Page 1

Operator’s Manual

RETURN TO MAIN MENU

AC-225-S & AC/DC 225/125

For use with machines having Code Numbers:

10420, 10421, 10422,

10423, 10424, 11074,

11602, 11603, 11604,

11674, 11675

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IMT237-P | Issue D ate Nov-13

© Lincoln Global, Inc. All Rights Reserved.

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Page 2

THANK YOU FOR SELECTING

A QUALITY PRODUCT BY

LINCOLN ELEC TRIC.

PLEASE EXAMINE CARTON AND EQUIPMENT FOR

DAMAGE IMMEDIATELY

When this equipment is shipped, title passes to the purchaser upon

receipt by the carrier. Consequently, Claims for material damaged in

shipment must be made by the purchaser against the transportation

company at the time the shipment is received.

SAFETY DEPENDS ON YOU

Lincoln arc welding and cutting equipment is designed and built with

safety in mind. However, your overall safety can be increased by

proper installation ... and thoughtful operation on your part.

DO NOT INSTALL, OPERATE OR REPAIR THIS EQUIPMENT

WITHOUT READING THIS MANUAL AND THE SAFETY PRECAUTIONS

CONTAINED THROUGHOUT. And, most importantly, think before you

act and be careful.

WARNING

This statement appears where the information must be followed

exactly to avoid serious personal injury or loss of life.

CAUTION

This statement appears where the information must be followed to

avoid minor personal injury or damage to this equipment.

KEEP YOUR HEAD OUT OF THE FUMES.

DON’T get too close to the arc. Use

corrective lenses if necessary to

stay a reasonable distance away

from the arc.

READ and obey the Material Safety

Data Sheet (MSDS) and the warning

label that appears on all containers

of welding materials.

USE ENOUGH VENTILATION or

exhaust at the arc, or both, to keep

the fumes and gases from your breathing zone and the general area.

IN A LARGE ROOM OR OUTDOORS, natural ventilation may be

adequate if you keep your head out of the fumes (See below).

USE NATURAL DRAFTS or fans to keep the fumes away from your

face.

If you de velop unusual symptoms, see your supervisor. Perhaps the

welding atmosphere and ventilation system should be checked.

WEAR CORRECT EYE, EAR & BODY PROTECTION

PROTECT your eyes and face with welding helmet

properly fitted and with proper grade of filter plate

(See ANSI Z49.1).

PROTECT your body from welding spatter and arc

flash with protective clothing including woolen

clothing, flame-proof apron and gloves, leather

leggings, and high boots.

PROTECT others from splatter, flash, and glare with

protective screens or barriers.

IN SOME AREAS, protection from noise may be

appropriate.

BE SURE protective equipment is in good condition.

Also, wear safety glasses in work area AT ALL

TIMES.

SPECIAL SITUATIONS

DO NOT WELD OR CUT containers or materials which previously had

been in contact with hazardous substances unless they are properly

cleaned. This is extremely dangerous.

DO NOT WELD OR CUT painted or plated parts unless special

precautions with ventilation have been taken. They can release highly

toxic fumes or gases.

Additional precautionary measures

PROTECT compressed gas cylinders from excessive heat, mechanical

shocks, and arcs; fasten cylinders so they cannot fall.

BE SURE cylinders are never grounded or part of an electrical circuit.

REMOVE all potential fire hazards from welding area.

ALWAYS HAVE FIRE FIGHTING EQUIPMENT READY FOR

IMMEDIATE USE AND KNOW HOW TO USE IT.

Page 3

SECTION A:

WARNINGS

CALIFORNIA PROPOSITION 65 WARNINGS

Diesel Engines

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and other

reproductive harm.

Gasoline Engines

The engine exhaust from this product contains chemicals known

to the State of California to cause cancer, birth defects, or other

reproductive harm.

ARC WELDING CAN BE HAZARDOUS. PROTECT

YOURSELF AND OTHERS FROM POSSIBLE SERIOUS

INJURY OR DEATH. KEEP CHILDREN AWAY. PACEMAKER WEARERS SHOULD CONSULT WITH THEIR

DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For additional

safety information, it is strongly recommended that you purchase a

copy of “Safety in Welding & Cutting - ANSI Standard Z49.1” from the

American Welding Society, P.O. Box 351040, Miami, Florida 33135 or

CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety”

booklet E205 is available from the Lincoln Electric Company, 22801

St. Clair Avenue, Cleveland, Ohio 44117-1199.

BE SURE THAT ALL INSTALLATION, OPERATION,

MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

SAFETY

1.d. Keep all equipment safety guards, covers and

devices in position and in good repair.Keep

hands, hair, clothing and tools away from

V-belts, gears, fans and all other moving parts

when starting, operating or repairing

equipment.

1.e. In some cases it may be necessary to remove safety guards to

perform required maintenance. Remove guards only when

necessary and replace them when the maintenance requiring

their removal is complete. Always use the greatest care when

working near moving parts.

1.f. Do not put your hands near the engine fan. Do not attempt to

override the governor or idler by pushing on the throttle control

rods while the engine is running.

1.g. To prevent accidentally starting gasoline engines while turning

the engine or welding generator during maintenance work,

disconnect the spark plug wires, distributor cap or magneto wire

as appropriate.

1.h. To avoid scalding, do not remove the radiator

pressure cap when the engine is

hot.

ELECTRIC AND

MAGNETIC FIELDS MAY

BE DANGEROUS

2.a. Electric current flowing through any conductor

causes localized Electric and Magnetic Fields (EMF). Welding

current creates EMF fields around welding cables and welding

machines

FOR ENGINE POWERED

EQUIPMENT.

1.a. Turn the engine off before troubleshooting

and maintenance work unless the

maintenance work requires it to be running.

1.b. Operate engines in open, well-ventilated

areas or vent the engine exhaust fumes outdoors.

1.c. Do not add the fuel near an open flame

welding arc or when the engine is running.

Stop the engine and allow it to cool before

refueling to prevent spilled fuel from

vaporizing on contact with hot engine parts

and igniting. Do not spill fuel when filling

tank. If fuel is spilled, wipe it up and do not start engine until

fumes have been eliminated.

2.b. EMF fields may interfere with some pacemakers, and welders

having a pacemaker should consult their physician before

welding.

2.c. Exposure to EMF fields in welding may have other health effects

which are now not known.

2.d. All welders should use the following procedures in order to

minimize exposure to EMF fields from the welding circuit:

2.d.1. Route the electrode and work cables together - Secure

them with tape when possible.

2.d.2. Never coil the electrode lead around your body.

2.d.3. Do not place your body between the electrode and work

cables. If the electrode cable is on your right side, the

work cable should also be on your right side.

2.d.4. Connect the work cable to the workpiece as close as possible to the area being welded.

2.d.5. Do not work next to welding power source.

3

Page 4

SAFETY

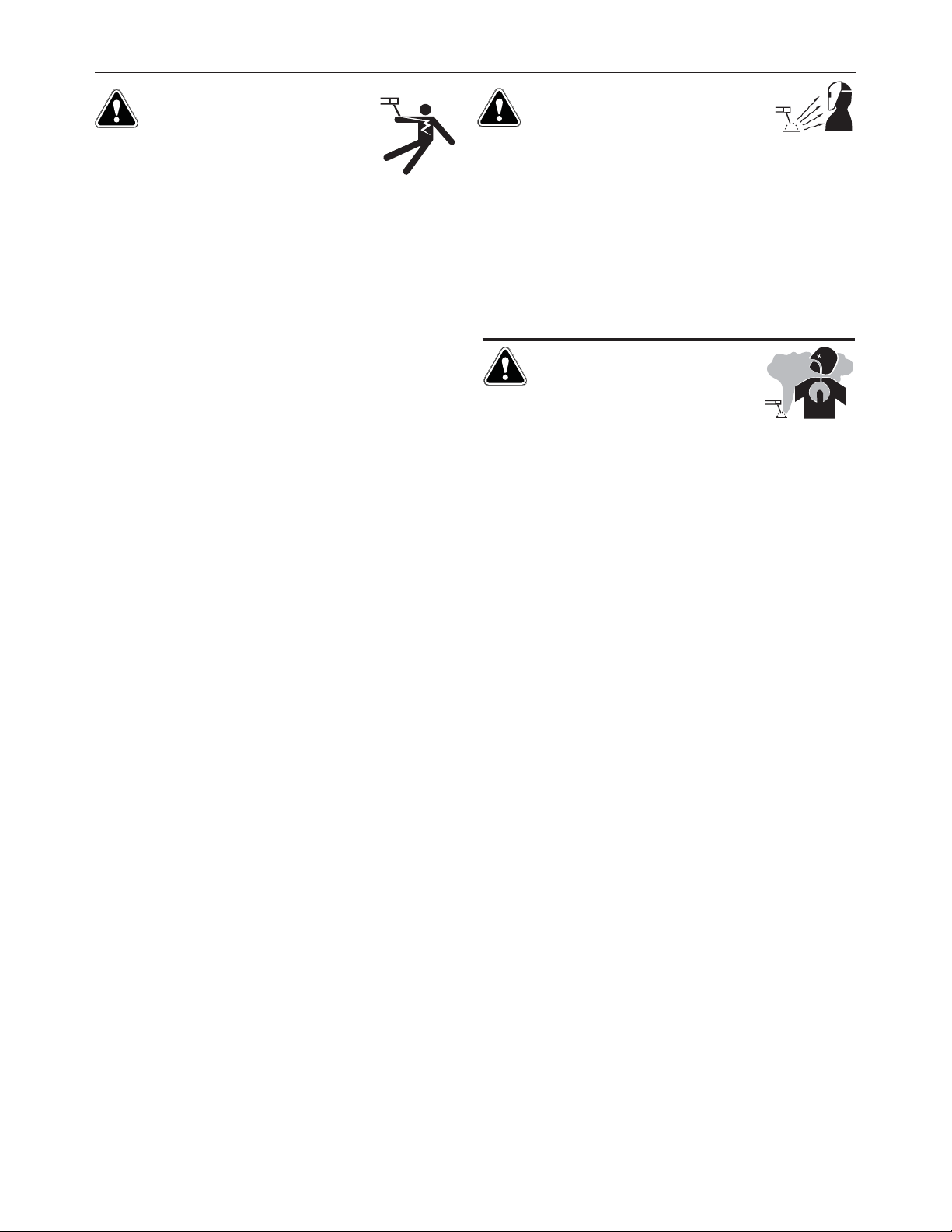

ELECTRIC SHOCK

CAN KILL.

3.a. The electrode and work (or ground) circuits are

electrically “hot” when the welder is on. Do

not touch these “hot” parts with your bare skin

or wet clothing. Wear dry, hole-free gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full area

of physical contact with work and ground.

In addition to the normal safety precautions, if

welding must be performed under electrically

hazardous conditions (in damp locations or while

wearing wet clothing; on metal structures such as

floors, gratings or scaffolds; when in cramped

positions such as sitting, kneeling or lying, if there

is a high risk of unavoidable or accidental contact

with the workpiece or ground) use the following

equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel, welding head, nozzle or semiautomatic welding

gun are also electrically “hot”.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection should

be as close as possible to the area being welded.

3.e. Ground the work or metal to be welded to a good electrical (earth)

ground.

3.f. Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Never simultaneously touch electrically “hot” parts of electrode

holders connected to two welders because voltage

two can be the total of the open circuit voltage of both

welders.

3.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

between the

ARC RAYS CAN BURN.

4.a. Use a shield with the proper filter and cover plates to protect your

eyes from sparks and the rays of the arc when welding or

observing open arc welding. Headshield and filter lens should

conform to ANSI Z87. I standards.

4.b. Use suitable clothing made from durable flame-resistant material

to protect your skin and that of your helpers from the arc rays.

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

FUMES AND GASES

CAN BE DANGEROUS.

5.a. Welding may produce fumes and gases

hazardous to health. Avoid breathing these

fumes and gases. When welding, keep your head out of the fume.

Use enough ventilation and/or exhaust at the arc to keep fumes

and gases away from the breathing zone. When welding

with electrodes which require special ventilation

such as stainless or hard facing (see instructions

on container or MSDS) or on lead or cadmium

plated steel and other metals or coatings which

produce highly toxic fumes, keep exposure as low

as possible and within applicable OSHA PEL and

ACGIH TLV limits using local exhaust or

mechanical ventilation. In confined spaces or in

some circumstances, outdoors, a respirator may

be required. Additional precautions are also

required when welding on galvanized steel.

5. b. The operation of welding fume control equipment is affected by

various factors including proper use and positioning of the

equipment, maintenance of the equipment and the specific

welding procedure and application involved. Worker exposure

level should be checked upon installation and periodically

thereafter to be certain it is within applicable OSHA PEL and

ACGIH TLV limits.

