Page 1

Operator’s Manual

RETURN TO MAIN MENU

™

PRODUCTION MONITORING 2.2

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM8001 | Issue D ate June -13

© Lincoln Global, Inc. All Rights Reserved.

Register your machine:

www.lincolnelectric.com/registration

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Need Help? Call 1.888.935.3877

to talk to a Service Representative

Hours of Operation:

8:00 AM to 6:00 PM (ET) Mon. thru Fri.

After hours?

Use “Ask the Experts” at lincolnelectric.com

A Lincoln Service Representative will contact you

no later than the following business day.

For Service outside the USA:

Email: globalservice@lincolnelectric.com

Page 2

THANK YOU FOR SELECTING

A QUALITY PRODUCT BY

LINCOLN ELEC TRIC.

PLEASE EXAMINE CARTON AND EQUIPMENT FOR

DAMAGE IMMEDIATELY

When this equipment is shipped, title passes to the purchaser upon

receipt by the carrier. Consequently, Claims for material damaged in

shipment must be made by the purchaser against the transportation

company at the time the shipment is received.

SAFETY DEPENDS ON YOU

Lincoln arc welding and cutting equipment is designed and built with

safety in mind. However, your overall safety can be increased by

proper installation ... and thoughtful operation on your part.

DO NOT INSTALL, OPERATE OR REPAIR THIS EQUIPMENT

WITHOUT READING THIS MANUAL AND THE SAFETY PRECAUTIONS

CONTAINED THROUGHOUT. And, most importantly, think before you

act and be careful.

WARNING

This statement appears where the information must be followed

exactly to avoid serious personal injury or loss of life.

CAUTION

This statement appears where the information must be followed to

avoid minor personal injury or damage to this equipment.

KEEP YOUR HEAD OUT OF THE FUMES.

DON’T get too close to the arc. Use

corrective lenses if necessary to

stay a reasonable distance away

from the arc.

READ and obey the Material Safety

Data Sheet (MSDS) and the warning

label that appears on all containers

of welding materials.

USE ENOUGH VENTILATION or

exhaust at the arc, or both, to keep

the fumes and gases from your breathing zone and the general area.

IN A LARGE ROOM OR OUTDOORS, natural ventilation may be

adequate if you keep your head out of the fumes (See below).

USE NATURAL DRAFTS or fans to keep the fumes away from your

face.

If you de velop unusual symptoms, see your supervisor. Perhaps the

welding atmosphere and ventilation system should be checked.

WEAR CORRECT EYE, EAR & BODY PROTECTION

PROTECT your eyes and face with welding helmet

properly fitted and with proper grade of filter plate

(See ANSI Z49.1).

PROTECT your body from welding spatter and arc

flash with protective clothing including woolen

clothing, flame-proof apron and gloves, leather

leggings, and high boots.

PROTECT others from splatter, flash, and glare with

protective screens or barriers.

IN SOME AREAS, protection from noise may be

appropriate.

BE SURE protective equipment is in good condition.

Also, wear safety glasses in work area AT ALL TIMES.

SPECI AL SI TUATI ONS

DO NOT WELD OR CUT containers or materials which previously had

been in contact with hazardous substances unless they are properly

cleaned. This is extremely dangerous.

DO NOT WELD OR CUT painted or plated parts unless special

precautions with ventilation have been taken. They can release highly

toxic fumes or gases.

Additional precautionary measures

PROTECT compressed gas cylinders from excessive heat, mechanical

shocks, and arcs; fasten cylinders so they cannot fall.

BE SURE cylinders are never grounded or part of an electrical circuit.

REMOVE all potential fire hazards from welding area.

ALWAYS HAVE FIRE FIGHTING EQUIPMENT READY FOR

IMMEDIATE USE AND KNOW HOW TO USE IT.

Page 3

SECTION A:

WARNINGS

CALIFORNIA PROPOSITION 65 WARNINGS

Diesel Engines

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and other

reproductive harm.

Gasoline Engines

The engine exhaust from this product contains chemicals known

to the State of California to cause cancer, birth defects, or other

reproductive harm.

ARC WELDING CAN BE HAZARDOUS. PROTECT

YOURSELF AND OTHERS FROM POSSIBLE SERIOUS

INJURY OR DEATH. KEEP CHILDREN AWAY. PACEMAKER WEARERS SHOULD CONSULT WITH THEIR

DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For additional

safety information, it is strongly recommended that you purchase a

copy of “Safety in Welding & Cutting - ANSI Standard Z49.1” from the

American Welding Society, P.O. Box 351040, Miami, Florida 33135 or

CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety”

booklet E205 is available from the Lincoln Electric Company, 22801

St. Clair Avenue, Cleveland, Ohio 44117-1199.

BE SURE THAT ALL INSTALLATION, OPERATION,

MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

SAFETY

1.d. Keep all equipment safety guards, covers and

devices in position and in good repair.Keep

hands, hair, clothing and tools away from

V-belts, gears, fans and all other moving parts

when starting, operating or repairing

equipment.

1.e. In some cases it may be necessary to remove safety guards to

perform required maintenance. Remove guards only when

necessary and replace them when the maintenance requiring

their removal is complete. Always use the greatest care when

working near moving parts.

1.f. Do not put your hands near the engine fan. Do not attempt to

override the governor or idler by pushing on the throttle control

rods while the engine is running.

1.g. To prevent accidentally starting gasoline engines while turning

the engine or welding generator during maintenance work,

disconnect the spark plug wires, distributor cap or magneto wire

as appropriate.

1.h. To avoid scalding, do not remove the radiator

pressure cap when the engine is

hot.

ELECTRIC AND

MAGNETIC FIELDS MAY

BE DANGEROUS

2.a. Electric current flowing through any conductor

causes localized Electric and Magnetic Fields (EMF). Welding

current creates EMF fields around welding cables and welding

machines

FOR ENGINE POWERED

EQUIPMENT.

1.a. Turn the engine off before troubleshooting

and maintenance work unless the

maintenance work requires it to be running.

1.b. Operate engines in open, well-ventilated

areas or vent the engine exhaust fumes outdoors.

1.c. Do not add the fuel near an open flame

welding arc or when the engine is running.

Stop the engine and allow it to cool before

refueling to prevent spilled fuel from

vaporizing on contact with hot engine parts

and igniting. Do not spill fuel when filling

tank. If fuel is spilled, wipe it up and do not start engine until

fumes have been eliminated.

2.b. EMF fields may interfere with some pacemakers, and welders

having a pacemaker should consult their physician before

welding.

2.c. Exposure to EMF fields in welding may have other health effects

which are now not known.

2.d. All welders should use the following procedures in order to

minimize exposure to EMF fields from the welding circuit:

2.d.1. Route the electrode and work cables together - Secure

them with tape when possible.

2.d.2. Never coil the electrode lead around your body.

2.d.3. Do not place your body between the electrode and work

cables. If the electrode cable is on your right side, the

work cable should also be on your right side.

2.d.4. Connect the work cable to the workpiece as close as possible to the area being welded.

2.d.5. Do not work next to welding power source.

3

Page 4

SAFETY

ELECTRIC SHOCK

CAN KILL.

3.a. The electrode and work (or ground) circuits are

electrically “hot” when the welder is on. Do

not touch these “hot” parts with your bare skin

or wet clothing. Wear dry, hole-free gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full area

of physical contact with work and ground.

In addition to the normal safety precautions, if

welding must be performed under electrically

hazardous conditions (in damp locations or while

wearing wet clothing; on metal structures such as

floors, gratings or scaffolds; when in cramped

positions such as sitting, kneeling or lying, if there

is a high risk of unavoidable or accidental contact

with the workpiece or ground) use the following

equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel, welding head, nozzle or semiautomatic welding

gun are also electrically “hot”.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection should

be as close as possible to the area being welded.

3.e. Ground the work or metal to be welded to a good electrical (earth)

ground.

3.f. Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Never simultaneously touch electrically “hot” parts of electrode

holders connected to two welders because voltage

two can be the total of the open circuit voltage of both

welders.

3.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

between the

ARC RAYS CAN BURN.

4.a. Use a shield with the proper filter and cover plates to protect your

eyes from sparks and the rays of the arc when welding or

observing open arc welding. Headshield and filter lens should

conform to ANSI Z87. I standards.

4.b. Use suitable clothing made from durable flame-resistant material

to protect your skin and that of your helpers from the arc rays.

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

FUMES AND GASES

CAN BE DANGEROUS.

5.a. Welding may produce fumes and gases

hazardous to health. Avoid breathing these

fumes and gases. When welding, keep your head out of the fume.

Use enough ventilation and/or exhaust at the arc to keep fumes

and gases away from the breathing zone. When welding

with electrodes which require special ventilation

such as stainless or hard facing (see instructions

on container or MSDS) or on lead or cadmium

plated steel and other metals or coatings which

produce highly toxic fumes, keep exposure as low

as possible and within applicable OSHA PEL and

ACGIH TLV limits using local exhaust or

mechanical ventilation. In confined spaces or in

some circumstances, outdoors, a respirator may

be required. Additional precautions are also

required when welding on galvanized steel.

