Page 1

Operator’s Manual

RETURN TO MAIN MENU

POWER FEED

™

25M NNS

For use with machines having Code Numbers:

12244

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM10180 | Issue D ate Nov-13

© Lincoln Global, Inc. All Rights Reserved.

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Page 2

THANK YOU FOR SELECTING

AT ALL

TIMES.

SPECIAL SITUATIONS

Additional precautionary measures

A QUALITY PRODUCT BY

LINCOLN ELEC TRIC.

PLEASE EXAMINE CARTON AND EQUIPMENT FOR

DAMAGE IMMEDIATELY

When this equipment is shipped, title passes to the purchaser upon

receipt by the carrier. Consequently, Claims for material damaged in

shipment must be made by the purchaser against the transportation

company at the time the shipment is received.

SAFETY DEPENDS ON YOU

Lincoln arc welding and cutting equipment is designed and built with

safety in mind. However, your overall safety can be increased by

proper installation ... and thoughtful operation on your part.

DO NOT INSTALL, OPERATE OR REPAIR THIS EQUIPMENT

WITHOUT READING THIS MANUAL AND THE SAFETY PRECAUTIONS

CONTAINED THROUGHOUT. And, most importantly, think before you

act and be careful.

WARNING

This statement appears where the information must be followed

exactly to avoid serious personal injury or loss of life.

CAUTION

This statement appears where the information must be followed to

avoid minor personal injury or damage to this equipment.

SAFETY

KEEP YOUR HEAD OUT OF THE FUMES.

DON’T get too close to the arc. Use

corrective lenses if necessary to

stay a reasonable distance away

from the arc.

READ and obey the Material Safety

Data Sheet (MSDS) and the warning

label that appears on all containers

of welding materials.

USE ENOUGH VENTILATION or

exhaust at the arc, or both, to keep

the fumes and gases from your breathing zone and the general area.

IN A LARGE ROOM OR OUTDOORS, natural ventilation may be

adequate if you keep your head out of the fumes (See below).

USE NATURAL DRAFTS or fans to keep the fumes away from your

face.

If you de velop unusual symptoms, see your supervisor. Perhaps the

welding atmosphere and ventilation system should be checked.

WEAR CORRECT EYE, EAR & BODY PROTECTION

PROTECT your eyes and face with welding helmet

properly fitted and with proper grade of filter plate

(See ANSI Z49.1).

PROTECT your body from welding spatter and arc

flash with protective clothing including woolen

clothing, flame-proof apron and gloves, leather

leggings, and high boots.

PROTECT others from splatter, flash, and glare with

protective screens or barriers.

IN SOME AREAS, protection from noise may be

appropriate.

BE SURE protective equipment is in good condition.

Also, wear safety glasses in work area

DO NOT WELD OR CUT containers or materials which previously had

been in contact with hazardous substances unless they are properly

cleaned. This is extremely dangerous.

DO NOT WELD OR CUT painted or plated parts unless special

precautions with ventilation have been taken. They can release highly

toxic fumes or gases.

PROTECT compressed gas cylinders from excessive heat, mechanical

shocks, and arcs; fasten cylinders so they cannot fall.

BE SURE cylinders are never grounded or part of an electrical circuit.

REMOVE all potential fire hazards from welding area.

ALWAYS HAVE FIRE FIGHTING EQUIPMENT READY FOR

IMMEDIATE USE AND KNOW HOW TO USE IT.

i

Page 3

SECTION A:

Diesel Engines

Gasoline Engines

WARNINGS

CALIFORNIA PROPOSITION 65 WARNINGS

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and other

reproductive harm.

The engine exhaust from this product contains chemicals known

to the State of California to cause cancer, birth defects, or other

reproductive harm.

ARC WELDING CAN BE HAZARDOUS. PROTECT

YOURSELF AND OTHERS FROM POSSIBLE SERIOUS

INJURY OR DEATH. KEEP CHILDREN AWAY. PACEMAKER WEARERS SHOULD CONSULT WITH THEIR

DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For additional

safety information, it is strongly recommended that you purchase a

copy of “Safety in Welding & Cutting - ANSI Standard Z49.1” from the

American Welding Society, P.O. Box 351040, Miami, Florida 33135 or

CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety”

booklet E205 is available from the Lincoln Electric Company, 22801

St. Clair Avenue, Cleveland, Ohio 44117-1199.

BE SURE THAT ALL INSTALLATION, OPERATION,

MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

SAFETY

1.d. Keep all equipment safety guards, covers and

devices in position and in good repair.Keep

hands, hair, clothing and tools away from

V-belts, gears, fans and all other moving parts

when starting, operating or repairing

equipment.

1.e. In some cases it may be necessary to remove safety guards to

perform required maintenance. Remove guards only when

necessary and replace them when the maintenance requiring

their removal is complete. Always use the greatest care when

working near moving parts.

1.f. Do not put your hands near the engine fan. Do not attempt to

override the governor or idler by pushing on the throttle control

rods while the engine is running.

1.g. To prevent accidentally starting gasoline engines while turning

the engine or welding generator during maintenance work,

disconnect the spark plug wires, distributor cap or magneto wire

as appropriate.

1.h. To avoid scalding, do not remove the radiator

pressure cap when the engine is

hot.

ELECTRIC AND

MAGNETIC FIELDS MAY

BE DANGEROUS

2.a. Electric current flowing through any conductor

causes localized Electric and Magnetic Fields (EMF). Welding

current creates EMF fields around welding cables and welding

machines

FOR ENGINE POWERED

EQUIPMENT.

1.a. Turn the engine off before troubleshooting

and maintenance work unless the

maintenance work requires it to be running.

1.b. Operate engines in open, well-ventilated

areas or vent the engine exhaust fumes outdoors.

1.c. Do not add the fuel near an open flame

welding arc or when the engine is running.

Stop the engine and allow it to cool before

refueling to prevent spilled fuel from

vaporizing on contact with hot engine parts

and igniting. Do not spill fuel when filling

tank. If fuel is spilled, wipe it up and do not start engine until

fumes have been eliminated.

2.b. EMF fields may interfere with some pacemakers, and welders

having a pacemaker should consult their physician before

welding.

2.c. Exposure to EMF fields in welding may have other health effects

which are now not known.

2.d. All welders should use the following procedures in order to

minimize exposure to EMF fields from the welding circuit:

2.d.1. Route the electrode and work cables together - Secure

them with tape when possible.

2.d.2. Never coil the electrode lead around your body.

2.d.3. Do not place your body between the electrode and work

cables. If the electrode cable is on your right side, the

work cable should also be on your right side.

2.d.4. Connect the work cable to the workpiece as close as possible to the area being welded.

2.d.5. Do not work next to welding power source.

2

Page 4

SAFETY

ELECTRIC SHOCK

CAN KILL.

3.a. The electrode and work (or ground) circuits are

electrically “hot” when the welder is on. Do

not touch these “hot” parts with your bare skin

or wet clothing. Wear dry, hole-free gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full area

of physical contact with work and ground.

In addition to the normal safety precautions, if

welding must be performed under electrically

hazardous conditions (in damp locations or while

wearing wet clothing; on metal structures such as

floors, gratings or scaffolds; when in cramped

positions such as sitting, kneeling or lying, if there

is a high risk of unavoidable or accidental contact

with the workpiece or ground) use the following

equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel, welding head, nozzle or semiautomatic welding

gun are also electrically “hot”.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection should

be as close as possible to the area being welded.

3.e. Ground the work or metal to be welded to a good electrical (earth)

ground.

3.f. Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Never simultaneously touch electrically “hot” parts of electrode

holders connected to two welders because voltage

two can be the total of the open circuit voltage of both

welders.

3.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

between the

ARC RAYS CAN BURN.

4.a. Use a shield with the proper filter and cover plates to protect your

eyes from sparks and the rays of the arc when welding or

observing open arc welding. Headshield and filter lens should

conform to ANSI Z87. I standards.

4.b. Use suitable clothing made from durable flame-resistant material

to protect your skin and that of your helpers from the arc rays.

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

FUMES AND GASES

CAN BE DANGEROUS.

5.a. Welding may produce fumes and gases

hazardous to health. Avoid breathing these

fumes and gases. When welding, keep your head out of the fume.

Use enough ventilation and/or exhaust at the arc to keep fumes

and gases away from the breathing zone. When welding

with electrodes which require special ventilation

such as stainless or hard facing (see instructions

on container or MSDS) or on lead or cadmium

plated steel and other metals or coatings which

produce highly toxic fumes, keep exposure as low

as possible and within applicable OSHA PEL and

ACGIH TLV limits using local exhaust or

mechanical ventilation. In confined spaces or in

some circumstances, outdoors, a respirator may

be required. Additional precautions are also

required when welding on galvanized steel.

5. b. The operation of welding fume control equipment is affected by

various factors including proper use and positioning of the

equipment, maintenance of the equipment and the specific

welding procedure and application involved. Worker exposure

level should be checked upon installation and periodically

thereafter to be certain it is within applicable OSHA PEL and

ACGIH TLV limits.

5.c. Do not weld in locations near chlorinated hydrocarbon vapors

coming from degreasing, cleaning or spraying operations. The

heat and rays of the arc can react with solvent vapors to form

phosgene, a highly toxic gas, and other irritating products.

3.j. Also see It ems 6.c. and 8.

5.d. Shielding gases used for arc welding can displace air and

injury or death. Always use enough ventilation, especially in

confined areas, to insure breathing air is safe.

5.e. Read and understand the manufacturer’s instructions for this

equipment and the consumables to be used, including the

material safety data sheet (MSDS) and follow your employer’s

safety practices. MSDS forms are available from your welding

distributor or from the manufacturer.