5.c. Do not weld in locations near chlorinated hydrocarbon vapors

coming from degreasing, cleaning or spraying operations. The

heat and rays of the arc can react with solvent vapors to form

phosgene, a highly toxic gas, and other irritating products.

3.j. Also see It ems 6.c. and 8.

5.d. Shielding gases used for arc welding can displace air and

injury or death. Always use enough ventilation, especially in

confined areas, to insure breathing air is safe.

5.e. Read and understand the manufacturer’s instructions for this

equipment and the consumables to be used, including the

material safety data sheet (MSDS) and follow your employer’s

safety practices. MSDS forms are available from your welding

distributor or from the manufacturer.

5.f. Also see item 1.b.

4

cause

Page 5

SAFETY

WELDING AND CUTTING

SPARKS CAN CAUSE

FIRE OR EXPLOSION.

6.a. Remove fire hazards from the welding area. If

this is not possible, cover them to prevent the

welding sparks from starting a fire. Remember that welding

sparks and hot materials from welding can easily go through

small cracks and openings to adjacent areas. Avoid welding near

hydraulic lines. Have a fire extinguisher readily available.

6.b. Where compressed gases are to be used at the job site, special

precautions should be used to prevent hazardous situations.

Refer to “Safety in Welding and Cutting” (ANSI Standard Z49.1)

and the operating information for the equipment being used.

6.c. When not welding, make certain no part of the electrode circuit is

touching the work or ground. Accidental contact can cause

overheating and create a fire hazard.

6.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures will

not cause flammable or toxic vapors from substances inside.

They can cause an explosion even though they have been

“cleaned”. For information, purchase “Recommended Safe

Practices for the Preparation for Welding and Cutting of

Containers and Piping That Have Held Hazardous Substances”,

AWS F4.1 from the American Welding Society (see address

above).

6.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

6.f. Sparks and spatter are thrown from the welding arc. Wear oil free

protective garments such as leather gloves, heavy shirt, cuffless

trousers, high shoes and a cap over your hair. Wear ear plugs

when welding out of position or in confined places. Always wear

safety glasses with side shields when in a welding area.

6.g. Connect the work cable to the work as close to the welding area

as practical. Work cables connected to the building framework or

other locations away from the welding area increase the

possibility of the welding current passing through lifting chains,

crane cables or other alternate circuits. This can create fire

hazards or overheat lifting chains or cables until they fail.

6.h. Also see item 1.c.

CYLINDER MAY EXPLODE IF

DAMAGED.

7.a. Use only compressed gas cylinders containing

the correct shielding gas for the process used

and properly operating regulators designed for

the gas and pressure used. All hoses, fittings,

etc. should be suitable for the application and

maintained in good condition.

7.b. Always keep cylinders in an upright position securely chained to

an undercarriage or fixed support.

7.c. Cylinders should be located:

• Away from areas where they may be struck or subjected

to physical damage.

• A safe distance from arc welding or cutting operations

and any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode holder or any other

electrically “hot” parts to touch a cylinder.

7.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. Valve protection caps should always be in place and hand tight

except when the cylinder is in use or connected for use.

7.g. Read and follow the instructions on compressed gas cylinders,

associated equipment, and CGA publication P-l, “Precautions for

Safe Handling of Compressed Gases in

Cylinders,” available

from the Compressed Gas Association 1235 Jefferson Davis

Highway, Arlington, VA 22202.

FOR ELECTRICALLY

POWERED EQUIPMENT.

8.a. Turn off input power using the disconnect

switch at the fuse box before working on the

equipment.

8.b. Install equipment in accordance with the U.S. National Electrical

Code, all local codes and the manufacturer’s recommendations.

6.I. Read and follow NFPA 51B “ Standard for Fire Prevention During

Welding, Cutting and Other Hot Work”, available from NFPA, 1

Batterymarch Park, PO box 9101, Quincy, Ma 022690-9101.

6.j. Do not use a welding power source for pipe thawing.

8.c. Ground the equipment in accordance with the U.S. National

Electrical Code and the manufacturer’s recommendations.

Refer to

http://www.lincolnelectric.com/safety

for additional safety information.

Welding Safety

Interactive Web Guide

for mobile devices

5

Page 6

AC-225-S & AC/DC 225/125

Installation.......................................................................................................Section A

Operating Instructions .................................................................................................................A-1

Input Power and Grounding Connections ............................................................................A-1

Attach Electrode Cable to Holder.........................................................................................A-1

Type A Holder with Octagon Shape.....................................................................................A-1

Type B Holder with Round Ribbed Handle...........................................................................A-2

Electrode and Work Replacement........................................................................................A-2

Operation.........................................................................................................Section B

Welding Polarity Selection....................................................................................................B-1

Duty Cycle............................................................................................................................B-1

Circuit Breakers....................................................................................................................B-1

How to Learn Stick Welding .................................................................................................B-1

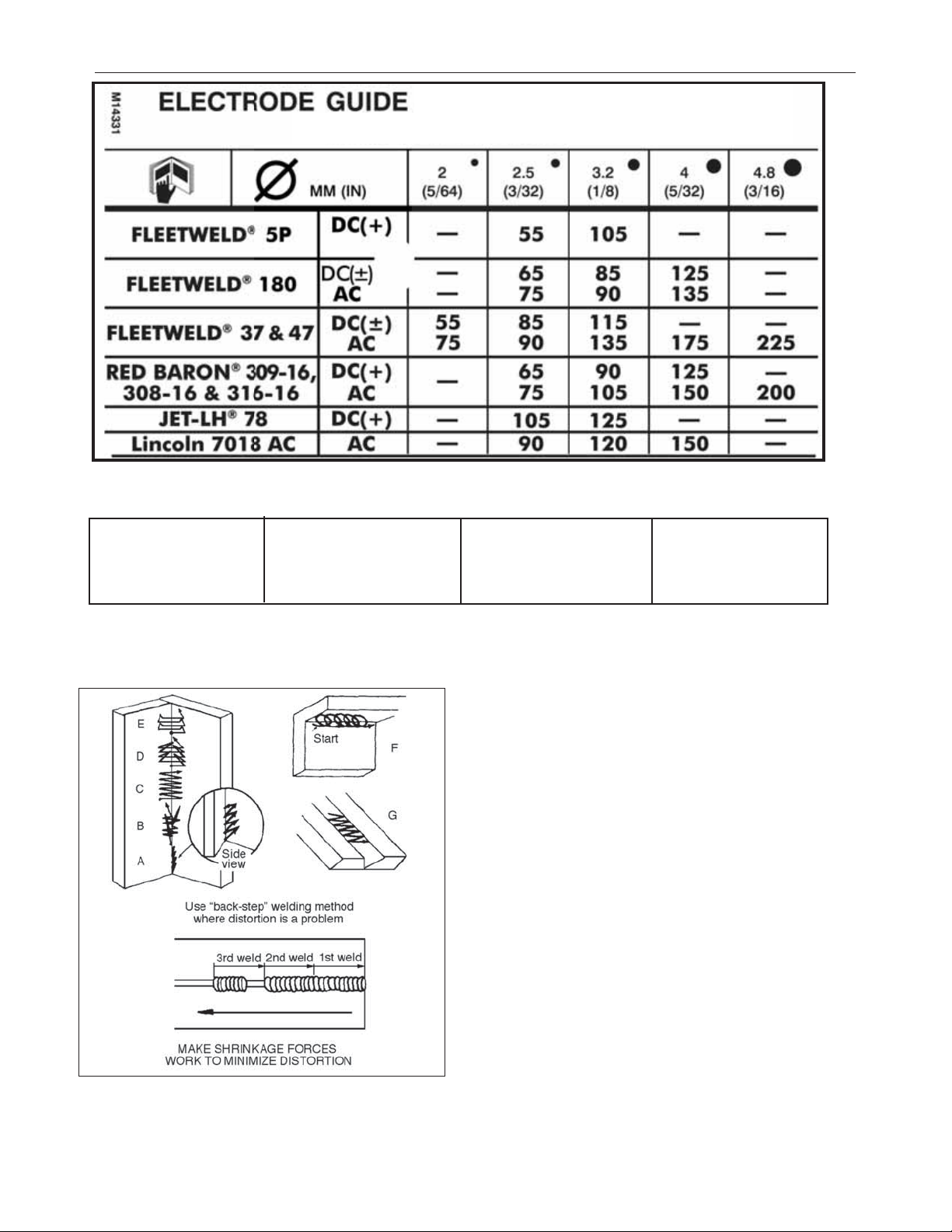

Electrode Selection Guide....................................................................................................B-1

Electrode Guide....................................................................................................................B-2

Stick Welding Motions A thru G............................................................................................B-2

Cutting and Piercing Holes ..................................................................................................B-3

Maintenance ....................................................................................................Section C

Routine preventative maintenance

Parts Pages.......................................................................................P-65, P-140 Series

TABLE OF CONTENTS

Page

...........................................................................................C-1

6

Page 7

INSTALLATIONAC-225-S & AC/DC 225/125

• Have an electrician ins ta ll and service this equipment.

• Turn the input power off at the fuse box before working on equipment.

• Do not touch electrically hot parts.

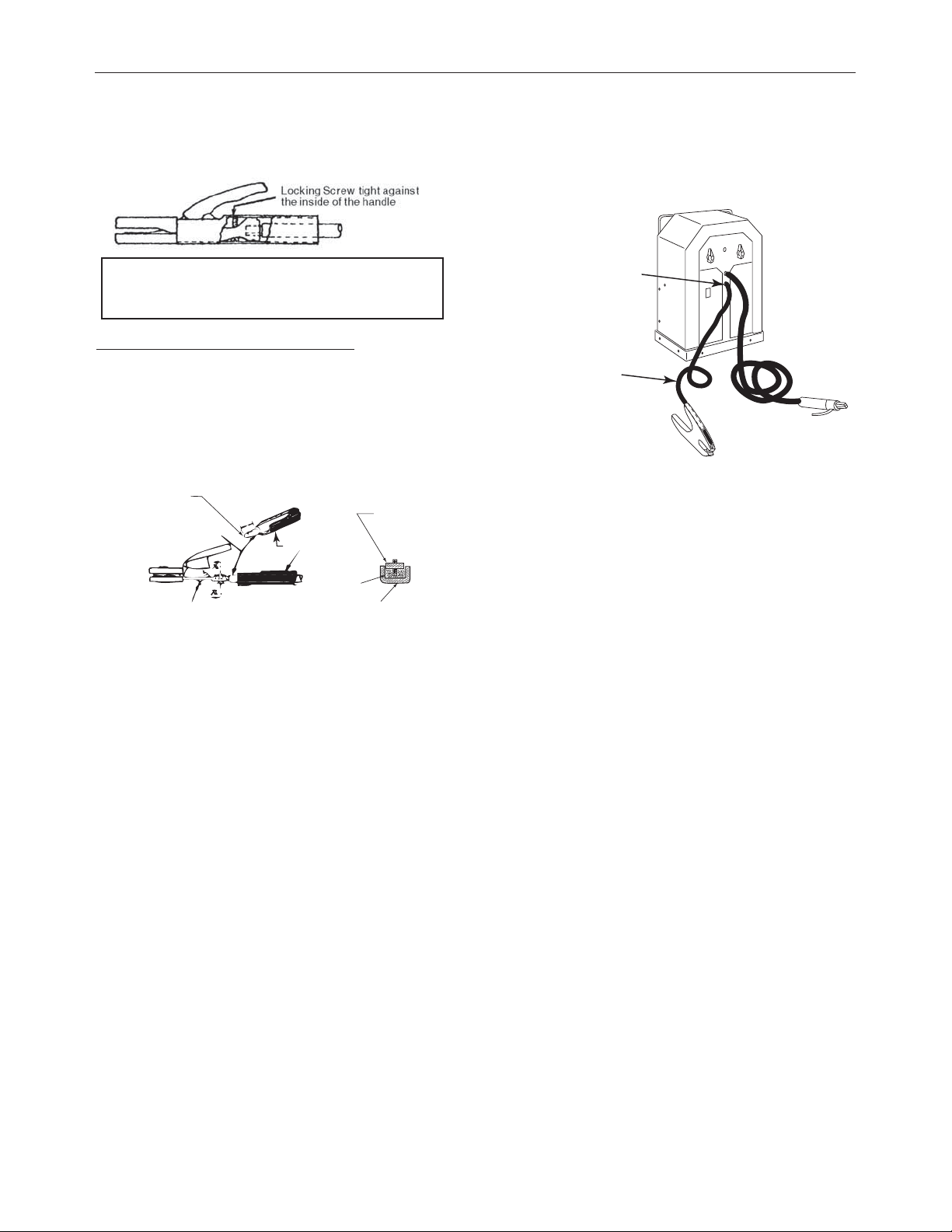

Identify the holder type before installing.

