Page 1

Handymig 170i

A Division of Lincoln Electric Company (Aust) Ply Ltd A.B.N. 36 000 040 308

Copyright © 2000 Lincoln Global Inc.

35 Bryant Street, Padstow, NSW2211, Australia

RETURN TO MAIN MENU

IM796

April, 2006

Safety Depends on You

LiquidArc machines are designed

and built with safety in mind.

However, your overall safety can

be increased by proper installation

... and thoughtful operation on

your part. DO NOT INSTALL,

OPERATE OR REPAIR THIS

EQUIPMENT WITHOUT READING THIS MANUAL AND THE

SAFETY PRECAUTIONS CONTAINED THROUGHOUT. And,

most importantly, think before you

act and be careful.

For use with machine Code Numbers

10984

Made exclusive for Australia

OPERATOR’S MANUAL

Page 2

i

SAFETY

i

WARNING

ARC WELDING CAN BE HAZARDOUS. PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH.

KEEP CHILDREN AWAY. PACEMAKER WEARERS SHOULD CONSULT WITH THEIR DOCTOR BEFORE OPERATING.

For more detailed information it is strongly recommended that you purchase a copy of "Safety in Welding and Cutting - ANSI

Standard Z49.1" and WTIA Technical Note 7. All WTIA publications and ANSI/AWS Standards are available from the

Welding Technology Institute of Australia, PO Box 6165 Silverwater NSW 2128. For copies of various Australian Standards

contact your local S.A.A. office.

BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

FOR ENGINE

powered equipment.

1.a. Turn the engine off before troubleshooting and maintenance

work unless the maintenance work requires it to be running.

------------------------------------------------------------------------

1.b. Operate engines in open, well-ventilated

areas or vent the engine exhaust fumes

outdoors.

____________________________________________________

1.c. Do not add the fuel near an open flame

welding arc or when the engine is running.

Stop the engine and allow it to cool before

refueling to prevent spilled fuel from vaporizing on contact with hot engine parts and

igniting. Do not spill fuel when filling tank. If

fuel is spilled, wipe it up and do not start

engine until fumes have been eliminated.

____________________________________________________

1.d. Keep all equipment safety guards, covers

and devices in position and in good

repair.Keep hands, hair, clothing and tools

away from V-belts, gears, fans and all

other moving parts when starting, operating

or repairing equipment.

1.e. In some cases it may be necessary to remove safety

guards to perform required maintenance. Remove

guards only when necessary and replace them when the

maintenance requiring their removal is complete.

Always use the greatest care when working near moving

parts.

___________________________________________________

1.f. Do not put your hands near the engine fan. Do not attempt to

override the governor or idler by pushing on the throttle control

rods while the engine is running.

___________________________________________________

1.g. To prevent accidentally starting gasoline engines while

turning the engine or welding generator during maintenance

work, disconnect the spark plug wires, distributor cap or

magneto wire as appropriate.

1.h. To avoid scalding, do not remove the

radiator pressure cap when the engine is

hot.

Oct ‘00

____________________________________________________

Page 3

ii

SAFETY

ii

ELECTRIC AND

MAGNETIC FIELDS

may be dangerous

2.a. Electric current flowing through any conductor causes

localized Electric and Magnetic Fields (EMF). Welding

current creates EMF fields around welding cables and

welding machines

2.b. EMF fields may interfere with some pacemakers, and

welders having a pacemaker should consult their physician

before welding.

2.c. Exposure to EMF fields in welding may have other health

effects which are now not known.

2.d. All welders should follow safe practices that minimize their

exposure to electric and magnetic fields (EMF).

2.e. For welders wearing implanted pacemakers, safe welding

practices are particularly important and additional procedures

should be followed by those who have decided to continue to

weld. (Hopefully in keeping with a doctor’s advice).

2.f. The following procedures will not eliminate exposure to EMF or

the possibility of arc welding having an effect on a pacemaker,

however if followed, they will significantly reduce exposure to

electric and magnetic fields. Electric and magnetic fields are

created any time electric current flows through a conductor,

however it is not clear whether such exposure affects ones

health.

2.g. Some researchers have reported that exposure to EMF may

cause leukemia or other illnesses. These claims originally

arose in relation to high voltage electric power lines and are

very much in dispute in the medical and scientific arena, however the best advice is to minimize your exposure to EMF to

protect your health should doctors eventually decide there is a

risk.

2.h. There are four fundamental facts about EMF:

2.h.1 With direct current (DC), the field strength is relatively

constant and does not change.

2.h.2 With alternating current (AC), the field strength constant-

ly changes.

2.h.3 The greater the current flow, i.e. the higher the amps,

the stronger the field created by the current

2.h.4 The closer the conductor or electrical device is to the

body the greater the exposure to the field.

MINIMIZE EXPOSURE TO EMF

2.i. All welders should use the following procedures to minimize

EMF exposure:

2.i.1 Route electrode or gun and work cables together. Secure

them with tape if possible.

2.i.2 Never coil the electrode lead around your body.

2.i.3 Do not place your body between the electrode and work

cables. If your electrode cable is on your right side the

work cable should also be on your right side.

2.i.4 Connect the work cable to the work piece as close as

possible to the area being welded. (This is also a good

practice to eliminate a common problem on welding - a

poor work connection.

2.i.5 Do not work next to the welding power source.

ADDITIONAL PRECAUTIONS FOR

WELDERS WITH PACEMAKERS

2.j. There is no question that the fields in arc welding can interfere

with a pacemakers function. Generally the interference does

not permanently damage the pacemaker. Once the wearer

leaves the arc welding environment or stops welding, the pacemaker returns to normal functioning. The welding arc has little

or no effect on the operation of some pacemakers, especially

designs that are bi-polar or designed to filter out such interference.

2.k. For a welder or anyone working around electrical equipment

the selection of a pacemaker is very important. Get a doctor’s

advice about which pacemaker is the least sensitive to interference from welding while still being medically suitable.

2.l. In addition to the normal safety precautions, the following additional procedures should be adopted by welders with pacemakers.

2.l.1 Use gas welding when the application is suitable.

2.l.2 Use the lowest current setting appropriate for the application. Do not exceed 400 amps. Low current (75-200

amps) direct current (DC) welding should be used if arc

welding is necessary. Do not TIG weld with high frequency.

2.l.3 Do not use repeated, short welds. Wait about ten seconds between stopping one weld and starting the next.

When having difficulty starting an electrode, do not restrike the rod repeatedly.

2.l.4 If you feel light headed, dizzy or faint, immediately stop

welding. Lay the electrode holder down so that it does not

contact the work and move away from any welding being

performed. Arrange your work in advance so that, if you

become dizzy and drop the electrode holder it will not fall

on your body or strike the work.

2.l.5 Do not work on a ladder or other elevated position or in a

cramped, confined place.

2.l.6 Do not work alone. Work only in the presence of an individual who understands these precautions and the possible effect welding may have on your pacemaker.

2.l.7 Do not work near spot welding equipment.

2.l.8 If you have a pacemaker and wish to continue arc welding, discuss this and any other questions you may have

with your physician and follow his or her advice. The doctor may wish to contact the pacemaker manufacturer for a

recommendation. As mentioned before, the design of the

pacemaker significantly affects the degree to which it is

subject to interference from a welding circuit. Do not rely

on the fact that you know another welder with a pacemaker who has welded for years without experiencing a problem.That welder and his or her pacemaker may be quite

different from you and your pacemaker.

Oct ‘00

Page 4

iii

SAFETY

iii

ELECTRIC SHOCK can

kill.

3.a. The electrode and work (or ground) circuits

are electrically “hot” when the welder is on.

Do not touch these “hot” parts with your bare

skin or wet clothing. Wear dry, hole-free

gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full

area of physical contact with work and ground.

In addition to the normal safety precautions, if welding

must be performed under electrically hazardous

conditions (in damp locations or while wearing wet

clothing; on metal structures such as floors, gratings or

scaffolds; when in cramped positions such as sitting,

kneeling or lying, if there is a high risk of unavoidable or

accidental contact with the workpiece or ground) use

the following equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel, welding head, nozzle or semiautomatic

welding gun are also electrically “hot”.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection

should be as close as possible to the area being welded.