5.f. Also see item 1.b.

3

cause

Page 5

SAFETY

WELDING AND CUTTING

SPARKS CAN CAUSE

FIRE OR EXPLOSION.

6.a. Remove fire hazards from the welding area. If

this is not possible, cover them to prevent the

welding sparks from starting a fire. Remember that welding

sparks and hot materials from welding can easily go through

small cracks and openings to adjacent areas. Avoid welding near

hydraulic lines. Have a fire extinguisher readily available.

6.b. Where compressed gases are to be used at the job site, special

precautions should be used to prevent hazardous situations.

Refer to “Safety in Welding and Cutting” (ANSI Standard Z49.1)

and the operating information for the equipment being used.

6.c. When not welding, make certain no part of the electrode circuit is

touching the work or ground. Accidental contact can cause

overheating and create a fire hazard.

6.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures will

not cause flammable or toxic vapors from substances inside.

They can cause an explosion even though they have been

“cleaned”. For information, purchase “Recommended Safe

Practices for the Preparation for Welding and Cutting of

Containers and Piping That Have Held Hazardous Substances”,

AWS F4.1 from the American Welding Society (see address

above).

6.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

6.f. Sparks and spatter are thrown from the welding arc. Wear oil free

protective garments such as leather gloves, heavy shirt, cuffless

trousers, high shoes and a cap over your hair. Wear ear plugs

when welding out of position or in confined places. Always wear

safety glasses with side shields when in a welding area.

6.g. Connect the work cable to the work as close to the welding area

as practical. Work cables connected to the building framework or

other locations away from the welding area increase the

possibility of the welding current passing through lifting chains,

crane cables or other alternate circuits. This can create fire

hazards or overheat lifting chains or cables until they fail.

6.h. Also see item 1.c.

CYLINDER MAY EXPLODE IF

DAMAGED.

7.a. Use only compressed gas cylinders containing

the correct shielding gas for the process used

and properly operating regulators designed for

the gas and pressure used. All hoses, fittings,

etc. should be suitable for the application and

maintained in good condition.

7.b. Always keep cylinders in an upright position securely chained to

an undercarriage or fixed support.

7.c. Cylinders should be located:

• Away from areas where they may be struck or subjected

to physical damage.

• A safe distance from arc welding or cutting operations

and any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode holder or any other electrically “hot” parts to touch a cylinder.

7.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. Valve protection caps should always be in place and hand tight

except when the cylinder is in use or connected for use.

7.g. Read and follow the instructions on compressed gas cylinders,

associated equipment, and CGA publication P-l, “Precautions for

Safe Handling of Compressed Gases in

Cylinders,” available

from the Compressed Gas Association 1235 Jefferson Davis

Highway, Arlington, VA 22202.

FOR ELECTRICALLY

POWERED EQUIPMENT.

8.a. Turn off input power using the disconnect

switch at the fuse box before working on the

equipment.

8.b. Install equipment in accordance with the U.S. National Electrical

Code, all local codes and the manufacturer’s recommendations.

6.I. Read and follow NFPA 51B “ Standard for Fire Prevention During

Welding, Cutting and Other Hot Work”, available from NFPA, 1

Batterymarch Park, PO box 9101, Quincy, Ma 022690-9101.

6.j. Do not use a welding power source for pipe thawing.

8.c. Ground the equipment in accordance with the U.S. National

Electrical Code and the manufacturer’s recommendations.

Refer to

http://www.lincolnelectric.com/safety

for additional safety information.

Welding Safety

Interactive Web Guide

for mobile devices

4

Page 6

SAFETY

ELECTROMAGNETIC

COMPATIBILITY (EMC)

CONFORMANCE

Products displaying the CE mark are in conformity with European

Community Council Directive of 3 May 1989 on the approximation of

the laws of the Member States relating to electromagnetic compatibility (89/336/EEC). It was manufactured in conformity with a national

standard that implements a harmonized standard: EN 60974-10

Electromagnetic Compatibility (EMC) Product Standard for Arc Welding

Equipment. It is for use with other Lincoln Electric equipment. It is

designed for industrial and professional use.

INTRODUCTION

All electrical equipment generates small amounts of electromagnetic

emission. Electrical emission may be transmitted through power lines

or radiated through space, similar to a radio transmitter. When

emissions are received by other equipment, electrical interference

may result. Electrical emissions may affect many kinds of electrical

equipment; other nearby welding equipment, radio and TV reception,

numerical controlled machines, telephone systems, computers, etc.

Be aware that interference may result and extra precautions may be

required when a welding power source is used in a domestic establishment.

INSTALLATION AND USE

The user is responsible for installing and using the welding equipment

according to the manufacturer’s instructions. If electromagnetic disturbances are detected then it shall be the responsibility of the user of

the welding equipment to resolve the situation with the technical

assistance of the manufacturer. In some cases this remedial action

may be as simple as earthing (grounding) the welding circuit, see

Note. In other cases it could involve construction of an electromagnetic screen enclosing the power source and the work complete with

associated input filters. In all cases electromagnetic disturbances

must be reduced to the point where they are no longer troublesome.

Note: The welding circuit may or may not be earthed for safety reasons

according to national codes. Changing the earthing arrangements should

only be authorized by a person who is competent to access whether the

changes will increase the risk of injury, e.g., by allowing parallel welding

current return paths which may damage the earth circuits of other equipment.

ASSESSMENT OF AREA

Before installing welding equipment the user shall make an

assessment of potential electromagnetic problems in the surrounding

area. The following shall be taken into account:

a. other supply cables, control cables, signaling and telephone cables;

above, below and adjacent to the welding equipment;

b. radio and television transmitters and receivers;

c. computer and other control equipment;

d. safety critical equipment, e.g., guarding of industrial equipment;

e. the health of the people around, e.g., the use of pacemakers and

hearing aids;

f. equipment used for calibration or measurement

g. the immunity of other equipment in the environment. The user shall

ensure that other equipment being used in the environment is

compatible. This may require additional protection measures;

h. the time of day that welding or other activities are to be carried out.

5

The size of the surrounding area to be considered will depend on the

structure of the building and other activities that are taking place. The

surrounding area may extend beyond the boundaries of the premises.

METHODS OF REDUCING EMISSIONS

Mains Supply

Welding equipment should be connected to the mains supply

according to the manufacturer’s recommendations. If interference

occurs, it may be necessary to take additional precautions such as

filtering of the mains supply. Consideration should be given to

shielding the supply cable of permanently installed welding

equipment, in metallic conduit or equivalent. Shielding should be

electrically continuous throughout its length. The shielding should be

connected to the welding power source so that good electrical contact

is maintained between the conduit and the welding power source

enclosure.

Maintenance of the Welding Equipment

The welding equipment should be routinely maintained according to

the manufacturer’s recommendations. All access and service doors

and covers should be closed and properly fastened when the welding

equipment is in operation. The welding equipment should not be

modified in any way except for those changes and adjustments

covered in the manufacturers instructio ns. In particular, the spark

gaps of arc striking and stabilizing devices should be adjusted and

maintained according to the manufacturer’s recommendations.

Welding Cables

The welding cables should be kept as short as possible and should be

positioned close together, running at or close to floor level.

Equipotential Bonding

Bonding of all metallic components in the welding installation and

adjacent to it should be considered. However, metallic components

bonded to the work piece will increase the risk that the operator could

receive a shock by touching these metallic components and the

electrode at the same time. The operator should be insulated from all

such bonded metallic components.

Earthing of the Workpiece

Where the workpiece is not bonded to earth for electrical safety, not

connected to earth because of its size and position, e.g., ships hull or

building steelwork, a connection bonding the workpiece to earth may

reduce emissions in some, but not all instances. Care should be taken

to prevent the earthing of the work piece increasing the risk of injury

to users, or damage to other electrical equipment. Where necessary,

the connection of the workpiece to earth should be made by a direct

connection to the work piece, but in some countries where direct

connection is not permitted, the bonding should be achieved by

suitable capacitance, selected according to national regulations.

Screening and Shielding

Selective screening and shielding of other cables and equipment in

the surrounding area may alleviate problems of interference.

Screening of the entire welding installation may be considered for

special applications.

1

Portions of the preceding text are contained in EN 60974-10: “Electromagnetic

Compatibility (EMC) product standard for arc welding equipment.”

