Page 1

Date of Purchase:______________

Serial Number:_________________

Code Number:_________________

Model:________________________

Where Purchased:______________

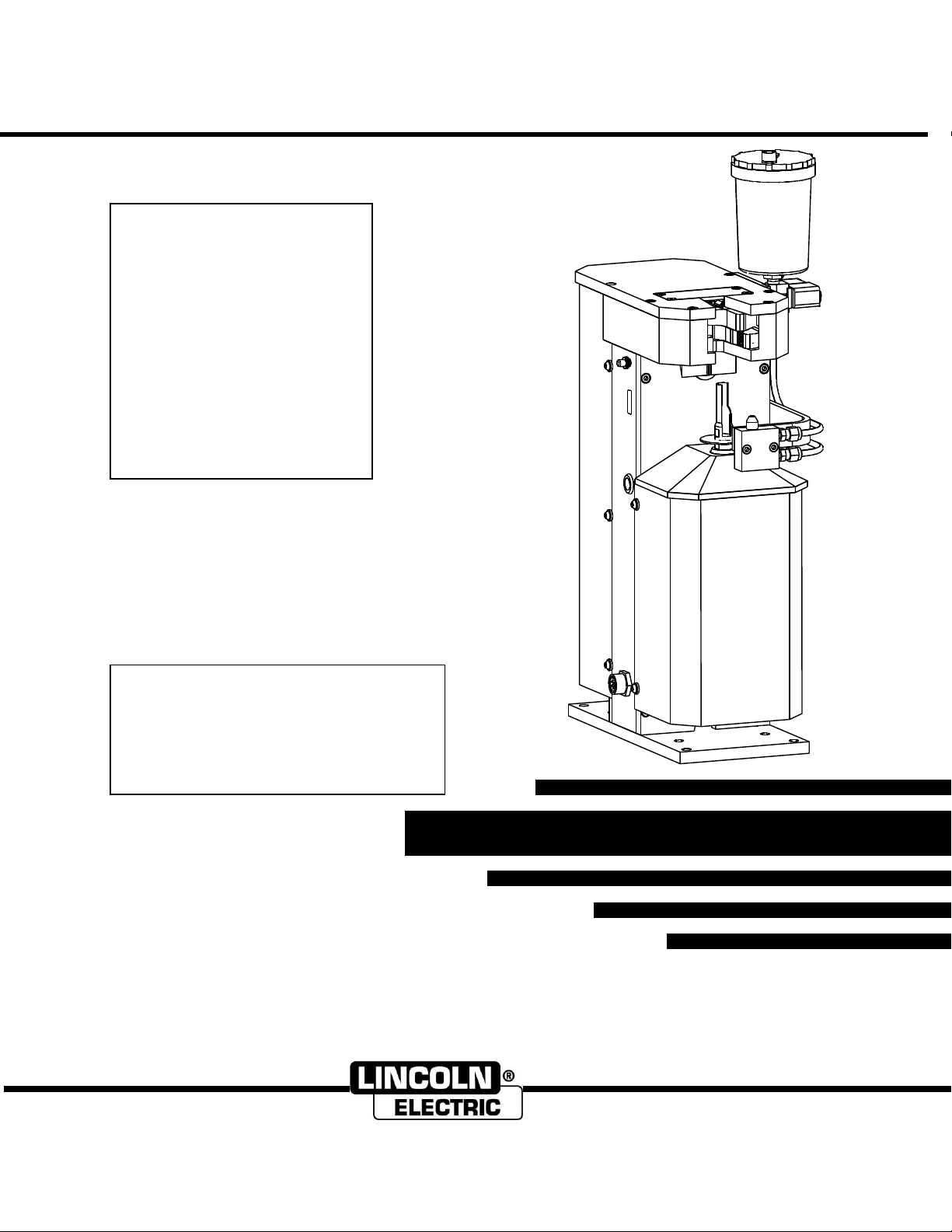

POWER REAM August, 2010

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However, your

overall safety can be increased by

proper installation ... and thoughtful

operation on your part.

DO NOT INSTALL, OPERATE OR

REPAIR THIS EQUIPMENT

WITHOUT READING THIS

MANUAL AND THE SAFETY

PRECAUTIONS CONTAINED

THROUGHOUT. And, most

importantly, think before you act

and be careful.

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

• World's Leader in Welding and Cutting Products •

OPERATOR’S MANUAL

RETURN TO MAIN MENU

For use with machines having code number 11172

IM866

Page 2

IM866

POWER REAM

Page 3

Safety Information - 3 -

Before installation and commissioning of the POWER REAM, please read and understand all of the

following safety information. Failure to follow these instructions may result in damage to the equipment or

personal injury.

The POWER REAM is constructed to be safe to operate provided

- Only authorized personnel shall perform installation, commissioning and maintenance and all safety

precautions in these operating instructions shall be observed.

-The accident prevention regulations as well as the safety specifications referenced below are

observed

ANSI/RIA R15.06-1999 Industrial Robots and Robot Systems —Safety Requirements

-For additional safety information see references below

This product shall be integrated into a robot cell with independent safety system by plant engineering.

Install within a secured area, which is only to be entered by qualified personnel for maintenance work or

robot programming.

Before assembling, adjusting or working with the reamer, ensure all equipment in the area is locked out

and disabled.

The torch-cleaning unit is to be used only for torch cleaning within the parameters of its technical

specification.

Do not exceed the specified operating pressure of 80 PSI.

The torch-cleaning unit may only be operated with the cover closed when operated independently.

Keep hands away from unit while in operation.

Keep hands away from the clamp and reamer operating space.

Keep hands away from the wire cutter

Keep eyes away from the sprayer

Shut off the air supply when making adjustment so that the equipment is not pressurized.

Additional fittings or accessories that are not offered from the manufacturer may only be installed with the

approval from the manufacturer.

Do not use the reamer with corrosive or aggressive vapors or liquids without first obtaining approval from

the manufacturer.

Ensure that there is nothing in the reamer unit when shutting down the system.

Warning and instruction labels from the unit are not to be removed or defaced.

For additional safety information, refer to the following publications:

ANSI STANDARD Z49.1, SAFETY IN WELDING AND CUTTING,

American Welding Society, 550 LeJeune Rd. P.O. Box 351040, Miami, FL 33126

ANSI/RIA STANDARD R15.06-1999 Industrial Robots and Robot Systems —Safety

Requirements

American National Standards Institute, 1430 Broadway, New York, NY 10018

Canadian Standards Association; Z434-03 Industrial Robots and Robot Systems – General Safety

Requirements.

5060 Spectrum Way, Mississauga, Ontario, L4W 5N6, CANADA

POWER REAM

Page 4

Safety Information - 4 -

Moving parts can crush and cut.

Keep hands away from the

operating area of the reamer,

clamp, and wire cutter

Rotating Cutter.

Keep hands away from the operating area of the cutter.

Entanglement Hazard.

Do not operate with exposed long hair, jewelry or loose clothing.

Turn off power before servicing.

Turn off air supply and disconnect air supply hose before servicing.

Do not use damaged, frayed or deteriorated air hoses and fittings.

Maintain safe operating pressure (80 psi).

