Page 1

IMT10097

RETURN TO MAIN MENU

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However,

your overall safety can be

increased by proper installation

... and thoughtful operation on

your part. DO NOT INSTALL,

OPERATE OR REPAIR THIS

EQUIPMENT WITHOUT READING THIS MANUAL AND THE

SAFETY PRECAUTIONS CONTAINED THROUGHOUT. And,

most importantly, think before

you act and be careful.

POWER MIG®216

For use with machine Code Numbers

For use with machine Code Numbers

11817

May, 2011

OPERATORʼS MANUAL

MANUAL DE OPERACIÓN

OPERATOR’S MANUAL

Copyright © Lincoln Global Inc.

• World's Leader in Welding and Cutting Products •

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

MANUEL DE LʼOPÉRATEUR

Page 2

i

SAFETY

i

WARNING

CALIFORNIA PROPOSITION 65 WARNINGS

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer, birth defects, and other reproductive harm.

The Above For Diesel Engines

ARC WELDING CAN BE HAZARDOUS. PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH.

KEEP CHILDREN AWAY. PACEMAKER WEARERS SHOULD CONSULT WITH THEIR DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For additional safety information, it is strongly recommended that you purchase a copy of “Safety in Welding & Cutting - ANSI Standard Z49.1” from the American Welding Society, P.O. Box 351040,

Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the

Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

The Above For Gasoline Engines

FOR ENGINE

powered equipment.

1.a. Turn the engine off before troubleshooting and maintenance

work unless the maintenance work requires it to be running.

____________________________________________________

1.b. Operate engines in open, well-ventilated

areas or vent the engine exhaust fumes

outdoors.

____________________________________________________

1.c. Do not add the fuel near an open flame

welding arc or when the engine is running.

Stop the engine and allow it to cool before

refueling to prevent spilled fuel from vaporizing on contact with hot engine parts and

igniting. Do not spill fuel when filling tank. If

fuel is spilled, wipe it up and do not start

engine until fumes have been eliminated.

____________________________________________________

1.d. Keep all equipment safety guards, covers and devices in

position and in good repair.Keep hands, hair, clothing and

tools away from V-belts, gears, fans and all other moving

parts when starting, operating or repairing equipment.

____________________________________________________

1.e. In some cases it may be necessary to remove safety

guards to perform required maintenance. Remove

guards only when necessary and replace them when the

maintenance requiring their removal is complete.

Always use the greatest care when working near moving

parts.

___________________________________________________

1.f. Do not put your hands near the engine fan.

Do not attempt to override the governor or

idler by pushing on the throttle control rods

while the engine is running.

1.h. To avoid scalding, do not remove the

radiator pressure cap when the engine is

hot.

ELECTRIC AND

MAGNETIC FIELDS

may be dangerous

2.a. Electric current flowing through any conductor causes

localized Electric and Magnetic Fields (EMF). Welding

current creates EMF fields around welding cables and

welding machines

2.b. EMF fields may interfere with some pacemakers, and

welders having a pacemaker should consult their physician

before welding.

2.c. Exposure to EMF fields in welding may have other health

effects which are now not known.

2.d. All welders should use the following procedures in order to

minimize exposure to EMF fields from the welding circuit:

2.d.1.

Route the electrode and work cables together - Secure

them with tape when possible.

2.d.2. Never coil the electrode lead around your body.

2.d.3. Do not place your body between the electrode and

work cables. If the electrode cable is on your right

side, the work cable should also be on your right side.

___________________________________________________

1.g. To prevent accidentally starting gasoline engines while

turning the engine or welding generator during maintenance

work, disconnect the spark plug wires, distributor cap or

magneto wire as appropriate.

2.d.4. Connect the work cable to the workpiece as close as

possible to the area being welded.

2.d.5. Do not work next to welding power source.

Page 3

ii

SAFETY

ii

ELECTRIC SHOCK can

kill.

3.a. The electrode and work (or ground) circuits

are electrically “hot” when the welder is on.

Do not touch these “hot” parts with your bare

skin or wet clothing. Wear dry, hole-free

gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full

area of physical contact with work and ground.

In addition to the normal safety precautions, if welding

must be performed under electrically hazardous

conditions (in damp locations or while wearing wet

clothing; on metal structures such as floors, gratings or

scaffolds; when in cramped positions such as sitting,

kneeling or lying, if there is a high risk of unavoidable or

accidental contact with the workpiece or ground) use

the following equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel, welding head, nozzle or semiautomatic

welding gun are also electrically “hot”.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection

should be as close as possible to the area being welded.

3.e. Ground the work or metal to be welded to a good electrical

(earth) ground.

3.f.

Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Never simultaneously touch electrically “hot” parts of

electrode holders connected to two welders because voltage

between the two can be the total of the open circuit voltage

of both welders.

3.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

3.j. Also see Items 6.c. and 8.

ARC RAYS can burn.

4.a. Use a shield with the proper filter and cover

plates to protect your eyes from sparks and

the rays of the arc when welding or observing

open arc welding. Headshield and filter lens

should conform to ANSI Z87. I standards.

4.b. Use suitable clothing made from durable flame-resistant

material to protect your skin and that of your helpers from

the arc rays.

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

FUMES AND GASES

can be dangerous.

5.a. Welding may produce fumes and gases

hazardous to health. Avoid breathing these

fumes and gases. When welding, keep

your head out of the fume. Use enough

ventilation and/or exhaust at the arc to keep

fumes and gases away from the breathing zone. When

welding with electrodes which require special

ventilation such as stainless or hard facing (see

instructions on container or MSDS) or on lead or

cadmium plated steel and other metals or coatings

which produce highly toxic fumes, keep exposure as

low as possible and within applicable OSHA PEL and

ACGIH TLV limits using local exhaust or mechanical

ventilation. In confined spaces or in some circumstances, outdoors, a respirator may be required.

Additional precautions are also required when welding

on galvanized steel.

5. b. The operation of welding fume control equipment is affected

by various factors including proper use and positioning of

the equipment, maintenance of the equipment and the specific welding procedure and application involved. Worker

exposure level should be checked upon installation and

periodically thereafter to be certain it is within applicable

OSHA PEL and ACGIH TLV limits.

5.c.

Do not weld in locations near chlorinated hydrocarbon

coming from degreasing, cleaning or spraying operations.

The heat and rays of the arc can react with solvent vapors

form phosgene, a highly toxic gas, and other irritating products.

5.d. Shielding gases used for arc welding can displace air and

cause injury or death. Always use enough ventilation,

especially in confined areas, to insure breathing air is safe.

vapors

OPERATORʼS MANUAL

to

5.e. Read and understand the manufacturerʼs instructions for this

equipment and the consumables to be used, including the

material safety data sheet (MSDS) and follow your

employerʼs safety practices. MSDS forms are available from

your welding distributor or from the manufacturer.

5.f. Also see item 1.b.

Page 4

iii

SAFETY

iii

WELDING and CUTTING

SPARKS can

cause fire or explosion.

6.a.

Remove fire hazards from the welding area.

If this is not possible, cover them to prevent

Remember that welding sparks and hot

materials from welding can easily go through small cracks

and openings to adjacent areas. Avoid welding near

hydraulic lines. Have a fire extinguisher readily available.

6.b. Where compressed gases are to be used at the job site,

special precautions should be used to prevent hazardous

situations. Refer to “Safety in Welding and Cutting” (ANSI

Standard Z49.1) and the operating information for the

equipment being used.

6.c. When not welding, make certain no part of the electrode

circuit is touching the work or ground. Accidental contact

can cause overheating and create a fire hazard.

6.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures

will not cause flammable or toxic vapors from substances

inside. They can cause an explosion even

been “cleaned”. For information, purchase “Recommended

Safe Practices for the

Containers and Piping That Have Held Hazardous

Substances”, AWS F4.1 from the American Welding Society

(see address above).

6.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

Sparks and spatter are thrown from the welding arc. Wear oil

6.f.

free protective garments such as leather gloves, heavy shirt,

cuffless trousers, high shoes and a cap over your hair. Wear

ear plugs when welding out of position or in confined places.

Always wear safety glasses with side shields when in a

welding area.

6.g. Connect the work cable to the work as close to the welding

area as practical. Work cables connected to the building

framework or other locations away from the welding area

increase the possibility of the welding current passing

through lifting chains, crane cables or other alternate circuits. This can create fire hazards or overheat lifting chains

or cables until they fail.

6.h. Also see item 1.c.

the welding sparks from starting a fire.

though

they have

Preparation

for Welding and Cutting of

CYLINDER may explode

if damaged.

7.a. Use only compressed gas cylinders

containing the correct shielding gas for the

process used and properly operating

regulators designed for the gas and

pressure used. All hoses, fittings, etc. should be suitable for

the application and maintained in good condition.

7.b. Always keep cylinders in an upright position securely

chained to an undercarriage or fixed support.

7.c. Cylinders should be located:

• Away from areas where they may be struck or subjected to

physical damage.

• A safe distance from arc welding or cutting operations and

any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode holder or any other

electrically “hot” parts to touch a cylinder.

7.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. Valve protection caps should always be in place and hand

tight except when the cylinder is in use or connected for

use.

7.g. Read and follow the instructions on compressed gas

cylinders, associated equipment, and CGA publication P-l,

“Precautions for Safe Handling of Compressed Gases in

Cylinders,” available from the Compressed Gas Association

1235 Jefferson Davis Highway, Arlington, VA 22202.

FOR ELECTRICALLY

powered equipment.

8.a. Turn off input power using the disconnect

switch at the fuse box before working on

the equipment.

8.b. Install equipment in accordance with the U.S. National

Electrical Code, all local codes and the manufacturerʼs

recommendations.

8.c. Ground the equipment in accordance with the U.S. National

Electrical Code and the manufacturerʼs recommendations.

6.I. Read and follow NFPA 51B “ Standard for Fire Prevention

During Welding, Cutting and Other Hot Work”, available

from NFPA, 1 Batterymarch Park, PO box 9101, Quincy, Ma

022690-9101.

6.j. Do not use a welding power source for pipe thawing.

Refer to http://www.lincolnelectric.com/safety for additional safety information.

Page 5

NOTES

OPERATORʼS MANUAL

Page 6

Thank You

vv

for selecting a QUALITY product by Lincoln Electric. We want you

to take pride in operating this Lincoln Electric Company product

••• as much pride as we have in bringing this product to you!

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the needs of our customers and to exceed their expectations. On occasion, purchasers may ask Lincoln

Electric for advice or information about their use of our products. We respond to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or advice. We expressly disclaim any warranty of any kind, including any warranty of fitness for any customerʼs particular purpose,

with respect to such information or advice. As a matter of practical consideration, we also cannot assume any responsibility for updating or

correcting any such information or advice once it has been given, nor does the provision of information or advice create, expand or alter any

warranty with respect to the sale of our products.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control

of, and remains the sole responsibility of the customer. Many variables beyond the control of Lincoln Electric affect the results obtained in

applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com

for any updated information.

CUSTOMER ASSISTANCE POLICY

Please Examine Carton and Equipment For Damage Immediately

When this equipment is shipped, title passes to the purchaser upon receipt by the carrier. Consequently, Claims

for material damaged in shipment must be made by the purchaser against the transportation company at the

time the shipment is received.

Please record your equipment identification information below for future reference. This information can be

found on your machine nameplate.

Product _________________________________________________________________________________

Model Number ___________________________________________________________________________

Code Number or Date Code_________________________________________________________________

Serial Number____________________________________________________________________________

Date Purchased___________________________________________________________________________

Where Purchased_________________________________________________________________________

Whenever you request replacement parts or information on this equipment, always supply the information you

have recorded above. The code number is especially important when identifying the correct replacement parts.

On-Line Product Registration

- Register your machine with Lincoln Electric either via fax or over the Internet.

• For faxing: Complete the form on the back of the warranty statement included in the literature packet

accompanying this machine and fax the form per the instructions printed on it.

• For On-Line Registration: Go to our

“Product Registration”. Please complete the form and submit your registration.

Read this Operators Manual completely before attempting to use this equipment. Save this manual and keep it

handy for quick reference. Pay particular attention to the safety instructions we have provided for your protection.

The level of seriousness to be applied to each is explained below:

WEB SITE at www.lincolnelectric.com. Choose “Quick Links” and then

WARNING

This statement appears where the information must be followed exactly to avoid serious personal injury or loss of life.

