Page 1

Wave Designer

TM

IM649

RETURN TO MAIN MENU

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However, your

overall safety can be increased by

proper installation ... and thoughtful operation on your part. DO

NOT INSTALL, OPERATE OR

REPAIR THIS EQUIPMENT

WITHOUT READING THIS

MANUAL AND THE SAFETY

PRECAUTIONS CONTAINED

THROUGHOUT. And, most

importantly, think before you act

and be careful.

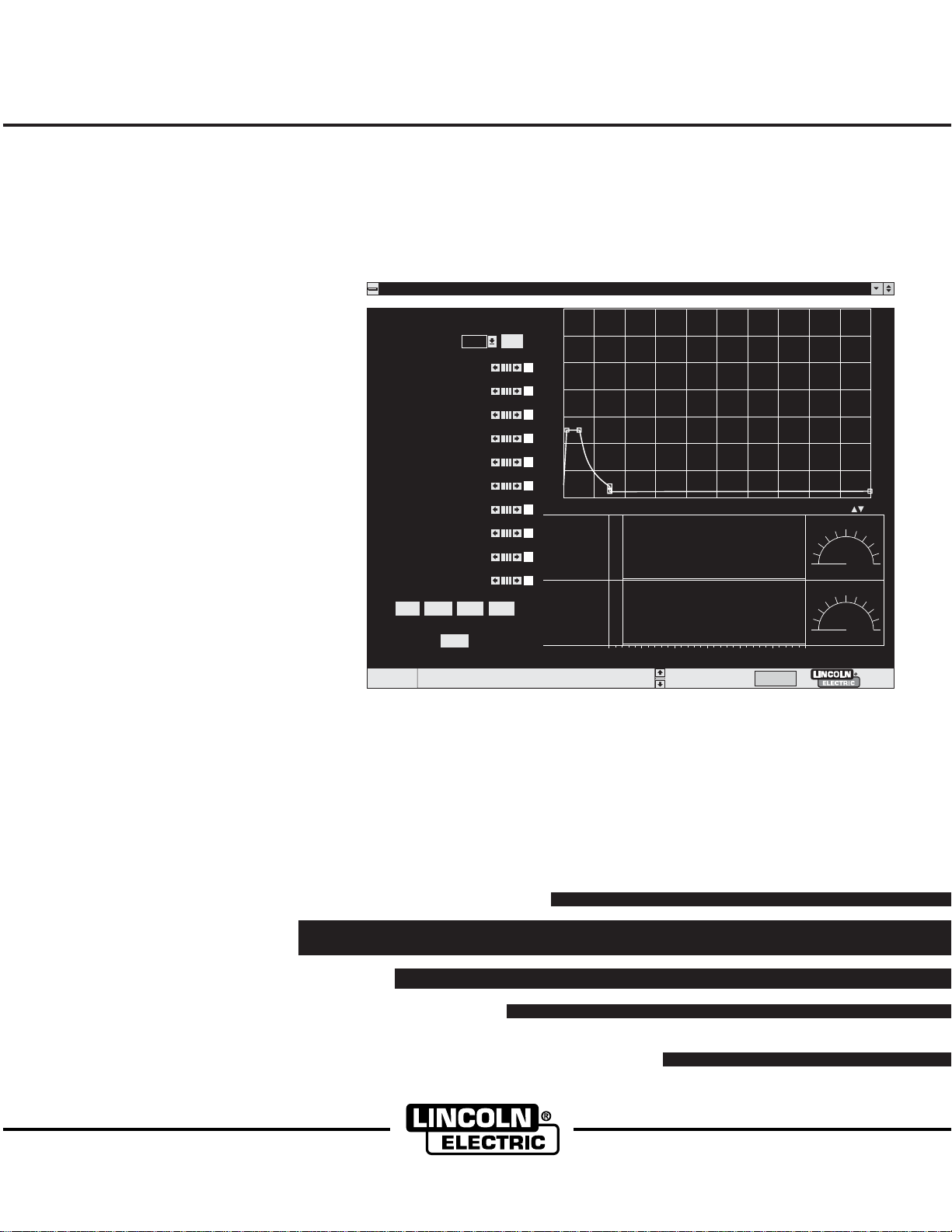

File Tools Print Help

Pulse Waveform Editor

Adapt

About

AC.sco loaded

50

600

-20

250

1.2

3.0

.100

40

21

33.4

26.4

Short

Wire Feed Speed

Ramp Up Rate

Ramp Overshoot %

Peak Amps

Peak Time ms

Tailout Time

Tailout Speed

Stepoff Amps

Backgrd Amps

Backgrd Time

Frequency

Start

Status

Wave Designer Pro Off Line - pulse.swf

700

600

Edit

500

400

300

200

100

0

0 3 6 9 12 15 18 21 24 27 30

End

Off Line Stand by

Adaptive

May, 1999

World's Leader in Welding and Cutting Products Premier Manufacturer of Industrial Motors

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

SOFTWARE OPERATOR’S MANUAL

• Sales and Service through Subsidiaries and Distributors Worldwide •

Page 2

Page 3

i

License Information ..................................................................................................... ii

Introduction .................................................................................................... Section 1

1.1 Product Overview .......................................................................................... 1-1

1.2 User Responsibility ....................................................................................... 1-1

1.3 Computer System Requirements .................................................................. 1-1

1.4 Software Release Data ................................................................................. 1-2

1.5 Welding Equipment Requirements ................................................................ 1-2

Software Installation ...................................................................................... Section 2

2.1 File Storage Locations ................................................................................. 2-1

2.2 Software Installation Procedure .................................................................... 2-1

2.3 Equipment Interface Connections ................................................................. 2-2

2.4 Equipment/Software Startup ......................................................................... 2-4

2.5 Upgrade Firmware ........................................................................................ 2-4

Software Operation ........................................................................................ Section 3

3.1 Synergic Welding and Workpoints ................................................................ 3-1

3.2 Working in Wave Designer ............................................................................ 3-2

3.3 Wave Design Process ................................................................................. 3-11

3.4 Downloading Wave Shapes ........................................................................ 3-12

3.5 Autosave ..................................................................................................... 3-13

TABLE OF CONTENTS

Page

i

ArcScope ........................................................................................................ Section 4

4.1 Introduction ................................................................................................... 4-1

Troubleshooting ............................................................................................ Section 5

5.1 Overview ....................................................................................................... 5-1

5.2 Wave Designer Troubleshooting Procedure ................................................. 5-1

Pulse Wave Shaping Principles ............................................................... Appendix A

A.1 Appendix Overview ...................................................................................... A-1

A.2 GMAW Pulse Overview ................................................................................ A-2

A.3 Adaptive and Non-Adaptive Mode ................................................................ A-4

A.4 Pulse Wave Design Process ........................................................................ A-5

A.5 Primary Pulse Waveform Components ...................................................... A-14

A.6 Secondary Waveform Parameters ............................................................. A-16

A.7 Application Exercise ................................................................................... A-17

STT Wave Shaping Principles .................................................................. Appendix B

B.1 Appendix Overview ...................................................................................... B-1

B.2 STT Overview ............................................................................................... B-2

B.3 STT (Surface Tension Transfer) ................................................................... B-4

B.4 STT Wave Design Process .......................................................................... B-6

B.5 Primary STT Waveform Components ........................................................ B-12

B.6 Secondary STT Waveform Components .................................................... B-14

B.7 Application Exercise ................................................................................... B-15

WAVE DESIGNER

Page 4

ii ii

LICENSE INFORMATION

By clicking the acceptance button or installing the software, you are consenting to be bound by and are becoming

a party to this agreement. If you do not agree to all of the terms of this agreement, click the button that indicates

you do not accept the terms and do not install the software. (If applicable, you may return the product to the place

of purchase for a full refund.) If the copy of the software you received was accompanied by a printed or other

form of "hard-copy" end user license agreement whose terms vary from this agreement, then the hard-copy end

user license agreement governs your use of the software.

WAVE DESIGNER SOFTWARE LICENSE AGREEMENT

LICENSE:

Lincoln grants you the right to use the Wave Designer Software ("the Software"). You will not use, copy, modify, rent, sell or transfer this

Software, or any portion thereof, except as provided for in this Agreement. The Software includes and utilizes Java Runtime software owned

by Sun Microsystems, Inc. and this license is conditioned upon your agreement to the Sun Microsystems Binary Code License which is

attached and made a part of this license. There is no legal or commercial association between Lincoln and Sun Microsystems, Inc.

You may use the Software on a single computer and with any Lincoln arc welding equipment which you own or lease. If the software is

installed on a networked computer, only one (1) copy can be used at a time.

RESTRICTIONS

1) Use the Software on more than one computer or with non-Lincoln arc welding equipment.

2) Sub-license the Software.

3) Reverse engineer, de-compile, disassemble, modify, or extract archived files from the Software.

4) Copy the Software, except for backup purposes.

5) Sell, license, or patent welding applications, waveforms, or other know how developed with this Software.

NON-DISCLOSURE

You agree that the Software is and shall remain the property of Lincoln Electric, and that you will hold the Software in confidence for Lincoln.

You agree to make reasonable efforts to prevent unauthorized use of the Software, and to prevent disclosure to third parties.

ROYALTY-FREE

Provided you have paid the initial license fee, you will be under no obligation to pay Lincoln a royalty for the use of the Software when used as

permitted under this license.

WARRANTY

Lincoln warrants to the original purchaser that the Software will perform substantially as described in the Software documentation for a period

of 90 days from the date of purchase. Lincoln's liability under this warranty shall not exceed the amount you paid for the Software. No

warranty is made by Lincoln that the Software is free of errors or limitations. No warranty is made by Lincoln with respect to the Java Runtime

software.

THE ABOVE WARRANTIES ARE THE ONLY WARRANTIES OF ANY KIND EITHER EXPRESSED OR IMPLIED, INCLUDING

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. LINCOLN SHALL NOT BE LIABLE FOR ANY

LOSS OF PROFITS, LOSS OF USE, INTERRUPTION OF BUSINESS, NOR FOR INDIRECT, SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OF ANY KIND WHICH RELATE TO USE OF THE SOFTWARE. SELECTION AND APPLICATION OF THE

SOFTWARE IS YOUR SOLE RESPONSIBILITY AND NO WARRANTY IS GIVEN WITH REGARD TO WELDING CHARACTERISTICS

DESIGNED USING THIS SOFTWARE OR THE SUITABILITY OF WELDS PRODUCED USING SUCH CHARACTERISTICS.

TRANSFER

You may transfer the Software, subject to this license, to another party if the receiving party also purchases from you the Invertec Power

Wave power source with which this Software is used. Prior to any such transfer, the transferee must agree to the terms of this license and

you must notify Lincoln, in writing, of the name and address of the party to whom the Software has been transferred. You must retain no

copies of the Software and accompanying documentation. Transfer of the license terminates your right to use the Software. This Software

may not be exported except as permitted by the export laws of the United States.

: You may not:

:

:

:

:

IMPROVEMENTS

From time-to-time, Lincoln may make improvements in the Software. You agree that there is no obligation on the part of Lincoln to provide

you with or notify you of any improvements. Such improvements may be purchased by you from Lincoln under the terms of a separate

License Agreement or Maintenance Agreement for that Software. Additional charges for installing and trouble-shooting may apply.

POST-TERMINATION OBLIGATIONS

If this Agreement is terminated, you must stop using the Software and, except in the case of transfer, destroy all copies. Your confidentiality

obligation shall survive termination and remain in effect for a period of five years following termination.

APPLICABLE LAW

This License Agreement shall be interpreted and construed in accordance with the laws of the State of Ohio, and any litigation brought under

this License Agreement shall be filed in the State or Federal Courts in the State of Ohio. The United Nations Convention for the International

Sales of Goods is expressly excluded. Any claim arising out of this License Agreement will first be submitted for resolution by arbitration.

TERM AND TERMINATION:

This Agreement shall remain in effect for so long as the Wave Designer Software is in use as permitted under this license. The license may

be terminated by you at any time by removing and returning to Lincoln all copies of the Software.

:

:

:

WAVE DESIGNER

Page 5

iii iii

JAVA RUNTIME ENVIRONMENT, VERSION 1.1.6, BINARY CODE LICENSE

This binary code license ("License") contains rights and restrictions associated with use of the accompanying Java Runtime Environment

software and documentation ("Software"). Read the License carefully before using the Software. By using the Software you agree to the

terms and conditions of this License.

1. License to Distribute. Licensee is granted a royalty-free right to reproduce and distribute the Software provided that Licensee: (i)

distributes the Software complete and unmodified (except for the specific files identified as optional in the Software README file), only as

part of, and for the sole purpose of running, Licensee's Java compatible applet or application ("Program") into which the Software is

incorporated; (ii) does not distribute additional software intended to replace any component(s) of the Software; (iii) agrees to incorporate

the most current version of the Software that was available 180 days prior to each production release of the Program; (iv) does not

remove or alter any proprietary legends or notices contained in the Software; (v) includes the provisions of Sections 2, 3, 5, 6, 8 and 9 in

Licensee's license agreement for the Program; and (vi) agrees to indemnify, hold harmless, and defend Sun and its licensors from and

against any claims or lawsuits, including attorneys' fees, that arise or result from the use or distribution of the Program.

2. Java Platform Interface. Licensee may not modify the Java Platform Interface ("JPI", identified as classes contained within the "java"

package or any subpackages of the "java" package), by creating additional classes within the JPI or otherwise causing the addition to or

modification of the classes in the JPI. In the event that Licensee creates any Java-related API and distributes such API to others for

applet or application development, Licensee must promptly publish broadly, an accurate specification for such API for free use by all

developers of Java-based software.

3. Restrictions. Software is confidential copyrighted information of Sun and title to all copies is retained by Sun and/or its licensors.

Licensee shall not decompile, disassemble, decrypt, extract, or otherwise reverse engineer Software. Software may not be leased,

assigned, or sublicensed, in whole or in part, except as specifically authorized in Section 1. Software is not designed or intended for use

in online control of aircraft, air traffic, aircraft navigation or aircraft communications; or in the design, construction, operation or

maintenance of any nuclear facility. Licensee warrants that it will not use or redistribute the Software for such purposes.

