Page 1

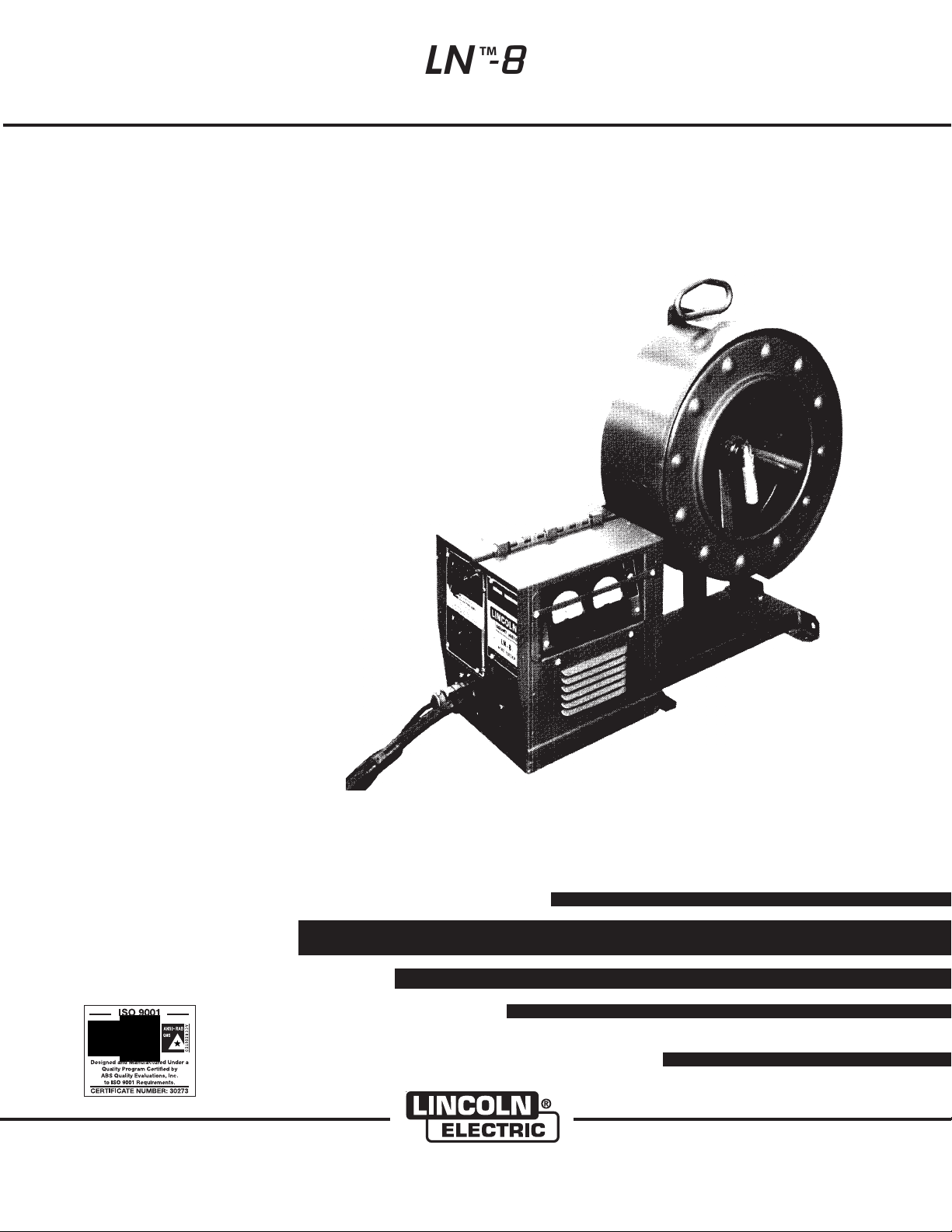

SEMIAUTOMATIC WIRE FEEDER

RETURN TO MAIN MENU

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. H oweve r,

your overall safety can be

increased by proper installation

... and thoughtful operation on

your part. DO NOT INS TALL,

OP ERAT E OR REPAIR T HIS

EQUIPMENT WITHOUT READING THIS MANUAL AND THE

SAFETY PRECAUTIONS CONTAINED THROUGHOUT. And,

most importantly, think bef

you act and be careful.

ore

TM

LN -8

IM274-A

June, 2010

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

OPERATOR’S MANUAL

Copyright © Lincoln Global Inc.

• World's Leader in Welding and Cutting Products •

• Sales and Service through Subsidiaries and Distributors Worldwide •

Page 2

i

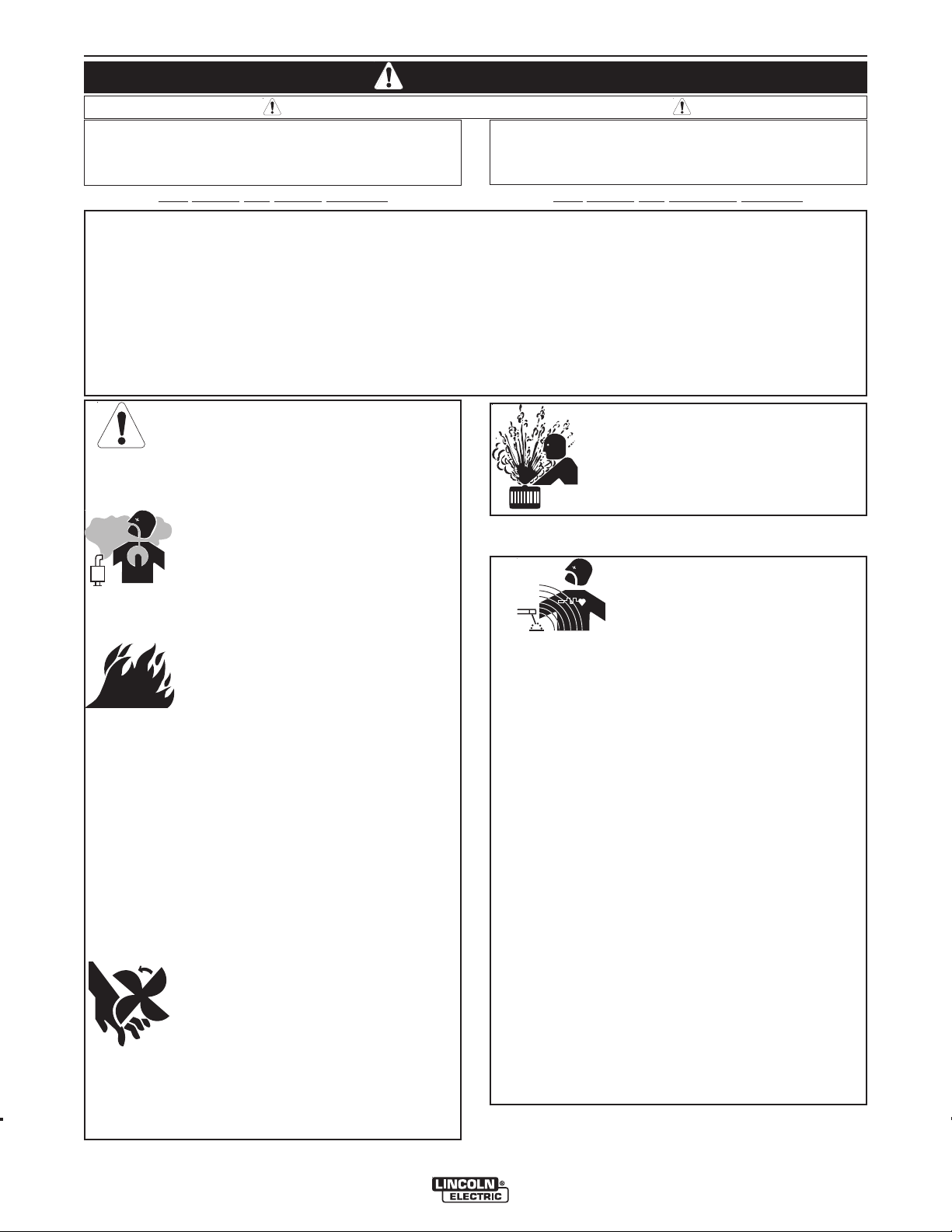

SAFETY

i

WARNING

CALIFORNIA PROPOSITION 65 WARNINGS

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer, birth defects, and other reproductive harm.

The Above For Diesel Engines

ARC WELDING CAN BE HAZARDOUS. PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH.

KEEP CHILDREN AWAY. PACEMAKER WEARERS SHOULD CONSULT WITH THEIR DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For additional safety information, it is strongly recommended that you

purchase a copy of “Safety in Welding & Cutting - ANSI Standard Z49.1” from the American Welding Society, P.O. Box

351040, Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available

from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

The Above For Gasoline Engines

FOR ENGINE

powered equipment.

1.a. Turn the engine off before troubleshooting and maintenance

work unless the maintenance work requires it to be running.

____________________________________________________

1.b. Operate engines in open, well-ventilated

areas or vent the engine exhaust fumes

outdoors.

____________________________________________________

1.c. Do not add the fue l near an open f lame

welding arc or when the engine is running.

Stop the engine and allow it to cool before

refueling to prevent spilled fuel from vaporizing on contact with hot engine parts and

igniting. Do not spill fuel when filling tank. If

fuel is spilled, wipe it up and do not start

engine until fumes have been eliminated.

____________________________________________________

1.d. Keep all equipment safety guards, covers and devices in

position and in good repair.Keep hands, hair, clothing and

tools away from V-belts, gears, fans and all other moving

parts when starting, operating or repairing equipment.

____________________________________________________

1.e. In s ome cas es it may b e nec ess ary to remov e saf ety

gu a r d s to perf o r m r equir e d m ainten a n c e. Rem o v e

guards only when necessary and replace them when the

ma i n t e nance re q uirin g th eir re m o v a l is c o m p lete.

Always use the greatest care when working near moving

parts.

___________________________________________________

1.f. Do not put your hands near the engine fan.

Do not attempt to override the governor or

idler by pushing on the throttle control rods

while the engine is running.

1.h. To avoid scalding, do not remove the

radiator pressure cap when the engine is

hot.

ELECTRIC AND

MAGNETIC FIELDS

may be dangerous

2.a. Electric curr en t flowing through any conduct or c au ses

localized Electric and Magnetic Fields (EMF). Welding

current creates EMF fields around welding cables and

welding machines

2.b. EMF field s may int erfer e with some pacemak ers, and

welders having a pacemaker should consult their physician

before welding.

2.c. Exposure to EMF fields in welding may have other health

effects which are now not known.

2.d. All welders should use the following procedures in order to

minimize exposure to EMF fields from the welding circuit:

2.d.1.

Route the electrode and work cables together - Secure

them with tape when possible.

2.d.2. Nev er coil the e lectrod e lead around your body.

2.d.3. Do not place your body between the electrode and

work cables. If the electrode cable is on your right

side, the work cable should also be on your right side.

___________________________________________________

1.g. To prevent accidentally starting gasoline engines while

turning the engine or welding generator during maintenance

work, disconnect the spark plug wires, distributor cap or

magneto wire as appropriate.

2.d.4. Connect the work cable to the workpiece as close as

possible to the area being welded.

2.d.5. Do not work next to welding power source.

Page 3

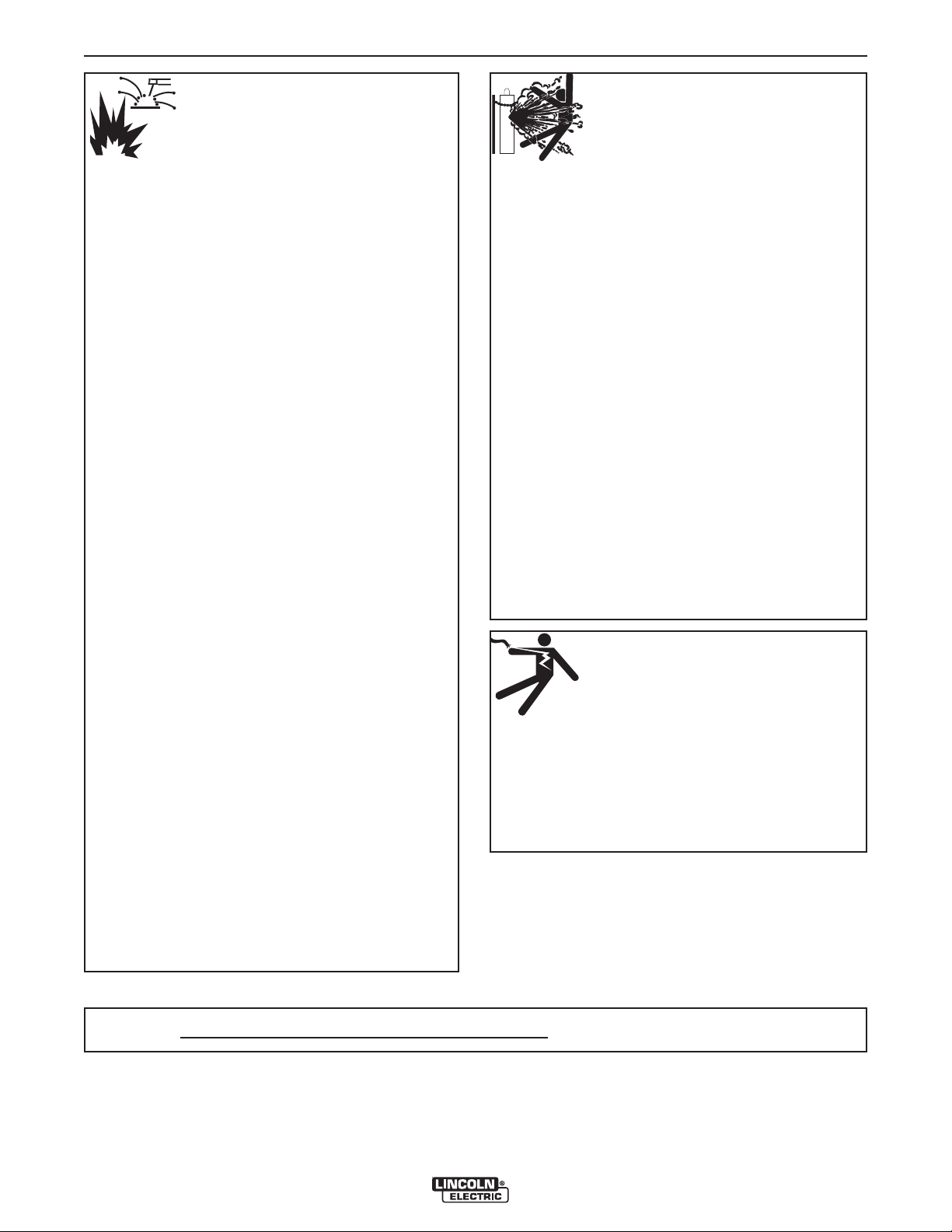

ii

SAFETY

ii

ELECTRIC SHOCK can

kill.