5. b. The operation of welding fume control equipment is affected by

various factors including proper use and positioning of the

equipment, maintenance of the equipment and the specific

welding procedure and application involved. Worker exposure

level should be checked upon installation and periodically

thereafter to be certain it is within applicable OSHA PEL and

ACGIH TLV limits.

5.c. Do not weld in locations near chlorinated hydrocarbon vapors

coming from degreasing, cleaning or spraying operations. The

heat and rays of the arc can react with solvent vapors to form

phosgene, a highly toxic gas, and other irritating products.

3.j. Also see It ems 6.c. and 8.

5.d. Shielding gases used for arc welding can displace air and

injury or death. Always use enough ventilation, especially in

confined areas, to insure breathing air is safe.

5.e. Read and understand the manufacturer’s instructions for this

equipment and the consumables to be used, including the

material safety data sheet (MSDS) and follow your employer’s

safety practices. MSDS forms are available from your welding

distributor or from the manufacturer.

5.f. Also see item 1.b.

4

cause

Page 5

SAFETY

a

m

WELDING AND CUTTING

SPARKS CAN CAUSE

FIRE OR EXPLOSION.

6.a. Remove fire hazards from the welding area. If

this is not possible, cover them to prevent the

welding sparks from starting a fire. Remember that welding

sparks and hot materials from welding can easily go through

small cracks and openings to adjacent areas. Avoid welding near

hydraulic lines. Have a fire extinguisher readily available.

6.b. Where compressed gases are to be used at the job site, special

precautions should be used to prevent hazardous situations.

Refer to “Safety in Welding and Cutting” (ANSI Standard Z49.1)

and the operating information for the equipment being used.

6.c. When not welding, make certain no part of the electrode circuit is

touching the work or ground. Accidental contact can cause

overheating and create a fire hazard.

6.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures will

not cause flammable or toxic vapors from substances inside.

They can cause an explosion even though they have been

“cleaned”. For information, purchase “Recommended Safe

Practices for the Preparation for Welding and Cutting of

Containers and Piping That Have Held Hazardous Substances”,

AWS F4.1 from the American Welding Society (see address

above).

6.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

6.f. Sparks and spatter are thrown from the welding arc. Wear oil free

protective garments such as leather gloves, heavy shirt, cuffless

trousers, high shoes and a cap over your hair. Wear ear plugs

when welding out of position or in confined places. Always wear

safety glasses with side shields when in a welding area.

6.g. Connect the work cable to the work as close to the welding area

as practical. Work cables connected to the building framework or

other locations away from the welding area increase the

possibility of the welding current passing through lifting chains,

crane cables or other alternate circuits. This can create fire

hazards or overheat lifting chains or cables until they fail.

6.h. Also see item 1.c.

CYLINDER MAY EXPLODE IF

DAMAGED.

7.a. Use only compressed gas cylinders containing

the correct shielding gas for the process used

and properly operating regulators designed for

the gas and pressure used. All hoses, fittings,

etc. should be suitable for the application and

maintained in good condition.

7.b. Always keep cylinders in an upright position securely chained to

an undercarriage or fixed support.

7.c. Cylinders should be located:

• Away from areas where they may be struck or subjected

to physical damage.

• A safe distance from arc welding or cutting operations

and any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode holder or any other

electrically “hot” parts to touch a cylinder.

7.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. Valve protection caps should always be in place and hand tight

except when the cylinder is in use or connected for use.

7.g. Read and follow the instructions on compressed gas cylinders,

associated equipment, and CGA publication P-l, “Precautions for

Safe Handling of Compressed Gases in

Cylinders,” available

from the Compressed Gas Association 1235 Jefferson Davis

Highway, Arlington, VA 22202.

FOR ELECTRICALLY

POWERED EQUIPMENT.

8.a. Turn off input power using the disconnect

switch at the fuse box before working on the

equipment.

8.b. Install equipment in accordance with the U.S. National Electrical

Code, all local codes and the manufacturer’s recommendations.

6.I. Read and follow NFPA 51B “ Standard for Fire Prevention During

Welding, Cutting and Other Hot Work”, available from NFPA, 1

Batterymarch Park, PO box 9101, Quincy, Ma 022690-9101.

6.j. Do not use a welding power source for pipe thawing.

8.c. Ground the equipment in accordance with the U.S. National

Electrical Code and the manufacturer’s recommendations.

Refer to

http://www.lincolnelectric.com/safety

for additional safety information.

Welding Safety

Interactive Web Guide

for mobile devices

Get t he f ree mobi l e app

http://gettag.

5

Page 6

Table of Contents

Preface

Typographical Conventions Used ........................................................................................................ 1

Cross-References ....................................................................................................................... 1

Text You Type Using the Keyboard ............................................................................................ 1

Keys You Press and Buttons You Click ........................................................................................ 1

Menus You Select .............................................................................................................. ........ 1

Dialog Box, Application Window Titles, a nd F ield Name s .......................................................... 1

Notes, Warnings, and Tips ................................................................................................................... 2

Revision History

General Information

Introduction to Production Monitoring™ ......................................................................................... 1.1

User Roles ............................................................................................................................... 1.1

Weld Profiles ........................................................................................................................... 1.2

Weld Logging .......................................................................................................................... 1.2

E-mail Capability ..................................................................................................................... 1.2

Traceability ............................................................................................................................. 1.3

WeldScore™ ..................................................................................................................................... 1.3

Production Monitoring™ Archit ect u re.............................................................................................. 1.3

Requirements and Limitations .......................................................................................................... 1.4

Server Computer Requirement s ............................................................................................. 1.4

User Computer Requirements ................................................................................................ 1.5

Power Wave® Requirements .................................................................................................. 1.5

Network Requirements ........................................................................................................... 1.6

System Limitations .................................................................................................................. 1.6

Upgrading from Production Monitoring™ 2.1

System Requirements ....................................................................................................................... 2.1

Preparing for the Upgrade ................................................................................................................ 2.1

Running the Production Monitoring™ 2.2 Patch .............................................................................. 2.2

Installing Product ion M onitoring™

Installation Preparat ion .................................................................................................................... 3.1

Prerequisites fo r Inst a lling P r oduc tion Monitoring™ 2.2 ........................................................ 3.1

Determining the Production Monitor ing™ Ve rsion ................................................................. 3.2

Uninstalling Product ion Mo nit or ing™ 2.0 ......................................................................................... 3.2

Uninstalling the Pr o duc t ion M onitoring™ 2.0 Application ...................................................... 3.3

Removing Production Monitoring™ 2.0 F ile s .......................................................................... 3.4

Uninstalling SQL Mana ge ment Studio..................................................................................... 3.4

IM8001 Production Monitoring™User Manual TOC.1

Page 7

Table of Contents

Uninstalling the SQL Ser ve r Instan ce ...................................................................................... 3.5

Removing the Production Monitoring™ Web Site .................................................................. 3.6

Installing Microsoft Inte r ne t Info rm ation S e r vices (IIS) .................................................................... 3.7

Windows XP Professional IIS Installation ................................................................................ 3.7

Windows Server 2003 IIS Installation ...................................................................................... 3.8

Windows Vista IIS Installation ............................................................................................... 3.10

Windows Server 2008 IIS Installation .................................................................................... 3.12

Windows 7 IIS Installation ..................................................................................................... 3.14

Enabling COM+ (Windows Server 2003) ......................................................................................... 3.16

Installing PowerS he ll for Window s Se r ver 2008 ............................................................................. 3.18

Install the Latest Firmware ............................................................................................................. 3.18

Install the Latest Power Wave® Manager ....................................................................................... 3.21

Installing Production Mo nit o ring™ 2.2 S oft w are ............................................................................ 3.23

Production Monitoring™ Administration

Overview .......................................................................................................................................... 4.1

Managing the Asset Tree .................................................................................................................. 4.2

About the Root Asset (or Company Group) ............................................................................ 4.3

Adding Groups ........................................................................................................................ 4.3

Adding a Welding Power Source ............................................................................................. 4.5

Displaying Welding Powe r S o urces t o Other Users ................................................................. 4.8

Enabling/Disabling Data C olle c tion from a Welding Power Source......................................... 4.9

Moving Welding Power Sources and Groups .......................................................................... 4.9

Deleting Welding Powe r Sources and Gr oups ....................................................................... 4.10

Shift Schedule Configura t ion .................................................................................................. ........ 4.10

Next Production Day ............................................................................................................. 4.11

General Shift Schedule Infor mat ion ...................................................................................... 4.12

Managing the Shift Schedule ................................................................................................ 4.13

Example Shift Setup .............................................................................................................. 4.16

Example Shift Setup .............................................................................................................. 4.17

Global Settings ................................................................................................................................ 4.18

Getting the Team Started ............................................................................................................... 4.19

Restricting Access to Administrat ion .............................................................................................. 4.20

Prerequisites ......................................................................................................................... 4.20

IIS 5.1 and IIS 6.0 ................................................................................................................... 4.20

IIS 7.0 and IIS 7.5 ................................................................................................................... 4.23

Using Production Monitoring™

Launching Production Monitoring™ ................................................................................................. 5.1

Overview of the Application ............................................................................................................. 5.1