FIGURE 1A

OPERATING

INSTRUCTIONS

WARNING

Input Power and Grounding Connections

Before starting the installation, check with the power company to be

sure your power supply is adequate for the voltage, amperes, phase

and frequency specified on the welder nameplate. Also, be sure the

planned installation will meet the United States National Electrical

Code and local code requirements. This welder may be operated

from a single phase line or from one phase of a two or three phase

line.

All models designed to operate on less than 250 volt input lines are

shipped with the input cable connected to the welder.

Place the welder so there is free circulation of air in through the

louvers in the back and sides of the case and out of the bottom on

all four sides. Mount a NEMA Type 6-50R receptacle in a suitable

location. Be sure it can be reached by the plug on the input cable

attached to the welder.

Using the following instructions, have a qualified electrician connect

this receptacle (NEMA 6-50R Type) to the power lines at the fuse

box. Three #10 or larger copper wires are required if conduit is

used. For long cable runs over 100'(31m), #8 or larger wire in

conduit will be needed to prevent excessive voltage drops. Fuse the

two hot lines with 50 ampere super lag type fuses as shown in the

following diagram. The center contact in the receptacle is for the

grounding connection. A green wire in the input cable connects this

contact to the frame of the welder. This insures proper grounding of

the welder frame when the welder plug is inserted into the

receptacle. If a separate disconnect switch is used, it should have

two poles for the two hot lines and both should be fused for 50

amperes.

Attaching Electrode Cable to Holder

WARNING

Before attaching the electrode cable to the electrode holder

or the work cable to clamp, be certain the welder is turned

off or the input power is disconnected.

Type A - Holder with Octagon shaped handle and Clamp in

Jaws

1. Loosen locking screw and slide handle off holder. Place handle over electrode cable. The longer cable is used for the

Electrode Cable and is located in the front of machine upper

hole as shown in

2. Remove insulation from electrode cable 1” ± 1/16” (25.4mm

± 1.6mm) from end.

3. Back out cable connecting screw until end is flush with inside

surface of jaw body.

4. Remove cable connecting clamp from holder jaws. Place

clamp over bare end of electrode cable and insert into holder

with clamp centered against connecting screw.

.

FIGURE 1A

Upper Hole

with Longer Cable

Electrode Cable

CONNECT TO A SYSTEM

GROUNDING WIRE. SEE THE UNITED STATES NATIONAL ELECTRICAL CODE AND/OR LOCAL CODES

FOR OTHER DETAILS AND MEANS

FOR PROPER GROUNDING.

CONNECT TO HOT WIRES

OF A THREE-WIRE, SINGLE

PHASE SYSTEM OR TO

}

ONE PHASE OF A TWO OR

THREE PHASE SYSTEM.

5. Tighten cable connecting screw securely against clamp.

A-1

Page 8

INSTALLATIONAC-225-S & AC/DC 225/125

Attaching Work Cable to Clamp

Electrode and Work Cable Replacement

6. Slide handle into position and secure by turning the locking

screw in until it is tight. The threaded end of the screw will

then pass against the inside of the handle and the head of the

screw will be completely inside the handle.

Important Safety Note: Make sure insulation is secure and that

screws are tight and cannot be touched. If screw can be touched,

DO NOT USE HOLDER, contact your distributor.

Type B - Holder with Round, Ribbed Handle

1. Remove handle mounting screw and slide handle off

holder. Place handle over electrode cable.The longer cable

is used for the Electrode Cable and is located in the front of

machine upper hole as shown in Figure 1A.

2. If electrode cable does not have a terminal on it, remove

insulation from electrode cable 1” ± 1/16” (25.4mm ±

Terminal or

bare strands

Electrode

cable

Handle mounting screw

1" ± 1/16"

Handle

Clamp connecting screw

Cable

connecting

clamp

Cable

1.6mm) from end.

3. Back out clamp connecting screw and remove cable

connecting clamp.

4. If electrode cable has a terminal attached (#10 clearance

hole), place terminal over cable connecting screw.

Otherwise, place bare end of electrode cable into holder

with cable strands divided equally on both sides of clamp

connecting screw.

5. Tighten cable connecting screw securely into clamp so clamp holds

cable in place.

6. Slide handle into position and secure with handle mounting screw.

Insert work cable (with 5/16” clearance hole terminal) through strain

relief hole in work clamp and fasten securely with bolt and nut

provided. The shorter cable is used for the Work Cable and is located

in the front of the machine lower hole as shown below.

Lower Hole

with Shorter

Cable

Work

Cable

Substitution of cables with larger sizes requiring connections to be

made internally is not recommended. Connections for additional

lengths or larger sizes should be properly made externally. Lincoln

Electric QD (Quick Disconnect) connectors are available for this

purpose.

If either cable requires replacement for other reasons, they should be

replaced with the appropriate Lincoln parts— and only by qualified

personnel.

A-2

Page 9

Welding Current Selection

Welding Polarity Selection

Duty Cycle

Circuit Breakers

How to Learn Stick Welding

Electrode Selection Guide

Selecting Electrodes

Out-of-Position Group (E6011)

High-Deposit Group (E6027, E7024)

High-Speed Group (E6012, E6013, E7014)

Low Hydrogen Group (E7018, E7028)

AC-225-S & AC/DC 225/125

OPERATION

Each position on the current selector switch is marked with the

output amperes for that setting. Turn the switch to the current

required for each application.

There is a slight amount of play in each switch position. It is good

practice to move the switch back and forth once within this play

after switching to a new position. This wiping action keeps the

contacts free from dirt and oxides.

CAUTION

Do not turn the selector switch while welding as this will

damage the contacts.

To get the best results with today’s arc welding electrodes, it is

important to use the proper polarity. The AC/DC Arc Welder permits

the choice of AC, DC(+) or DC(-), giving additional versatility.

Lincoln Electrodes are listed in the chart at the end of this manual.

Each electrode is designed to work best on either DC(+), DC(-) or AC.

In this electrode chart the preferred polarity is listed first. This is the

polarity which should be used - when available - for best results.

(For Codes 11604 and below). The 60 Hz welders are rated 20% duty

cycle and the 50 Hz welders are rated 15% duty cycle for the welding

current shown on each switch position.

(For Codes 11674 and above). The 60 Hz welders are rated 20% duty

cycle and the 50 Hz welders are rated 13% duty cycle for the welding

current shown on each switch position.

See the following Electrode Selection Guide and additional electrode

selection information. Also refer (C2.10) for Stick Electrode Welding

Guide and electrode sizes: www.lincolnelectric.com.

Which electrode is best for the particular job . . . how do you use it?

These are important questions because the cost, quality, and

appearance of your work depends on proper electrode selection and

application. MILD STEEL ELECTRODES may be classified into the

following groups:

This group includes electrodes which have a snappy, deep

penetrating arc and fast freezing deposits.

These electrodes are used for general purpose all-position fabrication

and repair welding; also the best choice for pipe welding and sheet

metal butt, corner and edge welds. They can be used for repair work

when dirt, grease, plating or paint cannot be completely cleaned from

the steel. Typically used with motions “A’’ and “B’’ (below) for the

first pass on vertical-up welds.

This group includes the heavy coated, iron powder electrodes with

their soft arc and fast deposit rates. These electrodes have a heavy

slag and produce exceptionally smooth beads. They are generally

used for production welding where all work can be positioned for

downhand welding. Stringer beads, with drag technique, are always

preferred over weave passes with these electrodes.

Duty cycle is based on a ten minute period. This means that the arc

can be drawn for 2 minutes out of each ten minute period (with a

20% duty cycle unit) without any danger of overheating. If the welder

is used for more than 2 minutes during several successive ten minute

periods, it may overheat. Be sure to leave the unit “on” during each

10 minute period to let the fan motor run for adequate cooling.

Overheating reduces welder life.

AC/DC models above Code 8800 have an internal circuit breaker to

prevent overheating when welding on DC. The breaker will trip and

shut off the DC welding output if the duty cycle is exceeded or if the

cooling air flow is blocked. The cooling fan will continue to run and

the DC welding output will automatically come on when the breaker

has cooled and resets.

Refer to “Learning to Stick Weld” (LTW2) in the operator manual

section of www.lincolnelectric.com

This group includes electrodes which have a moderately forceful arc

and deposit rates between those of the out-off position and highdeposit electrodes. They are primarily general purpose production

electrodes especially for downhill fillets and laps or short and irregular

welds that change direction or position. Also widely used in

maintenance and recommended for sheet metal fillet and lap welds.

Motion “D’’ (below) is generally used for vertical-up welding, but

motions “A” and “B” are also suitable.

These electrodes are generally called “low hydrogen.” The name

comes from the fact that their coating contains little hydrogen in

either moisture or chemical form. Low hydrogen electrodes offer

these benefits: outstanding crack resistance, lowest porosity on

sulphur bearing steels, and capable of X-ray quality deposits. Thus,

they are the first choice when welding “problem” steels. E7018 can

be used in all positions, with Motion “C” recommended for the first

pass on vertical-up welds. NEVER use a whipping technique or a long

arc with these electrodes. ALWAYS fill craters by drawing electrodes

away slowly. ALWAYS keep these electrodes dry. Electrodes not used

within a few hours after a container is opened must be stored in heat

cabinets. LH-73 is recommended with the AC-225. Normally, DC(+) is

preferred for these electrodes.

B-1

Page 10

Stick Welding Motions

Manipulation

AC-225-S & AC/DC 225/125

In Addition to the Electrodes Listed Above the ones listed below may also be used. To determine the correct electrode

diameter and current settings to use please consult the Lincoln Weldirectory (Bulletin #C2.10)

OPERATION

• Fleetweld® 35

• Jetweld® 1

• Blue Max® 2100

• Red Baron® 309/309L MR

• Red Baron® 308L MR

• Wearshield® ME

• Wearshield® MI

• Wearshield® BU

• Wearshield® Mangjet®

• Wearshield® ABR

• Ferroweld®

• Softweld® 99 Ni

shown below

depends on the joint. Some of the common motions are

.

Motion “A” is a straight whipping motion used with fastfreeze

electrodes to make stringer beads in all positions and on all types of

joints. It keeps the molten pool small and lets it freeze quickly so the

weld metal doesn’t spill down or through the joint. Keep arc short

when in the crater and longer during whip out from the crater.

Motion “B” is a whipping motion combined with a slight weave in the

crater. It is used with fast-freeze electrodes as the first pass on

vertical fillets and V-butts.

Motion “C” is a simple side-to-side weave used with all types of

electrodes to make fill passes on vertical fillets and V-butts. Also

sometimes used with fill-freeze and low hydrogen electrodes to make

the first pass on these joints.

Motion “D” is a triangular weave used with fill-freeze and low

hydrogen electrodes to make one pass vertical fillets and V-butts. It

results in a larger weld than Motion “C’’.

Motion “E” is a box weave used with all types of electrodes to make

fill passes on vertical fillets and V-butts. It is similar to Motion “C,’’

but with a distinct pause and slight upward motion at each edge of

the weld to assure complete crater filling and elimination of undercut.

Motion “F” is a circular motion used with all types of electrodes to

make overhead welds. Sometimes accompanied by a slight whip after

each oscillation in the crater. Always use a series of stringer beads

overhead; do not weave.

Motion “G” is a simple side-to-side weave used with all electrodes on

wide fillets or butts in the flat position.

B-2

Page 11

Cutting (Do not exceed the Duty Cycle — At the beginnig of this

Operation Section)

Piercing Holes

NOTE:

AC-225-S & AC/DC 225/125

The arc welder and the electrode can be used for cutting steel and cast

iron. Follow this procedure:

1. Use 1/8” (3.2mm) or 5/32" (4.0mm) Fleetweld 180 electrode.

2. Set welder on maximum (225 amps).

3. Hold long arc on edge of metal, melting it.

4. Push the arc through the molten metal, forcing it to fall away.

5. Raise the electrode, and start over again.

The important thing is to continue this up-and-down, sawing motion,

melting the metal and pushing it away.

1. Welder setting: Maximum (225

amps).

2. Electrode: 1/8” (3.2mm) or 5/32"

(4.0mm) Fleetweld 180.

3. Hold the electrode with a long arc

perpendicular over the spot

where the hole is to be made.

4. When the metal is molten, push

the electrode through the molten

puddle.

5. Give the molten metal a chance

to fall through the hole.

6. Circle with a long arc around the

edge of the hole until the desired

diameter hole has been made.