LICENSE INFORMATION

4. Trademarks and Logos. This License does not authorize Licensee to use any Sun name, trademark or logo. Licensee acknowledges

that Sun owns the Java trademark and all Java-related trademarks, logos and icons including the Coffee Cup and Duke ("Java Marks")

and agrees to: (i) comply with the Java Trademark Guidelines at http://java.sun.com/trademarks.html; (ii) not do anything harmful to or

inconsistent with Sun's rights in the Java Marks; and (iii) assist Sun in protecting those rights, including assigning to Sun any rights

acquired by Licensee in any Java Mark.

5. Disclaimer of Warranty. Software is provided "AS IS," without a warranty of any kind. ALL EXPRESS OR IMPLIED

REPRESENTATIONS AND WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE OR NON-INFRINGEMENT, ARE HEREBY EXCLUDED.

6. Limitation of Liability. SUN AND ITS LICENSORS SHALL NOT BE LIABLE FOR ANY DAMAGES SUFFERED BY LICENSEE OR ANY

THIRD PARTY AS A RESULT OF USING OR DISTRIBUTING SOFTWARE. IN NO EVENT WILL SUN OR ITS LICENSORS BE LIABLE

FOR ANY LOST REVENUE, PROFIT OR DATA, OR FOR DIRECT, INDIRECT, SPECIAL, CONSEQUENTIAL, INCIDENTAL OR

PUNITIVE DAMAGES, HOWEVER CAUSED AND REGARDLESS OF THE THEORY OF LIABILITY, ARISING OUT OF THE USE OF

OR INABILITY TO USE SOFTWARE, EVEN IF SUN HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

7. Termination. This license shall automatically terminate 180 days after production release of the next version of the Software by Sun.

Licensee may terminate this License at any time by destroying all copies of Software. This License will terminate immediately without

notice from Sun if Licensee fails to comply with any provision of this License. Upon such termination, Licensee must destroy all copies of

Software.

8. Export Regulations. Software, including technical data, is subject to U.S. export control laws, including the U.S. Export Administration Act

and its associated regulations, and may be subject to export or import regulations in other countries. Licensee agrees to comply strictly

with all such regulations and acknowledges that it has the responsibility to obtain licenses to export, re-export, or import Software.

Software may not be downloaded, or otherwise exported or re-exported (i) into, or to a national or resident of, Cuba, Iraq, Iran, North

Korea, Libya, Sudan, Syria or any country to which the U.S. has embargoed goods; or (ii) to anyone on the U.S. Treasury Department's

list of Specially Designated Nations or the U.S. Commerce Department's Table of Denial Orders.

9. Restricted Rights. Use, duplication or disclosure by the United States government is subject to the restrictions as set forth in the Rights in

Technical Data and Computer Software Clauses in DFARS 252.227-7013© (1) (ii) and FAR 52.227-19© (2) as applicable.

10. Governing Law. Any action related to this License will be governed by California law and controlling U.S. federal law. No choice of law

rules of any jurisdiction will apply.

11. Severability. If any of the above provisions are held to be in violation of applicable law, void, or unenforceable in any jurisdiction, then

such provisions are herewith waived or amended to the extent necessary for the License to be otherwise enforceable in such jurisdiction.

However, if in Sun's opinion deletion or amendment of any provisions of the License by operation of this paragraph unreasonably

compromises the rights or increase the liabilities of Sun or its licensors, Sun reserves the right to terminate the License.

WAVE DESIGNER

Page 6

iv iv

LICENSE INFORMATION

WAVE DESIGNER

Page 7

Section 1 1-1

INTRODUCTION

KEY TOPICS

This symbol indicates the location of key concepts throughout this manual.

1.1 PRODUCT OVERVIEW

Wave Designer is a visual, interactive software application used to modify wave shapes for use

with programmable waveform-controlled welding machines such as the Power Wave 455. The

Wave Designer software package includes a standard set of waveforms commonly used in

commercial and industrial welding applications.

The Wave Designer software package is intended for use by a weld application engineer in

concert with a skilled welding technician properly trained in welding applications.

This Instruction Manual guides you through the installation and operation of Wave Designer to

modify selected standard wave shapes and produce pulsed waveforms tailored to your specific

welding applications. The resulting custom waveforms automatically adjust your welding machine

to produce consistent weld transfers throughout a range of wire feed speeds and arc lengths.

1.2 USER RESPONSIBILITY

Because design, fabrication, erection, and welding variables affect the results obtained in

applying this type of information, the serviceability of a product or structure is the

responsibility of the user. Variations such as plate chemistry, plate surface condition (oil,

scale), plate thickness, preheat, quench, joint fit-up, gas type, gas flow rate, and

equipment may produce results different than those expected. Some adjustments to

procedures may be necessary to compensate for unique individual conditions. When

possible, test all procedures, duplicating actual field conditions.

1.3 COMPUTER SYSTEM REQUIREMENTS

Wave Designer software is intended for use on Windows 95, Windows 98, or Windows NT 4.0.

It will not work with Windows NT 3.51, Windows 3.1, or Windows for Workgroups. The core of

this product is architecture-neutral (operating system independent). If you would like to have

Wave Designer on Solaris SPARC, Solaris x86, MAC OS, AIX, OS/2, or Linux, please notify us

at wavedesigner@lincolnelectric.com. With Java Internationalization, Wave Designer can

support numerous European and Asian languages. Send your foreign language request to

wavedesigner@lincolnelectric.com.

We recommend a Pentium processor, 32 MB of RAM, and 6 MB of hard drive disk space for

efficient program operation. When running, Wave Designer occupies at least 10 MB of RAM. If

your computer is low in memory, we suggest you close other programs that consume large

memory. If you have less than 32 MB RAM, you may be able to run Wave Designer with “virtual

memory”. Set up virtual memory with one of the following command sequences.

In Windows 95 or 98

Start | Settings | Control Panel | System | Performance

Virtual Memory | Let me specify my own virtual memory settings

Minimum 100 | OK | Are you sure you want to continue? Yes | Close

Do you want to restart your computer now? Yes

WAVE DESIGNER

Page 8

1-2 Section 1

In Windows NT 4.0 log on as Administrator

An RS-232 serial communication cable is required to use Wave Designer software with Power

Wave power sources. The Power Wave requires an RS-232 DB25 male connector. Most

computers feature an RS-232 DB-9 female connector as the COM serial port. (e.g. Radio Shack

cat no. 26-269 serial cable connects to this combination). Verify the set up on your computer as

it may differ.

We recommend using an 800 x 600 pixel or larger display monitor. A 640 x 480 display will not

show all the features of the Wave Designer Editor Screens.

INTRODUCTION

Start | Settings | Control Panel | System | Performance

Virtual Memory Change... | Initial Size (MB): 100 | Set | OK

Do you want to restart your computer now? Yes

1.4 SOFTWARE RELEASE DATA

Wave Designer is a product of The Lincoln Electric Company. Please send your comments,

questions, suggestions, and problem reports to wavedesigner@lincolnelectric.com.

Refer to the Wave Designer Welcome screen for the applicable release version of the Wave

Designer software package. Wave Designer is a JAVA (TM) application (applet) and it comes

bundled with Java Runtime Environment (JRE Version 1.1.6) from SUN Microsystems. You may

directly download JRE from http://java.sun.com/products/jdk/1.1/jre/index.html. More information

about JAVA technology can be found at the http://java.sun.com web site.

1.5 WELDING EQUIPMENT REQUIREMENTS

Wave Designer works only with the Power Wave 455 or similar Lincoln Electric Company

Programmable Waveform Controlled welding systems. The following welding equipment is

required to interface with Wave Designer and to produce sample welds.

• power source (Power Wave 455 or similar)

• wire feeder and associated gears and drive rolls (Power Feed 10 or similar)

• welding gun

• regulated supply of shielding gas

• continuous-feed electrode

• interconnecting hoses and cables

• sample weld materials

• oscilloscope (optional)

WAVE DESIGNER

Page 9

Section 2 2-1

SOFTWARE INSTALLATION

2.1 FILE STORAGE LOCATIONS

The Wave Designer default home directory is C:\Program Files\WaveDesigner.

Subdirectories included with Wave Designer are as follows:

• arcScope - user data file for ArcScope traces (Wave Designer Pro option only)

• bin - system executables and support files, do not tamper with these files

• export - user waveform data table in ASCII text and html format

• firmware - bundled system firmware for PW455 machines

• jre - bundled Java Runtime Environment 1.1.6 from Sun Microsystems

• map - waveform editor template map files, do not tamper with them

• pictures - image files for GMAW droplet transfer movies

• systemWeldFile - user custom waveform files

• weldModeFile - copies of the weld mode directory (weld files for the welding machine)

2.2 SOFTWARE INSTALLATION PROCEDURE

Standard installation (CD ROM version): Start | Run | Browse; Run D:\setup.exe

Install the Wave Designer program as you would any Windows application. Select the Wave

Designer program icon from your START window to start up the program. Refer to Table 2-1 for

alternate installation procedures. On startup, the Wave Designer screens in Figure 2-1 will be

displayed.

NOTE: If upgrading a previous software release, save your data files (waveforms, scope traces,

etc.) and uninstall the previous software release before installing the new version.

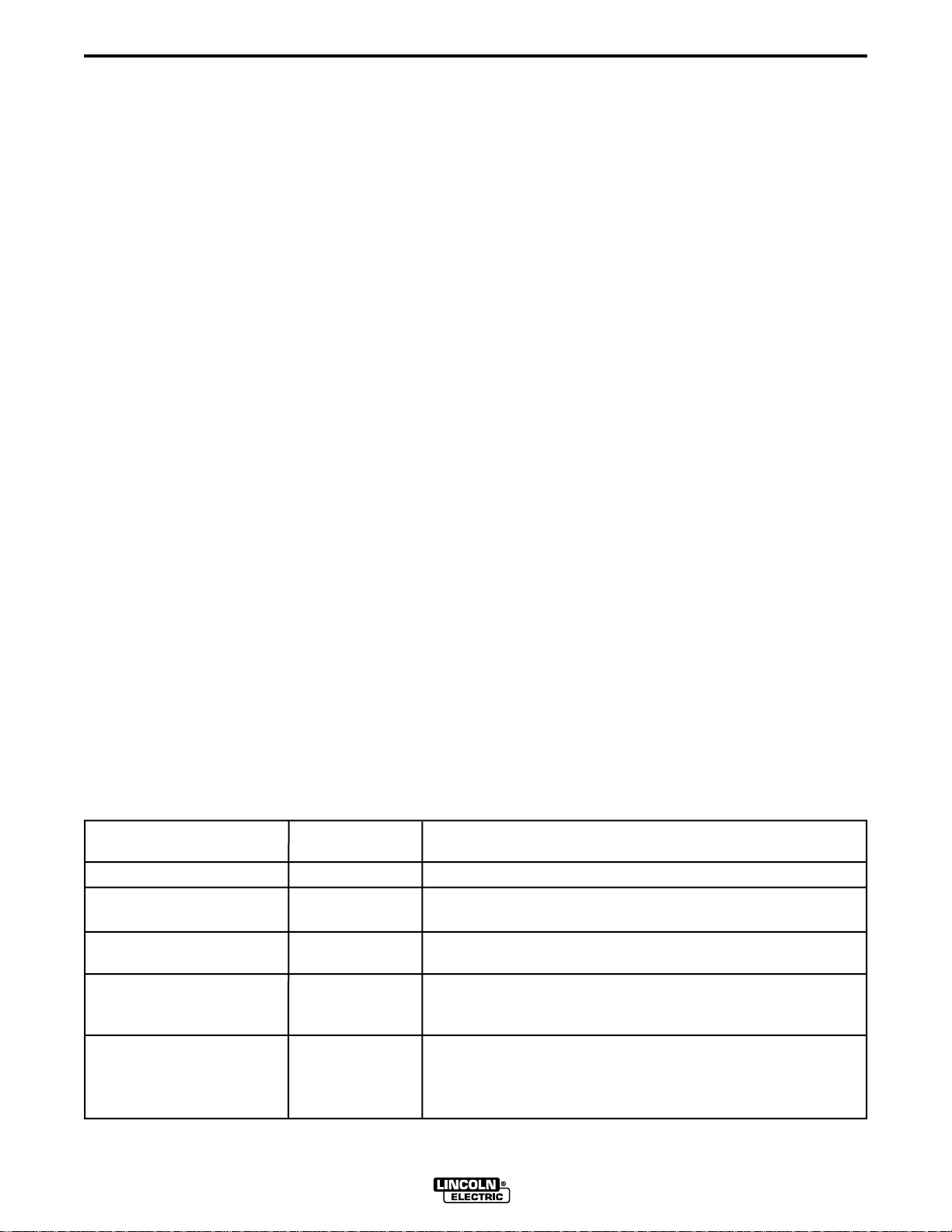

TABLE 2-1. ALTERNATE INSTALLATION PROCEDURES.

Application/

Operation Drive Command Sequence

Install Floppy Disk Version A Start | Run | Browse; Run setup.exe

Install Java Runtime All Create shortcut: <dir>\jrew.exe -ms12000000 -cp .\*.jar Pwgui

Executable Version Start Program: <dir>\Program Files\WaveDesigner\bin

Install Wave Designer Windows NT 4.0 Create Start Menu Shortcut; set icon for “All Users”

Icon

Start Wave Designer in a C Open C:\Program Files\WaveDesigner\bin

DOS Window Type: jre -ms12000000 -cp .\*.jar Pwgui

or:..\jre\bin\jre -ms12000000 -cp .\*.jar Pwgui

Start | Settings | Control Panel | Add/Remove Programs

Uninstall Program All Select Wave Designer in scroll window and click on

Add/Remove button. Use Windows Explorer or File Manager to

remove Wave Designer folder.

WAVE DESIGNER

Page 10

WAVE DESIGNER

2-2 Section 2

SOFTWARE INSTALLATION

FIGURE 2-1.

Copyright © 1998 The Lincoln Electric Company

Welcome to Wave Designer

Lincoln Electric Wave Designer Version 1.0

All Rights Reserved

STARTUP SCREEN.

