Page 1

Operator’s Manual

RETURN TO MAIN MENU

CHECKPOINT

™

Register your machine:

www.lincolnelectric.com/registration

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM8000 | Issue D ate Aug-13

© Lincoln Global, Inc. All Rights Reserved.

Need Help? Call 1.888.935.3877

to talk to a Service Representative

Hours of Operation:

8:00 AM to 6:00 PM (ET) Mon. thru Fri.

After hours?

Use “Ask the Experts” at lincolnelectric.com

A Lincoln Service Representative will contact you

no later than the following business day.

For Service outside the USA:

Email: globalservice@lincolnelectric.com

Page 2

THANK YOU FOR SELECTING

AT ALL

TIMES.

SPECIAL SITUATIONS

Additional precautionary measures

A QUALITY PRODUCT BY

LINCOLN ELEC TRIC.

PLEASE EXAMINE CARTON AND EQUIPMENT FOR

DAMAGE IMMEDIATELY

When this equipment is shipped, title passes to the purchaser upon

receipt by the carrier. Consequently, Claims for material damaged in

shipment must be made by the purchaser against the transportation

company at the time the shipment is received.

SAFETY DEPENDS ON YOU

Lincoln arc welding and cutting equipment is designed and built with

safety in mind. However, your overall safety can be increased by

proper installation ... and thoughtful operation on your part.

DO NOT INSTALL, OPERATE OR REPAIR THIS EQUIPMENT

WITHOUT READING THIS MANUAL AND THE SAFETY PRECAUTIONS

CONTAINED THROUGHOUT. And, most importantly, think before you

act and be careful.

WARNING

This statement appears where the information must be followed

exactly to avoid serious personal injury or loss of life.

CAUTION

This statement appears where the information must be followed to

avoid minor personal injury or damage to this equipment.

KEEP YOUR HEAD OUT OF THE FUMES.

DON’T get too close to the arc. Use

corrective lenses if necessary to

stay a reasonable distance away

from the arc.

READ and obey the Material Safety

Data Sheet (MSDS) and the warning

label that appears on all containers

of welding materials.

USE ENOUGH VENTILATION or

exhaust at the arc, or both, to keep

the fumes and gases from your breathing zone and the general area.

IN A LARGE ROOM OR OUTDOORS, natural ventilation may be

adequate if you keep your head out of the fumes (See below).

USE NATURAL DRAFTS or fans to keep the fumes away from your

face.

If you de velop unusual symptoms, see your supervisor. Perhaps the

welding atmosphere and ventilation system should be checked.

WEAR CORRECT EYE, EAR & BODY PROTECTION

PROTECT your eyes and face with welding helmet

properly fitted and with proper grade of filter plate

(See ANSI Z49.1).

PROTECT your body from welding spatter and arc

flash with protective clothing including woolen

clothing, flame-proof apron and gloves, leather

leggings, and high boots.

PROTECT others from splatter, flash, and glare with

protective screens or barriers.

IN SOME AREAS, protection from noise may be

appropriate.

BE SURE protective equipment is in good condition.

Also, wear safety glasses in work area

DO NOT WELD OR CUT containers or materials which previously had

been in contact with hazardous substances unless they are properly

cleaned. This is extremely dangerous.

DO NOT WELD OR CUT painted or plated parts unless special

precautions with ventilation have been taken. They can release highly

toxic fumes or gases.

PROTECT compressed gas cylinders from excessive heat, mechanical

shocks, and arcs; fasten cylinders so they cannot fall.

BE SURE cylinders are never grounded or part of an electrical circuit.

REMOVE all potential fire hazards from welding area.

ALWAYS HAVE FIRE FIGHTING EQUIPMENT READY FOR

IMMEDIATE USE AND KNOW HOW TO USE IT.

Page 3

SECTION A:

Diesel Engines

Gasoline Engines

WARNINGS

CALIFORNIA PROPOSITION 65 WARNINGS

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and other

reproductive harm.

The engine exhaust from this product contains chemicals known

to the State of California to cause cancer, birth defects, or other

reproductive harm.

ARC WELDING CAN BE HAZARDOUS. PROTECT

YOURSELF AND OTHERS FROM POSSIBLE SERIOUS

INJURY OR DEATH. KEEP CHILDREN AWAY. PACEMAKER WEARERS SHOULD CONSULT WITH THEIR

DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For additional

safety information, it is strongly recommended that you purchase a

copy of “Safety in Welding & Cutting - ANSI Standard Z49.1” from the

American Welding Society, P.O. Box 351040, Miami, Florida 33135 or

CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety”

booklet E205 is available from the Lincoln Electric Company, 22801

St. Clair Avenue, Cleveland, Ohio 44117-1199.

BE SURE THAT ALL INSTALLATION, OPERATION,

MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

SAFETY

1.d. Keep all equipment safety guards, covers and

devices in position and in good repair.Keep

hands, hair, clothing and tools away from

V-belts, gears, fans and all other moving parts

when starting, operating or repairing

equipment.

1.e. In some cases it may be necessary to remove safety guards to

perform required maintenance. Remove guards only when

necessary and replace them when the maintenance requiring

their removal is complete. Always use the greatest care when

working near moving parts.

1.f. Do not put your hands near the engine fan. Do not attempt to

override the governor or idler by pushing on the throttle control

rods while the engine is running.

1.g. To prevent accidentally starting gasoline engines while turning

the engine or welding generator during maintenance work,

disconnect the spark plug wires, distributor cap or magneto wire

as appropriate.

1.h. To avoid scalding, do not remove the radiator

pressure cap when the engine is

hot.

ELECTRIC AND

MAGNETIC FIELDS MAY

BE DANGEROUS

2.a. Electric current flowing through any conductor

causes localized Electric and Magnetic Fields (EMF). Welding

current creates EMF fields around welding cables and welding

machines

FOR ENGINE POWERED

EQUIPMENT.

1.a. Turn the engine off before troubleshooting

and maintenance work unless the

maintenance work requires it to be running.

1.b. Operate engines in open, well-ventilated

areas or vent the engine exhaust fumes outdoors.

1.c. Do not add the fuel near an open flame

welding arc or when the engine is running.

Stop the engine and allow it to cool before

refueling to prevent spilled fuel from

vaporizing on contact with hot engine parts

and igniting. Do not spill fuel when filling

tank. If fuel is spilled, wipe it up and do not start engine until

fumes have been eliminated.

2.b. EMF fields may interfere with some pacemakers, and welders

having a pacemaker should consult their physician before

welding.

2.c. Exposure to EMF fields in welding may have other health effects

which are now not known.

2.d. All welders should use the following procedures in order to

minimize exposure to EMF fields from the welding circuit:

2.d.1. Route the electrode and work cables together - Secure

them with tape when possible.

2.d.2. Never coil the electrode lead around your body.

2.d.3. Do not place your body between the electrode and work

cables. If the electrode cable is on your right side, the

work cable should also be on your right side.

2.d.4. Connect the work cable to the workpiece as close as possible to the area being welded.

2.d.5. Do not work next to welding power source.

III

Page 4

SAFETY

ELECTRIC SHOCK

CAN KILL.

3.a. The electrode and work (or ground) circuits are

electrically “hot” when the welder is on. Do

not touch these “hot” parts with your bare skin

or wet clothing. Wear dry, hole-free gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full area

of physical contact with work and ground.

In addition to the normal safety precautions, if

welding must be performed under electrically

hazardous conditions (in damp locations or while

wearing wet clothing; on metal structures such as

floors, gratings or scaffolds; when in cramped

positions such as sitting, kneeling or lying, if there

is a high risk of unavoidable or accidental contact

with the workpiece or ground) use the following

equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel, welding head, nozzle or semiautomatic welding

gun are also electrically “hot”.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection should

be as close as possible to the area being welded.

3.e. Ground the work or metal to be welded to a good electrical (earth)

ground.

3.f. Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Never simultaneously touch electrically “hot” parts of electrode

holders connected to two welders because voltage

two can be the total of the open circuit voltage of both

welders.

3.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

between the

ARC RAYS CAN BURN.

4.a. Use a shield with the proper filter and cover plates to protect your

eyes from sparks and the rays of the arc when welding or

observing open arc welding. Headshield and filter lens should

conform to ANSI Z87. I standards.

4.b. Use suitable clothing made from durable flame-resistant material

to protect your skin and that of your helpers from the arc rays.

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

FUMES AND GASES

CAN BE DANGEROUS.

5.a. Welding may produce fumes and gases

hazardous to health. Avoid breathing these

fumes and gases. When welding, keep your head out of the fume.

Use enough ventilation and/or exhaust at the arc to keep fumes

and gases away from the breathing zone. When welding

with electrodes which require special ventilation

such as stainless or hard facing (see instructions

on container or MSDS) or on lead or cadmium

plated steel and other metals or coatings which

produce highly toxic fumes, keep exposure as low

as possible and within applicable OSHA PEL and

ACGIH TLV limits using local exhaust or

mechanical ventilation. In confined spaces or in

some circumstances, outdoors, a respirator may

be required. Additional precautions are also

required when welding on galvanized steel.

5. b. The operation of welding fume control equipment is affected by

various factors including proper use and positioning of the

equipment, maintenance of the equipment and the specific

welding procedure and application involved. Worker exposure

level should be checked upon installation and periodically

thereafter to be certain it is within applicable OSHA PEL and

ACGIH TLV limits.

5.c. Do not weld in locations near chlorinated hydrocarbon vapors

coming from degreasing, cleaning or spraying operations. The

heat and rays of the arc can react with solvent vapors to form

phosgene, a highly toxic gas, and other irritating products.