Page 7

TABLE OF CONTENTS

Page

Product Description.........................................................................................................................................7

Installation.......................................................................................................................Section A

Technical Specifications.......................................................................................................A-1

Thumb Screw and Metal Tab of Welding Gun .....................................................................A-2

Safety Precautions ...............................................................................................................A-3

Location................................................................................................................................A-3

High Frequency Protection...................................................................................................A-3

Cable Connections...............................................................................................................A-3

Arclink Control Cable............................................................................................................A-3

Weld cable Sizes..................................................................................................................A-4

Coaxial Weld Cable..............................................................................................................A-4

Shielding Gas Connection....................................................................................................A-5

Procedure to Install Drive Rolls and Wire Guides ................................................................A-5

Remote Sense Lead Specification .......................................................................................A-6

Loading Spools of Wire ........................................................................................................A-6

Typical System Configurations.............................................................................................A-7

________________________________________________________________________________

Operation.........................................................................................................................Section B

S

afety Precautions ...............................................................................................................B-1

Graphic Symbols that appear on this Machine or in thi

Definition of Welding Terms .................................................................................................B-2

Duty Cycle............................................................................................................................B-2

Recommended Processes, Equipment Limitations, Recommended Power Sources..........B-3

Case Front Controls .............................................................................................................B-4

On-Off Switch.......................................................................................................................B-5

Power Wave System Operation, 2 Step - 4 Step Trigger Operation and Graphics

Set-Up Feature Menu for Parameters and Definition ........................................B-21 thru B-27

Dual Procedure/Memory Buttons .......................................................................B-28 thru B-30

Internal Controls.................................................................................................................B-31

Cold Feed / Gas Purge Switch, Light Switch, Heater Switch, Pressure Arm Adjustment ..B-32

Rear Controls .....................................................................................................................B-33

________________________________________________________________________________

Accessories ....................................................................................................................Section C

Factory Installed Equipment.................................................................................................C-1

Drive Roll Kits ......................................................................................................................C-1

________________________________________________________________________________

Maintenance....................................................................................................................Section D

Safety Precautions...............................................................................................................D-1

Routine Maintenance ...........................................................................................................D-1

Periodic Maintenance...........................................................................................................D-1

Calibration Specification.......................................................................................................D-1

________________________________________________________________________________

Troubleshooting .............................................................................................................Section E

How to Use Troubleshooting Guide .....................................................................................E-1

Error Fault Codes.................................................................................................................E-2

Troubleshooting Guide ...........................................................................................E-3 thru E-4

________________________________________________________________________________

s Manual

.........................................B-1

....B-5 thru B-20

Wiring Diagrams & Dimension Prints ...........................................................................Section F

________________________________________________________________________________

Parts Pages ................................................................................................................P-754 Series

_______________________________________________________________________

________

Page 8

GENERAL DESCRIPTION

General Physical Description

The POWER FEED™ 25M NNS is a premium portable wire feeder

for use with the Power Wave products. The wire feeder features a

2 roll MAXtrac™ drive coupled to a powerful motor for driving

wire through difficult situations. The easy-to-use, user interface

provides ready access to all welding modes in the Power Wave.

Built in memories are included with the POWER FEED™ 25M NNS

and allows quick recall of favorite weld procedures. Two cases

are available: an engineered aluminum case with replaceable

skids, or an impact resistant polycarbonate plastic case.

The heart of the POWER FEED™ 25M NNS is the MAXtrac™ drive.

The patented features on the wire drive offer tool-less changing of

the drive rolls and the wire guides for quick spool changes.

The POWER FEED™ 25M NNS continues Lincoln’s lead role of

environmental protection for electronics. P.C. boards are potted in

epoxy and electrical connections are protected with dielectric

grease. Noise suppression components protect the POWER

FEED™ 25M NNS from stray signals and keep the feeder from

interfering with other digital equipment.

PRODUCT DESCRIPTIONPOWER FEED™ 25M NNS

General Functional Description

The POWER FEED™ 25M NNS is best suited for applications were

quality welds are expected. Combined with a Power Wave power

source, the POWER FEED™ 25M NNS is great for aluminum, nickel, alloy and other difficult to weld materials. Easy to use controls

make it a great feeder for consistent results with mild steel applications too.

7

Page 9

INSTALLATIONPOWER FEED™ 25M NNS

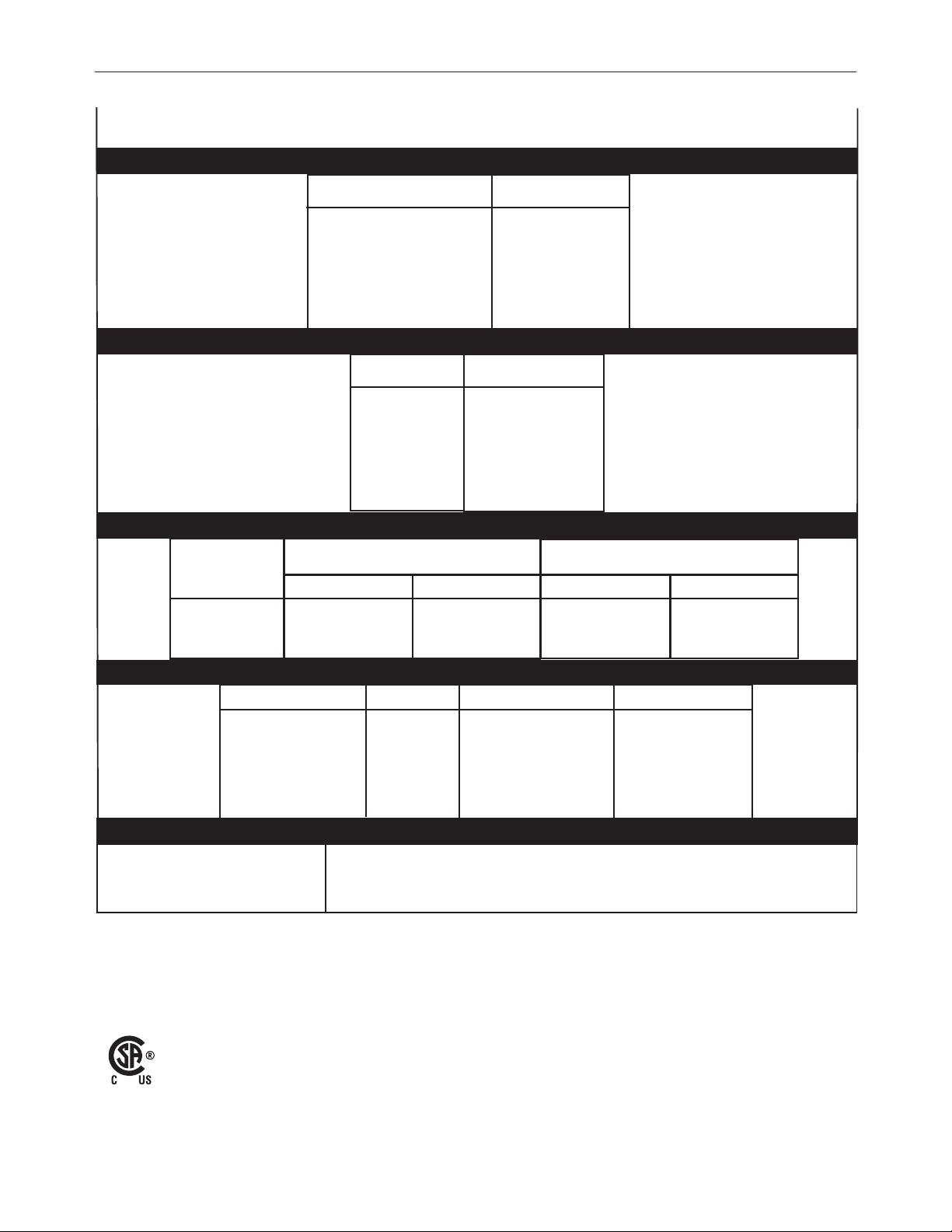

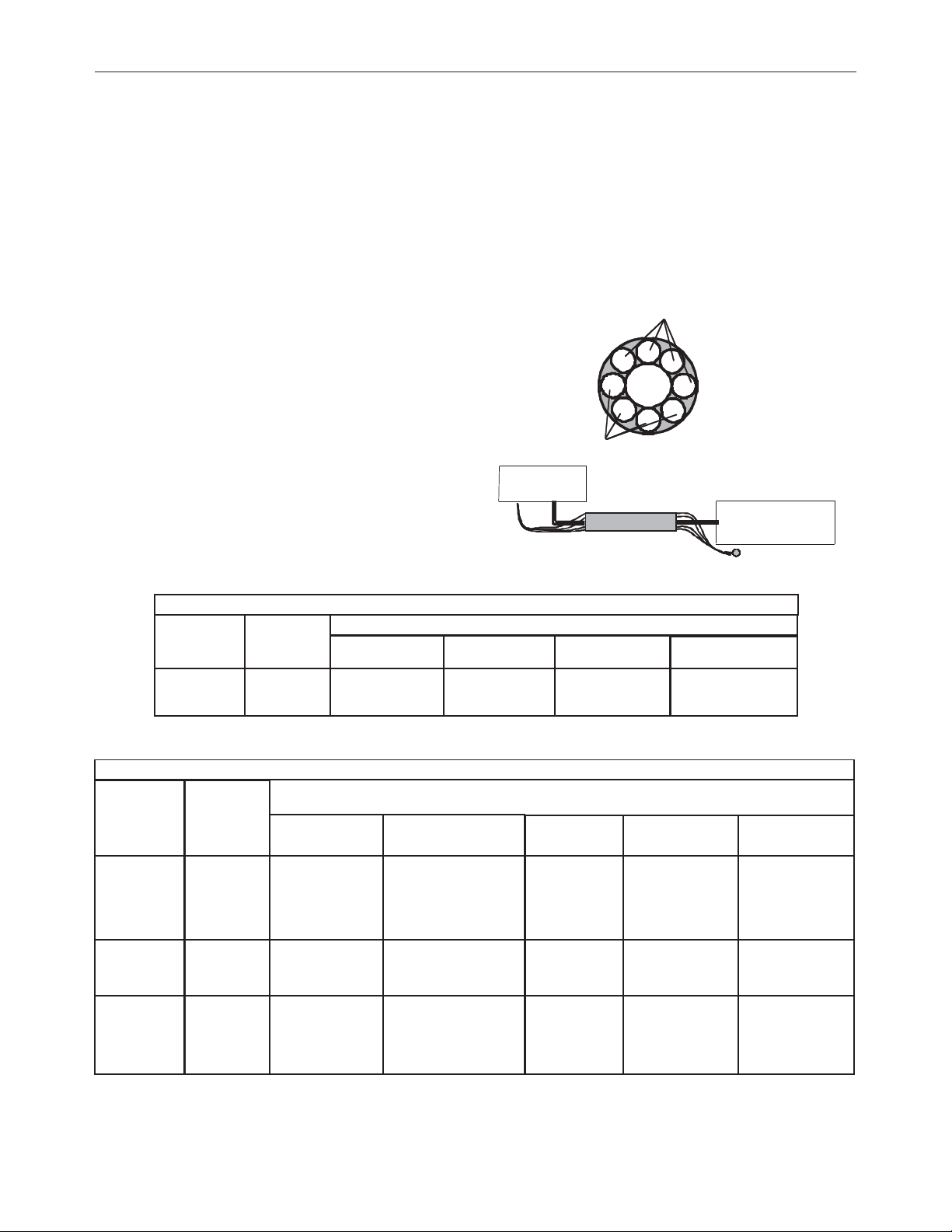

TECHNICAL SPECIFICATIONS –

INPUT VOLTAGE and CURRENT

INPUT VOLTAGE ± 10%

40 VDC

RATED OUTPUT @ 104°F (40°C)