3.a. The electrode and work (or ground) circuits

are electrically “hot” when the welder is on.

Do not touch these “hot” parts with your bare

skin or wet cloth in g. W ea r dr y, hole-free

gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full

area of physical contact with work and ground.

In addition to the normal safety precautions, if welding

mu s t be p e rformed under elec t rically hazar d ous

conditions (in damp locations or while wearing wet

clothing; on metal structures such as floors, gratings or

scaffolds; when in cramped positions such as sitting,

kneeling or lying, if there is a high risk of unavoidable or

accidental contact with the workpiece or ground) use

the following equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel, welding head, nozzle or sem ia ut om at ic

welding gun are also electrically “hot”.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection

should be as close as possible to the area being welded.

3.e. Ground the work or metal to be welded to a good electrical

(earth) ground.

3.f.

Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Ne ver s imu ltane ous ly touch ele ctr ica lly “ hot ” par ts of

electrode holders connected to two welders because voltage

between the two can be the total of the open circuit voltage

of both welders.

3.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

3.j. Also see Items 6.c. and 8.

ARC RAYS can burn.

4.a. Use a shield with the proper filter and cover

plates to protect your eyes from sparks and

the rays of the arc when welding or observing

open arc welding. Headshield and filter lens

should conform to ANSI Z87. I standards.

4.b. Use suitable clothing made from durable flame-resistant

material to protect your skin and that of your helpers from

the arc rays.

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

FUMES AND GASES

can be dangerous.

5.a. Weldi ng may produce fume s and gases

hazardous to health. Avoid breathing these

fumes and gases. When welding , keep

your head out of the fume. Use enough

ventilation and/or exhaust at the arc to keep

fumes and gases away from the breathing zone. When

we l ding w ith e lectrod e s wh i ch r e quire special

ve n tilati on s uch as s tainles s or hard facing (se e

instru ctio ns on container or MSDS ) o r o n l ead or

cadmium plated steel and other metals or coatings

which produce highly toxic fumes, keep exposure as

low as possible and within applicable OSHA PEL and

ACGIH TLV limits using local exhaust or mechanical

ventilation. In confined spaces or in some circumst a nces, outd o ors, a r espira tor may be r equired .

Additional precautions are also required when welding

on galvanized steel.

5. b. The operation of welding fume control equipment is affected

by various factors including proper use and positioning of

the equipment, maintenance of the equipment and the specific welding procedure and application involved. Worker

exposure level should be checked upon installation and

periodically thereafter to be certain it is within applicable

OSHA PEL and ACGIH TLV limits.

5.c.

Do not weld in locations near chlorinated hydrocarbon

coming from degreasing, cleaning or spraying operations.

The heat and rays of the arc can react with solvent vapors

form phosgene, a highly toxic gas, and other irritating products.

5.d. Shielding gases used for arc welding can displace air and

caus e injur y or dea th. Alw ays use e nough v entilat ion,

especially in confined areas, to insure breathing air is safe.

vapors

to

5.e. Read and understand the manufacturer’s instructions for this

equipment and the consumables to be used, including the

ma t e r i al s a f e ty d a t a shee t (MSDS) an d fo llow yo u r

employer’s safety practices. MSDS forms are available from

yo u r weld i n g di s t r ibuto r or fr om th e ma n u f actur e r .

5.f. Also see item 1.b.

Page 4

iii

SAFETY

iii

WELDING and CUTTING

SPARKS can

cause fire or explosion.

6.a.

Remove fire hazards from the welding area.

If this is not possible, cover them to prevent

Re m e m b er th a t w eldin g s p arks a n d h ot

materials from welding can easily go through small cracks

an d o pen i ngs to adja cen t a reas . A voi d w eldi ng nea r

hydraulic lines. Have a fire extinguisher readily available.

6.b. Where compressed gases are to be used at the job site,

special precautions should be used to prevent hazardous

situations. Refer to “Safety in Welding and Cutting” (ANSI

Standard Z49.1) and the operating information for the

equipment being used.

6.c. When not welding, make certain no part of the electrode

circuit is touching the work or ground. Accidental contact

can cause overheating and create a fire hazard.

6.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures

will not cause flammable or toxic vapors from substances

inside. They can cause an explosion even

been “cleaned”. For information, purchase “Recommended

Safe Practices for the

Co n t a i ners and Piping That Have Held Haza r d o u s

Substances”, AWS F4.1 from the American Welding Society

(see address above).

6.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

Sparks and spatter are thrown from the welding arc. Wear oil

6.f.

free protective garments such as leather gloves, heavy shirt,

cuffless trousers, high shoes and a cap over your hair. Wear

ear plugs when welding out of position or in confined places.

Always wear safety glasses with side shields when in a

welding area.

6.g. Connect the work cable to the work as close to the welding

area as practical. Work cables connected to the building

framework or other locations away from the welding area

increase the possibility of t he w el di ng current passing

through lifting chains, crane cables or other alternate circuits. This can create fire hazards or overheat lifting chains

or cables until they fail.

6.h. Also see item 1.c.

the welding s pa rks fro m startin g a fire.

though

they have

Preparation

for Welding and Cutting of

CYLINDER may explode

if damaged.

7.a. Us e o n ly com p r e ssed g a s c ylind e r s

containing the correct shielding gas for the

pr o c e s s used a n d p r operl y o p e ratin g

re g u l a tors d e signe d f or t h e gas a n d

pressure used. All hoses, fittings, etc. should be suitable for

the application and maintained in good condition.

7.b. Alwa ys keep cyl inder s in an upr ight posit ion sec urely

chained to an undercarriage or fixed support.

7.c. Cylinders should be located:

• Away from areas where they may be struck or subjected to

physical damage.

• A safe distance from arc welding or cutting operations and

any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode holder or any other

electrically “hot” parts to touch a cylinder.

7.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. Valve protection caps should always be in place and hand

tight except when the cylinder is in use or connected for

use.

7.g. Re ad and f oll ow the inst ruc tio ns on com pre sse d g as

cylinders, associated equipment, and CGA publication P-l,

“Precautions for Safe Handling of Compressed Gases in

Cylinders,” available from the Compressed Gas Association

1235 Jefferson Davis Highway, Arlington, VA 22202.

FOR ELECTRICALLY

powered equipment.

8.a. Turn off input power using the disconnect

switch at the fuse box before working on

the equipment.

8.b. Install equipment in accord ance with the U.S. National

Electrical Code, all local code s and the manufacturer’s

recommendations.

8.c. Ground the equipment in accordance with the U.S. National

Electrical Code and the manufacturer’s recommendations.

6.I. Read and follow NFPA 51B “ Standard for Fire Prevention

During Welding, Cutting and Other Hot Work”, available

from NFPA, 1 Batterymarch Park, PO box 9101, Quincy, Ma

022690-9101.

6.j. Do not use a welding power source for pipe thawing.

Refer to http://www.lincolnelectric.com/safety for additional safety information.

Page 5

iv

SAFETY

iv

PRÉCAUTIONS DE SÛRETÉ

Pour votre propre protection lire et observer toutes les instructions

et les précautions de sûreté specifiques qui parraissent dans ce

manuel aussi bien que les précautions de sûreté générales suivantes:

Sûreté Pour Soudage A L’Arc

1. Protegez-vous contre la secousse électrique:

a. Les circuits à l’électrode et à la piéce sont sous tension

quand la machine à souder est en marche. Eviter toujours

tout contact entre les parties sous tension et la peau nue

ou les vétements mouillés. Porter des gants secs et sans

trous pour isoler les mains.

b. Faire trés attention de bien s’isoler de la masse quand on

soude dans des endroits humides, ou sur un plancher

metallique ou des grilles metalliques, principalement dans

les positions assis ou couché pour lesquelles une grande

partie du corps peut être en contact avec la masse.

c. Maintenir le porte-électrode, la pince de masse, le câble

de soudage et la machine à souder en bon et sûr état

defonctionnement.

d.Ne jamais plonger le porte-électrode dans l’eau pour le

refroidir.

e. Ne jamais toucher simultanément les parties sous tension

des porte-électrodes connectés à deux machines à souder

parce que la tension entre les deux pinces peut être le

total de la tension à vide des deux machines.

f. Si on utilise la machine à souder comme une source de

courant pour soudage semi-automatique, ces precautions

pour le porte-électrode s’applicuent aussi au pistolet de

soudage.

2. Dans le cas de travail au dessus du niveau du sol, se protéger

contre les chutes dans le cas ou on recoit un choc. Ne jamais

enrouler le câble-électrode autour de n’importe quelle partie

du corps.

5. Toujours porter des lunettes de sécurité dans la zone de

soudage. Utiliser des lunettes avec écrans lateraux dans les

zones où l’on pique le laitier.

6. Eloigner les matériaux inflammables ou les recouvrir afin de

prévenir tout risque d’incendie dû aux étincelles.

7. Quand on ne soude pas, poser la pince à une endroit isolé de

la masse. U n cour t-circuit accidental peut provoquer un

échauffement et un risque d’incendie.

8. S’assurer que la masse est connectée le plus prés possible

de la zone de travail qu’il est pratique de le faire. Si on place

la masse sur la charpente de la construction ou d’autres

endroits éloignés de la zone de travail, on augmente le risque

de voir passer le courant de soudage par les chaines de levage, câbles de grue, ou autres circuits. Cela peut provoquer

des risques d’incendie ou d’echauffement des chaines et des

câbles jusqu’à ce qu’ils se rompent.

9. Assurer une ventilation suffisante dans la zone de soudage.

Ceci est particuliérement important pour le soudage de tôles

galvanisées plombées, ou cadmiées ou tout autre métal qui

produit des fumeés toxiques.

10. Ne pas souder en présence de vapeurs de chlore provenant

d’o pérations de d égraissage, nettoyage ou pist olage. La

chaleur ou les rayons de l’arc peuvent réagir avec les vapeurs

du solvant pour produire du phosgéne (gas fortement toxique)

ou autres produits irritants.

11. Pour obtenir de plus amples renseignements sur la sûreté,

voir le code “Code for safety in welding and cutting” CSA

Standard W 117.2-1974.

PRÉCAUTIONS DE SÛRETÉ POUR

3. Un coup d’arc peut être plus sévère qu’un coup de soliel,

donc:

a. Utiliser un bon masque avec un verre filtrant approprié

ainsi qu’un verre blanc afin de se protéger les yeux du rayonnement de l’arc et des projections quand on soude ou

quand on regarde l’arc.

b. Porter des vêtements convenables afin de protéger la

peau de soudeur et des aides contre le rayonnement de

l‘arc.

c. Proté ge r l’autre p er sonnel travaillant à p roximité au

soudage à l’aide d’écrans appropriés et non-inflammables.

4. Des gout tes de laitier en fusion sont émises d e l’arc de

soudage. Se protéger avec des vêtements de protection libres

de l’huile, tels que les gants en cuir, chemise épaisse, pantalons sans revers, et chaussures montantes.

LES MACHINES À SOUDER À

TRANSFORMATEUR ET À

REDRESSEUR

1. Relier à la terre le chassis du poste conformement au code de

l’électricité et aux recommendations du fabricant. Le dispositif

de montage ou la piece à souder doit être branché à une

bonne mise à la terre.

2. Autant que possible, I’installation et l’entretien du poste seront

effectués par un électricien qualifié.

3. Avant de faires des travaux à l’interieur de poste, la debrancher à l’interrupteur à la boite de fusibles.

4. Garder tous les couvercles et dispositifs de sûreté à leur

place.