3.j. Also see It ems 6.c. and 8.

5.d. Shielding gases used for arc welding can displace air and

injury or death. Always use enough ventilation, especially in

confined areas, to insure breathing air is safe.

5.e. Read and understand the manufacturer’s instructions for this

equipment and the consumables to be used, including the

material safety data sheet (MSDS) and follow your employer’s

safety practices. MSDS forms are available from your welding

distributor or from the manufacturer.

5.f. Also see item 1.b.

IV

cause

Page 5

SAFETY

WELDING AND CUTTING

SPARKS CAN CAUSE

FIRE OR EXPLOSION.

6.a. Remove fire hazards from the welding area. If

this is not possible, cover them to prevent the

welding sparks from starting a fire. Remember that welding

sparks and hot materials from welding can easily go through

small cracks and openings to adjacent areas. Avoid welding near

hydraulic lines. Have a fire extinguisher readily available.

6.b. Where compressed gases are to be used at the job site, special

precautions should be used to prevent hazardous situations.

Refer to “Safety in Welding and Cutting” (ANSI Standard Z49.1)

and the operating information for the equipment being used.

6.c. When not welding, make certain no part of the electrode circuit is

touching the work or ground. Accidental contact can cause

overheating and create a fire hazard.

6.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures will

not cause flammable or toxic vapors from substances inside.

They can cause an explosion even though they have been

“cleaned”. For information, purchase “Recommended Safe

Practices for the Preparation for Welding and Cutting of

Containers and Piping That Have Held Hazardous Substances”,

AWS F4.1 from the American Welding Society (see address

above).

6.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

6.f. Sparks and spatter are thrown from the welding arc. Wear oil free

protective garments such as leather gloves, heavy shirt, cuffless

trousers, high shoes and a cap over your hair. Wear ear plugs

when welding out of position or in confined places. Always wear

safety glasses with side shields when in a welding area.

6.g. Connect the work cable to the work as close to the welding area

as practical. Work cables connected to the building framework or

other locations away from the welding area increase the

possibility of the welding current passing through lifting chains,

crane cables or other alternate circuits. This can create fire

hazards or overheat lifting chains or cables until they fail.

6.h. Also see item 1.c.

CYLINDER MAY EXPLODE IF

DAMAGED.

7.a. Use only compressed gas cylinders containing

the correct shielding gas for the process used

and properly operating regulators designed for

the gas and pressure used. All hoses, fittings,

etc. should be suitable for the application and

maintained in good condition.

7.b. Always keep cylinders in an upright position securely chained to

an undercarriage or fixed support.

7.c. Cylinders should be located:

• Away from areas where they may be struck or subjected

to physical damage.

• A safe distance from arc welding or cutting operations

and any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode holder or any other

electrically “hot” parts to touch a cylinder.

7.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. Valve protection caps should always be in place and hand tight

except when the cylinder is in use or connected for use.

7.g. Read and follow the instructions on compressed gas cylinders,

associated equipment, and CGA publication P-l, “Precautions for

Safe Handling of Compressed Gases in

Cylinders,” available

from the Compressed Gas Association 1235 Jefferson Davis

Highway, Arlington, VA 22202.

FOR ELECTRICALLY

POWERED EQUIPMENT.

8.a. Turn off input power using the disconnect

switch at the fuse box before working on the

equipment.

8.b. Install equipment in accordance with the U.S. National Electrical

Code, all local codes and the manufacturer’s recommendations.

6.I. Read and follow NFPA 51B “ Standard for Fire Prevention During

Welding, Cutting and Other Hot Work”, available from NFPA, 1

Batterymarch Park, PO box 9101, Quincy, Ma 022690-9101.

6.j. Do not use a welding power source for pipe thawing.

8.c. Ground the equipment in accordance with the U.S. National

Electrical Code and the manufacturer’s recommendations.

Refer to

http://www.lincolnelectric.com/safety

for additional safety information.

Welding Safety

Interactive Web Guide

for mobile devices

V

Page 6

NOTES

Page 7

Table of Contents

Preface

Typographical Conventions Used ........................................................................................................ 1

Cross-References ....................................................................................................................... 1

Text You Type Using the Keyboard ............................................................................................ 1

Keys You Press and Buttons You Click ........................................................................................ 1

Menus You Select .............................................................................................................. ........ 1

Dialog Box, Application Window Titles, a nd F ield Name s .......................................................... 1

Notes, Warnings, and Tips ................................................................................................................... 2

Revision History

General Informa t io n

Introduction to CheckPoint™ ............................................................................................................ 1.1

CheckPoint™ Editions.............................................................................................................. 1.1

Weld Profiles ........................................................................................................................... 1.2

Weld Logging .......................................................................................................................... 1.2

Electronic Notificat ion S yste m ................................................................................................ 1.3

Traceability ............................................................................................................................. 1.3

Mobile Devices........................................................................................................................ 1.4

WeldScore™ ..................................................................................................................................... 1.4

CheckPoint™ Cloud-Based Architecture ........................................................................................... 1.4

Security and Da ta Storage ................................................................................................................ 1.5

Requirements and Network Capacity ............................................................................................... 1.5

Access Requirements .............................................................................................................. 1.5

Accessing Data in the CheckPoint ™ Data Center .................................................................... 1.5

Network Capacity .................................................................................................................... 1.6

Preparing for CheckPoint™

Providing Access to the Internet ....................................................................................................... 2.1

Update the Welding Power Source Firmw a re .................................................................................. 2.1

Install the Latest Power Wave® Manager ......................................................................................... 2.4

Enable CheckPoint™ for a Power Source .......................................................................................... 2.6

Establish Connection to the Welding Pow er Source ............................................................... 2.6

Enabling CheckPoint™ ............................................................................................................. 2.8

Save the Production Monitoring Installat ion Key F ile ........................................................... 2.10

Setting up CheckPoint™

Connecting to CheckPoint™ .............................................................................................................. 3.1

Create Administrato r Account .......................................................................................................... 3.2

Validate User Information in Chec kPoint ™ ....................................................................................... 3.3

IM8000 CheckPoint™User Manual TOC.1

Page 8

Table of Contents

Uploading the Installat ion Key File ................................................................................................... 3.4

Register Your Company .................................................................................................................... 3.5

Creating Multiple Site s ..................................................................................................................... 3.7

Managing CheckPoint™

Tabs in the CheckPoint™ Manager ................................................................................................... 4.1

Filtering Lists in the CheckP oint™ Manager ...................................................................................... 4.2

General Tab ...................................................................................................................................... 4.3

Company Information ............................................................................................................. 4.3

Allowable IP Addresses ........................................................................................................... 4.3

User Management ............................................................................................................................ 4.4

Display Current Users ............................................................................................................. 4.4

Add a User Account ................................................................................................................ 4.5

Edit a User Account ................................................................................................................. 4.6

Delete a User Account ............................................................................................................ 4.7

Shift Schedules ................................................................................................................................. 4.8

Next Production Day ............................................................................................................... 4.8

Add a Shift............................................................................................................................... 4.9

Edit a Shift .................................................................................................................. ........... 4.13

Remove a Shift ...................................................................................................................... 4.13

Shift Schedule Exa mple – Three Basic Shift s ......................................................................... 4.13

Shift Schedule Exa mple – Two Alternating Shifts, No Weekends .......................................... 4.15

Welding Power Sources .................................................................................................................. 4.17

Site Configurat ion and Overall Equipment Efficiency (OEE) .................................................. 4.19

Adding a Container ............................................................................................................... 4.20

Adding a Welding Power Source ........................................................................................... 4.21

Changing the Container for a Welding Power Sourc e ........................................................... 4.23

Alert History ................................................................................................................................... 4.24

Documents ..................................................................................................................................... 4.25

Access and Navigate the Library ........................................................................................... 4.25

Add a Document to the Library ............................................................................................. 4.26

Add a Link to the Document Library ..................................................................................... 4.28

Your CheckPoint™ User Account

Finalize User Registra t ion ................................................................................................................. 5.1

Accept the End-User License Agreeme nt ................................................................................ 5.1

Confirm Security Settings ........................................................................................................ 5.2

Managing Your User Account ........................................................................................................... 5.2

Notifications............................................................................................................................ 5.3

Personal Information .............................................................................................................. 5.3

Password Change .................................................................................................................... 5.4

play Preferenc e s ................................................................................................................ 5.4

Dis

Daily Digest ............................................................................................................................. 5.5

TOC.2 CheckPoint™ User Manual IM8000

Page 9

Overview

Navigating CheckPoint ™ ................................................................................................................... 6.1

Overview of Reports ......................................................................................................................... 6.4

Table of Contents

Alert Subscriptions .................................................................................................................. 5.6

Site Membership ..................................................................................................................... 5.9

Asset Tree ............................................................................................................................... 6.1

Report Tabs ............................................................................................................................. 6.2

Individual Reports ................................................................................................................... 6.3

Panel Resize ............................................................................................................................ 6.3

Generating Reports ................................................................................................................. 6.4

Report Criteria ........................................................................................................................ 6.4

Report Links ............................................................................................................................ 6.5

Sorting by Columns ................................................................................................................. 6.6

Report Page Numbers ............................................................................................................. 6.6

Exporting Report Data ............................................................................................................ 6.7

Refreshing Report Data ........................................................................................................... 6.7

Summary Tab – Container Level

Equipment Reports ........................................................................................................................... 7.1

Operator Reports .............................................................................................................................. 7.4

Overview Reports ............................................................................................................................. 7.6

Utilization................................................................................................................................ 7.6