OPERATION

If the electrode is pushed through too soon it will stick in the puddle. Be

sure the metal is molten before pushing through .

On heavy metal (5/16" (7.9mm) or thicker), position the plate to be

pierced vertically, and the electrode horizontally. This allows the molten

metal to drip away freely as you are boring through.

B-3

Page 12

AC-225-S & AC/DC 225/125

MAINTENANCE

Routine preventative maintenance is not required. See your

local Lincoln Electric Authorized Field Service Shop for necessary repairs.

MAINTENANCE

D-1

Page 13

AC-225-S & AC/DC 225/125

NOTES

Page 14

15A

2

2A

15

14A

14B

13

3

2

5

6

7

8

9A

10

11

9

16A

16

17

18

20

21

23

12

28

29

22B

22A

1

15B

15A

AC-225-S

Model Index

15B

P-65-A.aP-65-A.a

BELOW CODE 6300 ONLY

and Codes 6342, 6343 and 6453

2A

13

14A

14B

15

18

20

16

17

22B

21

16A

22A

23

12

28

10

11

9A

29

04-19-2010

Page 15

P-65-A.bP-65-A.b

PAGE NO./ PAGE NO./ PAGE NO./ PAGE NO./

CODE COL. NO. CODE COL. NO. CODE COL. NO. CODE COL. NO.

4665 A.1.a 1 7093 A.1a 7 9424 A.1a 12

4763 A.1a 2 7094 A.1a 7 9425 A.1a 12

4798 A.1a 2 7098 A.1a 7 9426 A.1a 12

4852 A.1a 2 7099 A.1a 7 9427 A.1a 12

4953 A.1a 2 7100 A.1a 7 9428 A.1a 12

5130 A.1a 2 7101 A.1a 7 10420 A.1a 13

5167 A.1a 3 7102 A.1a 7 10421 A.1a 13

5169 A.1a 3 7103 A.1a 7 10422 A.1a 13

5227 A.1a 3 7234 A.1a 7 10423 A.1a 13

5341 A.1a 4 7330 A.1a 8 10424 A.1a 12

5348 A.1a 4 7333 A.1a 7 11074 A.1a 14

5381 A.1a 3 7351 A.1a 8

5438 A.1a 4 7352 A.1a 8

5440 A.1a 4 7523 A.1a 7

5449 A.1a 4 7533 A.1a 9 11602 B.1.a 1

5451 A.1a 4 7731 A.1a 9 11603 B.1.a 2

5465 A.1a 4 7743 A.1a 9 11604 B.1.a 3

5470 A.1a 4 7744 A.1a 9 11674 B.1.a 4

5678 A.1a 4 7745 A.1a 9

5683 A.1a 4 7746 A.1a 9

5880 A.1a 5 7755 A.1a 9

5896 A.1a 4 7805 A.1a 9

5897 A.1a 4 7813 A.1a 9

5903 A.1a 4 8226 A.1a 9

6140 A.1a 5 8370 A.1a 10

6184 A.1a 5 7382 A.1a 10

6295 A.1a 5 8383 A.1a 10

6304 A.1a 6 8384 A.1a 10

6342 A.1a 5 8385 A.1a 10

6343 A.1a 5 8386 A.1a 10

6453 A.1a 5 8459 A.1a 10

6518 A.1a 5 8511 A.1a 10

6592 A.1a 6 8712 A.1a 10

6600 A.1a 6 8780 A.1a 10

6601 A.1a 6 8894 A.1a 10

6616 A.1a 6 8897 A.1a 10

6661 A.1a 6 8898 A.1a 10

6734 A.1a 6 8900 A.1a 10

6898 A.1a 6 8918 A.1a 10

6967 A.1a 6 8959 A.1a 10

6991 A.1a 6 8983 A.1a 10

7009 A.1a 6 9039 A.1a 10

7010 A.1a 6 9291 A.1a 11

7011 A.1a 6 9292 A.1a 11

7012 A.1a 6 9293 A.1a 11

7013 A.1a 6 9294 A.1a 11

7030 A.1a 6 9295 A.1a 11

7050 A.1a 7 9296 A.1a 11

7068 A.1a 6 9422 A.1a 12

7072 A.1a 6 9423 A.1a 12

04-19-2010

Page 16

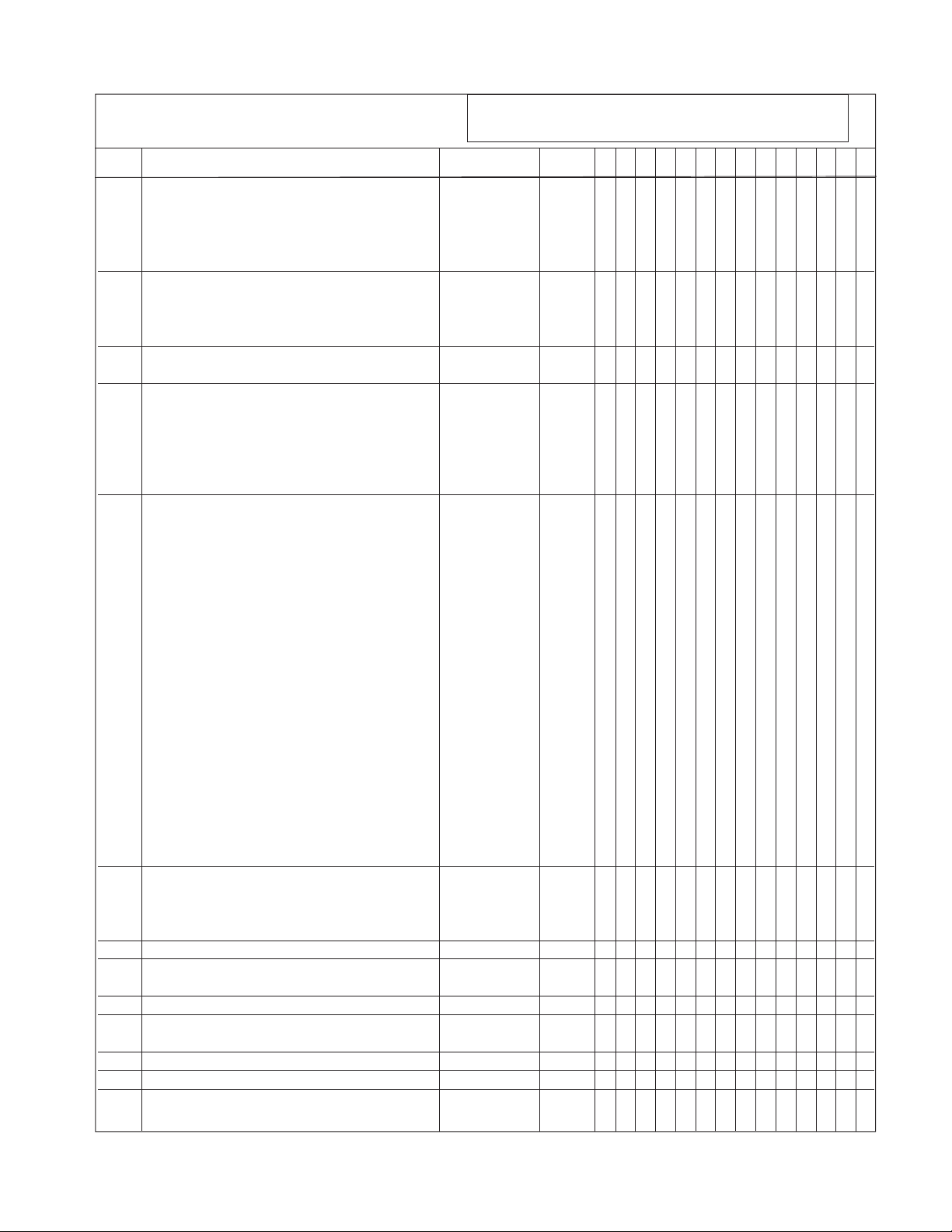

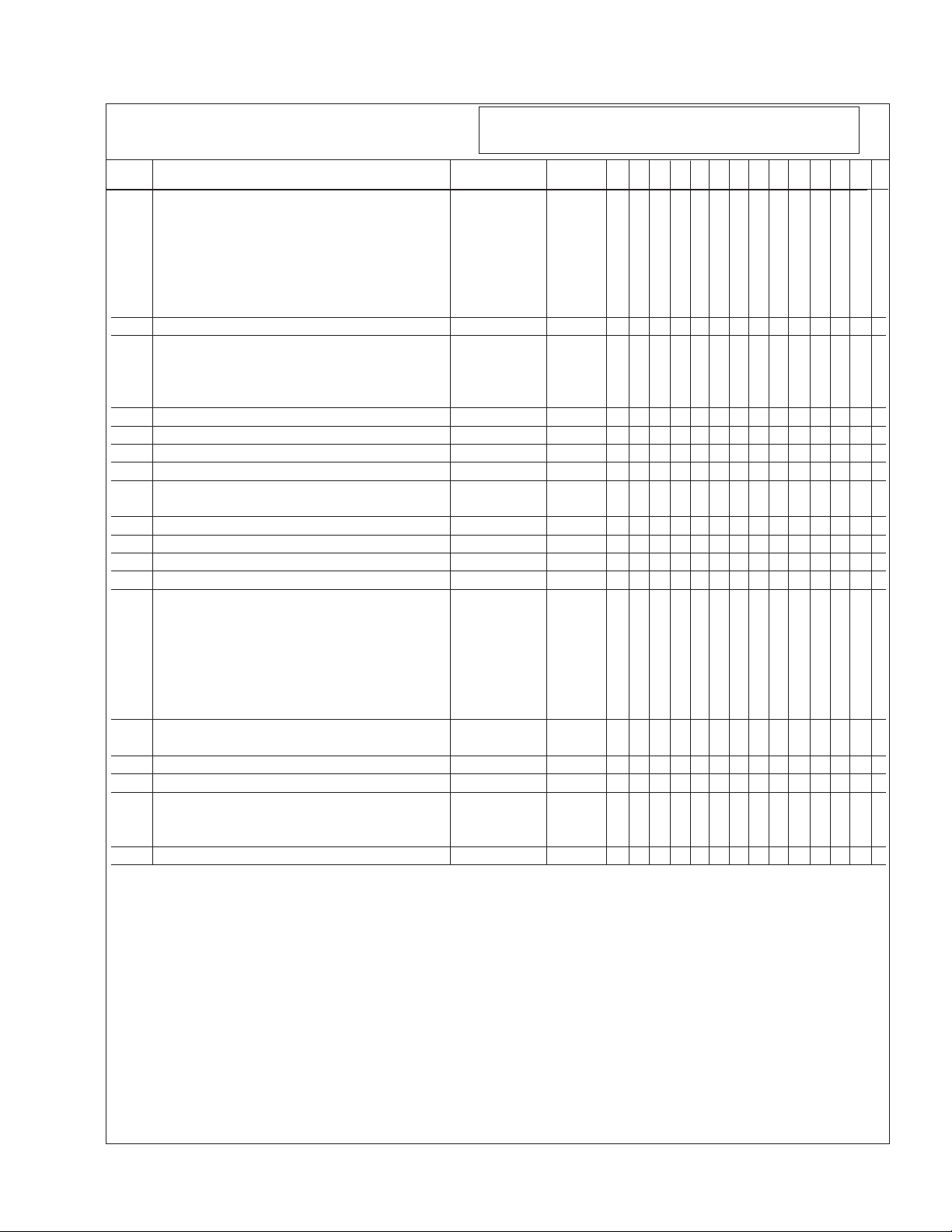

# Indicates a Change This Printing

P-65-A.1.aP-65-A.1.a

Use only the parts marked “X” in the column under the

heading number called for in the model index page.