Safety Symbols used in this manual

POWER REAM

Page 5

Table of Contents - 5 -

Page

Safety Information……………………………………………………….. 3

Specifications………………………………………………………………… 6

Installation…………………………………………………………………….. 7

I/O Configuration………………………………………………………….. 10

Robot Programming………………………………………………………. 12

Operation………………………………………………………………………. 15

Feature Setups………………………………………………………………. 16

Automatic I/O Configuration…………………………………………. 18

Maintenance and Troubleshooting………………………………… 19

Diagnostics…………………………………………………………………….. 20

Parts Replacement………………………………………………………… 21

Pneumatic Diagram………………………………………………………. 29

Electrical Diagram…………………………………………………………. 30

Parts Diagram………………………………………………………………… 32

Optional Accessories……………………………………………………… 35

POWER REAM

Page 6

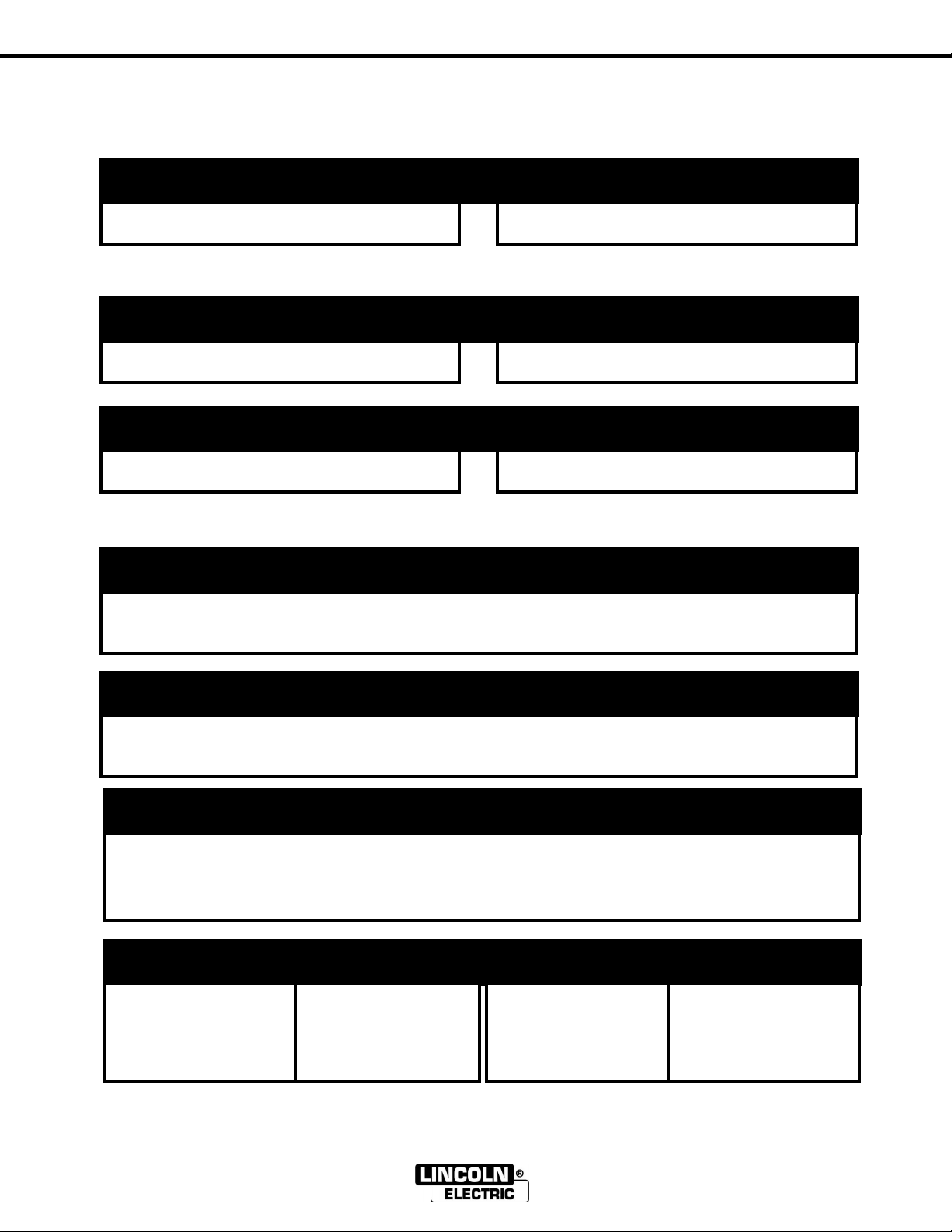

SPECIFICATIONS - 6 -

Pressure: 80 psi

Voltage: 24V DC

Speed: 1100 rpm

Flow: 15 scfm

Current: 0.5A DC

Power: 0.65 Hp

PNEUMATIC SPECIFICATIONS

ELECTRICAL SPECIFICATIONS

REAMING SPECIFICATIONS

PHYSICAL DIMENSIONS

HEIGHT

19.50 in. (495mm)

without Reservoir /

24.90 in. (633mm)

with Reservoir

WIDTH

8.47 in

228 mm

DEPTH

13.25 in

337 mm

NET WEIGHT

62 lbs.

28 kgs.

Nozzle inside diameter compatibility: 1/2‖, 5/8‖, 3/4‖

See section ―optional accessories‖ for product numbers

REAMING BIT SPECIFICATIONS

Minimum wire diameter: 0.030‖ (0.8mm)

Maximum wire diameter: 0.063‖ (1.6mm)

WIRE CUTTING SPECIFICATIONS

Use recommended water based anti spatter fluid in this product.

See section ―optional accessories‖ for product numbers.

Do not use oil based anti spatter fluid.

ANTI SPATTER FLUID SPECIFICATIONS

POWER REAM – (K2391-1)

Caution: Use Filtered (5 µm), Non Lubricated, Regulated Air

POWER REAM

Page 7

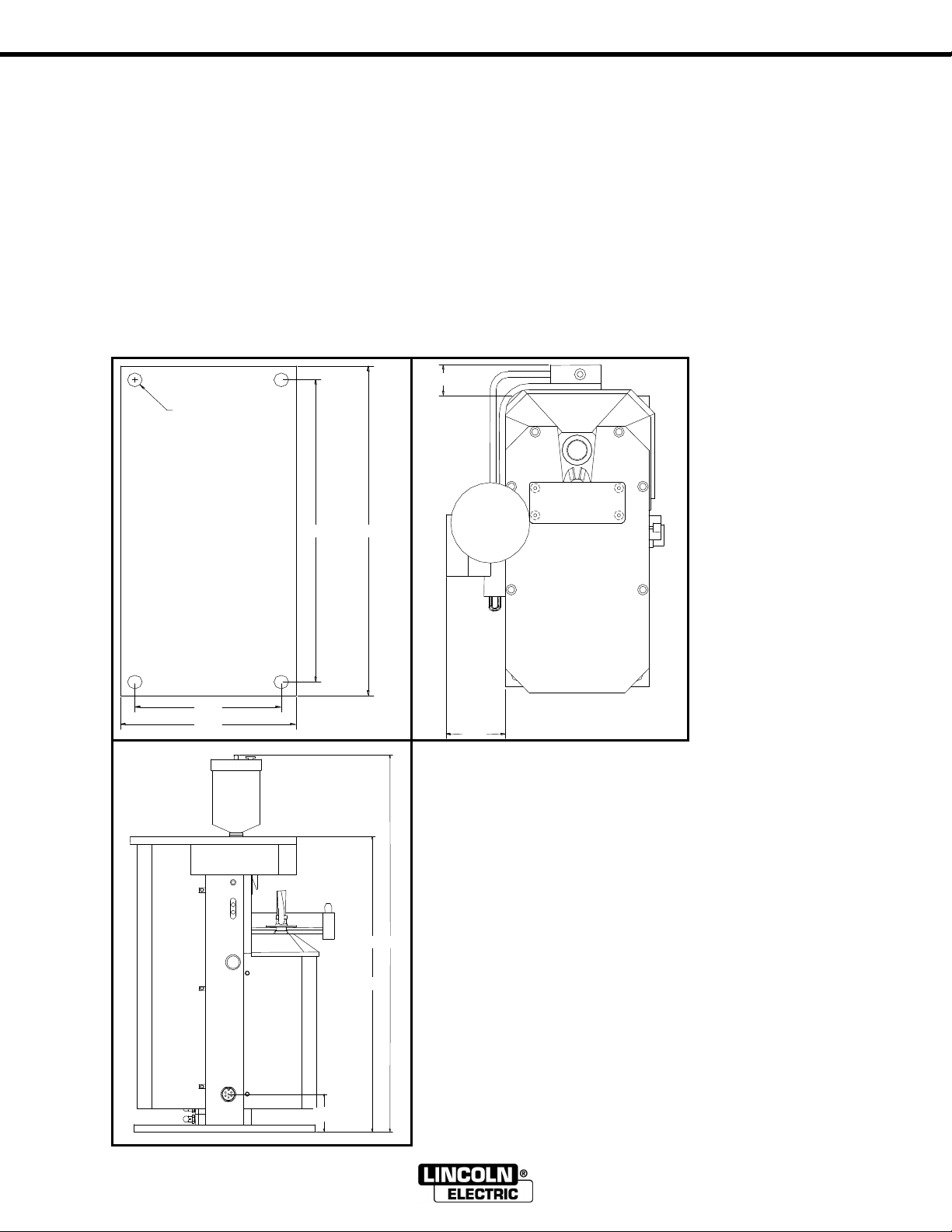

INSTALLATION - 7 -

12.00

11.00

5.00

6.00

Mounting Hole (4x)

1.25

2.47

2.50

24.90

19.50

Installation:

Before starting installation work in the area of the robot, ensure for your personal safety that all

protective measures have been taken and will remain in place while you are in the area of the

robot.

Danger of accident when connecting the pneumatic or electrical supply!

-Ensure that the air supply and electrical power to the torch maintenance center are

disconnected until the installation is complete.

-The torch maintenance center should be installed within the weld cell at a convenient location.