Wave Designer

WARNING: This computer program is protected by copyright law

and international treaties. Unauthorized reproduction or

distribution of this program, or any part of it, may be prosecuted to

the maximum extent possible under the law.

United States Patent Pending

Comments? Write to wavedesigner@lincolnelectric.com

Initializing ... Please wait

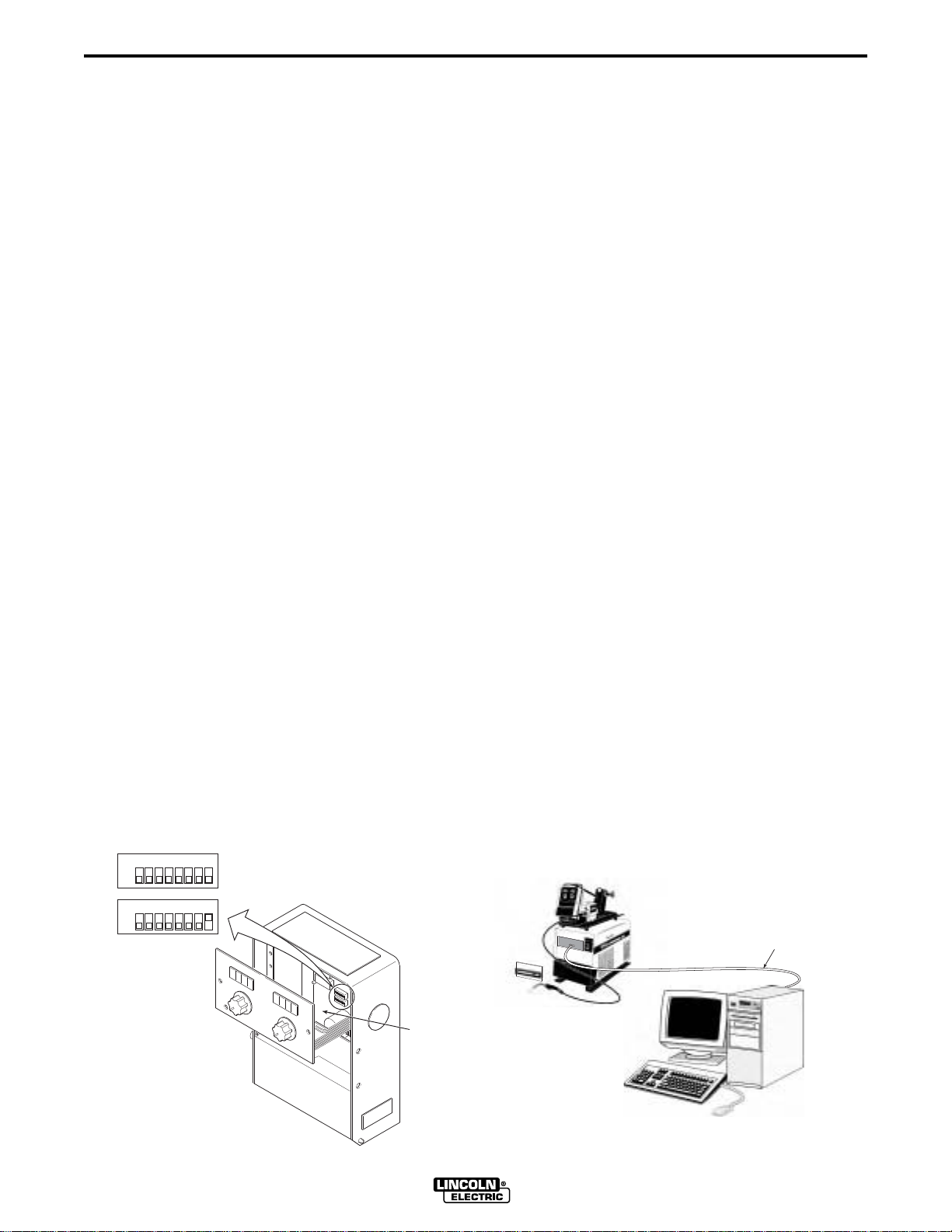

2.3 EQUIPMENT INTERFACE CONNECTIONS

Wave Designer communicates welding parameter changes to the welding machine controller in

real time (on-the-fly). To enable communication with Wave Designer, reconfigure the welding

machine settings as follows:

1. Disconnect the electrical power to the welding machine.

2. Remove the control box LED display panel, Figure 2-2. Be careful not to pull hard on the

panel wiring harness.

3. Locate the bottom DIP switch block (SW2) on the user interface control board. Move the last

DIP switch (position #8) up and reinstall the LED display panel.

4. Toggle the control box SELECT switch up and down until the Weld Mode indicator lights up.

Toggle the SET switch to get an OFF readout on the LED display.

5. An RS-232 serial communication cable is required to use Wave Designer software with

Power Wave power sources. The Power Wave requires an RS-232 DB25 male connector.

Most computers feature an RS-232 DB-9 female connector as the COM serial port. (e.g.

Radio Shack cat no. 26-269 serial cable connects to this combination). Verify the set up on

your computer as it may differ.

27850002

6. Connect the RS-232 cable between the COM1 port of your computer and the mating

connector behind the front center panel of the power source, Figure 2-3.

WAVE DESIGNER

Page 11

Section 2 2-3

SOFTWARE INSTALLATION

PLEASE NOTE: Some IBM ThinkPads® by default have the serial port disabled and instead the port is used for infrared. The

following information describes the procedure to disable the infrared feature and enable the serial port. Follow the instructions

below to use COM1 to communicate with the PowerWave. More instructions at the end discuss how to use other ports, if

necessary.

The following information can also be found at the IBM website at

http://www.pc.ibm.com/qtechinfo/DSHY-3P5QW4.html

How to enable the external serial port on your ThinkPad

SYMPTOM:

The ThinkPad is not communicating with the PowerWave serial device.

CONFIGURATION:

Any ThinkPad trying to utilize the external serial port using any applicable operating systems.

RESOLUTION:

By default, currently available ThinkPads come with the external serial port disabled and Infrared enabled on COM 1. To use

the serial port on COM 1 you must either disable infrared or change infrared so that it uses alternate resources. If you are not

using infrared for printing or file sharing it is recommended that it be disabled.

To disable infrared and enable the serial port on COM 1 do the following:

1. Double-click your ThinkPad Features or ThinkPad Configuration icon located in the ThinkPad folder on your desktop.

2. Locate the Infrared button located on the left-hand side of this configuration screen and click it once.

(Note: If you hold your mouse pointer over any of the icons in this configuration screen the button will be identified at the

bottom in the status window.)

3. Change Infrared from "Enable" to "Disable" and click "OK".

4. Locate the serial port icon and click it once.

5. Select serial port "enable" and insure that the COM PORT setting is "COM 1" and click "OK".

6. Shut down and restart the computer.

More Information:

There are many different combinations of port settings that are possible. The following table indicates the standard settings for

the four available COM Ports:

COM 1 03F8 4 COM 2 02F8 3

COM 3 03E8 4 COM 4 02E8 3

Please note that COM 1 and 3 share IRQ 4 and COM 2 and 4 share IRQ 3. You can not configure multiple devices to the

same IRQ.

If not successful, try to use COM3. Follow the instructions above while substituting COM1 with COM3. Configure Wave

Designer by changing the properties of the Wave Designer icon (right click mouse when pointing to the icon), add "-port com3"

to the command line.

FIGURE 2-2. CONTROL BOARD DIP SWITCH SETTING.

SW1

SW2

ON

ON

112

5

3

66778

4

5

3

2

8

4

CONTROL

BOX

CONTROL

BOARD

27850003

FIGURE2-3. INTERFACE CONNECTION.

POWER

SOURCE

FRONT

PAN E L

RS232

CABLE

COMPUTER

SYSTEM

27850004

WAVE DESIGNER

Page 12

2-4 Section 2

SOFTWARE INSTALLATION

2.4 EQUIPMENT/SOFTWARE STARTUP

When the Wave Designer software installation is complete, Wave Designer is listed among the

programs you can start up from the Windows startup screen. Click on START, point to the

programs option, then click on the Wave Designer option. The Wave Designer Welcome

screen is displayed followed by the Pulse Waveform Editor screen. When the Pulse Waveform

Editor screen is displayed, the software is ready for use.

Wave Designer Pro Off Line - pulse.swf

File Tools Print Help

Pulse Waveform Editor

Wire Feed Speed

50

Edit

700

600

Ramp Up Rate

Ramp Overshoot %

Peak Amps

Peak Time ms

Tailout Time

Tailout Speed

Stepoff Amps

Backgrd Amps

Backgrd Time

Frequency

Adapt

Start

Status

AC.sco loaded

600

-20

250

1.2

3.0

.100

40

21

33.4

26.4

About

Short

End

500

400

300

200

100

0

0 3 6 9 12151821242730

27850001

Off Line Stand by

Adaptive

2.5 UPGRADE FIRMWARE

An ArcScope application is provided with Wave Designer Pro. In order to run the ArcScope

application, it may be necessary to upgrade the welding machine firmware. If the old firmware

does not support ArcScope, the ArcScope application will display garbled data rather than

waveforms. Wave Designer will automatically detect the firmware version and prompt you to

upgrade the firmware if required.

WAVE DESIGNER

Page 13

Section 3 3-1

SOFTWARE OPERATION

3.1 SYNERGIC WELDING AND WORKPOINTS

Prior to using Wave Designer it is important to have a good understanding of the concepts of

synergic welding and workpoints. Synergic welding is basically “one knob control” of a welding

process; all other variables of the process are adjusted by the power source based on the single

controlling variable. This single controlling variable is known as a workpoint. For example, in

synergic pulse welding (GMAW-P), the operator can adjust the wire feed speed (WFS). The

WFS is the workpoint. The synergic power source will then set all other GMAW-P variables

based on the WFS by “looking up” the other variables from a pre-programmed weld table. See

Figure 3-1.

Wave Designer is a program that lets you develop a customized weld procedure by letting you

program each variable for multiple workpoints into a weld “look up” table.

Power Wave power sources go even a step further than simply “looking up” pre-programmed

variables from a weld table. If a selected WFS is between two pre-programmed workpoints, the

Power Wave will interpolate values for each of the welding variables. The result is a precise and

continuous range of welding control.

Refering to Figure 3-1, lets examine how this interpolation works by looking at one welding

variable — background amps. The operator selects a wire feed speed of 175 in/min. This value is

between the pre-programmed workpoints of 150 and 200 in/min. The Power Wave interpolates

between the pre-programmed background amp values of 80 and 60 and adjusts the background

amps to 70.

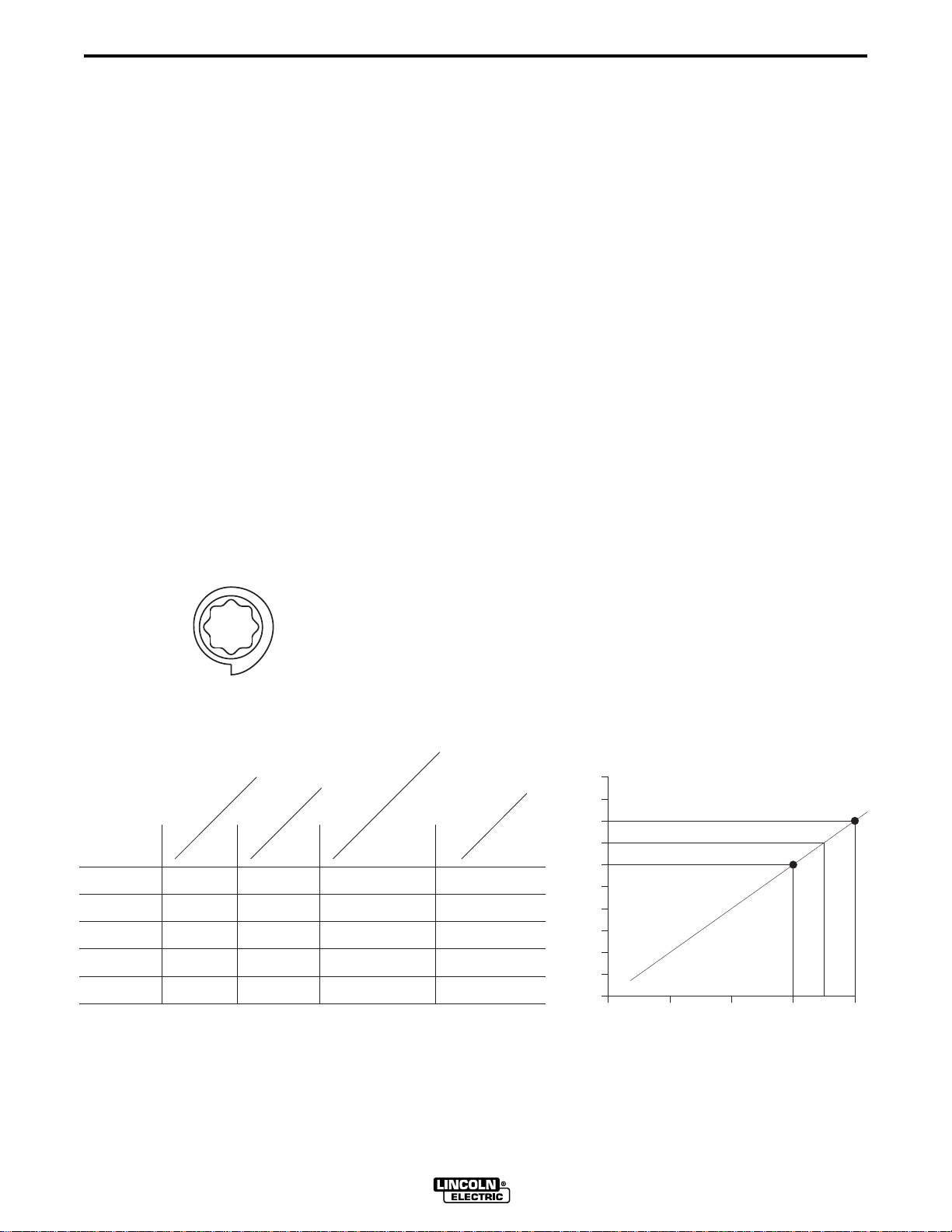

FIGURE 3-1. WFS ENCODER AND WELD DATA TABLE.

