Page 1

Power Wave 450 Water Cooler

RETURN TO MAIN MENU

Upgrade Kit

UPGRADE INSTALLATION INSTRUCTIONS

Table of Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Recommended Tools for Installation or Service . . . . . .2

G3503-[ ] Installation or Service Tool Usage . . . . . . . . .2

G3503-[ ] Water Cooler Upgrade Kit Contents . . . . . . .2

Recommended Coolants . . . . . . . . . . . . . . . . . . . . . . . .2

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . .3

Replacing a G2725 Cooler with a G3503-[ ] . . . . . . . .3

Removing and Installing the G3503-[ ] Cooler . . . . . .4

G3503-[ ] Cooler Periodic Maintenance . . . . . . . . . . .5

G3503-[ ] Cooler Service . . . . . . . . . . . . . . . . . . . . . .5

Parts List for Cooler (P261-K.2, -K.3) . . . . . . . . . . . . .6,7

Figure 1 (Specified Coolant Level) . . . . . . . . . . . . . . .8

Table 1 (Cooler Electrical Harness Pin-outs) . . . . . . .8

IM645-A

May, 2000

SAFETY

Follow all safety guidelines in your power source operator manual and any additional guidelines covered in this

manual.

GENERAL DESCRIPTION

This upgrade kit is designed to provide all necessary parts and instruction to replace a G2725 water cooler

assembly with an improved design G3503-[ ] water cooler assembly. The G3503-1 and G3503 Coolers are interchangeable as complete units only. These procedures are specified by Lincoln Electric and apply to domestic

Power Wave 450 machines requiring a Lincoln internal water cooler.

Date of Purchase:

Serial Number:

Code Number:

Model:

Where Purchased:

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

• Sales and Service through Subsidiaries and Distributors Worldwide •

Page 2

RECOMMENDED TOOLS FOR

INSTALLATION OR SERVICE:

S24505 WATER COOLER UPGRADE KIT

CONTENTS:

• absorbent towels

• alcohol wipe

• 3 mm allen wrench (G3503 only)

• socket wrench

• 4 inch long minimum socket extension

• 1/4, 5/16, and 3/8 hex standard depth sockets

• 5/32 allen socket

• medium blade slotted screwdriver

• large blade slotted screwdriver, 8 inches long

minimum

• two 7/16 open or box end wrenches

• one 7/8 open or box end wrench

• needlenose pliers

• two 10 inch long adjustable wrenches

• wire cutter

• molex pin removal tools

• tape measure

• small mechanic’s mirror

• flashlight

• dental pick

• digital multimeter (DMM)

G3503-[ ] INSTALLATION OR SER-

VICE TOOL USAGE

1 Cooler assembly, G3503-[ ]

• Empty Weight: 36 lbs.

• Overall Size: 22.38x14.00x12.50, LxWxH

•

Electrical Input: 230VAC, 2.8A max. steady state

• Coolant Connections:

Welding Industry Standard Quick-Disconnect

(QD) female fittings. Top: Coolant In,

Bottom: Coolant Out

1 Cooler access panel, L9387-2

1 “P4” Electrical power harness (long), S14165-467

1 “P3” Electrical extension harness (short), S14165-466

1 Circuit breaker, T12287-14, spare replacement

2 fasteners, S9225-8, (1/4-20 thread, spares for

cooler mounting)

4 fasteners, S8025-91, (spares for cooler access

panel mounting)

2 Hole plugs, T10397-11

1 Ground Decal, T13260-4

8 cable ties, T13770-2

1 Electrical sleeving, E1159/B-1.00-7.00

1 “B” Stencil, S21212

1 Power Wave machine label: S24503-1

2 Mounting Brackets, S10040-93

2 Fasteners, T9447-42, (#10-24 UNC-3A)

2 Plain washers, S9262-77 (Socket head- cap

screws)

RECOMMENDED COOLANTS

Fastener Usage Qty. Tool

Shroud to cooler base 4 all use 5/16 hex screw and 3/8 hex

Quick Disconnect (QD) bracket 2 nut. Relay may require large blade

Heat exchanger to cooler base 2 slotted screwdriver 8 in. long min.