Asset Tree ............................................................................................................................... 5.2

Report Tabs ................................................................................................................... .......... 5.2

Individual Re

TOC.2 Production Monitoring™ User Manual IM8001

ports ................................................................................................................... 5.3

Page 8

Table of Contents

Panel Resize ............................................................................................................................ 5.3

Overview of Reports ......................................................................................................................... 5.4

Generating Reports ................................................................................................................. 5.4

Report Criteria ........................................................................................................................ 5.4

Report Links ............................................................................................................................ 5.5

Report Page Numbers ............................................................................................................. 5.5

Exporting Report Data ............................................................................................................ 5.6

Refreshing Report Data ........................................................................................................... 5.6

Current Status Tab ............................................................................................................................ 5.7

Current Status by Time Period ................................................................................................ 5.7

System Capacity ...................................................................................................................... 5.9

Production Tab ............................................................................................................................... 5.10

Criteria for the Production Reports....................................................................................... 5.11

Grid Report ........................................................................................................................... 5.12

Weld Profiles Report ............................................................................................................. 5.13

WeldScore™ Report .............................................................................................................. 5.15

Current/Voltage Report ........................................................................................................ 5.16

Wire Feed Speed (and Deposition) Report............................................................................ 5.17

True Energy™ Report ............................................................................................................ 5.19

Duration/Count Report ......................................................................................................... 5.20

Weld Listing Tab ............................................................................................................................. 5.21

Criteria for the Weld Listing Re ports ..................................................................................... 5.21

Grid Report ........................................................................................................................... 5.23

WeldScore™ .......................................................................................................................... 5.25

Current/Voltage Report ........................................................................................................ 5.26

Wire Feed Speed Report ....................................................................................................... 5.27

True Energy™ (and Duration) Report .................................................................................... 5.28

Wire Deposition Report ........................................................................................................ 5.29

Weld Detail Tab .............................................................................................................................. 5.30

Weld Detail Criteria............................................................................................................... 5.30

Weld Detail Report ............................................................................................................... 5.30

Traceability Tab .............................................................................................................................. 5.35

Traceability C rite r ia ............................................................................................................... 5.36

Traceability Repo rt................................................................................................................ 5.37

Downtime Tab ................................................................................................................................ 5.39

Downtime Criteria................................................................................................................. 5.39

Grid Re

Chart Report ......................................................................................................................... 5.41

Fault Detail Tab............................................................................................................................... 5.41

Fault Detail Criteria ............................................................................................................... 5.41

Fault Detail Report ................................................................................................................ 5.43

port ........................................................................................................................... 5.40

Additional Information

IM8001 Production Monitoring™ User Manua l TOC.3

Page 9

Table of Contents

Archive of Data from the Database ................................................................................................. A.1

Archive Frequency ................................................................................................................. A.1

Archive File Name Format ...................................................................................................... A.1

Open an Archive File .............................................................................................................. A.2

Archive File Format ................................................................................................................ A.3

Troubleshooting

Cannot Connect to a Power Source ..................................................................................................B.1

Glossary

TOC.4 Production Monitoring™ User Manual IM8001

Page 10

Preface

Typographical Conventions Used

Before using this guide, it is importa nt to understa nd t he typographic al conventions used to identify and

describe information.

Cross-References

Cross-references t o chapter s, sections, page numbers, hea dings, e t c . a re shown in a n italic t yp e fa ce .

e.g., Refer to Text You Type Using the Keyboard on pa ge 1.

Text You Type Using the Keyboard

Text that you type using the keyboard is shown in a Courier typeface.

e.g., Type John Smi th in t he Name field.

Keys You Press and Buttons You Click

Keys tha t you press on the keyb o ar d and buttons/icons that you click with t hemouse are shown in a bold

sans-serif t y peface.

e.g., Press Enter.

e.g., Click OK to continue.

Menus You Select

Menus and the selections you make from the menus are shown in a bold sans-serif typeface.

e.g., Select Start > Control Panel from the main computer menu.

e.g., Select Tools > Options from the menu.

Dialog Box, Application Window Titles, and Field Names

The titles of dialog boxes and application windows are shown in italics. Field names and selections made

from drop-down menus, etc. are also shown in italics.

e.g., The Print Preview window opens .

e.g., Select All Shifts from the drop-down list.

IM8001 Production Monitoring™User Manual 1

Page 11

Preface

Notes, Warnings, and Tips

Notes, stops and tips appear throughout the manual. They provide additiona l informa t ion t hat is important

for you to know about the topic.

NOTE | A note is an important piece of informatio n.

STOP | You should definitely rea d t he information in a st op t a ble.

It could help y ou prevent a situation f rom which you cannot

recover.

TIP | A tip table helps you w it h s ome interesting or useful

informatio n about using the program.

2 Production Monitoring™ User Manua l IM8001

Page 12

Revision Histor y

Date Change Description

August 2012 Initial release a s IM8001

May 2013 Major revamp and update of manual

IM8001 Production Monitoring™User Manual REV.1

Page 13

Revision History

THIS PAGE INTENTIONALLY LEFT BLANK.

REV.2 Production Monitoring™ User Manual IM8001

Page 14

Chapter 1

General Information

Introduction to Production Monitoring™

Production Monitoring™ is a data colle c tion and reporting technology that is available fo r the la test models

of the Power Wave® fam ily of Welding Power Sources.

The term “Production Monitoring” does not refer to any single featur e . Instead, it refers to the ent ire

collection of feature s an d functionality included with a Welding Power Source. These features include, but

are not limite d to:

Collecting w elding logs complete with statist ic s for each recorded weld.

Setting logical limits on WeldScore™, arc current , a rc vo ltage, wire feed speed, and duration; and

reporting welds t h a t viola te the specified limits.

Creating d istinct Weld Profiles with separate limit se ttings for each pro file.

E-mailing users: Ea c h Welding Power Source has the ability to send e-mails co nt a ining r eports of

weld errors and other information.

Tracking wire usage and providing low-pac k age w arnings for ea c h Welding P ow e r Sour ce.

STOP | Production Monito ring™ does not support consumable

tracking f or dual wire-feeding syst ems.

NOTE | For Production Mo nit oring™ support in U S A and C a nada,

dial 1.800.691.5797. The direct dial number is

1.727.786.0121. The e-mail address is

support@lincolnproductionmonitoring.com

.

User Roles

For the purposes of this documentation, we use the follow ing t erms to help ident ify t he person gener a lly

responsible for the task being discussed. These ar e general terms to help illustrat e the use of Pro duct io n

Monitoring™ in your welding o pe r a tions.

Weld Engineer or Engineer: If you see one of these terms, we generally mean the person in

charge of setting up the weld before the weld is made. In some cases, the Weld Engineer and

the Weld Operator is the same person.

Weld Operator or Operator: This person is the person (or robot) who is actually running the

welder and making the weld.

Production Monitoring™ Administrator: This person is responsible for managing the Production

Monitoring™ application. Ther e could be more t han one, depending on your company’s policies.

IM8001 Production Monitoring™User Manual 1.1

Page 15

Chapter 1. General Information Introduction to Production Monitoring™

Weld Profiles

One of the principal goals of Production Monitoring™ is to report on welds that are outside of user-defined

limits with respect to WeldScore™, current, voltage, wire feed speed and duration. This goal would be

simple to impleme n t if the Welding Power Source were to perform on ly o ne t ype of we ld over a nd o ver.

However, in practica l a pplic ations, this is not the case. The assembly of many different industrial

components requires welds of varying type and length.

The concept of Weld Pr o file s allows the Welding Power Source to apply differ ent limit settings for each

weld that is performed on a certain part. Before the Welding Power Source begins a new weld, the wire

feeder or system controller selects the corresponding Weld Profile. The Weld Engineer can, therefore,

assign one Weld P r o file to each weld required for the part asse m bly .

For more in-dept h info r ma tion about Weld Profiles, please refe r to the Power Wave® Manager User

Manual.

Weld Logging

Production Monitoring™ records lar ge quantities of we ld st atistic s. Eac h log ent ry cont a ins the following

welding stat istics for each weld:

For current, voltage, wire feed speed and duration:

- Minimum

- Maximum

- Average

- Percent above limit

- Perce n t below limit

- Profile m aximum limit

- Profile m inim um limit

True Energy™

Date and time the weld was made

Duration of the weld

Weld stat us a f te r limit checking

Part Number, Consumable Lot and Operator ID

WeldScore™

E-mail Capability

When a Welding Powe r So ur ce ha s ac c e ss to an e-mail server on your net work and you have installed

Production Monitoring™ on the server compute r, the power source can send e-mail notifications to

multiple addre sse s. Each e-mail address can be configured to receive messages fr o m t h e Welding P o w e r

Source upon any of several event conditions.

1.2 P ro d uction Monitoring™ User Manual IM8001

Page 16

WeldScore™ Chapter 1. Gene ra l Information

Traceability

Production M onitoring™ provides you with the ability to re po rt on all th e we lds that were made on a

specific part numbe r , by a spe c ific o per ator or using a specific consumable lot co de. Before a weld is ma de,

this informatio n is c o mm unic a ted to the Welding Power Source, in a variety of wa ys. Every we ld that is

made after this is assigned with these ID numbers unt il a new numbe r is ente red. Production Monitoring™

users can gener ate a traceability report th at looks for this ID from all the Welding Power Sources in the

system. Trac eability solutions are typic a lly customized t o a c ustomer’s specific needs. Please contact

Lincoln Electric for a quotation on your needs.