ITEM DESCRIPTION PART NO. QTY

This Page for Codes Below 11600

1 Upper Back Panel M9873

1

Upper Back Panel (Code 5600 to 6600 except 6304)

2 Fan Motor & Blade (60 Hz), Includes; M13539-1 1 X X X X X X X X X X X X X X

2A Fan M13525 1 X X X X X X X X X X X X X X

2 Fan Motor & Blade (50 Hz), Includes: M13539-2 1 X X X X X X X X X X X X X X

2A Fan M13525-1 1 X X X X X X X X X X X X X X

3 Fan Mounting Bracket M9874 1 X X X • • • • • • • • • • •

3 Fan Mounting Bracket M10396

5 Case L3786-6 1 X • • • • • • • • • • • • •

5 Case L3786-7 1 • X X X • • • • • • • • • •

5 Case L3786-12 1 X • • • • • • • • • • • •

5 Case L3786-13

5 Case L3786-19 1 • • • • • • • • • X X X • •

5 Case L3786-14 1 • • • • • • • • • • • • X X

6 Nameplate, Lincoln, 60 Hz, 230 Volts M9803

6 Nameplate, Lincoln, 60 Hz, 230 Volts M13029 1 • • • • • • • • X • • • • •

6 Nameplate, Lincoln, 60 Hz, 230 Volts M14008 1 • • • • • • • • • X • • • •

6 Nameplate, Lincoln, 60 Hz, 230 Volts M15411 1 • • • • • • • • • • X • • •

6 Nameplate, Lincoln, 60 Hz, 208 Volts M15411-2 1 • • • • • • • • • X • • • •

6

Nameplate, Lincoln, 60 Hz, Above 250 Volts

Nameplate, Lincoln, 50 & 60 Hz, Other Voltages

6

6

Nameplate, Lincoln, 60 Hz, Above 250 Volts

6 Nameplate, Lincoln, 60 Hz, 208V Only M15725-1 1 • • • • • • • • • • • X X •

Nameplate, Lincoln, 50 & 60 Hz, Other Voltages

6

6

Nameplate, Lincoln, 50 & 60 Hz, Other Voltages

6 Nameplate, Lincoln, 60 Hz, 230V Only M15725 1 • • • • • • • • • • • X X X

Nameplate, Lincoln, 50 Hz, 15% Duty Cycle Only

6

Nameplate, Lincoln, 50 Hz, Duty Cycle 220V OnlyM14009 1 • • • • • • • • • X • • • •

6

6

Nameplate, Lincoln, 50 Hz, 15% Duty Cycle Other Volt.

6 Nameplate, Lincoln, 50 Hz M15727 1 • • • • • • • • • • • X X •

6 Nameplate, Montgomery Ward M9934

6 Nameplate, Lincoln, 60 Hz M22165 1 • • • • • • • • • • • • • •

Fastener Button (White) T14659

Fastener Button (Black) T14659-1

7 Selector Switch (50 Hz Only), Includes: M10830-8 1 • • • • • • X X • • • • • •

7 Selector Switch, Includes: M10830-3 1 X X X X X X X X • • • • • •

7 Selector Switch, Includes: M10830-9 1 • • • • • • • • X X X X X X

Switch Shaft S13206 1 X X X X X X X X X X X X X X

8 Switch Handle (Black) T13990-1 1 X X X X X X X X X X X X X X

9 Output Lead Grommets T9274-4 2 X X X • • • • • • • • • • •

9A Output Lead Clamp S15761 1 • • • X X X X X X X X X X X

10 Line Switch Nameplate S12070

11 Line Switch S7670 1 X X X X X X X X X X X X • •

11 Line Switch S18815 1 • • • • • • • • • • • • X X

12 Transformer & Base

13 Cover Panel, Terminal Block L3936-1 1 X X X • • • • • • • • • • •

14A Input Terminal Block T11813

14B Input Panel, 60 Hertz T11881 1 • X X • • • • • • • • • • •

ø

This part is obsolete and no longer available.

M10894 1 • • • X X • • • • • • • • •

M15411-1 1 • • • • • • • • • X • • • •

M9803-1 1 • X X X X X X • • • • • • •

M15726 1 • • • • • • • • • • • X X •

M13029-1 1 • • • • • • • • • • • • • •

M14008-1 1 • • • • • • • • • X • • • •

M13880 1 • • • • • • • • X • • • • •

M14009-1 1 • • • • • • • • • • X • • •

Not Available

ø

ø

ø

ø

ø

(As Req)

(As Req)

ø

ø

1234567891011121314

1 XXXX••••••••••

1 • • • X X • • • • • • • • •

1•• •••XXXX•••••

1 XXXXXXXXX • • • ••

1 •XXX••••••••••

XXXXXXXXXXXX ••

XXXXXXXXXXXXXX

1 X•••••••••••••

1 X•••••••••••••

04-19-2010

Page 17

# Indicates a Change This Printing

P-65-A.1.bP-65-A.1.b

Use only the parts marked “X” in the column under the

heading number called for in the model index page.

ITEM DESCRIPTION PART NO. QTY.

15 Back Cover L3936 1 • • • X • • • • • • • • • •

15 Back Cover L4143 1 • • • X • • • • • • • • • •

15 Back Cover L4143-1

15A Lower Back Panel L4595 1 • • • • • X X • • • • • • •

15A Lower Back Panel L4595-2 • • • • • • X X X X X X X X

15B Upper Back Panel G1239 1 • • • • • X X X • X X X • •

15B Upper Back Panel G1395 1 • • • • • • • • • • • • X

16A Cover Panel L3935-A 1 • • • X X • • • • • • • • •

16 Electrode Cable S11609-4 1 X X X X X X X X X X X X X X

17 Electrode Holder K909-1 1 X X X X X X X X X X X X X X

18 Ground Cable S11609-3 1 X X X X X X X X X X X X X X

19 Headshield M9673-6 1 X X X X X X X X X X X X X X

20 Ground Clamp M12033 1 X X X X X X X X X X X X X X

28 Receptacle (230 Volts Only) S7733

28 Receptacle (230 Volts Only) S13700 1 • • • • X X X X X X X X X •

29 Input Cord (230 Volts Only)

29 Input Cord (230 Volts Only) S13699-2 1 • • • • X X X • • • • • • •

29

Input Cord (230 Volts or Less Only) (60 Hz)

Input Cord 230V 50 Hz (Codes 8894, 9428 &

29

10424 Only)

Undercarriage Kit

(Includes Items 21, 22A, 22B & 23)

S13699-2 & S13700

S15599-1 1 • • • • • • • X X X X X X X

S18021 1 • • • • • • • • • X • X X •

Order K761 1 • • • • X X X X X X X X X X

ø

ø

1234567891011121314

1 ••••X•••••••••

1 XXXXX•••••••••

1 XXXXX•••••••••

Parts Not Illustrated

Warning Decal (Mounts to Case Upper Corner)

Electrode Selection Decal M14331 1 X X X X X X X X X X X X X X

Earth Ground Decal T13260-4 1 X X X X X X X X X X X X X •

M14330 1 X X X X X X X X X X X X X X

ø

This part is obsolete and no longer available.

04-19-2010

Page 18

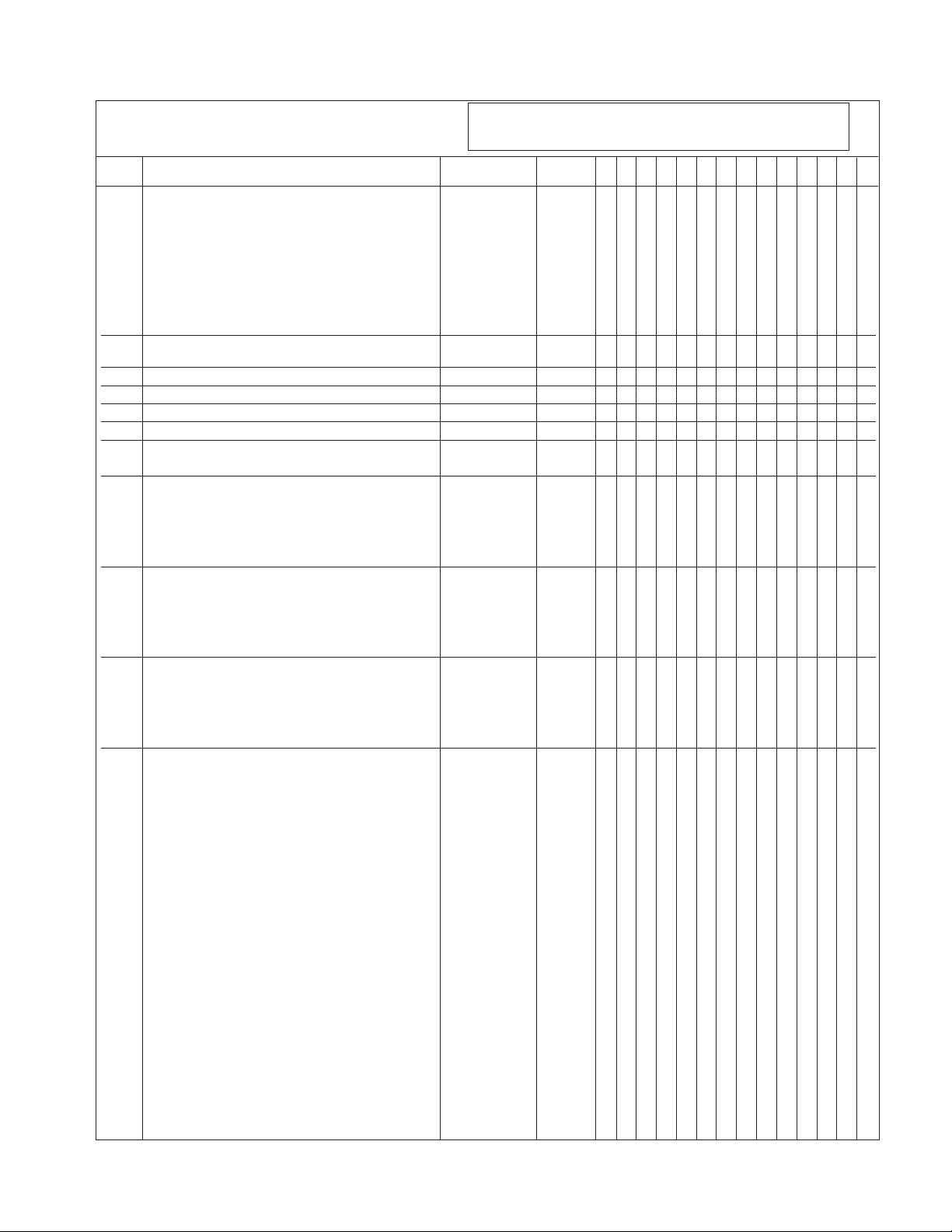

# Indicates a Change This Printing

P-65-B.1.aP-65-B.1.a

Use only the parts marked “X” in the column under the

heading number called for in the model index page.

ITEM DESCRIPTION PART NO. QTY.

This Page for Codes Above 11600:

2 Fan Motor & Blade, Includes: M13539-1 1 X • X •

Fan M13525 1 X • X •

2 Fan Motor & Blade, Includes: M13539-2 1 • X • X

Fan M13525-1 1 • X • X

5 Case L3786-14 1 X X X X

6 Nameplate (Codes 11602 & 11604) M22165 1 X • X •

6 Nameplate (Code 11603) M15727 1 • X • •

6 Nameplate (Code 11674) M22167 1 • • • X

Fastener Button (Black) T14659-1 1 X X X X

8 Handle Assembly T13990-1 1 X X X X

9A Lead Clamp S15761 1 X X X X

11 Line Switch S18815 1 X X X X

12 Transformer & Base NSS 1XXXX

15A Lower Case Back L4595-2 1 X X X X

15B Upper Case Back G1395 1 X X X X

16 Electrode Cable S11609-4 1 X X X X

17 Electrode Holder K909-1 1 X X X X

18 Ground Cable S11609-3 1 X X X X

20 Ground Clamp M12033 1 X X X X

Undercarriage Kit, Includes: K761

21 Wheel S11662-3 2 • • X •

22 Mounting Kit, Includes: T14160 1 • • X •

22A Plain Washer S9262-1 2 • • X •

22B Push Nut T12570 2 • • X •

22C 3/8-16 x 2.00 HHCS CF000071 1 • • X •

23 Axle M8809-61 1 • • X •

29 Power Input Cable

29 Power Input Cable (Code 11603 & 11674) S18021 1 • X • X

30 Warning Decal (Not Shown) M14330-3 1 X X X X

31 Electrode Selection Decal (Not Shown) M14331 1 X X X X

32

32

32

33 Warranty Decal (Not Shown) S22127-1 1 • X • •

Wiring Diagram (Not Shown) (Codes 11602 & 11604)

Wiring Diagram (Not Shown) (Code 11603)

Wiring Diagram (Not Shown) (Code 11674)

(Codes 11602 & 11604

) S15599-1 1 X • X •

* ••X•

S15621 1 X • X •

S16671 1 • X • •

S28364 1 • • • X

1234567891011121314

* Undercarriage Kit Optional on all Codes - Standard where indicated.

