged gun cable may

be replaced.

Page 30

MAINTENANCE

2. Remove liner assembly. (See Maintenance

Section)

3. Remove gun tube assembly. (See Maintenance

Section)

4. Remove wire drive assembly. (See Maintenance

Section)

5. Disconnect trigger. Use adjustable pliers to

remove cable strain relief from right handle half.

(See figure D.13)

6. Pull damaged cable out of the right handle half.

The cable connector will fit through the strain relief

opening. Mark the new cable at a point 4.750 to

4.813 inches from the end of the cable connector.

(See figure D.14)

7. Place the strain relief onto the new cable at the

mark as shown in figure D.15.

FIGURE D.13

FIGURE D.14

Liner assembly (S26612)

KP2632-1

1-piece

parts

Drive roll assembly (S26236-2)

KP2529-2

1-piece

replacement

Periodic

Gun tube assembly (S19703-1)

KP2631-1

1-piece

Gas cone assembly (M16294)

KP1938-1

1-piece

Gas diffuser (S19728)

KP2040-1

1-piece

parts

Contact tip, 0.035 wire (S19726-3)

KP2039-3B1

10-pack

Consumable

Contact tip, 0.030 wire (S19726-2)

KP2039-2B1

10-pack

TABLE D.2

Consumable

parts

Periodic

replacement

parts

TABLE D.2

Contact tip, 0.030 wire (S19726-2)

Contact tip, 0.035 wire (S19726-3)

Gas diffuser (S19728)

Gas cone assembly (M16294)

Gun tube assembly (S19703-1)

Drive roll assembly (S26236-2)

Liner assembly (S26612)

Mark for strain relief

8. Install the new gun cable. Pass the cable connector through the opening in the right handle, seat

the strain relief in place, and then check to insure

the cable is not kinked between strain relief and

connector. Reassemble gun by reversing steps 2

through 5.

CORRECTING WIRE SHAVING ISSUES

1. If the inlet of the liner assembly is shaving the alu-

minum wire (the wire is usually peeled off in curled

chips) during feeding, the wire feed centerlines of

the wire drive and the liner itself may be misaligned.

• This misalignment may occur whenever the gun

tube, wire drive, or welding cable assemblies are

replaced.

• A limited amount of adjustment is available at the

gun tube mounting to possibly eliminate the shaving problem.

2. Visually check if wire is centered in the linerʼs inlet

opening. Feed wire through the spool gun and note

which side the shaving seems to occur.

3. Remove left side of handle. See Figure D.10 Gun

FIGURE D.15

Tube Replacement. Slightly

loosen gun tubeʼs nut

as shown.

4. Slide the gun tube in the mounting plateʼs hole to

realign the wire and then retighten the nut as

shown. Reassemble the gun.

5. Repeat steps 2 thru 4 until shaving is eliminated. A

light accumulation of fine dust is also permissible

after feeding 1/4 of a spool during welding use.

KP2039-2B1

KP2039-3B1

KP2040-1

KP1938-1

KP2631-1

KP2529-2

KP2632-1

10-pack

10-pack

1-piece

1-piece

1-piece

1-piece

1-piece

D-5

Page 31

TROUBLESHOOTING

Lincoln Authorized Field Service Facilityfor technical troubleshooting assistance before you proceed.

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact yourLocal

CAUTION

the machine symptom.

the obvious external possibilities that may contribute to

The second column labeled “POSSIBLE CAUSE” lists

Step 2.POSSIBLE CAUSE.

describes the symptom that the machine is exhibiting.

local Lincoln Authorized Field Service Facility.

that the machine may exhibit. Find the listing that best

Recommended Course of Action safely, contact your

TOMS)”. This column describes possible symptoms

If you do not understand or are unable to perform the

Look under the column labeled “PROBLEM (SYMP-

Step 1.LOCATE PROBLEM (SYMPTOM).

local Lincoln Authorized Field Service Facility.

Possible Cause, generally it states to contact your

Simply follow the three-step procedure listed below.

This column provides a course of action for the

locate and repair possible machine malfunctions.

Step 3.RECOMMENDED COURSE OF ACTION

This Troubleshooting Guide is provided to help you

__________________________________________________________________________

observe all safety notes and precautions detailed throughout this manual.

operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please

Unauthorized repairs performed on this equipment may result in danger to the technician and machine

Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel.

WARNING

HOW TO USE TROUBLESHOOTING GUIDE

HOW TO USE TROUBLESHOOTING GUIDE

WARNING

Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel.

Unauthorized repairs performed on this equipment may result in danger to the technician and machine

operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please

observe all safety notes and precautions detailed throughout this manual.

__________________________________________________________________________

This Troubleshooting Guide is provided to help you

locate and repair possible machine malfunctions.

Simply follow the three-step procedure listed below.

Step 1. LOCATE PROBLEM (SYMPTOM).

Look under the column labeled “PROBLEM (SYMPTOMS)”. This column describes possible symptoms

that the machine may exhibit. Find the listing that best

describes the symptom that the machine is exhibiting.

Step 2. POSSIBLE CAUSE.

The second column labeled “POSSIBLE CAUSE” lists

the obvious external possibilities that may contribute to

the machine symptom.

Step 3. RECOMMENDED COURSE OF ACTION

This column provides a course of action for the

Possible Cause, generally it states to contact your

local Lincoln Authorized Field Service Facility.