DUTY CYCLE

60% rating

GEARING - WIRE FEED SPEED RANGE-WIRE SIZE

GMAW

POWER FEED™ 25M NNS K2536-6

INPUT AMPERES

4A

INPUT AMPERES

500A

FCAW

GEARING

Normal Speed

(factory setting)

WFS RANGE

50 – 800 ipm

(2.5 – 20.3m/min)

WIRE SIZES

.023 – 1/16"

(0.6 – 1.6mm)

WFS RANGE

50 – 800 ipm

(2.5 – 20.3m/min)

PHYSICAL DIMENSIONS

HEIGHT WIDTH DEPTH WEIGHT

14.5 Inches 8.5 Inches 23.5 Inches 35 lbs

(368 mm) ( 216 mm) (597 mm) (15.9 kg)

Handle folded down

TEMPERATURE RANGE

OPERATION: -40°F to 122°F (-40°C to 50°C)

STORAGE: -40°F to 185°F (-40°C to 85°C)

WIRE SIZES

.030 – 5/64"

(0.8 – 2.0mm)

IP23

IEC 60974-5

A-1

Page 10

THUMB SCREW AND METAL TAB OF WELDING GUN

INSTALLATIONPOWER FEED™ 25M NNS

WARNING

ELECTRIC SHOCK can kill.

• Turn the input power OFF at the disconnect switch or fuse box before attempting to

connect or disconnect input power lines, output cables or control cables.

• Only qualified personnel should perform this installation.

• Do not touch the wire drive, drive rolls, wire coil or electrode when welding output is

ON.

• Wire feeder may be connected to a piece of automatic equipment that may be

remotely controlled.

• Do not operate with covers, panels or guards removed.

• Do not let the electrode or wire spool touch the wire feeder housing.

• Insulate yourself from the work and ground.

• Always wear dry insulating gloves.

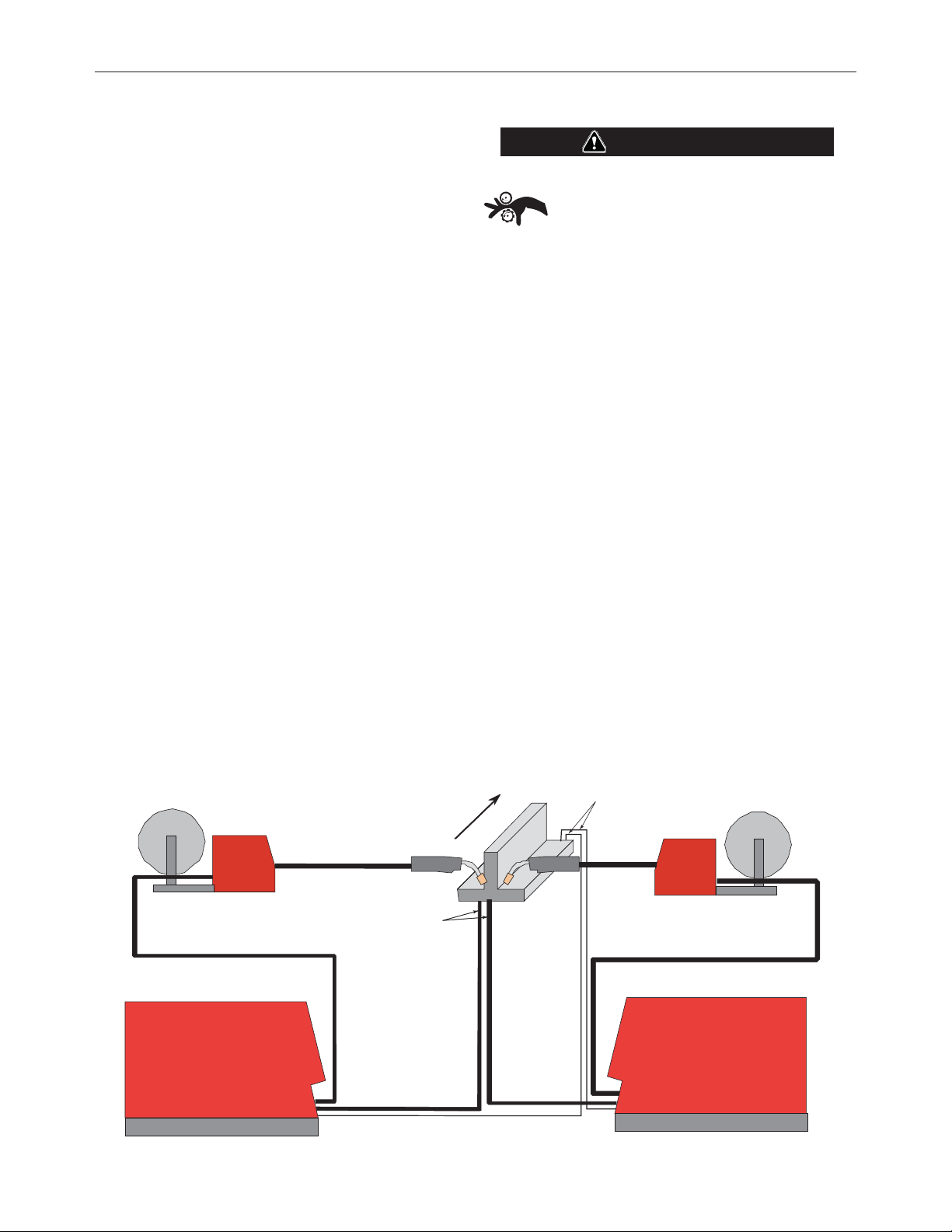

The metal tab of the welding gun and thumb screw securing the gun are at electrode potential when the

welding output is on. Do not touch the metal tab or thumb screw unless input power is turned OFF. Do

not allow the metal tab or thumb screw to touch other parts of the wire feeder or to touch part at work

potential.(See Figure A.1)

FIGURE A.1

THUMB SCREW

METAL TAB

OF THE WELDING GUN

A-2

Page 11

INSTALLATIONPOWER FEED™ 25M NNS

A

B

C

D

E

A

B

C

D

E

A

B

C

D

E

WARNING

ELECTRIC SHOCK CAN KILL.

• Turn the input power OFF at the welding

power source before installation or changing drive rolls and/or guides.

• Do not touch electrically live parts.

• When inching with the gun trigger, electrode and drive mechanism are "hot" to

work and ground and could remain energized several seconds after the gun trigger

is released.

• Welding power source must be connected to system ground

per the National Electrical Code or any applicable local

codes.

• Only qualified personnel should perform maintenance work.

------------------------------------------------------------------------

LOCATION

For best wire feeding performance, place the POWER FEED™

25M NNS on a stable and dry surface. Keep the wire feeder in

a vertical position. Do not operate the wire feeder on an angled

surface of more than 15 degrees.

Do not submerge the POWER FEED™ 25M NNS.

The POWER FEED™ 25M NNS is rated IP23 and is suitable for

outdoor use.

The handle of the POWER FEED™ 25M NNS is intended for

moving the wire feeder about the work place only.

CABLE CONNECTION

There is one connector on the front of the POWER FEED™ 25M

NNS for the gun trigger. (See 2-prong Figure A.2)

Figure A.2

ARCLINK CONTROL CABLES

There is one circular connector on the rear of the POWER FEED™

25M NNS. Maximum control cable length is 200 ft (61 m). (See

Figure A.3)

FIGURE A.3

Function

5-pin ArcLink

connector.

(See Figure A.4)

ArcLink/LincNet control cables are special high quality cables for

digital communication. The cables are copper 5 conductor cable

in a SO-type rubber jacket. There is one 20 gauge twisted pair for

network communications. This pair has an impedance of approximately 120 ohms and a propagation delay per foot of less than 2.1

nanoseconds. There are two 12 gauge conductors that are used

to supply 40VDC to the network. The fifth wire is 18 gauge and is

used as an electrode sense lead.

PIN

A

B

C

67 Electrode Voltage Sense

D

E

Wiring

ArcLink

ArcLink

40VDC

Common

When suspending a wire feeder, insulate the hanging device

from the wire feeder enclosure.

HIGH FREQUENCY PROTECTION

The control cables connect the power source to the wire feeder,

and the wire feeder to other wire feeders.

Control cables may be connected end to end to extend their

length. Use a maximum of 200 ft. (61.0m) of control cable

CAUTION

between components.

Figure A.4

Locate the POWER FEED™ 25M NNS away from radio controlled

machinery. The normal operation of the POWER FEED™ 25M

POWER SOURCE

WIRE FEEDER

NNS may adversely affect the operation of RF controlled equipment, which may result in bodily injury or damage to the equipment.