NSS - Not Sold Separately

04-19-2010

Page 19

NOTES

Page 20

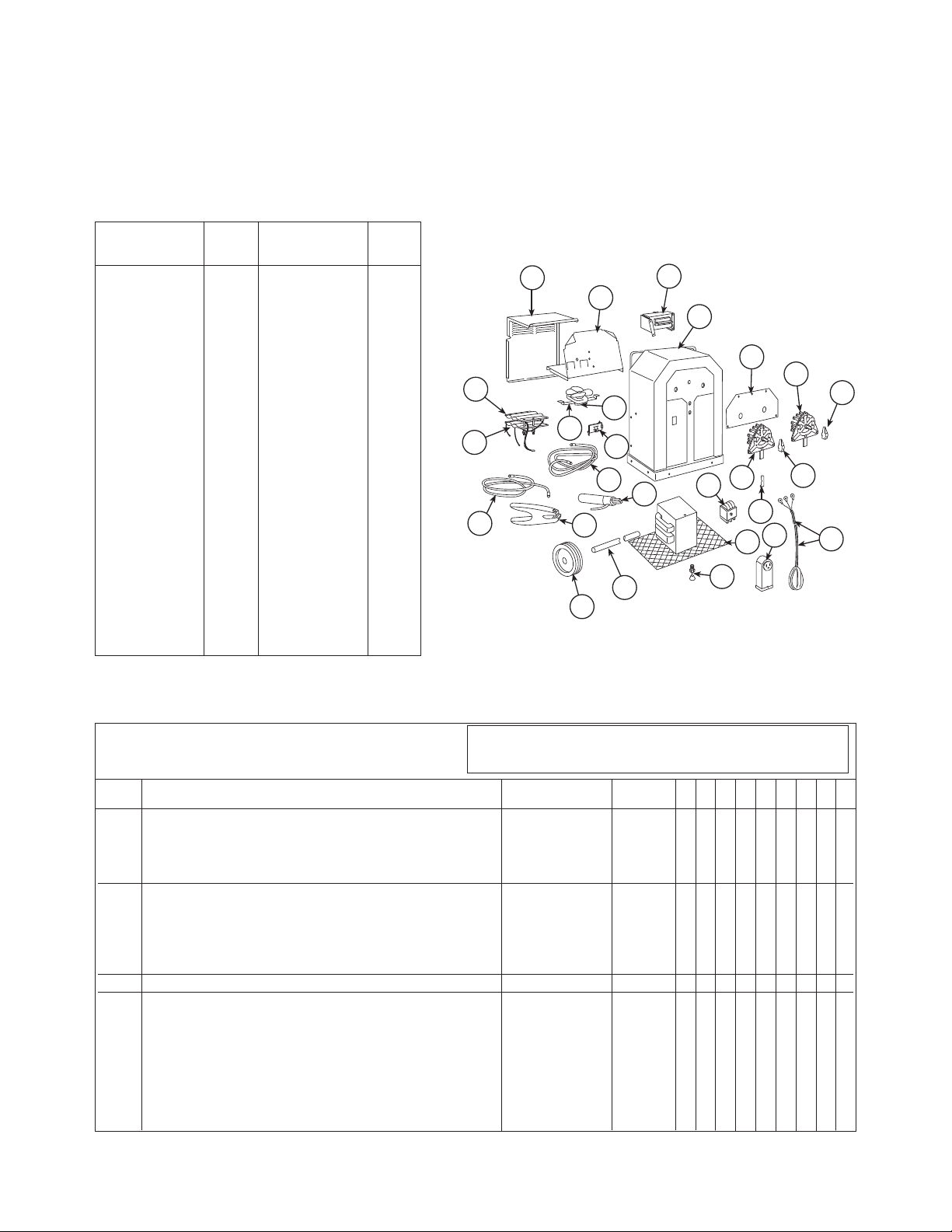

AC/DC 225/125

COL. COL.

CODE NO. CODE NO.

8566 1 9025 2

8581 1 9186 2

8650 1 9221 3

8663 1 9222 3

8666 1 9223 3

8700 1 9224 3

8737 1 9225 3

8742 1 9226 3

8777 1 9365 3

8788 1 10426 3

8811 2 10427 3

8815 2 10428 3

8817 1 10429 3

8893 2 11675 4

8901 2

8903 2

8910 2

8955 2

8986 2

9005 2

9015 2

Model Index

6A

1B

1A

10

4

20

31B

6B

P-140-AP-140-A

3

5

15

7

2

13

8

17

31A

14

11

9A

28

12

25

7A

14A

29

Use only the parts marked “X” in the column under the

# Indicates a Change This Printing

ITEM DESCRIPTION PART NO. QTY.

heading number called for in the model index page.

123456789

1 Rectifier Assembly, Includes: L7029 ø 1X•••

1A (–) Rectifier Half (Bottom) S12837-7A ø 1X•••

1B (+) Rectifier Half (Top) S12837-7B ø 1X•••

1 Rectifier Assembly, Includes: L6974 ø 1•X••

1 Rectifier Assembly (Below Code 10000), Includes: L7491 1 • X X •

1 A (–) Diode M9661-39R 2 • X X •

1 B (+) Diode M9661-39 2 • X X •

Suppressor Assembly M14705 1 • X X •

1 Rectifier Assembly, (Above Code 10000) G3648 1 • • X X

2 Fan Motor & Blade (60 Hz), Includes: M13539-1 1 X X X •

Fan M13525 1 X X X •

2 Fan Motor & Blade (50 Hz), Includes: M13539-2 1 X X X X

Fan M13525-1 1 X X X X

ø

This part is obsolete and no longer available

03-10-2010

Page 21

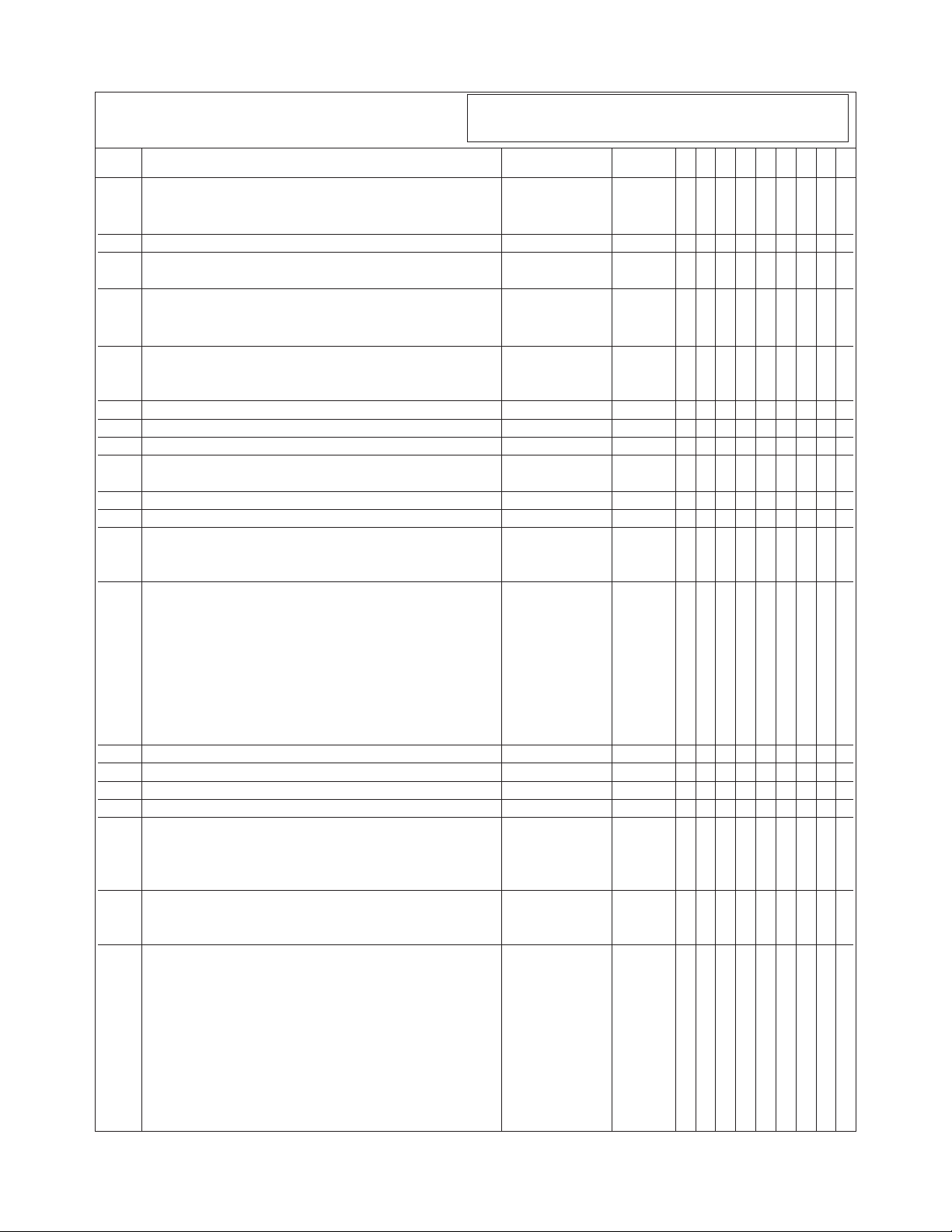

# Indicates a Change This Printing

P-140-A.1P-140-A.1

Use only the parts marked “X” in the column under the

heading number called for in the model index page.

ITEM DESCRIPTION PART NO. QTY.

3 Choke S18336 1 X X • •

3 Choke M15371 1 • • X X

4 Fan Motor Bracket S17194 1 X • • •

5 Case (Below Code 10400) L3786-19 1 X X X •

5 Case (Above Code 10400) L3786-14 1 • • X X

6A Lower Back Panel L6650 1 X X X X

6B Upper Back Panel L6651 ø 1X•••

6B Upper Back Panel G1395-1 1 • X X X

7 Range Selector Switch Includes: M10830-9 1 X X X X

Switch Shaft S13206 1 X X X X

7A Handle M13989-1 1 X X X X

8 Electrode Cable S11609-9 1 X X X X

9A Output Lead Clamp S15761 1 X X X X

10 Work Cable S11609-10 1 X X X X

11 Line Switch (Below Code 10400) S7670 1 X X X •

11 Line Switch (Above Code 10400) S18815 1 • • X X

12 Transformer and Base Not Available 1 X X X X

13 Suppressor S17203 1 X • • •

14 Polarity Switch, Includes: M14063 1 X X X X

Switch Shaft M14337 1 X X X X

14A Handle M13989-1 1 X X X X

15 Nameplate (60 Hz. 230 Volt Only) M15784 1 X X X •

15 Nameplate (60 Hz. All Voltages except 208 & 230 Volt) M15784-1 1 X X X •

15 Nameplate (60 Hz. 208 Volt Only) M15784-2 1 X X X •

15 Nameplate (50 Hz. All Voltages) M15785 1 X X X •

15 Nameplate (50 Hz) (Code 11675) M22168 1 • • • X

15A Warning Plate (Not Shown) M14330 1 X X X •

15A Warning Decal M14330-3 1 • • • X

15B Electrode Selector Plate (60 Hz) (Not Shown) M14331 1 X X X •

15B Electrode Selector Plate (50 Hz) (Not Shown) M14335 1 X X X •

16 Nameplate Fastener Button T14659-1 4 X X X X

17 Electrode Holder K909-1 1 X X X X

20 Work Clamp M12033 1 X X X X

28 Receptacle (60 Hz., 250 Volts or Less Only) S13700 1 X X X •

29 Input Cable (60 Hz., 250 Volts or Less Only) S15599-1 1 X X X X

29 Input Cable (50 Hz., 250 Volts or Less Only) S18021 1 • X X X

Circuit Breaker - Not Illustrated S10657-3 1 • X X X

Earth Ground Decal (Not Shown) T13260-4 1 X X X X

Optional Items:

30 Head Shield (Not Shown) Customerʼs1XXX•

Choice

31 Undercarriage Kit, Includes: K761 1 X X X X

31A Axle M8809-61 1 X X X X

31B Wheel S11662-3 2 X X X X

31C Mounting Kit T14160 1 X X X X

123456789

NSS - Not Sold Separately

ø

This part is obsolete and no longer available.

03-10-2010

Page 22

NOTES

Page 23

Manual del Operador

AC-225-S y AC/DC 225/125

Para usarse con máquinas con números de código:

10420, 10421, 10422,

10423, 10424, 11074,

11602, 11603, 11604,

11674, 11675

Registre su máquina:

www.lincolnelectric.com/register

Servicio Autorizado y Localizador de Distribuidores:

www.lincolnelectric.com/locator

Guarde para consulta futura

Fecha de Compra

Código: (ejemplo: 10859)

Número de serie: (ejemplo: U1060512345)

IMS237-P

© Lincoln Global, Inc. Todos los derechos reservados.

Page 24

GRACIAS POR SELECCIONAR UN

MANTENGA SU CABEZA ALEJADA DE LOS HUMOS.

PRODUCTO DE CALIDAD DE LINCOLN ELECTRIC.