Page 6

NOTES

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

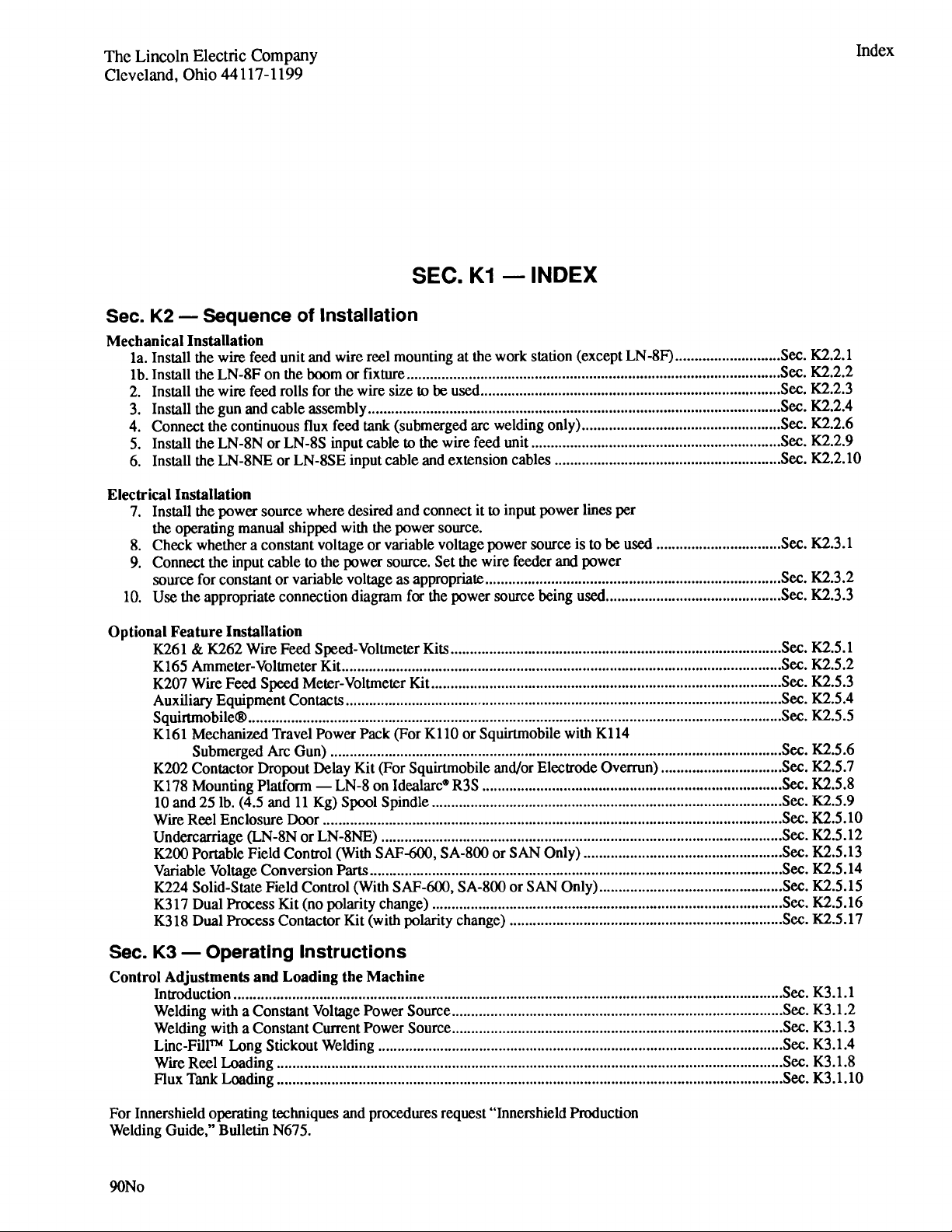

Sec. K3.1.1

Introduction

Input power (115VAC, 2.5A) is supplied by the Power Source.

Duty Cycle: The amount of welding perfromed in a 10 minute period,

expressed nas a percentage.

Page 35

Page 36

Page 37

NOTES

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

P-103-C, C.1

P-103-D, D.1

P-103-E, E.1, P-103-E.2

P-103-F, F.1

P-103-G, G.1

P-103-H, H.1

P-103-J, J.1

P-103-K, K.1

P-202-C, C.1, C.2, C.3

C.4, C.5, C.6

P-110-C, C.1

P-110-D, D.1

P-110-E, E.1

P-110-F, F.1, G, G.1

P-107-F.2, F.3

P-107-G, G.1

P-107-J

P-107-L

P-107-M

P-107-O, O.1

P-125-N, N.1

P-125-O, O.1

P-107-P

P-107-R

P-107-S, S.1

P-107-T

..............................................................................................

P-107-V.a, V.b

P-107-W, W.1

P-107-W.2a, W.2b

Page 55

P-28-H, J.b1

P-107-X

P-107-Y

P-110-Z

P-110-AA

P-110-AA

P-114-H

Order K202

Order K162

Order K178

Page 56

06-06-2005

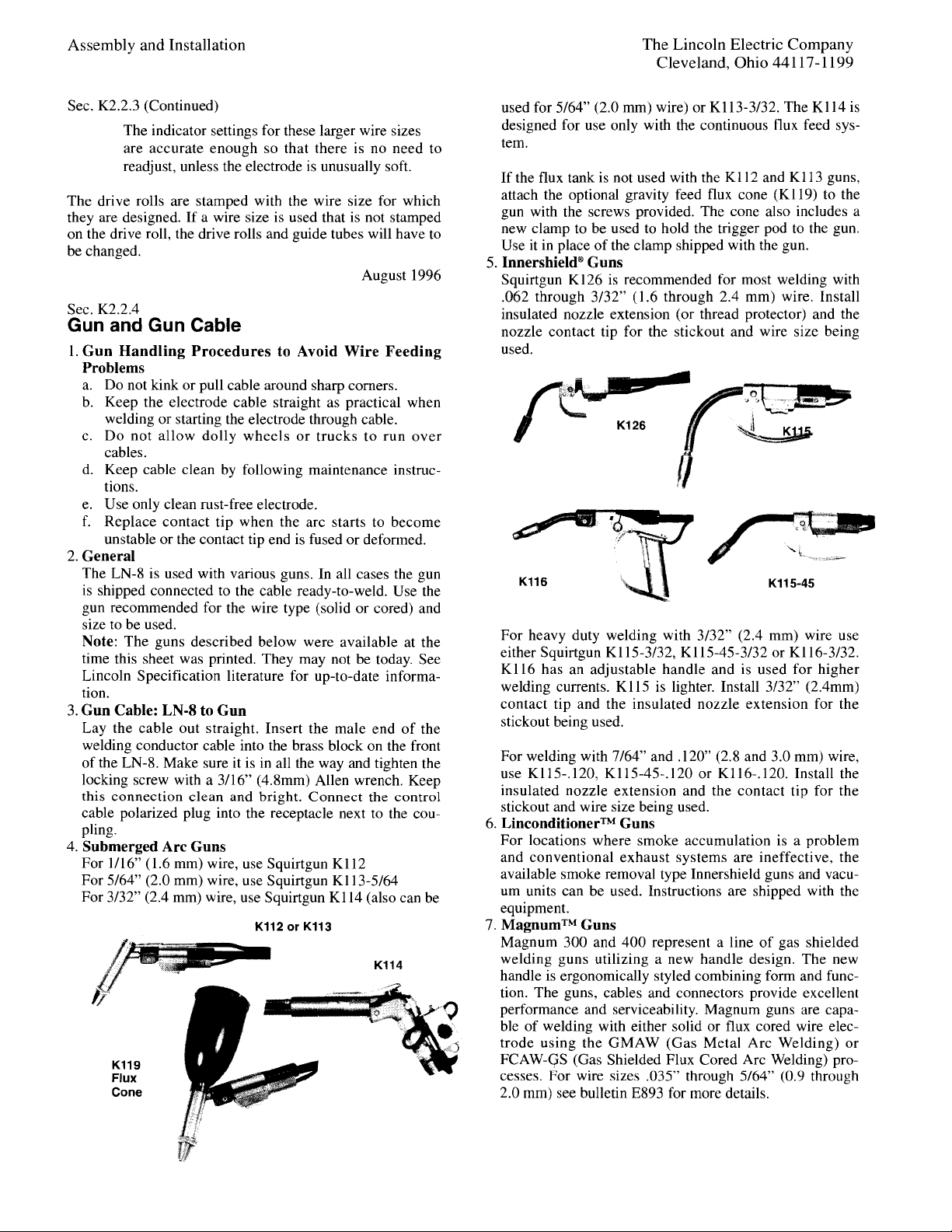

K112 & K113 SQUIRTGUNS & CABLES

P-103-CP-103-C

K112 & K113 Squirtguns & Cables

de o Gu s de o Gu s de o Gu s de o Gu s

Part Numbers Part Numbers Part Numbers Part Numbers

NOTE: In 1977 the semiautomatic guns were redesigned to conform to NEMA standards. To identify a new

design gun an ampere rating is stencilled on the clamp of the “Clamp and Tube Assembly” (Item 2). For

new design guns use columns 3 or 4. In 1979 the K112 and K113 guns were further redesigned. This latest redesign may be identified by a size molded in the nozzle insulation (Part of Item 1) near the handle to

gun connection.

1

7

8

9

10C10C

10D10D

5

4

2

6

3

1010

10A10A

10D10D

10B10B

Page 57

Gun & Cable Assembly (5/64” Electrode)

(No Electrode Size Stencil) K113 1 • • X •

Gun & Cable Assembly

(5/64” Electrode) (Stenciled 5/64)

K113-5/64 1 X • X •

Gun & Cable Assembly

(3/32” Electrode) (Stenciled 3/32)

K113-3/32 1 • • X •

1 Gun Assembly M10614-4

ø

1•X•X

1 Gun Assembly M10614-7 1 • • • X

1 Gun Assembly M10614-9 1 X • X •

1 Gun Assembly M10614-8 1 • • X •

Gun Parts See P-103-D

2 Clamp and Flux Tube Assembly S16165 1 X X X X

3 Handle M10102 1 X X • •

3 Handle M10102-1 1 • • X X

4 Socket Head Cap Screw T9447-9 1 X X • •

4 Socket Head Cap Screw T14438 1 • • X X

5 Trigger and Control Cable Assembly M12462-15 1 X X X X

Assembly Parts See P-103-K

6 8-32 x 1/4 Pan Head Screw CF000148 4 X X X X

7 Spatter Shield T12027 1 X X X X

8 Retaining Ring S9776-7 1 X X X X

9 Clamp S11598-1 1 X X • •

9 Clamp S15921-2 1 • • X X

10 Conductor Cable, Includes: L5728-7 1 • • X •

10 Conductor Cable, Includes: L4230-7 1 X • • •

10 Conductor Cable, Includes: L4230-1 1 • X • •

10 Conductor Cable, Includes: (350 Amp) L5728-1

ø

1•••X

10 Conductor Cable, Includes: (500 Amp) L6250-4 1 • • • X

10A Handle and Stiffener, Wire Feeder End M14048 1 X • X •

10A Handle and Stiffener, Wire Feeder End M14050-1 1 • X • X

10B Connector, Wire Feeder End S12801-6 X • X •

10B Connector, Wire Feeder End (350 Amp) S12801-1

ø

•X•X

10B Connector, Wire Feeder End (500 Amp) S12801-9 • • • X

10C Connector, Gun End (350 Amp) S12802-11 • • • X

10C Connector, Gun End (500 Amp) S12802-16 • • • X

10C Connector, Gun End S12802-6 X • • •

10C Connector, Gun End S12802-1 • X • •

10C Connector, Gun End S12802-14 • • X •

10D Clamping Tube, Both Ends (All Except 500A) S7748-40 2 X X X X

10D Clamping Tube, Both Ends (500A Only) S16997 2 • • • X

11

Cable Liner - For K112 (1/16” Electrode, 350 Amp Only)

S12898-5/64

ø

1•X••

Adapter Kit to use Squirtguns K113 with MN-1

and MN-3 (Not Illustrated) M10682

ø

1X•X•

Adapter Kit to use Squirtguns K113 with ML-2

(Not Illustrated) S12967

ø

1X•X•

11-22-2005

K112 & K113 SQUIRTGUNS & CABLES

Use only the parts marked “x” in the column under the

heading number called for in the model index page.

# Indicates a change this printing.

P-103-C.1

ITEM DESCRIPTION PART NO. QTY. 1 23456789

P-103-C.1

de o Gu s de o Gu s de o Gu s de o Gu s

Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration

For Squirtgun K113, use the parts marked “X” in Column 1 or 3 (see note).

For Squirtgun K112, use the parts marked “X” in Column 2 or 4 (see note).

ø This part is obsolete and no longer available.

