Page 1

(4X5) SHADE 10 HELMET INSTRUCTIONS

RETURN TO MAIN MENU

OMBRE 10 INSTRUCTIONS POUR

SOMBA 10 INSTRUCCIONES PARA CARETA

IMT10004

February, 2010

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

OPERATOR’S MANUAL

Copyright © Lincoln Global Inc.

• World's Leader in Welding and Cutting Products •

• Sales and Service through Subsidiaries and Distributors Worldwide •

Page 2

TABLE OF CONTENTS Page

SAFETY WARNINGS – READ BEFORE USING 1

OPERATING INSTRUCTIONS 2

SHADE GUIDE SETTINGS 3

(French)

AVERTISSEMENTS DE SÉCURITÉ – LIRE AVANT UTILISATION

INSTRUCTIONS DE FONCTIONNEMENT 5

ARRANGEMENTS DE GUIDE D'OMBRE 6

(Spanish)

ADVERTENCIAS DE SEGURIDAD – LEA ANTES DE USAR

INSTRUCCIONES DE OPERACIÓN 8

AJUSTES DE LA GUÍA DE LA CORTINA 9

Replacement Parts(Pièces de Rechange)(Piezas de Recambio)

(4X5) SHADE 10 - OMBRE 10 - SOMBRA 10 10,11

4

7

WARRANTY INFORMATION

INFORMATIONS CONCERNANT LA GARANTIE

INFORMACIÓN DE GARANTÍA

}

12

Page 3

CROWN

AD

JUSTMENT

TILT ADJUSTMENT

RATCHET KNOB

PIN HOLES FOR

A

DJUSTMENT

SAFETY WARNINGS – READ BEFORE USING

WARNING

ARC Rays can injure eyes and burn skin

• Before welding, always inspect helmet and filter lens to be sure they are fitted

properly, in good condition and not damaged.

• Check to see that the clear lens is clean and securely attached to the helmet.

• Always wear safety glasses or goggles under the welding helmet and protective

clothing to protect your skin from radiation, burns and spatter.

• Ensure that optical radiation from other welder’s arcs in the immediate area

does not enter in from behind the helmet and auto-darkening filter.

Auto-darkening filters in Lincoln helmets are designed to protect the user against harmful

Note:

ultra-violet and infrared rays both in the dark and light states. No matter what shade the filter is

set to, the UV/IR protection is always present.

FUMES AND GASES can be dangerous to your health.

• Keep your head out of fumes.

• Use enough ventilation or exhaust at the arc or both to keep fumes and gases

from your breathing zone and general area.

• When welding with electrodes which require special ventilation such as

stainless or hard facing (see instructions on container or MSDS) or on

lead or cadmium plated steel and other metals or coatings which produce highly toxic fumes, keep exposure as low as possible and within

applicable OSHA PEL and ACGIH TLV limits using local exhaust or

mechanical ventilation. In confined spaces or in some circumstances,

outdoors, a respirator may be required. Additional precautions are also

required when welding on galvanized steel.

Refer to http://www.lincolnelectric.com/safety

for additional safety information.

1

Page 4

OPERATING INSTRUCTIONS

CROWN

AD

JUSTMENT

TILT ADJUSTMENT

RATCHET KNOB

PIN HOLES FOR

A

DJUSTMENT

Headgear Adjustment

Head Size Adjustment: Headband tightness is adjusted by pushing in the

ratchet knob and turning to adjust to desired comfort level. This knob is

located at the back of the helmet. HEAD GEAR CROWN ADJUSTMENT is

made by adjusting crown strap for vertical placement on the head and snapping the pin into the hole to lock securely in place.

Tilt: Tilt is adjusted on the left side of the helmet. TILT is adjusted by loosening outside tension knob and releasing the adjustment lever from its current location and moving it to another location. Retighten the outside tension

knob when finished.

2

Page 5

SHADE GUIDE SETTINGS

N

T1

G

UIDE FOR SHADE NUMBERS

OPERATION ELECTRODE SIZE ARC MINIMUM SUGGESTED

(1)

1/32 in. (mm) CURRENT (A) PROTECTIVE SHADE NO.