WFS/AMPS

ENCODER

NOTE: WFS ENCODER SETTING

DETERMINES WELDING

PROCESS VARIABLES PER

RELATED WELD TABLE.

PRE-PROGRAMMED WELDING PROCESS VARIABLES INTERPOLATED

PARAMETER VALUE

100

90

WORK-

POINTS

(WFS)

80

100

150

200

250

PEAK CURRENT

280

280

280

280

280

PULSE WIDTH

1.2

1.2

1.2

1.2

1.2

BACKGROUND AMPS

FREQUENCY

20

40

60

80

100

50

60

80

90

100

80

70

60

50

40

30

BACKGROUND AMPS

20

10

0

INTERPOLATED

BACKGROUND AMPS

WIRE FEED SPEEDS

WFS = 175

1000 15050 200

27850005

WAVE DESIGNER

Page 14

WAVE DESIGNER

3-2 Section 3

SOFTWARE OPERATION

3.2 WORKING IN

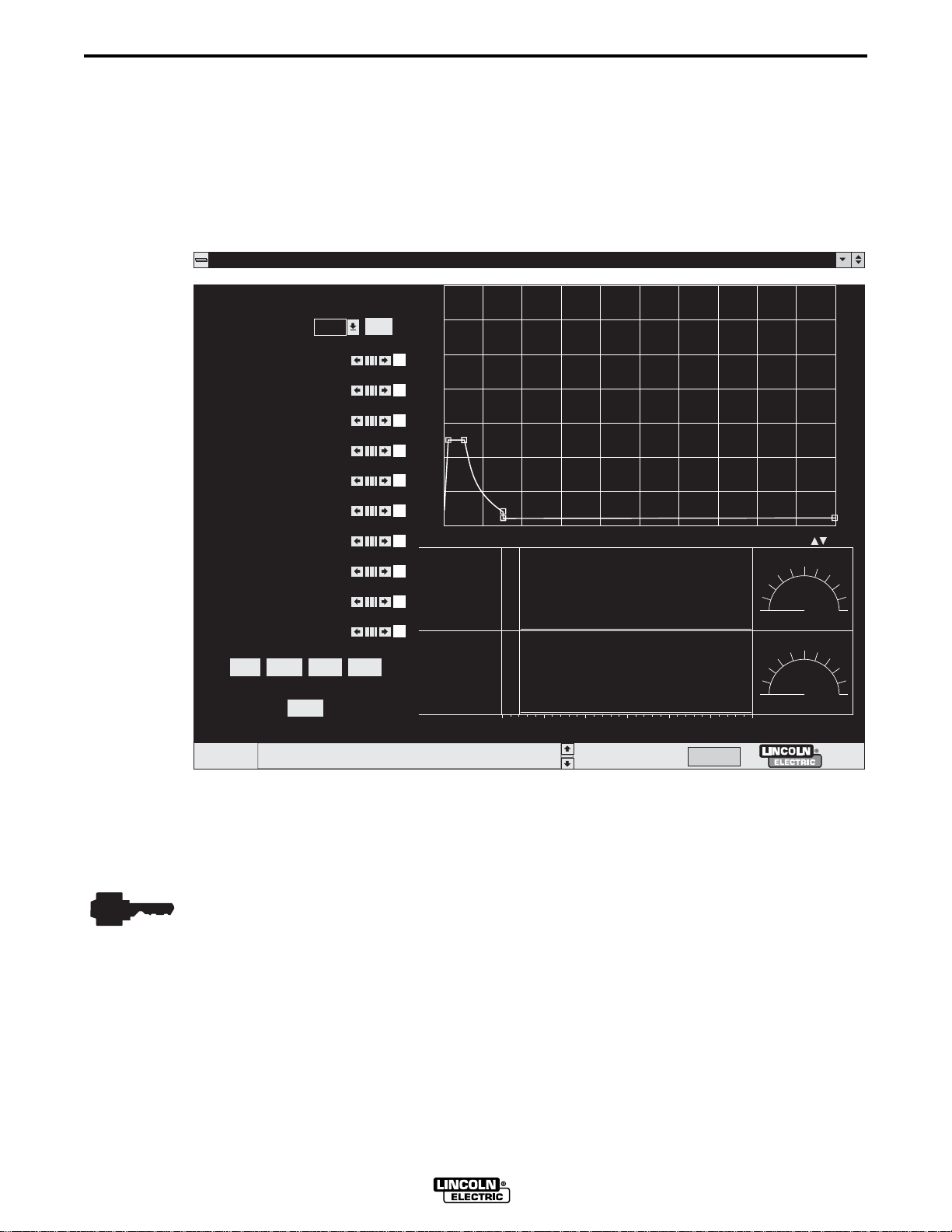

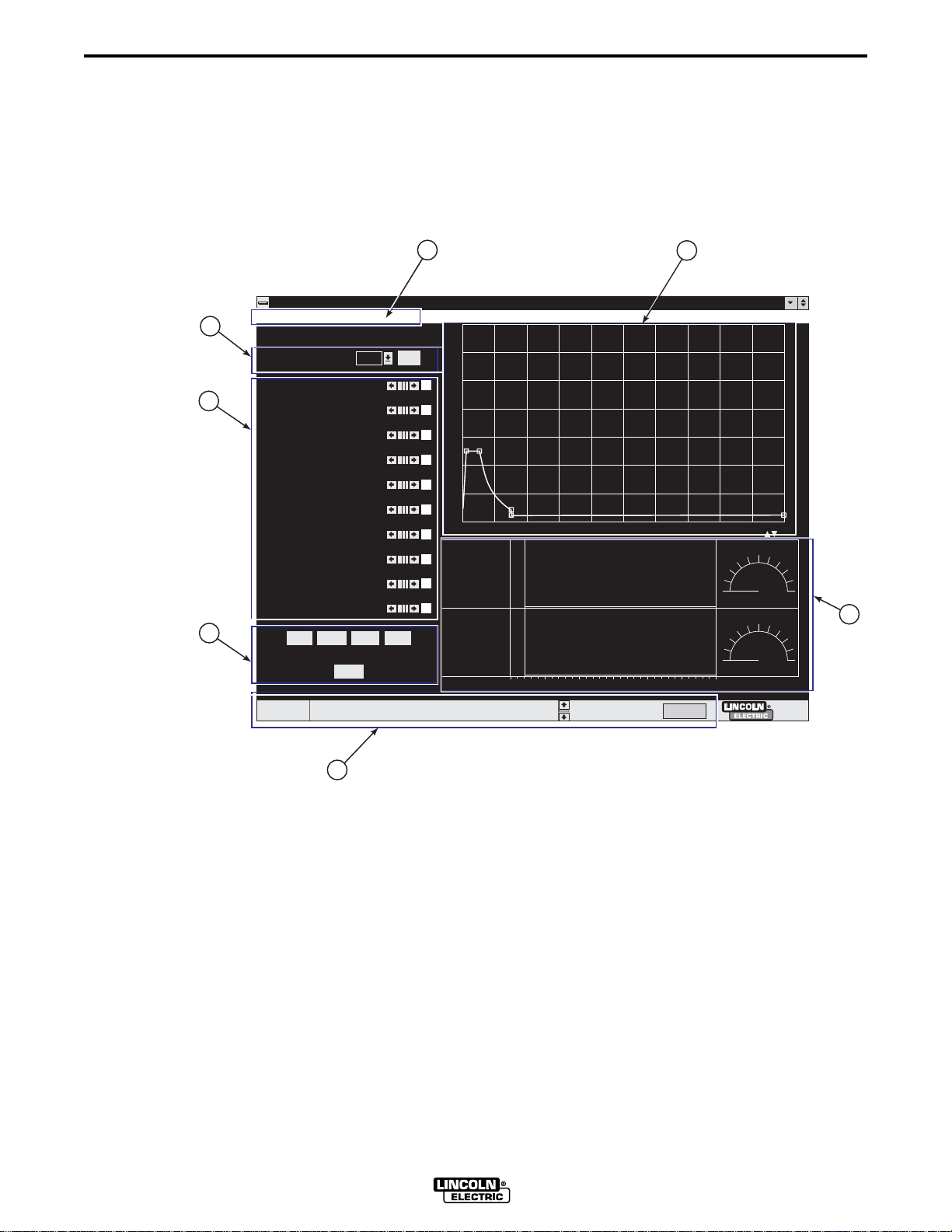

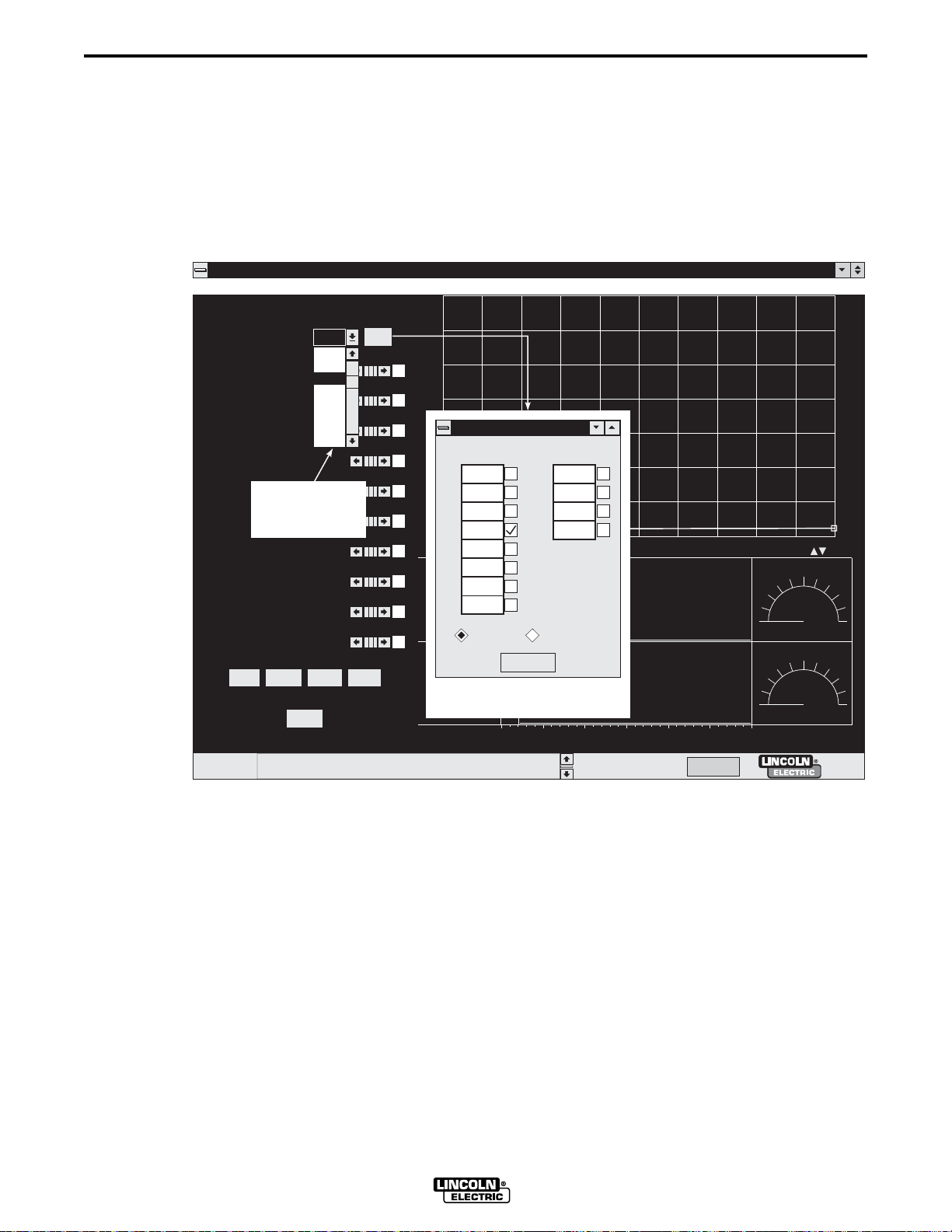

3.2.1 WAVEFORM EDITOR WINDOW

Refer to the Waveform Editor window in Figure 3-2 and the related usage instructions.

2

3

5

File Tools Print Help

Ramp Overshoot %

Status

FIGURE 3-2. WAVEFORM EDITOR WINDOW.

1

Wave Designer Pro Off Line - pulse.swf

Pulse Waveform Editor

Edit

600

-20

250

1.2

3.0

.100

40

21

33.4

26.4

Adapt

About

AC.sco loaded

50

Short End

Wire Feed Speed

Ramp Up Rate

Peak Amps

Peak Time ms

Tailout Time

Tailout Speed

Stepoff Amps

Backgrd Amps

Backgrd Time

Frequency

Start

4

700

600

500

400

300

200

100

0

0 3 6 9 12 15 18 21 24 27 30

Off Line Stand by

Adaptive

7

6

1. Tool Bar Tool bar menus access alternate windows, open and save files, etc. Detailed

instructions are provided in paragraph 3.2.2.

2. Workpoint Selector/Editor The workpoint selector includes a pulldown window for

selecting a workpoint and an edit window for changing the listing of workpoint values. For

the Pulse Waveform Editor, the workpoints are wire feed speeds. The workpoint parameter

(peak voltage, current, etc.) varies with the welding mode (pulse, STT, etc.). Refer to

paragraph 3.2.3 for more detail on selecting and editing workpoints.

3. Variable Parameters The listing of variable parameters display the active parameter

values for the selected WFS. The parameter values are changed (edited) with the related

arrows and slide bars or by moving parameter nodes in the waveform graphic editor. See

paragraph 3.2.4 for more details on editing variable parameters and the wave shape.

4. Graphic Editor The graphic editor displays the active wave shape. The wave shape

changes when the parameter values are changed. The displayed wave parameter nodes

(boxes) can be selected with your mouse to edit the variable parameters. Pressing the

<F1> key will also toggle from one selected node to another. See paragraph 3.2.4 for more

details on editing variable parameters and the wave shape.