------------------------------------------------------------------------

Power Source

Pin Function

A ArcLink

B ArcLink

C "67" voltage sense

D40 VDC

E Common

A-3

Wire Feeder

Pin Function

A ArcLink

B ArcLink

C "67" voltage sense

D 40 VDC

E Common

Page 12

INSTALLATIONPOWER FEED™ 25M NNS

Electrtrode

Work

Work

El ect r ode

W

or k

El ec t r ode

W

or k

Power Sour ce

Coax i al W

el d Cabl e

Wi r e Feeder

WELD CABLE SIZE

To install:

1. Turn the input power off at the welding power source.

Table A.1 located below are copper cable sizes recommended for different currents

and duty cycles. Lengths stipulated are the distance from the welder to work and

back to the welder again. Cable sizes are increased for greater lengths primarily for

the purpose of minimizing cable drop.

2. Connect one end of the center lead to the power source electrode

connection, and the other end to the wire feeder electrode connection.

3. Connect the outer lead bundle to the power source work connection,

and the other end to the work piece. Minimize the length of any work

COAXIAL WELD CABLE

(See Table A.2)

lead extension for best results.

4. Insulate all connections.

Coaxial welding cables are specially designed welding cables for pulse welding or

STT™ welding. Coaxial weld cables feature low inductance, allowing fast changes

in the weld current. Regular cables have a higher inductance which may distort the

pulse or STT™ wave shape. Inductance becomes more severe as the weld cables

become longer.

Coaxial cables work best for high performance waveforms and when:

• long cables are present.

• the cables are housed in a metal tray.

A coaxial weld cable is constructed with multiple small leads wrapped around one

large lead. The large inner lead connects to the electrode stud on the power source

and the electrode connection on the wire feeder. The small leads combine together

Power Sour c e

or k

El ec t r ode

to form the work lead, one end attached to the power source and the other end to

the work piece. See Figure A.5

FIGURE A.5

Coaxial W

el d Cabl e

El ec t r ode

Wi r e Feeder

or k

TABLE A.2

RECOMMENDED CABLE SIZES (RUBBER COVERED COPPER - RATED 75°C)**

COAXIAL CABLE LENGTH

AMPERES

250

300

350

DUTY

CYCLE

100%

60%

60%

0 to 25Ft.

(0 to7.6M)

1

1

1/0

25 to 50Ft.

(7.6 to 15.2M)

1

1

1/0

50 to 75 Ft.

(15.2 to 22.9M)

1

1

--

75 to 100 Ft.

(22.9 to 30.5M)

1

1/0

--

TABLE A.1

RECOMMENDED CABLE SIZES (RUBBER COVERED COPPER - RATED 167°F or 75°C)**

CABLE SIZES FOR COMBINED LENGTHS OF ELECTRODE AND WORK CABLES

PERCENT

DUTY

CYCLE

60

100

20

40 & 30

30

40

60

100

60

100

60

60

100

60

0 to 50Ft.

(0 to15M)

2

2

4 or 5

3

3

2

1

1

1

2/0

1/0

2/0

3/0

2/0

50 to 100Ft.

(15 to 30M)

2

2

3

3

3

2

1

1

1

2/0

1/0

2/0

3/0

2/0

100 to 150 Ft.

(30 to 46M)

2

2

2

2

2

1

1

1

1

2/0

2/0

2/0

3/0

3/0

150 to 200 Ft.

(46 to 61M)

1

1

1

1

1

1

1

1

1/0

2/0

2/0

3/0

3/0

3/0

200 to 250 Ft.

(61 to 76M)

1/0

1/0

1/0

1/0

1/0

1/0

1/0

1/0

2/0

3/0

3/0

4/0

4/0

4/0

AMPERES

200

200

225

225

250

250

250

250

300

325

350

400

400

500

** Tabled values are for operation at ambient temperatures of 104°F(40°C) and below. Applications above 104°F(40°C) may require cables

larger than recommended, or cables rated higher than 167°F(75°C).

A-4

Page 13

INSTALLATIONPOWER FEED™ 25M NNS

SHIELDING GAS CONNECTION

WARNING

CYLINDER may explode if damaged.

•Keep cylinder upright and chained

to support.

• Keep cylinder away from areas where it may be damaged.

• Never lift welder with cylinder attached.

• Never allow welding electrode to touch cylinder.

• Keep cylinder away from welding or other live electrical

circuits.

• Build up of shielding gas may harm health or kill.

• Shut off shielding gas supply when not in use.

• See American National Standard Z-49.1, "Safety

in Welding and Cutting” Published by the

American Welding Society.

----------------------------------------------------------------------

M

AXIMUM INLET PRESSURE IS

Install the shielding gas supply as follows:

100

PSI

. (6.9

BAR

.)

PROCEDURE TO INSTALL DRIVE ROLLS AND WIRE

GUIDES

WARNING

ELECTRIC SHOCK can kill.

• Turn the input power OFF at the welding

power source before installation or changing

drive rolls and/or guides.

• Do not touch electrically live parts.

• When inching with the gun trigger, electrode and drive

mechanism are "hot" to work and ground and could remain

energized several seconds after the gun trigger is released.

• Only qualified personnel should perform maintenance work.

-----------------------------------------------------------------

1. Turn power off at the welding power source.

2. Release the idle roll pressure arm.

3. Remove the outer wire guide by turning the knurled thumb-

screws counter-clockwise to unscrew them from the feed plate.

4. Rotate the triangular lock and remove the drive rolls.

1. Secure the cylinder to prevent it from falling.

2. Remove the cylinder cap. Inspect the cylinder valves and regulator

for damaged threads, dirt, dust, oil or grease. Remove dust and dirt

with a clean cloth. DO NOT ATTACH THE REGULATOR IF OIL,

GREASE OR DAMAGE IS PRESENT! Inform your gas supplier of this

condition. Oil or grease in the presence of high pressure oxygen is

explosive.

3. Stand to one side away from the outlet and open the cylinder valve

for an instant. This blows away any dust or dirt which may have

accumulated in the valve outlet.

4. Attach the flow regulator to the cylinder valve and tighten the union

nut(s) securely with a wrench. Note: if connecting to 100% CO

cylinder, insert regulator adapter between regulator and cylinder

2

valve. If adapter is equipped with a plastic washer, be sure it is

seated for connection to the CO2cylinder.

5. Attach one end of the inlet hose to the outlet fitting of the flow regulator. Attach the other end to the welding system shielding gas

inlet. Tighten the union nuts with a wrench.

6. Before opening the cylinder valve, turn the regulator adjusting knob

counterclockwise until the adjusting spring pressure is released.

7. Standing to one side, open the cylinder valve slowly a fraction of a

turn. When the cylinder pressure gage stops moving, open the

valve fully.

8. The flow regulator is adjustable. Adjust it to the flow rate recommended for the procedure and process being used before making a

weld.

5. Remove the inner wire guide.

6. Insert the new inner wire guide, groove side out, over the two

locating pins in the feed plate.

7. Install a drive roll on each hub assembly secure with the triangular lock.

8. Install the outer wire guide by aligning it with the pins and tightening the knurled thumbscrews.

9. Close the idle arm and engage the idle roll pressure arm.

Adjust the pressure appropriately

A-5

Page 14

CONNECT AALL SSENSE

LEADS

THE EEND

O

THE WWELD

CONNECT

A

LL

WORK

LEAD

S

AT

THE

BEGINN

IN

G

OF

THE WWELD

DIRE

C

TI ON

OF

TRAVEL

INSTALLATIONPOWER FEED™ 25M NNS

• Keep hands, hair, clothing and tools away from

rotating equipment.

• Do not wear gloves when threadin

g wire or

changing w ir e spool.

• Only qualified personnel should install, use or

servic e this equipment.