Productivity ............................................................................................................................. 7.7

Lowest Consumable Time Remaining ..................................................................................... 7.8

WeldScore™ ............................................................................................................................ 7.8

Avg. WeldScore™ Top 10 and Avg. WeldScore™ Bottom 10 ................................................... 7.9

Summary Tab – Power Source Level

Today ................................................................................................................................................ 8.1

Status ...................................................................................................................................... 8.2

Availability (Last 24 H our s)...................................................................................................... 8.3

Consumable Package .............................................................................................................. 8.5

Serial Numbers........................................................................................................................ 8.6

Utilization (Last 24 H our s) ....................................................................................................... 8.7

WeldScore™ Live Update ........................................................................................................ 8.7

Welder Detail .......................................................................................................................... 8.8

Productivity (Last 24 Hours) .................................................................................................... 8.9

ldScore™ (Last 24 Hours) ................................................................................................. 8.10

We

Last 7 Days ...................................................................................................................................... 8.10

Utilization (Last 7 Da ys)......................................................................................................... 8.10

Productivity (Last 7 Days) ...................................................................................................... 8.11

WeldScore™ (Last 7 Days) ..................................................................................................... 8.12

Avg. True Energy™ in Kilojoules (7 Days) .............................................................................. 8.13

IM8000 CheckPoint™ User Manual TOC.3

Page 10

Table of Contents

Custom ........................................................................................................................................... 8.14

Overall Equipment Efficiency (OEE)

OEE Tab ............................................................................................................................................ 9.1

Today Reports ......................................................................................................................... 9.2

Last 7 Days .............................................................................................................................. 9.3

Custom .................................................................................................................................... 9.4

Calculations of OEE in CheckP oint ™ ................................................................................................. 9.5

OEE Percentage....................................................................................................................... 9.5

Availability Fac t or ................................................................................................................... 9.5

Performance Factor ................................................................................................................ 9.8

Quality Factor ......................................................................................................................... 9.9

Establishing Planned Downt ime ..................................................................................................... 9.10

Planned Downtime Example ................................................................................................. 9.11

Adding Planned Downtime ................................................................................................... 9.11

Planned Downtime – Company Site ...................................................................................... 9.13

Planned Downtime – Container ............................................................................................ 9.14

Planned Downtime – Welding Power Source ....................................................................... 9.15

Assembly Li sting Tab

Overview Report ............................................................................................................................. 10.1

Main Overview List ............................................................................................................... 10.1

Overview Drilldown .............................................................................................................. 10.3

Weld Sequence Drilldown ..................................................................................................... 10.5

By Assembly.................................................................................................................................... 10.6

Weld Listing Tab

Summary Report............................................................................................................................. 11.1

Summary Criteria .................................................................................................................. 11.1

Data on the Report ............................................................................................................... 11.3

Weld Detail ........................................................................................................................... 11.5

Weld Profiles ................................................................................................................................ 11.10

Profile Reports .............................................................................................................................. 11.11

Criteria on the Profile Report s ............................................................................................ 11.12

WeldScore™ ........................................................................................................................ 11.13

Current/Voltage .................................................................................................................. 11.13

Wire Feed Speed ................................................................................................................. 11.13

Deposition ........................................................................................................................... 11.13

True Energy™ ...................................................................................................................... 11.14

Duration .............................................................................................................................. 11.14

ount .................................................................................................................................. 11.14

C

TOC.4 CheckPoint™ User Manual IM8000

Page 11

Limit Errors Tab

Overview ........................................................................................................................................ 12.1

Today .............................................................................................................................................. 12.1

Last 7 Days ...................................................................................................................................... 12.2

Custom ........................................................................................................................................... 12.2

Events Tab

Report Criteria ................................................................................................................................ 13.2

Summary ........................................................................................................................................ 13.3

History ............................................................................................................................................ 13.4

Documents Tab

Opening Documents and Links ....................................................................................................... 14.1

Operators Manuals ......................................................................................................................... 14.2

Troubleshooting

Cannot Connect to a Power Source ................................................................................................. A.1

Cannot Apply Settings ..................................................................................................................... A.1

Table of Contents

Overall Equipment Efficiency Examples

Availability Example 1 .......................................................................................................................B.1

Availability for Eac h Hour ........................................................................................................B.2

Availability for the Entir e Shift ................................................................................................B.2

Availability Example 2 .......................................................................................................................B.2

Availability for Eac h Hour ........................................................................................................B.3

Availability for the Entir e Shift ................................................................................................B.3

Availability Example 3 .......................................................................................................................B.4

Availability for Eac h Hour ........................................................................................................B.4

Availability for the Entir e Shift ................................................................................................B.5

Glossary

IM8000 CheckPoint™ User Manual TOC.5

Page 12

Table of Contents

TOC.6 CheckPoint™ User Manual IM8000

Page 13

Preface

Typographical Conventions Used

Before using this guide, it is importa nt to understa nd t he typographic al conventions used to identify and

describe information.

Cross-References

Cross-references t o chapter s, sections, page numbers, hea dings, e t c . a re shown in a n italic t yp e fa ce .

e.g., Refer to Text You Type Using the Keybo ard on page 1.

Text You Type Using the Keyboard

Text that you type using the keyboard is shown in a Courier typeface.

e.g., Type John Smi th in t he Name field.

Keys You Press and Buttons You Click

Keys tha t you press on the key board and buttons/icon s that you click with the mouse are shown in a bold

sans-serif t y peface.

e.g., Press Enter.

e.g., Click OK to continue.

Menus You Select

Menus and the selections you make from the menus are shown in a bold sans-serif typeface.

e.g., Select Start > Control Panel from the main computer menu.

e.g., Select Tools > Options from the menu.

Dialog Box, Application Window Titles, and Field Names

The titles of dialog boxes and application windows are shown in italics. Field names and selections made

from drop-down menus, etc. are also shown in italics.

e.g., The Print Preview window opens.

e.g., Select All Shifts from the drop-down list.

IM8000 CheckPoint™User Manual 1

Page 14

Preface Notes, Warnings, and Tips

Notes, Warnings, and Tips

Notes, stops and tips appear throughout the manual. They provide additiona l informa t ion t hat is important

for you to know about the topic.

NOTE | A note is a n important piece of information.

STOP | You should definitely read the informatio n in a stop table.

It could help y ou prevent a situation from which you cannot

recover.

TIP | A tip table helps you w it h s ome interesting or useful

informatio n about using the program.

2 CheckPoint™ User Manual IM8000

Page 15

Revision Histor y

Date Change Description

August 2012 Initial release a s IM8000

June 2013 Major revamp and update of manual

August 2013 Made the following updates reflecting t he new ver sion:

Added Overall Equipment Efficiency (OEE)features to setup instructions

Updated description of Daily Digest to reflect check mark behavior

Edited User Time/Company time descriptions for shifts

Edited chapters to reflect Summary tab changes

Added new OEE tab section

Added new Assembly Listing tab section

Updated screenshots to reflect new tabs, features and changes

IM8000 CheckPoint™User Manual REV.1

Page 16

Revision History

THIS PAGE INTENTIONALLY LEFT BLANK.

REV.2 CheckPoint™ User Manual IM8000

Page 17

Chapter 1

General Information

Introduction to CheckPoint™

CheckPoint™ is the newest data collection and repo r ting technology available for the latest models of t he

Lincoln Electric P owe r Wave® family of Welding Power Sources.

CheckPoint™ is cloud-based co mput ing ba sed on Production Monit or ing™ but with mor e funct ionalit y a nd

more flexibility. C he ckPoint™ does not require additional har dwa r e or softw are installation, allowing you

to work from you own computer using your Internet browser. CheckPoint™ enables you to measure the

Pulse™ of your Lincoln Electr ic ® welders with critical alerts and unpr ece de nte d pr oduction visibilit y.

CheckPoint™ is available for viewing on your smart phone, tablet and laptop or desktop of any computer or

device with Internet access.

Cloud-based computing refer s to the delive r y of computing a nd storage capacity a s a service to a

community of end users. End users access cloud-based applications through a web br owser or a desktop or

mobile app while the business software a nd data ar e store d on server s at a remote location. Cloud

computing allows compa nie s to get applications up and running faster, with improved manage a bilit y and

less maintenance. It relies on sh a ring of resources t o achieve coherence and economies of sca le similar to a

utility (like th e electricity grid) over a networ k (typ ic ally the Internet).

CheckPoint ™ allow s gr e a ter visibility. You can access your data anytime, anywhere, with any web device

without the need for VPN client software. CheckPoint ™ is ea sy to implem e nt and mainta in. You simply

plug the Welding Power Source into your network. (Refer to the Power Wave® Manager User Manual for

instructions.) There is low ove r hear d a nd no computer hardware required in the field; it is as user-friendly

as going to a website. CheckPoint™ is more dynamic in t ha t any updat e s to the applicat ion’s func t iona lit y

are instant across all users.