Be sure to consider movable fixtures, the confines of the robot and maintenance personnel

accessibility.

-Before operating the unit, ensure that the correct reaming bit for the torch is applied.

-Affix torch maintenance center base to sturdy platform using the four boltholes provided for 3/8‖

mounting hardware.

POWER REAM

Page 8

INSTALLATION - 8 -

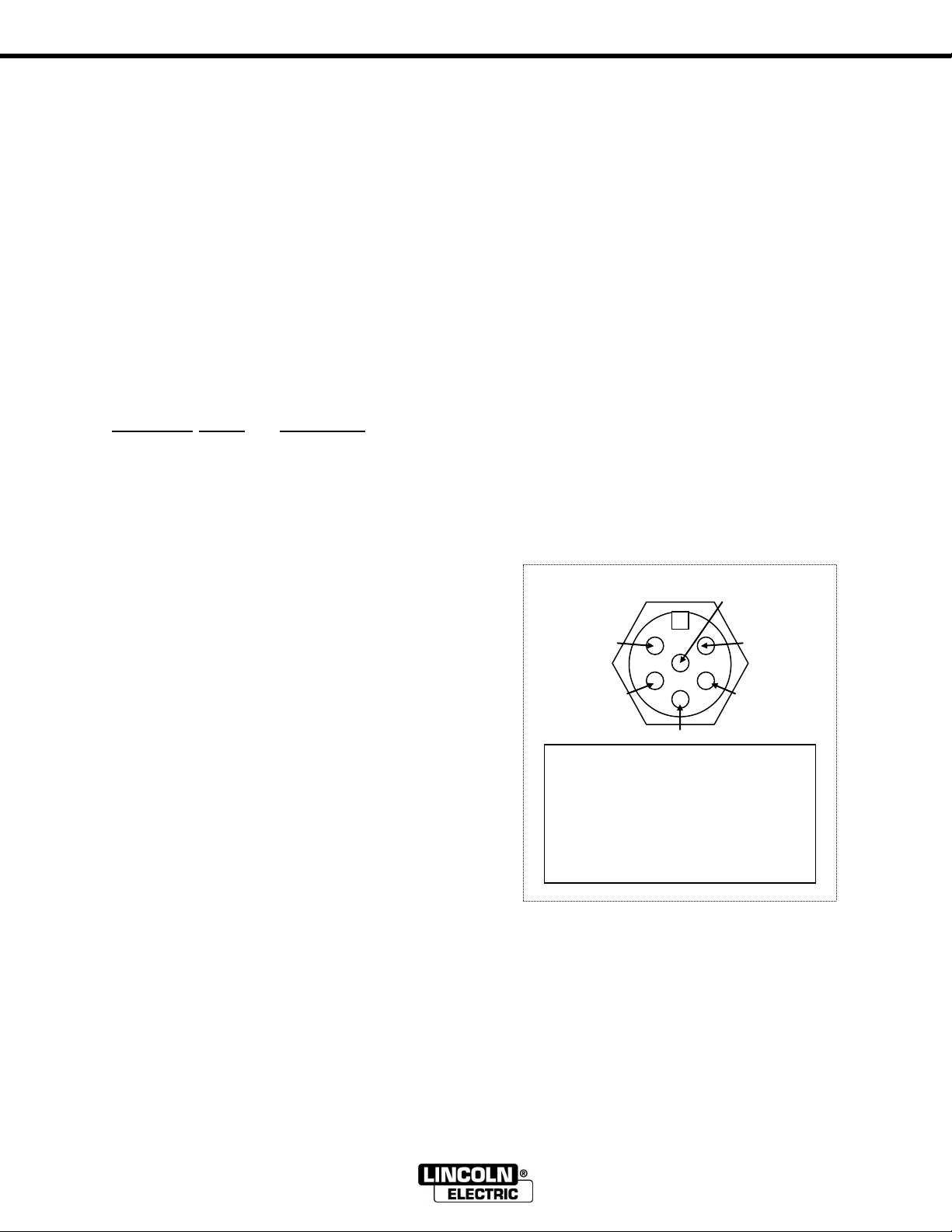

1 2 3 4 5

6

Wiring

1. 0V DC (WHT)

2. +24V DC (RED)

3. Complete (GRN)

4. Start (ORG)

5. Spray (BLK)

6. Error (BLU)

Interface Receptacle

Air Connection

Use only regulated, filtered, non lubricated air. Mount a 5 micron airline filter

(not supplied) in the airline of the reamer.

AIR SUPPLY REQUIREMENTS: 80 PSI at 15 SCFM. Connect the inlet

supply line to the quick connect pneumatic fitting located on the side of the

unit.

Electrical Connections

WARNING: Damage to equipment may occur if connected improperly.

Only a qualified technician should perform the following operation.

-Secure the 6-pin connector into the receptacle on the base of the POWER

REAM and feed the other end through a strain relief into the robot

controller cabinet or other connection points on the robotic cell.

-Connect robot I/O signals according to the following description.

Electrical Diagram

Wire Color Name Description

Red +24Vdc Power supply (+24Vdc, 0.5 amp)

White 0Vdc Power supply return.

It is recommended that power to the reamer be wired concurrent with robot servo power,

interrupt-able by an E-stop condition.

Orange Start Robot output. Pulse this

output from the robot for

0.5sec to start the ream cycle.

Black Spray Robot output. Pulse this

output from the robot for

approx. 0.5 sec while

positioned over the sprayer.

To activate the Wire Cutter,

turn on both the start and

spray outputs at the same

time or subsequently.

Green Complete Robot input. The robot should

check this input before and

after a reaming cycle.

Blue Error Robot input. The robot can

check this input after a

reaming cycle to ensure error

free operation. Refer to

Diagnostics section for error

codes.

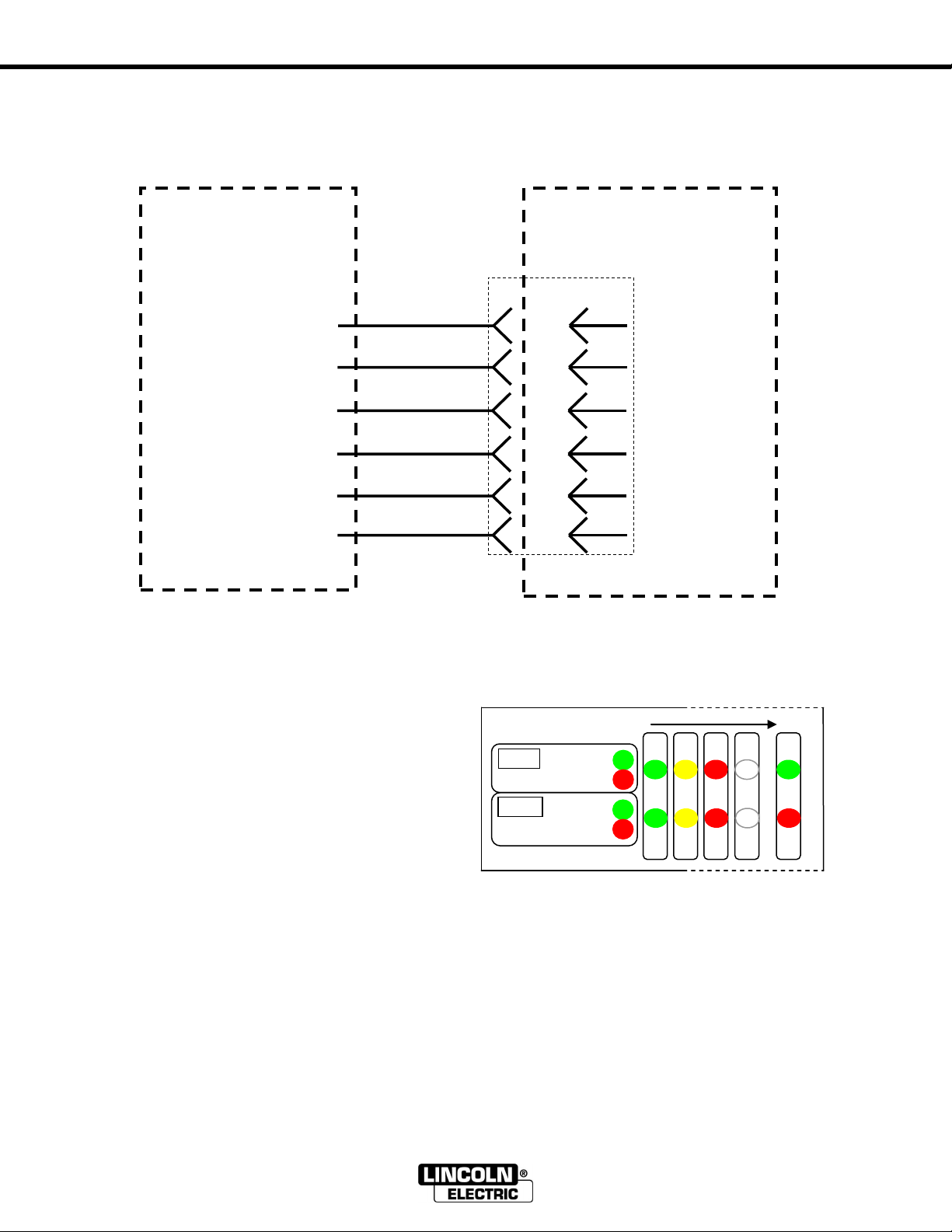

The POWER REAM detects sinking or sourcing outputs from the robot and is capable of sinking

or sourcing signals to the robot. Before connecting ensure I/O configuration is compatible with

robot. POWER REAM factory setup is for robots with sinking outputs and active high inputs.