NOTE | Production Monitoring™ does not support consumable

package t ra c king for dual wire feeding sy stems.

WeldScore™

WeldScore™, a new fe atur e ava ila ble in all third-generation Welding Power Source models (including the

i400, C300, S350, S500 and AC/DC 1000 SD), can be used to support a weld qua lit y c o ntrol program. It

assigns a scor e to welds on a 0% to 100% scale that indic a te s the acceptability of the weld. The score is

based on a comparison to previously trained welding condit ions. Any weld w ith a score of 85% to 90% or

above can be considered, with a reasonable amount of c onfidence, to be an acceptable weld. WeldScore™

can be used independently on the power source or together with Production Monitoring™. Please refer to

the Power Wave® Manager User Manual for more in-depth infor ma tion on WeldScore™.

NOTE | WeldScore™ is not a guarantee of quality and is not

intended t o replace a quality co nt rol system.

Production Monitoring™ Architecture

The Production Monitoring™ system uses a web-based front end (the part that you use to run reports and

set up the application) with a relational database for storing data (weld statistics sent from the Welding

Power Sources). The web-based front end allows users on multiple c o mput e r s to access the welding data

and generate reports using the Production Monitoring™ applic a tion. The main components of the

Production Monitoring™ system are:

Microsoft SQL Server Expr ess database for stor in g d ata sent from Welding Power Sources

Microsoft Internet Information Services (IIS) Web Server

IGear Data Transpor t Utility (DTU): This provides the connec tivity from Welding Power Source

to the database on the server computer. This piece of software queries the Welding Power

Sources for information and stores it in t he databa se.

IGear Web Framework: This provides users with a web portal to the database that enables them

to generate various reports.

You install the Production Monito ring™ a pplic a t ion on a single dedica te d ser ve r computer . This server

computer then communicates with the Welding Power Sources over an Ethernet network. Users can be

anywhere and, as long as they have an Ethernet link to the server compute r , they can access the Production

Monitoring™ application.

IM8001 Production Monitoring™ User Manua l 1.3

Page 17

Chapter 1. General Information Requirements and Limitations

Figure 1.1 Production Monitoring™ System

Requirements and Limitations

Server Compu t er Requiremen t s

You install Production Monitor ing™ on a single de dic ate d computer to which all other computers conne ct in

order to access the application. The following ar e th e requir e ments for tha t serve r computer :

Dedicated “alway s on” compute r : This is a server-t ype applica tion designed to run on a

computer tha t is on a ll the time. This application should not be installed on a laptop.

CPU: Dual core, 2 GHz

RAM: 2 GB

An Ethernet (IEEE 802.3–compliant ) 10Mbps 10-Ba seT or 10/ 100-Ba seT ne twork interface card.

Internet browser: Internet Explorer 7 or greater; Firefox; or Chrome

Microsoft Internet Information Services (IIS). Refer to page 3.7 for installa t io n inst r u c tions.

1.4 P ro d uction Monitoring™ User Manual IM8001

Page 18

Requirements and Limitations Chapter 1. General Information

Operating System: Window s 7, Window s Vista , Windows XP P r ofe ssional, Windows Ser ve r 2003

with Service Pack 1 or greater, and Windows Serve r 2008. Production Monit or ing™ support s

both 32-bit and 64-bit operating syste m s.

NOTE | If the system is Windows Server 2003, COM+ must be

enabled. Please see pa ge 3.16 for details.

If the system is Windows Server 2008, PowerShell must be

installe d ma nually. For details on ins t alling PowerShell,

refer to page 3.1 8.

Display: Minimum supported re solut ion is 10 24x768 (16-b it c olor or highe r ).

The Production Monitoring™ screens should alwa ys be expanded to use the full 1024x768

resolution of the monitor. Otherwise, certa in nec e ssary sections of the scre e n may be hidden

from view.

User Computer R equirements

Each user can access Production Monitoring™ from the computer at their desk or from another computer

on the network. The following requirement s apply for that c omputer to view Pr oduction Monitoring™:

Internet Explorer 6 (Service Pack 1) or greater

An Ethernet (IEEE 802.3–compliant ) 10Mbps 10-Ba seT or 10/ 100-Ba seT ne twork interface card

Display: Minimum supported resolution is 1024x768 (16-bit color or higher).

Connection to the same network as the server computer

Power Wave® Requirements

The Power Wave® Welding Power Source that you want to connec t to Production Monit or ing™ must meet

the following requireme nt s:

Ethernet port

- The Power Wa ve® 655, AC/ DC 1000, and a ll third-ge ne r a t ion P owe r Waves (i400, S 350, S 500,

etc.) come standard wit h an Ethernet port, so no a ddit iona l equipme nt is nee de d.

- The Power Wave® 455M, 455M/S TT, 455M Robotic, and 455M/ S TT Robot ic need a K2207-2

Ethernet/DeviceNet Module.

- The Power Wave® 355M, F355i, a nd 405M need a K2436-1 Co mmunic a t ion Interfa ce.

Static IP addre ss se t for each Welding Power Source

- Each Welding Po wer S o urce must have a unique IP address. IP addre sses ar e usually

obtained from your loc a l IT de partment.

- Once you retrieve an IP addre ss for each Welding Power Source, you can use the Lincoln

Electric Power Wave® Manager software to set the IP address in the Welding Power Source.

This software ut ility is available at www.powerwavesoftware.com

The Production Monitoring™ firmwa re revision (in the We lding Power Source) must be revision

5 or greater to use Production Monitoring™ 2.2. You can check the firmware revision using

IM8001 Production Monitoring™ User Manua l 1.5

.

Page 19

Chapter 1. General Information Requirements and Limitations

Power Wave® Manager software on the Diagnostics tab under Production Monitoring >

Register. If the revision is 4 or lower, see page 3.18 for details on updating the firmwa re.

Network Req uirements

Production Monitoring™ uses your computer networ k to communicate with the Welding Power Sources

and the users who want to view data in the application. The following a r e the net work requirement s you

need to meet in order for Production Monitoring™ to run properly:

Network Type: 10 Base-T or 10/100 Base-T network

Cabling: Solid shielded C AT 5 c a bles or better

Connectors: Use RJ-45 environmentally enclosed connectors when connecting the network to

the Welding Power Sourc e .

Connecting Ne tw o r k De vice : The ne twork lines going to the Welding Power Source should go t o

an industrial switch or a switc h with a har dened e nc losure .

Wireless Network Guidelines: A wire le ss networ k r e quir e s an 802.11 bridge. Several cu stomers

have had success using a NETGEAR wireless a dapter (Model: ENCE2001).