SÍRVASE EXAMINAR INMEDIATAMENTE SI LA CAJA

Y EL EQUIPO ESTÁN DAÑADOS

Cuando este equipo se envía, los derechos pasan al comprador en

cuanto lo recibe del transportista. En consecuencia, el comprador es

el que debe hacer los reclamos por daños en el material durante el

envío ante la compañía de transporte al momento en que lo recibe.

LA SEGURIDAD DEPENDE DE USTED

El equipo de soldadura y corte de Lincoln está diseñado y construido

con la seguridad en mente. Sin embargo, su seguridad general puede

mejorar a través de una instalación adecuada...y una operación

cuidadosa por su parte.

NO INSTALE, OPERE O REPARE ESTE EQUIPO SIN LEER ESTE MANUAL

Y LAS PRECAUCIONES DE SEGURIDAD QUE CONTIENE. Y, lo más

importante, piense antes de actuar y tenga cuidado.

ADVERTENCIA

Esta palabra aparece donde la información debe seguirse

exactamente para evitar lesiones personales serias o pérdida de la

vida.

PRECAUCIÓN

Esta palabra aparece donde la información debe seguirse para evitar

lesiones personales menores o daño a este equipo.

NO se acerque mucho al arco. Use

lentes correctivos si es necesario para

permanecer a una distancia razonable

del arco.

LEA y obedezca la Ficha Técnica de

Seguridad del Material (MSDS) y la

etiqueta de advertencia que aparece en

todos los contenedores de los

materiales de soldadura.

UTILICE SUFICIENTE VENTILACIÓN o

escape en el arco, o ambos, para

mantener los humos y gases alejados de su zona de respiración y del área en

general.

EN UN ESPACIO GRANDE O EN EXTERIORES, la ventilación natural es

adecuada si mantiene su cabeza fuera de los humos (Vea a continuación).

UTILICE LAS CORRIENTES NATURALES o ventiladores para mantener los

humos alejados de su cara.

Si desarrolla síntomas inusuales, vea a su supervisor. Tal vez se necesario

revisar la atmósfera de soldadura y sistema de ventilación.

UTILICE PROTECCIÓN ADECUADA PARA LOS OJOS, OÍDOS Y CUERPO

PROTEJA sus ojos y cara con la careta de soldadura bien

colocada y con el grado adecuado de placa de filtro (Vea

ANSi Z49.1).

PROTEJA su cuerpo contras las salpicaduras de soldadura

y las chispas del arco con ropa protectora incluyendo

vestimenta de lana, mandil y guantes a prueba de fuego,

pantalones de cuero y botas altas.

PROTEJA a otros de la salpicadura, chispas y

destellos con pantallas o barreras protectoras.

EN ALGUNAS ÁREAS, puede resultar útil la

protección contra el ruido.

ASEGÚRESE de utilizar equipo protector en buen estado.

Asimismo, use lentes de seguridad en el área de tra-

bajo EN TODO MOMENTO.

SITUACIONES ESPECIALES

NO SUELDE O CORTE contenedores o materiales que habían estado

previamente en contacto con sustancias peligrosas a menos que

se hayan limpiado adecuadamente. Esto es extremadamente

peligroso.

NO SUELDE O CORTE partes pintadas o enchapadas a menos que

tome precauciones especiales con la ventilación. Pueden liberar

humos o gases altamente tóxicos.

Medidas de precaución adicionales.

PROTEJA a los cilindros de gas comprimido del calor excesivo,

descargas mecánicas y arcos; sujete a los cilindros para que no

se caigan.

ASEGÚRESE de que los cilindros nunca estén aterrizados o sean

parte de un circuito eléctrico.

REMUEVA todos los riesgos potenciales de incendio del área de

soldadura.

SIEMPRE TENGA A LA MANO EQUIPO CONTRA INCENDIOS LISTO PARA SU

USO INMEDIATO Y SEPA CÓMO USARLO.

Page 25

1.d. Mantener todos los protectores, cubiertas y

SECCIÓN A:

ADVERTENCIAS

ADVERTENCIA DE LA LEY 65 DE CALIFORNIA

Motores Diesel

En el estado de California, se considera a las emisiones del motor de

diesel y algunos de sus componentes como dañinas para la salud, ya que

provocan cáncer, defectos de nacimiento y otros daños reproductivos.

Motores de Gasolina

Las emi sio nes de este tipo de pro duc tos con tie nen químicos que, para el

es ta do de Ca li for nia, pro vo can cáncer, de fec tos de na ci mien to y otros

daños reproduc tivos.

LA SOLDADURALA SOLDADURA AL ARCO PUEDE SER

PELIGROSA. PROTEJASE USTED Y A LOS DEMAS CONTRA POSIBLES LESIONES DE DIFERENTE GRAVEDAD,

INCLUSO MORTALES. NO PERMITA QUE LOS NIÑOS SE

ACERQUEN AL EQUIPO. LAS PERSONAS CON MARCAPASOS DEBEN CONSULTAR A SU MEDICO ANTES DE

USAR ESTE EQUIPO.

1.e. En algunos casos puede ser necesario quitar los protectores para hacer

1.f. No poner las manos cerca del ventilador del motor. No tratar de

1.g. Para impedir el arranque accidental de los motores de gasolina mientras

1.h. Para evitar quemarse con agua caliente, no quitar la

SEGURIDAD

dispositivos de seguridad del equipo en su lugar y en

buenas condiciones. No acercar las manos, cabello,

ropa y herramientas a las correas en V, engranajes,

ventiladores y todas las demás piezas móviles

durante el arranque, funcionamiento o reparación del

equipo.

algún trabajo de mantenimiento requerido. Quitarlos solamente cuando

sea necesario y volver a colocarlos después de terminado el trabajo de

mantenimiento. Tener siempre el máximo cuidado cuando se trabaje cerca

de piezas en movimiento.

sobrecontrolar el regulador de velocidad en vacío empujando las varillas

de control del acelerador mientras el motor está funcionando.

se hace girar el motor o generador de la soldadura durante el trabajo de

mantenimiento, desconectar los cables de las bujías, tapa del distribuidor

o cable del magneto, según corresponda.

tapa a presión del radiador mientras el motor está

caliente.

Lea y entienda los siguientes mensajes de seguridad. Para más información

acerca de la seguridad, se recomienda comprar un ejemplar de "Safety in

Welding & Cutting - ANIS Standard Z49.1" de la Sociedad Norteamericana

de Soldadura, P.O. Box 351040, Miami, Florida 33135 ó CSA Norma

W117.2-1974. Un ejemplar gratis del folleto "Arc Welding Safety"

(Seguridad de la soldadura al arco) E205 está disponible de Lincoln Electric

Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

ASEGURESE QUE TODOS LOS TRABAJOS DE

INSTALACION, FUNCIONAMIENTO, MANTENIMIENTO Y

REPARACION SEAN HECHOS POR PERSONAS

CAPACITADAS PARA ELLO.

PARA EQUIPOS ACCIONADOS POR

2.a. La corriente eléctrica que circula a través de un

2.b. Los campos EMF pueden interferir con los marcapasos y en otros

2.c. La exposición a los campos EMF en soldadura puede tener otros efectos

MOTOR.

1.a. Apagar el motor antes de hacer trabajos de localización

de averías y de mantenimiento, salvo en el caso que el

trabajo de mantenimiento requiera que el motor esté

funcionando.

1.b. Los motores deben funcionar en lugares abiertos bien

ventilados, o expulsar los gases de escape del motor al exterior.

1.c. No cargar combustible cerca de un arco de soldadura

cuando el motor esté funcionando. Apagar el motor y

dejar que se enfríe antes de rellenar de combustible

para impedir que el combustible derramado se vaporice

al quedar en contacto con las piezas del motor caliente.

No derramar combustible al llenar el tanque. Si se derrama, limpiarlo con un trapo

y no arrancar el motor hasta que los vapores se hayan eliminado.

2.d. Todo soldador debe emplear los procedimientos siguientes para reducir

LOS CAMPOS ELÉTRICOS

Y MAGNÉTICOS PUEDEN

SER PELIGROSOS.

conductor origina campos eléctricos y magnéticos (EMF) localizados. La

corriente de soldadura crea campos EMF alrededor de los cables y los

equipos de soldadura.

equipos médicos individuales, de manera que los operarios que utilicen

estos aparatos deben consultar a su médico antes de trabajar con una

máquina de soldar.

sobre la salud que se desconocen.

al mínimo la exposición a los campos EMF del circuito de soldadura:

2.d.1. Pasar los cables de pinza y de trabajo juntos - Encintarlos juntos

siempre que sea posible.

2.d.2. Nunca enrollarse el cable de electrodo alrededor del cuerpo.

2.d.3. No colocar el cuerpo entre los cables de electrodo y trabajo. Si

el cable del electrodo está en el lado derecho, el cable de trabajotambién debe estar en el lado derecho.

2.d.4. Conectar el cable de trabajo a la pieza de trabajo lo más cerca

posible del área que se va a solda.

2.d.5. No trabajar al lado de la fuente de corriente.

3

Page 26

Además de las medidas de seguridad normales, si es necesario

soldar en condiciones eléctricamente peligrosas (en lugares

húmedos o mientras se está usando ropa mojada; en las

estructuras metálicas tales como suelos, emparrillados o

andamios; estando en posiciones apretujadas tales como sentado,

arrodillado o acostado, si existe un gran riesgo de que ocurra

contacto inevitable o accidental con la pieza

de trabajo o con tierra,

usar el equipo siguiente:

Cuando se suelda con

electrodos de acero inoxidable o recubrimiento duro que requieren

ventilación especial (Ver instrucciones en el contenedor o la MSDS)

o cuando se suelda chapa galvanizada, chapa recubierta de Plomo

y Cadmio, u otros metales que producen humos tóxicos, se deben

tomar precauciones suplementarias. Mantenga la exposición lo más

baja posible, por debajo de los valores límites umbrales

(TLV) ,

utilizando un sistema de extracción local o una ventilación

mecánica. En espacios confinados o en algunas situaciones, a la

intemperie, puede ser necesario el uso de respiración asistida.

SEGURIDAD

LA DESCARGA ELÉCTRICA

PUEDE CAUSAR LA MUERTE.

3.a. Los circuitos del electrodo y de trabajo están

eléctricamente con tensión cuando el equipo de

soldadura está encendido. No tocar esas piezas con

tensión con la piel desnuda o con ropa mojada. Usar guantes secos sin

agujeros para aislar las manos.

3.b. Aislarse del circuito de trabajo y de tierra con la ayuda de material

aislante seco. Asegurarse de que el aislante es suficiente para

protegerle completamente de todo contacto físico con el circuito de

trabajo y tierra.

A

• Equipo de soldadura semiautomática de C.C. a tensión constante.

• Equipo de soldadura manual C.C.

• Equipo de soldadura de C.A. con control de voltaje reducido.

3.c. En la soldadura semiautomática o automática con alambre continuo, el

electrodo, carrete de alambre, cabezal de soldadura, boquilla o pistola

para soldar semiautomática también están eléctricamente con tensión.

3.d. Asegurar siempre que el cable de trabajo tenga una buena conexión

eléctrica con el metal que se está soldando. La conexión debe ser lo más

cercana posible al área donde se va a soldar.

3.e. Conectar el trabajo o metal que se va a soldar a una buena toma de

tierra eléctrica.

3.f. Mantener el portaelectrodo, pinza de trabajo, cable de soldadura y

equipo de soldadura en unas condiciones de trabajo buenas y seguras.

Cambiar el aislante si está dañado.

LOS RAYOS DEL ARCO

PUEDEN QUEMAR.

4.a. Colocarse una pantalla de protección con el filtro adecuado para

protegerse los ojos de las chispas y rayos del arco cuando se suelde o se

observe un soldadura por arco abierto. Cristal y pantalla han de

satisfacer las normas ANSI Z87.I.

4.b. Usar ropa adecuada hecha de material resistente a la flama durable para

protegerse la piel propia y la de los ayudantes de los rayos del arco.

4.c. Proteger a otras personas que se encuentren cerca del arco, y/o

advertirles que no miren directamente al arco ni se expongan a los rayos

del arco o a las salpicaduras.

LOS HUMOS Y GASES

PUEDEN SER

PELIGROS.

5.a. La soldadura puede producir humos y gases

peligrosos para la salud. Evite respirarlos. Durantela soldadura,

mantener la cabeza alejada de los humos. Utilice ventilación y/o

extracción de humos junto al arco para mantener los humos y

gasesalejados de la zona de respiración.