CAUTION

This statement appears where the information must be followed to avoid minor personal injury or damage to this equipment.

Page 7

TABLE OF CONTENT

Page

________________________________________________________________________

Installation .......................................................................................................Section A

Technical Specifications ........................................................................................A-1

Safety Precautions.................................................................................................A-2

Uncrating the POWER MIG® 216 .........................................................................A-2

Location .................................................................................................................A-2

Input Power, Grounding and Connection Diagram ........................................A-2, A-3

Output Polarity Connections..................................................................................A-3

Gun and Cable Installation ....................................................................................A-4

Shielding Gas ........................................................................................................A-4

Coil Claw™ Installation..........................................................................................A-5

________________________________________________________________________

vi vi

Operation .........................................................................................................Section B

Safety Precautions.................................................................................................B-1

Product Description ...............................................................................................B-2

Recommended Processes and Equipment ...........................................................B-2

Welding Capability.................................................................................................B-2

Limitations..............................................................................................................B-2

Description of Controls ..........................................................................................B-2

Wire Drive Roll.......................................................................................................B-3

Wire Size Conversion parts ...................................................................................B-3

Procedure for Changing Drive Roll........................................................................B-3

Wire Reel Loading .................................................................................................B-3

Mounting of 10 to 44 lbs. Spools ...........................................................................B-3

To Start the Welder................................................................................................B-4

Feeding Electrode..................................................................................................B-4

Idle Roll Pressure Setting ......................................................................................B-4

Wire Drive Configuration................................................................................B-4, B-5

Making a Weld.......................................................................................................B-5

Avoiding Wire Feeding Problems ..........................................................................B-6

Fan Control............................................................................................................B-6

Input Line Voltage Protection.................................................................................B-6

Wire Feed overload Protection ..............................................................................B-6

Welding Thermal Overload Protection...................................................................B-6

Welding Procedure Information .............................................................................B-6

Learning To Weld ..................................................................................................B-6

________________________________________________________________________

OPERATORʼS MANUAL

Accessories.....................................................................................................Section C

Drive Roll Kits........................................................................................................C-1

Dual Cylinder Mounting Kit ...................................................................................C-1

Small Spool Spindle Adapter.................................................................................C-1

Alternative Magnum GMAW Gun and Cable Assemblies .....................................C-1

Magnum Gun Connection Kit ...............................................................................C-1

Optional Spool Guns and Adapters.......................................................................C-1

Making a Weld with the Spool Gun Adapter Kit and Spool Gun Installed .............C-2

________________________________________________________________________

Page 8

vii vii

TABLE OF CONTENTS

Page

Maintenance ....................................................................................................Section D

Safety Precautions ................................................................................................D-1

General Maintenance ............................................................................................D-1

Drive Rolls and guide Tubes .................................................................................D-1

Contact Tip and Gas Nozzle Installation ...............................................................D-1

Gun Tubes and Nozzles........................................................................................D-1

Gun Cable Cleaning ..............................................................................................D-1

Liner Removal and Replacement ..........................................................................D-2

Gun Handle Disassembly......................................................................................D-3

Troubleshooting..............................................................................................Section E

How to Use Troubleshooting Guide.......................................................................E-1

Troubleshooting Guide ............................................................................E-2 thru E-4

Application Chart, Wiring Diagram and Dimension Print............................Section F

Parts Manual....................................................................................................Appendix

POWER MIG® 216 ..................................................................................................P-611

Magnum Pro 250L Gun ..............................................................................P-202-H.2

Page 9

A-1

INSTALLATION

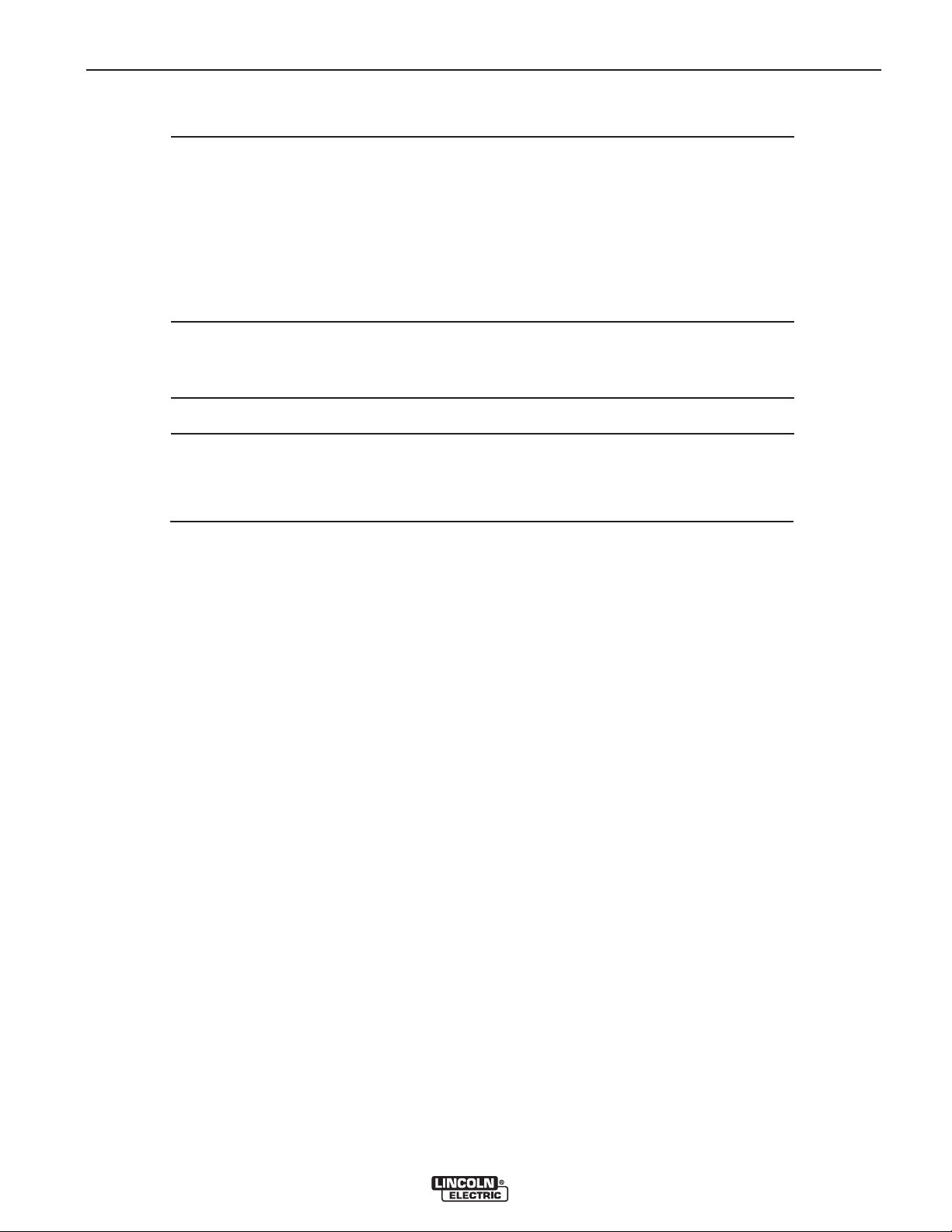

TECHNICAL SPECIFICATIONS – POWER MIG® 216

INPUT – SINGLE PHASE ONLY

Standard Voltage/Phase/Frequency

208/230/1/60 Hz 33/29 Amps 40/36 Amps

220/1/50 Hz 30 Amps 37 Amps

Duty Cycle Amps Volts at Rated Amperes

30% 216 Amps 22 Volts

40% 190 Amps 23 Volts

60% 170 Amps 24

Welding Current Range Maximum Open Circuit Voltage Welding Voltage Range

30 – 250Amps 36 Volts 13-24 Volts

RECOMMENDED INPUT WIRE AND FUSE SIZES

Input Voltage/ Fuse or Breaker Rating On

Frequency (Hz) Size (Super Lag) Nameplate

Input Current @ 170 Amp Rated Output Input Current @ 216 Amp Rated Output

RATED OUTPUT

OUTPUT

Input Ampere Power Cord

(30% Duty Cycle)

A-1

* Volts

OPERATORʼS MANUAL

208/60 50 40A 50 Amp, 250V

230/60 50 36A Three Prong Plug

220/50 50 37A (NEMA) Type 6-50P)

WIRE SPEED RANGE

Wire Speed 50 – 700 IPM (1.27 – 17.8 m/minute)

PHYSICAL DIMENSIONS

Height Width Depth Weight

With Coil Claw™ Without Coil Claw™

32.56 in. 20.12 in. 19.15 in. 39.92 in. 215.5 Ibs. 206.5 lbs.

827 mm 512 mm 487 mm 1014 mm 97.8 kg. 93.7 kg.

With Gun and Cable Without Gun and Cable

and Work Cable and Work Cable

TEMPERATURE RANGES

OPERATING TEMPERATURE RANGE

-4°F to 104°F(-20°C to +40°C)

STORAGE TEMPERATURE RANGE

-40°F to 185°F(-40°C to +40°C)

* 23 Volts at 50 Hz.

POWER MIG® 216

Page 10

A-2

INSTALLATION

A-2

Read entire installation section before starting

installation.

SAFETY PRECAUTIONS

WARNING

ELECTRIC SHOCK can kill.

• Only qualified personnel should

perform this installation.

• Only personnel that have read

and understood the POWER

MIG® 216 Operatorʼs Manual

should install and operate this

equipment.

• Machine must be grounded per

any national, local or other applicable electrical codes.

• The POWER MIG® 216 power

switch is to be in the OFF position when installing work cable

and gun and when connecting

other equipment.

UNCRATING THE POWER MIG® 216

Cut banding and lift off cardboard carton. Cut banding

holding the machine to the skid. Remove foam and

corrugated packing material. Untape accessories from

Gas Bottle Platform. Unscrew the two wood screws

(at the Gas Bottle Platform) holding the machine to

the skid. Roll the machine off the skid assembly.

LOCATION

Locate the welder in a dry location where there is free

circulation of clean air into the brickwork in the back

and the louvers out the front. A location that minimizes

the amount of smoke and dirt drawn into the rear

brickwork reduces the chance of dirt accumulation

that can block air passages and cause overheating.

INPUT POWER, GROUNDING AND

CONNECTION DIAGRAM

WARNING

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts such as

output terminals or internal wiring.

• All input power must be electrically disconnected before proceeding.

1. Before starting the installation, check with the local

power company if there is any question about

whether your power supply is adequate for the voltage, amperes, phase, and frequency specified on

the welder rating plate. Also be sure the planned

installation will meet the U.S. National Electrical

Code and local code requirements. This welder

may be operated from a single phase line or from

one phase of a two or three phase line.

2. Models that have multiple input voltages specified

on the rating plate (e.g. 208/230) are shipped connected for the highest voltage. If the welder is to be

operated on lower voltage, it must be reconnected

according to the instructions in Figure A.1 for dual

voltage machines.

WARNING

Make certain that the input power is electrically

disconnected before removing the screw on the

reconnect panel access cover.