POWER REAM

Page 9

INSTALLATION - 9 -

G

G

Clamp

Open

Closed

Lift

Top

Bottom

R R G

G

Y Y R

R

G

R

WELDING

ROBOT CELL

WIRES IN

CONTROL PANEL

0V

+24V

*DI-3

*DO-3

*DO-4

*DI-4

POWER REAM

K2391-1 or similar

equipment

1 0V

2 +24V

3 Complete

4 Start

5 Spray

6 Error

2 WHITE

1 or 27 RED

4 GREEN

3 ORANGE

5 BLACK

6 BLUE

Power Ream to Lincoln Electric Welding Robot Cell

*These labels are for reference only.

Power Up Sequence: Once the unit is wired into

the robot and power is applied the LEDs will

display the power up sequence (green – yellow –

red) and then show positions of the cylinders

according to the legend next to the LED window.

If the LEDs are not reporting the clamp open and

the lift at the bottom then check the air pressure or

position sensors. If the LEDs are flashing red or

green check for start lock (see below). If the LEDs

are flashing yellow ensure the setup pushbutton is

not pressed or defective.

Start Lock: The start lock feature guards against a start signal present when the unit is powered up. If a

start signal is present, the POWER REAM will not cycle immediately after powering up. The LEDs will

display the power up sequence (green-yellow-red) and then flash green / red if an output from the robot is

present.

Robot Input: With the clamp open and the lift at the bottom, the ―complete‖ input to the robot will be on.

If it is not, the robot input type may need to be configured.

Robot Output: If by forcing on the ―Start‖ or ―Spray‖ output from the robot no action occurs, the robot

output type may need to be configured.

POWER REAM

Page 10

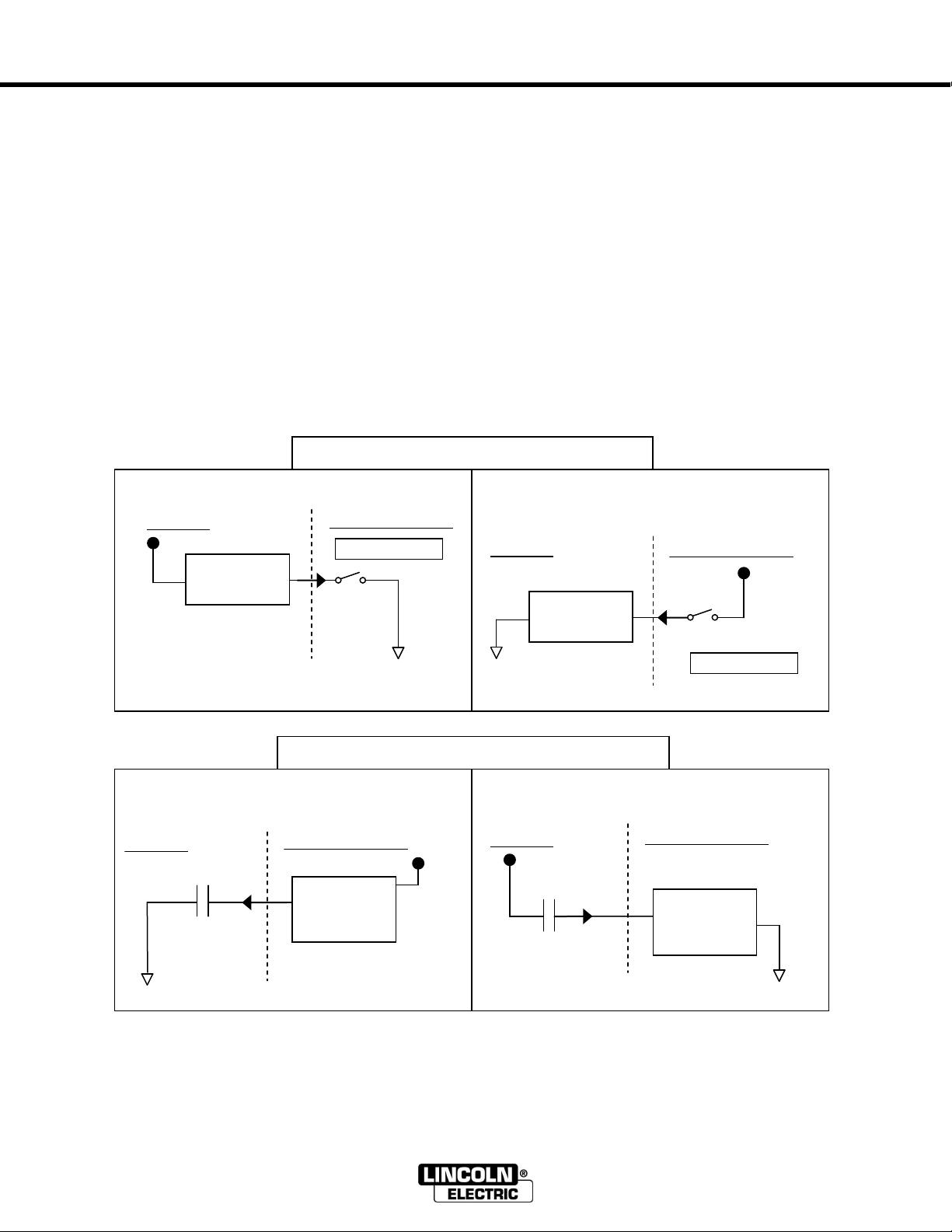

I/O Configuration - 10 -

Sinking Output: 0V when active

Sourcing Output: +24V when active

Active Low Input: 0V when activated

Active High Input: +24V when activated

Fanuc robots use the following output methods

Process I/O: Sink Output

Terminal I/O: Source Output

Model A I/O: Source Output

ROBOT INPUT TYPE

+24V

ROBOT OUTPUT TYPE

Input

Circuitry

(< 1mA)

ROBOT

POWER REAM

SINKING

OUTPUT*

0V

+24V

Input

Circuitry

(<1mA)

ROBOT

POWER REAM

SOURCING

OUTPUT

0V

+24V

Input

Circuitry

ROBOT

POWER REAM

ACTIVE LOW

INPUT

0V

+24V

Input

Circuitry

ROBOT

POWER REAM

ACTIVE HIGH

INPUT*

0V

Max. current is 1A

Max. current is 1A

+24V

I/O Explanation

The terms sinking and sourcing define the direction of DC current flow in a load.

A sinking output provides a path to 0V for the load. Common terms used to describe sinking devices

include NPN, Open Collector, Active Low and IEC Negative Logic. An active low input is connected to

the positive supply (+24V) to detect a sinking output.

A sourcing output provides the power to the load. Common terms used to describe sourcing devices

include PNP, Open Emitter, Active High and IEC Positive Logic. An active high input is connected to 0V

to detect a sourcing output.

Factory set options: Active high robot input. Sinking robot output.