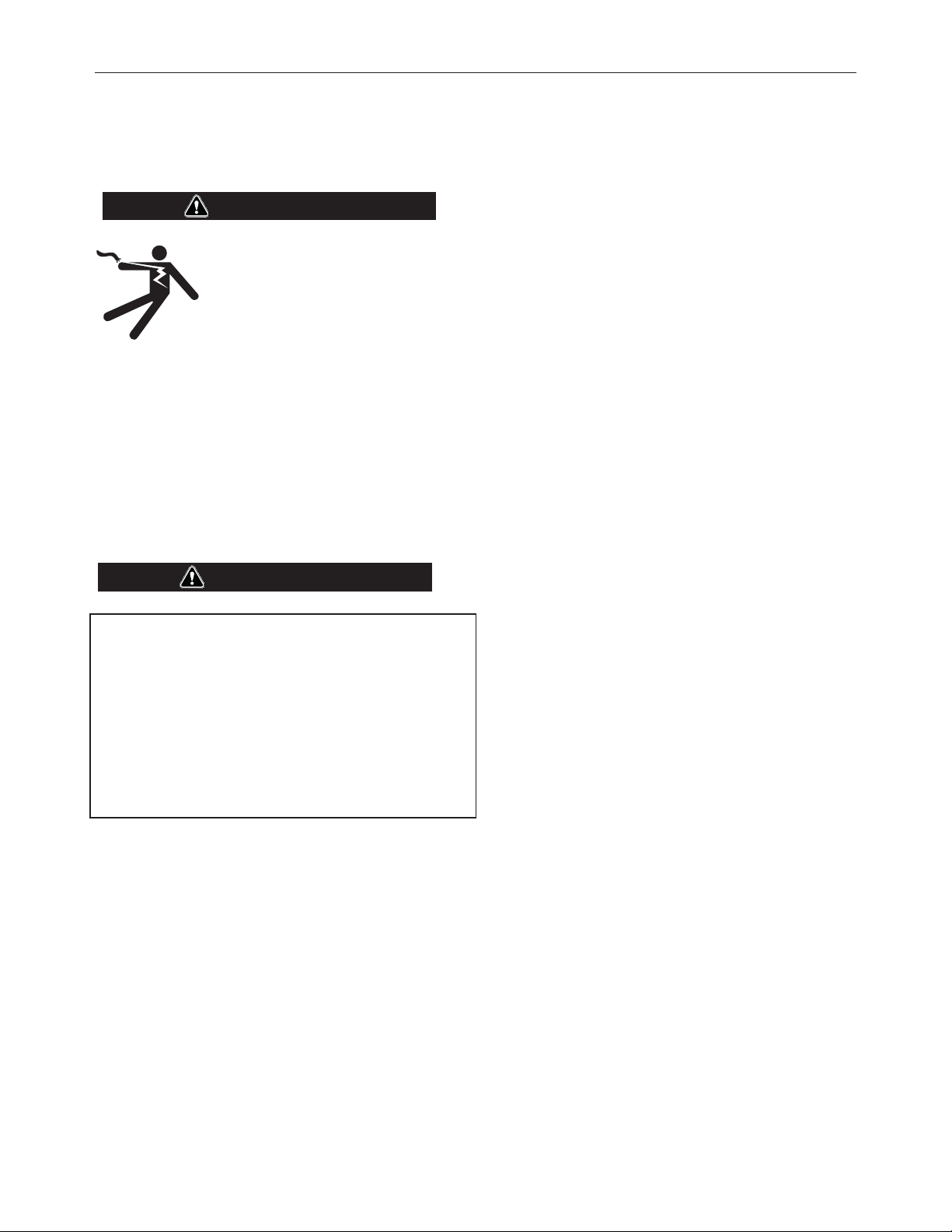

REMOTE SENSE LEAD SPECIFICATIONS

Welding with Multiple Arcs:

( See Figure A.6)

Special care must be taken when more than one arc is welding

imultaneously on a single part. Arc blow and arc interference

s

may occur or be magnified. Each power source requires a work

lead from the work stud to the welding fixture. Do not combine all

of the work leads into one lead. Performing welding in the direction away from the work leads. Connect all of the work sense

leads from each power source to the work piece at the end of the

weld, such that they are out of the path of the weld current. See

Figure A.6

For the best results when pulse welding, set the wire size and

wire feed speed the same for all the arcs. When these parameters

are identical, the pulsing frequency will be the same, helping to

stabilize the arcs.

LOADING SPOOLS OF WIRE

WARNING

----------------------------------------------------------------------

Loading 10 to 15 lb. (4.5 – 6.8kg) Spools.

A K468 spindle adapter is required for loading 2" (51mm) wide

spools on 2" (51mm) spindles. Use a K468 spindle adapter for

loading 2-1/2" (64mm) wide spools.

1. Squeeze the release bar on the retaining collar and remove it

from the spindle.

2. Place the spindle adapter on the spindle, aligning the spindle

brake pin with the hole in the adapter.

3. Place the spool on the spindle and align the adapter brake tab

with one of the holes in the back side of the spool. An indicator

mark on the end of the spindle shows the orientation of the

brake tab. Be certain the wire feeds off of the spool in the

proper direction.

OF

B

TH

OF

L

4. Re-install the retaining collar. Make sure that the release bar

snaps out and that the retaining collar fully engages the groove

on the spindle.

FIGURE A.6

TI O

A

A

G

AAT TH

F FTH

A-6

Page 15

TYPICAL SYSTEM CONFIGURATIONS

STANDARD FEATURES

Arc Performance

• STT™ capable when used with STT™ equipped Power

Waves.

• Waveform Control Technology™ for welds with good appearance and low spatter, even when welding nickel alloys.

Wire Drive

Patented 2 roll drive system. MAXTRAC™ technology delivers

great feeding because:

• The precision machined, rigid aluminum alloy frame results in

maximum drive roll clamping pressure.

• Patented split wire guides fully support the wire and virtually

eliminate birdnesting.

INSTALLATIONPOWER FEED™ 25M NNS

• No tools required to change the drive rolls and wire guides.

• Patented dual spring pressure arms have sensitivity for feeding soft wires without crushing them, and have plenty of compression force for feeding solid or stiff wires.

• All gear driven rolls for more feeding force.

• Powerful, quiet motor with integrated tachometer for accurate

WFS regulation.

Extras:

• Internal heater for keeping condensation off of the spool of

wire.

• Internal lights for illuminating the wire drive compartment.

A-7

Page 16

POWER FEED™ 25M NNS

OPERATION

SAFETY PRECAUTIONS

READ AND UNDERSTAND ENTIRE SECTION

BEFORE OPERATING MACHINE.

WARNING

• ELECTRIC SHOCK CAN KILL.

Unless using COLD FEED feature, when feeding with gun trigger, the electrode and drive

mechanism are always electrically energized and could

remain energized several seconds after the welding ceases.

• Turn the input power OFF at the welding power

source before installation or changing drive

rolls and/or guides.

• Do not touch electrically live parts.

• When inching with the gun trigger, electrode

and drive mechanism are "hot" to work and

ground and could remain energized several

seconds after the gun trigger is released.

• Do not operate with covers, panels or guards

removed or open.

• Only qualified personnel should perform maintenance work.

----------------------------------------------------------------------

• FUMES AND GASSES can be

dangerous.

• Keep your head out of fumes.

• Use ventilation or exhaust to

remove fumes from breathing

zone.

----------------------------------------------------------------------

• WELDING SPARKS can cause

fire or explosion.

• Keep flammable material away.

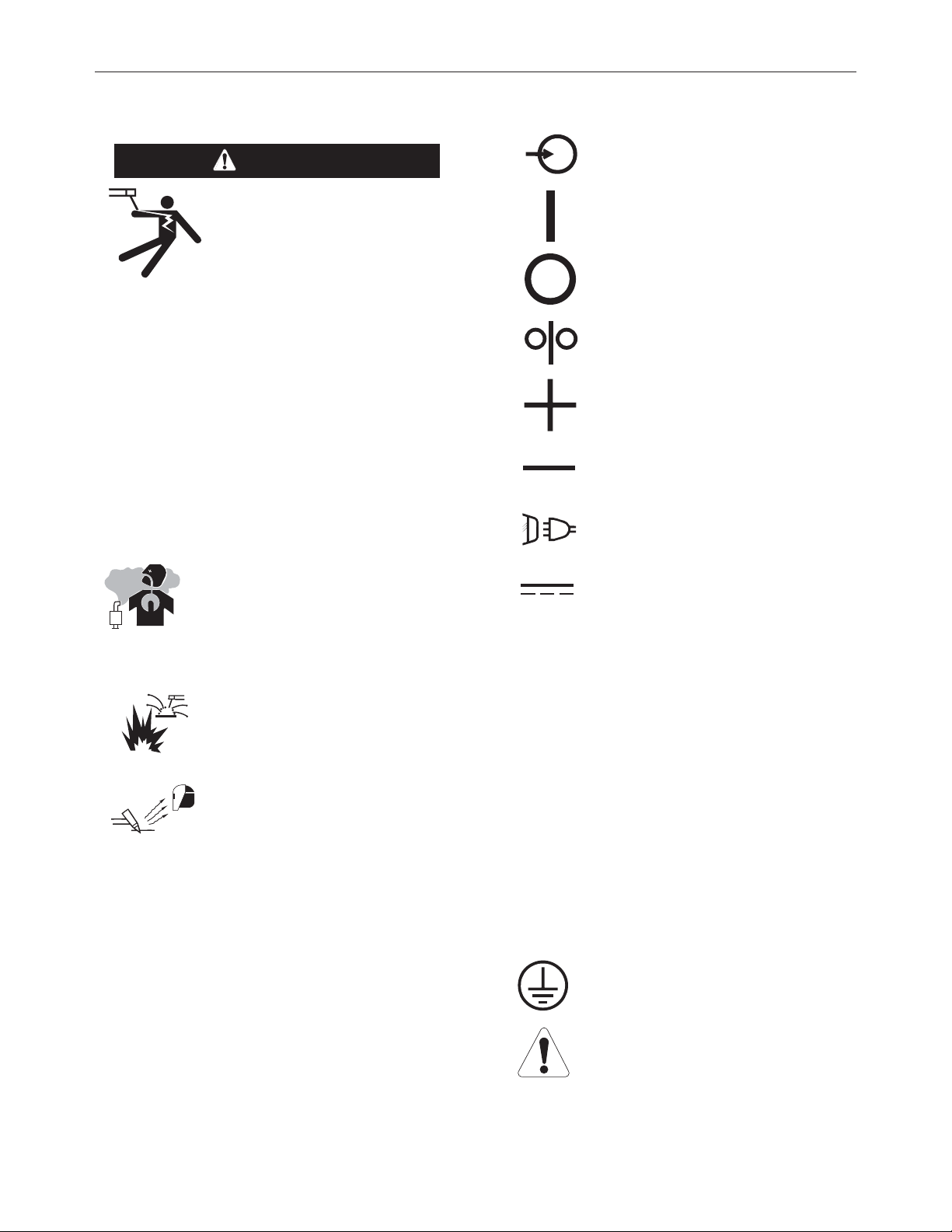

GRAPHIC SYMBOLS THAT APPEAR ON

THIS MACHINE OR IN THIS MANUAL

INPUT POWER

ON

OFF

WIRE FEEDER

POSITIVE OUTPUT

NEGATIVE OUTPUT

INPUT POWER

DIRECT CURRENT

U

U

0

1

OPEN CIRCUIT

VOLTAGE

INPUT VOLTAGE

----------------------------------------------------------------------

ARC RAYS can burn.

• Wear eye, ear and body protection.