#

Page 58

06-03-2005

SQUIRTGUNS K112 & K113

P-103-D

P-103-D

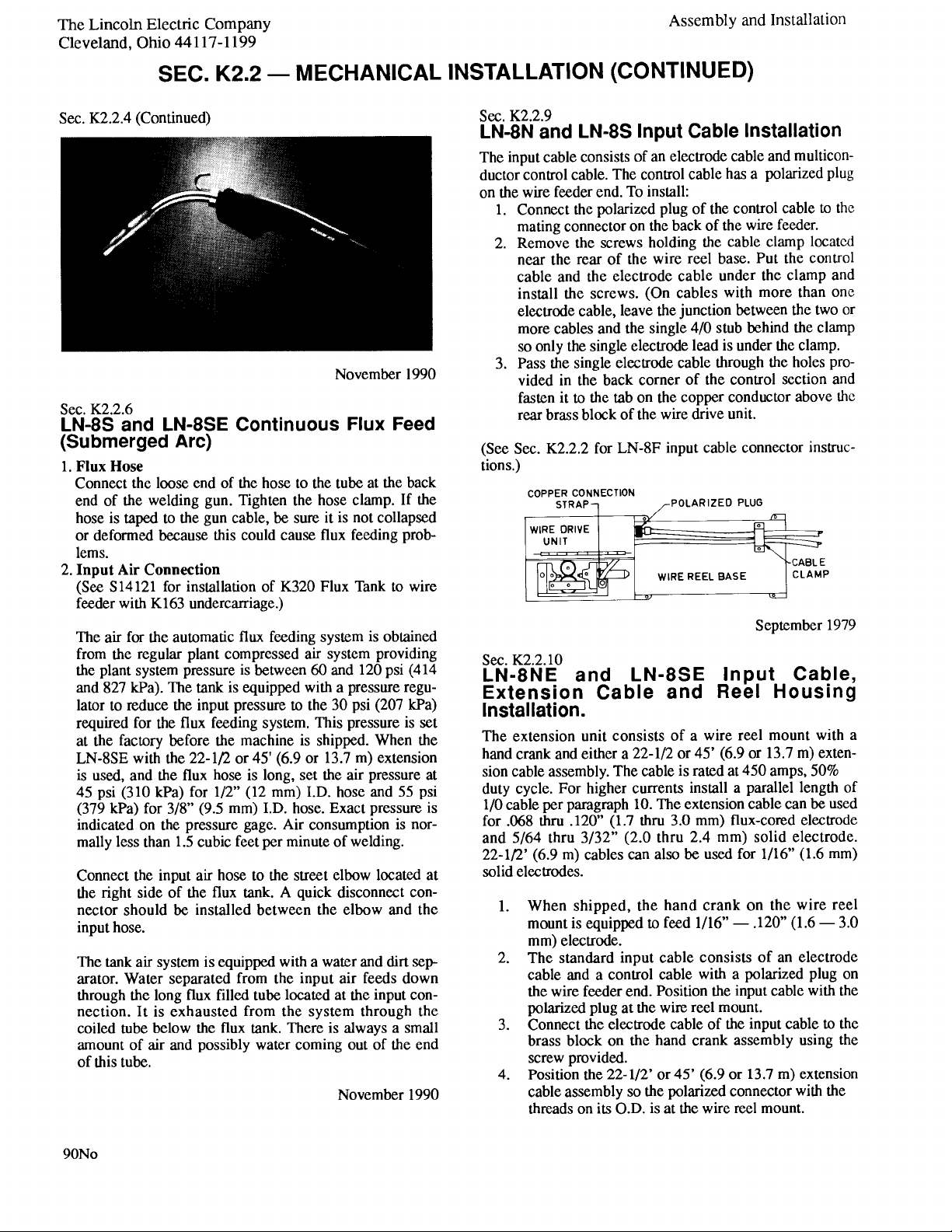

Gun Assembly - Squirtguns K112 & K113

de o Gu s de o Gu s de o Gu s

Part Numbers Part Numbers Part Numbers Part Numbers

NOTE: In 1977 the semiautomatic guns were redesigned to conform to NEMA standards. To identify a

new design gun an ampere rating is stencilled on the clamp of the “Clamp & Tube Assembly”

(Item 2 of P-103-C). For new design guns use columns 3, 4 or 5. In 1979 the K112 and K113

guns were further redesigned. This latest redesign may be identified by a size molded in the

nozzle insulation (Part of Item 2) near the handle to gun connection.

1

2A

2B

4

3

2A1

2A2

2A3

2A4

5

2A

2B

2A1

2A2

2A3

2A4

Page 59

08-28-2007

SQUIRTGUNS K112 & K113

Use only the parts marked “x” in the column under the

heading number called for in the model index page.

# Indicates a change this printing.

P-103-D.1

ITEM DESCRIPTION PART NO. QTY. 123 4 56789

P-103-D.1

de o Gu s de o Gu s de o Gu s de o Gu s

Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration

For Squirtgun K113, use the parts marked “X” in Column 1 or 3 (see note).

For Squirtgun K112, use the parts marked “X” in Column 2 or 4 (see note).

For Squirtgun K112 (500 Amp), use the parts marked “X” in Column 5 (see note).

ø This part is obsolete and no longer available.

1 Cap S12955 1 X X • • •

1 Cap T14181 1 • • X X X

2

Housing & Nozzle Asbly, Includes:

(5/64, Stenciled)

M10670-7 1 X • X • •

2

Housing & Nozzle Asbly, Includes:(

3/32, Stenciled)

M10670-6 1 • • X •

2 Housing & Nozzle Asbly, Includes: M10670-4

ø

1•X•X•

2 Housing & Nozzle Asbly, Includes: M10670-5 1 • • • • X

2A Nozzle S13813-1 1 • X • X X

2A Nozzle (3/32) S13813-3 1 • • X • •

2A Nozzle (5/64) S13813-4 1 • • X • •

2A1 Nozzle Liner, Tight Wound Steel Spring

(For 5/64, No Stencil) KP2095-1 1 X • X • •

2A1 Nozzle Liner, Tight Wound Steel Spring

(For 5/64 Stenciled) KP2095-12 1 • • X • •

2A1 Nozzle Liner, Tight Wound Steel Spring

(For 3/32 Stenciled) KP2095-11 1 • • X • •

2A1 Nozzle Liner, Tight Wound Steel Spring T12931-3 1 • X • X X

2A2 Ceramic Insert KP2094-2 1 • • X • •

2A3 Insert Retainer T12977-1 1 • • X • •

2A4 Hollow Lock Set Screw T12932-1 1 X X X X X

2B Housing S13486-1

ø

1•X•X•

2B Housing S13486-2 1 X • X • X

3 Collar S12964-1 1 X X X X X

4 Nozzle Flux Cone (S12957-1/2) KP1968-1 1 X X X X X

4 Nozzle Flux Cone (S12957-5/8) KP1968-5 1 X X X X X

4 Nozzle Flux Cone (S12957-3/4) KP1968-4 1 X X X X X

4 Nozzle Flux Cone (S12957-13/16) KP1968-2 1 X X X X X

4 Nozzle Flux Cone (S12957-15/16) KP1968-3 1 X X X X X

4 Chamfered 3/4” Nozzle Flux Cone T14278 1 X X X X X

5 Contact Tip, 1/16” Electrode T12011-1/16 KP2086-2 * • X • X •

5 Contact Tip, 5/64” Electrode T12011-5/64 KP2086-4 * X • X • •

5 Contact Tip, 3/32” Electrode T14050-3/32 (Note 1) T14050-3/32 * • • X • •

5 Contact Tip, 3/32” Electrode

T12011-3/32 (1) KP2086-3 (1)

••X••

5 Contact Tip, 1/16” Electrode T14050-1/16 (Note 1) T14050-1/16 * • • • • X

Nozzle Extension K113-5/64, 1-3/4 Stickout S13027-4 1 X • X • •

Nozzle Extension K113-3/32, 1-3/4 Stickout S13027-5 1 X • X • •

Nozzle Extension K113-3/32, 2-1/8 Stickout S13027-3 1 X • X • •

Guide Tips for Long Stickout Extensions K113-5/64

KP2104-2 1 X • X • •

Guide Tips for Long Stickout Extensions K113-3/32

KP2091-1 1 X • X • •

Guide Tips for Long Stickout Extensions K113-3/32

T14435-3/32 (1)

X•X••

* As Required

(1) To be used only when using S13027-5 extension

NOTE 1: When tip life is limited by tip being

fused over the use of T14726-[ ] tips

may result in a lower overall cost.

#

#

#

Page 60

07-18-2005

K114 SQUIRTGUN & CABLE

P-103-E

P-103-E

K114 Squirtgun & Cable

de o Gu s de o Gu s de o Gu s de o Gu s

Part Numbers Part Numbers Part Numbers Part Numbers

7

4

5

1

3

2020

4A4A

4B4B

2

1616

1313

1010

9

6

1717

1515

1414

1212

1818

1919

30A30A

8

3434

3333

31C31C

2626

3535

2727

2828

31B31B

31D31D

31A31A

30B30B

3030

3131

2929

3737

3636

4040

}

4141

4242

3939 3030

3838

3232

Page 61

Squirtgun & Cable K114

1 Nozzle Flux Cone 13/16” Opening (Opt)(S12957-13/16) KP1968-2 1 X

1 Nozzle Flux Cone 5/8” Opening (Std) (S12957-5/8) KP1968-5 1 X

1 Nozzle Flux Cone 3/4” Opening (Opt) (S12957-3/4) KP1968-4 1 X

1 Nozzle Flux Cone 15/16” Opening (Opt)(S12957-15/16) KP1968-3 1 X

2 Contact Tip (T12236-3/32) KP2088-2

As Reqʼd

X

2 Contact Tip (Optional) (T12236-5/64) KP2088-3 1 X

Gun Assembly, Includes: (Items 3 thru 20) L5757-A 1 X

3 Socket Head Cap Screw T9447-22 1 X

4 Nozzle, Includes: S13816 1 X

4A Nozzle Liner, Tight Wound Steel Spring T12931-2 1 X

4B Liner Locking Screw T12932-2 1 X

5 Gun Tube S13042 1 X

6 Right & Left Gun Mount L3828 1 X

7 Flux Shut Off Assembly S11686 1 X

8 Receptacle Clamp T11521 1 X

9 Spring T11514 1 X

10 Lever S11567-1 1 X

12 Pivot Pin T11546 1 X

13 Rivet T10167-1 1 X

14 Plain Washer S9262-39 1 x

15 Spring Clip S11685 1 X

16 Trigger S11569 1 X

17 Snap Ring S9776-16 1 X

18 Gun Hanger T11523 1 X

19 Roll Pin T9967-23 1 X

20 Collar S12964-1 1 X

Handle & Conductor Cable Asbly, Includes: (Items 26 thru 42)

L5757-B

26 Clamping Ring S12903 1 X

27 Tube Insulator T11584 1 X

28 Handle S11629 1 X

29 Flux Tube S11822 1 X

30 Control Cable, Includes: M9473 1 X

Micro Switch S12182-1 1 X

30A 3 Contact Receptacle, Gun End T11155-1 1 X

30B 5 Contact Receptacle, Wire End S12020-6 1 X

31 Conductor Cable, Includes: L5728-6 1 X

31A Handle & Stiffener, Wire Feeder End M14048 1 X

31B Connector, Wire Feeder End S12801-6 1 X

31C Connector, Gun End S12802-14 1 X

31D Clamping Tube, Both Ends S7748-40 2 X

32 #8-32 x 1.875 FHS CF000133 2 X

33 Socket Head Screw T9447-8 1 X

34 Snap Ring S9776-28 1 X

35 Socket Head Screw T9447-21 1 X

36 Switch Mounting Plate S11588 1 X

37 #8-32 x .50 RHS CF000033 3 X

38 Actuator T11527 1 X

39 Insulation T11522 3 X

40 #2-56 x .4375 RHS CF000135 2 X

08-28-2007

K114 SQUIRTGUN & CABLE

Use only the parts marked “x” in the column under the

heading number called for in the model index page.

# Indicates a change this printing.

P-103-E.1

ITEM DESCRIPTION PART NO. QTY. 123456789

P-103-E.1

de o Gu s de o Gu s de o Gu s de o Gu s

Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration

Page 62

41 Lock Washer T9695-10 2 X

42 #2-56 HN CF000136 2 X

Nozzle Extension, 2-1/4” Stickout, (Not Shown) S12891-1 1 X

Housing S13028-1 1 X

Insert T12329-1 1 X

Tip T12328-3/32 1 X

Nozzle Extension, 3-1/4” Stickout, (Not Shown) S12891-2

ø

1X

Housing S13028-2 1 X

Insert T12329-2

ø

1X

Tip T12328-3/32 1 X

Adapter Kit to use Squirtgun K114 w/MN-1 & ML-3

(Not Shown) KP24A-62 1 X

Adapter Kit to use Squirtgun K114 w/ML-2

(Not Shown) S12967

ø

1X

09-25-2008

K114 SQUIRTGUN & CABLE

Use only the parts marked “x” in the column under the

heading number called for in the model index page.

# Indicates a change this printing.

P-103-E.2

ITEM DESCRIPTION PART NO. QTY. 123456789

P-103-E.2

de o Gu s de o Gu s de o Gu s de o Gu s

Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration

ø This part is obsolete and no longer available.

#

Page 63

K114 SQUIRTGUN & CABLE

NOTES

de o Gu s de o Gu s de o Gu s de o Gu s

Page 64

07-16-2007

SQUIRTGUN & CABLE

P-103-F

P-103-F

K115 Squirtgun & Cable

de o Gu s de o Gu s de o Gu s de o Gu s

Part Numbers Part Numbers Part Numbers Part Numbers

NOTE 1: For old contact tips (length 7/8”)

used only with nozzles made before Fall 1968,

order: T12236 – .120

T12236 – 7/64”

T12236 – 3/32"

NOTE: In 1977 the semiautomatic guns were redesigned to conform to NEMA standards. To identify a new

design gun an ampere rating is stencilled on the “Switch Housing Clamp” (Item 14). For new design guns use

columns 5, 6, 7, 8, 9 or 10.

1

4

1717

7

1515

3

2

6

17A17A

17B17B

9

1111

9A9A

9B9B

9C9C

9D9D

1212

8

1414

5

1010

1

Page 65

Gun & Cable Asbly (82º Nozzle): .120 & 7/64 K115-.120* 1 X • • • X • • • • •

Gun & Cable Asbly (82º Nozzle): 3/32 Wire K115-3/32* 1 • X • • • X • • • •

Gun & Cable Asbly (82º Nozzle): 5/64 Wire K115-5/64* 1 • • • • • • • • X •

Gun & Cable Asbly (45ºNozzle): .