SHADE (COMFORT)

Shielded metal arc Less than 3 (2.5) Less than 60 7 –

w

elding 3-5 (2.5–4) 60-160 8 10

5-8 (4–6.4) 160-250 10 12

More than 8 (6.4) 250-550 11 14

Gas metal arc Less than 60 7 –

welding and flux 60-160 10 11

c

ored arc welding 160-250 10 12

250-500 10 14

G

as tungsten arc Less than 50 8 10

welding 50-150 8 12

150-500 10 14

Air carbon (Light) Less than 500 10 12

Arc cutting (Heavy) 500-1000 11 14

Plasma arc welding Less than 20 6 6 to 8

20-100 8 10

100-400 10 12

400-800 11 14

Plasma arc cutting (Light

)

(

2)

(2)

(

2)

Less than 300 8 9

(Medium) 300-400 9 12

(Heavy) 400-800 10 14

Torch brazing – – 3 or 4

Torch soldering – – 2

Carbon arc welding – – 14

PLATE THICKNESS

in. mm

Gas welding

Light Under 1/8 Under 3.2 4 or 5

Medium 1/8 to 1/2 3.2 to 12.7 5 or 6

Heavy Over 1/2 Over 12.7 6 or 8

Oxygen cutting

Light Under 1 Under 25 3 or 4

Medium 1 to 6 25 to 150 4 or 5

Heavy Over 6 Over 150 5 or 6

(1)

As

a

rule

of thumb, start with a shade that is too dark, then go to a lighter shade which gives sufficient view of the weld zone without going

below the

minimum. In oxyfuel gas welding or cutting where the torch produces a high yellow light, it is desirable to use a filter lens that absorbs

the

yellow or

sodium line the visible light of the (spectrum) operation

(2)

These values apply where the actual arc is clearly seen. Experience has shown that lighter filters may be used when the arc is hidden by the

.

• Periodic cleaning with soapy water solution or standard glass cleaner is

suggested. Air dry or use soft cloth to dry.

• ADF cartridges may be cleaned with soft, dry cloth. The ADF cartridge is

not to be submerged in water or other solution.

• Change or clean polycarbonate impact resistant clear lens when it

becomes dirty or cloudy.

• Store in a clean, dry location.

HELMET CARE AND MAINTENANCE

STORAGE

3

Page 6

AVERTISSEMENTS DE SÉCURITÉ – LIRE AVANT UTILISATION

AVERTISSEMENT

Les rayons d'ARC peuvent blesser des yeux et brûler la peau

• Avant la soudure, inspectez toujours le casque et objectif de filtre à être sûr qu'ils sont

en bon état et non endommagé.

• Vérifiez pour voir que l'objectif clair est propre et solidement attaché au casque.

• Portez toujours les verres de sûreté ou les lunettes sous le casque de soudure et les

vêtements de protection pour protéger votre peau contre le rayonnement, les brûlures et

l'éclaboussure.

• Soyez sûr que le rayonnement optique des arcs de autre soudeuse dans le secteur

immédiat entre pas dedans par derrière le casque et le filtre obscurcissants-automatique.

Des filtres obscurcissants-automatiques dans des casques de Lincoln sont conçus pour protéger l'util-

Note :

isateur contre les rayons nocifs ultra-violets et d'infrarouge dans les états d'obscurité et de lumière.

N'importe ce que l'ombre le filtre est placée à, la protection d'UV/IR est toujours présente.

Les VAPEURS ET LES GAZ peuvent être dangereux à votre santé.

• Gardez votre tête hors des vapeurs.

• Employez assez de ventilation ou l'épuisez à l'arc ou pour garder des vapeurs et des

gaz de votre zone de respiration et secteur général.