POWER REAM

Page 11

I/O Configuration - 11 -

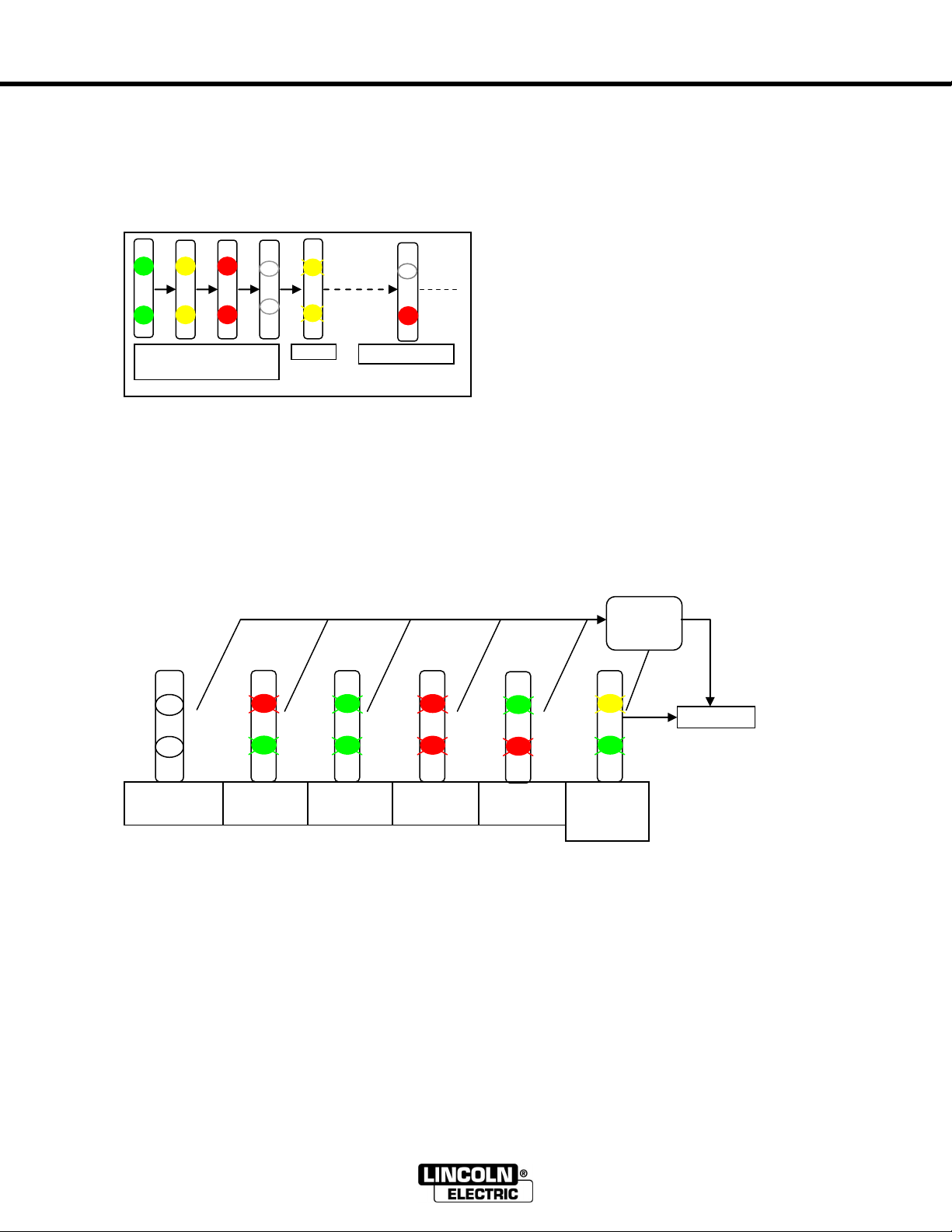

Power Up

Active High/

Sinking

Active Low/

Sinking

Active High/

Sourcing

Active Low/

Sourcing

AUTO

Active Low/

Sinking

Reset

button

PRESENT

Configuration

G G R

G

G

R R R Y G

G/R

G/R

(3 sec.)

Power up sequence

(1 sec.)

I/O configuration

-Release setup

pushbutton

Y Y R R R

G

G

Y

Y

The I/O types can be configured with the following procedure:

Press the reset and setup pushbuttons, release the reset pushbutton and continue to hold the

setup button for approximately 4 seconds (when the bottom LED is solid red).

During this time the LEDs will show the power-up sequence (green-yellow-red), then flash yellow for 3 seconds, then the bottom

LED will turn solid red. Release the setup button when the bottom LED is solid red. Continuing to hold the setup button will allow

access to further configurations as described in “Features Setup” section.

Upon releasing the setup push button, the lights will show the present I/O configuration. This is

the first in the sequence of teachable configurations.

Subsequent pressing and releasing of the setup button will sequence the following

configurations in order of appearance. To register the desired configuration, press the reset

button when that configuration is displayed.

The top indicator shows the robot input type (green = Active low, red = Active high*).

The bottom indicator shows the robot output type (green = Sinking*, red = Sourcing).

* Factory setup conditions

Auto Active Low/Sinking is for the automatic I/O configuration, setup as active low/sinking

initially (see automatic I/O configuration section for details). Choosing one of the other

configurations will disable this adaptability.

POWER REAM

Page 12

ROBOT PROGRAMMING - 12 -

―Complete‖ input

on?

Move to ―ream‖ position

Turn on ―Start‖ output

Move to ―wire cut‖

position

Inch wire for 0.5 sec.

Turn on ―spray‖ AND ― start‖ output

for 0.5 second.

Turn off ―start‖ and ―spray‖ outputs

Error

!

(at any time)

―Error‖ input

on?

Yes

No

Yes

Move to ―spray‖ position

Pulse ―spray‖ output for 0.5 second

Move to next position

Wait 0.5 sec

Turn off ―Start‖ output

Wait for ―Complete‖

input to turn on

The following flow diagram shows the recommended procedure for wire cutting, reaming, and

spraying sequences. Use the robot controller to implement this sequence.

POWER REAM

Page 13

ROBOT PROGRAMMING - 13 -

POWER REAM programming example for Fanuc robots

1: DO[28]=PULSE,.5SEC; Inch wire out for ½ second

2: CALL HOME; Safe home point position

3: IF DI[3]=OFF,JMP LBL[1]; Check if the reamer is ready

4: J P[1] 100% FINE; Safe approach point over wire cutter

5: L P[3] 500IPM FINE; Wire cut position (see illustration)

6: DO[3]=PULSE,.5SEC; Pulse reamer “start” signal, and…

7: DO[4]=PULSE,.5SEC; Pulse reamer “spray” signal to cut

8: WAIT .5SEC; Wait for the wire cutter

9: WAIT DI[3]=ON; Wait for reamer “complete” signal

10: L P[2] 500IPM FINE; Ream position (see illustration)

11: DO[3]=ON; Turn on reamer

12: WAIT 2SEC; Adjustable time for reaming operation

13: DO[3]=OFF; Turn off reamer

14: WAIT DI[3]=ON; Wait from reamer “complete” signal

15: L P[4] 500IPM FINE; Spray position (see illustration)

16: DO[4]=PULSE,.5SEC; Pulse anti-spatter spray

17: L P[5] 500IPM FINE; Pull out point from spray position

18: LBL[1]; Label for JMP statement, line 2

19: CALL HOME; Return to home point position

NOTE: The I/O points may be different, configuration specific.

How to teach reaming program instructions

CALL HOME; Press NEXT key, press F1 INST key, cursor to line CALL, Enter. At new

submenu, cursor to line Call Program, Enter. Now cursor to program

HOME, Enter.

DO[28]=PULSE,.5SEC; Press NEXT key, press F1 INST key, cursor to line I/O, Enter, cursor to

line DO=...., Enter, Key in (28), Enter, At new submenu, cursor to desired

line Pulse, Enter, key in desired time (.5), Enter.

IF DI[3]=OFF,JMP LBL[1]; Press NEXT, press F1 INST key, cursor to line IF/SELECT, Enter, cursor

to line IF?.=?., Enter, cursor to line DI, Enter, Key in 3, Enter, cursor to

OFF, Enter, cursor to JMP LBL, Enter Key in 1, Enter.

DO[3]=ON or OFF Press NEXT key, press F1 INST key, cursor to line I/O, Enter, cursor to

line DO[ ]=…, Enter, key in a 3, Enter, At new submenu, cursor to

desired line On or Off, Enter

WAIT 2SEC; Press NEXT key, cursor to line WAIT, Enter, at new submenu, cursor to

line WAIT… (sec), Enter, key in desired number of seconds, Enter.

WAIT DI[3]=ON; Press NEXT key, press F1 INST key, cursor to line WAIT, Enter, cursor

to line WAIT…, Enter. At new submenu, cursor to line DI[ ], Enter, key in

a 3, Enter. At new submenu, cursor to line ON, Enter.

DO[3]=PULSE,.3SEC; Press NEXT key, press F1 INST key, cursor to line I/O, Enter, cursor to

line DO[ ]=…, Enter, Key in desired output (3), Enter. At new submenu,

cursor to desired line Pulse, Enter, key in desired time (.5), Enter

POWER REAM

Page 14

ROBOT PROGRAMMING - 14 -

Robot Position Programming

The POWER REAM features a ―no trial, no error‖ position programming technique as described below:

1. Wire cut Position: Center the nozzle at the desired stick-out height above the wire cutter. Record this

position as the ―Wire Cut‖ position described in ―Robot Control Programming‖ section above.