If you do not understand or are unable to perform the

Recommended Course of Action safely, contact your

local Lincoln Authorized Field Service Facility.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local

Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

E-1

Page 32

Lincoln Authorized Field Service Facilityfor technical troubleshooting assistance before you proceed.

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact yourLocal

CAUTION

section)

1. Motor leads are connected in reverse.

1. Connect properly. (See maintenance

Drive roll turns in reverse direction.

ing machine s instruction manual.

4. See Troubleshooting section in weld-

4. Low motor voltage.

liner (See Maintenance Section ).

remove and clean or replace gun tube

the wire feed path in the gun.

wire shavings; remove kinked wire;

3. Wire is obstructed somewhere along

3. Check for obstructions: remove any

too low.

2. Machine s wire feed speed setting is

2. Increase wire feed speed.

minum.

replace drive roll.

Sluggish wire feed when trigger is pulled

1. Drive roll is worn or galled with alu-

1. Clean drive roll of all aluminum or

diameter used.

the correct size.

11. Contact tip size too small for wire

11. Replace contact tip with one that is

machine.

ing machine s instruction manual.

10. No motor voltage or current from

10. See Troubleshooting section in weld-

replacement.

9. Damaged spool gun motor.

9. Contact LASF for possible motor

check trigger circuit for continuity.

8. Defective trigger circuit in gun.

8. Disconnect gun from machine and

section)

7. Defective trigger. (contacts open)

7. Replace trigger. (See maintenance

set to spool gun mode.

tion.

6. Machine s toggle selector switch is not

6. Flip switch to proper operating posi-

wire s mechanical resistance.

check for proper wire alignment and

5. Bird nest.

5. Cut out bird nest, reload wire, and

liner. (See maintenance section)

4. Fully or partially blocked gun tube liner.

4. Remove and clean or replace gun tube

3. Contact tip burnback.

3. Replace contact tip.

2. Spool gun is out of wire.

2. Install full spool of specified wire.

pulled

No wire feed occurs when trigger is

1. Machine is switched off or unplugged.

1. Switch on or plug in machine.

PROBLEMS

(SYMPTOMS)

CAUSE

COURSE OF ACTION

PROBLEMS

POSSIBLE

RECOMMENDED

Observe all Safety Guidelines detailed throughout this manual

Observe all Safety Guidelines detailed throughout this manual

PROBLEMS

(SYMPTOMS)

No wire feed occurs when trigger is

pulled

Sluggish wire feed when trigger is pulled

Drive roll turns in reverse direction.

TROUBLESHOOTING

POSSIBLE

CAUSE

1. Machine is switched off or unplugged.

PROBLEMS

2. Spool gun is out of wire.

3. Contact tip burnback.

4. Fully or partially blocked gun tube liner.

5. Bird nest.

6. Machine s toggle selector switch is not

set to spool gun mode.

7. Defective trigger. (contacts open)

8. Defective trigger circuit in gun.

9. Damaged spool gun motor.

10. No motor voltage or current from

machine.

11. Contact tip size too small for wire

diameter used.

1. Drive roll is worn or galled with aluminum.

2. Machine s wire feed speed setting is

too low.

3. Wire is obstructed somewhere along

the wire feed path in the gun.

4. Low motor voltage.

1. Motor leads are connected in reverse.

1. Switch on or plug in machine.

2. Install full spool of specified wire.

3. Replace contact tip.

4. Remove and clean or replace gun tube

5. Cut out bird nest, reload wire, and

6. Flip switch to proper operating posi-

7. Replace trigger. (See maintenance

8. Disconnect gun from machine and

9. Contact LASF for possible motor

10. See Troubleshooting section in weld-

11. Replace contact tip with one that is

1. Clean drive roll of all aluminum or

2. Increase wire feed speed.

3. Check for obstructions: remove any

4. See Troubleshooting section in weld-

1. Connect properly. (See maintenance

RECOMMENDED

COURSE OF ACTION

liner. (See maintenance section)

check for proper wire alignment and

wire s mechanical resistance.

tion.

section)

check trigger circuit for continuity.

replacement.

ing machine s instruction manual.

the correct size.

replace drive roll.

wire shavings; remove kinked wire;

remove and clean or replace gun tube

liner (See Maintenance Section ).

ing machine s instruction manual.

section)

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local

Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

E-2

Page 33

Lincoln Authorized Field Service Facilityfor technical troubleshooting assistance before you proceed.

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact yourLocal

CAUTION

nique.

6. See Operation Section for information.

6. Improper welding parameters or tech-

to electrode positive polarity.

5. Reconnect machine s welding output

5. Improper electrode polarity.

windy location before welding.

4. Erect a wind shield or move to a non-

4. Welding in a windy environment..

for appearance improvement.

alternate, known gas supply and check

reads 100% argon. Temporarily use

gas.

3. Check that the gas supply s labeling

3. Improper or contaminated shielding

2. See symptom "Low or no gas flow"

2. Low gas flow.

dull gray oxidized surface).

1. See symptom "Low or no gas flow"

Poor weld bead appearance (porosity or

1. No gas flow.

gish wire feed.

2. See symptoms on intermittent or slug-

2. Wire may be feeding intermittently.

to Work Distance) is incorrect.

Welding information.

back.

nique. (Example: CTWD (Contact Tip

1. See Operation Section for proper

Frequent occurrence of contact tip burn-