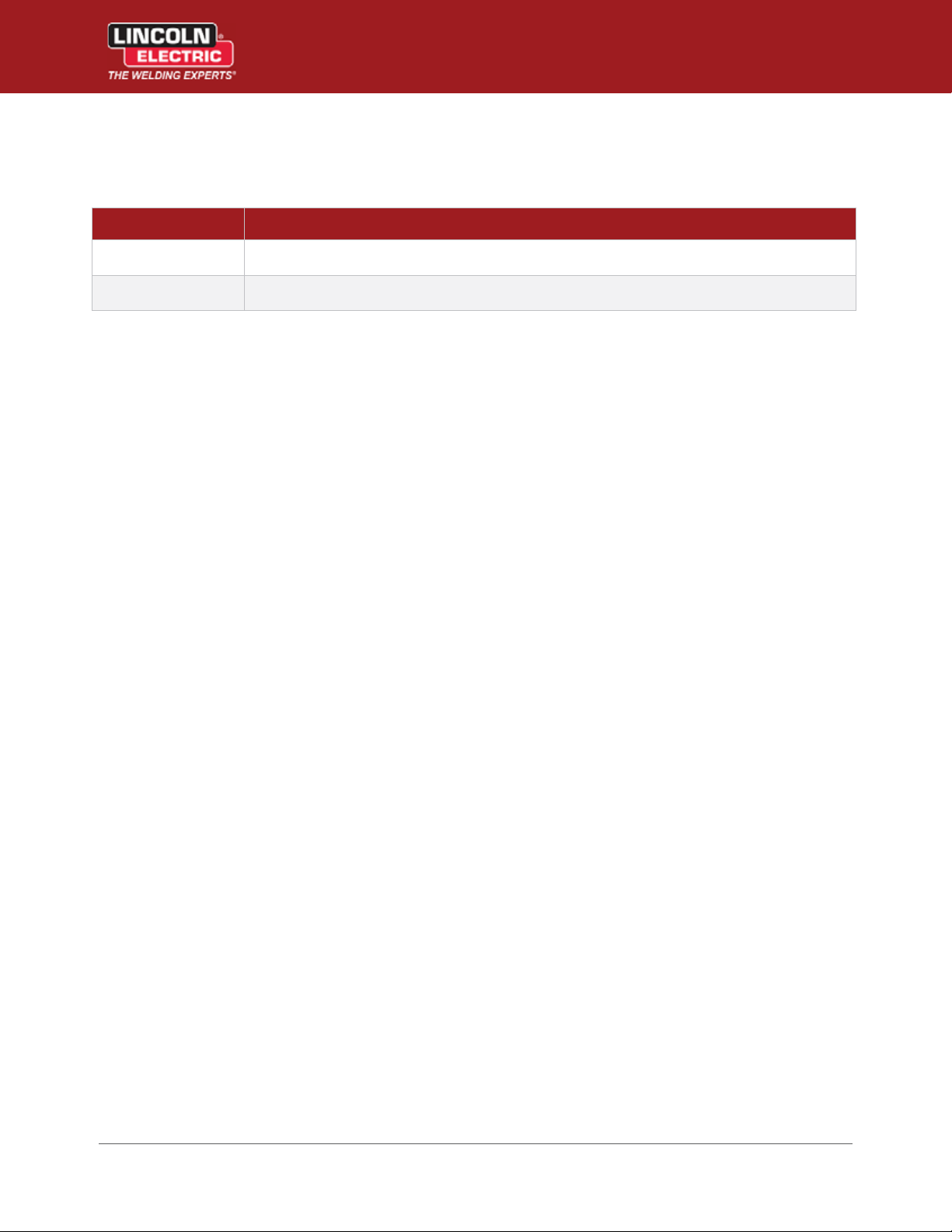

System Limitat ions

Table 1.1 compares the two recent versions with r e spe ct to limitations. While Production Monitor ing™ is a

great tool for monitoring your welding operations, please m a k e no te o f the fo llo w ing limitations:

Welds with a tot a l duration less than 0.2 seconds will not be recorde d in Pro duc tion

Monitoring™ 2.2.

Welds wit h a duration less than th e su m o f the Sta rt De la y time plus the End Delay time will be

recorded as a Short Weld.

In Production Monitoring™ 2.2, you have the option to discard Short Welds (i.e., w e lds wit h a

duration less than the sum of the Start Delay time plus the End Delay time).

The maximum number of records the weld table can store is 250,000.

The maximum number of records the event table can store is 250,000.

The maximum number of weld records stored on the Welding P ower S ource itself is 1000. The

oldest rec or d s w ill be replaced with a new recor d w h e n a new record is generated.

NOTE | In the event there is an Ethernet co nnection issue with the

Welding Power Source, the Production Monitoring™ weld

records will be stored in the Welding Power Source up to

the maximum num ber of records. The power s ource will

transfer the data to the Production Monitoring™ database

once the connec tion has been reestablished. Please keep in

mind that if t he W elding Power Source is powered down or

reset for any reason, these stored wel d rec ords will be lost.

Non-synergic modes (such as the Power Mode or Non-Synergic CV modes) are not supported

when you use the Last Digit of Workpoint method for select ing W e ld Profiles. (Please refer t o

the Power Wave® Manager User Manual for more details on this method.)

1.6 P ro d uction Monitoring™ User Manual IM8001

Page 20

Requirements and Limitations Chapter 1. General Information

FANUC® Se r vo To r c h Wire Fe e d Speed (WFS) will not be recorded for olde r soft w are versions of

ArcTool® software and older versions of the Welding Po w e r Sourc e ’s firm w a re. Start ing with the

V7.70P/07 release of the ArcTool® softw are, Ser voTor ch WFS feedbac k is support e d.

The robotic analog interface is not recommended when you use the Last Digit of Workpoint

method for selecting Weld Profiles. (Please refe r to t he Power Wave® Manager User Manual for

more details on this method.)

Production Monitoring™ does not support consumable pac ka ge tracking or the calculation of

Wire Deposition with Dual-Head Wire Fee ders.

When using the Windows XP Pro operating system for the server computer, only five (5) users at

a time can view reports.

When you have multiple machines wit h memory pane ls co nne cte d to your system (e.g., two

wire feeders that each have a memory panel of their own), the Weld Operator should not use

these buttons to choose the Weld Profile for the ir weld. You c ould potentially select the wrong

profile for the weld.

Table 1.1 Limitation Differences between Version 2 .1 and Version 2.2

Item Version 2.1 Version 2.2

Maximum weld duration (sec onds) 6,553 429,496,729

Maximum weld re c ords in Welding Power

Source memory

Shortest weld duration that can be

recorded (seconds)

Minimum total delay (i.e ., S tar t De la y plus

End Delay) (seconds)

Maximum serial number length 16 32

Maximum out-of-lim it tolerance time

(seconds)

TIG and stick welding supported No Yes

WeldScore™ supported No On third-generation We lding

5,000 1,000

0.5 0.2

0.7 0.2

1310.7 85,899,345

Power Sources

IM8001 Production Monitoring™ User Manua l 1.7

Page 21

Chapter 1. General Information Requirements and Limitations

THIS PAGE INTENTIONALLY LEFT BLANK.

1.8 P ro d uction Monitoring™ User Manual IM8001

Page 22

Chapter 2

Upgrading from Production Monitoring™ 2.1

If you already have Production Monitor ing™ 2.1 installed a nd simply nee d t o upgr a de to version 2.2, this

section provides simple information for you to accomplish this as quickly as possible.

STOP | If you have Producti on M onitoring™ 2.0 or l ow er ( or you

need to install for the first time), you must refer to Chapter

3 for instruc tions. Upgrading to t he new v ersion requires

that you unins t all all older versions and install the ne w

version fresh.

System Requirements

The system must meet the requirements liste d on pa ge 1.4 to install and r un t he Product ion Monitoring™

2.2 application. If on e of these requirements is missing, th e installation will fail. For assist ance with these

requirements, please cont act your loca l IT department or contact support at

support@lincolnproductionmonitoring.com

.

Preparing for the Upgrade

To upgrade from Production Mo nit o ring™ 2.1 t o Produc tion Monitoring™ 2.2, you will need the following:

Administ rator permissions o n y o u r server computer.

Production Monitoring™ 2.2 Patch

If you do not have the Production Monitoring™ 2.2 Patch, contact Production Monitor ing™

support at support@lincolnproductionmonitoring.com

software.

A standard installation of Product ion Monit oring™ 2.1 running on the se rve r comput er.

STOP | If your Production Monitoring™ 2.1 insta llation is non-

standard, you will need to contact s upport for assistance

with the upgrade pr oc ess.

A non-stan dard installation wo uld include any instal lation

where the Pro duc t ion Monitoring™ database has been

moved to a diffe rent server or the password for the

Productio n Monitoring™ databa s e has been changed within

Microsoft ® S Q L E nt erprise Manager.

for assistance with obtaining the

IM8001 Production Monitoring™User Manual 2.1

Page 23

Chapter 2. Upgrading from Production Monitoring™ 2.1 Running the Production Monitoring™ 2.2 Patch

Running the Production Monitoring™ 2.2 Patch

The Production Monitoring™ 2.2 Patch upgrades Produc t ion Monit or ing™ 2.1 softw are to the late st

Production Monitoring™ 2.2.x rele a se .

NOTE | If you do not have the patc h file and do not know how to

obtain it, contact Production M onitoring™ support a t

support@lincolnproductionmonitoring.com

Lincoln sales representative.

NOTE | These instructio ns ma y v ary depending on the operat ing

system installed on the server computer.