2. Hold the ―Setup Sequencer‖ button to raise the reamer. This will lift the reamer without spinning.

WARNING: the lift will operate under this condition. KEEP HANDS CLEAR

of the operating space of the reamer. This device is intended for one-man

operation during setup.

Once the reamer is at the top position (―Lift‖ indicator is green), release the ―Setup

Sequencer‖ button.

3. Using the robot, move the torch nozzle into the clamp such that the reaming bit is inset to the full depth

required inside the nozzle.

4. Press and release the ―Setup Sequence‖ button to verify all four faces of the clamp engage the

cylindrical body of the nozzle equally, and that the nozzle does not change orientation or position when

clamped.

WARNING: the clamp will operate under this condition,

KEEP HANDS CLEAR of the operating space of the clamp

and wire cutter. This device is intended for one-man

operation during setup.

5. Register this position in the robot controller using a fine position level as the ―ream position‖ described

in flow diagram above.

6. Press the ―Reset‖ button until the reamer lowers. The reamer will lower without spinning, and the clamp

will open

WARNING: the lift and clamp will operate under this

condition. KEEP HANDS CLEAR of the operating space of

the reamer. This device is intended for one-man operation

during setup.

7. Spray Position: Center the nozzle 1½ inches above the spray head. Record this position as the

―Spray‖ position described in the flow diagram above.

Note: The fluid line takes approximately 10 seconds to prime. The sprayer has a built in post-flow timer of

1 second. Airflow from the nozzle will be present for 1 second after the spray output is turned off.

Wire Cut Position Ream Position Spray Position

POWER REAM

Page 15

OPERATION - 15 -

G R G

R

Clamp

Open

Closed

Lift

Top

Bottom

R R R Y R G R Y R R G R G

R

Ready

Clamp

Closed

Raising

Reamer

Reamer at

Top

Lowering

Reamer

Reamer at

Bottom

Clamp

Open

1 2 3 4 5 6 7

Pulse 0.5s

Off

Off

Off

Off

Off

On

Off

Off

Off

Off

Off

On

On

―Start‖ Output from robot

―Complete‖ Input to robot

Operation

The following diagram shows the 7-step reaming sequence and color of the indicator lights at each stage.

The indicator lights show the position of the clamp and lift cylinders on the user interface.

The above diagram shows the robot input and output as the sequence progresses.

Automatic Retry

If excessive spatter is built up in the nozzle, or programmed position of the nozzle is off center

not allowing reamer to extend to full depth within a specific amount of time, the POWER REAM

will automatically retry once.

Cycle Optimization

The lift rate of the reaming bit will determine how many reaming

revolutions will occur within the nozzle. This parameter should be

set based on the amount of spatter built up in the nozzle between

reaming cycles. More spatter buildup will require a slower lift rate.

Less spatter buildup will allow a faster lift rate.

To set the lift rate, remove the front cover and adjust the top

needle valve. Turning clockwise will decrease the lift rate (for more

spatter removal), and turning counter clockwise will increase the lift

rate.

To set the retracting rate, adjust the bottom needle. Turning

clockwise will decrease the retracting rate, and turning counter

clockwise will increase the retracting rate.

POWER REAM

Page 16

FEATURE SETUPS - 16 -

[Off]

[On]

[Off]

Power-up

Reset button

R Y G

3 sec

5 sec

7 sec

10 sec

Blow-off

Mode

I/O

Power-up

Press and Hold

Release

Setup

Press and Release

G G Y Y R

R

Y Y Y

Y

Power up sequence

Setup

Several features may be setup to optimize performance of the POWER REAM. To access the

configuration menus press the reset and setup pushbuttons, release the reset pushbutton and

continue to hold the setup button for the specified time shown below. The LEDs will change

color pattern to indicate the menu that is accessible at a specific time. Release the setup button

when the color pattern is shown for the desired configuration menu.

The default setting is first and last in the sequence of each configuration menu.

I/O configuration menu: See I/O configuration section on previous pages.

Blow-off: The motor spins and exhausts (blowing off over spray) for two seconds after spraying.

The blow-off feature can be configured by the following procedure.

Follow the steps outlined above to access the blow-off configuration menu. Upon releasing the

setup push button, the lights will flash red on top and blank on bottom. This is the first in the

sequence of teachable configurations.

Subsequent pressing and releasing of the setup button will sequence the following

configurations in order of appearance. To register the desired configuration, press the reset

button when that configuration is displayed.

Blow-off configurations;

Off: This feature is disabled.

On: This feature is enabled.

POWER REAM

Page 17

FEATURE SETUPS - 17 -

[Dry Run]

[Timed]

[Open]

[Blind]

[Automatic]

Power up

Reset

button

[Automatic]

G

G

Running Modes. Several running modes are available to select from.

Automatic: Every aspect of the operation is commanded, monitored and checked by the

controller.

Dry Run: Same as automatic mode, but the motor is disabled.

Timed: Bypass the "extended" sensor on the lift cylinder. The robot must hold the start signal

on for the reaming time. Auto Retry is disabled in this and the following modes.

Open: Bypass the "extended" and "retracted" sensor. The robot must hold the start signal on

for the reaming time and hold the robot in the clamp until the reaming bit is fully retracted.

Blind: Bypass all sensors. The robot must hold the start signal on for the ream time and hold

the torch in the jaws until the reaming bit is fully retracted and the clamp is fully opened.

Mode configuration: A specific running mode can be configured by the following procedure.

Follow the steps outlined above to access the mode configuration menu. Upon releasing the

setup push button, the lights will flash green on top and bottom. This is the first in the sequence

of teachable configurations.

Subsequent pressing and releasing of the setup button will sequence the following

configurations in order of appearance. To register the desired configuration, press the reset

button when that configuration is displayed.

POWER REAM

Page 18

AUTOMATIC I/O CONFIGURATION - 18 -

Power-up

―Complete‖

input on?

Turn on/off ―Spray‖ output

Sprayer

operates?

Turn off ―Spray‖ output.

I/O configuration complete

Turn OFF the ―Spray‖ signal.

Set I/O configuration using

the procedure outlined on

pg. 11

Yes

Yes

No

No

Power up sequence

G G G

R

Ready

Y Y R

R

G

R

Clamp

Open

Closed

Lift

Top

Bottom

R R G

G

Ensure the clamp is open

and the lift is at the bottom.

The LEDs on the control

panel should show the

following colors:

―Complete‖

input on?

Yes

Set I/O configuration using

the procedure outlined on

pg. 11

No

Automatic I/O configuration procedure:

The POWER REAM has an auto configuration I/O feature that is turned on by setting the I/O

configuration to AUTO (see I/O configuration section). The automatic I/O configuration works as

follows;

-The POWER REAM detects the type of robot input (active high / active low) when power is

applied or after resetting. Once detected, the POWER REAM outputs are configured.

-The POWER REAM senses and configures its inputs when the robot sends an output signal

(sinking or sourcing).

Use the following procedure to ensure that the POWER REAM is configured to the correct I/O

type using auto configuration. ―Spray‖ refers to the spray output from the robot and ―Complete‖

refers to the complete input to the robot.

CAUTION: the sprayer will operate in this procedure;

KEEP EYES AWAY from the sprayer

POWER REAM

Page 19

MAINTENANCE AND TROUBLESHOOTING - 19 -

Problem

Possible Cause

Solution

No Indicator lights

-Power is off

-Fuse is blown (robot cabinet)

-Reset button defective

-Circuit board defective

-Turn power on

-Replace fuse

-Replace reset button

-Replace circuit board

Reamer stops rotating

-Insufficient air supply

-Excessive spatter buildup

-Dry run mode selected

-Set to 80psi

-Ream more often

-Select automatic mode

Clamp/Motor/Lift not working

-Insufficient air supply

-Air line cut or twisted

-Reset button defective

-Check error codes

-Set to 80psi min

-Replace airline

-Replace reset button

Reamer does not go down

-Ream bit jammed in nozzle

-Lift cylinder defective

-Top sensor defective

-―Start‖ output held on

-Check error codes

-Replace damaged parts

-Replace lift cylinder

-Replace top sensor

-Pulse ―Start‖ output 0.5 sec

Robot cannot start a cycle

or

Robot cannot complete a cycle

- ―Complete‖ signal not

responding

-Check error codes

No Anti-Spatter liquid

Or air flow from sprayer

-Insufficient air supply

-Solenoid valve defective

-Spray nozzle clogged

-Set to 80psi

-Replace solenoid valve

-Clean or replace spray nozzle

*hand tighten only

Air flow from sprayer but

no Anti-Spatter liquid

-Check anti-spatter level

-Check vent on reservoir

-Fluid line blocked

-Spray nozzle clogged

-Refill reservoir

-Open vent if closed

-Clean or repair fluid line

-Clean or replace spray nozzle

*hand tighten only

MAINTENANCE

The POWER REAM will require periodic maintenance to ensure a dependable service life. The following

schedule is recommended.