120 & 7/64 Wire

K115-45-.120* 1 • • X • • • X • • •

Gun & Cable Asbly (45º Nozzle): 3/32 Wire K115-45-3/32* 1 • • • X • • • X • •

Gun & Cable Asbly (45º Nozzle): 5/64 Wire K115-45-5/64* 1 • • • • • • • • • X

1 Conductor Cable, Includes:

L4230-5* or -10*

1 XXXX••••••

1 Conductor Cable, Includes:

L5728-5* or -10*

1••••XXXX••

1 Conductor Cable, Includes:

L5728-7* or -14*

1 • •••••••XX

Handle, Wire Feeder End M14048 1 X X X X X X X X X X

Connector, Wire Feeder End S12801-6 1 • • • • • • • • X X

Connector, Gun End S12802-4 1 X X X X • • • • • •

Connector, Gun End S12802-13 1 X X X X X X X X X •

Connector, Gun End S12802-14 1 • • • • • • • • X X

Clamping Tube, Both Ends S7748-40 2 X X X X X X X X X X

2 Snap Ring S9776-7 1 X X X X X X X X X X

3 Clamp S15921-1 1 X X X X X X X X X X

4 Clamp & Shield Assembly S12880 1 X X X X X X X X X X

5 #8-32 x .25 Pan Head Screw CF000148 4 X X X X X X X X X X

6 Spatter Shield T12027 1 X X X X X X X X X X

7 Socket Head Cap Screw T9447-9 1 X X X X • • • • • •

7 Socket Head Cap Screw T14438 1 • • • • X X X X X X

8 Handle M10102 1 X X X X • • • • • •

8 Handle M10102-1 1 • • • • X X X X X X

9 Nozzle (82º), Includes:

(M11474-.120) KP1907-1 1 X • • • X • • • • •

9 Nozzle (82º), Includes:

(M11474-3/32) KP1907-2 1 • X • • • X • • • •

9 Nozzle (82º), Includes:

(

M14027-82-5/64) KP1919-2

1 • •••••••X•

9 Nozzle (45º), Includes:

(M11510-.120) KP1910-1 1 • • X • • • X • • •

9 Nozzle (45º), Includes:

(M11510-3/32) KP1910-2 1 • • • X • • • X • •

9 Nozzle (45º), Includes: (

M14027-45-5/64) KP1919-1

1 • ••••••••X

9A

Nozzle Liner, Tight Wound Steel Spring (.120) (T12931-7)

KP2095-6 1 X • X • X • X • • •

9A

Nozzle Liner, Tight Wound Steel Spring (3/32) (T12931-5)

KP2095-5 1 • X • X • X • X • •

9A

Nozzle Liner, Tight Wound Steel Spring (5/64) (T12931-32)

KP2095-13 1 • • • • • • • • X X

9B Nozzle Insert (.120)

(T12576-3) KP2094-3 1 X • X • X • X • • •

9B Nozzle Insert (3/32)

(T12576-1) KP2094-1 1 • X • X • X • X • •

9B Nozzle Insert (5/64)

(T12576-1) KP2094-1 2 • • • • • • • • X X

9C Nozzle Insert Retainer T12977-2 1 X X X X X X X X • •

9D Liner Locking Screw T12932-2 1 X X X X X X X X X X

10 Trigger & Control Cable Assembly

M12462-10 or -15*

1 X XX XXXXXXX

Assembly Parts See P-103-K

11 Insulated Guide, 2-3/4” Electrical Stickout S12691-1 1 X X X X X X X X • •

11 Insulated Guide, 3-3/4” Electrical Stickout S12691-2 1 X X X X X X X X • •

11 Insulated Guide, 1-1/4” Electrical Stickout S13358 1 X X X X X X X X • •

12 Contact Tip (Length 1-1/8”) Note 1

(T14157-.120) KP2103-3 X • X • X • X • • •

12 Contact Tip (Length 1-1/8”) Note 1

(T14157-7/64) KP2103-6 X • X • X • X • • •

12 Contact Tip (Length 1-1/8”) Note 1

(T14157-3/32) KP2103-4 • X • X • X • X • •

12 Contact Tip (Length 1-1/8”) Note 1

(T14157-5/64) KP2103-5 • • • • • • • • X X

12 Contact Tip (Length 1-1/8”) Note 1 (T14157-072) KP2103-1 1 • • • • • • • • X X

14 Switch Housing Clamp S12339 1 X X X X • • • • • •

14 Switch Housing Clamp S15922-1 1 • • • • X X X X X X

15 Shield Mounting Block (Early Guns Only)

(Not Illustrated) T12385

ø

1 X XX XXXXX • •

17 #8-32 x 1.50 RHS CF000119 2 X X X X X X X X X X

17A Lock Washer T9695-3 2 X X X X X X X X X X

17B #8-32 HN CF000042 2 X X X X X X X X X X

18 CCC Decal (Not Shown) T13086-192 1 X X X X X X X X X X

Adapter Kit to use K115 Squirtgun with MN-1 & ML-3 (Not Shown)

M10682

ø

1 X XX XXXXXXX

Adapter Kit to use K115 Squirtgun with ML-2 (Not Shown)

S12967

ø

1 X XX XXXXXXX

08-28-2007

SQUIRTGUN & CABLE

For .120 & 7/64” Electrode Gun, use the parts marked “X” in Column 1, 3, 5 or 7.

For 3/32” Electrode Gun, use the parts marked “X” in Column 2, 4, 6 or 8.

For 5/64” Electrode Gun, use the parts marked “X” in Column 9 or 10

# Indicates a change this printing.

P-103-F.1

ITEM DESCRIPTION PART NO. QTY. 123 456789 10

P-103-F.1

de o Gu s de o Gu s de o Gu s de o Gu s

Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration

#

#

#

#

#

#

#

#

#

#

#

Page 66

06-06-2005

K116 SQUIRTGUN & CABLE

P-103-G

P-103-G

K116 Squirtgun & Cable

de o Gu s6 de o Gu s de o Gu s de o Gu s

Part Numbers Part Numbers Part Numbers Part Numbers

Note: In 1977 the semiautomatic guns were redesigned to conform to NEMA standards. To identify a new

design gun an ampere rating is stencilled in the handle of “ Assembly” (Item 7). For new design guns use

columns 3 or 4.

NOTE 1: For old contact tips (length 7/8”) used only with

nozzles made before Fall 1968, order: T12236-.120

T12236-7/64”

T12236-3/32”

13

1

8

9

10

4C

4D

2

5

3

11

6

7

4

4D

4B

12

1D

1C

1B

1A

4A

4B

4D

4A

13

4D

4C

11

10

1A

1B

1C

1D

12

Page 67

Gun & Cable Assembly-.120” & 7/64” Electrode K116-.120* 1 X • X •

Gun & Cable Assembly - 3/32” Electrode K116-3/32* 1 • X • X

1 Nozzle, Includes: M11475-.120 1 X • X •

1 Nozzle, Includes: M11475 - 3/32 1 • X • X

1A Nozzle Liner, Tight Wound Steel Spring (T12931-8) KP2095-7 1 X • X •

1A Nozzle Liner, Tight Wound Steel Spring T12931-6

ø

1•X•X

1B Nozzle Insert (T12576-3) KP2094-3 1 X • X •

1B Nozzle Insert (T12576-1) KP2094-1 1 • X • X

1C Nozzle Insert Retainer T12977-2 1 XXXX

1D Liner Locking Screw T12932-2 1 XXXX

2 Switch Housing Clamp S12339-1 1 XXXX

3 Handle M10102 1 X X • •

3 Handle M10102-1 1 • • X X

4 15ʼ Conductor Cable, Includes: L5728-5* 1 XXXX

4 15ʼ Conductor Cable, Includes: L5728-10* 1 XXXX

4 10ʼ Conductor Cable, Includes: L4230-10* 1 X X • •

4 10ʼ Conductor Cable, Includes: L5728-10* 1 • • X X

4A Handle, Wire Feeder End M14048 1 XXXX

4B Connector, Wire Feeder End S12801-4 1 XXXX

4C Connector, Gun End S12802-4 1 X X • •

4C Connector, Gun End S12802-13 1 • • X X

4D Clamping Tube, Both Ends S7748-40 2 XXXX

5 8-32 x 1/4 Pan Head Screw CF000049 4 XXXX

6 Socket Head Screw S11604-9 2 XXXX

7 Handle & Control Cable Assembly - 15ʼ Length L5734-15*

ø

1 XXXX

7 Handle & Control Cable Assembly - 10ʼ Length L4189-10* 1 X X • •

7 Handle & Control Cable Assembly - 10ʼ Length L5734-10* 1 • • X X

Assembly Parts See P-103-H 1 • • X X

8 Spatter Shield T12027 1 XXXX

9 Snap Ring S9776-7 1 XXXX

10 Clamp S11598-1 1 X X • •

10 Clamp S15921-2 1 • • X X

11 Socket Head Cap Screw T9447-9 1 X X • •

11 Socket Head Cap Screw T14438 1 • • X X

12 Contact Tip (Length 1-1/8”) Note 1 (T14157-.120) KP2103-3

As Reqʼd

X• X•

12 Contact Tip (Length 1-1/8”) Note 1

(T14157-7/64) KP2103-6

As Reqʼd

X• X•

12 Contact Tip (Length 1-1/8”) Note 1 (T14157-3/32) KP2103-4

As Reqʼd

•X•X

13 Insulated Guide, 2-3/4” Electrical Stickout (S12691-1) KP1965-1 1 XXXX

13 Insulated Guide, 3-3/4” Electrical Stickout (S12691-2) KP1965-2 1 X • • •

13 Insulated Guide, 1-1/2” Electrical Stickout (S13358) KP1971-1 1 • X X X

Adapter Kit to Use K116 w/MN-1 & ML-3 (Not Shown)

M10682

ø

1 XXXX

Adapter Kit to Use K116 with ML-2 (Not Shown) S12967

ø

1 XXXX

08-28-2007

K116 SQUIRTGUN & CABLE

Use only the parts marked “x” in the column under the

heading number called for in the model index page.

# Indicates a change this printing.

P-103-G.1

ITEM DESCRIPTION PART NO. QTY. 123456789

P-103-G.1

de o Gu s de o Gu s de o Gu s de o Gu s

Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration

For .120 & 7/64” Electrode Gun, use the parts marked “X” in Column 1 or 3 (See Note).

For 3/32” Electrode Gun, use the parts marked “X” in Column 2 or 4 (See Note)

ø This part is obsolete and no longer available.

#

#

#

#

#

#

* Specify 15ʼ or 10ʼ Cable as Appropriate

Page 68

08-26-2008

K116 SQUIRTGUN HANDLE & CONTROL CABLE

P-103-HP-103-H

K116 Squirtgun Handle & Control Cable

de o Gu s de o Gu s de o Gu s de o Gu s

Part Numbers Part Numbers Part Numbers Part Numbers

4

1

3

6

21

5

11

12

26

17

22

20

19

13A

25

7

24

10

9

13

13C

13B

8

15

14

16

13B

13C

13

13A

14

19

16

20

10

24

25

26

22

12

11

21

17

15

Page 69

Squirtgun Handle & Control Cable K116

Handle & Control Cable Assembly - 15ʼ Length L5734-15 1 X

Handle & Control Cable Assembly - 10ʼ Length L5734-10 1 X

Handle & Control Cable Assembly - 15ʼ Length L4189-15 1 X

Handle & Control Cable Assembly - 10ʼ Length L4189-10 1 X

1 Handle Mounting Bracket S12905 1 X

3 Socket Head Cap Screw T9447-36 2 X

4 Socket Head Cap Screw T9447-22 2 X

5 #8-32 x .5 RHS CF000033 12 X

6 Handle Pivot Block S12690 2 X

7 #8-32 x .625 FHS CF000147 2 X

8 Lock Washer T10441-1 2 X

9 Insulating Pad T12241 1 X

10 #8-32 x .5 FHS CF000146 3 X

11 Lock Washer T4291-A 2 X

12 #8-32 HN CF000042 2 X

13 Control Cable, Includes: 15ʼ Length M10427-15 1 X

13 Control Cable, Includes: 10ʼ Length M10427-10 1 X

13A Micro Switch T12485 1 X

13B Polarized Plug, Wire Feeder End S12020-6 1 X

13C Clamp at Plug S12024-1 1 X

14 Friction Bushing T12233 2 X

15 Handle Pivot Shaft T12239 1 X

16 Snap Ring S9776-25 2 X

17 Trigger Assembly S23982 [*] 1 X

19 Spring T12025 1 X

20 Trigger Mounting Block (Straight Pull Trigger) S12688 1 X

20 Trigger Mounting Block (Pivoting Trigger) M18910 1 X

21 Gun Shield L4188 1 X

22 #3-48 x .75 RHS CF000312 2 X

24 Handle S12687-1 1 X

25 Switch Insulation S14878 1 X

26 Roll Pin T9967-52 1 X

08-26-2008

K116 SQUIRTGUN HANDLE & CONTROL CABLE

# Indicates a change this printing.

P-103-H.1

ITEM DESCRIPTION PART NO. QTY. 123456789

P-103-H.1

de o Gu s de o Gu s de o Gu s de o Gu s

Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration

[*] For earlier design “straight pull” (non-pivoting) trigger, contact Customer Service

for replacement parts

#

Page 70

06-06-2005

K126 SQUIRTGUN & CABLE

P-103-JP-103-J

K126 Squirtgun & Cable

de o Gu s de o Gu s de o Gu s de o Gu s

Part Numbers Part Numbers Part Numbers Part Numbers

Note: In 1977 the semiautomatic guns were redesigned to conform to Nema standards. To identify a new

design gun an ampere rating is stencilled on the “Clamp” (Item 12). For new design guns use column 2.

Note 1: For old contact tips (length 7/8”) used only

with nozzles made before Fall 1968, order:

T12011-5/64”

T12011-3/32”

T12011-.068

Note 2: When tip life is limited by tip being fused

over the use of T14726-[ ]

ø

tips may result in a

lower overall cost.