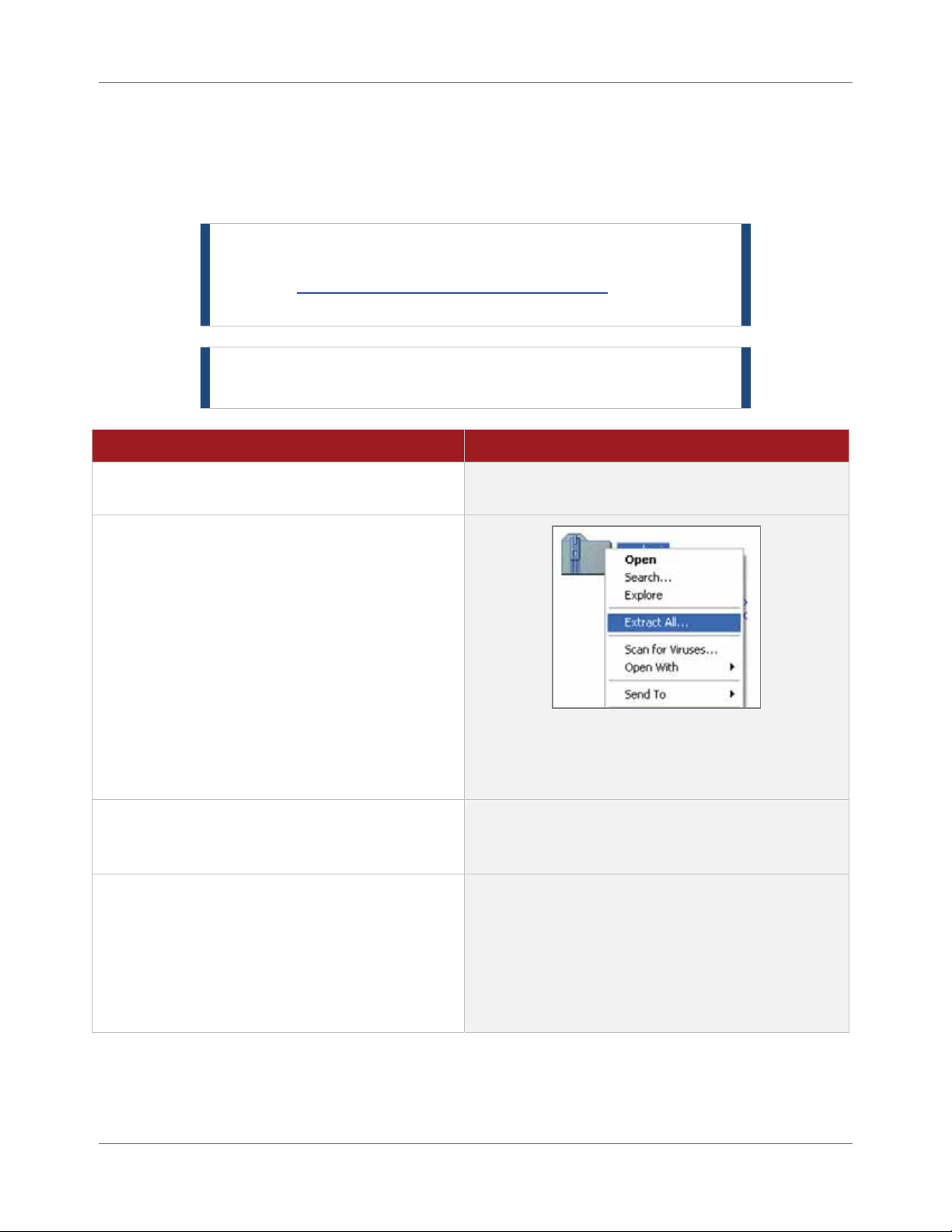

Procedure Details

or your loca l

1. Locate the Production Monitoring™ 2.2 patch

file you saved on your computer.

2. Right-click the patch file a nd select Extract All

from the pop-up menu.

3. Double-click the setup.exe file to begin the

installation of the Production Monitoring™

2.2 Patch.

4. When the installation process finishes, c lick

OK to close the applic a tion.

TIP | To find the files easily, crea te an empty

folder on your Desktop and extract the files to that

folder.

This process is aut om a ted and should not require

user involvement once the application begins to run.

The title bar of the a pplic ation should now read

Production Monitoring™ 2.2.

NOTE | If the patch encounters an error duri ng

install or th e s y s t em does not appear to be running

version 2.2, y ou should contact support for

assistance.

2.2 Production Monitoring™User Manual IM8001

Page 24

Chapter 3

Installing Production Monitoring™

If you have a new installation or you need to upgrade from Production Monit or ing™ 2.0 or lower , the

information in th is c hapter provides easy-to-follow instruc tions.

Installation Preparation

This section will guide yo u through the step-by-step proc e ss o f ho w to prep a r e the server compute r fo r th e

Production M onitoring™ software install. This installation section also includes how t o determine which

version is currently running in th e event you are performing a n upgr a de.

Prerequisit es f or Installing Production Monitoring™ 2.2

Before you can begin insta lling Production Monitoring™, you need to make sure that you have met certain

requirements and have certa in informa tion available to you. This helps ensure you have as efficient an

installation a s po ssible.

You must be logged on as an Administrator to the server computer .

Determine the current version being used if you ar e per forming a Pr oduction Monit or ing™

upgrade. Refer to page 3.2 to determine the version installed on your serve r co mputer .

STOP | If you need to upgrade from P roduction Monitoring™ 2.0,

you must completely uninstal l t his v ersion prior to installing

Production Monitoring™ 2.2. Refer to page 3.2 for uninst all

instructions.

If you need to upgrade from Productio n M onitoring™ 2.1,

you must run the P roduction Monitoring™ 2.2 patch. Refer

to Chapter 2 for instructions on running the patch.

The computer name must not contain any underscores (_). Exam ple : If the computer name is

“My_ Computer”, it should be changed to something like “MyComput e r”.

During installatio n , it is best to turn off any Firewalls o r se curity software on the

server computer.

Microsoft Inte r net Information Server (IIS) must be insta lle d before installing Production

Monitoring™. Refer to page 3.7 for information on how to install IIS for your ope rat ing sy st em.

If you are installing the soft w a re on a Windows Se r ver 2003 operating system, che c k to make

sure that Servic e Pa c k 1 or greater is installed. (Right-clic k the My Computer or Computer icon

on the desktop or Start menu and select Properties.)

For the Windows Server 2003 operating system, ver ify t ha t CO M+ is ena ble d. Refer to page 3.16

for information o n ho w to verify if this is enabled.

If your server computer is Windows Ser ve r 2008, Pow e r S hell must be inst a lle d ma nually. Refer

to page 3.18 to install P o w e rShell.

IM8001 Production Monitoring™User Manual 3.1

Page 25

Chapter 3. Installing Production Monitoring™ Uninstalling Production Monitoring™ 2.0

Determini ng the Prod uction Monitoring™ Version

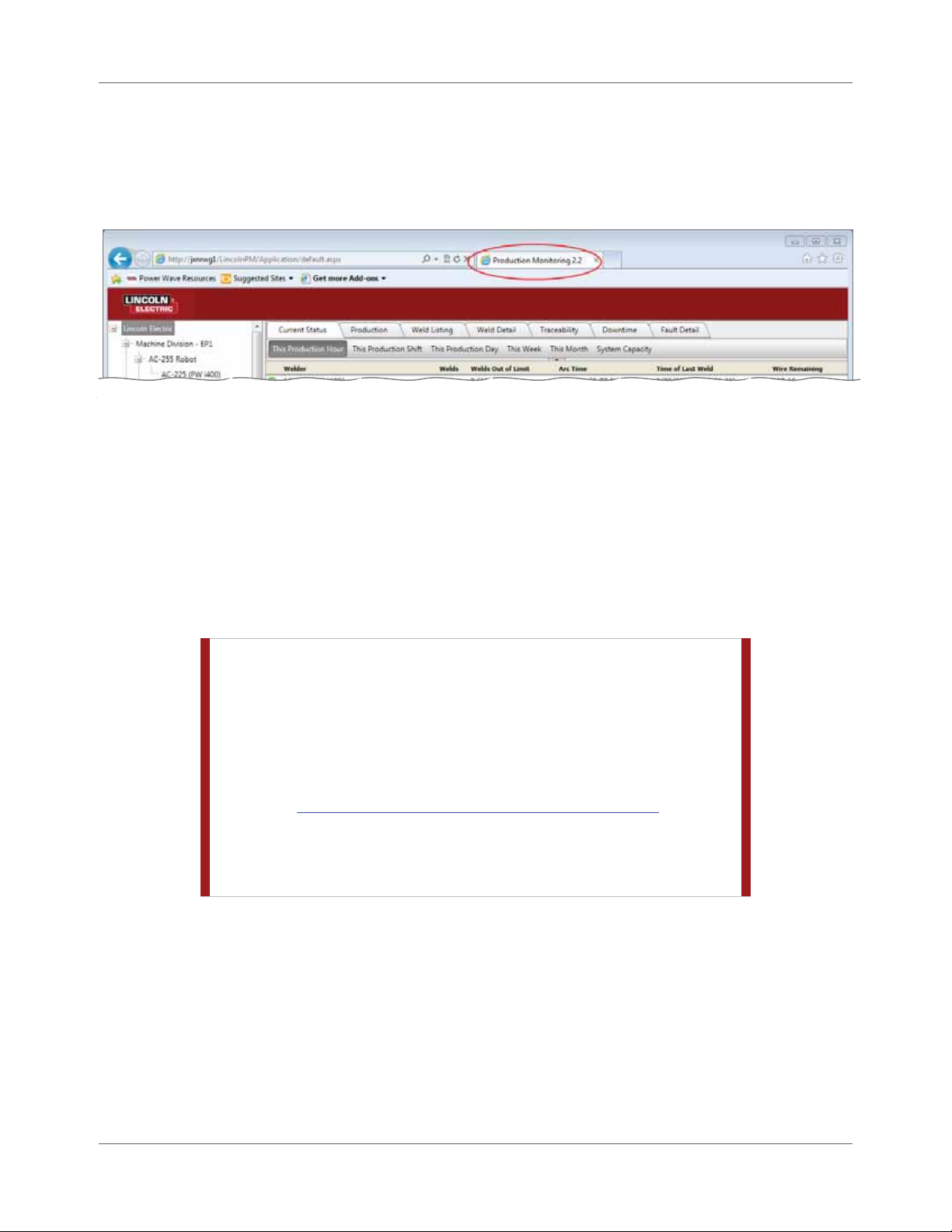

To determine the version of Production Monitor ing™ installe d on your se rver computer, simply launch

Production Monitoring™ on that computer and look at the Inter net browser tab for the applicat ion (Figure

3.1).

Figure 3.1 Verify Production Monitoring™ Version Number

In the event your browser does not display tabs, the applica tion also displays the version number in the

title bar of the window or in the address bar.