Shut off the air supply and disconnect robot control cable when making adjustments.

DAILY

• Clean surface under reaming bit.

• Check airlines for leaks and robot control cable for splits or cracks.

• Clean clamp gripping surfaces to ensure optimal nozzle gripping.

WEEKLY

• Check the fluid level in spray reservoir.

• Check the reaming bit visually.

• Check the wire cutter visually.

The service life of the cutting edges are dependant on the type of application. Inspect for dullness and

possible breakage.

YEARLY

• Inspect drive belt for wear and tension. Replace if excessive wear is evident.

TROUBLESHOOTING

POWER REAM

Page 20

Diagnostics - 20 -

2: Closing Fault: the clamp took too long to close.

-Check air inlet pressure

-Check clamp sensor

-Check clamp air lines

-Check clamp solenoid.

-Check clamp cylinder

3: Raising Fault: The lift cylinder took too long to extend from the bottom limit

-Check air inlet pressure

-Check extending needle valve (top needle valve on lift cylinder)

-Check bottom sensor.

-Check lift air lines

-Check lift solenoid.

-Check lift cylinder

4: Extending Fault: The lift cylinder took too long to fully extend.

-Automatic retry; excessive spatter build up in the nozzle (ream more often), or incorrect programmed position of

the nozzle, not allowing reamer to extend to full depth.

-Check air inlet pressure

-Check extending needle valve (top needle valve on lift cylinder)

-Check top sensor.

-Check lift air lines

-Check lift solenoid.

-Check lift cylinder

5: Lowering Fault: The lift cylinder took too long to retract from the top while lowering

-Check air inlet pressure

-Check retracting needle valve (bottom needle valve on lift cylinder)

-Check top sensor.

-Check lift airlines.

-Check lift solenoid.

-Check lift cylinder.

6: Retracting Fault: The lift cylinder took too long to fully retract.

-Check air inlet pressure

-Check retracting needle valve (bottom needle valve on lift cylinder)

-Check bottom sensor.

-Check lift airlines.

-Check lift solenoid.

-Check lift cylinder.

7: Opening Fault: the clamp took too long to open.

-Check air inlet pressure

-Check clamp sensor.

-Check clamp cylinder airlines.

-Check clamp solenoid.

-Check clamp cylinder.

Y

The POWER REAM reports errors using the indicator lights on the user interface

When an error is reported, the indicator light flashes at a rate of 2 flashes per second

Error: When an error occurs during the reaming process; the clamp opens, the lift lowers, and the

diagnosis is shown with the top indicator light in yellow. The light will flash a certain number of times,

pause, then repeat. The error count begins at 2.

Count the number of flashes between the pause and use the following chart to find the cause of the

problem.

Note: The robot ―start‖ signal may be used to reset an error so that the operator does not have to go

inside the robotic welding cell. For example, if the air supply was not turned on the operator may turn it

on and reset the error by cycling the start output from the robot pendant.

POWER REAM

Page 21

Parts Replacement - 21 -

1 2 3

4

1

Reaming Bit Replacement

Disconnect air and electrical supply.

Hold the reaming rod, item 1, from

rotating with 5/8‖ wrench under the

washer.

Unfasten the reaming bit, item 2,

with a second 5/8‖ wrench.

Remove the reaming bit, item 3.

Insert the new reaming bit through

the flat washer, item 4.

Insert the reaming bit into the ream

rod.

Hold the reaming rod from rotating

with a 5/8‖ wrench under the

washer.

Tighten the reaming bit with a

second 5/8‖ wrench.

Reconnect air and electrical supply.

Spray Nozzle Replacement

Disconnect air and electrical supply.

Unscrew spray nozzle, item 1, by

hand.

Insert new spray nozzle.

TIGHTEN BY HAND ONLY

Reconnect air and electrical supply.

POWER REAM

Page 22

Parts Replacement - 22 -

1

4 2 3

1

2

Wire Cutter Replacement

Disconnect air and electrical supply.

Unfasten (4) #8-32 flat head socket

cap screws, item 1.(3/32‖ hex drive)

Remove wire cutter module, item 2.

Insert new wire cutter module.

NOTE: The cutters will close slightly

when positioning the rollers against the

wedge.

Fasten (4) #8-32 flat head socket

cap screws, item 1. Apply medium

strength threadlocker. (3/32‖ hex

drive)

Reconnect air and electrical supply.

PC Board Replacement

Disconnect air and electrical supply.

Loosen (6) button head cap screws ,

item 1, to remove rear cover.

(5/32‖ hex drive)

Remove (7) connectors, item 2,

from PC board.

Remove (5) #6-32 socket head cap

screws, item 3, from PC board.

(7/64‖ hex drive)

Remove PC board, item 4.

Insert new PC board.

Follow steps in reverse order to

reassemble unit.

POWER REAM

Page 23

Parts Replacement - 23 -

9

10

1

2

3 4 5 6 8

7

Belt Replacement

Disconnect air, item 1,

and electrical supply, item2.

Loosen (6) button head cap

screws, item 3, to remove rear

cover. (5/32‖ hex drive)

Check and note the belt tension, item 4.

Remove (2) 6mm hex head bolts,

item 5. (10 mm wrench)

Slide motor forward to slip belt off

motor gear and remove motor,

item 6.

Remove (4) button head cap screws,

item 7, to remove front cover

(5/32‖ hex drive)

Remove (4) socket head cap screws

and lock washers, item 8, from

bottom plate of motor carriage.

(3/16‖ hex drive)

Remove (2) side plates, item 9.

Lift up on the front gear, slip belt off

and remove belt, item 10.

Lift up on the front gear, slip new

belt over front gear.

Follow steps in reverse order to

reassemble unit.

Apply medium strength threadlocker

to item 5.

POWER REAM

Page 24

Parts Replacement - 24 -

4

1 2 5 3 6 5 4 3 2

1

Air Motor Replacement

Disconnect air and electrical supply.

Loosen (6) button head cap screws,

item 1, to remove rear cover.

(5/32‖ hex drive)

Disconnect hoses 111 and 112,

item 2, from the motor.

Check and note the belt tension,

item 3.

Hold the motor from below and

remove (2) 6mm hex head bolts,

item 4. (10mm wrench)

Slip belt off motor gear and remove

motor, item 5.

Insert new motor into mount.

Follow steps in reverse order to

reassemble unit.

Apply medium strength threadlocker

to item 4.

Motor Solenoid Replacement

Disconnect air and electrical supply.

Loosen (6) button head cap screws,

item 1, to remove rear cover.

Remove electrical connector, item 2,

from motor solenoid.

(Star screwdriver)

Disconnect hose 111, item 3,from

motor solenoid.

Remove (2) #8-32 socket head cap

screws, item 4, from solenoid.

(9/64‖ hex drive)

Remove motor solenoid, item 5.

Disconnect hose 110, item 6,from

motor solenoid.

Follow steps in reverse order to

reassemble unit.

POWER REAM

Page 25

Parts Replacement - 25 -

7

1 2 3 4 5

6

Lift\Clamp Solenoid Replacement

Note: The lift and clamp cylinder solenoids are stacked. The top solenoid is for the clamp cylinder, the

bottom solenoid is for the lift cylinder. Similar procedures are used for each solenoid.

Disconnect air and electrical supply.

Loosen (6) button head cap screws,

item 1, to remove rear cover.

(5/32‖ hex drive)

Lift Solenoid: Disconnect hose 130

from solenoid in-port, item 2.

Clamp Solenoid: Disconnect hose

120, item 3, from solenoid in-port.

Remove(2) #4-40 socket head cap

screws, item 4, from solenoids.

(3/32‖ hex drive)

Remove electrical connector, item 5,

from solenoid. (star screwdriver)

Lift Solenoid: Disconnect hose 131

and 132 from solenoid out-port,

item 6.

Clamp Solenoid: Disconnect hose

121 and 122 from solenoid out-port,

item 7.

Remove solenoid, insert new

solenoid.

Follow steps in reverse order to

reassemble unit.

POWER REAM

Page 26

Parts Replacement - 26 -

6 8 1 4 5 3 2

Clamp Cylinder Replacement

Disconnect air and electrical supply.

Loosen (6) button head cap screws,

item 1, to remove rear cover.