------------------------------------------------------------------------

POWER MIG® 216

Page 11

INSTALLATION

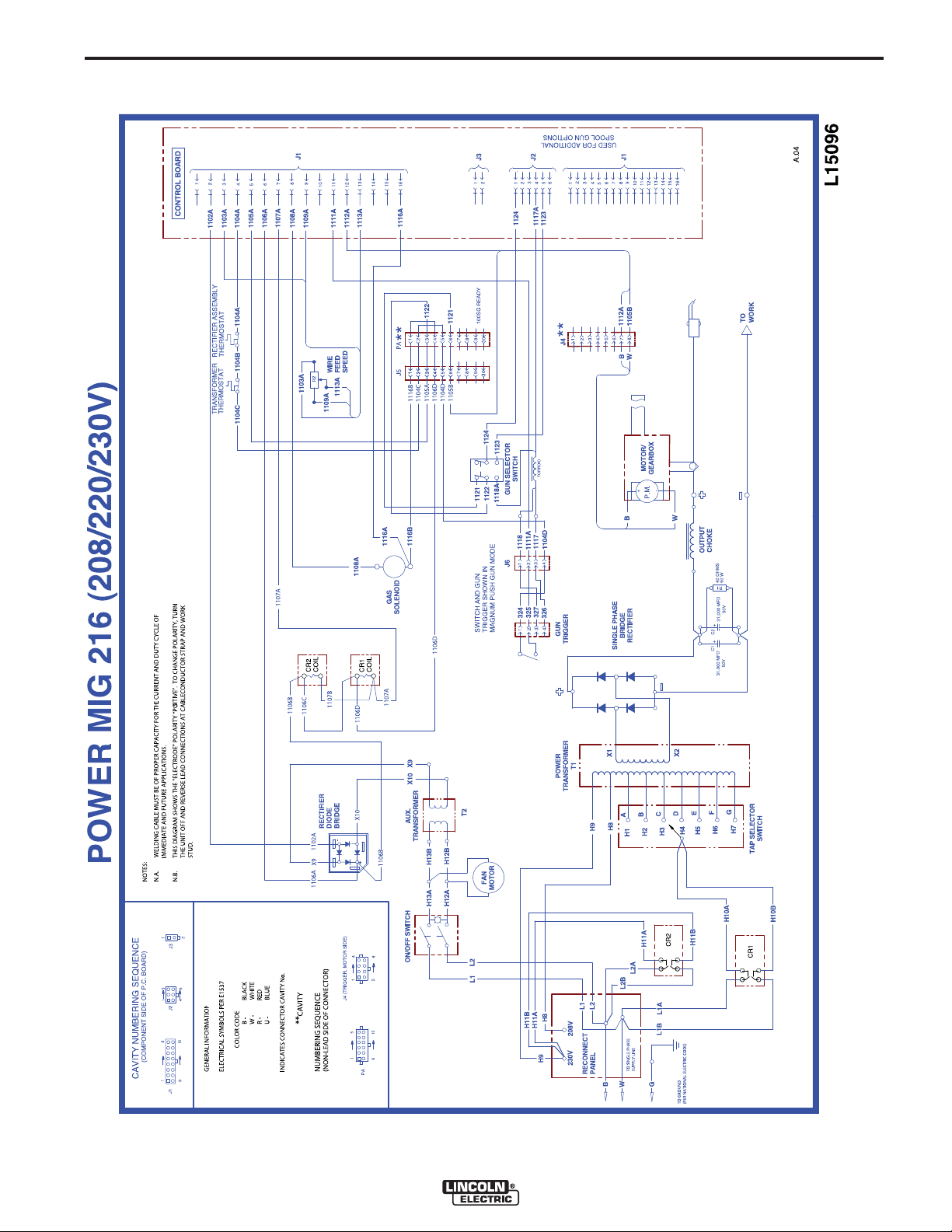

FIGURE A.1 — Dual Voltage Machine Input Connections

WARNING ADVERTISSEMENT ADVERTENCIA

Disconnect input power before inspecting

or servicing machine.

Do not operate with covers removed.

Do not touch electrically live parts.

Use CU wire only .

Install and Ground machine per National Electrical Code and local codes. Use Grounding Stud or Lug inside.

Only qualified persons should install, use, or service this equipment.

Consult instruction manual before installing or operating.

Débrancher l’alimentation d’entrée avant de réaliser l’inspection ou l’entretien de la machine.

Ne pas faire fonctionner sans les couvercles.

Ne pas toucher les pièces sous alimentation électrique.

Utiliser uniquement du fil CU.

Installer et mettre la machine à la terre conformément au Code Électrique National et aux réglementations locales.

Utiliser une Borne ou un Ergot de Terre à l’intérieur.

Seules des personnes qualifiées peuvent installer

Consulter le Manuel d’Instructions avant d’installer ou de faire fonctionner la machine.

Desconecte elcable de alimentación antes de iniciar caulquier inspeccion ó servicio.

No opere la máquina con las cubiertas removidas.

No toque las partes elécticas vivas.

Use solo cable con alambre de cobre.

Instale y aterrice la máquina de acuerdo a las normas eléctricas locales y nacionales. Use el Tornillo de

Tierra de la máquina.

Únicamente personal calificado debe instalar

Antes de instaler u poerar éste equipo consulte el Manual de Intruccion.

INPUT SUPPLY CONNECTION DIAGRAM

DIAGRAMME DE CONNEXION DE L’ALIMENTATION D’ENTRÉE

DIAGRAMA DE CONEXION DE LA FUENTE DE ENTRADA

Connect leads for

desired voltage range

Connecter les câbles

pour obtenir la tension

désirée.

Conecte cable selector

para el voltage de

alimentacion deseado.

, utilizar ó dar servicio a éste equipo.

ELECTRIC SHOCK can kill

LES CHOCS ÉLECTRIQUES peuvent être mortels

DESCARGAS ELECTRICAS pueden matar

, utiliser ou réaliser l’entretien de cet appareil.

SINGLE PHASE

MONOPHASE

MONOFASICO

A-3 A-3

OPERATORʼS MANUAL

RECONNECT

RECONEXION

REBRANCHER

ALIMENTACION

INPUT

ENTRÉE

3. The 208/230 volts 50/60 Hz model POWER MIG is

shipped with a 10ft.(3.0m) input cable and plug

connected to the welder.

4. Have a qualified electrician connect a receptacle

(Customer Supplied) or cable to the input power

lines and the system ground per the U.S. National

Electrical Code and any applicable local codes.

OUTPUT POLARITY CONNECTIONS

The welder, as shipped from the factory, is connected

for electrode positive (+) polarity. This is the normal

polarity for GMAW.

If negative (–) polarity is required, interchange the

connection of the two cables located in the wire drive

compartment near the front panel. The electrode

cable, which is attached to the wire drive, is to be connected to the negative (–) labeled terminal and the

work lead, which is attached to the work clamp, is to

be connected to the positive (+) labeled terminal.

POWER MIG® 216

Page 12

A-4

INSTALLATION

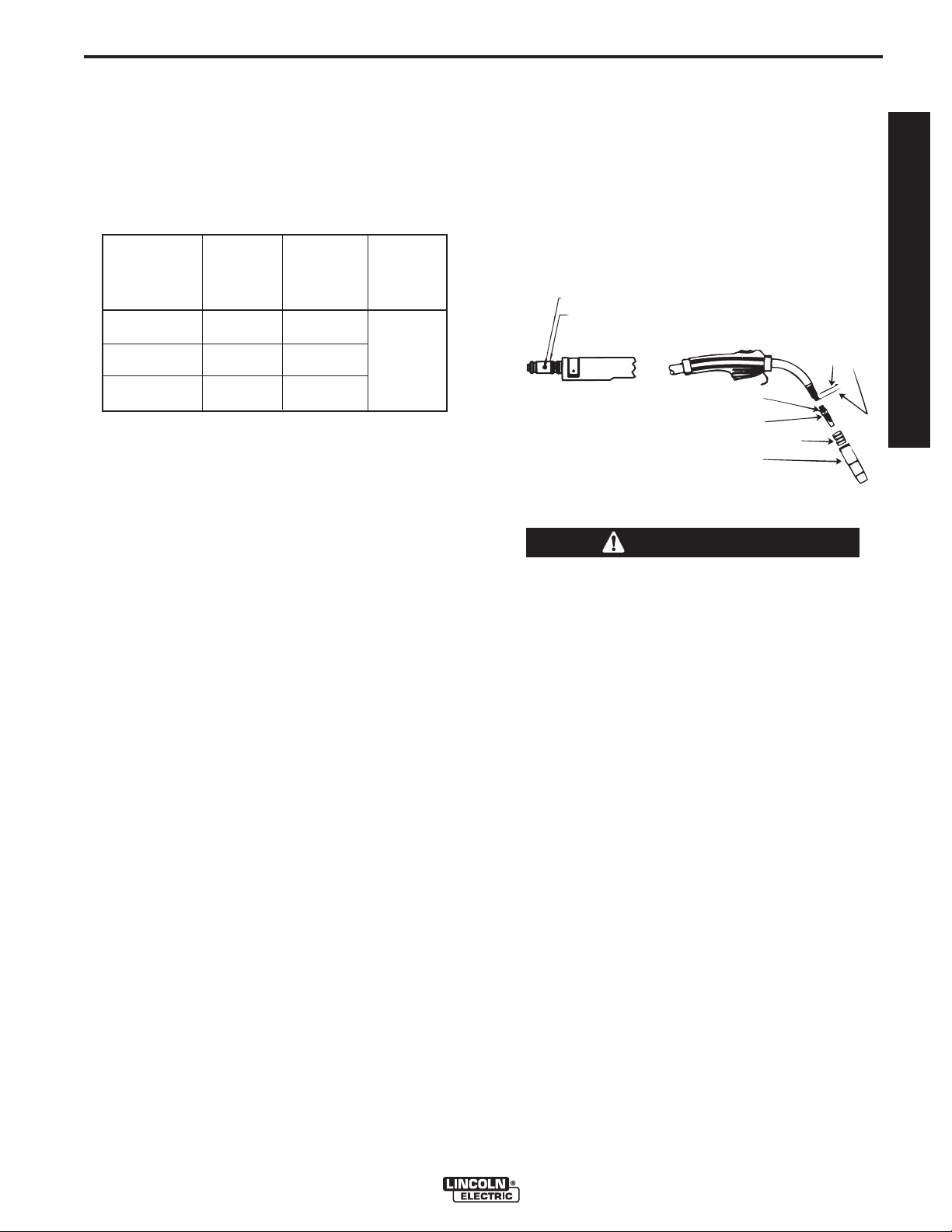

GUN AND CABLE INSTALLATION

The Magnum Pro 250L gun and cable provided with the

POWER MIG® 216 is factory installed with a liner for .035.045" (0.9-1.1 mm) electrode and an .035" (0.9 mm) contact

tip. Be sure that the contact tip, liner, and drive rolls all

match the size of the wire being used.

WARNING

Turn the welder power switch off before installing gun

and cable.

1. Lay the cable out straight.

2. Unscrew the Hand Screw on the drive unit front end

(inside wire feed compartment) until tip of screw no

longer protrudes into Gun Adapter opening as seen

from front of machine. (See Figure A.2)

3. Insert the male end of gun cable into the Gun Adapter

through the opening in front panel. Make sure connector

is fully inserted and tighten Hand Screw.

4. Connect the Gun Trigger Connector from the gun and

cable to the mating Receptacle outside the compartment

located left of the opening on the Front Panel. Make sure

that the keyways are aligned, insert and tighten retaining

ring.

SHIELDING GAS

[For Gas Metal Arc Welding(GMAW) Processes]

Customer must provide cylinder of appropriate type shielding gas for the process being used.

A gas flow regulator, for Argon blend gas, and an inlet gas

hose are factory provided with the POWER MIG® 216.

When using 100% CO2an additional adapter will be

required to connect the regulator to the gas bottle.

A-4

INSTALL SHIELDING GAS SUPPLY AS FOLLOWS:

1. Set gas cylinder on rear platform of POWER MIG® 216.

Hook chain in place to secure cylinder to rear of welder.

2. Remove the cylinder cap. Inspect the cylinder valves and

regulator for damaged threads, dirt, dust, oil or grease.

Remove dust and dirt with a clean cloth.

DO NOT ATTACH THE REGULATOR IF OIL, GREASE

OR DAMAGE IS PRESENT! Inform your gas supplier of

this condition. Oil or grease in the presence of high pressure oxygen is explosive.

3. Stand to one side away from the outlet and open the

cylinder valve for an instant. This blows away any dust or

dirt which may have accumulated in the valve outlet.

WARNING

Be sure to keep your face away from the valve outlet

when “cracking” the valve.

4. Attach the flow regulator to the cylinder valve and tighten

the union nut(s) securely with a wrench.

NOTE: If connecting to 100% CO

regulator adapter must be installed between the regulator and cylinder valve. If adapter is equipped with a plastic washer, be sure it is seated for connection to the CO

cylinder.

5. Attach one end of the inlet gas hose to the outlet fitting of

the flow regulator, the other end to the POWER MIG®

216 rear fitting, and tighten the union nuts securely with

a wrench.

6. Before opening the cylinder valve, turn the regulator

adjusting knob counterclockwise until the adjusting

spring pressure is released.

7. Standing to one side, open the cylinder valve slowly a

fraction of a turn. When the cylinder pressure gauge

pointer stops moving, open the valve fully.

cylinder, an additional

2

2

WARNING

WARNING

CYLINDER may explode if

damaged.

