Page 1

K1570-1

RETURN TO MAIN MENU

CYLINDERUNDERCARRIAGE KIT

-INSTALLATION-

REQUIRED TOOLS

3/8” Nut driver 6” x 3/8” Socket Extension

9/16” Socket & Ratchet Electric chain hoist (recommended)

UNPACK THE KIT

Your Undercarriage Kit is a Dual Cylinder kit. Check your Undercarriage Kit for the following.

K1570-1

Dual Cylinder Undercarriage Kit

IM600

June, 2005

WARNING

CYLI

mayexplode

ifdamaged

NDER

Kee

and

pclin

Kee

whe

cha

pc

Ne

re

ine

cl

der

er

lin

Ne

it

dt

ind

t

lif

der

upr

er

ma

Kee

er

tu

tw

igh

all

r

awa

pc

upp

att

be

ch

eld

t

the

ww

ach

dam

lin

rt

cl

er

fr

rl

eld

ed

age

der

ind

wit

ma

ie

ing

d

er

h

rea

awa

ele

ele

ctr

fr

ctrde

ica

mw

lc

eld

irc

ing

uit

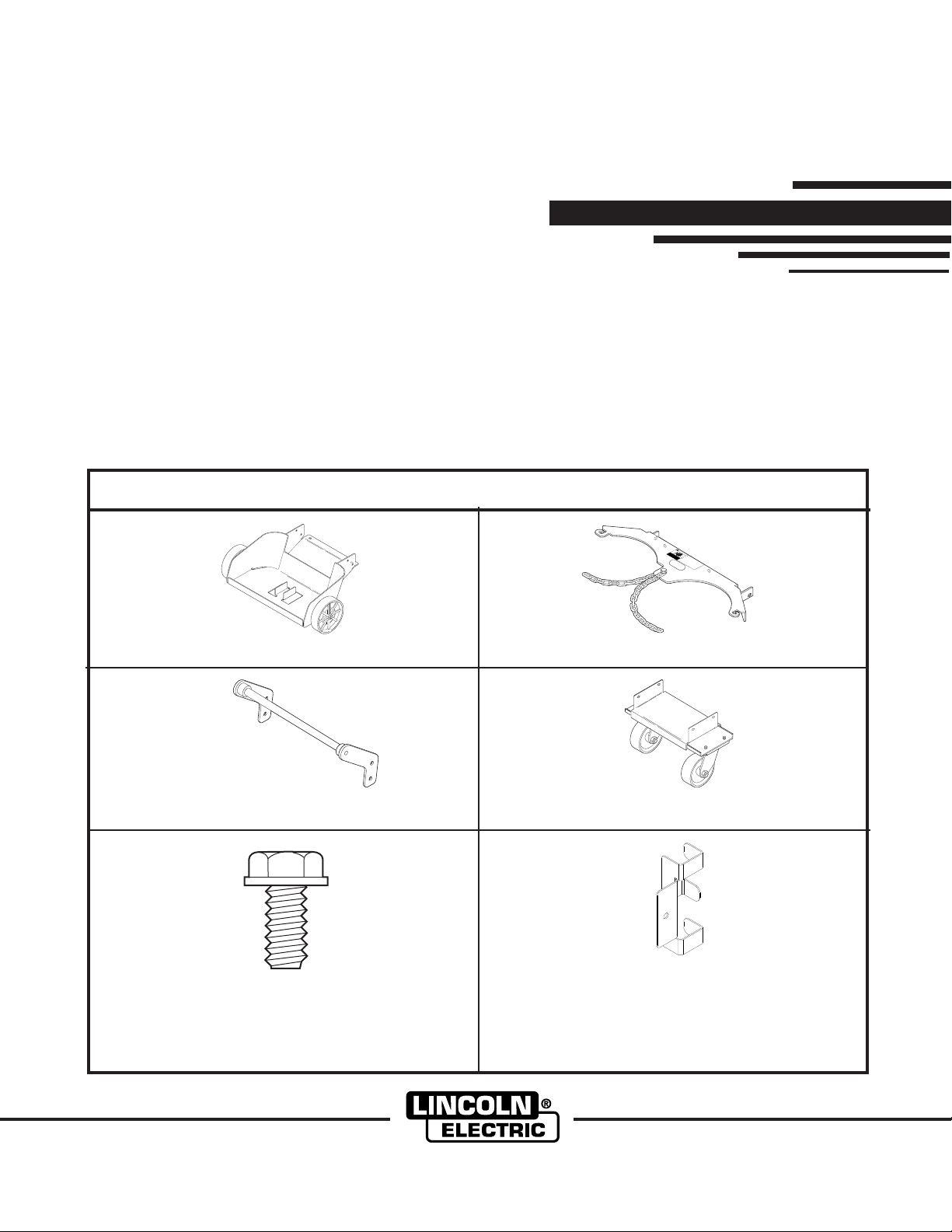

Lower Cylinder Support Wheel Assembly Upper Cylinder Support Bracket and Warning Decal