• Lorsqu'on soude avec des électrodes ayant besoin d'une ventilation spéciale

telles que celles en acier inoxydable ou pour le rechargement dur (voir les

instructions ou le conteneur ou la MSDS) ou sur le plomb ou de l'acier cadmié ou

sur d'autres métaux ou recouvrements produisant des vapeurs très toxiques,

maintenir le niveau d'exposition aussi bas que possible et dans les limites

OHAS-PEL et ACGIH TLV au moyen de l'échappement local ou d'une ventilation

mécanique. Dans des espaces confinés ou dans certaines circonstances à l'extérieur, un respirateur peut s'avérer nécessaire. Des précautions supplémentaires doivent également être prises pour souder sur de l'acier galvanisé.

Visitez http://www.lincolnelectric.com/safety pour obtenir

l´information additionnelle.

4

Page 7

INSTRUCTIONS DE FONCTIONNEMENT

B

OUTON À CLIQUET

RÉGLAGE DE L’INCLINAISON

RÉGLAGE DE

LA COURONNE

ORIFICES DES GOUPILLES

POUR LE RÉGLAGE

NT 1

GUIDE POUR DES NOMBRES D'OMBRE

OPÉRATION

T

AILLE D'ÉLECTRODE

D'ARC

NUANCE

P

ROTECTRICE

MINIMUM

NOMBRE

SUGGÉRÉ D'OMBRE

(

CONFORT)

(

1

)

1/32 in. (mm)

COURANT

(A) .

F

Soudure à l'arc électrique protégée

3

(2.5)

60 7 –

en métal

3-5 (2.5–4) 60-160 8 10

5-8 (4–6.4

)

160-250 10 12

8

(6.4)

250-550 11 14

Intoxiquez la soudure à l'arc

é

lectrique en métal et la soudure

à l'arc électrique creusée par flux

6

07–

6

0-160 10 11

160-250 10 12

250-500 10 14

Soudure à l'arc électrique de

tungstène de gaz

5

0810

5

0-150 8 12

1

50-500 10 14

Soudure à l'arc de carbone

d

'airr carbon

(

L

umière

)

M

oins que

Moins que

M

oins que

M

oins que

500 10 12

(

Lourd

)

5

00-1000 11 14

Soudure à l'arc électrique

de plasma

M

oins que 20 6 6 to 8

20-100 8 10

100-400 10 12

400-800 11 14

S

oudure à l'arc de plasma

(

Lumièret

(

2)

(2)

(2)

Moins que

3

00 8 9

(Milieum)

)

300-400 9 12

(Lourd

)

400-800 10 14

Incendiez la soudure

–

–3or4

Incendiez la soudure

––2

Soudure à l'arc électrique de carbone

––14

ÉPAISSEUR DE PLAT

in. mm

Soudage à gaz

Lumière

Sous 1/8

Sous

3.2 4 or 5

Milieu

Milieu

1/8 to 1/2 3.2 to 12.7 5 or 6

Lourd

Lourd

1/2

12.7 6 or 8

Oxycoupage

Lumière

Sous 1

Sous 25 3 or 4

1to6 25to150 4or5

Plus de

Plus de

6

Plus de

Plus de

150

5or6

(1)

Commencez en général par une nuance qui est trop foncée, vont alors à une nuance plus légère qui donne l'avis suffisant de la zone de

soudure sans aller au-dessous du minimum. Dans le soudage à gaz ou le découpage d'oxyfuel où l'incendier produit une lumière jaune

élevée, il est souhaitable d'utiliser un objectif de filtre qui absorbe le jaune ou la ligne de sodium la lumière visible de l'opération (de spectre).

(2)

Ces valeurs appliquent où l'arc réel est clairement vu. L'expérience a prouvé que des filtres plus légers peuvent être utilisés quand l'arc est

caché par l'objet.

Data from ANSI Z49.1-2005

Plus que

Ajustement du Harnais

Réglage de la Taille de la Tête: le serrage de la bande antisudation se

règle en poussant sur le bouton à cliquet et en le faisant tourner pour ajuster

le niveau de confort souhaité. Ce bouton se trouve sur l’arrière du casque.

LE RÉGLAGE DE LA COURONNE DU HARNAIS se fait en ajustant la courroie de la couronne pour un placement vertical sur la tête et en faisant

tomber la goupille dans l’orifice pour la verrouiller bien en place.