• Gas under pressure is explosive.

Always keep gas cylinders in an

upright position and always keep

chained to undercarriage or stationary

support.

See American National Standard Z-49.1, “Safety in

Welding and Cutting” published by the American

Welding Society.

------------------------------------------------------------------------

POWER MIG® 216

Never stand directly in front of or behind the flow regulator when opening the cylinder valve. Always stand to

one side.

--------------------------------------------------------------------------------

8. The flow regulator is adjustable. Adjust it to the flow rate

recommended for the procedure and process being used

before making the weld.

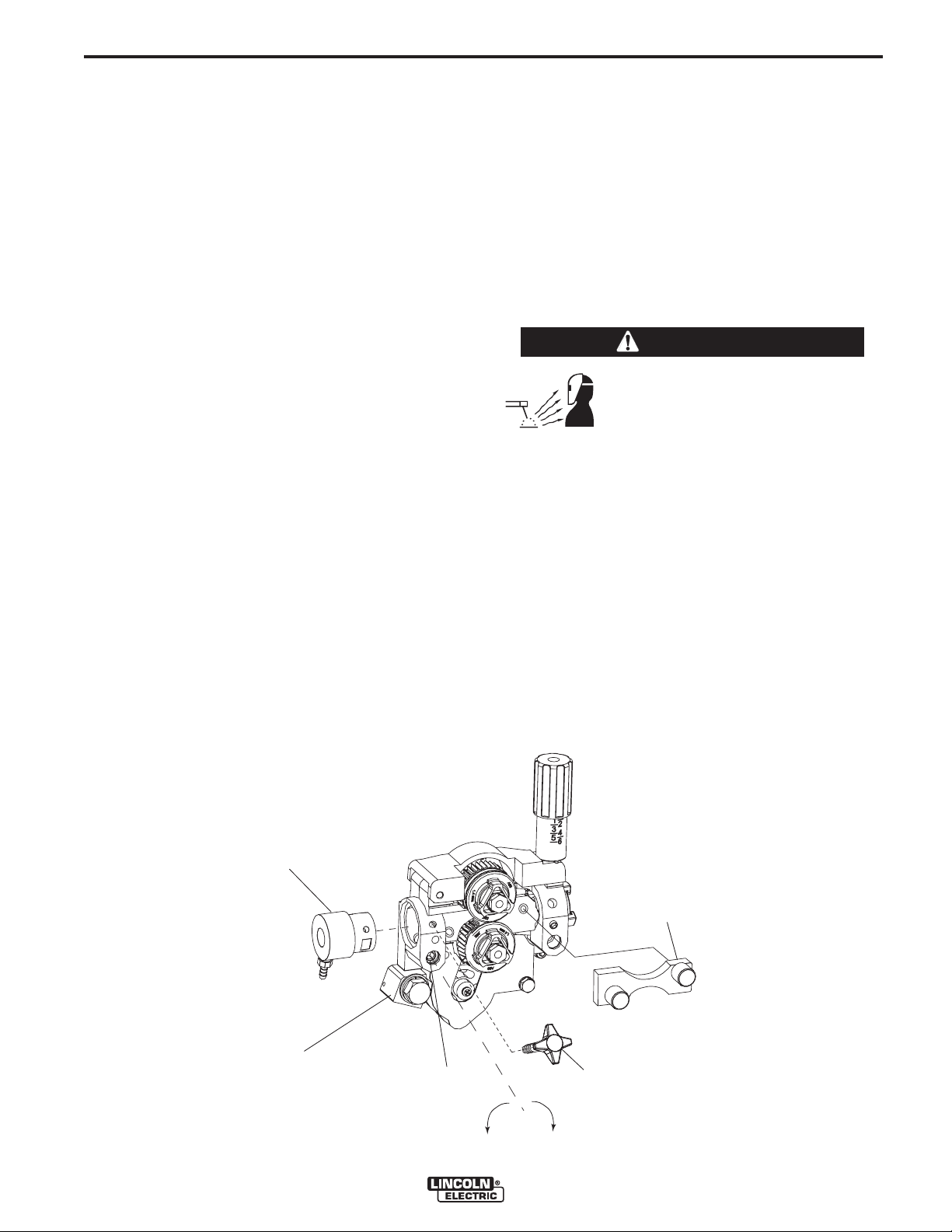

FIGURE A.2

Hand Screw

Gun Adapter

Male End

Gun and Cable

Receptacle

Gun Trigger

Connector

Page 13

A-5

INSTALLATION

COIL CLAW™ INSTALLATION

The Coil Claw™ and mounting screws are provided

as an optional accessory for the POWER MIG® 216.

This user-install accessory provides cable management for the machine.

WARNING

Turn the welder power switch OFF

before installing Coil Claw™.

------------------------------------------------------------------------

1. Unwrap Coil Claw™ from its protective paper and

remove the bag of mounting screws from the back

of the Coil Claw™.

2. Mount

ing screws to the left side of the machine, when

viewed from the front. Make sure the Coil Claw™ is

firmly mounted. (See Figure A.3)

the Coil Claw™ using the provided mount-

A-5

OPERATORʼS MANUAL

MOUNTING

SCREWS

FIGURE A.3

COIL CLAW™

POWER MIG® 216

Page 14

B-1

OPERATION

Read entire Operation section before

operating the POWER MIG® 216.

WARNING

ELECTRIC SHOCK can kill.

• Do not touch electrically live

parts or electrode with skin or

wet clothing. Insulate yourself

from work and ground.

• Always wear dry insulating

gloves.

FUMES AND GASES can be

dangerous.

• Keep your head out of fumes.

• Use ventilation or exhaust to

remove fumes from breathing

zone.

B-1

WELDING SPARKS can

cause fire or explosion.

• Keep flammable material away.

• Do not weld on closed containers.

ARC RAYS can burn eyes

and skin.

• Wear eye, ear and body protection.

Observe all safety information throughout

this manual.

------------------------------------------------------------

POWER MIG® 216

Page 15

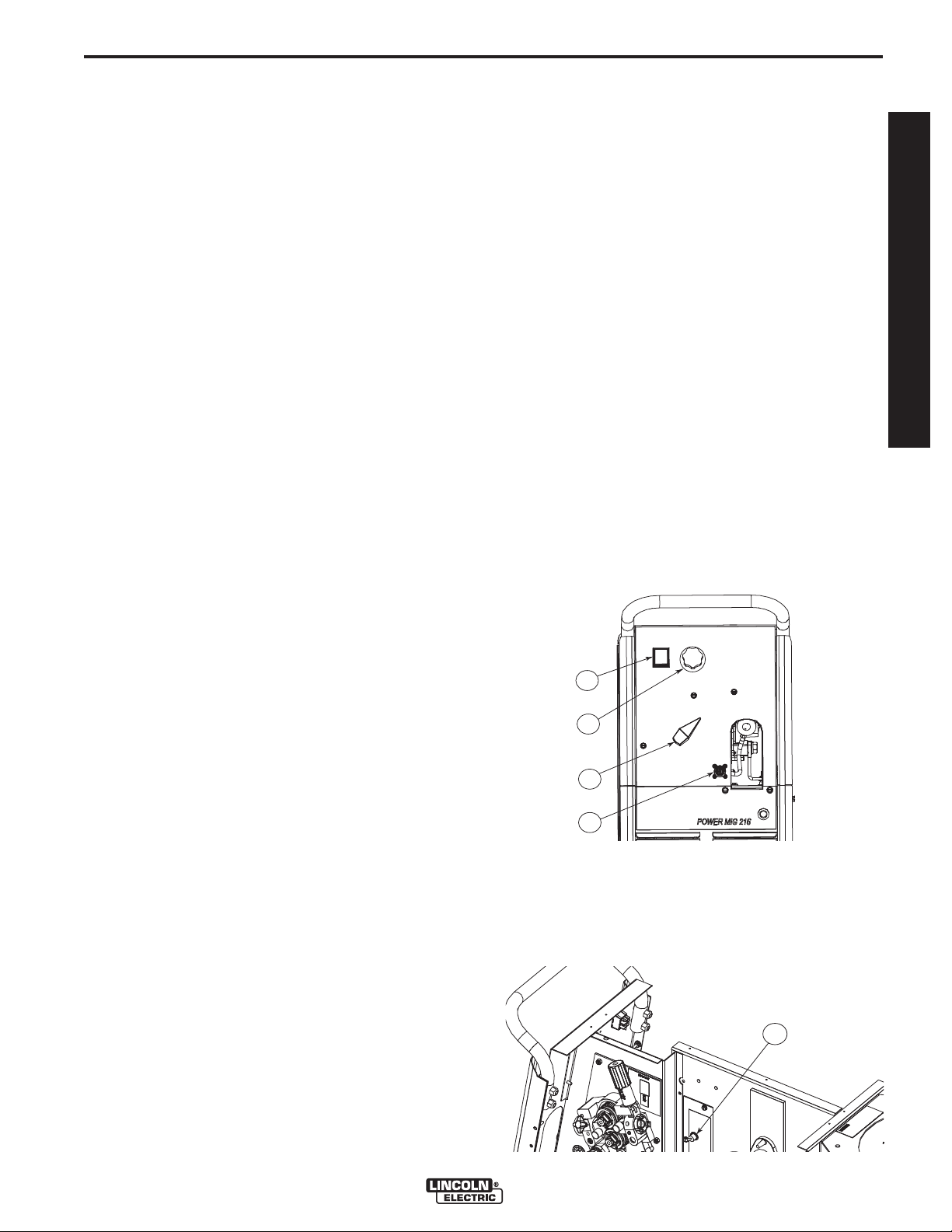

B-2 B-2

3

2

1

4

5

OPERATION

PRODUCT DESCRIPTION

The POWER MIG® 216 is a complete semiautomatic

DC voltage arc welding machine built to meet NEMA

specifications. It combines a tapped transformer voltage power source with a constant speed wire feeder

to form a reliable and robust performance welding

system. A simple control scheme, consisting of continuous full range wire feed speed control, and 7 output

voltage tap selections provides versatility with ease of

use and accuracy. An enhanced feature to the

POWER MIG® 216, is that it is Magnum 100SG Spool

Gun ready.

Other features include a 2" (51 mm) O.D. wire reel

spindle with adjustable brake, an integral gas cylinder

mounting undercarriage, an adjustable Argon blend

flow regulator with cylinder pressure gauge and inlet

hose, a 15 ft. (3.6 m) Magnum Pro 250L GMAW gun

and cable with fixed (flush) nozzle, a 10 ft. (3.0 m)

power cable with plug, and a 10 ft. (3.0 m) work cable

with clamp.

Optional Magnum Spool Gun, Adapter kits and Dual

Cylinder Mounting kit for push feeding with standard

built in feeder are also available.

RECOMMENDED PROCESSES AND

EQUIPMENT

LIMITATIONS

The output voltage/current of the POWER MIG® 216

is subject to vary if the input power to the machine

varies, due to its tapped transformer power topology.

In some cases an adjustment of WFS preset and/or

voltage tap selection may be required to accommodate a significant drift in input power.