3.e. Ground the work or metal to be welded to a good electrical

(earth) ground.

ARC RAYS can burn.

4.a. Use a shield with the proper filter and cover

plates to protect your eyes from sparks and

the rays of the arc when welding or observing

open arc welding. Headshield and filter lens

should conform to ANSI Z87. I standards.

4.b. Use suitable clothing made from durable flame-resistant

material to protect your skin and that of your helpers from

the arc rays.

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

FUMES AND GASES

can be dangerous.

5.a. Welding may produce fumes and gases

hazardous to health. Avoid breathing these

fumes and gases.When welding, keep

your head out of the fume. Use enough

ventilation and/or exhaust at the arc to keep

fumes and gases away from the breathing zone. When

welding with electrodes which require special

ventilation such as stainless or hard facing (see

instructions on container or MSDS) or on lead or

cadmium plated steel and other metals or coatings

which produce highly toxic fumes, keep exposure as

low as possible and below Threshold Limit Values (TLV)

using local exhaust or mechanical ventilation. In

confined spaces or in some circumstances, outdoors, a

respirator may be required. Additional precautions are

also required when welding on galvanized steel.

3.f.

Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Never simultaneously touch electrically “hot” parts of

electrode holders connected to two welders because voltage

between the two can be the total of the open circuit voltage

of both welders.

3.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

3.j. Also see Items 6.c. and 8.

5.b.

Do not weld in locations near chlorinated hydrocarbon

coming from degreasing, cleaning or spraying operations.

The heat and rays of the arc can react with solvent vapors

form phosgene, a highly toxic gas, and other irritating products.

5.c. Shielding gases used for arc welding can displace air and

cause injury or death. Always use enough ventilation,

especially in confined areas, to insure breathing air is safe.

5.d. Read and understand the manufacturer’s instructions for this

equipment and the consumables to be used, including the

material safety data sheet (MSDS) and follow your

employer’s safety practices. MSDS forms are available from

your welding distributor or from the manufacturer.

5.e. Also see item 1.b.

vapors

Mar ‘95

to

Page 5

iv

SAFETY

iv

WELDING SPARKS can

cause fire or explosion.

6.a.

Remove fire hazards from the welding area.

If this is not possible, cover them to prevent

the welding sparks from starting a fire.

materials from welding can easily go through small cracks

and openings to adjacent areas. Avoid welding near

hydraulic lines. Have a fire extinguisher readily available.

6.b. Where compressed gases are to be used at the job site,

special precautions should be used to prevent hazardous

situations. Refer to “Safety in Welding and Cutting” (ANSI

Standard Z49.1) and the operating information for the

equipment being used.

6.c. When not welding, make certain no part of the electrode

circuit is touching the work or ground. Accidental contact

can cause overheating and create a fire hazard.

6.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures

will not cause flammable or toxic vapors from substances

inside. They can cause an explosion even

been “cleaned”. For information, purchase “Recommended

Safe Practices for the

Containers and Piping That Have Held Hazardous

Substances”, AWS F4.1 from the American Welding Society

(see address above).

6.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

Sparks and spatter are thrown from the welding arc. Wear oil

6.f.

free protective garments such as leather gloves, heavy shirt,

cuffless trousers, high shoes and a cap over your hair. Wear

ear plugs when welding out of position or in confined places.

Always wear safety glasses with side shields when in a

welding area.

6.g. Connect the work cable to the work as close to the welding

area as practical. Work cables connected to the building

framework or other locations away from the welding area

increase the possibility of the welding current passing

through lifting chains, crane cables or other alternate circuits. This can create fire hazards or overheat lifting chains

or cables until they fail.

6.h. Also see item 1.c.

Remember that welding sparks and hot

though

they have

Preparation

for Welding and Cutting of

CYLINDER may explode

if damaged.

7.a. Use only compressed gas cylinders

containing the correct shielding gas for the

process used and properly operating

regulators designed for the gas and

pressure used. All hoses, fittings, etc. should be suitable for

the application and maintained in good condition.

7.b. Always keep cylinders in an upright position securely

chained to an undercarriage or fixed support.

7.c. Cylinders should be located:

• Away from areas where they may be struck or subjected to

physical damage.

• A safe distance from arc welding or cutting operations and

any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode holder or any other

electrically “hot” parts to touch a cylinder.

7.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. Valve protection caps should always be in place and hand

tight except when the cylinder is in use or connected for

use.

7.g. Read and follow the instructions on compressed gas

cylinders, associated equipment, and CGA publication P-l,

“Precautions for Safe Handling of Compressed Gases in

Cylinders,” available from the Compressed Gas Association

1235 Jefferson Davis Highway, Arlington, VA 22202.

FOR ELECTRICALLY

powered equipment.

8.a. Turn off input power using the disconnect

switch at the fuse box before working on

the equipment.

8.b. Install equipment in accordance with the National

Electrical Code, all local codes and the manufacturer’s

recommendations.

8.c. Ground the equipment in accordance with the National

Electrical Code and the manufacturer’s recommendations.

Mar ‘95

Page 6

v

SAFETY

INSTRUCTIONS FOR ELECTROMAGNETIC COMPATIBILITY

Conformance

Products displaying the C-Tick mark are in conformity with

Australian/New Zealand requirements for Electromagnetic

Compatibility (EMC) according to standard (emission) AS/NZS

3652 "Electromagnetic Compatibility – Arc Welding

Equipment".

Products displaying the CE mark are in conformity with

European Community Council Directive 89/336/EEC requirements for EMC by implementing EN50199 "Electromagnetic

Compatibility (EMC) – Product standard for arc welding equipment".

Products are:

• For use with other Lincoln Electric/LiquidArc equipment.

• Designed for industrial and professional use.

Introduction

All electrical equipment generates small amounts of electromagnetic emission. Electrical emission may be transmitted through power

lines or radiated through space, similar to a radio transmitter. When

emissions are received by other equipment, electrical interference

may result. Electrical emissions may effect many kinds of electrical

equipment: other nearby welding equipment, radio and TV transmitters and receivers, numerical controlled machines, telephone

systems, computers, etc. Be aware that interference may result

and extra precautions may be required when a welding power

source is used in a domestic establishment.

Installation and Use

The purchaser/user is responsible for installing and using the welding equipment according to the manufacturer’s instructions. If electromagnetic disturbances are detected then it shall be the responsibility of the purchaser/user of the welding equipment to resolve the

situation with the technical assistance of the manufacturer. In some

cases this remedial action may be as simple as earthing (grounding) the welding circuit (see note below). In other cases it could

involve constructing an electromagnetic screen enclosing the

power source and the work complete with associated input filters.

In all cases electromagnetic disturbances must be reduced to the

point where they are no longer troublesome.

Note: The welding circuit may or may not be earthed for safety reasons according to national codes. Changing the earthing arrangements should only be authorized by a person who is competent to

assess whether the changes increase the risk of injury, eg. by

allowing parallel welding current return paths which may damage

the earth circuits of other equipment.

Assessment of Area

Before installing welding equipment the purchaser/user shall make

an assessment of potential problems in the surrounding area.

The following shall be taken into account:

• Other supply cables, control cables, signalling and telephone

cables above, below and adjacent to the welding equipment;

• Radio and television transmitters and receivers;

• Computer and other control equipment;

• Safety critical safety equipment, eg. guarding of industrial

equipment;

• The health of people around, eg. the use of pacemakers and

hearing aids;

• Equipment used for calibration or measurement;

• The immunity of other equipment in the environment. The

purchaser/user shall ensure that other equipment being used

in the environment is compatible. This may require additional

protection measures;

• The time of the day that welding or other activities are to be

carried out.

v

The size of the surrounding area to be considered will depend on

the structure of the building and other activities that are taking

place. The surrounding area may extend beyond the boundaries of

the premises.

Methods of Reducing Emissions

Mains Supply

Welding equipment should be connected to the mains supply

according to the manufacturer’s recommendations.If interference

occurs, it may be necessary to take additional precautions such as

filtering the mains supply. Consideration should be given to shielding the supply cable of permanently installed welding equipment in

metallic conduit or equivalent. Shielding should be electrically continuous throughout its length. The shielding should be connected to

the welding power source so that good electrical contact is maintained between the conduit and the welding power source enclosure.