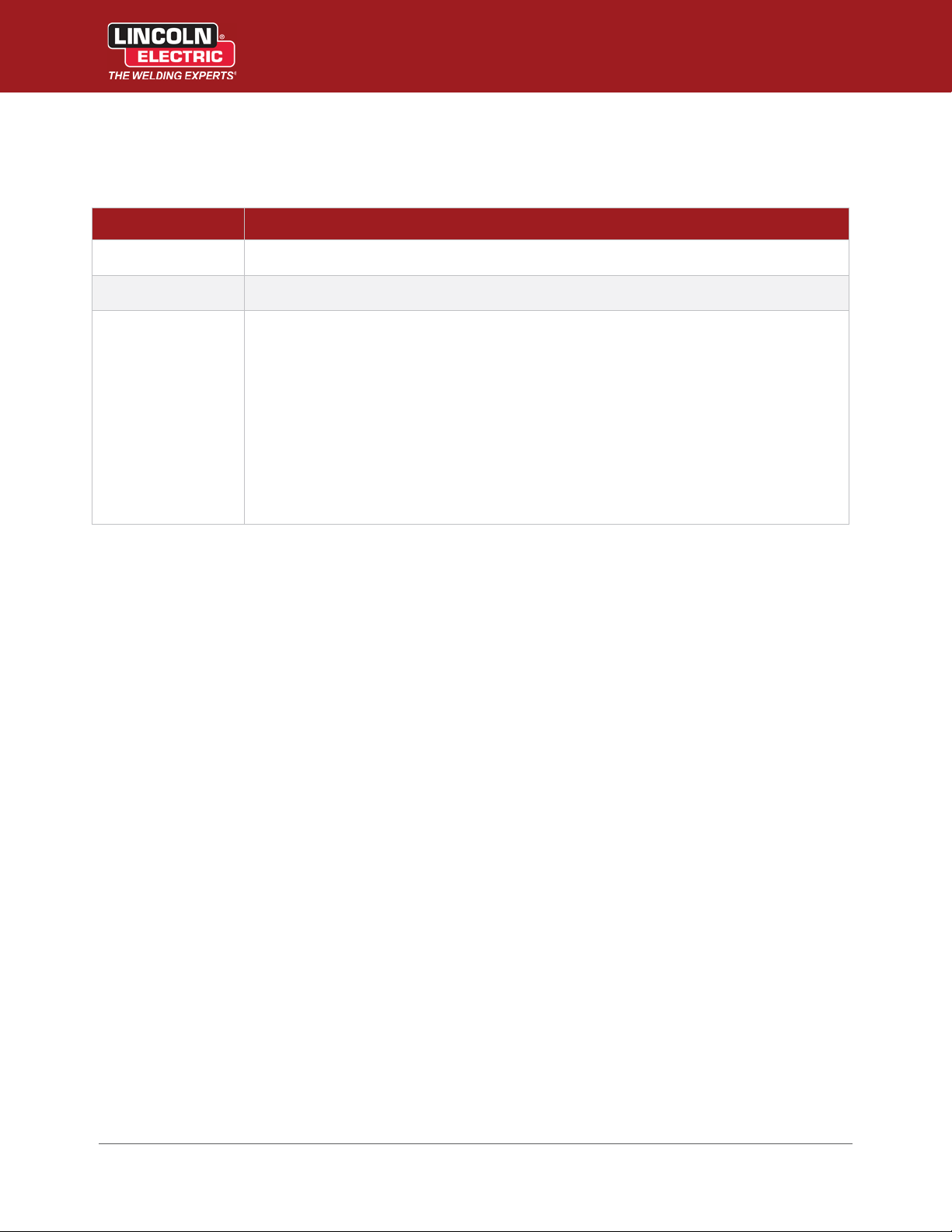

CheckPoin t ™ Editions

CheckPoint™ offers two options: Standard E dit ion and Premium Edition. The Standard Edition is available

free of charge w it h eve r y Powe r Wa ve®. Sta ndar d Edition includes a rolling 30 days of data storage after

which point the data is permanent ly de lete d from the system. The Premium Edition is available for an

annual subscription fee , w hich includes a rolling 12 months of data storage with a permanent offline

archive. With CheckPoint™, it is possible to have a combina tion of Standard and Premium Editions based

on your needs. Table 1.1 details the differ ences in features.

NOTE | For details on the Premi um Edition, please send a n e-mail

with your conta c t information to sales@igearonline.com

.

IM8000 CheckPoint™User Manual 1.1

Page 18

Chapter 1. General Information Introduction to CheckPoint™

Table 1.1 Features in Each Versi on

Field Standard Premium

Mobile Ready, Global Data Access

Cloud Ready, Global Data Access

E-mail Notification System

Reporting

Manual Data Export

Document Library

Extended Document Library

(Upload and store up to 15 GB of custom documents and files)

1 Year of Live Rolling Data Storage

Automated Data Archiving

Share Data wit h Third-P a r ty Applications and Systems

(with ODATA API)

Weld Profiles

One of the principal goals of CheckPoint™ is to report on welds that are outside of user-defined limits with

respect to WeldScore™, current, voltage, wire feed speed and duration. This goal would be simple to

implement if th e Welding P o w e r So ur ce we r e to per for m on ly on e t y pe of we ld ov e r and over. H owe ver, in

practical applicat ions, t his is not the case. The assembly of many different industrial components re quires

welds of varying type and length .

The concept of Weld Pr o file s allows the Welding Power Source to apply differ ent limit settings for each

weld that is performed on a certain part. Before the Welding Power Source begins a new weld, the wire

feeder or system controller selects the corresponding Weld Profile. The Weld Engineer can, therefore,

assign one Weld P r o file to each weld required for the part asse m b ly.

For more in-dept h info r ma tion about Weld Profiles, please refer to the Power Wave® Manager User

Manual.

Weld Logging

CheckPo int ™ records large quantities of weld statistics. Each log entry contains th e fo llowing welding

statistics for each weld:

For current, voltage, wire feed speed and duration:

- Minimum

- Maximum

- Average

- Percent above limit

1.2 CheckPoint™User Manual IM8000

Page 19

Introduction to CheckPoint™ Chapter 1. General Information

- Percent belo w lim it

- Profile ma ximu m limit

- Profile minimum lim it

True Energy™

Date and time the weld was made

Duration of the weld

Weld stat us a f te r limit checking

Part Number, Consumable Lot and Operator ID

WeldScore™

Electronic Notificat ion System

When a Welding Power Source is used with CheckPoint ™, t he data center can send e-mail and text-message

notifications to multiple use r s. Eac h user’s e-mail a ddr e ss and mobile numbe r can be configur e d t o receive

messages from the CheckPoint™ data center upon any of several e ve nt condit ions. See page 5.6 for more

details on the alerts available.

Traceability

CheckPoint ™ pr o vides you with the ability t o repo r t on all the welds that were made on a specific part

number, by a specific o per ator or using a specific consumable lot c ode. Before a w e ld is made , this

information is communic ated to the Welding Power Source, in a variety of ways. Every weld that is ma de

after this is assigned with these ID numbe r s until a ne w number is e ntered. CheckP oint ™ users can

generate a traceability report that looks fo r this ID from a ll t h e W e lding Power Sources in the system.

Traceability solutions are typica lly c u stomized to a customer’s specific needs. Please contact Linco ln

Electric for a quote on your needs.

NOTE | CheckPoint™ does not s upport consumable package

tracking f or dual wire feeding syst ems .

IM8000 CheckPoint™ User Manual 1.3

Page 20

Chapter 1. General Information WeldScore™

Mobile Devices

With CheckPoint™, you can download native apps for iPhone®, Bla ckbe r r y® and Android t o provide mobile

users access to their welder data anytime from anywhe re. Users can view da shboa rd widget s, history a nd

alarm events, receive real-time text and e-mail messages, download the latest documents, and scan

barcodes a s part o f an ea sy-to-use traceability solution.

Links for downloading m o bile a pplic ations are available at www.lincolncheckpoint.com under the Mobile

Enabled portion of the home page. For more information on using the mobile version, please refer to the

CheckPoint™ Mobile App User Manual.

WeldScore™

WeldScore™, a new fe atur e ava ila ble in all third-generation Welding Power Sour ce mo de ls (including the

i400, C300, S350, S500 and AC/DC 1000 SD), can be used to support a weld qua lity control program. It

assigns a scor e to welds on a 0% to 100% scale that indicates the acceptability of the weld. The score is

based on a comparison to previously trained welding condit ions. Any weld w ith a score of 85% to 90% or

above can be considered, with a reasonable amount of confidence, to be an acceptable weld. WeldScore™

can be used independently on the power source or together with CheckPoint™. Please refer to the Power

Wave® Manager User Manual for more in-depth information on WeldScore™.

NOTE | WeldScore™ is not a guarantee of quality and is not

intended t o replace a quality co ntrol system.

CheckPoint™ Cloud-Based Architecture

The CheckPoint™ system uses a cloud-based ar c hit e ctur e . This means that ther e is no dedicate d compute r

required at your company to collect and store the data. Each piece of welding e quipme nt simply require s a

network connection. The Welding P o w e r Source initiates the transfer of information through firewallfriendly communications to the data center. (The data transfer does not initiat e fr om outside the power

source.) At that point, the data is accessible using a w e b brow se r and a secure login.

Figure 1.1 CheckPoint™ Cloud-Based Architecture

1.4 CheckPoint™User Manual IM8000

Page 21

Security and Data Storage Chapter 1. General Information

Security and Data Storage

Each CheckPoint™ customer’s data is stored in a state-of-the -art data cent e r in dedicate d and par t it ione d

databases, exclusive t o eac h custome r . Additionally, when viewing the CheckPoint™ application, highsecurity, industr y-st andard encryption is utilized.

The hosting cent er is a SAS 70 Ty pe II c om pliant fa c ility. SAS 70 is designated by the U.S. Securities and

Exchange Commission (SEC) as an acceptable method to obtain assurance of a service organization’s

internal controls without c o nducting separ ate assessment s. Suc c essful complet ion of t he SAS 70 Type II

examination indicat es that the processes, procedures, and contro ls have been formally e valuate d and

tested by an independent auditing firm.