DESCRIPTION OF CONTROLS

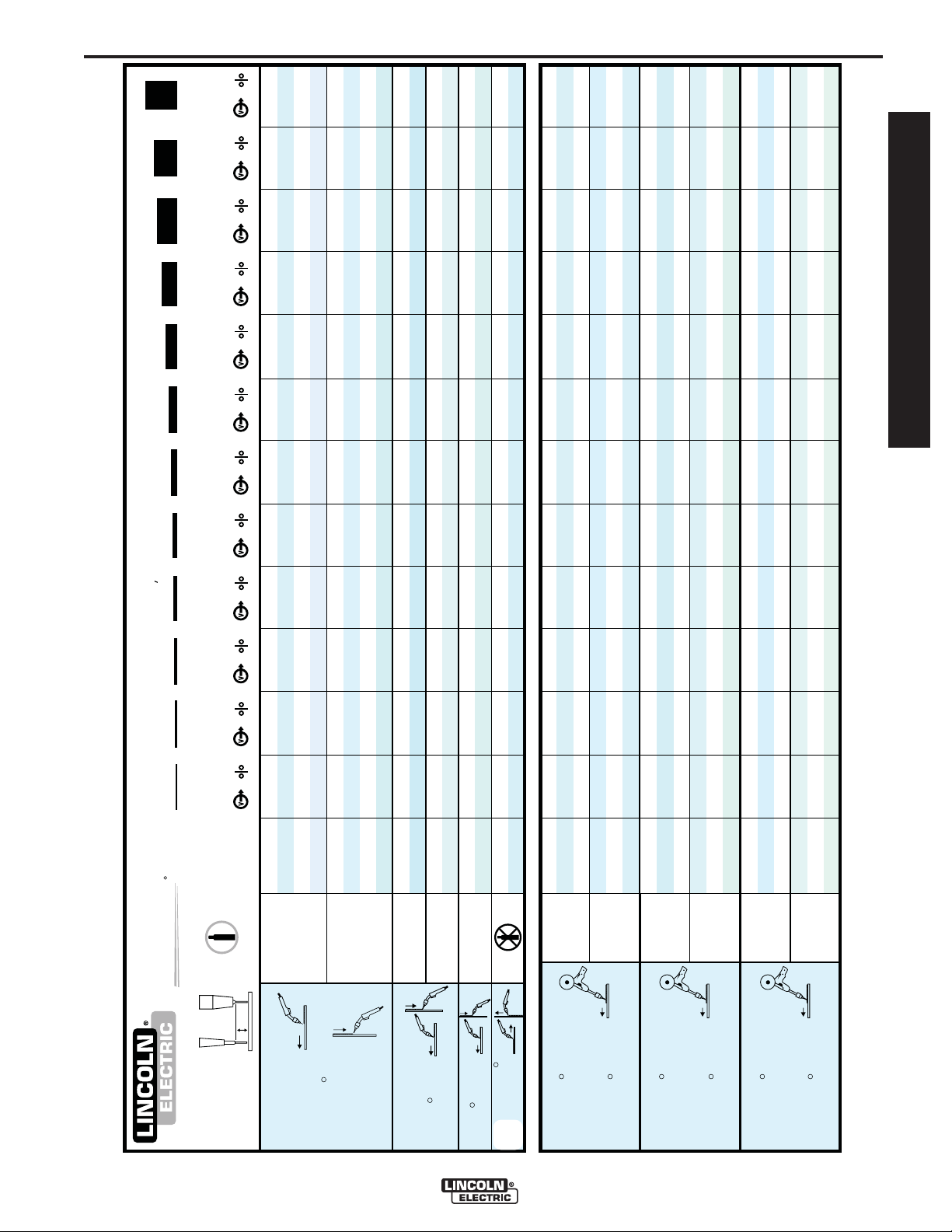

See Figure B.1

1. Power ON/OFF Switch - Press the switch to "ON"

position to energize the POWER MIG® 216.

2. Voltage Control - Seven voltage tap selections are

provided labeled "A" (minimum voltage) through "G"

(maximum voltage). It should only be adjusted

when NOT welding. The control selection can be

preset to the setting specified on the Application

Chart / Procedure Decal on the inside of the wire

compartment door or Section F of this Instruction

Manual.

3. Wire Speed Control - This controls the wire feed

speed from 50 – 700 inches per minute (1.2 – 17.8

m/min). Wire speed is not affected when changes

are made in the voltage control.

4. 4-Pin Connector - For Push Gun and Spool Gun

Operations.

FIGURE B.1

OPERATORʼS MANUAL

The POWER MIG® 216 is recommended for GMAW

processes using 10 to 44 lb (4.5 to 20 kg) 2" (51 mm)

I.D. spools of .025" through .045" (0.6 – 1.1 mm) solid

wire, .035" (0.9 mm) stainless, 3/64" (1.2 mm) aluminum, .035” (0.9 mm), .045" (1.1 mm) Outershield

and .045”(1.1mm) Ultracore® as well as .035" (0.9

mm) and .045" (1.1 mm) Innershield®self-shielding

electrodes.

The POWER MIG® 216 is factory equipped to feed

.035" (0.9 mm) electrodes. It also includes a 200A,

60% duty cycle (or 250A, 40% duty cycle) rated, 15 ft.

(3.6 m) GMAW gun and cable assembly equipped for

these wire sizes. Use of GMAW processes requires a

supply of shielding gas.

®

5. Magnum Push Gun and Spool Gun toggle

switch - Toggle the switch (Item 5 see Figure B.2)

to select between push gun and spool gun. When

either operation is selected, insert the cable to 4-pin

Connector. (Item 4, See Figure B.1)

FIGURE B.2

WELDING CAPABILITY

The POWER MIG® 216 is rated at 216 amps @ 22

volts, at a 30% duty cycle based on a ten minute cycle

time. It is capable of higher duty cycles at lower output

currents. The tapped transformer design makes it

well suited for use with most portable or in-plant generating systems.

POWER MIG® 216

Page 16

OPERATION

B-3 B-3

WIRE DRIVE ROLL

The drive rolls installed with the POWER MIG® 216

have two grooves, one for .035”(0.9mm) wire and the

other for .045”(1.1mm) wire. Drive roll size is indicated

by the stenciling on the exposed side of the drive roll.

WIRE SIZE CONVERSION PARTS

The POWER MIG® 216 is rated to feed .025” through

.045" (0.6-1.1mm) solid or cored electrode sizes.

The drive roll kits and Magnum Pro 250L gun and

cable parts are available to feed different sizes and

types of electrodes. See Accessories and

Maintenance sections of this Instruction Manual.

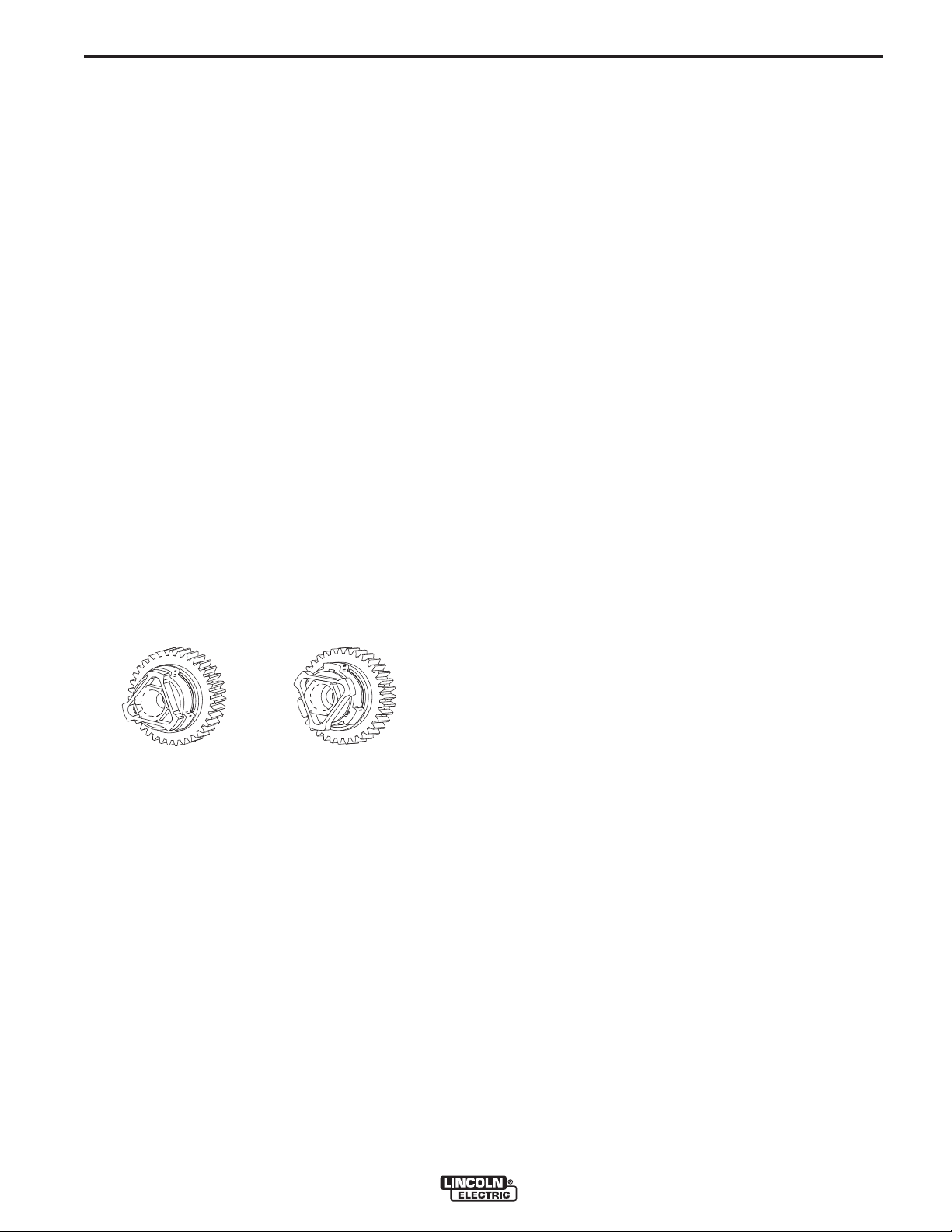

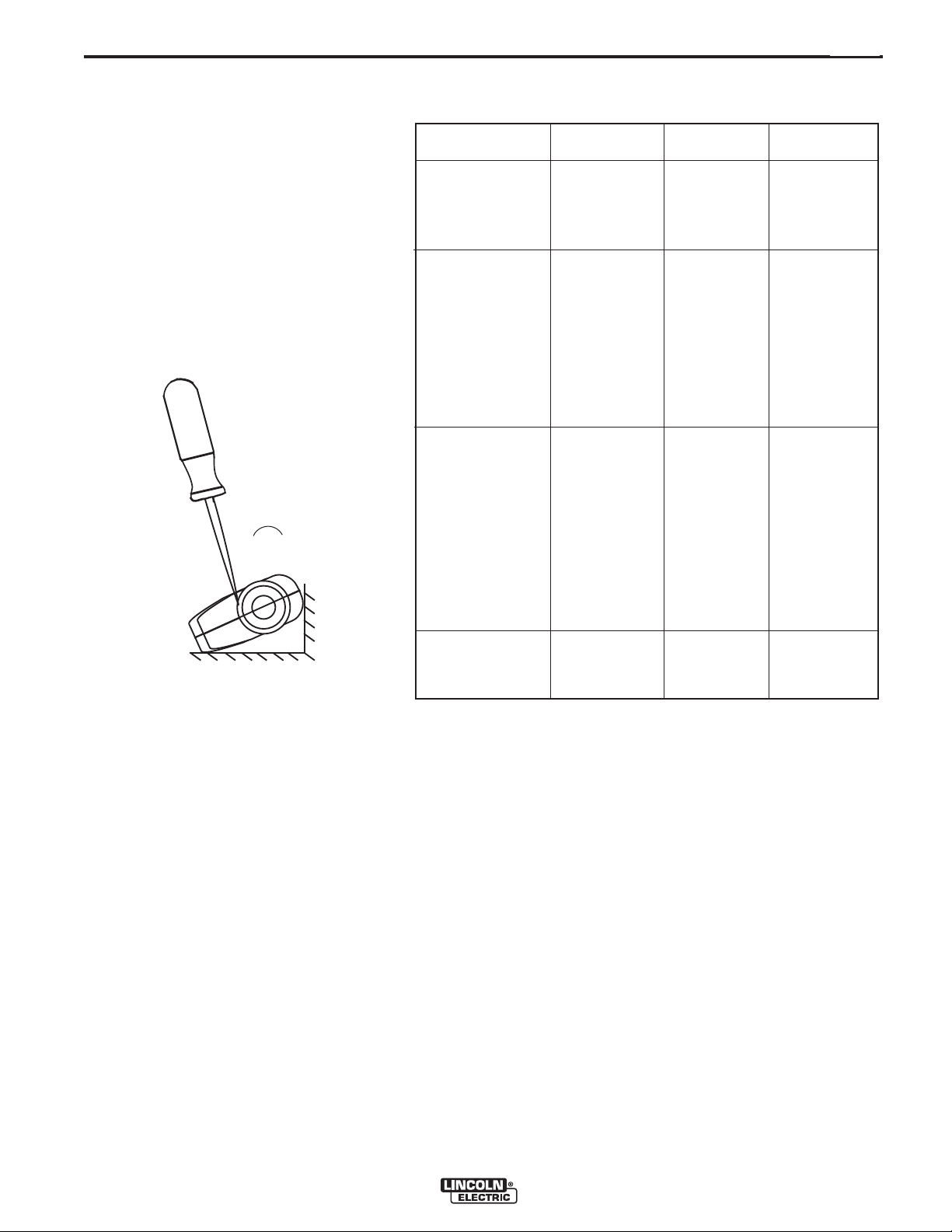

PROCEDURE FOR CHANGING

DRIVE AND IDLE ROLL SETS

1. Turn OFF the power source.

2. Release the pressure on the idle roll by swinging

the adjustable pressure arm down toward the back

of the machine. Lift the cast idle roll assembly and

allow it to sit in an upright position.