Inclinaison: L'inclinaison est ajustée de l'aile gauche du casque. L'INCLINAISON est ajustée en détachant le bouton extérieur de tension et en

libérant le levier d'ajustement de son endroit courant et en le déplaçant à un

autre endroit. Resserrer les bouton de tension extérieure lorsque le réglage

est terminé.

5

Page 8

NT 1

GUIDE POUR DES NOMBRES D'OMBRE

OPÉRATION

T

AILLE D'ÉLECTRODE

D'ARC

NUANCE

P

ROTECTRICE

MINIMUM

NOMBRE

SUGGÉRÉ D'OMBRE

(

CONFORT)

(

1

)

1/32 in. (mm)

COURANT

(A) .

F

Soudure à l'arc électrique protégée

3

(2.5)

60 7 –

en métal

3-5 (2.5–4) 60-160 8 10

5-8 (4–6.4

)

160-250 10 12

8

(6.4)

250-550 11 14

Intoxiquez la soudure à l'arc

é

lectrique en métal et la soudure

à l'arc électrique creusée par flux

6

07–

6

0-160 10 11

160-250 10 12

250-500 10 14

Soudure à l'arc électrique de

tungstène de gaz

5

0810

5

0-150 8 12

1

50-500 10 14

Soudure à l'arc de carbone

d

'airr carbon

(

L

umière

)

M

oins que

Moins que

M

oins que

M

oins que

500 10 12

(

Lourd

)

5

00-1000 11 14

Soudure à l'arc électrique

de plasma

M

oins que 20 6 6 to 8

20-100 8 10

100-400 10 12

400-800 11 14

S

oudure à l'arc de plasma

(

Lumièret

(

2)

(2)

(2)

Moins que

3

00 8 9

(Milieum)

)

300-400 9 12

(Lourd

)

400-800 10 14

Incendiez la soudure

–

–3or4

Incendiez la soudure

––2

Soudure à l'arc électrique de carbone

––14

ÉPAISSEUR DE PLAT

in. mm

Soudage à gaz

Lumière

Sous 1/8

Sous

3.2 4 or 5

Milieu

Milieu

1/8 to 1/2 3.2 to 12.7 5 or 6

Lourd

Lourd

1/2

12.7 6 or 8

Oxycoupage

Lumière

Sous 1

Sous 25 3 or 4

1to6 25to150 4or5

Plus de

Plus de

6

Plus de

Plus de

150

5or6

(1)

Commencez en général par une nuance qui est trop foncée, vont alors à une nuance plus légère qui donne l'avis suffisant de la zone de

soudure sans aller au-dessous du minimum. Dans le soudage à gaz ou le découpage d'oxyfuel où l'incendier produit une lumière jaune

élevée, il est souhaitable d'utiliser un objectif de filtre qui absorbe le jaune ou la ligne de sodium la lumière visible de l'opération (de spectre).

(2)

Ces valeurs appliquent où l'arc réel est clairement vu. L'expérience a prouvé que des filtres plus légers peuvent être utilisés quand l'arc est

caché par l'objet.

Data from ANSI Z49.1-2005

Plus que

ARRANGEMENTS DE GUIDE D'OMBRE

• Le nettoyage périodique avec la solution savonneuse de l'eau ou le décapant en

verre standard est suggéré. Aérez tissu mou sec ou d'utilisation pour sécher.

• Des cartouches de radiogoniomètre automatique peuvent être nettoyées avec le

tissu mou et sec. La cartouche de radiogoniomètre automatique ne doit pas être

submergée dans l'eau ou toute autre solution.

• Changez ou nettoyez l'objectif clair résistant aux chocs de polycarbonate quand

elle devient sale ou nuageuse.

• Magasin dans un endroit propre et sec.

SOIN ET ENTRETIEN DE CASQUE

STOCKAGE

6

Page 9

PERILLA DEL TRINQUETE

AJUSTE DE INCLINACIÓN

A

JUSTE DE

LA CORONILLA

ORIFICIOS DE PIN

PARA AJUSTE

PRECAUCIONES DE SEGURIDAD – LEA ANTES DE USAR

ADVERTENCIA

Los rayos del ARCO pueden dañar ojos y quemarse la piel.