WAVE DESIGNER

27850006

Page 15

Section 3

SOFTWARE OPERATION

5. Optional Windows The optional window buttons open additional windows used during

wave shaping. Optional windows in the pulse Waveform Editor include Start, Adapt, Short,

End, and About. Details about the use of most optional windows is covered in the applicable

appendix (i.e. Appendix A for Pulse Wave Shaping). We use the About window shown in

Figure 3-3 to record descriptive weld application data for custom wave shape files. This

information is stored with the program in the computer and in the Power Wave.

FIGURE 3-3. THE “ABOUT” EDIT WINDOW.

About the Procedure

About the Procedure

Process Type

GMAW

3-3

Wire Size

Steel Pulse A

.035 Steel

super GAS

Other

6.3mm

27850007

Wire Type

Process Name

Procedure

Gas

6. Wave Designer Status Bar This status bar provides a scrolled listing of recent program

∂ ƒ

events, error conditions, etc. Use the arrow keys

to scroll through the listings. The status

bar includes three system status indicators: on line/off line, standby/welding, and

adaptive/non-adapt. The adaptive indicator is also a button that toggles between the

adaptive and non-adaptive mode.

7. Volts/Amps Display The Volts/Amps display, Figure 3-4, provides real time, oscilloscope

type displays of the voltage and amperage outputs from the connected power source.

Smaller display monitors (640 x 480 pixels or less) will not show the volts/amps display.

FIGURE 3-4. TYPICAL VOLTS/AMPS DISPLAY.

On Line

Welding

WAVE DESIGNER

Adaptive

27850008

Page 16

3-4 Section 3

SOFTWARE OPERATION

3.2.2 WAVEFORM EDITOR TOOL BAR

There are four menu selections available on the pulse waveform editor tool bar. The following

describes how to use the File, Tools, and Print menus. The Help menu is self explanatory.

3.2.2.1 FILE MENU

The File menu provides options for accessing

and managing waveform data files. The File

menu options include the following:

Open Waveform Ctrl+O

Use the Open Waveform option to open a

Wave Designer waveform or an in-house

custom waveform you created and saved

earlier.

Save Waveform As ...

Use the Save Waveform As ... option to save

an open waveform under a different filename.

Save Waveform Ctrl+S

The Save Waveform option saves all recent

changes to an open waveform file.

Open Scope Trace (Wave Designer Pro option only)

Use the Open Scope Trace option to open a graphical display of oscilloscope type waveforms

(volts, ohms, amps, etc.) for any stored waveform (.swf) file.

File

Tools Print Help

Open Waveform Ctrl+O

Save Waveform As ...

Save Waveform

Ctrl+S

Open Scope Trace

Save Scope As ...

Save Scope

Export to Text File

Export to HTML Web Pages

Import Text File

Quit

Ctrl+Q

27850009

Save Scope As ... (Wave Designer Pro option only)

Use this option to save an open Scope Trace file under a different filename.

Save Scope (Wave Designer Pro option only)

The Save Scope option saves changes to the parameters in a .sco file caused by recent changes

to an open waveform file. Failure to actively open and save the Scope Trace file may result in an

inaccurate parameter record for a waveform undergoing design changes.

Export to Text File

Use the Export to Text File option to save a tabular record of the waveform variables data at

each of its design (Wire Feed Speed) workpoints.

Export to HTML Web Pages

Use the Export to Web Pages option to copy a custom waveform to a web page for transmission

of the waveform to Lincoln Electric for review.

Quit Ctrl+Q

Use the Quit option to exit the Wave Designer program.

WAVE DESIGNER

Page 17

Section 3 3-5

SOFTWARE OPERATION

3.2.2.2 TOOLS MENU

The Tools menu includes waveform display

options and other tools required to operate

Wave Designer. The Tools menu options

include the following:

Pulse Editor Ctrl+P

Display the Pulse Waveform Editor screen.

STT Editor Ctrl+E

Display the STT Waveform Editor screen.

Simplify Editor

Tools Print

Help

Pulse Editor Ctrl+P

STT Editor

Simplify Editor

ArcScope

Flash Custom Waveform

Browse Mode Directory

Upgrade Firmware

Go Offline

Display the primary wave shaping parameters

only. (See page A-1.)

ArcScope Ctrl+A

(Wave Designer Pro option only)

Display the Scope Trace screen for the currently displayed waveform.

Flash Custom Waveform Ctrl+F

Transmit selected waveforms to the welding

machine. This option requires that the

equipment interconnections are made and

that the welding machine is on-line

(communicating).

Browse Mode Directory Ctrl+B

Display the Weld Mode Directory screen. The

Weld Mode Directory lists the waveforms that

are presently downloaded into the welding

machine controller memory. You can

download up to ten custom waveforms to the

weld mode directory, memory slots (Modes)

File Tools Print Help

Mode 12: NST3510C.SWG: Steel Pulse, .035 Steel, Argon CO2 Blends

Mode 20: N45ST00C.SWG: Mig 3, .045 Steel, CO2

Mode 21: N45ST10C.SWG: Mig 3, .045 Steel, Argon CO2 Blends

Mode 22: NST4510C.SWG: Steel Pulse, .045 Steel, Argon CO2 Blends

Mode 24: N52ST00C.SWG: Mig 3, .052 Steel, CO2

Mode 25: N52ST10C.SWG: Mig 3, .052 Steel, Argon CO2 Blends

Mode 26: NST5210C.SWG: Steel Pulse, .052 Steel, Argon CO2 Blends

Mode 31: N35SS02.SWG: Mig 3, .035 Stainless, Argon Oxy Blends

Mode 32: NSS3502.SWG: Stainless Pulse2, .035 Stainless, Argon Oxy Blends

Mode 41: N45SS02.SWG: Mig 3, .045 Stainless, Argon Oxy Blends

Mode 42: NSS4502.SWG: Stainless Pulse2, .045 Stainless, Argon Oxy Blends

Mode 71: N48AL43.SWG: MIG 1, 3/64 4043, 100% Argon

Mode 72: NAL4843.SWG: Aluminum Pulse, 3/64 4043, 100% ARGON

Mode 73: N62AL43.SWGL MIG 1, 1/16 4043, 100% Argon

Mode 74: NAL6243.SWG: Aluminum Pulse, 1/16 4043, 100% Argon

Mode 75: N48AL56.SWG: MIG 1, 3/64 5356, 100% Argon

Mode 76: NAL4856.SWG: Aluminum Pulse, 3/64 5356, 100% Argon

Mode 77: N62AL56.SWG: MIG 1, 1/16 5356, 100% Argon

Mode 78: NAL6256.SWG: Aluminum Pulse, 1/16 5356, 100% Argon

Mode 81: N45MC10C.SWG: FCAW_GS, .045 MC-710, Argon CO2 Blends

Mode 82: NMC4510C.SWG: Pulse Metal Core, .045 MC-710, Argon CO2 Blends

Mode 90: N45OS00C.SWG: FCAW_GS, .045 FCAW-GS, 100% CO2

Mode 91: N45OS20C.SWG: FCAW_GS, .045 FCAW-GS, Argon CO2 Blends

Mode 200: mode200.SWG: CC TEST USING WP, 25A-600A,

Mode 201: MODE201.SWG: CV TEST USING WP, 10V-35V,

Mode 202: MODE202.SWG: CC TEST, NO WP, FIXED AT 10A,

Mode 203: MODE203.SWG: CC TEST, NO WP, FIXED AT 355A,

Mode 204: MODE204.SWG: CC TEST, NO WP, FIXED AT 455A,

Mode 205: MODE205.SWG: CC TEST, NO WP, FIXED AT 550A,

Mode 206: MODE206.SWG: CV TEST, NO WP, FIXED AT 30V,

weldfile uploaded

Status

Wave Designer Pro Off Line - pulse.swf

Search Weld Mode Directory

Search for:

Upload from Machine

155 through 164.

Ctrl+E

Ctrl+A

Ctrl+F

Ctrl+B

Search Browse All

0% done

Off Line

Stand by

27850010

Adaptive

27850011

Upgrade Firmware

Use this option when installing new firmware on your welding machine. The new firmware is

required to run this Wave Designer software release. When later software releases are issued,

they may or may not include firmware upgrades. If firmware upgrades are included, you will use

the Upgrade Firmware option to install the upgrades.

Go Offline

Use the Go Offline option to temporarily interrupt and re-establish communications between the

welding machine / wire feeder and Wave Designer.

WAVE DESIGNER

Page 18

3-6 Section 3

SOFTWARE OPERATION

3.2.2.3 PRINT MENU

Print menu options enable you to print out a waveform display, ArcScope screen, or tabular

waveform data listing as shown below. The Print menu options include the following:

Wave Designer Pro Waveform Editor

Printed on Thu Jul 09 07:24:50 EDT 1998

..\systemWeldFile\pulse.swf

For Wire Feed Speed 150 inch / min

700

600

500

400

300

200

100

0

0 3 6 9 1215 182124 2730

Print

Ramp Up Rate

Tailout Time

Peak Amps

Stepoff Amps

Backgrd Amps

Peak Time ms

Backgrd Time

Frequency

Tailout Speed

Ramp Overshoot %

Peak Voltage

Adaptive Type

Inductance

Short Detect Volt

Pinch Current Rise Rate

Arc Restablish Volt

End Amp

End Time

Open Circuit Volt

Strike Peak Time

Strike Peak Amps

Start Volt

Start Time

Start Amps

Help

600

1.5

280

25

20

1.4

8.7

83.3

.100

-7

30.0

Fresa

2.625

5.0

55

15.0

550

2.5

48.0

2.5

550

28.0

87.5

172

Waveform Ctrl+W

ArcScope Capture

Ctrl+C

Variable Table Ctrl+T

Wave Designer Pro Data Table Created on Thu Jul 09 07:26:41 EDT 1998

..\systemWeldFile\pulse.swf

Weld Process: SMAW

Wire Type: Other

Wire Size: 6.3mm

Process Name: Steel Pulse A

Procedure: .035 Steel

Gas: super GAS

WireFeed inch / min 50 80 110 150 205 300 400 600 700 850 1000 1200

Ramp Up Rate

Tailout Time

Peak Amps

Stepoff Amps

Backgrd Amps

Peak Time ms

Backgrd Time

Frequency

Tailout Speed

Ramp Overshoot %

Peak Voltage

Adaptive Type

Inductance

Short Detect Volt

Pinch Current Rise Rate

Arc Restablish Volt

End Amp

End Time

Open Circuit Volt

Strike Peak Time

Strike Peak Amps

Start Volt

Start Time

Start Amps

600

3.0

250

40

21

1.2

33.4

26.4

.100

-20

24.00

Mora

2.999

5.0

55

15.0

550

2.5

48.0

1.5

550

28.0

50.0

50

600

3.0

250

45

28

1.4

20.2

40.2

.100

-17

26.0

Naranja

2.251

5.0

55

15.0

550

2.5

48.0

2.5

550

28.0

50.0

83

600

3.0

260

25

20

1.5

9.1

71.9

.100

-23

27.00

Manzana

2.251

5.0

55

15.0

550

2.5

48.0

2.5

550

28.0

75.0

145

600

1.5

280

25

20

1.4

8.7

83.3

.100

-7

30.0

Fresa

2.625

5.0

55

15.0

550

2.5

48.0

2.5

550

28.0

87.5

172

600

1.5

300

30

25

1.4

4.7

125.0

.250

-12

31.0

Sandia

2.999

5.0

55

15.0

550

2.5

48.0

2.5

550

28.0

100.0

200

600

1.5

350

70

45

.8

3.8

151.5

.250

-1

34.00

Mora

1.499

5.0

55

15.0

550

2.5

48.0

2.5

550

28.0

75.0

250

800

1.5

420

60

60

.8

3.0

175.4

.250

-10

39.50

Mora

-0.00

5.0

55

15.0

550

2.5

48.0

2.5

550

28.0

50.0

325

800

1.0

470

90

90

.8

2.3

222.2

.250

-13

41.0

Mora

-0.00

5.0

55

15.0

550

2.5

48.0

2.5

550

28.0

50.0

350

800

1.0

500

150

150

.8

2.2

227.3

.250

-6

41.50

Mora

-0.00

5.0

55

15.0

550

2.5

48.0

2.5

550

28.0

50.0

425

800

1.0

535

190

190

.8

2.0

238.1

.250

-5

43.0

Mora

-0.00

5.0

55

15.0

550

2.5

48.0

2.5

550

28.0

50.0

438

800

1.0

520

230

230

.9

1.7

256.4

.250

-10

43.5

Mora

-0.00

5.0

55

15.0

550

2.5

48.0

2.5

550

28.0

50.0

450

800

1.0

540

270

270

.9

1.7

256.4

.250

-6

44.00

Mora

-0.00

5.0

55

15.0

550

2.5

48.0

2.5

550

28.0

50.0

475

Wave Designer ArcScope

Printed on Thu Jul 09 07:25:58 EDT 1998

50

---

Volt

---

Amp

.00

dV/dt

1.0

Ohm

7840

Watt

0 Amp

0.0 Volt

0.0 KW

0.0 KJ

0.0 Sec

Measured: N/A

25

0

700

350

0

100

0

-100

1

.5

0

10000

5000

0

0 10 20 30 40

WAVE DESIGNER

27850012

Page 19

Section 3 3-7

SOFTWARE OPERATION

3.2.3 EDITING AND SELECTING WORKPOINTS

For each custom welding application, unique wave shapes are developed for specific workpoints

within the range of workpoints defined for the application. In Wave Designer the range of

workpoints and the specific workpoint values are defined in a Workpoint Editor window. After the

workpoints are defined, we use a workpoint pulldown menu to select a specific workpoint for

wave shaping. The following describes how workpoints are defined (edited) and selected for a

Pulse (GMAW) mode welding application.