A service auditor ’s exa minat ion pe r formed in accordance with SAS No. 70 (SAS 70 audit) is widely

recognized. It represents that a service orga nization ha s bee n thro ugh a n in-depth audit of the ir contr ol

objectives and control act ivit ies, w hic h oft e n include c ontrols over information technology and related

processes. A Type II report not only includes the service organiza t ion’s descr iption of c o nt rols but also

includes detaile d testing of the design and operating effec t iveness.

The hosting center environme nt is built w it h stat e-of-t he-art equipment, technology investments and

operational expert ise . The re is an esta blished disa ster recovery program with redundancy and failover to

protect the information stored in the system.

Requirements and Network Capacity

Access Requ irements

Each computer or mobile device that wants to conne ct t o CheckPoint™ must have access to the Inte r net.

All Welding Power Sources also need to have access to the Internet to report information back to the

CheckPoint™ data center . Every Welding Power Sourc e has a unique 16-charact er serial number.

This identification serial number is save d dur ing the registra t ion pr ocess and sent to the CheckPoint™ data

center with each welding data packet. When data arrives at the CheckPoint™ data center, the identification

serial number is used to save the data into your customer database.

See Chapter 2 for details on preparing for CheckPoint™.

Accessing Dat a in the CheckPoint™ Data Center

Each customer has a separate partition in the database for the ir data . You control acce ss to your data with

usernames and passwords that are created by your CheckPoint™ Administrator. The administrator

provides access to the data, as needed, for those users who need to access the data and generate reports.

See page 4.4 for details on User Management.

IM8000 CheckPoint™ User Manual 1.5

Page 22

Chapter 1. General Information Requirements and Network Capacity

Network Cap acity

Networks and Internet connections have a limited amount of bandw idt h for sending dat a . Each Welding

Power Source uses a small amount of bandwidth. In order to estimate the total ba ndw idt h on your

network, you can multiply the number of power welding source s by the data qua ntit y of data pack ets

described:

Every 20 seconds, each power source sends a status update to the Chec kP oint ™ data center; th e

data packet is about 1 KB in size.

If a power source has completed a weld, or multiple welds, ever y 92 seconds it will send the new

data; the data packet is about 2 KB per weld.

If there is an oc c urr e nce of a powe r so ur c e e vent o r fault , every 66 seconds it w ill se nd the new

data; the data packet is 0.5 KB in size per event.

In the event the network or Internet connection goes down due to unexpected problems or scheduled

maintenanc e , the Welding Power Sources will continue to c ollect and hold the welding data until the

network connection is reest a blished.

Each power source has enough internal memory to hold welding da t a for 1000 welds. Once t he Interne t

connection is r eest ablished, all welding data will be sent to the CheckPoint™ data center. If more than

1000 welds are made before the Internet connect ions is ree st a blished, only the data from the la st 1000

welds will be saved; data for the oldest welds will be lost.

STOP | If the power source is turned off before the Internet

connecti on is reestablished, al l w e lding data will be lost.

1.6 CheckPoint™ User Manual IM8000

Page 23

Chapter 2

Preparing for CheckPoint™

It is essential to have at least one Welding Power Source set up in CheckPoint ™ pr ior to creating a n acc ount

for your company. This chapt er walks you through t h e necessary step s to c omplete this task. Af ter

successfully c om pleting these steps, you will becom e the Che ckPoint™ Site Administrator and have the

ability to add Welding P o w e r So ur ces a nd user s through the CheckPoint™ Manager function of the

application.

Providing Access to the Internet

You need to open up the following information on your server in order to grant the Welding P ow er S ources

access to the Internet: http://ws.lincolncheckpoint.com at IP address 216.26.175.3 (subject to change)

using port 80 to send out TCP/IP and HTTP messages.

TIP | Contact y our local IT department for assistance.

Update the Welding Power Source Firmware

“Firmware ” is th e memo r y and programming code within the Welding Power So ur ce t hat is the co nt r o l

program for the machine. Making sure you have the latest firmware ensures that you have the latest

features available for the power source, inc luding th e most rec e nt ver sion of the Production Monitoring™

and CheckPoint™ software .

To install the latest firmware:

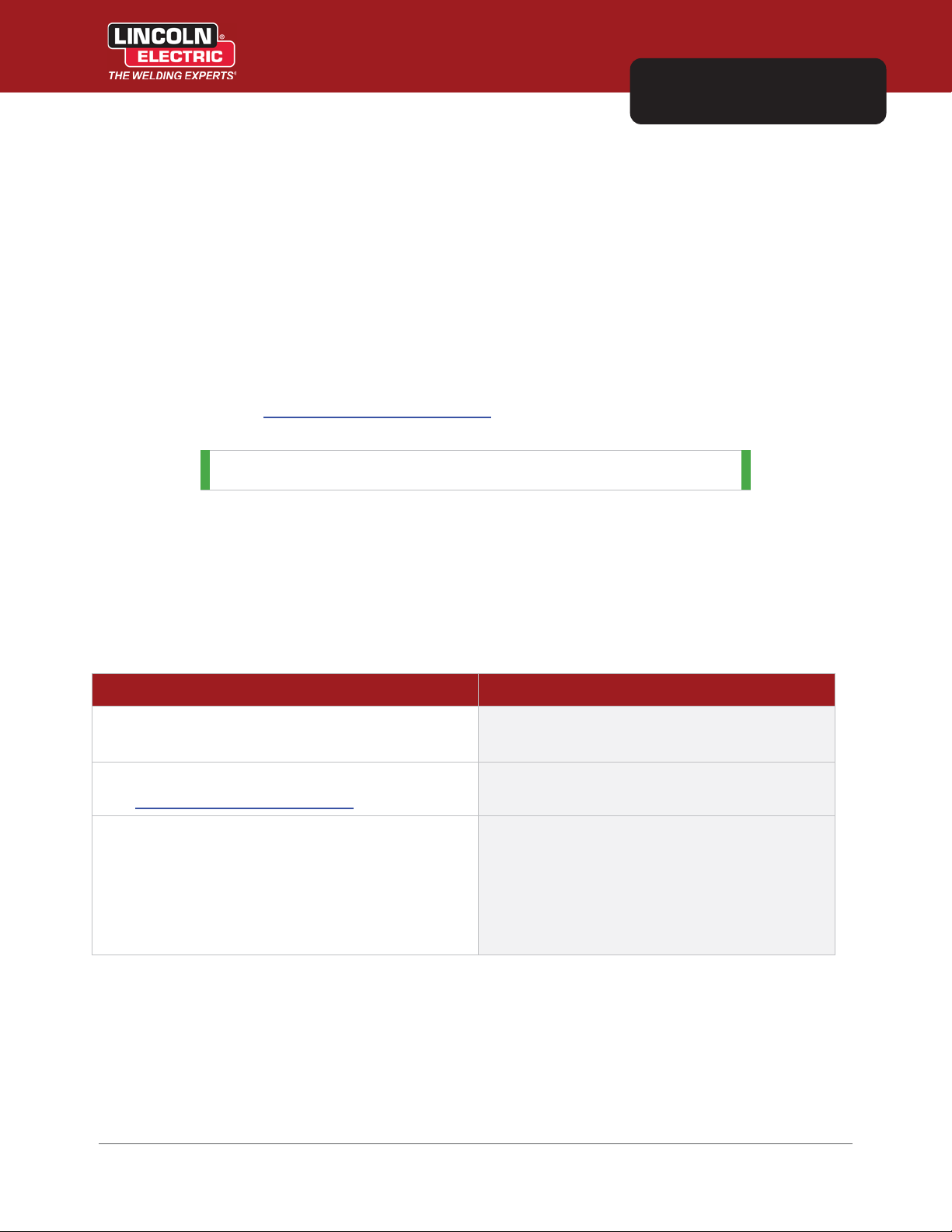

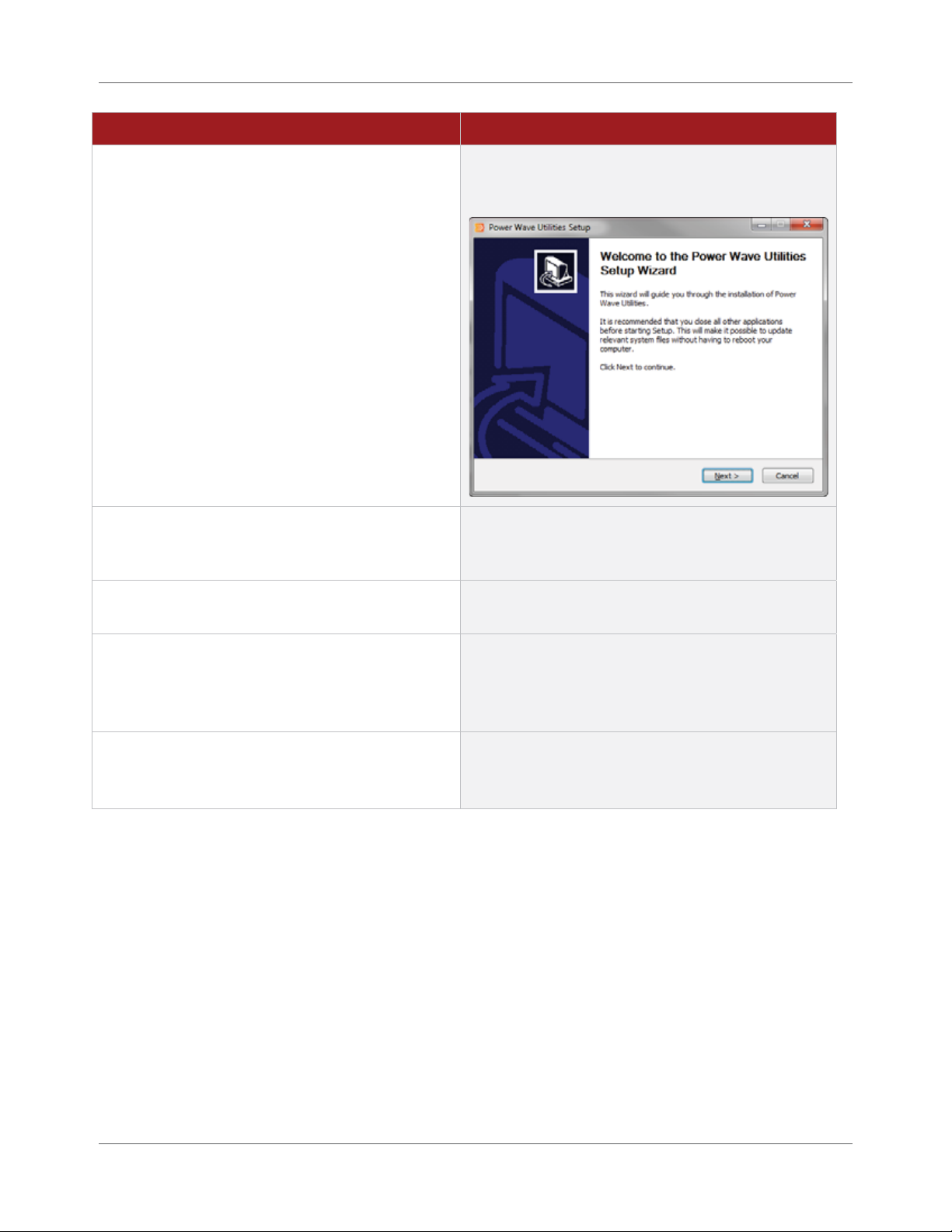

Procedure Details

1. Log in to the computer as a user with

administrat ive pr ivileges.

2. Open your browser and go to

www.powerwavesoftware.com.

3. Enter your username and password in the Email

and Password fields and click Sign In.

OR

Click the Register Today link to create an

account.

Contact your IT department if you do not have

administrat o r pr ivile ges.

The Login page displays.

If you’re creating a new account, follow t he

onscreen instructions and return to this st ep

when finished.

Once yo u log in , t h e system displays the Power

Wave Resource Center.

IM8000 CheckPoint™User Manual 2.1

Page 24

Chapter 2. Preparing for CheckPoint™ Update the Welding Power Source Firmware

Procedure Details

4. In the Quick Li n k s se c tion, click the Power

Wave®, Power Feed®/MAXsa® Software link.

5. Click the Download Power Wave® Bundle-FREE

button to run the update.

The system displays a page co ntaining t he

Download Power Wave® Bundle-FREE button.

NOTE | Depending on your Windows version,

you may have to click Run or Allow to permit

your system to launch the file.

The system opens the Lincoln Electric System

Update Utility window where you tell t he ut ility

how to find the Welding Power Source you want

to update.

6. Choose the Connect through E thernet option

and enter the IP address of the Welding Power

Source you want to update.

2.2 CheckPoint™User Manual IM8000

TIP | If there is an IP address a lready

displaye d, it is the IP address of the las t

Welding Pow er Source that wa s c onnected.

Be sure you enter the correct address f or t he

current We lding Power Source you w a nt t o

Page 25

Update the Welding Power Source Firmware Chapter 2. Preparing for CheckPoint™

Procedure Details

update.

You can enter the IP address for the Welding

Power Source in one of two ways:

Type the specific IP address into t he I

know the IP address of the welder field.

Choosing the I do not know the IP

address of the welder option. The

update utility scans your network and

displays a list of W e lding P o w er Source

IP addresses on the same subnet.

NOTE | If this Welding P ow er Source has

older firmware, the IP address will not show up

using this method.

TIP | If you run into a problem, please refer to

the Troubleshooting section (0).

7. Click the Connect button once you have

entered the IP address for the power source

you are updating.

The soft ware scans the We ld in g Power Source to

verify if the firmware currently on the machine

is up to date.

TIP | You can also see this i nformation under

System Status > Module Information > Software

Version in Power Wave® Manager. See Error!

Reference source not found. on page Error!

Bookmark not defined..

IM8000 CheckPoint™ User Manual 2.3

Page 26

Chapter 2. Preparing for CheckPoint™ Install the Latest Power Wave® Manager

Procedure Details

8. If the firmware is not up to date, you must click

Continue to update the Welding Power Source.

9. Exit the program once the firmware has

finished updating.

10. Repeat steps 4 through 9 for each power source

you need to update.

The system proceeds with the update.

If the firmware is a lr ea dy up to dat e , yo u will

receive the message Update not required and

you can click Exit to close the window.

Install the Latest Power Wave® Manager

Once you update the Welding Power Source(s), you need t o upgrade to the latest version of Powe r Wave ®

Manager. If installing P ower Wave® Manager for the first time, these instructions are also for you. Power

Wave® Manager is a software application that allows you to manage a mult it ude o f set t ings and

configuration options within the Lincoln Electric Power Wa ve® fam ily of W e lding Power Sources. It also

provides in-depth diagnostics of t he We lding Power Source’s hardware and firmware to help identify and

eliminate issues w it h w e lding o r c o nfigur a tion.

TIP | If you already have P ow e r Wave® Manager installed, you

can simply ope n t he s oftware. Depending o n y our v ersion

of the software, the syst em a ut omatically checks for and

installs any updates. If it doesn’t do t his a utomatically, you

can click the Check for Updates button. If the software

updates, y ou c a n s kip ahead to the next section.

2.4 CheckPoint™ User Manual IM8000

Page 27

Install the Latest Power Wave® Manager Chapter 2. Preparing for CheckPoint™

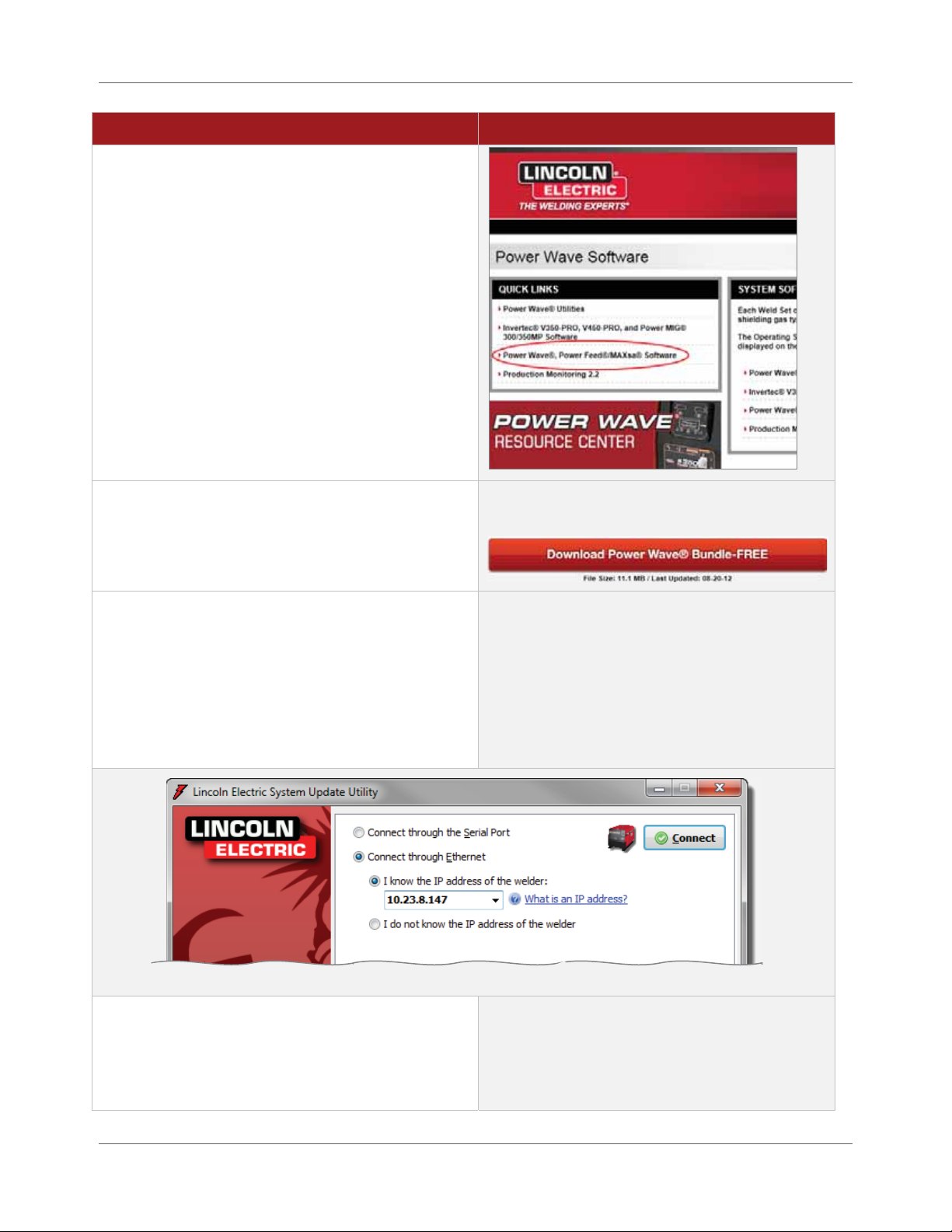

Procedure Details

1. Log in to the computer as a user with

administrat ive pr ivileges.