• Antes de soldar con autógena, examine siempre el casco y lente del filtro a ser segura que están en buenas condiciones y no dañado.

• Compruebe para ver que la lente clara sea limpia y unida con seguridad al casco.

• Use siempre las gafas de seguridad o los anteojos debajo del casco de la soldadura

y de la ropa protectora para proteger su piel contra la radiación, quemaduras y

salpicón.

• Esté seguro que la radiación óptica de los arcos del otro soldador en el

área inmediata no entra adentro de detrás el casco y el filtro de automático-oscurecimiento.

Nota: Los filtros que obscurecen-automáticos en los cascos de Lincoln se diseñan para proteger al usuario

contra rayos ultravioletas y del infrarrojo dañosos en los estados de la obscuridad y de la luz. No importa qué

la cortina el filtro se fija a, la protección de UV/IR está siempre presente

Los HUMOS Y LOS GASES pueden ser peligrosos a su salud.

• Guarde su cabeza fuera de humos.

• Utilice bastante ventilación o agótela en el arco o para guardar humos y los gases de

su zona de respiración y área general.

• Cuando se suelda con electrodos que requieren ventilación especial (Ver in-

strucciones en el contenedor o la MSDS) o cuando se suelda con chapagalvanizada

u otros metales o revestimeintos que producen humos tóxicos, evite exponerse

lo más posible y dentro de los límites aplicables según OSHA PEL y ACGIH TLV

utilizando un sistema de ventilación de extracción o mecánica local. En espacios

confinados y a la intemperie, puede ser necesario el uso de respiración asistida.

Asimismo se deben tomar precauciones al soldar con acero galvanizado.

.

Visite http://www.lincolnelectric.com/safety para obtener

información adicional.

7

Page 10

INSTRUCCIONES DE OPERACIÓN

PERILLA DEL TRINQUETE

AJUSTE DE INCLINACIÓN

A

JUSTE DE

LA CORONILLA

ORIFICIOS DE PIN

PARA AJUSTE

Ajuste del Dispositivo para la Cabeza

Ajuste al Tamaño de la Cabeza: La tensión del dispositivo para la cabeza

se ajusta oprimiendo la perilla del trinquete y girando para ajustar al nivel de

comodidad deseado. Esta perilla se localiza en la parte posterior de la careta. El AJUSTE DE LA CORONILLA DEL DISPOSITIVO PARA LA CABEZA

se logra adaptando la cinta de la coronilla para colocación vertical sobre la

cabeza e introduciendo el pin en el orificio para asegurar en su lugar.

Inclinación: La inclinación se ajusta en el lado izquierdo del casco. La

INCLINACIÓN es ajustada aflojando la perilla exterior de la tensión y lanzando la palanca del ajuste de su localización actual y moviéndola a otra localización. Vuelva a apretar las perilla de tensión externas cuando acabe.

8

Page 11

NT 1

GUÍA PARA LOS NÚMEROS DE LA CORTINA

O

PERACIÓN

TAMAÑO DEL ELECTRODO

CORRIENTE DEL

A

RCO

CORTINA

PROTECTORA

M

ÍNIMA

NÚMERO

SUGERIDO DE LA

C

ORTINA (COMODIDAD)

(1)

1

/32 in. (mm) (A)

Soldadura de arco blindada

del metal

3 (2.5) 60 7 –

3

-5 (2.5–4) 60-160 8 10

5-8 (4–6.4) 160-250 10 12

Más que

8 (6.4)

250-550 11 14

P

rovea de gas la soldadura de

a

rco del metal y la soldadura

de arco base flujo

60 7 –

60-160 10 11

160-250 10 12

250-500 10 14

Soldadura de arco del

tungsteno del gas

50 8 10

50-150 8 12

150-500 10 14

C

orte de arco del carbón

del aire

(Luz

) Menos que

M

enos que

Menos que

Menos que

Menos que

500 10 12

(Pesado

)