3. Remove the outside wire guide retaining plate by

loosening the two large knurled screws.

4. Twist the drive roll retaining mechanism to the

unlocked position as shown below and remove the

drive rolls.

FIGURE B.3

WIRE REEL LOADING - SPOOLS

OR COILS

To Mount 10 to 44 Lb. (4.5-20 kg) Spools

(12"/300 mm Diameter) or 14Lb.(6 Kg)

Innershield Coils:

(For 13-14 lb. (6 Kg) Innershield coils, a K435 Coil

Adapter must be used).

1. Open the Wire Drive Compartment Door

2. Depress the Release Bar on the Retaining Collar

and remove it from the spindle.

3. Place the spool on the spindle making certain the

spindle brake pin enters one of the holes in the

back side of the spool

Note: The arrow marked on the spindle lines up

with the brake holding pin to assist in lining

up a hole. Be certain the wire comes off the

reel in a direction so as to de-reel from the

top of the coil.

4. Re-install the Retaining Collar. Make sure that the

Release Bar “pops up” and that the collar retainers

fully engage the retaining ring groove on the spindle.

UNLOCKED POSITION

(See Figure B.3)

5. Remove the inside wire guide plate.

6. Replace the drive rolls and inside wire guide with a

set marked for the new wire size.

NOTE: Be sure that the gun liner and contact tip

are also sized to match the selected wire

size.

7. Manually feed the wire from the wire reel, over the

drive roll groove and through the wire guide and

then into the brass bushing of the gun and cable

assembly.

8. Replace the outside wire guide retaining plate by

tightening the two large knurled screws. Reposition

the adjustable pressure arm to its original position

to apply pressure. Adjust pressure as necessary.

LOCKED POSITION

POWER MIG® 216

Page 17

B-4

OPERATION

B-4

TO START THE WELDER

Turn the “Power Switch” switch to “ON”. With the desired voltage

and wire speed selected, operate the gun trigger for welder output

and to energize the wire feed motor.

The pressure arm controls the amount of force the drive

rolls exert on the wire. Proper adjustment of pressure

arm gives the best welding performance. For best

results, set pressure arm to the suggested value.

FEEDING WIRE ELECTRODE

Set the pressure arm as follows (See Figure B.4):

WARNING

When triggering, the electrode and

drive mechanism are electrically

“hot” relative to work and ground and

remain “hot” for several seconds

after the gun trigger is released.

------------------------------------------------------------------------

NOTE: Check that drive rolls, guide plates and gun

parts are proper for the wire size and type being used.

Refer to Table C.1 in Accessories section.

1. Turn the spool until the free end of the electrode is

accessible.

2. While securely holding the electrode, cut off the

bent end and straighten the first six inches. If the

electrode is not properly straightened, it may not

feed properly through the wire drive system.

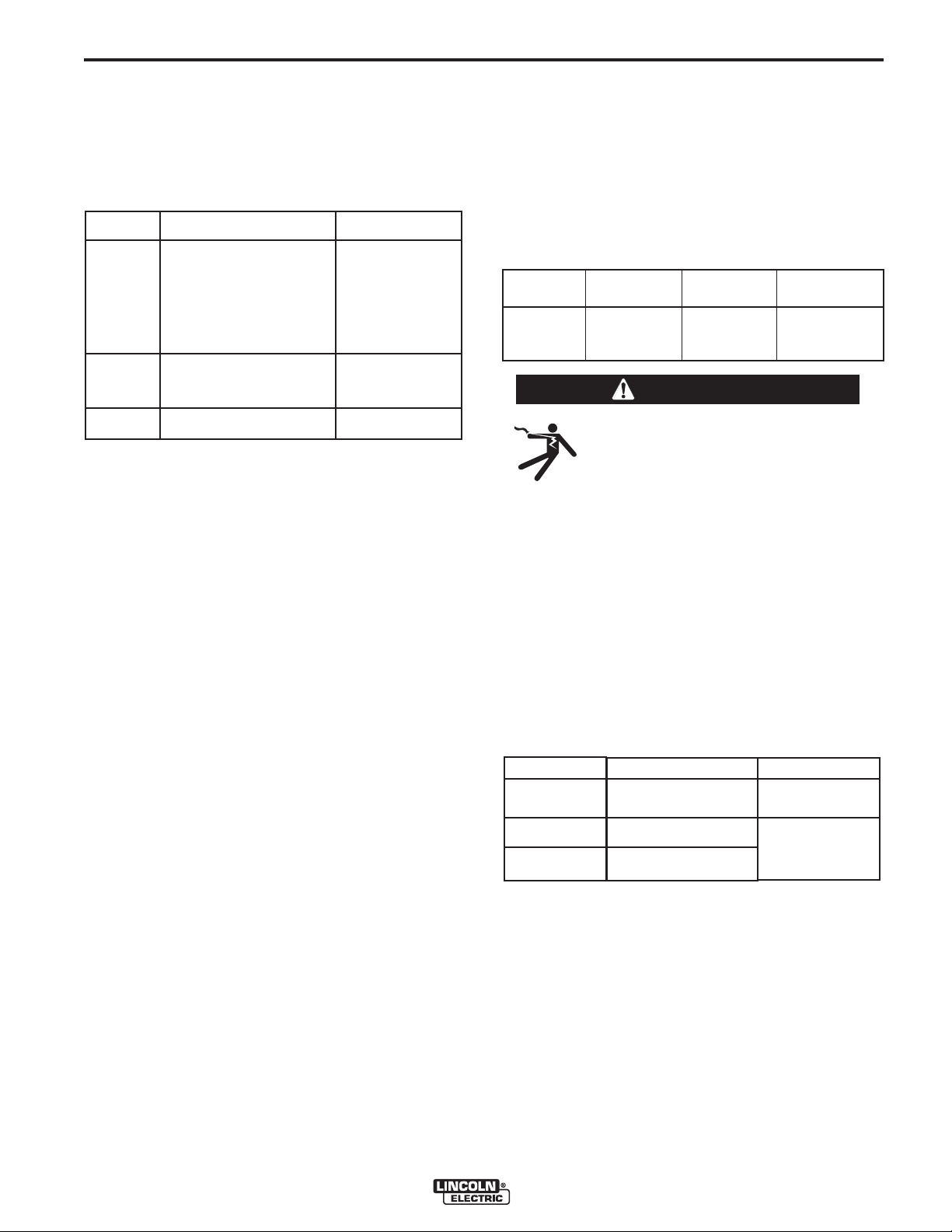

WIRE DRIVE CONFIGURATION

See Figure B.5

Aluminum wires between 1 and 3

Cored wires between 3 and 4

Steel, Stainless wires between 4 and 6

FIGURE B.4

CORED WIRES

OU TE R S HI E L D

METAL SHIELD

INNERSHIELD

1

3

5

SOLID WIRES

2

4

6

ALUMINUM

STEEL

STAINLESS

OPERATORʼS MANUAL

3. Release the pressure on the idle roll by swinging

the adjustable pressure arm down toward the back

of the machine. Lift the cast idle roll assembly and

allow it to sit in an upright position. Leave the outer

wire guide plate installed. Manually feed the wire

through the incoming guide bushing and through

the guide plates (over the drive roll groove). Push a

sufficient wire length to assure that the wire has fed

into the gun and cable assembly without restriction.

Reposition the adjustable pressure arm to its original position to apply pressure to the wire.

4. Press gun trigger to feed the electrode wire through

the gun.

IDLE ROLL PRESSURE SETTING

WARNING

ELECTRIC SHOCK can kill.

• Turn the input power OFF at the welding power source before installation or

changing drive rolls and/or guides.

• Do not touch electrically live parts.

• When inching with the gun trigger, electrode

and drive mechanism are "hot" to work and

ground and could remain energized several seconds after the gun trigger is released.

• Only qualified personnel should perform maintenance work.

------------------------------------------------------------------------

POWER MIG® 216

Changing the Gun Adapter

WARNING

ELECTRIC SHOCK can kill.

• Turn the input power OFF at the welding power source before installation or

changing drive rolls and/or guides.

• Do not touch electrically live parts.

• When inching with the gun trigger, electrode

and drive mechanism are "hot" to work and

ground and could remain energized several seconds after the gun trigger is released.

• Only qualified personnel should perform maintenance work.

-----------------------------------------------------------------------

Tools required:

• 1/4" hex key wrench.

NOTE: Some gun adapters do not require the use of

the hand screw.

1. Turn power OFF at the welding power source.

2. Remove the welding wire from the wire drive.

3. Remove the hand screw from the wire drive.

4. Remove the welding gun from the wire drive.

Page 18

B-5 B-5

5. Loosen the socket head cap screw that holds the

connector bar against the gun adapter.

Important: Do not attempt to completely

remove the socket head cap screw.

OPERATION

3. Press the trigger to feed the wire electrode through

the gun and cable. For solid wire cut the electrode

within approximately 3/8" (10 mm) of the end of the

contact tip [3/4" (20 mm) for Outershield®].

6. Remove the outer wire guide, and push the gun

adapter out of the wire drive. Because of the precision fit, light tapping may be required to remove

the gun adapter.

4. When welding with gas, turn on the gas supply and

set the required flow rate (typically 30-40 CFH; 1419 liters/min).

7. Disconnect the shielding gas hose from the gun

adapter, if required.

8. Connect the shielding gas hose to the new gun

adapter, if required.

9. Rotate the gun adapter until the hand screw hole

5. Connect work cable to metal to be welded. Work

clamp must make good electrical contact to the

work. The work must also be grounded as stated in

“Arc Welding Safety Precautions”.

aligns with the hand screw hole in the feed plate.

Slide the gun adapter into the wire drive and verify

the hand screw holes are aligned.

10. Tighten the socket head cap screw.

11. Insert the welding gun into the gun adapter and

tighten the hand screw.

• When using an open arc process, it

is necessary to use correct eye,

head, and body protection.

WARNING

MAKING A WELD

1. Check that the electrode polarity is correct for the

process being used, then turn the power switch ON.

2. Set desired arc voltage tap and wire speed for the

particular electrode wire, material type and thickness, and gas (for MIG and Outershield

used. Use the Application Chart on the door inside

the wire compartment as a quick reference for

some common welding procedures.

NOTE: Application Chart can also be found in

Section F of this Instruction Manual.

GUN ADAPTER

®

) being

Figure B.5

-----------------------------------------------------------------------

6. Position electrode over joint. End of electrode may

be lightly touching the work.

7. Lower welding helmet, close gun trigger, and

begin welding. Hold the gun so that the contact tip

to work distance is about 3/8" (10 mm) [3/4" (20

mm) for Outershield®].

8. To stop welding, release the gun trigger and then

pull the gun away from the work after the arc goes

out.

CONNECTOR BLOCK

SOCKET HEAD

CAP SCREW

LOOSEN TIGHTEN

POWER MIG® 216

OUTER WIRE GUIDE

HAND SCREW

Page 19

OPERATION

9. When no more welding is to be done, close valve

on gas cylinder (if used), momentarily operate gun

trigger to release gas pressure, and turn OFF

POWER MIG® 216.

NOTE: When using Innershield electrode, the gas

nozzle may be removed from the insulation

on the end of the gun and replaced with the

gasless nozzle. This will give improved visibility and eliminate the possibility of the gas nozzle overheating.

AVOIDING WIRE FEEDING

PROBLEMS

Wire feeding problems can be avoided by observing

the following gun handling procedures:

1. Do not kink or pull cable around sharp corners.

2. Keep the gun cable as straight as possible when

welding or loading electrode through cable.

3. Do not allow dolly wheels or trucks to run over

cables.

4. Keep cable clean by following maintenance instruc-

tions.