Maintenance of the Welding Equipment

The welding equipment should be routinely maintained according

to the manufacturer’s recommendations. All access and service

doors and covers should be closed and properly fastened when the

welding equipment is in operation. The welding equipment should

not be modified in any way except for those changes and adjustment covered in the manufacturer’s instructions. In particular, the

spark gaps of arc initiation and stabilizing devices should be adjusted and maintained according to the manufacturer’s recommendations.

Welding Cables

The welding cables should be kept as short as possible and should

be positioned close together, running at or close to the floor level.

Equipotential Bonding

Bonding of all metallic components in the welding installation and

adjacent to it should be considered. However, metallic components

bonded to the work piece will increase the risk that the operator

could receive a shock by touching these metallic components and

the electrode at the same time. The operator should be insulated

from all such bonded metallic components.

Earthing of the workpiece

Where the workpiece is not bonded to earth for electrical safety,

nor connected to earth because of its size and position, eg. ship’s

hull or building steelwork, a connection bonding the workpiece to

earth may reduce emissions in some, but not all instances. Care

should be taken to prevent the earthing of work pieces increasing

the risk of injury to users, or damage to other electrical equipment.

Where necessary, the connection of the workpiece to earth should

be made by direct connection to the workpiece, but in some countries where direct connection is not permitted, the bonding should

be achieved by suitable capacitance, selected according to national

regulations.

Screening and Shielding

Selective screening and shielding of other cables and equipment in

the surrounding area may alleviate problems of interference.

Screening of the entire welding installation may be considered for

special applications.

Portions of the preceding text are extracted from:

• Australian/New Zealand standard AS/NZS 3652. Permission to

reproduce has been granted by Standards Australia and

Standards New Zealand. For further explanation, readers should

be referred to the standard itself.

• British Standards Institution standard BS EN 50199:1995.

Reproduced with permission of BSI under license number

2000SK0631. Complete standards can be obtained from BSI

Customer Services, 389 Chiswick High Road, London W4 4AL.

United Kingdom. (Tel +44 (0) 20 8996 9001).

Copyright of above text is property of Standards Australia,

Standards New Zealand and British Standards Institution.

Permission to reproduce the text must be obtained.

JAN ‘01

Page 7

for selecting a QUALITY product by Lincoln Electric. We want you

Thank You

to take pride in operating this Lincoln Electric Company product

••• as much pride as we have in bringing this product to you!

Please Examine Carton and Equipment For Damage Immediately

When this equipment is shipped, title passes to the purchaser upon receipt by the carrier. Consequently, Claims

for material damaged in shipment must be made by the purchaser against the transportation company at the

time the shipment is received.

Please record your equipment identification information below for future reference. This information can be

found on your machine nameplate.

Product _________________________________________________________________________________

Model Number ___________________________________________________________________________

Code Number or Date Code_________________________________________________________________

Serial Number____________________________________________________________________________

Date Purchased___________________________________________________________________________

vivi

Where Purchased_________________________________________________________________________

Whenever you request replacement parts or information on this equipment, always supply the information you

have recorded above. The code number is especially important when identifying the correct replacement parts.

On-Line Product Registration

- Register your machine with Lincoln Electric either via fax or over the Internet.

• For faxing: Complete the form on the back of the warranty statement included in the literature packet

accompanying this machine and fax the form per the instructions printed on it.

• For On-Line Registration: Go to our

“Product Registration”. Please complete the form and submit your registration.

Read this Operators Manual completely before attempting to use this equipment. Save this manual and keep it

handy for quick reference. Pay particular attention to the safety instructions we have provided for your protection.

The level of seriousness to be applied to each is explained below:

WEB SITE at www.lincolnelectric.com. Choose “Quick Links” and then

WARNING

This statement appears where the information must be followed exactly to avoid serious personal injury or

loss of life.

CAUTION

This statement appears where the information must be followed to avoid minor personal injury or damage to

this equipment.

Page 8

vii

vii

TABLE OF CONTENTS

Page

Installation .......................................................................................................Section A

Technical Specifications ........................................................................................A-1

Identify and Locate Components...........................................................................A-2

Select Suitable Location ........................................................................................A-3

Stacking ..........................................................................................................A-3

Tilting...............................................................................................................A-3

Output Connections...............................................................................................A-3

Work Clamp Installation ..................................................................................A-3

Work Cable Installation ...................................................................................A-4

Gun Installation......................................................................................................A-4

Connecting Gun Cable to the Handymig 170i.................................................A-4

Gas Connection.....................................................................................................A-4

Input Connections..................................................................................................A-5

Electrical Input Connection for Rated Output ........................................................A-6

Line Cord Connection .....................................................................................A-6

Operation .........................................................................................................Section B

Safety Precautions ................................................................................................B-1

General Description...............................................................................................B-1

Recommended Processes ..............................................................................B-1

Optional Features and Controls ......................................................................B-1

Design Features and Advantages .........................................................................B-1

Welding Capability.................................................................................................B-2

Limitations..............................................................................................................B-2

Controls and Settings ............................................................................................B-2

Welding Operations ...............................................................................................B-3

Sequence of Operations .................................................................................B-3

Wire Loading ..............................................................................................B-3

Friction Brake Adjustments ........................................................................B-3

Wire Threading...........................................................................................B-4

Making a Weld ...........................................................................................B-5

Cleaning Tip and Nozzle ............................................................................B-5

Process Guidelines................................................................................................B-5

Changing Over to Feed Other Wire Sizes .............................................................B-6

Welding with GMAW..............................................................................................B-6

Welding with FCAW...............................................................................................B-6

Application Chart.................................................................................................B-7

Handymig 170i

Page 9

viii

viii

TABLE OF CONTENTS

Page

Maintenance ....................................................................................................Section D

Safety Precautions ................................................................................................D-1

Routine Maintenance.............................................................................................D-1

Wire Feed Compartment.................................................................................D-1

Fan Motor........................................................................................................D-1

Wire Reel Spindle ...........................................................................................D-1

Gun and Cable................................................................................................D-1

Gun Cable Cleaning................................................................................D-1

Contact Tips, Nozzles, and Gun Tubes ..................................................D-1

Component Replacement Procedures ..................................................................D-2

Changing the Contact Tip ...............................................................................D-2

Changing Drive Roll ........................................................................................D-2

Changing Liner................................................................................................D-3

Gun Handle Parts ...........................................................................................D-3

Ground Test Procedure.........................................................................................D-4

Troubleshooting..............................................................................................Section E

Safety Precautions.................................................................................................E-1

How to Use Troubleshooting Guide.......................................................................E-1

Troubleshooting Guide.............................................................................E-2 thru E-4

Wiring Diagrams..............................................................................................Section F

Handymig 170i Wiring Diagram .............................................................................F-1

Handymig 170i Parts ............................................................................P463,P202,P189