500-1000 11 14

Soldadura de arco del plasma

Menos que 20 6 6 to 8

20-100 8 10

100-400 10 12

4

00-800 11 14

Corte de arco del plasma (Luzi

(

2)

(

2)

(

2)

Menos que

300 8 9

(Medio

Medio

)

)

)

300-400 9 12

(Pesado 400-800 10 14

El soldar de la antorcha

––3or4

El soldar de la antorcha

––2

Soldadura de arco del carbón

––14

GRUESO DE LA PLACA

in. mm

Soldadura de gas

Luz

Debajo

Debajo

Debajo

Debajo

1/8 3.2 4 or 5

1/8 to 1/2 3.2 to 12.7 5 or 6

Pesado

1/2

12.7

6or8

Corte de oxígeno

Luz 1 25 3 or 4

Mediodi1to625 to 150 4 or 5

Pesado

Encima

Encima

Encima

Encima

6

150 5 or 6

(1)

En general comience con una cortina que sea demasiado oscura, entonces van a una cortina más ligera que dé la suficiente vista de la zona de la

autógena sin ir debajo del mínimo. En la soldadura o el corte de gas del oxyfuel donde la antorcha produce una alta luz ámbar, es deseable utilizar

una lente del filtro que absorba el amarillo o la línea del sodio la luz visible de la operación (del espectro).

(2)

Estos valores se aplican donde el arco real se ve claramente. La experiencia ha demostrado que filtros más ligeros pueden ser utilizados cuando

el arco es ocultado por el objeto.