Wave Designer Pro Off Line - pulse.swf

File Tools Print Help

Pulse Waveform Editor

Adapt

600

-20

250

1.2

3.0

.100

40

21

33.4

26.4

About

50

80

110

150

205

300

400

600

700

Short

Wire Feed Speed

Ramp Up Rate

Ramp Overshoot %

Peak Amps

Peak Time ms

Tailout Time

WORKPOINT

PULLDOWN

Tailout Speed

MENU

Stepoff Amps

Backgrd Amps

Backgrd Time

Frequency

Start

Edit

End

700

600

500

400

300

WorkPoint Editor

WorkPoint Editor

200

80 700

0

80 700

1

100

110 700

2

150 700

3

0

0 3 6 9 12151821242730

205

4

300

5

400

6

600

7

inch / min meter / min

WORKPOINT

EDITOR WINDOW

8

9

10

11

700

350

0

60

Go Figure

30

0

0 102030405060

0

0

350

0

30

0

700

60

Status

AC.sco loaded

WAVE DESIGNER

Off Line Stand by

Adaptive

27850013

Page 20

3-8 Section 3

SOFTWARE OPERATION

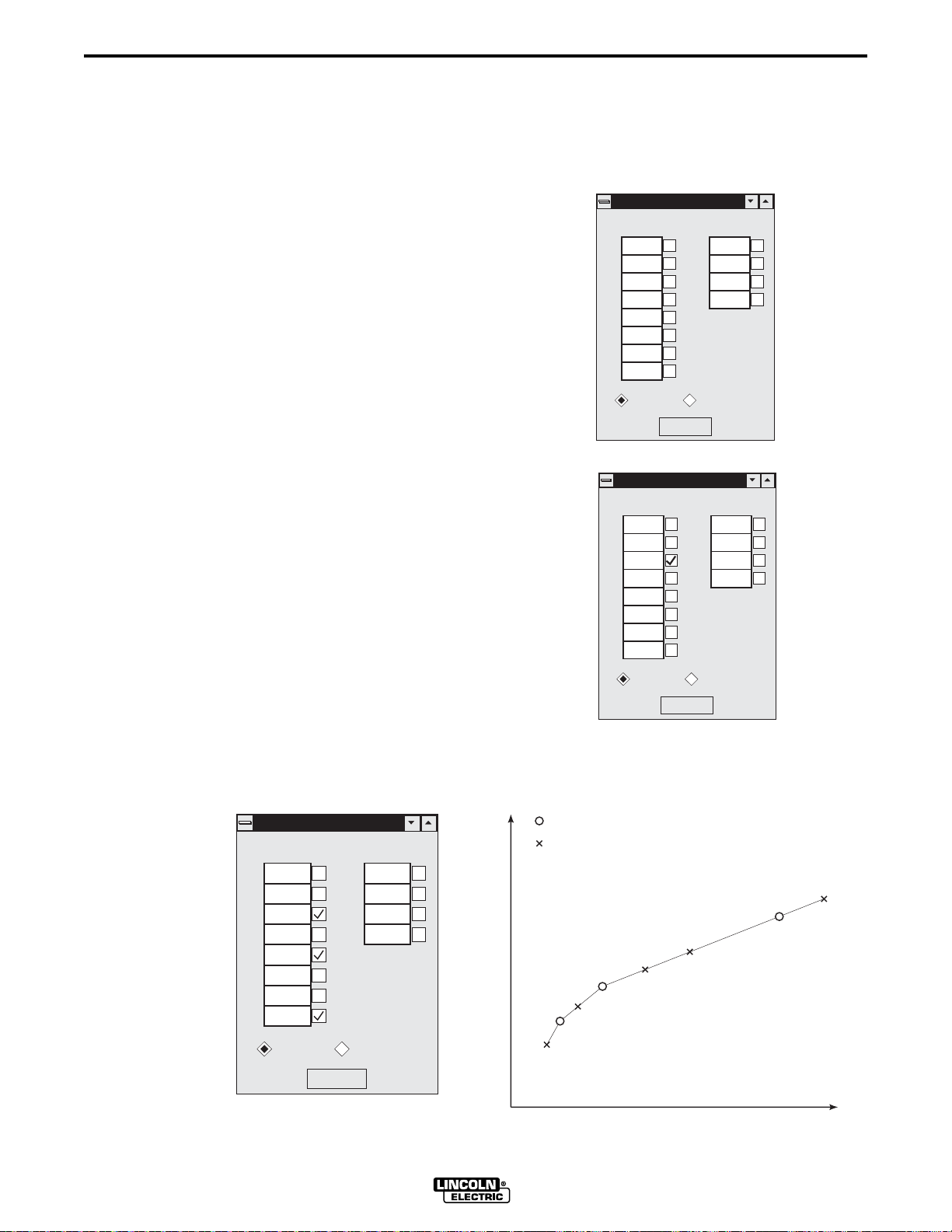

3.2.3.1 EDITING WORKPOINTS

Clicking on the Edit button in the waveform Editor window opens a Workpoint Editor window. The

Workpoint Editor window displays a listing of workpoints for the selected standard waveform. Use

the Workpoint Editor window according to the following descriptions and guidelines:

• Each workpoint value must be equal to or greater

than the preceding workpoint value.

• The workpoints range is from the lowest defined

workpoint to the highest.

• Successive workpoint boxes can share the same

value. Equivalent workpoints will share the same

wave shape. Wave Designer selects the last

workpoint of equal value as the controlling

workpoint.

• You can click on the related check box to lock (fix)

the wave shape variables for a developed

workpoint.

• You can click on the Go Figure button to

extrapolate/interpolate fixed workpoint parameter

values for all non-checked workpoints.

• When only one workpoint is fixed (checked), Go

Figure copies the workpoint (sets the wave shape

parameters for all other defined workpoints equal

to those of the fixed workpoint). This function

should be used just after the wave shape for the

first workpoint is fully developed.

• When two or more workpoints are developed and

fixed, selecting Go Figure performs a linear

interpolation of the wave shape parameters

between checked workpoints and extrapolation to

unchecked workpoints outside the checked ones.

WorkPoint Editor

WorkPoint Editor

80 700

0

80 700

1

110 700

2

150 700

3

205

4

300

5

400

6

600

7

inch / min meter / min

WorkPoint Editor

8

9

10

11

Go Figure

WorkPoint Editor

80 700

0

80 700

1

110 700

2

150 700

3

205

4

300

5

400

6

600

7

inch / min meter / min

10

11

Go Figure

28750014

8

9

28750015

WorkPoint Editor

WorkPoint Editor

80 700

0

80 700

1

110 700

2

150 700

3

205

4

300

5

400

6

600

7

inch / min meter / min

8

9

10

11

Go Figure

WP2

WORKPOINT VARIABLE

WP0, 1

WAVE DESIGNER

FIXED VALUE

INTERPOLATED/

EXTRAPOLATED VALUE

WP4

WP3

WP6

WP5

WORKPOINT

WP8, 9, 10, 11

WP7

28750016

Page 21

Section 3 3-9

SOFTWARE OPERATION

3.2.3.2 SELECTING WORKPOINTS

Clicking on the workpoint display box in the waveform Editor window opens a Workpoint

pulldown menu. The pulldown menu displays the listing of workpoints defined for the active

waveform. Use the pulldown menu according to the following descriptions and guidelines:

• Click on any one of the listed workpoints

to access the related waveform.

• The related welding machine control

must be set to the selected parameter

value. If the welding machine setting is

not equal to the selected workpoint

value, changes to the wave shape will

be applied to the workpoint value

nearest the welding machine setting.

• The welding machine Trim encoder must

be set to 1.00; the Arc control to “OFF”,

and the Mode control to “OFF”. Failure

to verify these welding machine

settings will defeat all wave shaping

efforts.

File Tools Print Help

Pulse Waveform Editor

600

-7

280

1.4

3.0

.100

50

80

110

150

205

300

400

600

700

Wire Feed Speed

Ramp Up Rate

Ramp Overshoot %

Peak Amps

Peak Time ms

Tailout Time

Tailout Speed

Wave Designer Pro Off

700

Edit

600

500

400

300

200

100

0

024

27850017

WAVE DESIGNER

Page 22

3-10 Section 3

SOFTWARE OPERATION

3.2.4 EDITING VARIABLE PARAMETERS

The following is a summary of the different methods available for changing (editing) parameter

values on the Waveform Editor screen and other display screens accessible through Wave

Designer. Read the following information carefully before making parameter changes on the

Waveform Editor screen.

• The variable editor and wave shape graphic functions are interrelated.

• Click once on an edit parameter arrow to increase or

decrease the parameter value by one unit; click and

hold the arrow to ramp the value up or down.

• Click on and drag the parameter display scroll bar to

scroll through the value range.

• Select (highlight) the parameter value. Select and

∂ ƒ

use the up/down keys

to change the value. Hold

down the Ctrl key while using the up/down keys to

change the value 10 times faster. You may directly

type in the desired value.

• Click on a node (hot spot) on the waveform graphic

and use the parameter arrows or drag the node with

your mouse as needed to achieve the desired

parameter value readout. Use the keyboard arrow

∂ ƒ ß ©

keys

to move the hot spot. Press Ctrl and an

arrow key to move the hot spot 10 times faster. Use

the F1 key to jump to the next hot spot.

Peak Amps

250

PARAMETER

VALUE

NODES

300

200

100

0

036

EDIT PARAMETER

ARROWS

SCROLL

BAR

27850018

CONTRACT

GRAPHIC

EXPAND

GRAPHIC

27850019

CAUTION

Uncontrolled drag with the mouse can result in large changes to the welding

machine output. Large changes can result in unexpected and undesired results.

We recommend using the edit arrows or keyboard entry to change parameter

values on-line.

• The expand and contract graphic arrows change the time scale on the X-axis to expand or

contract the wave shape.

To select a Waveform Editor parameter for edit, click on

the parameter check boxes as needed to erase the

checkmarks for all other parameters.

If a parameter has a visible checkmark, the related

Peak Amps

250

parameter value will remain fixed; you cannot change it.

When a parameter is known to be set properly, you may

wish to leave it fixed while adjusting other parameters. However, the variables are interrelated;

changing parameters while one or more is fixed may unpredictably effect other variables.