Handymig 170i

Page 10

A-1

INSTALLATION

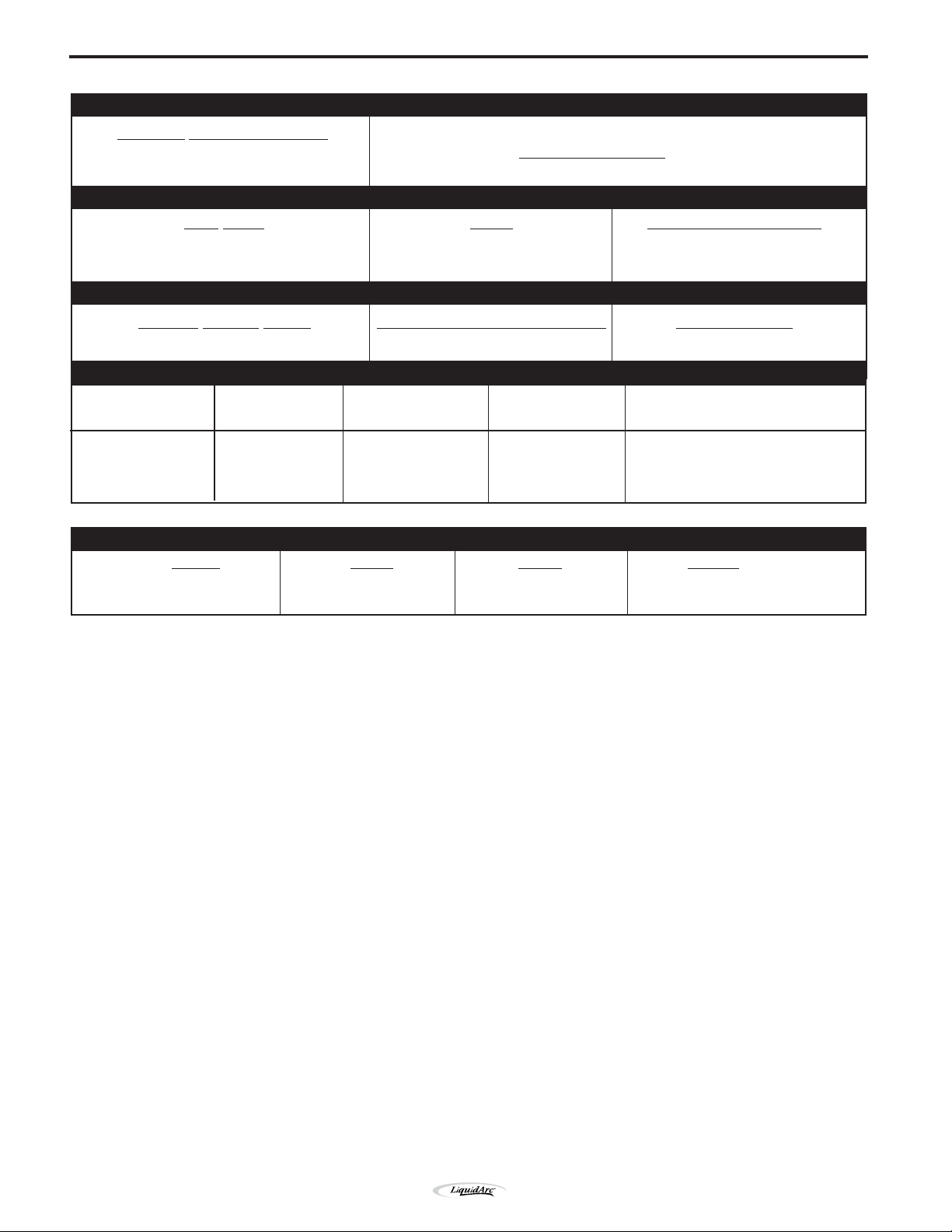

TECHNICAL SPECIFICATIONS – Handymig 170i

INPUT – SINGLE PHASE ONLY

Standard Voltage/Frequency AS1966.1

240V/50Hz Rated Input Current

RATED OUTPUT

Duty

Cycle Amps Volts at Rated Amperes

20% 130 20

OUTPUT

A-1

12.7 Amps

Welding

Rated DC Output: 30 – 170 amps 33 N/A

Current Range Maximum Open Circuit Voltage Auxiliary Power

RECOMMENDED INPUT CABLE AND FUSE SIZES

Fuse or

Output Mode Input Voltage Breaker Size Input Amps Power Cord

RATED 240V/50Hz 25 Super Lag 12.7 15Amp, 240V,

Three Pin Plug

PHYSICAL DIMENSIONS

Height Width Depth Weight

305 mm 248 mm 419 mm 25.9 kg

Handymig 170i

Page 11

A-2

1

2

3

4

5

Handymi

g

17

0i

WELDING AMP RANGEWELDING AMP RANGE

25-125 25-12

5

6

INSTALLATION

A-2

SAFETY PRECAUTIONS

• Read entire installation section before starting

installation.

WARNING

ELECTRIC SHOCK can kill.

• Only qualified personnel should perform

this installation.

• Only personnel that have read and understood the Handymig 170i Operating

Manual should install and operate this

equipment.

• Machine must be plugged into a receptacle

which is grounded per any national, local

or other applicable electrical codes.

• The Handymig 170i power switch is to be

in the OFF (“O”) position when installing

work cable and gun and when connecting

power cord to input power.

FIGURE A.1

IDENTIFY AND LOCATE

COMPONENTS

If you have not already done so, unpack the

Handymig 170i from its carton and remove all packing

material around the Handymig 170i. Remove the following loose items from the carton (see Figure A.1):

1. Handymig 170i

2. Gun and cable assembly

3. Literature and miscellaneous includes:

a) This operating manual

b) A separate .030" (0.8 mm) contact tip

c) Hex key wrench for removal of drive roll.

4. 10 ft (3,0 m) work cable.

5. Work clamp.

6. Adjustable mixed-Gas Regulator & Hose.

(1)

(1)

The gun is ready to feed .023" – .025" (0.6 mm)

diameter wire.

Handymig 170i

Page 12

Handymig 170i

1

2

E

WELDING AMP RANGE

30-70

4

5

8

3

6

7

+

-

A-3

INSTALLATION

A-3

SELECT SUITABLE LOCATION

Locate the welder in a dry location where there is free

circulation of clean air into the louvers in the back and

out the front of the unit. A location that minimizes the

amount of smoke and dirt drawn into the rear louvers

reduces the chance of dirt accumulation that can block

air passages and cause overheating.

STACKING

Handymig 170i’s cannot be stacked.

TILTING

Each machine must be placed on a secure, level surface, either directly or on the recommended cart. The

machine may topple over if this procedure is not followed.

OUTPUT CONNECTIONS

6. Wire Feed Gearbox.

7. Cable Hanger.

8. Thumbscrew.

Work Clamp Installation

Attach the work clamp per the following: Refer to

Figure A-3.

FIGURE A.3

Refer to Figure A.2.

1. Work Cable Access Hole.

2. Gun Cable and Control Lead Access Hole.

3. Connector Block.

4. Gun Trigger Lead Connectors.

5. Positive (+) and negative (–) output terminals.

1. Insert the work cable terminal lug with the larger

hole through the strain relief hole in the work clamp

as shown above.

2. Fasten securely with the bolt and nut provided.

FIGURE A.2

Handymig 170i

Page 13

A-4

2

4

3

1

INSTALLATION

Work Cable Installation

Refer to Figure A.2.

1. Open the wire feed section door on the right side of

the Handymig 170i.

2. Pass the end of the work cable that has the terminal lug with the smaller hole through the Work

Cable Access Hole (1) in the case front.

3. Route the cable under and around the back of the

Wire Feed Gearbox (6).

4. For GMAW Only: Refer to Figure A.2. As deliv-

ered, the machine is connected for positive electrode polarity. This is the appropriate configuration

for the GMAW (MIG) process. To complete installation, use the provided wing nut to connect the work

cable’s terminal lug to the negative (–) output terminal (5) located above the Wire Feed Gearbox

(6). Make sure that both wing nuts are tight.

5. For Innershield Only: Refer to Figure A.4. To wire

for negative polarity (required for the Innershield

process), connect the short cable attached to the

connector block (1) to the negative (–) output terminal (2) and the work cable (3) to the positive (+) terminal (4).

FIGURE A.4

A-4

NOTE: If .045" or 1.2 mm) Innershield flux-cored wire

is to be used, the appropriate Innershield kit is

required.

Connecting Gun Cable to the Handymig

170i.

1. Refer to Figure A.2. Unplug the machine or turn

power switch to the OFF “O” position.

2. Pass the insulated terminals of the gun trigger control leads, one at a time, through the Gun Cable

and Control Lead Access Slot (2) in the case front.

The leads are to be routed up the inside of the

case front, behind the gas line.

3. Insert the connector on the gun conductor cable

through the Gun Cable Access Hole (2) in the

Handymig 170i case front. Make sure the connector is all the way in the brass connector block to

obtain proper gas flow. If the gun connector will not

fully insert, unscrew the thumbscrew on the connector block a few turns. Rotate the connector so

control leads are on the underside and tighten the

Thumbscrew on the connector block.

4. Connect the gun trigger control lead terminals to

the two insulated 1/4" (6,4 mm) tab terminal connector bushings located above the “Gun Trigger

Connection” decal in the wire feed section (4).