Relay to cooler base 2

Screw to 4 3 mm allen wrench (G3503 only)

fasten reservoir to cooler base 5/16 Hex Socket (G3503-1 only)

Hose Clamp 10 1/4 hex or medium slotted screwdriver

Fan set screw 1 5/32 allen socket with wrench and 4

in. min. extension

Pump carbonator clamp screw 1 5/16 hex socket with ratchet wrench

Motor mounting bolts 4 two 7/16 open or box end wrenches

Motor access door 2 1/4 hex socket with wrench

Motor harness ground at motor 1 1/4 hex socket with wrench

terminals 2 needlenose pliers

relay terminals 1 and 2 2 large blade slotted screwdriver 8 in.

minimum long.

relay terminals 3 and 4 2 medium slotted screwdriver

All plumbing components N/R two 10 inch adjustable wrenches

1. The following coolants have been determined to be

compatible with the wetted materials used in the

G3503-[ ] cooler assembly:

• Distilled or deionized water

• Potable tap water

• Sediment-free mixtures containing a maxi-

mum of 50% ethylene glycol or automotivegrade antifreeze and the balance of distilled

or deionized water.

2. Ethylene glycol mixtures should be selected if the

cooler may be exposed to a temperature below the

freezing point of water.

3. Consult gun, torch, and wire feeder manuals for

coolant recommendations and select one from the

above list.

4. Pure solutions and mixtures of, or materials (i.e.

towels) wetted with ethylene glycol are toxic to

humans and animals. They must not be haphazardly discarded, especially by pouring liquids down

the drain. Contact the local EPA office for responsible disposal methods or for recycling information.

5. The cooler’s reservoir has a nominal liquid capacity

of 1.6 gallons.

G3503-[ ] POWER WAVE 450 WATER COOLER UPGRADE KIT

2

Page 3

INSTALLATION INSTRUCTIONS

WARNING

ELECTRIC SHOCK Can Kill

• Only qualified persons should perform this installation.

HOT COOLANT CAN BURN SKIN

• Always be sure coolant is not hot before doing any

work on cooler parts.

ROTATING FAN BLADES ARE HAZARDOUS

i. Peal off "coolant in / coolant out" decal from

machine’s case back and discard. Remove

residual adhesive from case back with an alcohol wipe.

j. Remove auxiliary transformer #2 (mounted to

Power Wave base, ahead of G2725 cooler) and

set aside. It is no longer needed.

3. Slide electrical sleeving over the non-P4 connector

in the Power Wave’s harness that runs from its terminal strip.

• Fold sleeving over itself and firmly secure it to

the harness with a cable tie.

• Do not put your hands near an operating fan.

• Keep all equipment safety guards, covers and devices in position

and in good repair.Keep hands, hair, clothing and tools away from

fans and all other moving parts when starting, operating or repairing equipment.

• In some cases it may be necessary to remove safety guards to

perform required maintenance. Remove guards only when necessary and replace them when the maintenance requiring their

removal is complete.

near moving

parts.

Always use the greatest care when working

------------------------------------------------------------------------

REPLACING A G2725 COOLER WITH A

G3503-[ ] COOLER

1. Preparation:

• Always switch off the Power Wave machine

power.

• Always disconnect the Power Wave machine

from service input power.

2. Remove the G2725 cooler assembly:

a. Remove gas cylinder(s) from machine’s rear

tray.

b. Remove cooler access panel P/N L9387-1 and

set aside. It is no longer needed.

c. Remove machine’s left side panel (adjacent to

power input cord).

d. Disconnect coolant hoses’ mounting bracket

from machine’s case back.

e. Disconnect all of the coolant hoses’ tie-down

points. These plastic clips may be removed and

discarded if desired.

f. Remove and save both fasteners from Power

Wave base holding cooler in place. Carefully

pull cooler rearward, partially out of the Power

Wave.

g. Disconnect Molex in-line connectors P4 or P5

(cooler power) and P3 (cooler relay and pressure switch) and slide cooler completely from

machine.

h. Optionally remove circuit breaker from case

back and install replacement.

4. Install cooler G3503-[ ]:

a. Install plugs into case back to fill coolant hose

holes. Bend tabs as required to secure plugs in

place.

b. Install new circuit breaker into case back if

replacing the old part.

c. Install new P4 electrical harness into Power

Wave:

• Mate together the labeled P4 connectors.

• Note: H[X]A lead in new harness carries 230

VAC cooler power: (See Table for [X] valve).