Data from ANSI Z49.1-2005

AJUSTES DE LA GUÍA DE LA CORTINA

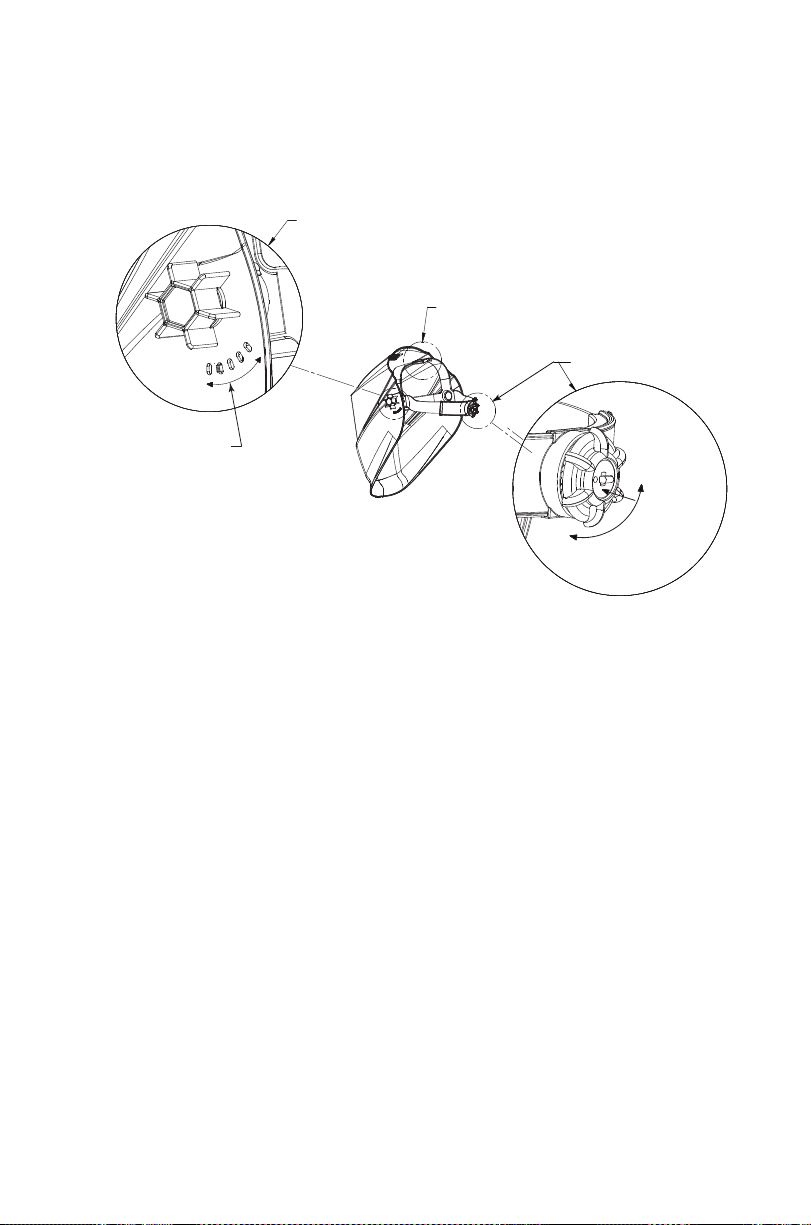

RETIRO DE LA LENTE DEL SOSTENEDOR DEL FILTRO

LENS REMOVAL FROM FILTER HOLDER

DÉPLACEMENT D'OBJECTIF DU SUPPORT DE FILTRE

5

• La limpieza periódica con la solución jabonosa del agua o el limpiador de cristal

estándar se sugiere. Ventile paño suave seco o del uso para secarse.

• Los cartuchos del alimentador de originales se pueden limpiar con el paño suave,

seco. El cartucho del alimentador de originales no debe ser sumergido en el agua

o la otra solución.

• Cambie o limpie la lente clara resistente a los choques del policarbonato cuando

llega a ser sucio o nublado.

• Almacén en una localización limpia, seca

SOIN ET ENTRETIEN DE CASQUE

ALMACENAJE

9

Page 12

RETIRO DE LA LENTE DEL SOSTENEDOR DEL FILTRO

LENS REMOVAL FROM FILTER HOLDER

DÉPLACEMENT D'OBJECTIF DU SUPPORT DE FILTRE

5

10

Page 13

6

6

6

SHELL

PAROI

CUBIERT

1

2

3

4

5

(4X5) SHADE 10 (OMBRE 10) (SOMBRA 10)

ITEM

ARTICLE

ARTÍCULO

PART NO.

NUMÉRO DE

PIÈCE

DESCRIPTION

DESCRIPCIÓN

NÚMERO DE

PIEZA

FRONT COVER LENS SEAL

1

S27978-32

JOINT D'OBJECTIF DE COUVERTURE

SELLO DE LA LENTE DE LA PORTADA

CLEAR PLASTIC LENS

(Size-Tailles-Tamaño: 4.50”x 5.25” x .040”)

2

S27978-36

VISÈRE EN PLASTIQUE TRANSPARENT

LENTE DE PLASTCO TRANSPARENTE

ADAPTOR

3

S27978-20

ADAPTEUR

ADAPTADOR

#10 FILTER PLATE

4

S27978-15

(Size-Tailles-Tamaño: 4.50”x 5.25” x .120”)

PLAQUE DE FILTRE #10

PLACA DE FILTRO #10

FILTER HOLDER

5

S27978-19

SUPPORT DE FILTRE

SOSTENEDOR DEL FILTRO

HEADGEAR

6

S27978-24

ENSEMBLE DU HARNAIS

SOMBRERO

SWEATBAND

7*

S27978-4

BANDEAU

BANDANA

*Item not shown-(Article non montré)-(Artículo no demostrado)

11

QTY.

QTE.

CANT.

1

1

1

1

1

1

1

Page 14

WARRANTY INFORMATION:

These helmets are warranted for a period of two years. Please contact us at

1 (800) 833-9353 for any service or warranty questions.

INFORMATIONS CONCERNANT LA GARANTIE:

Ces casques sont garantis pour une période de deux ans. Prière de nous contacter au 1 (800) 833-9353 pour toute question concernant le service ou la

garantie.

INFORMACIÓN DE GARANTÍA:

Estas caretas están garantizadas por un periodo de dos años. Para

cualquier pregunta sobre el servicio o garantía, sírvase contactarnos al 1

(800) 833-9353.

12

Page 15

NOTES

NOTAS

Page 16

• World's Leader in Welding and Cutting Products •

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

Loading...

Loading...