Either lead can go to either connector.

CAUTION

If the gun trigger switch being used is other than

that supplied, the switch must be a normally open,

momentary switch. The terminals of the switch

must be insulated from the welding circuit.

Malfunction of the Handymig 170i may result if

this switch shorts to the Handymig 170i welding

output circuit or is common to any electrical circuit other than the Handymig 170i trigger circuit.

GUN INSTALLATION

As shipped from the factory, the Handymig 170i gun is

ready to feed .023" – .025"(.6mm) solid wire. If .030".035” (0.8-.09 mm) solid wire is to be used, change the

contact tip to the appropriate size. If .035” Flux-cored

wire is to be used, change the contact tip and nozzle

to the appropriate types and orient the drive roll to the

appropriate groove size

Handymig 170i

GAS CONNECTION

The Handymig 170i is supplied with a mixed gas

Regulator and a 3m gas hose. A cylinder of an appropriate shielding gas must be obtained from your gas

distributor.

Page 14

POWER INPUT

CABLE

GAS SOLENOID

INLET FITTING

A-5

INSTALLATION

A-5

WARNING

CYLINDER may explode if damaged. Keep cylinder upright and

chained to support

• Keep cylinder away from areas

where it may be damaged.

• Never lift welder with cylinder

attached.

• Never allow welding electrode to

touch cylinder.

• Keep cylinder away from welding

WARNING

or other live electrical circuits.

BUILDUP OF SHIELDING GAS may

harm health or kill.

• Shut off shielding gas supply

when not in use.

WARNING

BE SURE TO KEEP YOUR FACE AWAY FROM THE

VALVE OUTLET WHEN “CRACKING” THE VALVE.

Never stand directly in front of or behind the flow

regulator when opening the cylinder valve. Always

stand to one side.

3. Attach the flow regulator to the cylinder valve and

tighten the union nut securely with a wrench..

4. Refer to Figure A.6. Attach one end of inlet gas

hose to the outlet fitting of the flow regulator and

tighten the union nut securely with a wrench.

Connect the other end to the Handymig 170i Gas

Solenoid Inlet Fitting (5/8-18 female threads — for

CGA — 032 fitting). Make certain the gas hose is

not kinked or twisted.

5. Reinstall case side before connecting input power.

INPUT CONNECTIONS

1. Chain the cylinder to a wall or other stationary sup-

Flow Regulator

Gas Hose

2. With the cylinder securely installed, remove the

port to prevent the cylinder from falling over.

Insulate the cylinder from the work circuit and earth

ground. Refer to Figure A.5.

FIGURE A.5

Cylinder Valve

cylinder cap. Stand to one side away from the outlet and open the cylinder valve very slightly for an

instant. This blows away any dust or dirt which may

have accumulated in the valve outlet.

Handymig 170i

FIGURE A.6

Refer to Figure A.6.

Page 15

A-6

INSTALLATION

ELECTRICAL INPUT CONNECTION

FOR RATED OUTPUT

WARNING

ELECTRIC SHOCK can kill.

• Disconnect input power by

removing plug from receptacle

before working inside Handymig

170i.

• Use only grounded receptacle.

• Do not touch electrically “hot”

parts inside Handymig 170i.

• Have qualified personnel do the

maintenance and troubleshooting

work.

Line Cord Connection

A-6

A three conductor line cord with a 15 amp, 240 volt,

three pin plug is factory installed. Connect this plug to

a mating grounded receptacle which is connected to

an appropriate power supply per the Wiring Rules and

any applicable local codes.

WARNING

• This welding machine must be connected to a

power source in accordance with applicable

electrical codes.

• If there is any question about the installation

meeting applicable electrical code requirements,

consult a qualified electrician.

Handymig 170i

Page 16

B-1

OPERATION

B-1

SAFETY PRECAUTIONS

WARNING

ELECTRIC SHOCK can kill.

• Do not touch electrically live

parts or electrode with skin or

wet clothing. Insulate yourself

from work and ground.

• Always wear dry insulating

gloves.

FUMES AND GASES can be

dangerous.

• Keep your head out of fumes.

• Use ventilation or exhaust to

remove fumes from breathing

zone.

WELDING SPARKS can

cause fire or explosion.

• Keep flammable material away.

• Do not weld on closed containers.

GENERAL DESCRIPTION

The Handymig 170i is a complete semiautomatic constant voltage DC portable arc welder. Included is a

tap-switch controlled, single phase constant voltage

transformer/rectifier power source and a wire feeder

with welding gun for feeding .023" (0.6 mm) through

.030" (0.8 mm) solid steel electrode. Optional kits are

available for .035" (0.9 mm) and .045" (1.2 mm)

Innershield

It is ideally suited for individuals having access to 240

volts 50 Hz AC input power and want the ease of use,

quality and dependability of both gas metal arc welding or GMAW (also known as MIG welding) and the

Innershield

FCAW). A convenient chart is mounted inside the wire

feed section door for setting welding procedures for 24

gauge (.60 mm) through 5/16" (8.0 mm) mild steel.

The machine is rugged and reliable and has designed

for dependable service and long life.

RECOMMENDED PROCESSES

The Handymig 170i can be used for welding mild steel

using the GMAW, single pass, process which requires

a supply of shielding gas or it can be used with the

self-shielded, Innershield

OPERATIONAL FEATURES AND

CONTROLS

®

NR-211-MP.

®

process (self-shielded flux-cored or

®

process (FCAW).

ARC RAYS can burn eyes

and skin.

• Wear eye, ear and body protection.

See additional warning information at

front of this operator’s manual.

The Handymig 170i has the following controls as standard: Power ON/OFF Switch, Voltage Control, Wire

Speed Control, Trigger Switch, and a Circuit Breaker.

DESIGN FEATURES AND

ADVANTAGES

• “Cold electrode” until gun trigger is pressed for an

added measure of safety.

• Overload protection — incorporates both a thermo-

stat and a circuit breaker.

• Quality wire drive with electronic overload protection.

• “Quick Release” idle roll pressure arm is easily

adjusted.

• Reversible, dual groove drive roll, shipped ready to

feed .023"/.025" (0.6 mm) diameter wire. The drive

roll is easily reversed to feed .030" (0.8 mm) diameter solid wire and .035" (0.9 mm) flux-cored diameter

wire. Optional drive roll included in .045" (1.2 mm)

Innershield

.045" (1.2 mm) flux-cored wire.

• No external shielding gas is required when used with

Liquid Arc steelcore 71T-GS electrode.

®

welding kit must be installed to feed

Handymig 170i

• Spindle accommodates both 8 in. (200 mm) diameter

and 4 in. (100 mm) diameter spools of wire.

Page 17

B-2

OFF

ON

ARC VOLTS

WIRE SPEED

4

OPERATION

WELDING CAPABILITY

The Handymig 170i is rated at 130 amps, 20 volts, at

20% duty cycle on a ten minute basis. It is capable of

higher output currents at lower duty cycles. .

LIMITATIONS

Arc Gouging cannot be performed with the Handymig

170i. The Handymig 170i is not recommended for pipe

thawing or TIG welding.

CONTROLS AND SETTINGS

Refer to Figure B.1a.

1. Power ON/OFF Switch —

When the power is on the

fan motor will run and air will

be exhausted out the louvers

in the front of the machine.

The welding output and wire

feeder remain off until the

gun trigger is pressed.

B-2

FIGURE B.1a

2. Wire Speed Control —

Controls the wire feed speed

from 50 – 400 in/min (1.2 –

10.2 m/min). The control can

be preset on the dial to the

setting specified on the

Handymig 170i Application

Chart located on the inside

of the wire feed section door.

3. Voltage Control — A 5-position tap selector switch gives

full range adjustment of

power source output voltage.

Do not switch while welding.

4. Circuit Breaker – Protects machine from damage if

maximum output is exceeded. Button will extend

out when tripped (Manual reset).Refer to Figure

B.1b.

FIGURE B.1b

+

-

Handymig 170i

Page 18

B-3

WELDING OPERATIONS

SEQUENCE OF OPERATION

OPERATION

B-3

FIGURE B.3

Wire Loading

Refer to Figure B.2 and B.3.