5. Use only clean, rust-free electrode. The Lincoln

electrodes have proper surface lubrication.

6. Replace contact tip when the arc starts to become

unstable or the contact tip end is fused or

deformed.

7. Keep wire reel spindle brake tension to minimum

required to prevent excess reel over-travel which

may cause wire “loop-offs” from coil.

8. Use proper drive rolls and wire drive idle roll pres-

sure for wire size and type being used.

B-6 B-6

WIRE FEED OVERLOAD

PROTECTION

The POWER MIG® 216 has solid state overload protection of the wire drive motor. If the motor becomes

overloaded, the protection circuitry turns off the wire

drive motor and gas solenoid. Check for proper size

tip, liner, and drive rolls, for any obstructions or bends

in the gun cable, and any other factors that would

impede the wire feeding. To resume welding, simply

pull the trigger. There is no circuit breaker to reset, as

the protection is done with reliable solid state electronics.

WELDING THERMAL OVERLOAD

PROTECTION

The POWER MIG® 216 has built-in protective thermostats that respond to excessive temperature. They

open the wire feed and welder output circuits if the

machine exceeds the maximum safe operating temperature because of a frequent overload, or high

ambient temperature plus overload. The thermostats

automatically reset when the temperature reaches a

safe operating level and welding and feeding are

allowed again, when gun is retriggered.

WELDING PROCEDURE

INFORMATION

NOTE: See inside cover of machine or Section F of this

Instruction Manual for additional, commonly used welding

procedure.

LEARNING TO WELD

OPERATORʼS MANUAL

FAN CONTROL

The fan is designed to come on when input power is

applied to the POWER MIG® 216 and go off when

power is removed.

INPUT LINE VOLTAGE VARIATIONS

High Line Voltage — Higher than rated input voltage

will result in output voltages higher than normal for a

given tap setting. If your input line is high, you may

want to select a lower voltage tap than given on the

recommended procedure chart.

Low Line Voltage — You may not be able to get

maximum output from the machine if the line voltage

is less than rated input. The unit will continue to weld,

but the output may be less than normal for a given tap

setting. If your input line is low, you may want to select

a higher voltage tap than given on the recommended

procedure chart.

POWER MIG® 216

Welding is a skill that can only be learned by practicing. No one can become an accomplished welder

simply by reading about it. The following link

“Learning to Weld” document will help the inexperienced operator to understand the basics about wire

welding and provide guidance to help develop this

skill.

“Learning to Weld” link:

http://content.lincolnelectric.com/pdfs/products/

navigator/im/LTW1tri.pdf

Page 20

C-1 C-1

ACCESSORIES

DRIVE ROLL KITS

Refer to Table C.1 for various drive roll kits that are

available for the POWER MIG® 216.The item in Bold

is supplied standard with the POWER MIG® 216.

TABLE C.1

Wire Size Drive Roll Kit

Solid

Steel

Cored

Aluminum

.023”-.030” (0.6-0.8 mm)

.035” (0.9 mm) KP1696-035S

.045” (1.1 mm) KP1696-045S

.035”-.045” (0.9-1.1mm) KP1696-1

.040” (1.0mm) KP1696-2

.035” (0.9 mm) KP1697-035C

.045” (1.1 mm) KP1697-045C

3/64” (1.2 mm) KP1695-3/64A

KP1696-030S

DUAL CYLINDER MOUNTING KIT

(K1702-1)

Permits stable side-by-side mounting of two full size

228.6mm dia x 1.524m high(9" dia. x 5' high) gas

cylinders with “no lift” loading. Simple installation and

easy instructions provided. Includes upper and lower

cylinder supports, wheel axles and mounting hardware.

SMALL SPOOL SPINDLE ADAPTER

(K468)

ALTERNATIVE MAGNUM GMAW

GUN AND CABLE ASSEMBLIES

The following Magnum Pro 250L gun and cable

assemblies are separately available for use with the

POWER MIG® 216. Each is rated at 250 amps 40%

duty cycle and is equipped with the integrated connector, twist-lock trigger connector, fixed nozzle and insulator, and includes a liner, diffuser, and contact tips for

the wire sizes specified:

English Wire Metric Wire

Length Part No. Size Size

10' (3.0 m)

12' (3.6 m) KP42-4045-15 .035” – .045" 0.9 – 1.1 mm

15' (4.5 m)

WARNING

• Unplug or Disconnect all input power

from the POWER MIG® 216 before

installing the Spool Gun and Kit.

------------------------------------------------------------------------

MAGNUM GUN CONNECTION KIT

(K466-6)

Using the optional K466-6 Magnum Connection kit for

the POWER MIG® 216 permits use of standard

Magnum 200, 300 or 400 gun and cable assemblies.

OPTIONAL SPOOL GUNS AND

ADAPTERS

The K468 spindle adapter allows the use of 8" diameter small spools.

SPINDLE ADAPTER FOR 14 LBS.

COILS (K435)

The K435 spindle adapter allows 14lbs. (6kg.)

Innershield Coils to be mounted on 2” (51mm) O.D.

spindle.

POWER MIG® 216

The

POWER MIG® 216

following optional spool guns:

SPOOL GUN

Magnum 100SG

(K2532-1)

Magnum SG

(K487-25)

Magnum 250LX

(K2490-1)

Spool gun Adapter (K2703-1)

This kit is designed to allow the Magnum SG or Magnum

250LX spool gun to operate with the

The kit includes the gas solenoid, gas lines, wiring harness

and gun connection panel. The gun connection panel features a 6 pin ms-type connector for the Magnum SG spool

gun and a 7 pin ms-type connector for the Magnum 250LX

spool gun and a selector switch to choose which gun you

are using.

NOTE: The K2703-1 spool gun adapter disables the

Magnum 100SG capability.

130amp 30% Duty Cycle

250Amp 60% Duty Cycle

300 Amp 60% Duty Cycle

is capable of operating with the

RATING

Light Duty

Medium Duty

Heavy Duty

POWER MIG® 216

ADAPTER

Factory Ready

No Adapter Required

Spool Gun Adapter

K2703-1

.

Page 21

C-2

ACCESSORIES

MAKING A WELD WITH THE SPOOL GUN

ADAPTER KIT AND SPOOL GUN

INSTALLED

CAUTION

In either toggle switch position, closing either gun

trigger will cause the electrode of both guns to be

electrically “HOT”. Be sure unused gun is positioned so electrode or tip will not contact metal

case or other metal common to work.

------------------------------------------------------------------------

1. Setting the toggle switch to “Push Gun” position

disables the spool gun operation and spool gun

gas solenoid valve. Closing the gun trigger enables

the push gun welding and both electrodes will be

electrically “HOT”.

2. Setting the toggle switch to the “Spool Gun” position disables the built-in push gun operation and

feeder gas solenoid valve. It will also enables the

spool gun operation and spool gun gas solenoid

valve. Closing the spool gun trigger enables spool

gun welding and both electrodes will be electrically

“HOT”.

C-2

OPERATORʼS MANUAL

3. Operation with POWER MIG® 216:

• Turn the POWER MIG® 216 input power ON.

• Adjusting the voltage tap control will increase or

decrease your welding voltage.

• Adjusting the wire speed control on the spool

gun will increase or decrease the spool gun

wire feed speed.

NOTE: Adjusting the wire feed speed control on the

Machineʼs Front Panel has no affect on the spool

gunʼs wire feed speed.

4. Refer to the welding procedure on the machine or

Section F of this Instruction Manual for initial aluminum settings. Make a test weld to determine the

final settings.

5. Set the spool gun selector switch to “Push Gun”

position to return to push gun operation.

POWER MIG® 216

Page 22

D-1

SAFETY PRECAUTIONS

WARNING

MAINTENANCE

• Be sure the nozzle insulator is fully screwed

onto the gun tube and does not block the gas

holes in the diffuser.

D-1

ELECTRIC SHOCK can kill.

• Have an electrician install and

service this equipment.

• Turn the input power OFF at the

fuse box before working on

equipment

• Do not touch electrically hot

parts.

GENERAL MAINTENANCE

In extremely dusty locations, dirt may clog the air passages causing the welder to run hot. Blow dirt out of

the welder with low-pressure air at regular intervals to

eliminate excessive dirt and dust build-up on internal

parts.

The fan motors have sealed ball bearings which

require no service.

DRIVE ROLLS AND GUIDE PLATES

After every coil of wire, inspect the wire drive mechanism. Clean it as necessary by blowing with low pressure compressed air. Do not use solvents for cleaning

the idle roll because it may wash the lubricant out of

the bearing. All drive rolls are stamped with the wire

sizes they will feed. If a wire size other than that

stamped on the roll is used, the drive roll must be

changed.

• Slip the appropriate gas nozzle onto the nozzle

insulator. Either a standard .50" (12.7 mm) or

optional .62" (15.9 mm) I.D. slip-on gas nozzle

may be used and should be selected based on

the welding application.

• Adjust the gas nozzle as appropriate for the

GMAW process to be used. Typically, the contact tip end should be flush to .12" (3.2 mm)

extended for the short-circuiting transfer

process and .12" (3.2 mm) recessed for spray

transfer.

GUN TUBES AND NOZZLES

1. Replace worn contact tips as required.

2. Remove spatter from inside of gas nozzle and from

tip after each 10 minutes of arc time or as required.

GUN CABLE CLEANING

To help prevent feeding problems, clean cable liner

after using approximately 300 pounds (136 kg) of

electrode. Remove the cable from the wire feeder and

lay it out straight on the floor. Remove the contact tip

from the gun. Using an air hose and only partial pressure, gently blow out the cable liner from the gas diffuser end.

CAUTION

For instructions on replacing or changing drive roll,

see “Wire Drive Rolls” in Operation section.

CONTACT TIP AND GAS NOZZLE

INSTALLATION

1. Choose the correct size contact tip for the electrode being used (wire size is stenciled on the side

of the contact tip) and screw it snugly into the gas

diffuser.

2. Screw the appropriate fixed gas nozzle fully onto

the diffuser. Either the standard .50" (12.7 mm)

flush nozzle or other optional flush or recessed

(spray arc) nozzle sizes may be used. (See Table

D.2 in this section.)

3. If using optional adjustable slip-on nozzles, see

Table D.2 in this section.

POWER MIG® 216

Excessive pressure at the beginning of the cleaning procedure may cause the dirt to form a plug.

-----------------------------------------------------------------------

Flex the cable over its entire length and again blow

out the cable. Repeat this procedure until no further

dirt comes out. If this has been done and feed problems are experienced, try liner replacement, and refer

to trouble shooting section on rough wire feeding.