Handle Assembly Caster Wheel Assembly

Cable Retainer (Quantity 2)

(Actual Size)

3/8 - 16 x 1.00 Hex Head Thread Cutting Screw

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

(Cadium Plated - Quantity 8)

Copyright © 2005 Lincoln Global Inc.

• World's Leader in Welding and Cutting Products •

• Sales and Service through Subsidiaries and Distributors Worldwide •

Page 2

INSTALLATION OF THE K1570-1 DUAL

CYLINDER UNDERCARRIAGE KIT

STEP 1. INSTALL THE HANDLE.

a. With the 3/8" nut driver or wrench, remove the

four existing screws from the case sides. Save

the screws to install the handle.

b. Install the handle using the four screws saved

from the previous step.

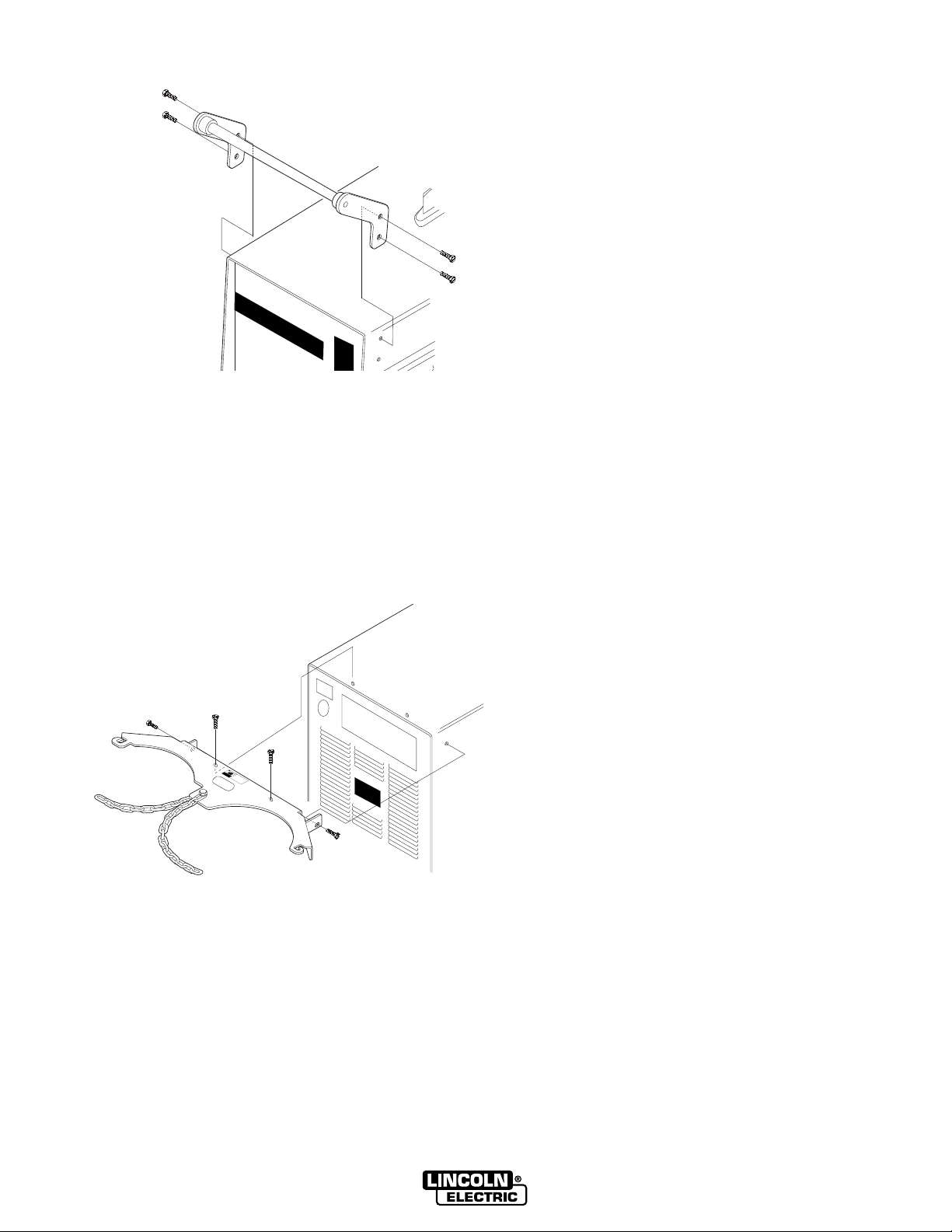

STEP 2. INSTALL THE UPPER CYLINDER SUPPORT BRACKET.