The machine power switch should be turned to the

OFF (“O”) position before working inside the wire feed

enclosure.

The machine is shipped from the factory ready to feed

8” (200 mm) diameter spools [2.2” (56 mm) max.

width]. These spools fit on a 2” (50 mm) diameter

spindle that has a built-in adjustable friction brake to

prevent overrun of the spool and excess slack in the

wire.

Note:When loading and removing the 8” Spools

make

sure that the wing nut (inside the wire spool spindle

hub) is turned 90° from the wire spool spindle locking

tab. If the wing nut is positioned in line with the locking

tab, the tab cannot be depressed to load or unload

FIGURE B.2

the wire spool.

Wire Spool Spindle

8” Wire Spool

Wire Spindle Shaft

To wire drive

4" Wire Spool

Wing Nut

and Spacer

Note: The brake should be adjusted with a spool of

wire installed. When properly adjusted it should

move freely but not coast.

CAUTION

Some spools can have the start wire protruding

from the side of the spool. This must be insulated

from internal metal components otherwise electrical grounding faults will result and the machine

will be seriously damaged.

Be sure that this stud engages

the hole in the wire spool.

To Wire Drive

Wire Spool must be pushed all the way on the spindle so that the

spindle’s tab will hold it in place. The Wire Spool will rotate clockwise when wire is dereeled.

Load an 8” (200 mm) diameter spool on the wire spool

spindle shown in Figure B.2.

To use 4” (100 mm) diameter spools, the 2” (50 mm)

diameter spindle must be removed (See Figure B.3).

Remove the wing nut and spacer at the end of the

shaft and remove the outside plastic wire spool spindle. The spindle can be stored in the wire feed compartment. A 4” (100 mm) diameter spool is mounted

directly on the 5/8” (16 mm) diameter shaft and held in

place with the previously removed hardware. Also

make certain the start end of the wire, which may protrude through the side of the spool does not contact

any metallic case parts.

Friction Brake Adjustments

1. With wire spool installed, check free movement

and coast of the spool.

2. To tighten the brake turn the wing nut clockwise in

1/4 turn increments until coasting stops.

3. To loosen the brake turn the wing nut counterclockwise in 1/4 turn increments until the wire spool

moves freely without coasting.

Handymig 170i

Page 19

B-4

OPERATION

B-4

Wire Threading

Refer to Figure B.4

1. Release the Spring Loaded Pressure Arm (1)

rotate the Idle Roll Arm (2) away from the Wire

Feed Drive Roll (3). Ensure that the groove size in

the feeding position on the drive roll matches the

wire size being used. See Maintenance section for

further information.

2. Carefully detach the end of the wire from the

spool. To prevent the spool from unwinding, maintain tension on the wire until after step 5.

3. Cut the bent portion of wire off and straighten the

first 4” (100 mm).

4. Thread the wire through the incoming guide tube

(4), over the drive roll (3), and into the outgoing

guide tube (5).

5. Close the idle roll arm and latch the spring loaded

pressure arm (2) in place. Rotate the spool counterclockwise if required to take up extra slack in

the wire.

FIGURE B.4

2

1

5

3

8. Turn the Handymig 170i ON (“I”).

9. Straighten the gun cable assembly.

4

The Wire Drive Feed Roll can

accommodate two wire sizes by

flipping the wire drive feed roll

over.

6. The idle roll pressure adjustment wing nut is normally set for mid-position on the pressure arm

threads. If feeding problems occur because the

wire is flattened excessively, turn the pressure

adjustment counter-clockwise to reduce distortion

of the wire. Slightly less pressure may be required

when using 0.023 – 0.025” (0,6 mm) wire. If the

6. drive roll slips while feeding wire, the pressure

should be increased until the wire feeds properly.

WARNING

When inching the welding wire, the drive rolls, the

gun connector block and the gun contact tip are

electrically energized relative to work and ground

and remain energized for several seconds after

the gun trigger is released.

------------------------------------------------------------------------

7. Refer to Figure B.5. Remove gas nozzle and contact tip from end of gun.

10. Depress the gun trigger switch and feed welding

wire through the gun and cable. (Point gun away

from yourself and others while feeding wire.)

Release gun trigger after wire appears at end of

gun.

11. Turn the Handymig 170i OFF (“O”).

FIGURE B.5

Gun Handle

Gas Diffuser/

Contact Tip

Gas Nozzle

12. Replace contact tip and gas nozzle.

13. Refer to Figure B-6. Cut the wire off 3/8”– 1/2” (10

Handymig 170i

– 12 mm) from the end of the tip. The Handymig

170i is now ready to weld.

Page 20

B-5

WORKPIECE

GUN CABLE

ARC

WORK CLAMP

OPERATION

B-5

FIGURE B.6

Contact Tip

Wire Electrode

3/8" – 1/2" Contact Tip To Work Distance

(10-12 mm) (CTWD)

Making A Weld

1. See “Process Guidelines” in this section for selection of welding wire and shielding gas and for

range of metal thicknesses that can be welded.

2. See the Application chart on the inside of the wire

feed compartment door for information on setting

the Handymig 170i controls. Refer to Table B.1 for

aluminum and stainless wire.

3. Set the Voltage (“V”) and Wire Speed (“olo’”) controls to the settings suggested for the welding wire

and base metal thickness being used, refer to

3. Applications chart on the inside of the wire drive

compartment door.

FIGURE B.7

10. When no more welding is to be done, close valve

on gas cylinder (if used), momentarily operate gun

trigger to release gas pressure, and turn off the

Handymig 170i.

Cleaning Tip And Nozzle

Clean the contact tip and nozzle to avoid arc bridging

between the nozzle and contact tip which can result in

a shorted nozzle, poor welds and an overheated gun.

Hint: Anti-stick spray or gel, available from a welding

supply distributor, may reduce buildup and aid in spatter removal.

4. Check that the polarity is correct for the welding

wire being used and that the gas supply, if

required, is turned on.

5. When using Innershield electrode, remove the gas

nozzle and install the gasless nozzle. This will

improve visibility of the arc and protect the gas diffuser from weld spatter. Refer to the MAINTENANCE section for details on nozzle replacement.

6. Refer to Figure B.7. Connect work clamp to metal

to be welded. Work clamp must make good electrical contact to the workpiece. The workpiece

must also be grounded as stated in “Arc Welding

Safety Precautions” in the beginning of this manual.

7. Position gun over joint. End of wire may be lightly

touching the work.

8. Lower welding helmet, close gun trigger, and

begin welding. Hold the gun so the contact tip to

work distance is about 3/8 inch (10 mm).

9. To stop welding, release the gun trigger and then

pull the gun away from the work after the arc goes

out.

PROCESS GUIDELINES

The Handymig 170i can be used for welding mild steel

using the GMAW, single pass, process which requires

a supply of shielding gas or it can be used for the selfshielded, Innershield

The recommended gases and electrodes for GMAW

are welding grade CO

gas (75 to 80% argon and 25 to 20% CO

(0.6 mm) diameter Liquid Arc S6 mild-steel welding

wire, supplied on 12-1/2 lb (5 kg) spools. The blended

gas is recommended for welding on heavier steel, 14

gauge (2.0 mm), for example.

The recommended electrode for the self-shielded

process is Liquid Arc steelcore 71T-GS on 10 lb (4.5

kg) spools. This electrode is available as .035" (0.9

mm) and .045" (1.2 mm) NR-211-MP for all position

welding of 18 gauge (1.2 mm) through 5/16" (8.0 mm)

steel. Thickness of 1/4" (6.4 mm) and 5/16" (7.9 mm)

require multiple passes. both wire sizes can also be

used for the welding of galvanized coated sheet

metal.

®

process (FCAW).

gas or an argon-CO2blended

2

) and .025"

2

Handymig 170i

Page 21

OPERATION

B-6B-6

The Handymig 170i is suitable for .035"(0.9mm) aluminum wire and .023"–.035"(0.6-0.9mm) stainless

wire. Refer to Table B.1 for recommended procedure

settings. (Requires K664-2 Aluminum - Stainless

Feeding Kit.)

CAUTION

It is important when changing between welding

with steel wire and aluminum to exchange feeding

components due to the lubricant applied to steel

wire. Failure to do so may result in contaminated

welds when welding aluminum.