[X] Power Wave Wiring

Code Numbers Diagram

2 10406 G2153-5

2 10431 G2153-4

2 10433 G2153-6

3 10106, 10195, 10366 G2153-1

3 10197, SPLC14895 G2153-2

3 10345, 10347 G2153-3

3 10512 G2153-7

3 10514, 10516 G2153-8

3 10520 G3177-1

• Connect insulated terminals to circuit breaker

(order is unimportant).

d. Connect P3 electrical extension harness to the

machine.

e. Apply ground decal to cooler’s base:

• Apply next to mounting screw hole nearest to

circuit breaker.

f. Mate cooler’s connector to the P3 extension

harness.

g. Mate cooler’s power connector to the P4 electri-

cal harness.

h. Carefully slide retrofit cooler G3503-[ ] forward

into Power Wave. Verify that front tabs on cooler base are properly guided into slots in base of

Power Wave (base’s underside may be examined with a mirror and flashlight).

i. Attach ground lead in P4 harness to top of cool-

er’s base or top of mounting bracket, ( if brackets are necessary). Secure cooler to Power

Wave base by installing both fasteners.

j. Install Power Wave machine’s left side panel.

G3503-[ ] POWER WAVE 450 WATER COOLER UPGRADE KIT

3

Page 4

l. Attach Power Wave machine label from retrofit

kit to its case back.

m. Stamp or etch "B" as the suffix of Power

Wave’s code number located on its rating

plate. Include this suffix for all future parts

orders.

n. Install gas cylinder(s) onto tray.

5. Select a recommended coolant and fill cooler to

specified level (see Figure 1).

6. Attach desired water-cooled accessory (gun and

wire feeder or TIG torch) to cooler’s QDs.

4. Reinstall cooler by reversing tasks in step 2. Be

sure to reattach ground lead, if previously removed.

5. If necessary, fill cooler with selected coolant to

specified level (see Fig. 1).

6. Attach desired water-cooled accessory (gun and

wire feeder or TIG torch) to cooler’s QDs.

7. Reconnect service input power to the Power Wave:

• verify that the reconnect panel setting and lead

placement match the service voltage.

7. Reconnect service input power to the Power Wave:

• Verify that the reconnect panel setting and

lead placement match the service voltage.

8. Prime the cooler:

a. Install the Set-up overlay.

b. Keep accessories’ hose lengths horizontal,

either coiled or straight, and no higher than 4

feet of the specified coolant level (Fig. 1).

c. Switch on the Power Wave machine.

d. Press the "WATER COOLER ENABLE" button

so that the "WATER COOLER ENABLED" light

is illuminated.

e. Press the "PRIME WATER COOLER" button

until the "WATER COOLER PRESSURE" light

is steadily illuminated.

9. Check coolant level. Add more if required.

REMOVING AND INSTALLING THE G3503-[ ]

COOLER

1. Preparation:

• Always switch off the Power Wave machine

power.

• Always disconnect the Power Wave machine

from service input power.

8. Prime the cooler:

a. Install the Set-up overlay.

b. Keep accessories’ hose lengths horizontal,

either coiled or straight, and no higher than 4

feet of the specified coolant level (Fig. 1).

c. Switch on the Power Wave machine.

d. Press the "WATER COOLER ENABLE" button

so that the "WATER COOLER ENABLED" light

is illuminated .

e. Press the "PRIME WATER COOLER" button

until the "WATER COOLER PRESSURE" light

is steadily illuminated.

9. Check coolant level. Add more if required.

2. Remove cooler assembly G3503-[ ]:

a. remove gas cylinder(s) from tray.

b. remove cooler access panel.

c. Remove both fasteners from base that hold

cooler and mounting brackets (if equipped) in

place. Remove ground lead, if present.

Carefully pull cooler assembly rearward, until

cooler’s Molex connectors are visible.

d. disconnect cooler’s connectors from the P3 and

P4 harnesses. Continue pulling the cooler out

of the Power Wave.

3. If necessary, perform periodic maintenance or ser-

vice on the cooler.

G3503-[ ] POWER WAVE 450 WATER COOLER UPGRADE KIT

4

Page 5

G3503-[ ] COOLER PERIODIC MAINTENANCE

G3503-[ ] COOLER SERVICE

1. Preparation:

• Always switch off the Power Wave machine power.

• Always disconnect the Power Wave machine from

service input power.

• Do not remove the pump relief valve’s 3/4 in. acorn

hex nut or attempt to adjust the relief valve setting.

2. Remove the G3503-[ ] cooler from the Power Wave

machine.