2. Open your browser and go to

www.powerwavesoftware.com

.

3. Enter your username and password in the

Email and Password fields and click Sign In.

Contact your IT department if you do not have

administrat o r pr ivile ges.

The Login page displays.

These are the same credentials you used when

updating the Welding Power Sour ce fir mw are.

Once yo u log in , t h e system displays the Power

Wave Resource Center.

4. In the Quick Li n k s se c tion, click the Power

Wave® Utilit ies link.

5. Click the Download Power Wave® Ut ilities

FREE button to run the update.

6. Select your language from the drop-down

and click OK.

The system displays a page co ntaining t he

Download Power Wave® Utilities FREE button.

NOTE | Depending on your Windows version,

you may have to click Run or Allow to permit your

system to launch the file.

TIP | If you haven’t logged in as a user with

administrative privileges, you may have to

download the f ile, open the location where y ou

downloaded it, right-click the file and select Run

as administrator.

The syste m d isp lays the Installer Langua ge dialog.

If you are running an older version of Power Wave®

Manager, the system pr o m pt s y o u to remove the

old version. Click OK to allow the installer to

remove the old version.

IM8000 CheckPoint™User Manual 2.5

Page 28

Chapter 2. Preparing for CheckPoint™ Enable CheckPoint™ for a Power Source

Procedure Details

If this is a new inst a llation (or once the old version

is removed), t he system displays the installation

welcome windo w.

7. Click Next on the Welcomescreen to move to

the License Agreement and continue the

installation.

8. You must accept the License Agreement and

click Next to continue.

9. Leave the default value in the Destination

Folder field and click Install.

10. Click the Finish button to exit the installer.

The syste m extracts files and in stalls the Power

Wave® Utilities o n yo ur c o mputer. Once it is

complete, the final page of the Setup Wizard

opens.

Congratulations! You have installed Power Wave®

Manager and can now configure your Welding

Power Source.

Enable CheckPoint™ for a Power Source

Now that you have upgraded the firmwa re on the Welding P ow er Source and installed the latest version of

Power Wave® Manager on your computer, you can now use Power Wave® Manager to enable CheckPoint™

on the Welding Power Source.

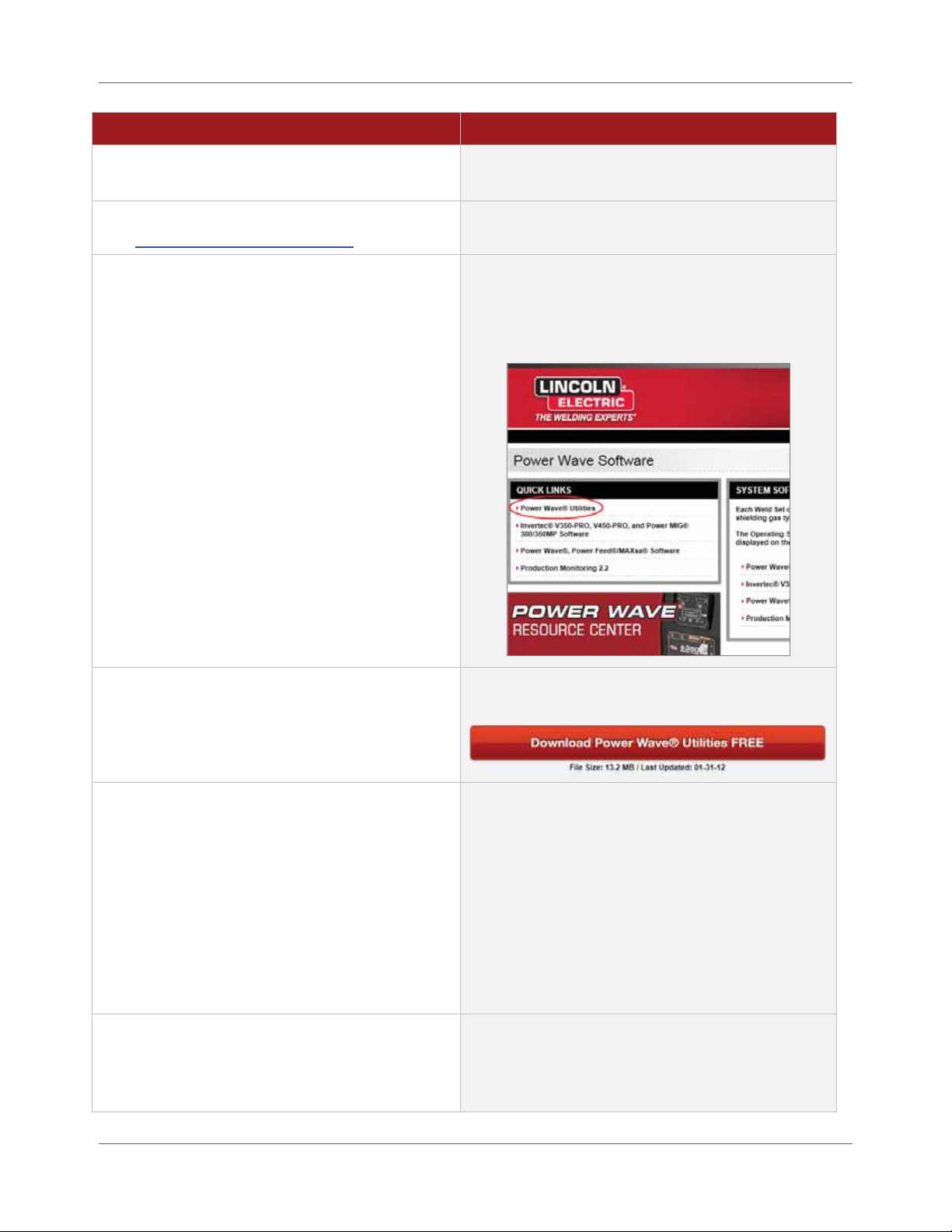

Establish Connection to the Welding Power Source

When you updated the firmware on the Welding Power Source (page 2.1), you needed to tell the Update

Utility whe r e to find the Welding Power Source on your network. Now you need to tell P owe r Wave®

Manager where to find the Welding Power Source on your network so you can enable CheckPoint ™ for t hat

power source.

2.6 CheckPoint™User Manual IM8000

Page 29

Enable CheckPoint™ for a Power Source Chapter 2. Preparing for CheckPoint™

Figure 2.1 Connecting to the Welding Power Source

NOTE | Remember that the IP address displayed is either the last

Welding Pow er Source to which Pow er Wave® Manager

connected o r t hat you recently upda t e d w ith the Update

Utility.

Procedure Details

1. Select Start > Programs > Lincoln Electric >

Power Wave® Utilities from the computer’s

main program menu.

2. Select Power Wave® Manager to launch

the utility.

3. Choose the Connect through E thernet option

and enter the IP address of the Welding

Power Source.

4. Click the Connect button.

The Power Wave® Manager window opens and

defaults to the Connect screen. See Figure 2.1.

For more details or information on finding t he IP

address of the Welding Powe r Sour ce, ple a se refer

to the Power Wave® Manager User Manual.

The system establishes the connection and

automatically displays the Registration page of

Power Wave® Manager so you can enable

CheckPoint™ (Figure 2.2 on page 2.8). Please

continue to Enabling CheckPoint™ on page 2.8.