------------------------------------------------------------------------

TABLE B.1 — Handymig 170i

Process Welding Wire Gas 22 ga 16 ga 12 ga 1/8” 3/16” 1/4”

.035 Dia(0.9mm 100% Argon A-4.5 B-6.5 D-8.5 D-10

4043 Aluminum

Wire

MIG DC+

.030 Dia 98% Argon/ A-2 B-3 C-5 D-7 E-10

308L Stainless 2% Oxygen

Steel Wire

NOTES:

* Test assembly preheated to 250°F(121°C)

Shielding

18 ga 16 ga 14 ga 12 ga 10 ga

Voltage/Wire Speed

E-10 E10*

CHANGING MACHINE OVER TO

FEED OTHER WIRE SIZES

The Handymig 170i is shipped from the factory ready

to feed 0.023”– .025" (0.6 mm) diameter wire. To

operate the Handymig 170i with other sizes of wire, it

maybe necessary to change the contact tip, change

drive roll and gun liner configuration. Refer to the

MAINTENANCE section, for component configuration

and replacement procedures.

WELDING WITH GMAW (MIG)

Shielding Gas

When using the GMAW process, install a gas regulator and hose kit.

• For CO

mixed gas, open cylinder valve slowly a fraction of

a turn. When the cylinder pressure gauge pointer

stops moving, open the valve fully.

• If using a regulator with an adjustable flow meter,

close the gun trigger and adjust the flow to give 15

– 20 cubic ft per hour (CFH) (7 – 10 I/min) [use 20

– 25 CFH (10 – 12 I/min) when welding out of posi-

tion or in a drafty location.

• Keep the cylinder valve closed, except when using

the Handymig 170i. When finished welding:

, open the cylinder very slowly. For argon-

2

• Depress the gun trigger briefly to release the

pressure in the gas hose.

• Turn off the Handymig 170i.

WELDING WITH FCAW (Innershield)

When using the FCAW process, the correct drive roll

and electrode polarity must be used. See Work Cable

Installation in INSTALLATION section for changing the

polarity.

Use optional Innershield welding kit K549-1 (for 0.9

mm) or K549-2 (for 1.2 mm), as appropriate.

• K549-1 0.9mm (.035”) Innershield® Welding Kit—

Includes a contact tip, a gasless nozzle and a 0.9-

1.2mm cable liner to permit the Magnum™ 100L gun

and cable to use 0.9mm diameter flux-cored electrode. The fitting on the end of the liner is stencilled

with the maximum rated wire size (.045”/1.2mm).

Also included is a spool of 0.9mm

211-MP.

• K549-2 1.2mm (.045”) Innershield® Welding Kit—

Includes a contact tip, a gasless nozzle and a 0.9-

1.2mm cable liner to permit Magnum™ 100L gun

and cable to use 1.2mm diameter flux-cored electrode. The fitting on the end of the liner is stencilled

with the maximum rated wire size (.045”/1.2mm).

Also included is a spool of 1.2mm Innershield® NR-

211-MP and a knurled drive roll.

Several changes are needed to convert the unit for

operation with the Innershield (FCAW) process. The

K549-1 or K549-2 Innershield Kits include all the necessary accessories for this conversion and are provided for this purpose. The following conversions should

be made using the contents of this kit:

• Change the output polarity to DC(-). See “Work

Cable Installation” in Installation Section for details.

• Install proper drive roll for wire size selected. See

“Changing Drive Roll” in Maintenance Section for

details.

• Install the proper gun liner and tip for the wire size

selected. See “Component Replacement” in the

Maintenance Section for details.

• Remove gas nozzle (if installed) and install gasless

nozzle. To remove, simply unscrew.

• Load wire into machine and thread into gun and

cable per “Welding Wire Loading” section.

Innershield® NR-

• Close the cylinder valve to stop gas flow.

Handymig 170i

Page 22

B-7

APPLICATION CHART

B-7

Handymig 170i

Page 23

D-1

MAINTENANCE

D-1

SAFETY PRECAUTIONS

WARNING

ELECTRIC SHOCK can kill.

• Disconnect input power by

removing plug from receptacle

before working inside Handymig

170i. Use only grounded receptacle. Do not touch electrically

“hot” parts inside Handymig 170i.

• Have qualified personnel do the

maintenance and trouble shooting work.

ROUTINE MAINTENANCE

POWER SOURCE COMPARTMENT

In extremely dusty locations, dirt may clog the air passages causing the welder to run hot. Blow dirt out of

the welder with low pressure air at regular intervals to

eliminate excessive dirt and dust build-up on internal

parts.

WIRE FEED COMPARTMENT

• When necessary, vacuum accumulated dirt from

gearbox and wire feed section.

• Occasionally inspect the incoming guide tube and

clean inside diameter if necessary.

• Motor and gearbox have lifetime lubrication and

require no maintenance.

GUN AND CABLE

MAINTENANCE

FOR MAGNUM™ 100L GUN

Gun Cable Cleaning

Clean cable liner after using approximately 300 lbs

(136 kg) of solid wire or 50 lbs (23 kg) of flux-cored

wire. Remove the cable from the wire feeder and lay it

out straight on the floor. Remove the contact tip from

the gun. Using low pressure air, gently blow out the

cable liner from the gas diffuser end.

CAUTION

Excessive pressure at the start may cause the dirt

to form a plug.

Flex the cable over its entire length and again blow

out the cable. Repeat this procedure until no further

dirt comes out.

Contact Tips, Nozzles, and Gun Tubes

• Dirt can accumulate in the contact tip hole and

restrict wire feeding. After each spool of wire is

used, remove the contact tip and clean it by pushing a short piece of wire through the tip repeatedly.

Use the wire as a reamer to remove dirt that may

be adhering to the wall of the hole through the tip.

• Replace worn contact tips as required. A variable

or “hunting” arc is a typical symptom of a worn contact tip. To install a new tip, choose the correct size

contact tip for the electrode being used (wire size is

stenciled on the side of the contact tip) and screw it

snugly into the gas diffuser.

FAN MOTOR

Has lifetime lubrication — requires no maintenance.

WIRE REEL SPINDLE

Requires no maintenance. Do not lubricate shaft.

• Remove spatter from inside of gas nozzle and from

• Be sure the gas nozzle is fully screwed onto the

Handymig 170i

tip after each 10 minutes of arc time or as required.

diffuser for gas shielded processes. For the

Innershield

screwed onto the diffuser.

®

process, the gasless nozzle should be

Page 24

MAINTENANCE

D-2D-2

COMPONENT

REPLACEMENT

PROCEDURES

CHANGING THE CONTACT TIP

1. Refer to Figure D.2. Remove the gas nozzle from

the gun by unscrewing counter-clockwise.

2. Remove the existing contact tip from the gun by

unscrewing counter-clockwise.

3. Insert and hand tighten desired contact tip.

4. Replace gas nozzle.

CHANGING DRIVE ROLL

The drive roll has two grooves; one for .023" – .025"

(0.6 mm) solid steel electrode and a larger groove for

.030" (0.8 mm) solid and .035" (0.9 mm) flux-cored

steel electrode. As shipped, the drive roll is installed in

the .023"-.025" (0.6 mm) position.

If .030"/.035" (0.8/0.9 mm) wire is to be used, the

drive roll must be reversed as follows:

8. Push a length of straightened welding wire through

the wire feeder guide tubes and adjust the position

of the drive roll so that the groove is centered on

the wire. Make certain the set screw is located on

the flat portion of the shaft and tighten.

3

2

1

1. Connect the machine to its rated input power per

instructions in Installation section.

2. Release the spring-loaded pressure arm and lift the

idle roll arm away from the drive roll.

3. Turn the power switch to ON (marked “I”).

4. Set the wire speed to minimum and jog the drive

unit with the trigger switch until the drive roll set

screw is facing up.

CAUTION

When inching the welding wire, the drive rolls,

gun connector block, and gun contact tip are

energized relative to work and ground and remain

energized for several seconds after the gun trigger is released.

5. Turn the power switch to OFF (marked “O”).

6. Loosen the drive roll set screw with the 5/64" (2.0

mm) hex wrench supplied.