3. Clean, or replace the pump’s inlet strainer: Clogged or

partially blocked strainer is the most common cause for

unacceptal coolant flow.

• Drain the reservoir of coolant and dispose of it in an

environmentally responsible manner (see

Recommended Coolants).

• Place absorbent towels underneath pump head.

• Hold pump head to apply countertorque when loos-

ening strainer’s 7/8 acorn nut. Do not confuse with

3/4 acorn nut. Remove nut and slide inlet strainer

down and out from pump head.

• Replace or gently rinse strainer under running water

to thouroughly clean it.

• Use the mirror to inspect inside of pump for contamination. Carefully remove hardened debris with dental pick if necessary, without scratching inside of the

pump.

• Reinstall strainer and acorn nut, tightening with

75±15 in.-lbs. of torque. Wipe dry all areas wetted

by coolant. Dispose of towels in an environmentally

responsible manner (see Recommended Coolants).

4. Remove fan shroud and inspect hoses and electrical harnesses for kinking or damage (cut, abrasion, swelling,

etc.). Replace if necessary.

5. Remove accumulated dust from cooler, especially from

the motor and heat exchanger, by blowing it off with shop

air or vacuuming it out.

• The heat exchanger fins are sharp but can be easily

bent. Treat them with care to avoid personal injury

and damaging them.

• Remove the cooler from the machine for a more

thorough cleaning job.

6. Motor lubrication is recommended once a year:

• Remove plug over lube port at top of motor near fan

end.

• Add 20 drops of electric motor or SAE 10 oil then

reinstall plug.

7. Flush coolant from the system and replace with fresh,

recommended coolant at least once a year. More frequent flushing may be necessary, depending upon a

user’s particular system or its usage.

NOTE: Never run the pump dry. Always use a recommend-

ed coolant, otherwise pump damage may result.

8. Reinstall the G3503-[ ] cooler into the Power Wave

machine.

1. Preparation:

• Always switch off the Power Wave machine power.

• Always disconnect the Power Wave machine from

service input power.

• Do not remove the pump relief valve’s 3/4 in. acorn

hex nut or attempt to adjust the relief valve setting.

2. Remove the G3503-[ ] cooler from the Power Wave

machine whenever:

• replacing major cooler components (i.e. pump,

motor, heat exchanger, etc.).

• replacing hoses and electrical harnesses that are

kinked or damaged (cut, abraded, deteriorated or

swollen, etc.).

• investigating suspect coolant leakage.

3. Pump replacement:

a. Drain the reservoir of coolant and dispose of it in an

environmentally responsible manner (see

Recommended Coolants).

b. Remove fan shroud.

c. Place absorbent towels underneath pump head and

wherever coolant system is opened.

d. Carefully pull pump inlet hose and its elbow from

reservoir (bottom).

e. Loosen pump outlet hose clamp at QD then carefully

remove from fitting.

f. Disconnect v-band clamp from motor and remove

pump:

• Do not drop or lose drive coupling between pump

and motor.

• Do not discard old pump. Remove both fittings,

Keep v-clamp, Seal old pump in a waterproof bag,

Package into protective container, and Return to

nearest Lincoln Electric FSS center.

g. Install new pump and v-band clamp:

• Do not apply any lubricant to pump’s drive coupling.

• Pump body is properly oriented with its strainer at

the 6:00 position.

• Tighten v-clamp with 15 to 30 in-lbs. of torque.

h. Attach coolant lines to QD and reservoir.

i. Wipe dry all areas wetted by coolant. Dispose of tow-

els in an environmentally responsible manner (see

Recommended Coolants).

j. Reinstall cooler into machine.

4. Motor removal or replacement:

• Do not reuse the 4 internal-tooth star washers.

Replace with new parts..

5. Installing the fan:

• Slide onto motor shaft until the fan is located

between 0.25 to 0.50 inches from the heat exchanger.

• Tighten set screw with 65 to 75 in-lbs of torque

against motor shaft’s flat.

• Fan rotation is counterclockwise, as viewed from

fan-end of motor’s shaft.

• Fan pulls air through the heat exchanger, blows it

over the motor, then exhausts it through the reservoir.