If the title bar or tab does not show P r o duction M onitoring™ 2.1, you will then proceed as if your

Production Monitoring™ version is 2.0.

Uninstalling Production Monitoring™ 2.0

This section descr ibe s ho w to uninstall Production Monitoring™ 2.0. You m ust do this prior to installing

Production Monitoring™ 2.2.

STOP | Uninstalling will erase all previous da t a c ollected with

Productio n M onitoring™ 2.0. If you want t o s ave any

previously c ollected data, then d o not c ontinue. Contact

Productio n Monitoring™ suppo rt for assistance in sa v ing

your data. For P roduction Monitoring™ support in the USA

or Canada, dial 1.800.691.5797. The direct dial number is

1.727.786.0121. You can also e-mail support at:

support@lincolnelectricproductionmonitor ing.com

Support will need to log in to the server computer remotely

in order to bac k up the previous database from Production

Monitoring ™ 2 .0.

3.2 P ro d uction Monitoring™ User Manual IM8001

Page 26

Uninstalling Production Monitoring™ 2.0 Chapter 3. Installing Production Monitoring™

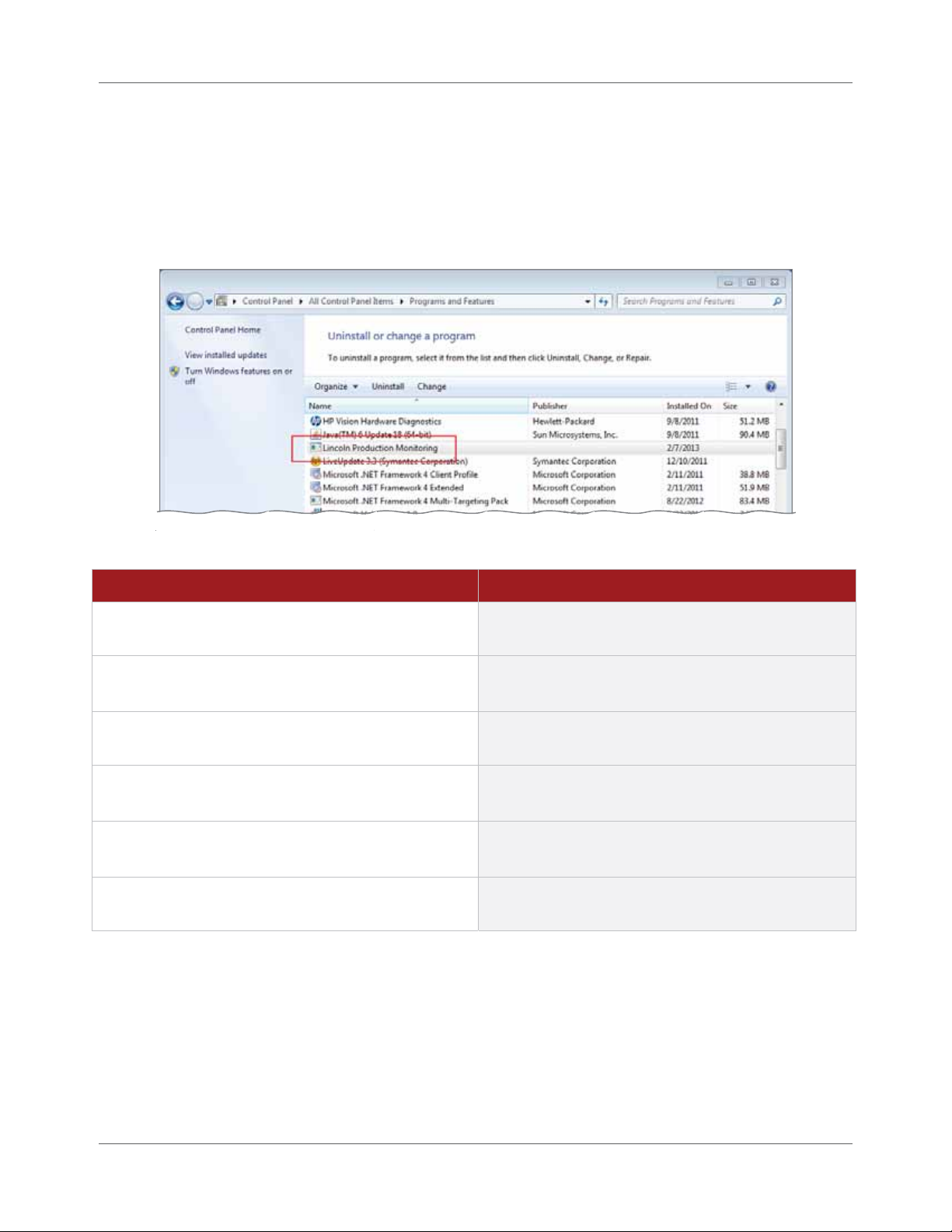

Uninstalling the Production Monitoring™ 2.0 Application

As you begin to uninstall P r oduc tion Monitoring™ 2.0, you will uninstall various applic ations that comprise

the Production Monitoring™ “system”. This section explains how to remove the Production Monitoring™

2.0 software application. Ke e p in mind these steps may va ry depending on t he compute r Operating

System.

Figure 3.2 Uninstalling Software

Procedure Details

1. Select the Start > Control Panel from the

computer’s main program menu.

2. Double-click the Add or Remove Programs icon.

3. Locate Lincoln Production Monitoring in the list

of software.

4. Click the Remove button.

5. Select the Uninstall button.

6. Click the Close button when the system finish es

uninstalling Product ion Monit or ing™ 2.0.

In newer versions of the Windows operating

system, the option is called Programs and Features.

See Figure 3.2.

The system prompts you to confirm that you want

to uninstall the software.

The system uninstalls the program and will inform

you when it is co mp le te.

IM8001 Production Monitoring™ User Manua l 3.3

Page 27

Chapter 3. Installing Production Monitoring™ Uninstalling Production Monitoring™ 2.0

Removing Production Monitoring™ 2.0 Files

This section describes how to remove any remaining Product ion Monit or ing™ 2.0 files from the default

installation location on the serve r comput er. Keep in mind t he se inst ructions ma y va ry depending on the

operating system installed on your computer.

Procedure Details

1. Open the Start menu and click My Computer.

2. Double-click the Local Disk (C:) icon.

3. Open the Program Files folder.

4. Open the Lincoln Electric folder.

5. Right-click the Production Monitoring folder

and select Delete from the pop-up me nu.

6. Click Yes.

Depending on your operating system, the option

could be called Computer . The contents of the

computer display.

The syste m d isp lays the folders sto r ed on your

local drive.

TIP | If there is no Production Monitoring folder

when you open the Lincoln Electric folder, you can

move to the next s ec t ion a nd skip the remaining

steps.

The system prompts you to confirm the deletion of

the folder.

Uninstalling SQL Management Studio

You must uninstall SQL Management Studio if you have it inst a lle d on your comput e r.

Procedure Details

1. Select the Start > Control Panel from the

computer’s main program menu.

2. Double-click the Add or Remove

Programs icon.

3. Locate Microsoft SQL Server Management

Studio in the list of software.

4. Click the Remove button.

5. Click Yes if prompted to confirm you want to

remove the program.

3.4 P ro d uction Monitoring™ User Manual IM8001

In newer versions of the Windows operating system,

the option is calle d P rog ra ms a nd Features.

The system proceeds with uninstalling Microso ft SQL

Server Management Studio Express.

Page 28

Uninstallin g Production Monitoring ™ 2.0 Chap t er 3. Installing P r oduction Monitoring™

Uninstalling the SQL Server Instance

After you uninstall Microsoft SQL Se rver Manage me nt St udio Expr e ss, you need to remove the SQL

database used in version 2.1 so you can start fresh with version 2.2.

To remove the SQL Server Instance:

Procedure Details

1. Select the Start > Control Panel from the

computer’s main program menu.

2. Double-click the Add or Remove

Programs icon.

3. Locate Microsoft SQL Server 2005 in the list

of software.

4. Click the Remove button.

In newer versions of the Windows operating system,

the option is calle d P rog ra ms a nd Features.

The system proceeds to uninstall t he insta nc e.

During th e process, the syste m st ops and displays

the Component Selection window.

5. Choose LINCOLN: Database Engine and

click Next.

6. Click Finish to continue.

7. Exit the Add or Remove Programs window

when the process is complete.

IM8001 Production Monitoring™User Manual 3.5

STOP | Only remove the LINCOLN: Database

Engine entry. DO NOT remove any other

databases.

The syste m di splays a confirmatio n m essage.

The syste m completes the uninst all process.

Page 29

Chapter 3. Installing Production Monitoring™ Uninstalling Production Monitoring™ 2.0

Removing the Production Monitoring™ Web Site

This section outlines the steps necessary to completely remove the Production Monitoring™ 2.0 website

from the server computer.

Procedure Details

1. Select the Start > Control Panel from the

computer’s main program menu.

2. Double-click the Administrative Tools icon.

3. Double-click the Internet Information

Services shortcut.

4. Click the plus sign ( + ) next to Machine

Name (local computer) to expand it.

5. Click the plus sign ( + ) next to the Web Sites

folder to expand it.