10

15

10A

10B

10C

10D

8

14

18

17

16

5

3

4

2C

2D

1

7

11

12

6

2

2A

2D

2B

ø This part is obsolete and no longer available.

12

2B

2D

2A

15

10

18

2D

2C

17

10B

10C

10D

10A

16

14

11

Page 71

Gun & Cable Assembly, Includes: K126* 1 X X

1 Handle M10102-1 1 • X

1 Handle M10102 1 X •

2 Conductor Cable, Includes: (15ʼ) L6250-1* 1 • X

2 Conductor Cable, Includes: (15ʼ) L4230-4* 1 X •

2 Conductor Cable, Includes: (10ʼ) L6250-2* 1 • X

2 Conductor Cable, Includes: (10ʼ) L4230-11* 1 X •

2A Handle & Stiffener, Wire Feeder End S13099 1 X X

2A Handle & Stiffener, Wire Feeder End M14050-1 1 • X

2B Connector, Wire Feeder End S12801-3 1 X X

2C Connector, Gun End S12802-12 1 • X

2C Connector, Gun End S12802-3 1 X •

2D Clamping Tube, Both Ends S16997 2 • X

2D Clamping Tube, Both Ends S7748-40 2 X •

3 Snap Ring S9776-7 1 X X

4 Clamp S15921-2 1 • X

4 Clamp S11598-1 1 X •

5 Spatter Shield T12027 1 X X

6 8-32 x 1/4 PHS CF000148 4 X X

7 Socket Head Cap Screw T14438 1 • X

7 Socket Head Cap Screw T9447-9 1 X •

8 Contact Tip, 5/64” Electrode

(Length 1-1/8”) Note 1 & 2

KP2100-4

As Reqʼd

XX

8 Contact Tip, 3/32” Electrode

(Length 1-1/8”) Note 1 & 2

KP2100-3

As Reqʼd

XX

8 Contact Tip, .068” & .072”

Electrode (Length 1-1/8”) Note 1 & 2

KP2100-1

As Reqʼd

XX

8 Contact Tip, .062” Electrode

(Length 1-1/8”) Note 2

KP2100-2

As Reqʼd

XX

10 Nozzle, Includes: (M11476) KP1909-1 1 X X

10A Nozzle Liner, Tight Wound Steel Spring (T12931-4) KP2095-4 1 X X

10B Nozzle Insert (T12576-2) KP2094-2 1 X X

10C Nozzle Insert Retainer T12977-1 1 X X

10D Liner Locking Screw T12932-1 1 X X

11 Trigger & Control Cable Assembly M12462* 1 X X

Assembly Parts See P-103-K 1 X X

12 Clamp S15922-1 1 • X

12 Clamp S12339 1 X •

13 Insulated Guide, 2-3/4” Electrical Stickout

(Optional)t

(Not Shown) T12315 1 X X

13 Insulated Guide, 2.00” Electrical Stickout

(Optional)

(Not Shown) S17217-1 1 X X

14 Heat Shield Assembly S13037 1 X X

15 Thread Protector, 3/4 to 1-1/2” Stickout (T12313) KP2089-1 1 X X

16 #8-32 x 1-1/2 Round Head Screw CF000119 4 X X

17 Lock Washer T9695-3 2 X X

18 #8-32 Hex Nut CF000042 2 X X

Adapter Kit to use K126 with MN-1 or ML-3 M10682

ø

1XX

Adapter Kit to use K126 with ML-2 S12967

ø

1XX

* Specify Length 15ʼ or 10ʼ as appropriate.

08-28-2007

K126 SQUIRTGUN & CABLE

Use only the parts marked “x” in the column under the

heading number called for in the model index page.

# Indicates a change this printing.

P-103-J.1

ITEM DESCRIPTION PART NO. QTY. 123456789

P-103-J.1

de o Gu s de o Gu s de o Gu s de o Gu s

Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration

This part is obsolete and no longer available.

#

#

#

#

Page 72

P-103-K

suGoedsuGoedsuGoedsuGoed

Trigger & Control Cable Assembly

srebmuN traPsrebmuN traPsrebmuN traPsrebmuN traP

P-103-K

12

12A

13D

8

13B

13A

4

13C

1

2

9

7

5

3

TRIGGER & CONTROL CABLE ASSEMBLY

07-25-2006

Page 73

P-103-K.1

suGoedsuGoedsuGoedsuGoed

P-103-K.1

# Indicates a change this printing.

K183, K289 & K206 guns. Use the parts marked “X” in column 2 for

K264, K345, K355, & K361 guns.

.YTQ .ON TRAP NOITPIRCSED METI 1 2 3 4 5 6 7 8 9

Trigger & Control Cable Assembly, Includes: M12462-15ʼ 1 X •

Trigger & Control Cable Assembly, Includes: M12462-10ʼ 1 X X

Trigger & Control Cable Assembly, Includes: M12462-8ʼ 1 • X

XX158421ThctiwS orciM1

XX160701LgnisuoH2

XX1]*[ 28932SylbmessA reggirT3

XX12-96611TpmalC droC4

XX152021TgnirpS5

XX125-7699TniP lloR6

XX2213000FCSHR 57. x 84-3#7

XX187841SnoitalusnI hctiwS8

XX122-40611SwercS teS9

Use the parts marked “X” in column 1 for K112, K113, K115, K126,

12 Polarized Plug, Wire Feeder End,

(Not Shown) (Old Style)

S12020-6 1 X •

12 Polarized Plug, Wire Feeder End S12020-16 1 • X

12A Clamp at Polarized Plug (Old Style) (Not Shown) S12024-1 1 X •

X•14-42021SgulP deziraloP ta pmalCA21

XX175791S:sedulcnI ,tiK gulP dedloM

13A Connector Body NSS 1 X X

13B Connector Cover NSS 1 X X

13C Connector Pin NSS 2 X X

13D Insulating Washer NSS 1 X X

13E Strain Relief (Not Shown) NSS 1 X X

[*] For earlier design “straight pull” (non-pivoting) trigger, contact Service Department

for replacement parts.

Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration

NSS - Not Sold Separately

TRIGGER & CONTROL CABLE ASSEMBLY

07-25-2006

Page 74

05-03-2010

MAGNUM

®

300 & 400 GMAW GUN

P-202-CP-202-C

Magnum 300 & 400 GMAW Gun

6

8

9

5

15

2A

2B

1

2C

2A

16A

3

17

16B

4

18

20

12

11

7

de o ag u Gu s de o ag u Gu s de o ag u Gu s de o ag u Gu s

Part Numbers Part Numbers Part Numbers Part Numbers

2A

2C

18

20

17

16B

15

2A

16A

2B

11

12

Page 75

Gun & Cable Assembly:

300 Amp-Specify cable length & wire size. K470-[ ] 1 X •

300 Amp-Specify cable length & wire size. K2951-[ ] 1 • X

400 Amp-Specify cable length & wire size. K471-[ ] 1 X •

**400 Amp-Specify cable length & wire size. K541-[ ] 1 X •

400 Amp-Specify cable length & wire size. K2952-[ ] 1 • X

1 Connector Assembly See P-202-C.2 1 X X

2A Gun Handle (Left & Right) G1927 1 X X

2B Pan Head Screw (for Handle) S18825-1 3 X X

2C Handle Nut (Knurled) S18773 3 X X

3 Trigger Assembly (Non Interlocking-Standard) S21002 1 X X

3 Trigger Assembly (Interlocking-Parts Order Only) S20677 * 1XX

4 Spring Boot Retainer (Gun End Only) S24719 1 X X

5 Connector Cover L7723 1 X X

6 Nut (Cable Handle) S18690 1 X X

7 Gun Tube Assembly

See Chart P-202-C.4 1 X •

7 Gun Tube Assembly

See Chart P-202-C.6 1 • X

8 Tail Piece M15607 1 X X

9 Gas Plug Assembly S18695 1 X X

11 Slip on Nozzle Insulator

See Chart P-202-C.4

1X•

11 Slip on Nozzle Insulator

See Chart P-202-C.6 1 • X

12 Gas Nozzle

See Chart P-202-C.4

1X•

12 Gas Nozzle

See Chart P-202-C.6 1 • X

15 Decal 300 Amp S18750-1 1 X X

15 Decal 400 Amp S18750-2 1 X X

16 Collar Assembly, Includes: S18831 1 X X

16A Collar S18830 1 X X

16B Set Screw S11604-46 1 X X

17 Hanger M15693 1 X X

18 Contact Tip

See Chart P-202-C.4 1X•

18 Contact Tip See Chart P-202-C.6 1 • X

20 Gas Diffuser

See Chart P-202-C.4

1X•

20 Gas Diffuser

See Chart P-202-C.6 1 • X

Items Not Shown:

Cable Liners

See Chart P-202-C.4 1X•

Cable Liners

See Chart P-202-C.6 1 • X

Options:

Magnum Connector Kits

See Chart P-202-C.4 1XX

Magnum Fast-Connect Gas Tube Kit (for K466-1) Order K481 1 X X

05-03-2010

MAGNUM

®

300 & 400 GMAW GUN

Use only the parts marked “x” in the column under the

heading number called for in the model index page.

# Indicates a change this printing.

P-202-C.1

ITEM DESCRIPTION PART NO. QTY. 123456789

P-202-C.1

*Trigger requires latest version of Gun Handles.

** Comes with 300 Amp Gun Tube

de o ag u Gu s de o ag u Gu s de o ag u Gu s de o ag u Gu s

Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration

Page 76

05-03-2010

MAGNUM

®

300 & 400 GMAW GUN

P-202-C.2P-202-C.2

Connector Assembly

de o ag u Gu s de o ag u Gu s de o ag u Gu s de o ag u Gu s

Part Numbers Part Numbers Part Numbers Part Numbers

8

2

7

6

1

10

11

7

3

11

10

Page 77

Connector Assembly (300A/10ʼ Cable) L7773-1 1 X

Connector Assembly (300A/15ʼ Cable) L7773-2 1 X

Connector Assembly (400A/10ʼ Cable) L7773-3 1 X

Connector Assembly (400A/15ʼ Cable) L7773-4 1 X

Connector Assembly (300A/12ʼ Cable) L7773-5 1 X

Connector Assembly (400A/12ʼ Cable) L7773-6 1 X

Connector Assembly (400A/20ʼ Cable) L7773-7 1 X

Connector Assembly (400A/25ʼ Cable) L7773-8 1 X

Includes:

1 Incoming Connector Assembly S18789 1 X

2 Connector Nut (300 Amp) S18749-1 2 X

2 Connector Nut (400 Amp) S18749-2 2 X

3 Cable Handle L7725 1 X

4 Cable Assembly: (Includes 4A)

300 Amp, 10 Ft. Cable L7761-3 1 X

300 Amp, 12 Ft. Cable L7761-17 1 X

300 Amp, 15 Ft. Cable L7761-4 1 X

400 Amp, 10 Ft. Cable L7761-5 1 X

400 Amp, 12 Ft. Cable L7761-18 1 X

400 Amp, 15 Ft. Cable L7761-6 1 X

400 Amp, 20 Ft. Cable L7761-19 1 X

400 Amp, 25 Ft. Cable L7761-20 1 X

4A Terminal (For Mating Gun Connector End) S19492-1 2 X

5 Spring Boot S24676 2 X

6 Strain Relief Housing S18786 1 X

7 Strain Relief S18787 2 X

8 Gun Tube Connector Assembly, Includes: S18655 1 X

Gun Tube Connector M15635 1 X

Tube S18847 1 X

“O” Ring T13483-8 1 X

Nozzle Clamp S15921-2 1 X

Clamping Screw T14438 1 X

Retaining Ring S9776-7 1 X

9 Spring Boot Retainer S24678 1 X

10 Incoming End Nut (300 Amp) S23822-300 1 X

10 Incoming End Nut (400 Amp) S23822-400 1 X

11 Strain Relief Housing S24677 1 X

05-03-2010

MAGNUM

®

300 & 400 GMAW GUN

Use only the parts marked “x” in the column under the

heading number called for in the model index page.

# Indicates a change this printing.

P-202-C.3

ITEM DESCRIPTION PART NO. QTY. 123456789

P-202-C.3

de o ag u Gu s de o ag u Gu s de o ag u Gu s de o ag u Gu s

Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration Sub Assembly Illustration

Page 78

PARTS

MAGNUM®300 & 400 GMAW GUN

P-202-C.4P-202-C.4

CHART A

Contact Tips/ Part Number English Metric

Gas Diffuser (Industry Ref.) Wire Size Wire Size

Standard Duty KP14-25 or KP14-25-B100 .025” 0.6 mm

KP14-30 or KP14-30-B100 .030” 0.8 mm

KP14-35 or KP14-35-B100 .035” 0.9 mm

KP14-40 or KP14-40-B100 .040” 1.0 mm

KP14-45 or KP14-45-B100 .045” 1.2 mm

KP14-52 or KP14-52-B100 .052” 1.3 mm

KP14-116 or KP14-116-B100 1/ 16” 1.6 mm

KP14-564 or KP14-564-B100 5/64” 2.0 mm

KP14A-364 or KP14A-364-B100 3 /6 4A 1.2mm

Heavy D uty KP14H-35 or KP14H-35-B100 .035” 0.9 mm

KP14H-40 or KP14H-40-B100 .040” 1.0 mm

KP14H-45 or KP14H-45-B100 .045” 1.2 mm

KP14H-52 or KP14H-52-B100 .052” 1.3 mm

KP14H-116 or KP14H-116-B100 1/ 16 ” 1.6 mm

KP14H-564 or KP14H-564-B100 5/ 64 ” 2.0 mm

KP14AH-364 or KP14AH-364-B100 3/64”A 1.2 mm

KP14AH-116 or KP14AH-116-B100 1/16”A 1.6 mm

Tapered KP14T-25 or KP14T-25-B100 .025” 0.6 mm

KP14T-30 or KP14T-30-B100 .030” 0.8 mm

KP14T-35 or KP14T-35-B100 .035” 0.9 mm

KP14T-40 or KP14T-40-B100 .040” 1.0 mm

KP14T-45 or KP14T-45-B100 .045” 1.2 mm

KP14T-52 or KP14T-52-B100 .052” 1.3 mm

KP14T-116 or KP14T-116-B100

1/16” 1.6 mm

Notched KP2010-4B1 .035” 0.9mm

Aluminum -5B1 3/64” 1.2mm

Gas Diffuser Asbly.