G3503-[ ] POWER WAVE 450 WATER COOLER UPGRADE KIT

5

Page 6

P-261-K.2 P-261-K.2

COOLER ASSEMBLY PARTS

13

34

12

35

11

8

22

10

6

7

1

36

37

31

23

22

26

3

26

24

29

15

14

26

28

2

26

27

9

5

25

26

25

26

19

20

18

26

21

4

30

19

20

16

17

G3503-[ ] POWER WAVE 450 WATER COOLER UPGRADE KIT

6

10-2-98

Page 7

P-261-K.3

P-261-K.3

# Indicates a change this printing.

Recommended Spare Parts are Highlighted in Bold

ITEM DESCRIPTION PART NO. QTY. 123456789

Powerwave 450 Water Cooler Upgrade Assembly, G3503 & -1 1 X

Includes:

1 Base Assembly (G3503 Only) S24504-1 1 X

1 Base Assembly (G3503-1 Only) S24504-36 1 X

2 Motor S24504-2 1 X

3 Fan Blade S24504-3 1 X

4 Pump with Torque Coupling S24504-4 1 X

5 V-Clamp, Pump S24504-5 1 X

6 Torque Coupling, Pump S24504-6 1 X

7 Pump Inlet Strainer S24504-7 1 X

8 Heat Exchanger S24504-8 1 X

9 Pressure Switch S24504-9 1 X

10 Solid-State Relay S24504-10 1 X

11 Electrical Harness, Motor S24504-11 1 X

12 Electrical Harness, Pressure Switch & Relay S24504-12 1 X

13 Fan Shroud (G3503 Only) S24504-13 1 X

13 Fan Shroud (G3503-1 Only) S24504-37

14 Quick Disconnect Fitting S24504-14 2 X

15 Quick Disconnect Bracket with Label S24504-15 1 X

16 Reservoir (G3503 Only) S24504-16 1 X

16 Reservoir (G3503-1 Only) S24504-38 1 X

16 Replacement Reservoir & Fan Shroud (G3503 Only) S24504-39 1 X

17 Reservoir Inlet Strainer (G3503 Only) S22067-3 1 X

17 Reservoir Inlet Strainer (G3503-1 Only) S24504-40 1 X

18 Reservoir Cap (G3503 Only) S22067-2 1 X

18 Reservoir Cap (G3503-1 Only) S24504-41 1 X

19 Reservoir Elbow Fitting S24504-34 2 X

20 Reservoir Sealing Bushing S24504-35 2 X

21 Hose, Pump Inlet S24504-17 1 X

22 Hose, Pump Outlet S24504-18 1 X

23 Hose, Heat Exchanger Inlet (G3503 Only) S24504-19 1 X

23 Hose, Heat Exchanger Inlet (G3503-1 Only) S24504-42 1 X

24 Hose, Heat Exchanger Outlet S24504-20 1 X

25 Hose, Reservoir Inlet (G3503 Only) S24504-21 1 X

25 Hose, Reservoir Inlet (G3503-1 Only) S24504-43 1 X

26 Hose Clamp S24504-22 10 X

27 Hydraulic Manifold S24504-23 1 X

28 Manifold Inlet Fitting, 1/4 NPT to 3/8 ID Hose Barb S24504-24 1 X

29 Orifice Fitting, 1/89 NPT to 3/8 ID Hose Barb S24504-25 1 X

30 Pump Elbow Fitting S24504-26 2 X

31 Screw, Reservoir (G3503 Only) S24504-27 4 X

31 Screw, Reservoir (G3503-1 Only) S24504-45 1 X

32 Internal-tooth Star Washer, Motor (Not Shown) S24504-28 4 X

33 Warranty Label (Not Shown) S24504-29 2 X

34 Data Plate (G3503 Only) S24504-30 1 X

34 Data Plate (G3503-1 Only) S24504-44 1 X

35 Cable Holder, Push Mount S24504-31 2 X

36 Grommet Edging, Heat Exchanger S24504-32

37 Trim, Motor Mount S24504-33

39 Platform (Not used on 450 w/stand) G2391 1 X

40 Axle M8809-129 1 X

41 Wheel S13127-3 2 X

42 Push Nut T12570-2 2 X

43 Base Assembly L8860 1 X

44 Caster S11124-4 2 X

44A Thread Forming Screw S9225-28 8 X

Use only the parts marked “x” in the column under the

heading number called for in the model index page.

1.75in.

X

1.5in.