WAVE DESIGNER

PARAMETER

CHECK BOX

27850020

Page 23

Section 3 3-11

SOFTWARE OPERATION

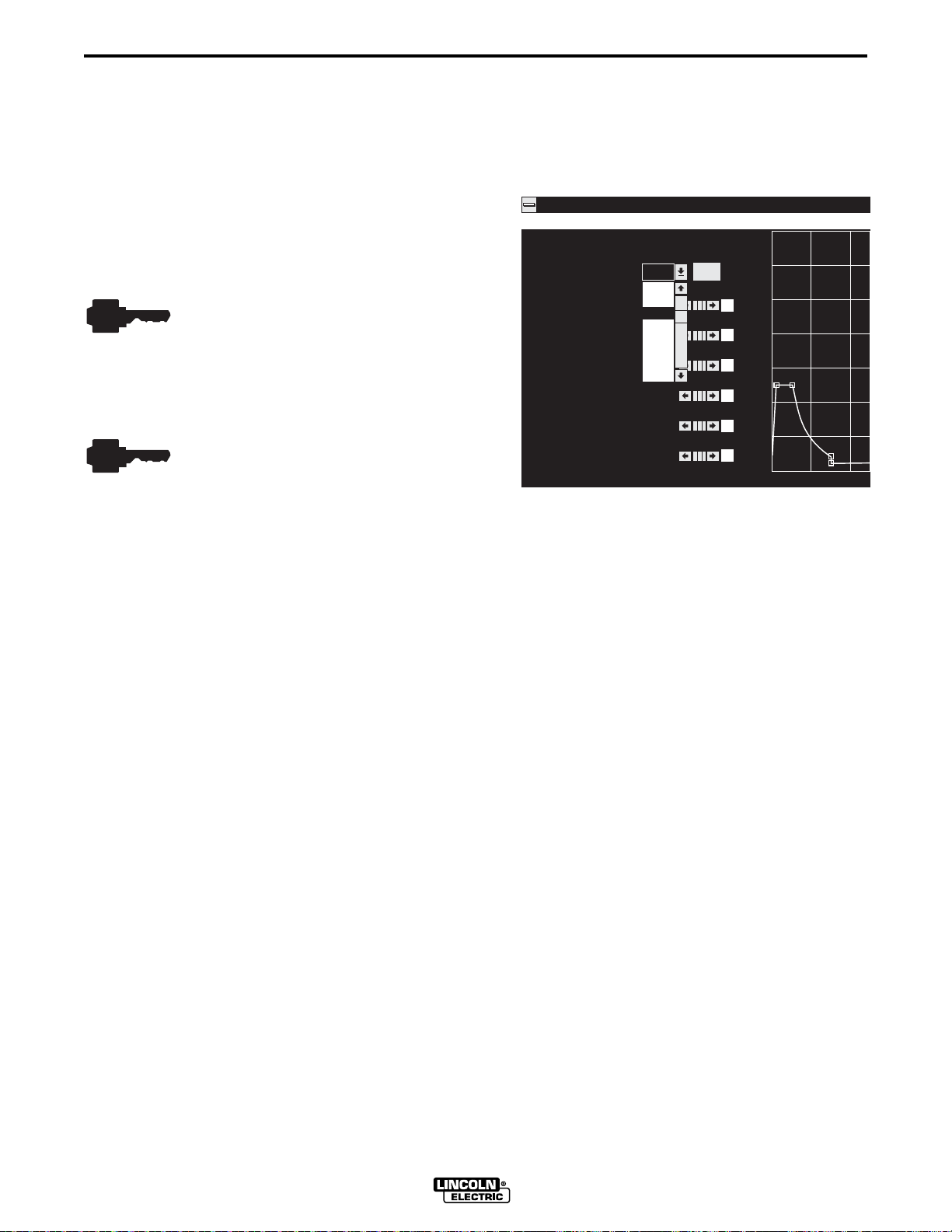

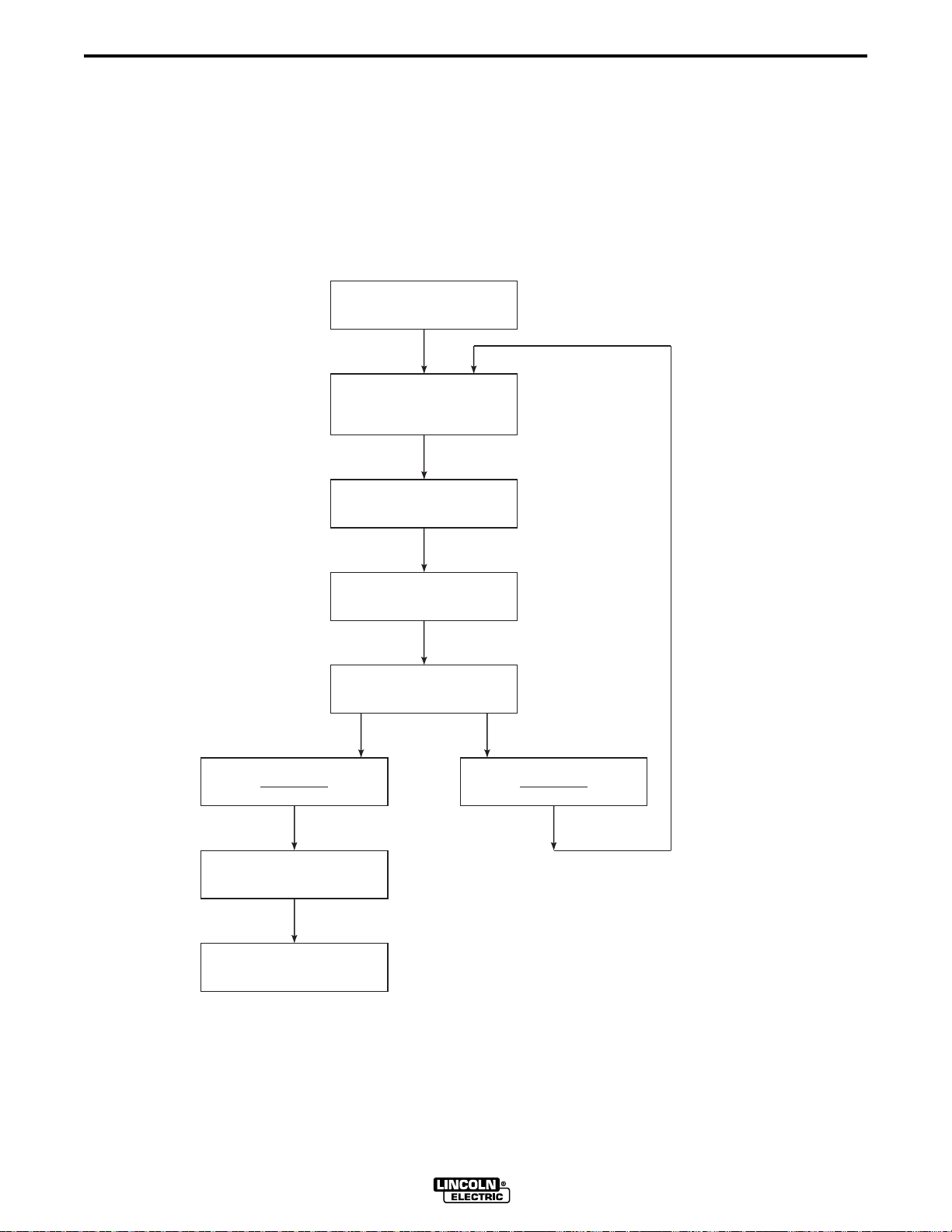

3.3 WAVE DESIGN PROCESS

The wave design process is a series of operations that allows you to quickly modify a standard

waveform to fit your specific welding application. The following process flowchart applies to a

pulse waveform, but is similar to the process used to modify STT and other waveforms.

Examples of each process step can be found in the listed reference paragraphs.

PROCESS FLOW: REFERENCE

PARAGRAPH:

Select a Waveform

from Memory

Mode = OFF

Select Workpoint

Set Powerwave WFS

Set Trim = 1.00

Set Arc Control = OFF

Set NO-ADAPT

(SEE APPENDIX A)

A-4.1

A-4.2 Step 1

GO FIGURE

Save File to Disk

Adjust Pulse

Variables at

Fixed Stickout

Set ADAPT

Adjust Peak Volts

and

Adaptive Type

Adjust Optional

Variables

(if needed)

GO FIGURE

A-4.2 Step 2

A-4.2 Steps 3 & 4

A-4.2 Steps 5, 6, & 7

Save File to Disk; Develop Next Workpoint

A-4.2 Step 8

Download File to Welding

Machine Memory

Section 3, paragraph 3.4

27850021

WAVE DESIGNER

Page 24

3-12 Section 3

SOFTWARE OPERATION

3.4 DOWNLOADING WAVE SHAPES

The Power Wave stores wave shapes in the welding machine controller memory. The memory

structure does not allow an upload or download of individual wave shapes. When downloading

wave shapes to the welding machine, the entire welding machine memory must be overwritten.

Each wave shape must be re-selected for download to the flash memory. Two methods are

available to access desired weld files; use the “Upload From Machine” option in the Weld Mode

Directory window or (if the weld files are all factory default files) select the “Bundled Factory

Default” option from the Flash Custom Waveform window. Any custom wave shapes not

specifically selected for download will not be re-written to the welding machine’s flash memory.

When downloading files to a new Power Wave welding machine, be aware that the bundled

factory default files in the Wave Designer software may be out of date, but needed for use with

older welding machines. Save the old factory default files in a new, “old weld files” directory and

access the latest factory default files from the Lincoln Electric web site for use on the newer

Power Wave machine(s).

Weld files can be corrupted during upload from a welding machine. If a weld file is corrupted, you

will not be able to upload the machine’s weld mode directory.

You can download up to ten custom waveforms to the weld mode directory. The assigned

memory slots are Modes 155 through 164. When all ten slots are in use, the only way to install

another custom waveform is to overwrite one of the ten allocated memory slots. Use the

following procedure to download acceptable wave shapes to the allocated welding machine

memory.

1. Select the Flash Custom Waveform option from the Tools menu to display the Flashing

PowerWave Custom Weld Files screen.

File Tools Print Help

This procedure re-programs the custom weld files i n permanent memory (flash) storage

Mode 155

Mode 156

Mode 157

Mode 158

Mode 159

Mode 160

Mode 161

Mode 162

Mode 163

Mode 164

Wave Designer Pro Off Line - pulse.swf

Flashing PowerWave Custom Weld Files

It allows welding with custom weld files without Wave Designer in production

This will erase existing custom weld files. It will take a few minutes to complete.

Choose...

Choose...

Choose...

Choose...

Choose...

Choose...

Choose...

Choose...

Choose...

Choose...

Desc

Desc

Desc

Desc

Desc

Desc

Desc

Desc

Desc

Desc

Size

Size

Size

Size

Size

Size

Size

Size

Size

Size

Status

AC.sco loaded

Custom Weld File Storage Space Left:

Merge your files int o: Bundled factory default

Bundled factory default

Save t

Last uploaded files

Newly uploaded files

Off Line Stand by

WAVE DESIGNER

0% done

No Adapt

27850022

Page 25

Section 3 3-13

2. Select a blank Mode or a defined Mode for overwrite by clicking on a box to the left of the

Modes listing. When the Mode is selected, a checkmark appears in the Mode box.

3. Enter the file name of the desired waveform in the box to the right of the selected Mode

number. Click on the Choose button to find the exact name of the weld file(s) you wish to

download. Click on the weld file name to select the file for download.

4. Use steps 2 and 3 to assign up to ten new file names to the weld Modes list. If a good weld

file was already stored in the welding machine’s memory, you must re-enter the name of the

stored weld file to download it to the welding machine.

5. Click on one of the three “Merge your files into:” options. Select the desired option per the

following descriptions.

a. Bundled factory default — Merges selected files with factory default files for download.

b. Last uploaded files — Merges selected files with weld mode directory last uploaded

from a welding machine. Overwrites modes 155 through 164 if like mode I.D.

number(s) are assigned to selected file(s).

c. Newly uploaded files — Merges selected files with directory of connected welding

machine. Overwrites modes 155 through 164 if like I.D. number(s) are assigned to

selected file(s).

SOFTWARE OPERATION

6. Click on the button at the bottom of the screen to download the selected

files to the welding machine’s Weld Mode Directory.

3.5 AUTOSAVE

When working in Wave Designer, the autosave function will automatically back up the waveform

in a file called ‘backup.swf’ every 5 minutes. In case of a program or computer glitch, exit and

restart the program, open the ‘backup.swf’ file, and use the Save As ... file menu option to save

the backup file under a different file name. When you modify a waveform, but fail to manually

save it, the waveform title will change to ‘Wave Designer Pro – xxx.swf [modified]’, thereby

indicating that the waveform has not been manually saved.

WAVE DESIGNER

Page 26

3-14 Section 3

SOFTWARE OPERATION

WAVE DESIGNER

Page 27

Section 4 4-1

ARCSCOPE

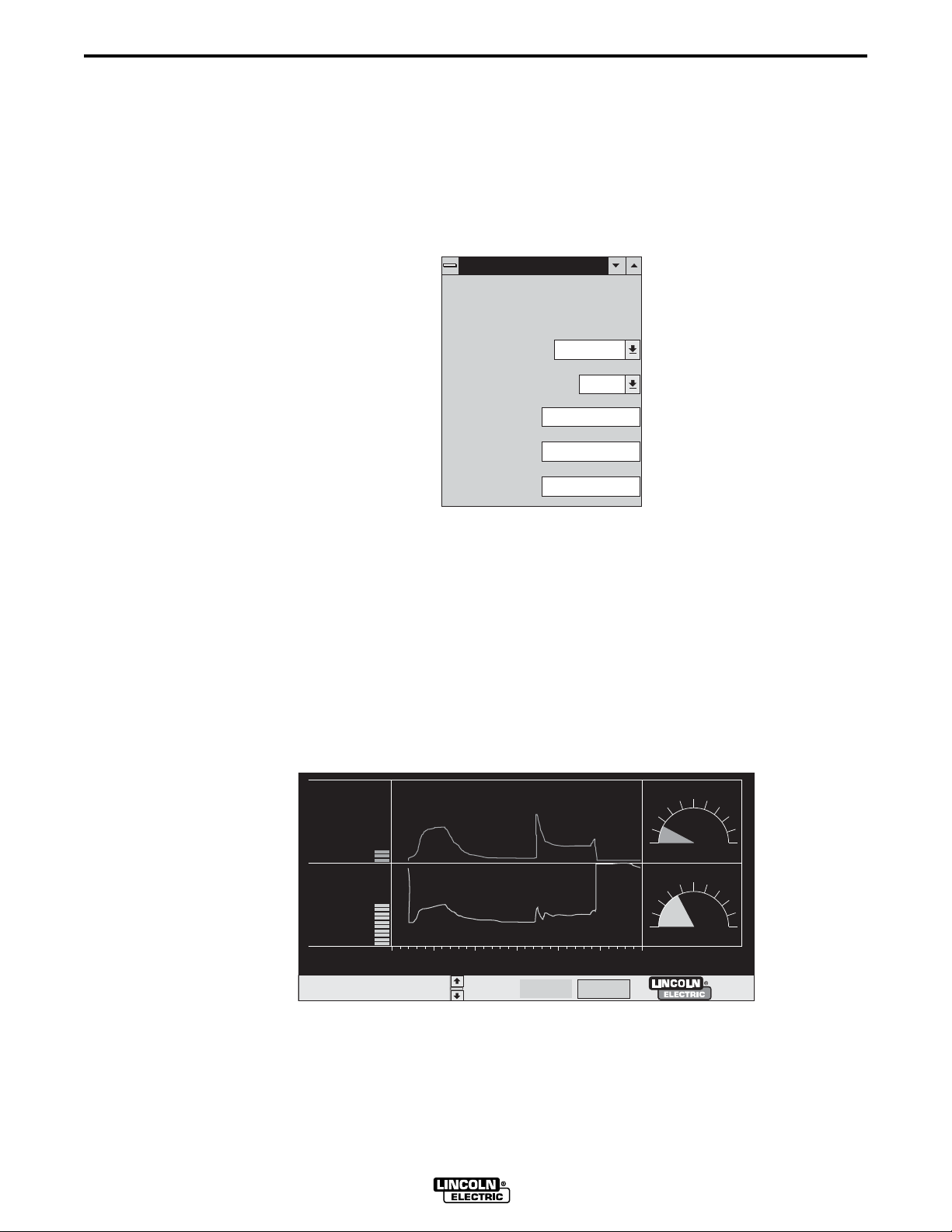

4.1 INTRODUCTION

The following describes the ArcScope application included with Wave Designer Pro. The

ArcScope application provides oscilloscope type displays of power source output waveforms on

your computer monitor.

4.1.1 USING THE ARC SCOPE WINDOW

Refer to the ArcScope window in Figure 4-1 and the related window usage instructions.

FIGURE 4-1. ARC SCOPE WINDOW.

File Tools Print Help

1

2

3

4

5

Status

ARC SCOPE

Live Update

Condense

Browse >

Browse <

Let Go

Configure ...

0.0 Volt

0 Amp

0.0 KW

0.0 Hz

0.0 KJ

0.0 Sec

3.5 ms, 285.7 Hz

1077.6 Joule

AC.sco loaded

Wave Designer Pro Off Line - pulse.swf

25

0

700

350

30

2000

0

-2000

1

.5

0

15000

7500

0

0 10203040

MEASUREMENT

LINE

Off Line Stand by

No Adapt

6

7

27850023

1. Tool Bar The tool bar is the same tool bar displayed in the waveform editor window. The

Tools and Print menus provide ArcScope capture and print options for storage and printout

of the active ArcScope graphics.

2. Toggle Options

Additional information about the

Live Update

and

Condense

Live Update

are toggled on and off with the mouse.

and

Condense

options is provided in

paragraph 4.1.2.

3. Measurement Scroll Bar Use the measurement scroll bar to move the vertical blue

measurement line left and right in the waveform display area. The measurement line

indicates where the data values are being taken among the various waveforms. Use the

scroll bar arrows to move the line incrementally. You can also click and drag the scroll bar or

measurement line.

4. Optional Windows The optional window buttons select ArcScope windows and options to

tailor the ArcScope data sample and display. Refer to paragraph 4.1.2 for additional

information about the optional windows.

5. Sample Statistics With the blue measurement line at the zero reference point, you can

click on any point to the right of the line to get a sample readout of the time period (ms),

pulse frequency (Hz), and weld system heat input (kJ) between the reference line and the

selected points measured: N/A is shown when no measurement has been taken.