----------------------------------------------------------------------

SEE ADDITIONAL WARNING INFORMATION

UNDER ARC WELDING SAFETY PRECAUTIONS

AND IN THE FRONT OF THIS OPERATING MANUAL.

----------------------------------------------------------------------

B-1

U

I

I

2

1

2

OUTPUT VOLTAGE

INPUT CURRENT

OUTPUT CURRENT

PROTECTIVE

GROUND

WARNING OR

CAUTION

Page 17

POWER FEED™ 25M NNS

OPERATION

DEFINITION OF WELDING TERMS

NON-SYNERGIC WELDING MODES

• A Non-synergic welding mode requires all welding process variables to be set by the operator.

SYNERGIC WELDING MODES

• A Synergic welding mode offers the simplicity of single knob

control. The machine will select the correct voltage and amperage based on the wire feed speed (WFS) set by the operator.

WFS

• Wire Feed Speed

CC

• Constant Current

CV

• Constant Voltage

GMAW

• Gas Metal Arc Welding

DUTY CYCLE

The POWER FEED™ 25M NNS is rated for 500 amps, 60% duty

cycle. The duty cycle is based on a 10 minute cycle.

For example, when welding at 500 amps, the POWER FEED™

25M NNS may run continuously for 6 minutes and then must sit

idle for 4 minutes.

GMAW-P

• Gas Metal Arc Welding-(Pulse Arc)

GMAW-STT

• Gas Metal Arc Welding-(Surface Tension Transfer)

SMAW

• Shielded Metal Arc Welding

FCAW

• Flux Core Arc Welding

CAG

• Carbon Arc Gouging

B-2

Page 18

POWER FEED™ 25M NNS

RECOMMENDED PROCESSES

• GMAW (CV, Synergic CV, Pulse, STT™, Power, Pulse on

Pulse™)

• FCAW

• SMAW

GTAW (Lift Start only)

•

• Solid wires .025" to 1/16"

• Cored wires .035" to 5/64"

EQUIPMENT LIMITATIONS

• Works only on ArcLink®Power Wave power sources.

• Maximum gun length is 25ft.(7.6m) for push-only systems.

• Maximum spool size is 12 in. (305 mm) diameter

• Maximum spool weight is 44 lb (20 kg).

• Maximum control cable length is 200 ft (61 m).

• No more than 2 wire feeders may be connected to one ArcLink

power source at a time.

RECOMMENDED POWER SOURCES

• Power Wave®355M

• Power Wave

• Power Wave

• Power Wave

• Power Wave

• Power Wave

®

455M

®

455M/STT

®

S350

®

R350

®

i400

OPERATION

B-3

Page 19

POWER FEED™ 25M NNS

CASE FRONT CONTROLS

(SEE FIGURE B.1)

OPERATION

10. Gun Trigger Connection

1. Left DISPLAY window

Shows WIRE FEED SPEED or AMPERAGE.

2. Left KNOB

Adjusts values in left display.

3. Main display

Shows detailed welding and diagnostic information.

4. Left Button

Changes the Main display to show the Weld Mode or

UltimArc.

5. Procedure Button

Selects A or B procedure, or gun control.

6. 2-Step/4-Step Button

Toggles between 2-step and 4-step trigger operation.

7. Gun Shielding Gas Connections

8. ON/OFF switch

Controls power to the POWER FEED™ 25M NNS.

9. Gun Electrode Connection

FIGURE B.1

11. Right Display window

Shows VOLTAGE or TRIM.

12. Right Knob

Adjusts values in the right display.

13. Thermal

Lights when the drive overheats.

14. Set-Up

Lights when feeder is set-up.

15. Right Button

Changes the Main display to show Start Options or

End Options.

16. Set Knob

Changes the value on the Main display.

17. Memories Buttons

For selection of common procedures.

18. Gun Conduit Connection

1

2

11

12

3

13

4

14

15

5

6

16

17

7

18

8

9

10

B-4

Page 20

ELECTRI C SHOCK can kill.

• Turn the input power OFF at the welding

pow er source before installation or

chang-

ing drive rolls and/or guides.

• Do not touch el ectrically live parts.

• When inching with the g

un trigger, electrode and drive

mechanism are "hot" to work and ground and could remain

energized sever

al seconds after the gun trigger is released.

• Welding power source must be connected to system groun

d

per the National Electrical Code or any applicable loca l

codes.

• Only qualified personnel should perf

orm maintenance work.

The serviceability of a product or structure utilizing the welding

p r o g r a m s is and mus t b e th e so l e r e

s p on s ib i li t y of t he

builder/user. Many variables beyond the control of The Li ncoln

Electric Company aff

ect the results obtained in applying these

programs. These variables include, but are not limited to,

welding proced ur e, plate ch emistry and temperatu r e , weldmen t

design, fabrication methods and service

requirements. The availab le rang e o f a welding p rogr am m ay not be suit able fo r a ll

appli cations, and

the build/user is and must be solely responsi-

ble for welding pro gram selection.

POWER FEED™ 25M NNS

OPERATION

8. ON-OFF SWITCH

The On-Off Switch turns the wire feeder power on and off. It does

not control the power to the welding power source.

WARNING

----------------------------------------------------------------------

POWER WAVE SYSTEM OPERATION

Second, find the program in the welding software that best matches the desired welding process. The standard software shipped

with the Power Waves encompasses a wide range of common

processes and will meet most needs. If a special welding program

is desired, contact the local Lincoln Electric sales representative.

All adjustments are made on the user interface. Because of the

different configuration options your system may not have all of the

following adjustments. Regardless of availability, all controls are

described below.

WARNING

---------------------------------------------------------------------The steps for operating the Power Wave will vary depending upon

the user interface of the welding system. The flexibility of the

Power Wave lets the user customize operation for the best performance.

First, consider the desired welding process and the part to be

welded. Choose an electrode material, diameter, shielding gas and

process (GMAW, GMAW-P, GMAW-STT™, etc.)

B-5

Page 21

POWER FEED™ 25M NNS

WIRE FEED SPEED / AMPS DISPLAY AND KNOB

FIGURE B.2

The left display and knob are used to adjust either wire feed

speed or amperage, depending upon the process selected.

While welding, the amps LED lights when amperage is

displayed and the wire feed speed LED lights when WFS is

displayed.

OPERATION

B-6

Page 22

POWER FEED™ 25M NNS

OPERATION

VOLTAGE / TRIM DISPLAY AND KNOB

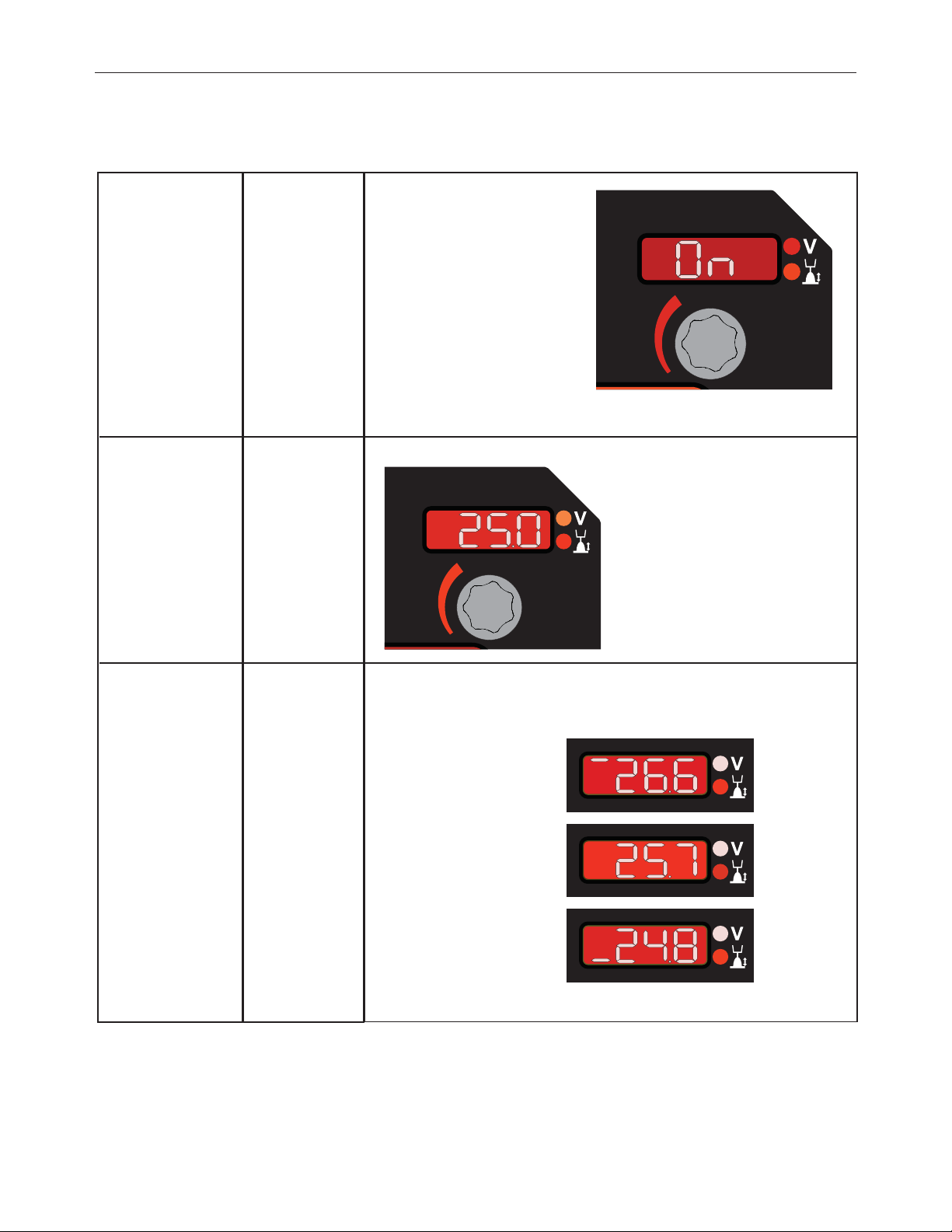

The right display and knob control voltage, trim or output depending upon the process selected. Once welding is complete, the display

continues to show the welding voltage for 5 seconds.