X

#

#

#

#

G3503-[ ] POWER WAVE 450 WATER COOLER UPGRADE KIT

7

7-26-99

Page 8

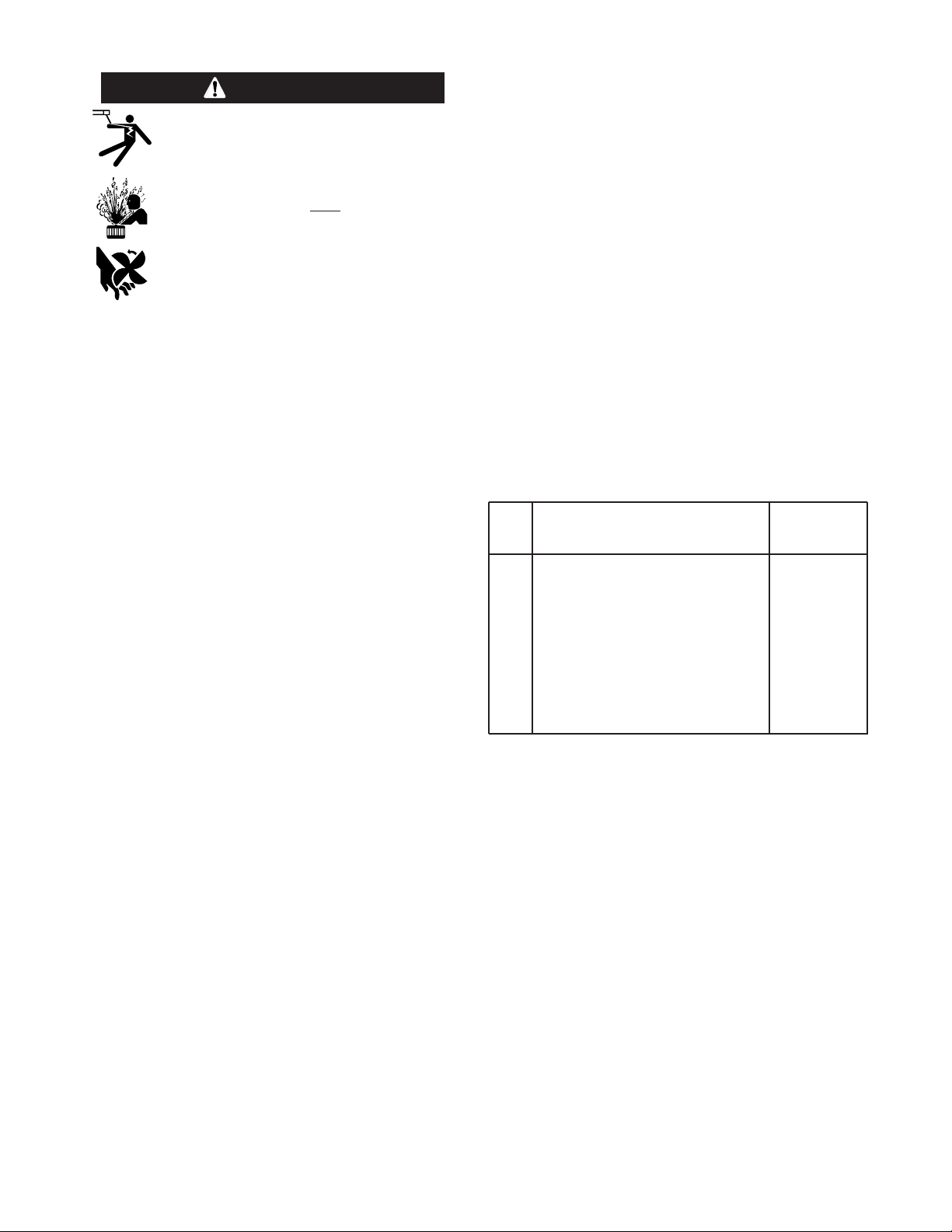

Rear Panel of

Reservoir Screen

Power Wave

Visible Coolant Level

0.25 to 0.50

inches

Figure 1. Specified coolant level.

TABLE 1

COOLER ELECTRICAL HARNESS PIN-OUTS

Molex Molex Description

Connector Pin No.

large 1 Ground

large 2 Motor Common

large 3 Unused

large 4 Unused

large 5 Motor 230 VAC (PW 450 only)

large 6 Motor 230 Vac (PW 455 only)

small 1 Unused

small 2 Unused

small 3 Relay coil

small 4 Relay coil

small 5 Pressure Switch - NO contact

small 6 Pressure Switch - common contact

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

• Sales and Service through Subsidiaries and Distributors Worldwide •

Loading...

Loading...