7. Remove the drive roll, flip over and reinstall with the

.030/.035" (0.8/0.9 mm) groove (the larger groove)

closest to the gearbox.

Handymig 170i

Page 25

CHANGING LINER

MAINTENANCE

Set Screw Brass Cable

Connector

Liner Assembly

(Liner bushing to be sealed tight

against brass cable connector)

FIGURE D.2

Liner trim length

D-3D-3

1-1/4 (31.8 mm)

Liner Trim Length

Gas Diffuser

Gas Nozzle or

Gasless Nozzle

8. Screw the gas diffuser onto the end of the gun tube

and securely tighten.

NOTICE: The variation in cable lengths prevents the

interchangeability of liners. Once a liner has been cut

for a particular gun, it should not be installed in another gun unless it can meet the liner cutoff length

requirement. Refer to Figure D.2.

1. Remove the gas nozzle from the gun by unscrewing counter-clockwise.

2. Remove the existing contact tip from the gun by

unscrewing counter-clockwise.

3. Remove the gas diffuser from the gun tube by

unscrewing counter-clockwise.

4. Lay the gun and cable out straight on a flat surface.

Loosen the set screw located in the brass connector at the wire feeder end of the cable. Pull the liner

out of the cable.

5. Insert a new untrimmed liner into the connector end

of the cable. Be sure the liner bushing is stenciled

appropriately for the wire size being used.

6. Fully seat the liner bushing into the connector.

Tighten the set screw on the brass cable connector. At this time, the gas diffuser should not be

installed onto the end of the gun tube.

9. Replace the contact tip and nozzle.

GUN HANDLE PARTS

The gun handle consists of two halves that are held

together with a collar on each end. To open up the

handle, turn the collars approximately 60 degrees

counter-clockwise until the collar reaches a stop. Then

pull the collar off the gun handle. If the collars are difficult to turn, position the gun handle against a corner,

place a screwdriver against the tab on the collar and

give the screwdriver a sharp blow to turn the collar

past an internal locking rib. See Figure D-3.

➣

Counter-clockwise

7. With the gas nozzle and diffuser removed from the

gun tube, be sure the cable is straight, and then

trim the liner to the length shown in the Figure D.2.

Remove any burrs from the end of the liner.

Handymig 170i

FIGURE D.3

Page 26

GROUND TEST PROCEDURE

D-4D-4

WARNING

WARNING ELECTRIC SHOCK can kill

WARNING: This procedure is only suitable for applications using DC mega testers up to 500V.

Note: This procedure is for ‘machines as built’ many

modifications could have taken place over the life of a

particular machine, so details of this procedure may

need to be ‘adjusted’ to suit these modifications.

For prompt service contact your local authorized Liquid

Arc Field Service shop.

The insulation resistance values listed below are from

Australian Standard AS1966.1.

• Disconnect input power by removing plug from mains

supply.

• Remove welding leads (gun and work lead) from the

machine before any tests are carried out.

• Remove plug from PCB, install a shorting socket into

the harness plug. (The shorting socket is to have pins

4 & 5 jumpered together and all other pins jumpered

together separately and insulated.)

• Connect a shorting jumper across the connections to

the capacitor and from the capacitor to each rectifier

heat sink plate.

• Set power switch to ‘on’ position.

• Input circuit test: Connect one lead of the mega tester

to the frame of the machine and the other lead to

both the ‘active’ & ‘neutral’ terminals of the 240V

input plug. Apply the test. (Minimum resistance 1M•)

• Welding circuit test: Connect one lead of the mega

tester to the frame of the machine and the other lead

to the positive output stud. Apply the test. (Minimum

resistance 1M•)

• Auxiliary circuit test: Connect one lead of the mega

tester to the frame of the machine and the other lead

to jumper on pins 4 & 5 in the shorting socket. Apply

the test. (Minimum resistance 1M•)

• Input circuit to welding circuit test: Connect one lead

of the mega tester to both the ‘active’ & ‘neutral’ terminals of the 240V input plug and the other to the

positive output stud. Apply the test(s). (Minimum

resistance 10M•)

• Input circuit to auxiliary circuit test: Connect one lead

of the mega tester to both the ‘active’ & ‘neutral’ terminals of the 240V input plug and the other to the

jumper on pins 4 & 5 in the shorting socket. Apply the

test. (Minimum resistance 1M•)

• Welding circuit to auxiliary circuit test: Connect one

lead of the mega tester to the positive output stud

and the other to the jumper on pins 4 & 5 in the

shorting socket. Apply the test. (Minimum resistance

1M•)

• Wire drive test: Connect one lead of the mega tester

to the positive output stud and the other to the drive

roll shaft. Apply the test. (Minimum resistance 1M•)

• Remove all harness shorting plugs and connect all

plug and leads to PCB. Remove all shorting jumpers.

If any problems are encountered, refer to your nearest authorized Liquid Arc Field Service Shop.

Handymig 170i

Page 27

E-1

TROUBLESHOOTING

HOW TO USE TROUBLESHOOTING GUIDE

WARNING

Service and Repair should only be performed by Liquid Arc Factory Trained Personnel.

Unauthorized repairs performed on this equipment may result in danger to the technician and

machine operator and will invalidate your factory warranty. For your safety and to avoid

Electrical Shock, please observe all safety notes and precautions detailed throughout this

manual.

__________________________________________________________________________

This Troubleshooting Guide is provided to

help you locate and repair possible machine

malfunctions. Simply follow the three-step

procedure listed below.

Step 1. LOCATE PROBLEM (SYMPTOM).

Look under the column labeled “PROBLEM

(SYMPTOMS)”. This column describes possible symptoms that the machine may

exhibit. Find the listing that best describes

the symptom that the machine is exhibiting.

Symptoms are grouped into three main categories: output problems, function problems, welding problems.

Step 2. PERFORM EXTERNAL TESTS.

The second column labeled “POSSIBLE

AREAS OF MISADJUSTMENT(S)” lists the

obvious external possibilities that may contribute to the machine symptom. Perform

these tests/checks in the order listed. In

general, these tests can be conducted without removing the case wrap-around cover.

Step 3. PERFORM COMPONENT TESTS.

If you have exhausted all of the recommended tests in Step 2, Consult your Local

Authorized Field Service Facility.

E-1

CAUTION

If for any reason you do not understand the test procedures or are unable to perform

the tests safely, contact your LOCAL AUTHORIZED LIQUID ARC FIELD SERVICE

FACILITY for assistance before you proceed.

_____________________________________________________________________

Handymig 170i

Page 28

E-2

TROUBLESHOOTING

E-2

TROUBLESHOOTING GUIDE

PROBLEMS

(SYMPTOMS)

Major physical or electrical damage

is evident.

No wire feed, weld output or gas

flow when gun trigger is pulled. Fan

does NOT operate.

No wire feed, weld output or gas

flow when gun trigger is pulled Fan

operates normally.

POSSIBLE

CAUSE

None

Contact your local Authorized Field

Service Facility.

1. Make sure correct voltage is

2. Make certain that power switch

3. Make sure circuit breaker is

1. The thermostat may be tripped

OUTPUT PROBLEMS

applied to the machine. See

Installation section, “Electrical

Connections”.

is in the ON position.

reset.

due to overheating. Let machine

cool. Weld at lower duty cycle.

Observe Safety Guidelines

detailed in the beginning of this manual.

RECOMMENDED

COURSE OF ACTION

If all recommended possible areas

of misadjustments have been

checked and the problem persists,

contact your local Liquid Arc

Authorized Field Service Facility.

2. Check for obstructions in air

flow.

3. Check Gun Trigger connections.

See Installation section.

4. Gun trigger may be faulty.

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

LOCAL AUTHORIZED

LIQUID ARC FIELD SERVICE FACILITY for assistance before you proceed.

Handymig 170i

Page 29

E-3

TROUBLESHOOTING

E-3

Observe Safety Guidelines

detailed in the beginning of this manual.

PROBLEMS

(SYMPTOMS)

No wire feed when gun trigger is

pulled. Fan runs, gas flows and

machine has correct open circuit

voltage (33 vcd maximum) – weld

output.

Low or no gas flow when gun