IM8000 CheckPoint™ User Manual 2.7

Page 30

Chapter 2. Preparing for CheckPoint™ Enable CheckPoint™ for a Power Source

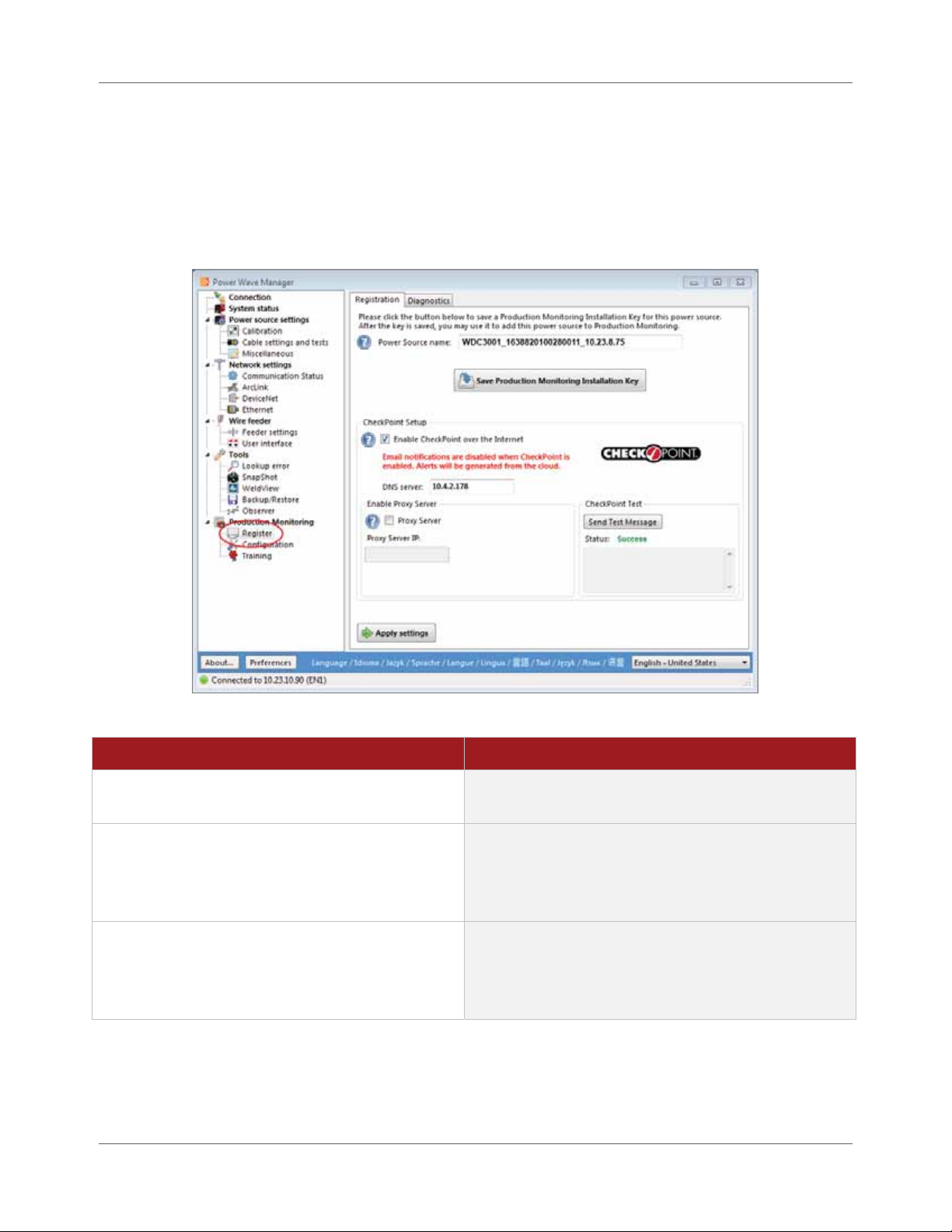

Enabling CheckPoint™

Once you connect the Welding Power Source to Powe r Wave® Manage r, you can now enable and set up

CheckPoint™ for that power source. Once you enable Chec kPoint ™ for the power source, the CheckPoint™

administrato r w ill be able to begin adding Welding Power Sources to the C hec kPoint™ system for

monitoring and reporting.

Figure 2.2 Registration Section of P ower Wave® Manager

Procedure Details

1. Select Register under Production Monitoring

in Power Wave® Manager.

2. Enter a name for the Welding Power Source

in the Power Source name field.

3. Place a check mark in the Enable

CheckPoint™ over the Internet checkbox

under CheckPo int™ Set u p .

If you do not see this section, the firmware on the

connected Welding Power S ource is not up to date.

Please refer to page 2.1 to update the firmware of

the power source. Return here when complete.

Once you enable CheckPoint™ for the power source,

the Welding Power Source no longer sends e-mail

notifications. With Chec kPoint ™, e-ma il a nd text

message notifications come from the data center.

2.8 CheckPoint™ User Manual IM8000

Page 31

Enable CheckPoint™ for a Power Source Chapter 2. Preparing for CheckPoint™

Procedure Details

4. Enter an IP address in the DNS server field.

5. If you are using a proxy server, place a check

mark in the Proxy Server checkbox under

Enable Proxy Server and enter the IP address

of that server in the Proxy Server IP field.

6. Once you have entered all require d

information, clic k t h e Apply s e t tings button.

7. Accept the End User Agreement to continue.

This information is not mandator y. If you are unable

to obtain it, you can still continue.

If you are using a proxy server, continue with step 5.

If you are not using a proxy server, skip to step 6.

If you are not using a Proxy Server, you can leave

these options blank and continue with step 6.

You can obtain the proxy information from the

Network Adm inist r ator. This information is necessa r y

in order to gain access to the Internet from your

network through the proxy server.

The syste m d isp lays the End User License Agreement.

STOP | Power Wave® Manager resets the Welding

Power Source when you click the Apply settings

button. Be careful that the power source is not

currently welding.

Once you have applied your settings, you need to test

those settings and make sure the connection to the

data center is successful.

8. Click the Send Test Message button.

If the settings were correct, you should rec eive the

Status: Success message displayed under the butto n

(Figure 2.2).

TIP | If you received a Status: Failed message, you

can hover your m ouse over the message to see why

your test fa iled. Please refer to Appendix A for

more details.

One final ste p rem a ins and that is to save an

installation key file for the Welding Power S ourc e

that you will upload to Chec kPoint ™ in o r de r to

create your company’s account. See page 2.10 for

more information.

IM8000 CheckPoint™ User Manual 2.9

Page 32

Chapter 2. Preparing for CheckPoint™ Enable CheckPoint™ for a Power Source

Save the Production Monitoring Installation Key File

Each individual power sour c e has a unique installa tion key file. The system uses these files to register the

equipment in CheckPoint™. The steps be low walk you thr ough how to save the installa t ion ke y file for the

Welding Power Sour c e . Each Welding Power Source you add to CheckPoint™ needs its own key file .

Figure 2.3 Save an Installation Key File

On the Registration tab of Power Wave ® Manager (F igur e 2.3), simply click the Save Production Monitoring

Installat ion Key button and save the file on your computer or network. Close Power Wave® Manager when

finished

STOP | It is recommended that y ou do not change the text in t he

Power Source name field, especia lly after creating files f rom

the power so urc e ( e.g., training files or ba c kups). Power

Wave® Manag er us es t he Power Source name to organize

and name weld training, backups, S na pShot files, weld log s ,

calibration logs, and more. If you cha ng e a name, you will

have to find and load files manually .

2.10 CheckPoint™ User Manual IM8000

Page 33

Chapter 3

Setting up CheckPoint™

Now that you have updated the Welding Power Source fir mware , have the latest version of Power Wave®

Manager software installe d, a nd ha ve e na bled Che c kPoint ™ for the fir st Welding P ow e r Source , you are

ready to create the Administrator user account in CheckPoint™ and register your company in the data

center.

Connecting to CheckPoint™

When you want to connect to CheckPoint™—which you can do anytime, anywhere—you simply visit the

following web site: www.lincolncheckpoint.com (Figure 3.1). From this page, you can log in to

CheckPoint™ (once you have a user account), take a tour of all the features of CheckPoint™ and lear n all

about using CheckPoint™ on the move.

Figure 3.1 CheckPoint™ Welcome Page

To set up your company’s account for the first time, you need to navigate to that web address now. When

you click Get Started, the Get Started page (Figure 3.2) acts as a basic checklist to make sure you have

completed all the nece ssary prepa rat ion be fore you c ontinue.

IM8000 CheckPoint™User Manual 3.1

Page 34

Chapter 3. Setting up CheckPoint™ Create Administrator Account

Figure 3.2 Get Started Page

Create Administrator Account

When you create your company’s account in CheckPoint™, the very first step is to create the administrator

user account. Once you create your user account, you can add your first Welding Power Source a nd

register your company.

Figure 3.3 New Account Page

3.2 CheckPoint™ User Manual IM8000

Page 35

Validate User Information in CheckPoint™ Chapter 3. Setting up CheckPoint™

Procedure Details

1. Click Get Started on the Home page.

2. Read through each step on the page and

click the link in the final step to begin.

3. Complete the info r m atio n o n the New

Account page and click Submit.

See Figure 3.1 on page 3.1. The Getting Started page

opens (Figure 3.2).

The New Account page opens (Figur e 3.3). This is

where you w ill create the administra tor user account.

NOTE | The first user creat ed is the CheckPoint™

administ ra tor account. This user ha s a c c e ss t o se t up

other users a nd add Welding Power Sources in

CheckPoint™.

After you submit the informat ion, t he system sends a

verification e-mail to the e-mail address you entered.

Validate User Information in CheckPoint™

Validating your user informat ion is simple and ge t s you closer to using CheckP oint ™ to monitor your

welding opera tions. Check your e-mail inbox for a message fro m CheckPoint™. Open the e-mail and click

the validatio n link c o nta ine d w it h in it (Figur e 3.4).

Figure 3.4 Validation E-mail

TIP | If you do not see an e-mail f rom C hec k Point™, check your

Junk Mail f older.

Once you click t he va lida tion link, the administrator account is now a ctive an d you ca n add the fir st Welding

Power Source and register your compa ny in the data center.

IM8000 CheckPoint™ User Manual 3.3

Page 36

Chapter 3. Setting up CheckPoint™ Uploading the Installation Key File

Uploading the Installation Key File

Once you validate the administra t o r user account, you nee d to registe r your first Welding Power Source.

You register a pow er sour ce by uploading the installation key file yo u sa ve d o n page 2.10. Only t he n will

you be able to finish registering your c o mpa ny and begin a dding more users and powe r sources to

CheckPoint™.

NOTE | You must register at lea s t one Welding Power Sourc e t o

create a valid c ompany account. You will not be able to

continue without the installation key file. See page 2.10 for

details on saving the key file.

After you click the va lidation link in the e-mail, the system o pens a page detailing instr uc tions on how to

save the Welding Power Source installatio n key file fo r those without access to this ma nual. You can click

Continue on that page.

Figure 3.5 Uploading the Installation Key File

To create the first W e lding P o w er S o urce ent ry in C he ckPoint™ and uploa d the inst allation key file:

Procedure Details

1. Click the Continue button at the bottom of

the Registration Step 1 page.

2. Enter the name of the power source in the

Welder Name field.

3. Enter informat ion about the Welding Power

Source in the Welder Description field.

4. Next to the Installation File field, click the

Select button

3.4 CheckPoint™ User Manual IM8000

The CheckPoint™ Registration Step 2 page opens

(Figure 3.5).

The text you enter here appears as the name of

the welder in the Asset Tree for all users (Figure

4.21 on page 4.22). Be sure you can distinguish

multiple Welding P ower Sources from one

another.