Remove (6) socket head cap

screws, item 2, to remove top

cover.(3/16‖ hex drive).

Disconnect hose 121 and 122,

item 3, from cylinder in-ports.

Remove reed switch, item 4, from

cylinder.(5/64‖ hex drive)

Remove (2) #10-24 flat head socket

cap screws, item 5, to remove

wedge plate. (1/8‖ hex drive)

Unfasten cylinder rod, item 6, from

T-nut. (3/8‖ wrench)

Loosen and remove cylinder nut,

item 7, (1 1/8‖ wrench)

Remove cylinder, item 8.

Follow steps in reverse order to

reassemble unit.

Apply medium strength threadlocker

to item 5, 6 and 7.

Check the position of

reed switch, item 4. The led

should be on when the clamp is

open with electrical supply

connected.

POWER REAM

Page 27

Parts Replacement - 27 -

1 3 4 5 6

7

1

10

2

Spray Solenoid Replacement

Disconnect air and electrical supply.

Loosen (6) button head cap screws,

item 1, to remove rear cover.

Remove (2) wires, item 2, from

10-position connector

(pins 9 and 10 at the bottom).

Pull wires, item 3, through the hole

in main unit to the outside.

Unfasten bottom nut, item 4, of

compression fitting. (9/16‖ wrench)

DO NOT REMOVE

Remove (2) #4-40 socket head cap

screws, item 5, from spray solenoid.

(3/32‖ hex drive)

Raise spray solenoid valve while

detaching plastic fitting, item 6, from

the side.

Remove spray solenoid, item 7.

Follow steps in reverse order to

reassemble unit.

When tightening bottom nut, item 4,,

DO NOT OVER TIGHTEN

POWER REAM

Page 28

Parts Replacement - 28 -

1 2 3 4 5 6 7

Fluid Solenoid Replacement

Disconnect air and electrical supply.

Remove anti spatter fluid reservoir,

item 1. (3/4‖ wrench)

WARNING: Contents may spill.

Remove bottom nut, item 2, of

compression fitting. (9/16‖ wrench)

Remove electrical connector, item 3,

from fluid solenoid valve.

(star screwdriver)

Remove (2) 4-40 socket head cap

screws, item 4, from spray solenoid.

(3/32‖ hex drive)

Remove (2) #8-32 socket head cap

screws, item 5, from spray assembly

plate. (9/64‖ hex drive)

Raise spray plate item 6.

Remove (2) 3mm socket head cap

screws, item 7, from back of spray

assembly plate and replace fluid

solenoid. (3/32‖ hex drive)

Follow steps in reverse order to

reassemble unit.

When tightening bottom nut, item 2,

DO NOT OVER TIGHTEN

POWER REAM

Page 29

PNEUMATIC DIAGRAM - 29 -

112

R1

P

B

A

R2

R2

A

P

R1

B

111

110

100

120

130

140

121

122

131

132

Note: All locations are referenced from the back of the unit

Additional pneumatic troubleshooting information:

Air enters the unit through hose 100 and is distributed to the solenoids through the manifold

Hose 110 feeds the motor solenoid. Air flows through hose 111 and 112 when the motor is on.

Hose 120 feeds the clamp solenoid. Hose 121 is normally pressurized, keeping the clamp in the open

position. When the clamp is closed hose 122 become pressurized. Air flows through lines 121, 122,

and out the breather vents of the clamp solenoid when opening or closing.

Hose 130 feeds the lift solenoid. Hose 131 is normally pressurized, keeping the lift in the bottom

position. When the lift is raised hose 132 becomes pressurized. Air flows through lines 131, 132, and

out the breather vents of the lift solenoid when raising or lowering

Hose 140 feeds the spray solenoid. Air flows through the tubing when the sprayer is on.

POWER REAM

Page 30

ELECTRICAL DIAGRAM - 30 -

Note: All locations are referenced

from the back of the unit

POWER REAM

Page 31

ELECTRICAL DIAGRAM - 31 -

Wire #

Description

Active

Voltage

Inactive

Voltage

101 to 102

Start output from robot

24V sourcing

0V sinking

0V sourcing

24V sinking

12V auto detect

103 to 102

24V power

24V

0V

104 to 102

Finished input to robot

24V sourcing

0V sinking

Floating

105 to 102

Spray output from robot

24V sourcing

0V sinking

0V sourcing

24V sinking

12V auto detect

106 to 102

Error input to robot

24V sourcing

0V sinking

Floating

201 to 203

Extended reed sensor

1.5V

23.3V

301 to 302

Retracted reed sensor

1.5V

23.3V

502 to 501

Fluid solenoid

24V

0V

504 to 503

Motor solenoid

24V

0V

506 to 505

Lift solenoid

24V

0V

508 to 507

Clamp solenoid

24V

0V

510 to 509

Spray solenoid

24V

0V

601 to 602

Setup pushbutton

0V

5V

604 to 603

Reset pushbutton

0V

5V

Additional electrical troubleshooting information:

Use the wire numbers in the following table to take readings with a voltmeter.

Connect the (+) lead to the first wire number and the (-) lead to the second wire number.

Note: all voltage readings +/- 10%

POWER REAM

Page 32

PARTS DIAGRAM - 32 -

4

1

2

3

ITEM

PART #

DESCRIPTION

1

G4827-3

CLAMP ASSEMBLY

2

G4827-4

WEDGE ASSEMBLY

3

G4827-5

CLAMP CYLINDER ASSEMBLY

4

G4827-6

WIRE CUTTER ASSEMBLY

POWER REAM

TABLE 2

Page 33

PARTS DIAGRAM - 33 -

14

10a

11a

15a

15b

9a

5a

6

7

10

11

12

15

13

9

8

5

ITEM

PART #

DESCRIPTION

5

G4827-7

FLUID RESERVOIR ASSEMBLY

5A

G4827-8

RESERVOIR LID

6

G4827-9

FLUID SOLENOID ASSEMBLY

7

G4827-10

SPRAY SOLENOID ASSEMBLY

8

KP2435-4

REAMING BIT, 5/8‖ (W/WASHER)

8A

G4827-1

REAMING BIT WASHER

9

G4827-11

SPRAY NOZZLE ASSEMBLY

9A

G4827-12

SPRAY NOZZLE

10

G4827-13

DOME ASSEMBLY

10A

G4827-14

ROD WIPER SEAL

11

G4827-15

CARRIAGE ASSEMBLY

11a

G4827-16

TIMING BELT

12

G4827-17

LIFT CYLINDER ASSEMBLY

13

G4827-18

EXTENDED SENSOR ASSEMBLY

14

G4827-19

RETRACTED SENSOR ASSEMBLY

15

G4827-20

FRAME ASSEMBLY

15A

G4827-21

FRONT COVER

15B

G4827-22

BACK COVER

POWER REAM

Page 34

PARTS DIAGRAM - 34 -

21

19

24

16

18

20

17

25

22

23

26

ITEM

PART #

DESCRIPTION

16

G4827-23

OPEN SENSOR ASSEMBLY

17

G4827-24

EXHAUST MUFFLER ASSEMBLY

18

G4827-25

RESET PUSHBUTTON ASSEMBLY

29

G4827-26

MOTOR SOLENOID ASSEMBLY

20

G4827-27

P.C. BOARD W/ MICROCONTROLLER

21

G4827-28

SETUP PUSHBUTTON ASSEMBLY

22

G4827-29

AIR MOTOR ASSEMBLY

23

G4827-30

AIR DISTRIBUTION ASSEMBLY

24

G4827-31

ROBOT CONNECTOR ASSEMBLY

24A

K2433-1

POWER REAM ROBOT CABLE, 20 FT

25

G4827-32

CYLINDER SOLENOID ASSEMBLY (2)

26

S23044

PNEUMATIC FITTING (1/4 ― NPT)

POWER REAM

Page 35

OPTIONAL ACCESSORIES - 35 -

PART NO.

DESCRIPTION

KP2435-1

REAMING BIT, ½‖ (W/WASHER)

KP2435-3

REAMING BIT, 5/8‖ (15.5mm) (W/WASHER)

KP2435-5

REAMING BIT, ¾‖ (W/WASHER)

KP2457-1

ANTI SPATTER FLUID, 1 GALLON

K2433-1

POWER REAM ROBOT CABLE, 20FT

K2434-1

REMOTE POWER REAM RESERVOIR KIT

S22633-50

CONNECTOR, PLUG, HONDA, 50 SOCKET

S22510-1

CONNECTOR, COVER, HONDA, STRAIGHT, 50 PIN

POWER REAM

Page 36

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

• World's Leader in Welding and Cutting Products •

Loading...

Loading...