KP54A or KP54A-B25 .025-5/64” 0.6-2.0 mm

Gas Diffuser Asbly.

KP2024-2 or -2B1 .025-.035” 0.6-0.9 mm

CHART B

Gas Nozzles/ Part Number English Metric

Insulator (Industry Ref.) I.D. Size I.D. Size

Adjustable Slip-On KP24A-62 .62” 15.9 mm

(Requires Nozzle KP24A-50 .50” 12.7 mm

Insulator Assembly)

Recessed Slip-On KP24A-62-SS .62” 15.9 mm

(Requires Nozzle KP24A-50-SS .50” 12.7 mm

Insulator Assembly) KP24A-37-SS .37” 9.5 mm

Nozzle Insulator KP34A or KP34A-B25 — —

Assembly

Fixed Nozzle KP23-37 .38” 9.5 mm

Tip Recessed .12 in. KP23-50 .50” 12.7 mm

(3 mm) for KP23-62 .62” 15.9 mm

Spray Transfer KP23-75 .75” 19.1 mm

KP23T-37 .37” 9.5mm

Fixed Nozzle (Heavy Duty) Tip

KP23H-62 .62” 15.9mm

Recessed .12 in. (3mm)

KP1954-2 .75” 19.1mm

Spray Transfer

Fixed Nozzle KP23-37F .38” 9.5 mm

Tip Flush for KP23-50F .50” 12.7 mm

Short-Circuiting KP23-62F .62” 15.9 mm

Transfer KP23-75F .75” 19.1 mm

Coarse Thread Nozzle

(1)

1/8” (3.2mm) Recess KP24CT-62-S .62” 16mm

1/8” (3.2mm) Recess KP24CT-75-S .75” 19mm

1/4” (6.4mm) Recess KP24CT-62-R .62” 16mm

1/4” (6.4mm) Recess KP24CT-75-R .75” 19mm

Coarse Thread KP34CT

——

Insulator Assembly

Gun Tube Insulator KP2169-1 — —

CHART D

Gun Tube Part Number

60° KP1928-1 (400 amp)

-2 (300 amp)

45° KP1929-1 (400 amp)

-2 (300 amp)

82° KP1941-1 (300, 400 amp)

CHART E

Connector Kits

(1)

Trigger Gas Tube

Product Feeder Power Lead and Connector

Number Type Connector Connector Fitting Tools

K466-1 Lincoln

(2)

4444

K466-2

Tweco Adapted

4——4

Lincoln 10 Series

K466-3 Miller 4 4 — 4

K466-4 Hobart 27 4 4 4 4

K466-5 L-Tec 4 4 — 4

Adapted

K466-6 Wirematic &

Power Mig 4 4 — 4

K466-7 Hobart 4 4 — 4

Series 2000

K466-8 Lincoln

(3)

4444

K466-9 SP100T and 4 4 — 4

Related Units

K466-10

Lincoln 10 Series

44—4

(1)

See Magnum 300 & 400 Parts Manual for part numbers.

(2)

Except LN8 or LN9 using 1/16 and larger electrodes.

(3)

LN8 or LN9 using 1/16 and larger electrodes.

(1)

Requires Coarse Thread Insulator Assembly.

05-03-2010

CHART C

Cable Liner Part Number English Metric

For Steel (Industry Ref.) Wire Size Wire Size

For 15 ft (4.5 m) KP44-3545-15 .035 - .045” 0.9-1.2 mm

and less KP44-116-15 .052 - 1/16” 1.3-1.6 mm

Trim to Fit KP44-564-15 1/16 - 5/64” 1.6-2.0 mm

KP42-25-15 .025-.030” 0.6-0.8 mm

For cables 25 ft KP44-3545-25 .035 - .045” 0.9-1.2 mm

(7.6 m) and less KP44-116-25 .052 - 1/16” 1.3-1.6 mm

Trim to Fit KP44-564-25 1/16 - 5/64ʼʼ 1.6-2.0 mm

Cable Liner Part Number English Metric

for Aluminum (Industry Ref.) Wire Size Wire Size

For 10 ft (3 m) KP1958-1 .030 - .035” 0.8-0.9 mm

Trim to Fit KP1958-5 .035 - 3/64” 0.9 - 1.2mm

KP1958-3 1/16” 1.6 mm

For 15 ft (4.5 m) KP1958-2 .030 - .035” 0.8-0.9 mm

Trim to Fit KP1958-6 .035 - 3/64” 0.9 - 1.2mm

KP1958-4 1/16” 1.6 mm

KP42N354515 .035 - 3/64” 0.9 - 1.2mm

KP1955-2 1/16” 1.6mm

de o ag u Gu s de o ag u Gu s de o ag u Gu s de o ag u Gu s

Page 79

PARTS

MAGNUM®300 & 400 GMAW GUN

Part No.

K466-1 Connector Kit (Lincoln Wire Feeders)

Gas Tubing T10642-127

Tubing Clamp (2 required) T13777-4

Connector Assembly, Includes: S18645

Set Screw S11604-51

Insulation Tube T7028-234

Gun Control Cable M15608

Hose Nipple T14557-7

Socket Key T11563-4

Wrench S18845

K466-2 Connector Kit (For Tweco Adapted

Feeders)

Connector Assembly, Includes: S18653

Set Screw S11604-51

“O” Ring (2 required) T13483-8

Socket Key T11563-4

Wrench S18845

Hair Spring Cotter Pin S19762

K466-3 Connector Kit (For Miller Feeders)

Connector Assembly (Miller), Includes: S19760

“O” Ring (2 required) T13483-8

Connector Cap Assembly (Miller), Includes: S19761

Set Screw S11604-51

Gun Control Assembly (Miller) M16325

Wrench S18845

Socket Key T11563-4

Liner Material - .045” (1.2 mm) maximum S18685-12

Liner Material - 1/16” (1.6 mm) maximum S18685-13

Liner Material - 5/64” (2.0 mm) maximum S18685-14

K466-4 Connector Kit (For Hobart Feeders)

Connector (Hobart) S19763

Connector Cap Assembly (Hobart), Includes: S19765

Set Screw S11604-51

Gun Control Assembly (Hobart) M16328

Wrench S18845

Socket Key T11563-4

Liner Material - .045” (1.2 mm) maximum S18685-15

Liner Material - 1/16” (1.6 mm) maximum S18685-16

Liner Material - 5/64” (2.0 mm) maximum S18685-17

Hose Nipple T14557-7

Tubing Clamps (2 required) T13777-4

Gas Tubing T10642-166

K466-5 Connector Kit (For L-Tec Adapted

Feeders)

Connector Assembly (L-Tec), Includes: S20044

Set Screw S11604-51

“O” Ring (2 required) T13483-8

Socket Key T11563-4

Wrench S18845

Gun Control Assembly (L-Tec) M16520

Part No.

K466-6 Connector Kit (Wirematic)

Connector Assembly, Includes: S18653

Set Screw S11604-51

“O” Ring (2 required) T13483-8

Gun Control Assembly M16325

Socket Key T11563-4

Wrench S18845

K466-7 Connector Kit (Hobart Series 2000)

Connector Assembly, Includes: S18653

Set Screw S11604-51

“O” Ring (2 required) T13483-8

Socket Key T11563-4

Wrench S18845

Gun Control Cable Assembly M18003

K466-8 Connector Kit (Lincoln Wire Feeders)

Gas Tubing T10642-127

Tubing Clamp (2 required) T13777-4

Connector Assembly, Includes: S18645-2

Set Screw S11604-51

Insulation Tube T7028-234

Gun Control Cable M15608

Hose Nipple T14557-7

Socket Key T11563-4

Wrench S18845

K466-9 Connector Kit (Lincoln SP100T, SP125

& SP170T)

Connector Assembly, Includes: S18653-2

Set Screw S11604-51

“O” Ring (2 required) T13483-8

Socket Key T11563-4

Wrench S18845

Gun Control Cable Assembly M18003

K466-10 Connector Kit (Lincoln 10 Series)

Connector Assembly, Includes: S18653

Set Screw S11604-51

“O” Ring (2 required) T13483-8

Socket Key T11563-4

Wrench S18845

Gun Control Cable M15608

PARTS LIST OF MAGNUM CONNECTOR KITS

P-202-C.5P-202-C.5

05-03-2010

de o ag u Gu s de o ag u Gu s de o ag u Gu s de o ag u Gu s

Page 80

de o Sub sse b es de o Sub sse b es de o Sub sse b es de o Sub sse b es

PARTS

MAGNUM®300 & 400 GMAW GUN

P-202-C.6P-202-C.6

05-03-2010

CHART A

Contact Tips/ Part Number English Metric

Gas Diffuser (Industry Ref.) Wire Size Wire Size

250A/350A

KP2744-035 or KP2744-035-B100

.035” 0.9 mm

KP2744-045 or KP2744-045-B100

.045” 1.2 mm

KP2744-052 or KP2744-052-B100

.052” 1.3 mm

KP2744-116 or KP2744-116-B100

1/16” 1.6 mm

KP2744-564 or KP2744-564-B100

5/64” 2.0 mm

450A/550A

KP2745-035 or KP2745-035-B100

.035” 0.9 mm

KP2745-045 or KP2745-045-B100

.045” 1.2 mm

KP2745-052 or KP2745-052-B100

.052” 1.3 mm

KP2745-116 or KP2745-116-B100

1/16” 1.6 mm

KP2745-564 or KP2745-564-B100

5/64” 2.0 mm

Gas Diffuser Asbly:

250A/350A Thread-On

KP2746-1 or KP2746-1-B25

250A/

350A Slip-On

KP2746-2 or KP2746-2-B25

450A/550A Thread-On

KP2747-1 or KP2747-1-B25

4

50A/550A Slip-On

KP2747-2 or KP2747-2-B25

CHART B

Gas Nozzles Part Number English Metric

(Industry Ref.) I.D. Size I.D. Size

250A/350A Thread-On

1/8” Recess KP2742-1-50R .50” 12.7 mm

KP2742-1-50R-B25 .50” 12.7 mm

KP2742-1-62R .625” 15.9 mm

KP2742-1-62R-B25 .625” 15.9 mm

Flush KP2742-1-50F .50” 12.7 mm

KP2742-1-50F-B25 .50” 12.7 mm

KP2742-1-62F .625” 15.9 mm

KP2742-1-62F-B25 .625” 15.9 mm

1/8” Stickout KP2742-1-50S .50” 12.7 mm

KP2742-1-50S-B25 .50” 12.7 mm

KP2742-1-62S .625” 15.9 mm

KP2742-1-62S-B25 .625” 15.9 mm

250A/350A Slip-On

1/8” Recess KP2742-2-50R .50” 12.7 mm

KP2742-2-50R-B25 .50” 12.7 mm

KP2742-2-62R .625” 15.9 mm

KP2742-2-62R-B25 .625” 15.9 mm

Flush KP2742-2-50F .50” 12.7 mm

KP2742-2-50F-B25 .50” 12.7 mm

KP2742-2-62F .625” 15.9 mm

KP2742-2-62F-B25 .625” 15.9 mm

1/8” Stickout KP2742-2-50S .50” 12.7 mm

KP2742-2-50S-B25 .50” 12.7 mm

KP2742-2-62S .625” 15.9 mm

KP2742-2-62S-B25 .625” 15.9 mm

450A/550A Thread-On

1/8” Recess KP2743-1-62R .625” 15.9 mm

KP2743-1-62R-B25 .625” 15.9 mm

KP2743-1-75R .75” 19.1 mm

KP2743-1-75R-B25 .75” 19.1 mm

Flush KP2743-1-62F .625” 15.9 mm

KP2743-1-62F-B25 .625” 15.9 mm

KP2743-1-75F .75” 19.1 mm

KP2743-1-75F-B25 .75” 19.1 mm

1/8” Stickout KP2743-1-62S .625” 15.9 mm

KP2743-1-62S-B25 .625” 15.9 mm

KP2743-1-75S .75” 19.1 mm

KP2743-1-75S-B25 .75” 19.1 mm

450A/550A Slip-On

1/8” Recess KP2743-2-62R .625” 15.9 mm

KP2743-2-62R-B25 .625” 15.9 mm

KP2743-2-75R .75” 19.1 mm

KP2743-2-75R-B25 .75” 19.1 mm

Flush KP2743-2-62F .625” 15.9 mm

KP2743-2-62F-B25 .625” 15.9 mm

KP2743-2-75F .75” 19.1 mm

KP2743-2-75F-B25 .75” 19.1 mm

1/8” Stickout KP2743-2-62S .625” 15.9 mm

KP2743-2-62S-B25 .625” 15.9 mm

KP2743-2-75S .75” 19.1 mm

KP2743-2-75S-B25 .75” 19.1 mm

CHART C (250/350/450 Amp)