5. b. La operación de equipo de control de humos de soldadura se ve afectada

por diversos factores incluyendo el uso adecuado y el posicionamiento

del equipo así como el procedimiento de soldadura específico y la

aplicación utilizada. El nivel de exposición del trabajador deberá ser

verificado durante la instalación y después periodicamente a fin de

asegurar que está dentro de los límites OSHA PEL y ACGIH TLV

permisibles.

3.g. Nunca sumergir el electrodo en agua para enfriarlo.

3.h. Nunca tocar simultáneamente la piezas con tensión de los

portaelectrodos conectados a dos equipos de soldadura porque el voltaje

entre los dos puede ser el total de la tensión en vacío de ambos

equipos..

3.i. Cuando se trabaje en alturas, usar un cinturón de seguridad para

protegerse de una caída si hubiera descarga eléctrica.

3.j. Ver también 6.c. y 8.

5.c. No soldar en lugares cerca de una fuente de vapores de hidrocarburos

clorados provenientes de las operaciones de desengrase, limpieza o

pulverización. El calor y los rayos del arco puede reaccionar con los

vapores de solventes para formar fosgeno, un gas altamente tóxico, y

otros productos irritantes.

5.d. Los gases protectores usados para la soldadura por arco pueden

desplazar el aire y causar lesiones graves, incluso la muerte. Tenga

siempre suficiente ventilación, especialmente en las áreas confinadas,

para tener la seguridad de que se respira aire fresco.

5.e. Lea atentamente las instrucciones del fabricante de este equipo y el

material consumible que se va a usar, incluyendo la hoja de datos de

seguridad del material (MSDS) y siga las reglas de seguridad del

empleado, distribuidor de material de soldadura o del fabricante.

5.f. Ver también 1.b.

4

Page 27

SEGURIDAD

LAS CHISAS DE

SOLDADURA PUEDEN

PROVOCAR UN INCENDIO

O UNA EXPLOSIÓN.

6.a. Quitar todas las cosas que presenten riesgo de

incendio del lugar de soldadura. Si esto no es posible, taparlas para

impedir que las chispas de la soldadura inicien un incendio. Recordar

que las chispas y los materiales calientes de la soldadura puede pasar

fácilmente por las grietas pequeñas y aberturas adyacentes al área. No

soldar cerca de tuberías hidráulicas. Tener un extintor de incendios a

mano.

6.b. En los lugares donde se van a usar gases comprimidos, se deben tomar

precauciones especiales para prevenir situaciones de riesgo. Consultar

“Seguridad en Soldadura y Corte“ (ANSI Estándar Z49.1) y la información

de operación para el equipo que se esté utilizando.

6.c. Cuando no esté soldando, asegúrese de que ninguna parte del circuito

del electrodo haga contacto con el trabajo o tierra. El contacto accidental

podría ocasionar sobrecalentamiento de la máquina y riesgo de incendio.

6.d. No calentar, cortar o soldar tanques, tambores o contenedores hasta

haber tomado los pasos necesarios para asegurar que tales

procedimientos no van a causar vapores inflamables o tóxicos de las

sustancias en su interior. Pueden causar una explosión incluso después

de haberse “limpiado”. Para más información, consultar “Recommended

Safe Practices for the Preparation for Welding and Cutting of Containers

and Piping That Have Held Hazardous Substances”, AWS F4.1 de la

American Welding Society.

6.e. Ventilar las piezas fundidas huecas o contenedores antes de calentar,

cortar o soldar. Pueden explotar.

6.f. Las chispas y salpicaduras son lanzadas por el arco de soldadura. Usar

ropa adecuada que proteja, libre de aceites, como guantes de cuero,

camisa gruesa, pantalones sin bastillas, zapatos de caña alta y una

gorra. Ponerse tapones en los oídos cuando se suelde fuera de posición

o en lugares confinados. Siempre usar gafas protectoras con

protecciones laterales cuando se esté en un área de soldadura.

6.g. Conectar el cable de trabajo a la pieza tan cerca del área de soldadura

como sea posible. Los cables de la pieza de trabajo conectados a la

estructura del edificio o a otros lugares alejados del área de soldadura

aumentan la posibilidad de que la corriente para soldar traspase a otros

circuitos alternativos como cadenas y cables de elevación. Esto puede

crear riesgos de incendio o sobrecalentar estas cadenas o cables de izar

hasta hacer que fallen.

6.h. Ver también 1.c.

6.I. Lea y siga el NFPA 51B “ Estándar para Prevención de Incendios Durante

la Soldadura, Corte y otros Trabajos Calientes”, disponible de NFPA, 1

Batterymarch Park, PO box 9101, Quincy, Ma 022690-9101.

6.j. No utilice una fuente de poder de soldadura para descongelación de

tuberías.

LA BOTELLA DE GAS

PUEDE EXPLOTAR SI ESTÁ

DAÑADA.

7.a. Emplear únicamente botellas que contengan el gas

de protección adecuado para el proceso utilizado, y

reguladores en buenas condiciones de funcionamiento diseñados para el

tipo de gas y la presión utilizados. Todas las mangueras, rácores, etc.

deben ser adecuados para la aplicación y estar en buenas condiciones.

7.b. Mantener siempre las botellas en posición vertical sujetas firmemente

con una cadena a la parte inferior del carro o a un soporte fijo.

7.c. Las botellas de gas deben estar ubicadas:

• Lejos de las áreas donde puedan ser golpeados o estén sujetos

a daño físico.

• A una distancia segura de las operaciones de corte o soldadura

por arco y de cualquier fuente de calor, chispas o llamas.

7.d. Nunca permitir que el electrodo, portaelectrodo o cualquier otra pieza

con tensión toque la botella de gas.

7.e. Mantener la cabeza y la cara lejos de la salida de la válvula de la botella

de gas cuando se abra.

7.f. Los capuchones de protección de la válvula siempre deben estar

colocados y apretados a mano, excepto cuando la botella está en uso o

conectada para uso.

7.g. Leer y seguir las instrucciones de manipulación en las botellas de gas y

el equipamiento asociado, y la publicación P-I de CGA, “Precauciones

para un Manejo Seguro de los Gases Comprimidos en los Cilindros“,

publicado por Compressed Gas Association 1235 Jefferson Davis

Highway, Arlington, VA 22202.

PARA EQUIPOS ELÉCTRICOS.

8.a. Cortar la electricidad entrante usando el interruptor de

desconexión en la caja de fusibles antes de trabajar en

el equipo.

8.b. Conectar el equipo a la red de acuerdo con U.S. National Electrical Code,

todos los códigos y las recomendaciones del fabricante.

8.c. Conectar el equipo a tierra de acuerdo con U.S. National Electrical Code,

todos los códigos y las recomendaciones del fabricante.

Vaya a

http://www.lincolnelectric.com/safety para

información adicional de seguridad.

Guía Web Interactiva de

Seguridad de Soldadura

para los dispositivos

móviles.

Page 28

AC-225-S & AC/DC 225/125

Instalación.......................................................................................................Sección A

Instrucciones de operación..........................................................................................................A-1

Alimentación y Conexiones a Tierra.....................................................................................A-1

Conexión del cable del electrodo al portaelectrodo .............................................................A-1

Portaelectrodo Tipo A con Forma Octagonal .......................................................................A-1

Portaelectrodo Tipo B con Forma Circular Estriado.............................................................A-2

Reemplazo del electrodo y trabajo.......................................................................................A-2

Operación........................................................................................................Sección B

Selección de la polaridad de soldadura ...............................................................................B-1

Ciclo de Trabajo .................................................................................................................B-1

Interruptores Automáticos ...................................................................................................B-1

Cómo Aprender a Soldar con Electrodo Revestido .............................................................B-1

Guía de Selección de Electrodos ........................................................................................B-1

Guía de Electrodos ..............................................................................................................B-2

Movimientos A a G de la Soldadura con Electrodo Revestido.............................................B-2

Corte y Perforación ............................................................................................................B-3

Mantenimiento................................................................................................Sección C

Mantenimiento Preventivo de Rutina ..................................................................................C-1

Páginas de Partes ............................................................................. Serie P-65, P-140

TABLA DE CONTENIDO

Página

6

Page 29

INSTRUCCIONES DE

INSTALACIÓNAC-225-S & AC/DC 225/125

OPERACIÓN

ADVERTENCIA

• Haga que un electricista instale y dé servicio a este equipo.

• Apague la alimentación en la caja de fusibles antes de trabajar en este equipo.

• No toque las partes eléctricamente calientes.

Alimentación y Conexiones a Tierra

Antes de empezar la instalación, consulte con la

compañía de electricidad para saber si su fuente de

energía es adecuada para el voltaje, amperios, fase y

frecuencia especificados en la placa de identificación de

la soldadora. Asimismo, asegúrese de que la instalación

planeada cumplirá con el Código Eléctrico Nacional de

los Estados Unidos y los requerimientos del código local.

Esta soldadora se puede operar desde una línea

monofásica, o desde una fase de una línea bifásica o

trifásica.

Todos los modelos que están diseñados para operar con

líneas de entrada de menos de 250 voltios se envían con

el cable de alimentación conectado a la soldadora.

Coloque la soldadora donde el aire pueda circular

libremente a través de la rejillas posteriores y a los lados

del gabinete y hacia fuera por la parte inferior de todos

los cuatro lados. Monte un receptáculo NEMA Tipo 650R en un lugar adecuado. Asegúrese de que el enchufe

del cable de alimentación conectado a la soldadora

pueda alcanzarlo.

Basándose en las siguientes instrucciones, haga que un

electricista calificado conecte este receptáculo (Tipo

NEMA 6-50R) a las líneas de alimentación de la caja de

fusibles. Se requieren tres cables de cobre #10 o

mayores si se utiliza un conducto. Para cables largos de

más de 31m (100'), se necesitará un cable #8 o mayor

en el conducto para evitar caídas excesivas de voltaje.

Instale en las dos líneas calientes fusibles tipo quemado

lento de 50 amperios como se muestra en el siguiente

diagrama. El contacto central en el receptáculo es para

la conexión a tierra. Un alambre verde en el cable de

entrada conecta este contacto al armazón de la

soldadora.

Esto asegura un aterrizamiento adecuado al armazón de

la soldadora cuando el enchufe de la misma se inserta

en el receptáculo. Si se utiliza un interruptor de

desconexión separado, deberá tener dos polos para dos

líneas calientes y ambos deberán tener fusibles para 50

amperios.

CONECTE A UN CABLE DE ATERRIZAMIENTO DEL SISTEMA. CONSULTE EL CÓDIGO

ELÉCTRICO NACIONAL DE LOS ESTADOS

UNIDOS Y/O CÓDIGOS LOCALES PARA

OBTENER OTROAS DETALLES Y MEDIOS

PARA UN ATERRIZAMIENTO ADECUADO.

CONECTE A CABLES CALIENTES

DE UN SISTEMA MONOFÁSICO DE

TRES ALAMBRES O A UNA FASE

}

DE UN SISTEMA BIFÁSICO O

TRIFÁSICO.

ADVERTENCIA

Orificio Superior con

Cable Más Largo

Cable del Electrodo

FIGURA 1A

Conexión del Cable del Electrodo al Portaelectrodo

Antes de conectar el cable del electrodo al portaelectrodo o

el cable de trabajo a la pinza, asegúrese de que la soldadora esté apagada o la alimentación desconectada.

Identifique el tipo de portaelectrodo antes de instalarlo

Tipo A – Portaelectrodo con Manija Octagonal y Pinza

con Mordazas

1. Afloje el tornillo de fijación y deslice la manija fuera

del portaelectrodo. Coloque la manija sobre el

cable del electrodo. El cable más largo se utiliza

para el cable del electrodo y se localiza enfrente de

los orificios superiores de la máquina como se

muestra en la siguiente figura.

PINZA DE

PINZA DE CONEXIÓN

DE CABLE EN

POSICIÓN DE ENVÍO

TORNILLO DE FIJACIÓN

CONEXIÓN

DE CABLE

CABLE DEL

ELECTRODO

PINZA DE CONEXIÓN DE CABLE

TORNILLO DE CONEXIÓN DE CABLE

MANIJA

FIGURA 1A

2. Remueva 25.4mm ± 1.6mm (1” ± 1/16”) del ais-

lamiento de la punta del cable del electrodo.

3. Mueva hacia atrás el tornillo de conexión del cable

hasta que esté nivelado con la superficie interna

del cuerpo de la mordaza.

4. Remueva la pinza de conexión del cable de las

mordazas del portaelectrodo. Coloque la pinza

sobre la punta desnuda del cable del electrodo e

inserte en el portaelectrodo con la pinza centrada

contra el tornillo de conexión.

5. Apriete bien el tornillo de conexión del cable contra

la pinza.

.