WAVE DESIGNER

Page 28

4-2 Section 4

ARCSCOPE

6. Status Bar The status bar provides a scrolled listing of recent Wave Designer program

operations, error conditions, etc., and three operational status indicators. The adaptive

indicator is also a button that toggles between the Adaptive and Non-Adaptive mode.

7. Graphical Display Area The graphical display provides refreshed displays of the selected

waveforms from the output of the connected power source. The power source sampling rate

is 10kHz, unless the Condense option is selected.

4.1.2 OTHER ARC SCOPE OPTIONS

Live Update: The Live Update option is normally on (checked) to display changing output data

during the weld application. To maintain an existing display for study while welding, turn the Live

Update option off.

Condense: The Condense option is normally off (not checked). When turned on, the Condense

option forces the welding machine to sample data only during weld state transitions. This extends

the length (time) of the sample stored in the welding machine buffer and records only what

happens during weld state transitions.

Browse: The Browse left/right options allow you to display the contents of the welding machine

storage buffer following a weld application. The buffer stores the last 300 milliseconds of

sampling data when the Condense option is off. (Longer samples are stored when the Condense

option is on.)

Pause/Let Go: The Pause option allows you to freeze an ArcScope display while the welding

application is running. The Let Go option disables the Pause function.

Configure: Use the Scope Configuration window to select the power source measurements for

the graphical display area.

Centerline: Select the Centerline option to place a

gray centerline in each of the displays.

Available measurement/display options include:

Volt: average power source output voltage

Amp: average arc current

GSF: (Global Scale Factor) correction factor

forcing the weld application to the desired

arc length

State: the state progression of the welding

application (ramp-up, peak, tailout, etc.)

Channel 1

Channel 2

Channel 3

Channel 4

Channel 5

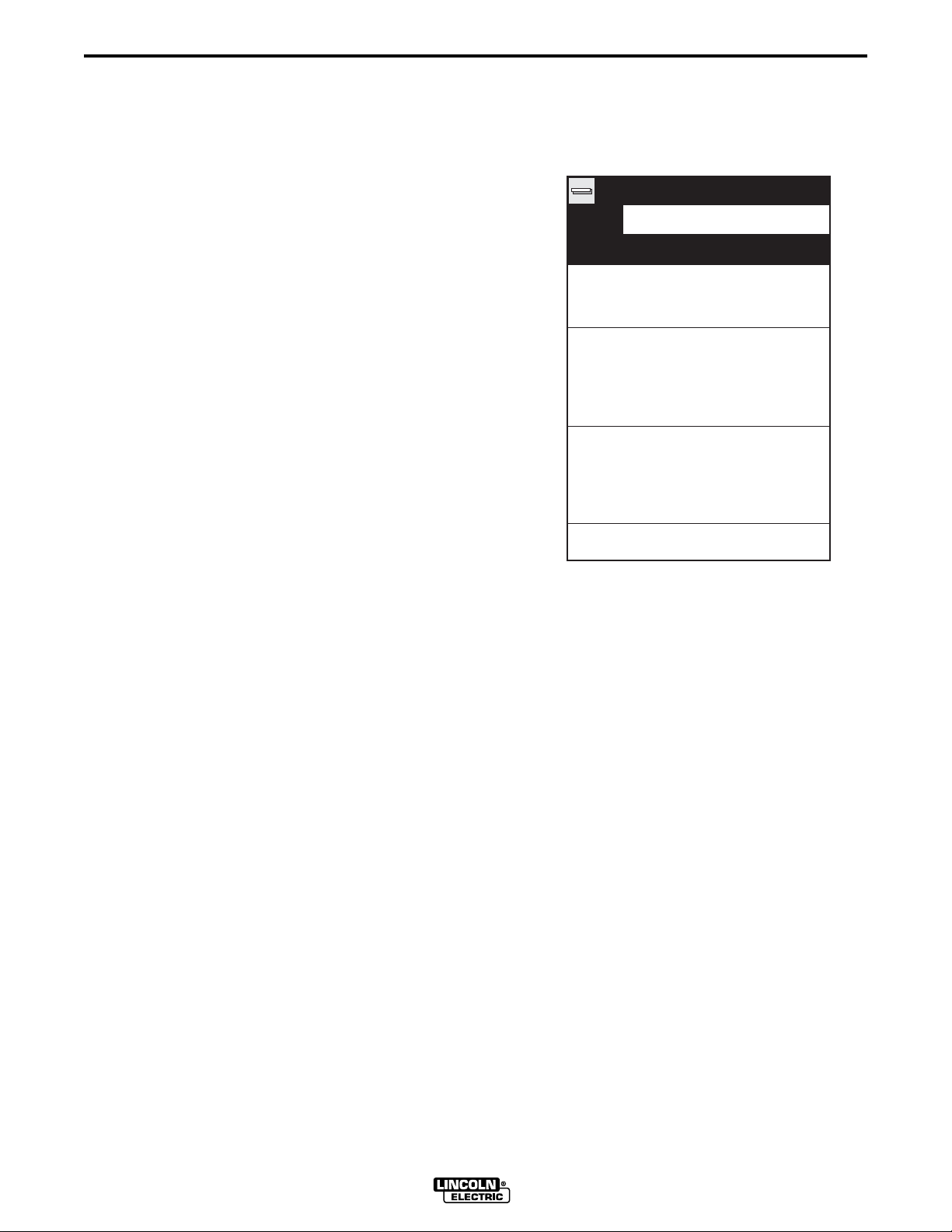

Scope Configuration

Scope Configuration

Name

Volt

Amp

dV/dt

Ohm

Watt

Reverse Polarity State

Minimum Maximum

.0

0

-100

.0

0

0

50.0

700

100

1.0

10000

Watt: instantaneous power output

dv/dt: rate of voltage change per unit time

calculated at a 10 kHz sampling rate

Waveform Start State

Centerline

8

dI/dt: rate of amperage change per unit time @

10 kHz

dp/dt: rate of power change per unit time @ 10

OK

27850024

kHz

ohm: arc impedance

dr/dt: rate of resistance change per unit time @ 10 kHz

Reverse Polarity State: For machines with an AC welding option, Reverse Polarity State

selects the State (0 to 19) for electrode negative.

Waveform Start State: Specifies which Power Wave state (0 to 19) is used to calculate the

actual frequency displayed on the bottom left side of the ArcScope window. Wave Designer

counts the elapsed time between the start of this state to calculate the frequency. The Waveform

Start State is set to 8 by default. Call Lincoln Electric for more details.

WAVE DESIGNER

Page 29

Section 4 4-3

File | Save Scope: Use the Save Scope option to

save the scope trace data in ASCII text format for use

in a word editor or spreadsheet data processing

application.

File | Open Scope Trace: Use the Open Scope

Trace option to open a saved scope trace data file.

ARCSCOPE

File

Tools Print Help

Open Waveform Ctrl+O

Save Waveform As ...

Save Waveform

Ctrl+S

Open Scope Trace

Save Scope As ...

Save Scope

Export to Text File

Export to HTML Web Pages

Import Text File

Quit

Ctrl+Q

27850009

WAVE DESIGNER

Page 30

4-4 Section 4

ARCSCOPE

WAVE DESIGNER

Page 31

WAVE DESIGNER

Section 5 5-1

TROUBLESHOOTING

5.1 OVERVIEW

Wave Designer troubleshooting is limited to the software application. If the welding machine

does not respond, recheck the interface connection and communication setup requirements in

section 2 of this manual. Refer to the welding machine service manuals for troubleshooting

suspected equipment malfunctions.

5.2

If you believe the Wave Designer software program is malfunctioning, use the following

procedure to launch the Wave Designer program with a DOS console window for diagnostic

messages in the background.

a. From your Windows™ Start screen, move the mouse over the Wave Designer icon.

b. Right click the mouse, and select Properties.

c. Select Shortcut and change ‘jrew.exe’ to read ‘jre.exe’, then select OK.

d. Start up the program from the Wave Designer icon. The opening screen should display a

DOS window titled ‘jre’. Copy down any abnormal message displayed in the ‘jre’ window,

especially messages with the word ‘Exception’ in them.

TROUBLESHOOTING PROCEDURE

e. Send the message(s) via E-mail on the world wide web to:

wavedesigner@lincolnelectric.com.

We will respond to your problem as quickly as possible.

WAVE DESIGNER

Page 32

5-2 Section 5

TROUBLESHOOTING

WAVE DESIGNER

Page 33

Appendix A A-1

PULSE WAVE SHAPING PRINCIPLES

A.1 APPENDIX OVERVIEW

This appendix provides a series of discussions on pulse wave shaping principles and the

development of custom GMAW pulse waveforms. The contents of this appendix are arranged as

follows:

Paragraph No./Title Contents Description

A.2 GMAW Pulse Overview How the pulse waveform transfers weld droplets to the

weld surface

A.3 Adaptive and Non-Adaptive How WFS and primary wave shape parameters effect

Mode welding

A.4 Pulse Wave Design Process Flowchart and step by step descriptions of the pulse

wave design process

A.5 Primary Pulse Waveform How peak current, peak time, frequency, and

Components background current effect weld droplet transfer

A.6 Secondary Pulse Waveform How ramp up rate, % ramp overshoot, tailout speed,

Components tailout time, stepoff amperage, and background time

effect weld droplet transfer

A.7 Application Exercise Sample development of a power wave welding program

using Wave Designer

WAVE DESIGNER

Page 34

A-2 Appendix A

PULSE WAVE SHAPING PRINCIPLES

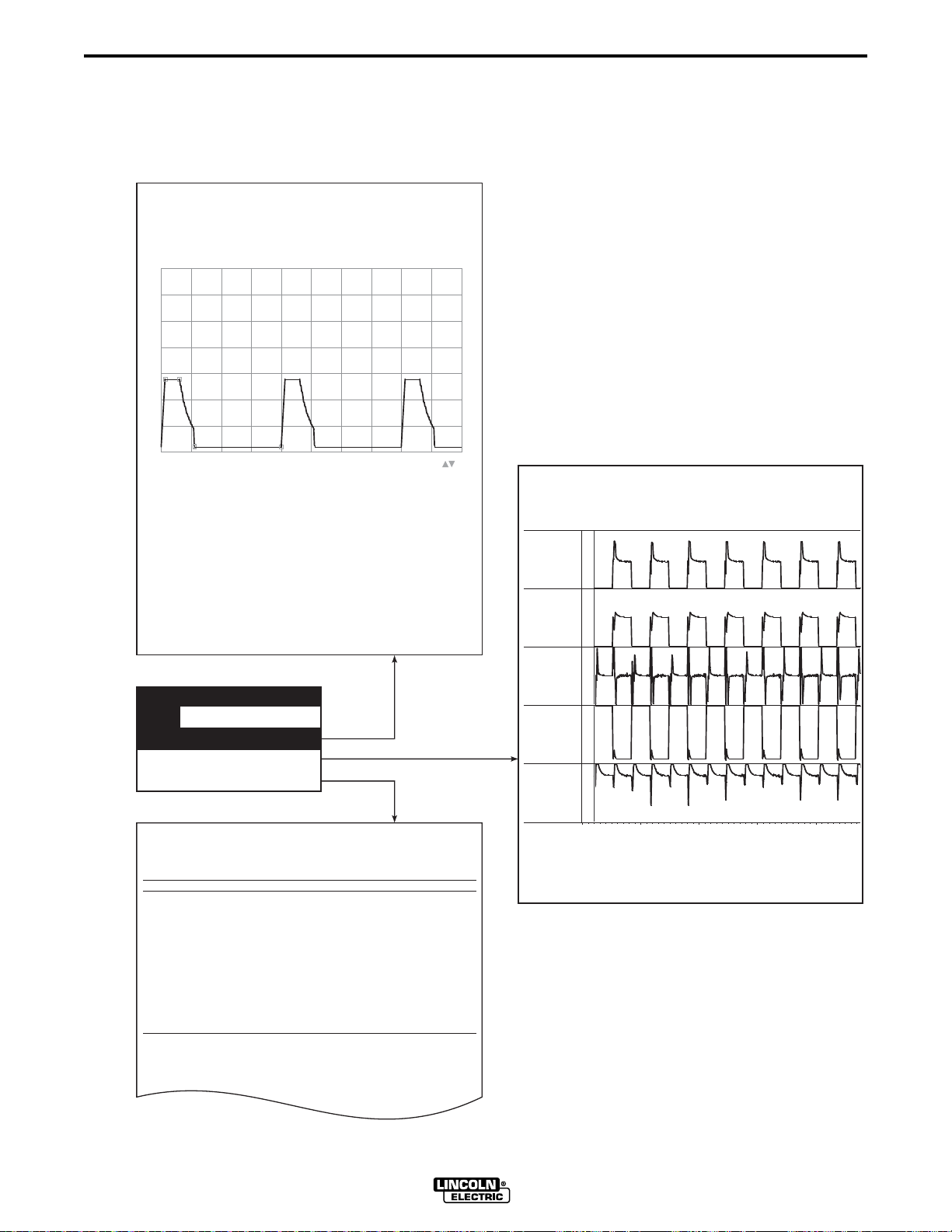

A.2 GMAW PULSE OVERVIEW

Figure A-1 illustrates the variables of the GMAW-P welding process. Each of these variables can

be programmed into a weld table using the Wave Designer software. Figure A-2 shows how the

pulse waveform and the primary variables shape, detach and propel a weld droplet across the

arc.

For more details on each of these variables, refer to

and

Secondary Pulse Waveform Components

in paragraphs A.5 and A.6 of this appendix.

FIGURE A-1. PULSE WAVEFORM PARAMETERS.

PEAK TIME

TAILOUT

TIME

% OVERSHOOT

TAILOUT

SPEED

PEAK

RAMP-UP RATE

AMPS

1/FREQUENCY

File Tools Print Help

Pulse Waveform Editor

Adapt

About

AC.sco loaded

50

600

-20

250

1.2

3.0

.100

40

21

33.4

26.4

Short

Wire Feed Speed

Ramp Up Rate

Ramp Overshoot %

Peak Amps

Peak Time ms

Tailout Time

Tailout Speed

Stepoff Amps

Backgrd Amps

Backgrd Time

Frequency

Start

Status