a. Remove the two existing screws from the case

top and one screw from each case side. Save

the four screws.

b. Position the bracket as shown so that the two

holes in the bracket line up with the two exist-

WARNING

CYLINDER

mayexpl

if

damaged

p

od

y

p

e

v

y

y

v

p

y

p

b

pp

y

y

y

v

y

ing holes in the machine case top.

c. With the 3/8" nut driver or wrench, install the

bracket at the top using the two previously

removed screws. Secure the bracket at the

sides with the two remaining screws. Note

that one of the slots is slightly smaller than the

diameter of the screw to insure proper electrical grounding.

2

Page 3

STEP 3. INSTALL THE CABLE RETAINERS.

a. Locate the existing 1/4-20 screws located half

way up at the back of each case side.

b. Remove these screws with the 3/8 nut-driver

and mount the 2 cable retainers to each case

side as shown. NOTE: The cable retainer

should be oriented as shown when mounting. It should wrap around the case back

corner and lay flat.

STEP 4. INSTALL THE CASTER ASSEMBLY

WARNING

FALLING EQUIPMENT can

cause injury.

• Lift only with equipment of adequate lifting capacity.

• Be sure the machine is stable

when lifting it.

------------------------------------------------------------------

a. Attach the hoist lifting hook to the lift bail of the

machine. Lift the machine to allow enough

clearance to slide the caster assembly into

place.

b. Position the caster assembly at the front of the

machine between the machine base channels.

c. Mount with four 3/8-16x1.00 threading cutting

screws provided with the kit, using two on

each side of the base.

3

Page 4

STEP 5. INSTALL THE LOWER CYLINDER

STEP 5. INSTALL THE LOWER CYLINDER

SUPPORT WHEEL ASSEMBLY

SUPPORT WHEEL ASSEMBLY

WARNING

WARNI

N

G

CYLINDER

mayexp

ifdam

K

e

an

e

aged

p

lod

Ke

d

cy

w

ep

c

h

h

li

N

e

a

e

e

r

c

i

nd

cy

e

y

n

e

l

e

er

N

li

rli

i

i

d

e

t

n

t

n

d

to

oto

up

e

d

ma

e

K

r

era

f

r

e

r

twe

y

or

e

su

i

al

aw

pc

uc

gh

be

p

l

t

ot

ay

p

h

t

o

ta

ld

y

o

w

d

h

l

r

c

c

e

a

e

f

i

t

y

w

h

r

ma

r

r

nd

li

e

ed

om

l

wi

g

li

e

nd

d

e

raw

i

t

d

a

er

n

h

e

r

g

e

el

a

ay

e

s

l

e

ec

c

fr

tr

tr

o

i

m

o

c

d

a

w

e

l

e

l

c

d

i

i

r

n

c

g

u

i

ts

------------------------------------------------------------------

a. Lift the machine to allow enough clearance to

slide the lower cylinder support wheel assembly into place.

a. Position the wheel assembly as shown in the

illustration so that the four holes line up with

the four existing holes in the machine base

channels (two on each side).

b. With the 9/16" socket, 6” x 3/8” extension and

the ratchet, install the wheel assembly to the

sides of the machine base channels using the

remaining four 3/8-16x1.00 thread cutting

screws provided with the kit.

FALLING EQUIPMENT can

cause injury.

• Lift only with equipment of adequate lifting capacity.

• Be sure the machine is stable

when lifting it.

Assembly of the Dual Cylinder Undercarriage Kit

is now complete. Carefully lower the machine to

the floor and detach the hoist.

PARTS LIST

K1570-1

DUAL CYLINDER UNDERCARRIAGE KIT

Item Part No. Description Qty.

No.

1 M17891-1 Lower Cylinder 1

2 S22166-1 Upper Cylinder 1

3 M17889-1 Caster Wheel 1

4 M17130-1 Handle Assembly 1

5 M18239 Cable Retainer 2

6 S9225-53 3/8-16x1.00 Thread Cutting

Support Wheel Assembly

Support Bracket

Assembly

Screw 8

4

Loading...

Loading...