6. Click the plus sign ( + ) next to Default Web

Site folder to expand it .

The Control Panel opens.

The Administrative Tools window opens.

The system opens the Internet Information Services

window.

Where MachineName is the name of your computer

7. Right-click the LincolnPM option and select

Delete from the pop-up menu.

8. Click Yes to delete the item.

9. Right-click the IGear.Lincoln.Configuration

option and select Delete from the popup menu.

3.6 Production Monitoring™User Manual IM8001

The system prompts you to confirm the deletion.

The system prompts you to confirm the deletion.

Page 30

Installing Microsoft Internet Information Services (IIS) Chapter 3. Installing Production Monitoring™

Procedure Details

10. Click Yes to delete the item.

11. Restar t your computer .

After uninstalling a nd r e m oving a ll pr evious items, you

must restart your computer before continuing.

Installing Microsoft Internet Information Services (IIS)

Production Monitoring™ is an int ernal w e b-based applica tion that allows you and other users to access

data collected from the Welding P ower Sources co nne c ted to the applica t ion. In order for you and others

to access this data, you need to set up the server computer to be a web server. You do this by activating or

installing Micr o soft’s Internet Information Service s (or IIS) components.

TIP | When installing IIS on o lder computers, please be sure you

have the Windows installation C D for your operating

system. Check w it h y our local IT department for more

information.

The instructions are slight ly diffe r e nt de pending on th e Opera t ing S ystem (OS) of your Production

Monitoring™ server comput er. Click the link below to navigate directly to the section related to your OS.

Windows XP Professional

Windows Server 2003

Windows Vista

Windows Server 2008

Windows 7

Windows XP Prof essional IIS Installation

With Windows XP P r o fe ssio nal, IIS is not installed by default. Follow the instructions below to inst a ll IIS.

Procedure Details

1. Log in to the server computer as the

administrator user.

2. Insert the original Microsoft Operating

System d isk .

3. Choose the Install Windows XP option under

the What do you want to do? question.

Contact your IT department for appropriate user

name and password if necessary.

The Welcome to Microsoft Windows XP should

appear.

The Windows Components Wizard window opens.

IM8001 Production Monitoring™ User Manua l 3.7

Page 31

Chapter 3. Installing Production Mon ito ring™ Installing Micros o ft Inte rn et In fo rmation Services (IIS)

Procedure Details

4. Place a check mark next to Internet

Information Services (IIS) and click Next.

The syste m in stalls IIS and comple tes the process.

Congratulations! You have activated IIS for your

server computer. Continue to page 3.18 to install

or upgrade Power Wave® Manager.

Windows Server 2003 II S Installat ion

With Windows Server 2003, IIS is installed by de fa ult, but you need to let the system know you want to use

it. Follow the inst r u c t io ns below to add the IIS components.

Procedure Details

1. Log in to the server computer as the

administrator user.

2. Select the Start > Control Panel from the

computer’s main program menu.

3. Double-click Add or Remove Programs.

Contact your IT department for appropriate user

name and password if necessary.

The Add or R emove Programs L i stopens.

3.8 Production Monitoring™User Manual IM8001

Page 32

Installing Microsoft Internet Information Services (IIS) Chapter 3. Installing Production Monitoring™

Procedure Details

4. Click the Add/Remove Windows

Components button.

5. Place a check mark next to Application

Server and click the Details but t o n.

The Windows Components Wizard wi nd ow o pen s .

The Applicat io n Se rve r window opens.

6. Place a check mark next to Internet

The Internet Information Services (IIS) window opens.

Information Services (IIS) and click the

Details button.

IM8001 Production Monitoring™ User Manua l 3.9

Page 33

Chapter 3. Installing Production Mon ito ring™ Installing Micros o ft Inte rn et In fo rmation Services (IIS)

Procedure Details

7. Place a check mark next to World

Wide Web Service and click the

Details button.

8. Place a check mark next to Server Side

Includes and click OK.

9. Click OK on any open windows until you

get back to the Windows Component

Wizard.

The World Wide Web Service window opens.

10. Click Finish.

The syste m c o m p letes the installatio n .

Congratulations! You have activated IIS for your

server computer. If you haven’t enabled COM+ on

your server or you’re not sure, continue to page 3.16.

Otherwise, continue t o page 3.18to install or update

Power Wave® Manager.

Windows Vista IIS Installat ion

With Windows Vista, the installation files were saved to the computer when the Operating System was

installed on the computer . Since you want to turn the computer into a n inter nal web server, you nee d to

run the IIS installation to enable the appropriate components.

Procedure Details

1. Log in to the server computer as the

administrator user.

2. Select the Start > Control Panel from the

computer’s main program menu.

Contact your IT department for appropriate user

name and password if necessary.

3.10 Production Monitoring™User Manual IM8001

Page 34

Installing Microsoft Internet Information Services (IIS) Chapter 3. Installing Production Monitoring™

Procedure Details

3. Open Programs and Features.

4. Click the Turn Windows features on or off

link under Tasks.

5. Click the plus ( + ) icon next to Internet

Information Services to expand the list.

The Programs and Features list opens.

The Windows Features wi n d o w opens.

6. Verify there is a check mark next to IIS 6

Management Compatibility and all of the

options under it.

7. Click the plus ( + ) icon next to Application

Development Features to expan d th e li s t.

IIS 6 Management Console

IIS 6 Scripting Tools

IIS 6 WMI Compatibility

IIS Me taba se a n d IIS 6 configuration

compatibility

IM8001 Production Monitoring™User Manual 3.11

Page 35

Chapter 3. Installing Production Mon ito ring™ Installing Micros o ft Inte rn et In fo rmation Services (IIS)

Procedure Details

8. Verify there is a check mark next to the

appropriate options.

9. Click the plus ( + ) icon next to Common

HTTP Features to expand the list.

10. Verify there is a check mark next to the

appropriate options.

11. Click OK to close the window.

ASP

ASP.NET

Server Side Includes

Static Content

Congratulations! You have activated IIS for your

server computer. Continue to page 3.18 to install or

upgrade Power Wave® Manager.

Windows Server 2008 II S Installat ion

The installation files we r e saved to the computer when the Windows Server 2008 operating syste m w a s

installed on the computer . Since you want to turn the computer into an internal web server, you need to

tell the server that it need s to play t he ro le of a web ser ver (i.e ., one that hosts a web site and allows other

users to connect). Follow the instruct ions below to add the IIS components.

Procedure Details

1. Log in to the server computer as the

administrator user.

2. Select Server Manager from the Start menu.

Contact your IT department for appropriate user

name and password if necessary.

The Server Manager window opens.

3.12 Production Monitoring™User Manual IM8001

Page 36

Installing M icro s o ft Inte rnet Information Services (IIS) Chapter 3. Installing Produ ction Monitoring™

Procedure Details

3. Right-click the Roles option and select Add

Roles from the pop-up menu.

4. Click Next on the Befor e You Begin page if

it appears.

5. Place a check mark in the Web Server (II S)

checkbox and click Next.

6. Click the Add Required Features button.

7. Click Next on the Serve r Roles screen.

The Add Roles Wizard window opens.

The Select Server Ro les w indow appears.

The system prompts you to add the features

required for Web Server (IIS).

The Web Server (IIS) scre en appears.

8. Click Next on the Web Server (IIS)screen.

9. Click the plus ( + ) icon next to Web Server to

expand the list.

10. Click t h e plus ( + ) icon ne xt t o Application

Development to expand the list.

The Select Role Service sscreen displa y s.

IM8001 Production Monitoring™User Manual 3.13

Page 37

Chapter 3. Installing Production Mon ito ring™ Installing Micros o ft Inte rn et In fo rmation Services (IIS)

Procedure Details

11. Verify there is a check mark next to the

appropriate options.

12. Click t h e plus ( + ) icon ne xt t o Management

Tools to expand the list.

13. Click t h e plus ( + ) icon ne xt t o IIS 6

Management Compatibility to expand the list.

14. Verify there is a check mark next to IIS 6

Management Compatibility and all of the

options under it.

15. Click Next to continue the installation.

16. Verify your sele c t ions and click Install.

ASP.NET

This should produce a dialog requesting t he

addition of ISAPI Extensions. Add them as

well.

ASP

Server Side Includes

IIS Metabase Compatibility

IIS 6 WMI Compatibility

IIS 6 Scripting Tools

IIS 6 Management Console

The Confirm Ins t a llation Selections screen appears.

The system inst alls all the components necessary to

turn your computer into an internal web server for

Production Monitoring™.

17. Click the Close button when the installation is

complete.

Congratulations! You have activated IIS for your

server computer. Continue to page 3.18 to install

PowerShell on your server computer.

Windows 7 IIS Inst allation

With Windows 7, the installation files were saved to the computer when the Operating System was

installed on the computer . Since you want to turn the computer into an internal web server, you need to

run the IIS installation to ena ble the appropr iate componen t s so users and Welding P ow er Source s can

access Production Monitoring™.

Procedure Details

1. Log in to the server computer as the

administrator user.

2. Select the Start > Control Panel from the

computer’s main program menu.

Contact your IT department for appropriate user

name and password if necessary.