Page 23

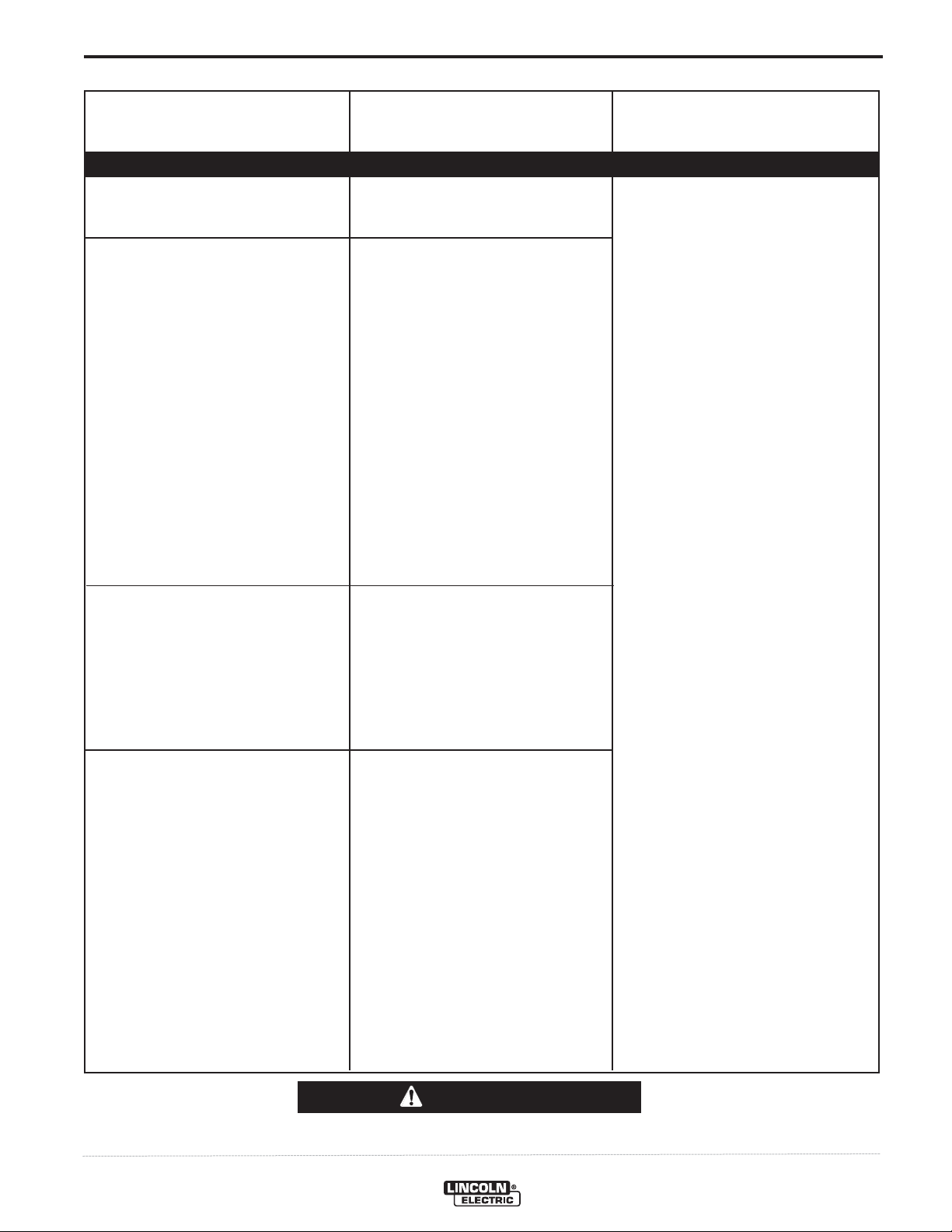

D-2

MAINTENANCE

LINER REMOVAL AND REPLACEMENT

NOTE: Changing the liner for a different wire size

requires replacement of the gas diffuser per Table D.1

to properly secure the different liner.

TABLE D.1

Fixed

Diameter of Liner Part on End of Part No.

Replacement Size Stencilled Gas Diffuser

Electrodes Used Number Liner Bushing (and Stencil)

.025”-.030" Steel KP42-25-15 .030” (0.8 mm)

(0.6-0.8 mm)

.035”-.045" Steel KP42-4045-15 .045” (1.1 mm) KP2746-1

(0.9-1.1 mm)

3/64" Aluminum KP42-4045-15 3/64" (1.2 mm)

(1.2 mm)

LINER REMOVAL, INSTALLATION AND TRIMMING

INSTRUCTIONS FOR MAGNUM PRO 250L

Nozzle

D-2

7. Screw the gas diffuser onto the end of the gun tube

and securely tighten. Be sure the gas diffuser is

correct for the liner being used. (See table and diffuser stencil.)

8. Tighten the set screw in the side of the gas diffuser

against the cable liner using a 5/64" (2.0 mm) Allen

wrench.

FIGURE D.1

SET SCREW

BRASS CABLE CONNECTOR

SET SCREW

GAS DIFFUSER

NOZZLE INSULATOR (IF USED)

GAS NOZZLE

1-1/4"

(31.8mm)

LINER

TRIM

LENGTH

OPERATORʼS MANUAL

NOTE: The variation in cable lengths prevents the

interchangeability of liners between guns. Once a liner

has been cut for a particular gun, it should not be

installed in another gun unless it can meet the liner

cutoff length requirement. Liners are shipped with the

jacket of the liner extended the proper amount.

1. Remove the gas nozzle and nozzle insulator, if

used, to locate the set screw in the gas diffuser

which is used to hold the old liner in place. Loosen

the set screw with a 5/64" (2.0 mm) Allen wrench.

2. Remove the gas diffuser from the gun tube.

3. Lay the gun and cable out straight on a flat surface.

Loosen the set screw located in the brass connector at the feeder end of the cable and pull the liner

out of the cable.

4. Insert a new untrimmed liner into the connector

end of the cable. Be sure the liner bushing is stencilled appropriately for the wire size being used.

5. Fully seat the liner bushing into the connector.

tighten the set screw on the brass cable connector.

The gas diffuser, at this time, should not be

installed onto the end of the gun tube.

CAUTION

This screw should only be gently tightened.

Overtightening will split or collapse the liner and

cause poor wire feeding.

------------------------------------------------------------------------

6. With the gas diffuser still removed from the gun

tube, be sure the cable is straight, and then trim

the liner to the length shown in Figure D.1.

Remove any burrs from the end of the liner.

POWER MIG® 216

Page 24

D-3

MAINTENANCE

GUN HANDLE DISASSEMBLY

The internal parts of the gun handle may be

inspected or serviced if necessary.

The gun handle consists of two halves that are

held together with a collar on each end. To

open up the handle, turn the collars approximately 60 degrees counterclockwise (the same

direction as removing a right hand thread) until

the collar reaches a stop. Then pull the collar

off the gun handle. If the collars are difficult to

turn, position the gun handle against a corner,

place a screwdriver against the tab on the collar and give the screwdriver a sharp blow to

turn the collar past an internal locking rib.

Counterclockwise

„

D-3

TABLE D.2

ACCESSORIES AND EXPENDABLE REPLACEMENT PARTS

FOR MAGNUM PRO 250L GUN AND CABLE ASSEMBLIES

Description Part No. Size Size

CABLE LINER

For 15' (4.5 m) or KP42-25-15 .025" – .030" 0.6 – 0.8 mm

shorter Cable KP42-4045-15 .035" – .045" 0.9 – 1.1 mm

KP42-4045-15 3/64" 1.2 mm

CONTACT TIPS

Standard Duty KP2744-025 .025" 0.6 mm

KP2744-030 .030" 0.8 mm

KP2744-035 .035" 0.9 mm

KP2744-045 .045" 1.1 mm

Tapered KP2744-030T .030" 0.8 mm

KP2744-035T .035" 0.9 mm

KP2744-045T .045" 1.1 mm

Tab (For Aluminum) KP2744-364A 3/64" 1.2 mm

GAS NOZZLES

Fixed (Flush) KP2742-1-38F 3/8" 9.5 mm

KP2742-1-50F* 1/2" 12.7 mm

KP2742-1-62F 5/8" 15.9 mm

Fixed (Recessed) KP2742-1-38R 3/8" 9.5 mm

KP2742-1-50R

KP2742-1-62R 5/8" 15.9 mm

Requires: Gas

Diffuser As'bly KP2746 * .025" – .045" 0.6 – 1.1 mm

English Metric

(Alum. wire) (Alum. wire)

(Alum. Wire) (Alum. Wire)

1/2" 12.7 mm

Insulator KP2773-2 *

GUN TUBE ASSEMBLIES

Standard (60°) KP3078-60 *

45° KP3078-45 *

* Included with POWER MIG® 216

** Tapered tips are required with 3/8” I.D. and 1/2” I.D. Nozzles.

See www.lincolnelectric.com for complete offering of Magnum Pro consumables.

POWER MIG® 216

Page 25

TROUBLESHOOTING

HOW TO USE TROUBLESHOOTING GUIDE

WARNING

Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel.

Unauthorized repairs performed on this equipment may result in danger to the technician and

machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical

Shock, please observe all safety notes and precautions detailed throughout this manual.

__________________________________________________________________________

E-1 E-1

This Troubleshooting Guide is provided to help you

locate and repair possible machine malfunctions.

Simply follow the three-step procedure listed below.

Step 1. LOCATE PROBLEM (SYMPTOM).

Look under the column labeled “PROBLEM (SYMPTOMS)”. This column describes possible symptoms

that the machine may exhibit. Find the listing that

best describes the symptom that the machine is

exhibiting.

Step 2. POSSIBLE CAUSE.

The second column labeled “POSSIBLE CAUSE” lists

the obvious external possibilities that may contribute

to the machine symptom.

Step 3. RECOMMENDED COURSE OF ACTION

This column provides a course of action for the

Possible Cause, generally it states to contact your

local Lincoln Authorized Field Service Facility.

If you do not understand or are unable to perform the

Recommended Course of Action safely, contact your

local Lincoln Authorized Field Service Facility.

OPERATORʼS MANUAL

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

POWER MIG® 216

Page 26

TROUBLESHOOTING

Observe all Safety Guidelines detailed throughout this manual

E-2 E-2

PROBLEMS

(SYMPTOMS)

Major Physical or Electrical

Damage is Evident

There is no wire feed or open circuit voltage when the gun trigger is

pulled. Input power is applied to

POWER MIG® 216.

Output voltage and wire feed is present when gun trigger is not pulled

(not activated).

POSSIBLE

CAUSE

OUTPUT PROBLEMS

1. Contact your Local Lincoln

Authorized Field Service Facility.

1 The gun trigger or cable may be

faulty. Check or replace gun

assembly.

2. The thermal protection circuit

may be activated. If this is the

case, allowing the machine to

cool will clear the error condition.

3. Make sure input voltage is correct and matches nameplate rating and reconnect panel configuration.

4. If spool gun option kit is in-

stalled, check to see that it is set

to “Push Gun” if pulling the gun

trigger associated with built in

feeder, and “Spool Gun” if pulling

spool gun trigger.

1. Remove gun assembly from

machine. If problem is solved,

gun assembly is faulty. Repair or

replace.

2. If problem persists when gun

assembly is removed from

machine, then the problem is

within the POWER MIG® 216.

RECOMMENDED

COURSE OF ACTION

If all recommended possible areas

of misadjustment have been

checked and the problem persists,

Contact your local Lincoln

Authorized Field Service Facility.

Machine output is low. Welds are

“cold”, weld bead is rounded or

bumped up demonstrating poor

wetting into plate.

1. Check input voltage. Make sure

input voltage matches nameplate rating and reconnect panel

configuration.

2. Make sure settings for wire feed

speed and voltage are correct

for process being used.

3. Make sure output polarity is correct for process being used.

4. Check welding cables and gun

assembly for loose or faulty connections.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

LOCAL AUTHORIZED LINCOLN ELECTRIC FIELD SERVICE FACILITY for assistance before you proceed.

POWER MIG® 216

Page 27

TROUBLESHOOTING

Observe all Safety Guidelines detailed throughout this manual

E-3 E-3

PROBLEMS

(SYMPTOMS)

Poor arc striking with electrode

sticking or blasting off.

Rough wire feeding or wire will not

feed but drive rolls are turning.

POSSIBLE

CAUSE

OUTPUT PROBLEMS

1. Make sure settings for wire feed

speed and voltage are correct

for process being used.

2. The gas shielding may be

improper for process being used.

3. Check input line voltage to be

within machineʼs recommended

rating range.

4. Check that the machine recon-

nect panel is configured properly

for the applied voltage.

FEEDING PROBLEMS

1.

The gun cable may be kinked or twisted.

2.

The wire may be jammed in the gun

cable, or gun cable may be dirty.

3. Check drive roll tension and

position of grooves.

4.

Check for worn or loose drive rolls.

5.

The electrode may be rusty or dirty.

6. Check for damaged or incorrect

contact tip.

7. Check wire spindle for ease of

rotation and adjust break tension knob if necessary.

8. Check that the gun is pushed all

the way into gun mount and

properly seated.

RECOMMENDED

COURSE OF ACTION

OPERATORʼS MANUAL

If all recommended possible areas

of misadjustment have been

checked and the problem persists,

Contact your local Lincoln

Authorized Field Service Facility.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

LOCAL AUTHORIZED LINCOLN ELECTRIC FIELD SERVICE FACILITY for assistance before you proceed.

POWER MIG® 216

Page 28

E-4 E-4

Observe all Safety Guidelines detailed throughout this manual

TROUBLESHOOTING

PROBLEMS

(SYMPTOMS)

The wire feed stops while welding.

When trigger is released and

pulled again the wire feed starts.

No control of wire feed speed.

Other machine functions are normal.

Gas does not flow when gun trigger

is pulled.

POSSIBLE

CAUSE

FEEDING PROBLEMS

1. Check the wire feed drive rolls

and motor for smooth operation.

2. Check for restrictions in the wire

feed path. Check the gun and

cable for restrictions.