Cable Liner Part Number English Metric

For Steel (Industry Ref.) Wire Size Wire Size

For 15 ft (4.5 m) KP44-3545-15 .035 - .045” 0.9-1.2 mm

and less KP44-116-15 .052 - 1/16” 1.3-1.6 mm

Trim to Fit KP44-564-15 1/16 - 5/64” 1.6-2.0 mm

KP42-25-15 .025-.030” 0.6-0.8 mm

For cables 25 ft KP44-3545-25 .035 - .045” 0.9-1.2 mm

(7.6 m) and less KP44-116-25 .052 - 1/16” 1.3-1.6 mm

Trim to Fit KP44-564-25 1/16 - 5/64ʼʼ 1.6-2.0 mm

Cable Liner Part Number English Metric

for Aluminum (Industry Ref.) Wire Size Wire Size

For 10 ft (3 m) KP1958-1 .030 - .035” 0.8-0.9 mm

Trim to Fit KP1958-5 .035 - 3/64” 0.9 - 1.2mm

KP1958-3 1/16” 1.6 mm

For 15 ft (4.5 m) KP1958-2 .030 - .035” 0.8-0.9 mm

Trim to Fit KP1958-6 .035 - 3/64” 0.9 - 1.2mm

KP1958-4 1/16” 1.6 mm

KP42N354515 .035 - 3/64” 0.9 - 1.2mm

KP1955-2 1/16” 1.6mm

CHART E

Gun Tube Part Number

60° KP2925-60 (300 Amp)

60° KP2926-60 (400 Amp)

CHART D

Insulators Part Number

250A/350A KP2773-2 or KP2773-2-B25

450A/550A KP2773-1 or KP2773-1-B25

Page 81

MAGNUM®300 & 400 GMAW GUN

NOTES

de o Sub sse b es de o Sub sse b es de o Sub sse b es de o Sub sse b es

Page 82

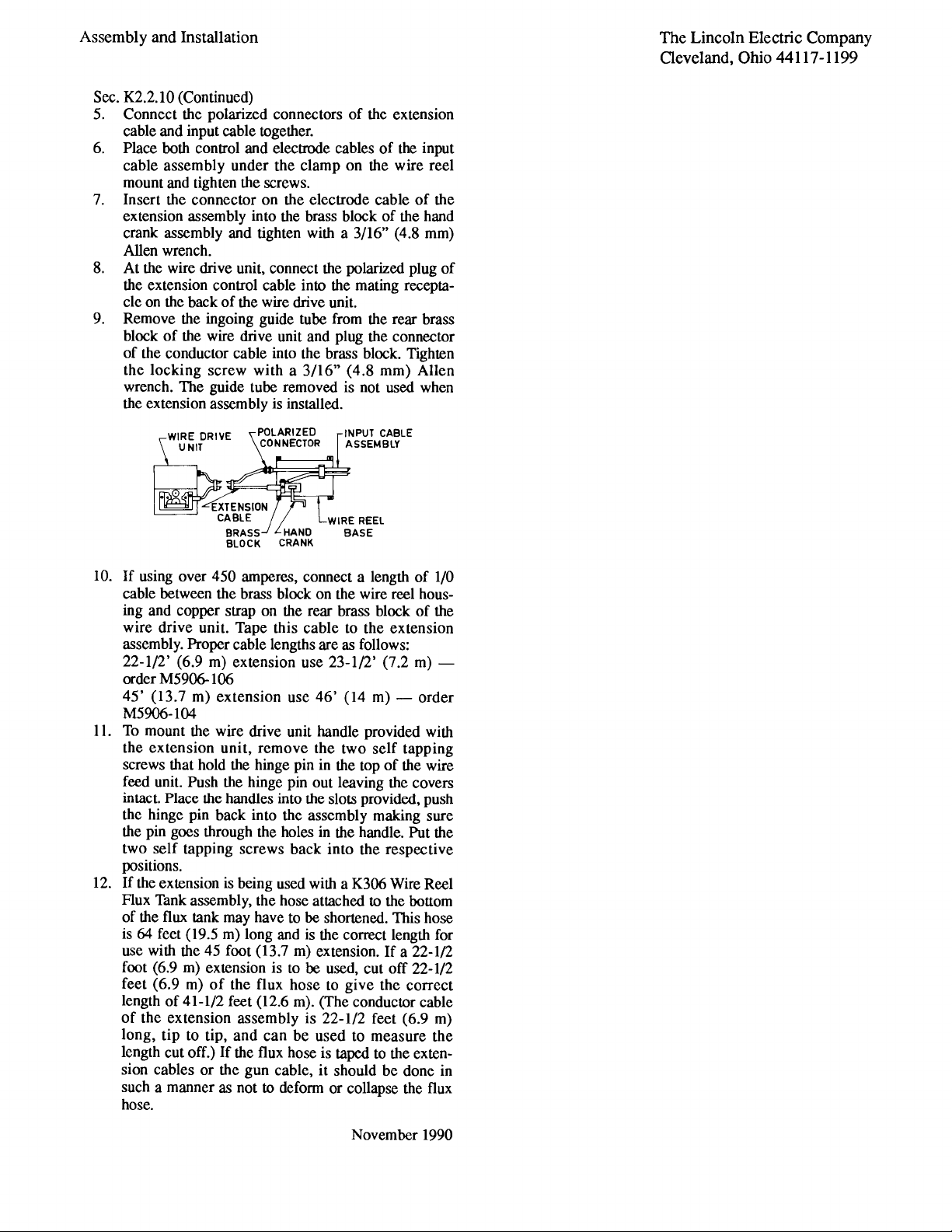

LN-8 WIRE FEED UNIT

(Except LN-8F)

P-110-CP-110-C

21 30 29 40

7

10

1

2

3

45

FRONT VIEW

17

18

34

24

41

39

12

SIDE VIEW BACK VIEW

33

19

32

152614

Par t Number s Par t Numbers Part Number s Par t Number s

11-86

L5741-B

11-14-86F

Page 83

1 Instrument Panel Assembly See P-110-D 1

2 Potentiometer T10812-71 1

3 Potentiometer Insulation T12792-1 2

4 Dial Plate (Constant Voltage) (Below Code 9900) M12229 1

5 Dial Plate (Variable Voltage) LN-8S & LN-8SE Only M12230 1

7 Nameplate (Below Code 7900) S14629 1

7 Nameplate (Above Code 7900) S16029 1

10 Base Assembly (Below Code 7575) M11467 1

10 Base Assembly (Code 7575 to 9100) L5778 1

10 Base Assembly (Above Code 9100) L5778-6 1

12 Wire Drive Motor & Gear Box Assembly

See Model Index

1

14 Door Assembly (Below Code 9000) M11490 1

14 Door Assembly (Between Code 9000 & 9900) M14850-1 1

14 Door Assembly (Above Code 9900) M14850-3 1

15 Cover Assembly (Below Code 9000) M12216 1

15 Cover Assembly (Between Code 9000 & 9900) M14851-1 1

15 Cover Assembly (Above Code 9900) M14851-4 1

Door Bumper (Above Code 9100) T14882 1

17 Hinge Pin M8809-53 1

18 Self Tapping Screw S8025-68 2

19 Warning Decal T13470 1

21 Plug Button T13597-2 1

22

Trimmer PC Board & Bracket Assembly (Code 7575 thru 7900)

(Not Illustrated) S15679

ø

1

Trimmer PC Board S15680 1

24

Door Cover Panel (Without Meters Only) (Below Code 9900)

M11662-2 1

24

Door Cover Panel (Without Meters Only) (Above Code 9900)

M11662-3 1

26 Drive Roll Decal S14140 1

27

Optional Meter Kits (Below Code 7575) (Not Illustrated)

See P-107-J or L

1

27

Optional Meter Kits (Above Code 7575) (Not Illustrated)

See P-110-A

29 Knob T10491 2

30 Potentiometer T10812-40 1

32

Grounding Lead Protector Assembly (Below Code 7900)

S15102

32

Grounding Lead Protector Assembly

(Above Code 7900 to 9100)

S15102-3 1

33 Resistor S10404-75 1

Round Head Screw #10-24 x 5.00 1

Insulating Washer T4479-A 2

34 Reset Decal T13086-4 1

35 Resistance Coil (Code 7900 to 9100) T14104 1

39 Roll Pin T9967-22 1

40 Warning Label M16196 1

41 Shunt Assembly M11502 1

Items Not Illustrated:

Collar Assembly (Drive Roll Mounting) T12341 1

Button Head Socket Screw (Drive Roll Mounting) T11551-6 1

Key (Drive Roll Mounting) M8776-31 1

Handle (Optional) S13863 1

07-19-2001

ITEM DESCRIPTION PART NO. QTY.

123456789

P-110-C.1P-110-C.1

# Indicates a Change This Printing

Sub As sembl y I l l ust r at i on Sub Assembl y I l l ust r at i on Sub Assembl y I l l ust r at i on Sub Assembl y I l l us t r at i on

ø This part is obsolete and no longer available.

Page 84

LN-8 INSTRUMENT PANEL ASSEMBLY

(All Models Except LN-8F Above Code 7575)

P-110-DP-110-D

5

11

18

17

16

14

13

4

9

19

8

1

2

3

4

Par t Number s Par t Numbers Part Number s Par t Number s

11-86

L5742

11-14-86G

NOTE: Obtain both item number and complete description for

parts listed. Some older operating manuals were printed with

item numbers which do not correspond with recent printings.

Page 85

1 Instrument Mounting Panel M12428-1 1 X X •

1 Instrument Mounting Panel M12428-2 1 • • X

2 Control P.C. Board Insulation (Above Code 7900) S15961 1 X X •

2 Control P.C. Board Insulation (Below Code 7900) S14819 1 X X X

3 Control P.C. Board (Above Code 7900) L5767-1 1 X X •

3 Control P.C. Board (Below Code 7900) L5040 1 X X X

Plastic Expansion Nut S14020-1 3 X X X

Self Tapping Screw S8025-14 3 X X X

4 Lead Clamp T13496-1 3 X X X

5 Decal (Below Code 7575 and Above Code 7900) T13086-1 1 X X X

5 Decal (Code 7575 thru 7900) T13086-15 1 X X •

8

Transformer & Receptacle Assembly (Above Code 7900)

S14165-140 1 X X •

8 Transformer Assembly (Below Code 7900) S14651-1

ø

1XXX

Transformer Insulation T14070 1 X X X

9 Relay P.C. Board Insulation (Above Code 7900) S14820-1 1 X X •

9 Relay P.C. Board Insulation (Below Code 7900) S14820

ø

1XXX

11 Relay P.C. Board (Above Code 8750) L5769-2 1 X X •

11* Relay P.C. Board (Code 7900 to 8750)

L5769 Note 1

1XX•

11* Relay P.C. Board (Below Code 7900) L5142-1 1 X X X

Relay S13929-9 1 X X X

Plastic Expansion Nut S14020-1 2 X X X

Self Tapping Screw S8025-14 2 X X X

13 Direction Switch T13495 1 X X X

14 Interlock Switch T10800-20 1 X X X

16 Variable Voltage P.C. Board Insulation S14818

ø

1•X•

17 Variable Voltage P.C. Board Assembly L5039-1 1 • X •

18 Circuit Breaker T12287-10 1 X X X

19 Decal T13086-3 1 X X •

Parts Not Illustrated (Below Code 7900 Only)

Unless Otherwise Specified:

Fuse Holder S10289 1 X X X

Fuse T10728-14 1 X X X

Identification Sticker T12607-14 1 X X X

Instrument Panel Mounting Bracket S14768 1 • • X

Output Polarized Plug (All Codes) S12021-3 1 X X •

Input Polarized Connector (All Codes) S12021-12 1 X X •

* For replacement of a Relay P.C. Board that has a

soldered-to-board relay, also order a relay.

Note 1: This P.C. Board can be replaced with the same

basic numbered P.C. Board with the same or

higher dash number.

01-31-2003

For LN-8N or NE use only the parts marked “X” in Column 1.

For LN-8S or SE use only the parts marked “X” in Column 2.

For LN-8F (Below Code 7575 Only) use only the parts marked “X” in Column 3.

ITEM DESCRIPTION PART NO. QTY.

123456789

P-110-D.1P-110-D.1

# Indicates a Change This Printing

Sub As sembl y I l l ust r at i on Sub Assembl y I l l ust r at i on Sub Assembl y I l l ust r at i on Sub Assembl y I l l us t r at i on

ø This part is obsolete and no longer available.

#

Page 86

LN-8F GENERAL ASSEMBLY

P-110-EP-110-E

1

3

5

8

6

7

Par t Number s Par t Numbers Part Number s Par t Number s

7-84

7-30-84

Page 87

1 Control Box (Above Code 7575) See P-110-F 1

1 Control Box Case (Below Code 7575 Only) L5126 1

Instrument Panel Assembly (Below Code 7575 Only)

See P-110-D 1

Instrument Panel Assembly (Above Code 7575) See P-110-G 1

Terminal Strip Assembly (With Leads) S14896-1 1

Number Plate T10726-83 1

5” Resistor S10404-75 1

Insulating Washer T4479-A 2

Round Head Screw, Resistor Mounting 10-24 x 5” 1

3 Decal T13086-3 1

5 Box Cover S14771 1

6 Dial Plate M12229 1

7 ʻVoltsʼ Potentiometer T10812-40 1

8 ʻAmpsʼ Potentiometer T10812-71 1

8 Potentiometer Knob T10491 2

Insulation T12792-1 2

LN-8 Nameplate S14629 1

Control Box to Wire Feed Unit Cable Assembly,