Process

SMAW

(Stick) and GTAW (TIG)

Non-synergic

GMAW (MIG) and FCAW

(Flux-cored)

Display / Function

Weld Output

Voltage

Description

Rotate clockwise to turn output ON.

Rotate counterclockwise to turn output OFF.

Adjusts the voltage. The display is blank for non-synergic STT modes.

Synergic

GMAW (MIG) and FCAW

(Flux-cored)

When the voltage knob is rotated, the display will show an upper or lower bar indicating if the voltage is above or below the ideal voltage. The display is blank for synergic

STT modes.

• Preset voltage above ideal

voltage. (upper bar displayed).

Voltage

• Preset voltage at idealvoltage.

(no bar displayed).

• Preset voltage below idealvoltage. (lower bar displayed)

B-7

Page 23

POWER FEED™ 25M NNS

VOLTAGE / TRIM DISPLAY AND KNOB

OPERATION

Process

Pulse

GMAW (MIG) and FCAW

(Flux-cored)

Display / Function

Trim

Description

Pulse welding controls the arc

length with 'Trim' instead of voltage. When trim (arc length) is

adjusted, the Power Wave automatically recalculates the voltage,

current and time of each part of

the pulse waveform for the best

result. Trim adjusts the arc length and ranges from 0.50 to 1.50. Increasing the trim

value increases the arc length, while decreasing the trim value decreases the arc

length.

Trim .50

Arc Length Short

Trim 1.00

Arc Length Medium

Trim 1.50

Arc Length Long

B-8

Page 24

POWER FEED™ 25M NNS

SELECTING A WELD MODE

Weld modes may be selected by mode number or through a search

function.

To select a weld mode:

1. Press the left button until the Weld Mode Menu LED illuminates.

2. Rotate the center knob to select the weld mode.

To enter the search function:

1. Rotate the center knob until “Weld Mode Search” is displayed and

then press the right button.

2. Rotate the center knob to select the wire material. Press the right

button to accept and the left button to cancel.

3. Rotate the center knob to select the wire size. Press the right

button to accept and the left button to cancel.

4. Rotate the center knob to make the final selection about the

process, gas type and waveform. Press the right button to accept

and the left button to cancel.

OPERATION

B-9

Page 25

POWER FEED™ 25M NNS

OPERATION

WAVE CONTROL

Wave Control is used to adjust the arc for exact preferences. The wave control functions vary for different processes and weld modes.

Process

SMAW

(Stick)

GMAW

(MIG) and

FCAW

(Flux-cored)

Wave Control

Name

Arc Force

Pinch

Effect / Range

Soft (-10.0) to

Crisp (10.0)

Soft (-10.0) to

Crisp (10.0)

Description

Arc Force adjusts the short circuit current for a soft arc, or for a forceful, driving

arc. It helps to prevent sticking and shorting of organic coated electrodes, particularity globular transfer types such as stainless and low hydrogen. Arc Force is

especially effective for root pass on pipe with stainless electrode and helps to

minimize spatter for certain electrodes and procedure as with low hydrogen, etc.

Pinch controls the arc characteristics when short-arc welding.

Ultimarc regulates the focus or shape of the arc. Ultimarc values greater than

0.0 increase the pulse frequency while decreasing the background current,

resulting in a tight, stiff arc best for high speed sheet metal welding. Ultimarc

values less than 0.0 decrease the pulse frequency while increasing the background current, for a soft arc good for out-of-position welding.

GMAW-P (Pulsed

MIG), Steel and

Stainless

Ultimarc

Soft (-10.0) to

Stiff (10.0)

Arc Control -10.0

Low Frequency, Wide

Arc Control OFF

Medium Frequency and Width

Arc Control +10.0

High Frequency, Focused

For Pulse modes, Arc Control changes the pulsing frequency. When the frequency changes, the Power Wave system automatically adjusts the background current to maintain a similar heat input into the weld. Low frequencies give more

control over the puddle and high frequencies minimize spatter.

B-10

Page 26

POWER FEED™ 25M NNS

WAVE CONTROL

OPERATION

Process

GMAW-STT

(Surface Tension

Transfer

Wave Control

Name

Peak Current

Effect / Range

Controls arc

length

Description

Peak Current acts similar to an arc pinch control. Peak Current sets the arc

length and promotes good fusion. Higher peak current levels will cause the arc

to broaden momentarily while increasing arc length. If set too high, globular

transfer may occur. Setting it too low may cause instability and wire stubbing.

Best practice is to adjust for minimum spatter and puddle agitation.

Peak also affects the shape of the root. When using 100% CO2, the peak current will be higher than when welding with blended shielded gases. A longer arc

length is required with CO2 to reduce spatter.

Background current adjusts the overall heat input into the weld. Changing the

background current changes the shape of the back bead. 100% CO2 requires

less background current than when welding with blended shielding gases.

GTAW (TIG)

Background

Current

Tail-out

No wave

controls

available.

Regulates bead

contour

Provides additional power to

the arc.

----

Tail out provides additional power without the molten droplet becoming too

large. Increase as necessary to add heat input without increasing arc length.

Often this results in faster travel speeds. Note that as tail out increases, the peak

current and/or background current may need to be reduced.

----

B-11

Page 27

POWER FEED™ 25M NNS

2-St

2- STEP 4- STEP- TRIGGER OPERATION

OPERATION

The 2-Step - 4-Step switch changes the function of the

gun trigger. 2-Step trigger operation switches the welding output ON-OFF in direct response to the trigger. 4Step trigger operation provides 'trigger interlock' capability and gives the ability to control the amount of time

spent in the arc start and arc crater steps.

Press the push button on the case front to toggle

between 2-Step and 4-Step operation.

The 2-Step, 4-Step trigger has no effect when welding

with SMAW or CAG procedures.

2-Step Trigger

2-Step trigger operation is the most common. When the

gun trigger is pulled, the welding system (power source

and wire feeder) cycles through the arc starting

sequence and into the main welding parameters. The

welding system will continue to weld as long as the gun

trigger is activated. Once the trigger is released, the

welding system cycles through the arc ending steps

4-Step Trigger

4-Step trigger operation gives the welder additional

control in the welding sequence. 4-Step trigger allows

the welder to choose the arc start, weld and arc end

time. It may also be set-up to work as a trigger interlock.

ep Trigger

B-12

Page 28

POWER FEED™ 25M NNS

OPERATION

2-Step T rigger

2-Step Trigger controls the welding sequence in direct response to the trigger. When the gun trigger is pulled, the welding system

(power source and wire feeder) cycles through the arc starting sequence and into the main welding parameters. The welding system

will continue to weld as long as the gun trigger is activated. Once the trigger is released, the welding system cycles through the arc

ending steps.

Example 1: 2-Step Trigger: Simple operation

The simplest trigger operation occurs with a 2-Step trigger and Start and Crater set to OFF.

For this sequence,

PREFLOW: Shielding gas begins to flow immediately when the gun trigger is pulled.

RUN-IN: After preflow time expires, the power source regulates to the welding output and wire is advanced towards the work piece at

the Run-In WFS. If an arc is not established within 2.0 seconds, the wire feed speed will jump to the welding wire feed

speed.

WELD: The power source output and the wire feed speed continue at the weld settings for as long as the trigger is pulled.

POSTFLOW: As soon as the trigger is released, the power source output and the wire feed speed are turned OFF. Shielding gas

continues until the post flow timer expires.

Trigger Pulled

Arc Established

Trigger Released

B-13

Page 29

POWER FEED™ 25M NNS

Trigger Pulled

Arc Established

Trigger Released

OPERATION

2-Step T rigger

Example 2: 2-Step Trigger: Improved Arc Start and Arc End

Tailoring the arc start and arc end is a common method for reducing spatter and improving weld quality. This can be accomplished

with the Start and Burnback functions set to a desired values and Crater set to OFF.

For this sequence,

PREFLOW: Shielding gas begins to flow immediately when the gun trigger is pulled.

RUN-IN: After preflow time expires, the power source regulates to the start output and wire is advanced towards the work piece at

the Run-In WFS. If an arc is not established within 2.0 seconds, the power source output and wire feed speed skips to

the weld settings.

START: Once the wire touches the work and an arc is established, both the machine output and the wire feed speed ramp to the

weld settings throughout the start time. The time period of ramping from the start settings to the weld settings is called

UPSLOPE.

WELD: After upslope, the power source output and the wire feed speed continue at the weld settings.

BURNBACK: As soon as the trigger is released, the wire feed speed is turned OFF and the machine output continues for the burnback

time.

POSTFLOW: Next, the machine output is turned OFF and shielding gas continues until the post flow timer expires.

B-14

Page 30

POWER FEED™ 25M NNS

Trigger Pulled

Arc Established

Trigger Released

OPERATION

2-Step T rigger

Example 3: 2-Step Trigger: Customized Arc Start, Crater and Arc End

Aluminum is an example of where start, crater and burnback are commonly used to improve welding performance.

For this sequence,

PREFLOW: Shielding gas begins to flow immediately when the gun trigger is pulled.

RUN-IN: After preflow time expires, the power source regulates to the start output and wire is advanced towards the

work piece at the Run-In WFS. If an arc is not established within 2.0 seconds, the power source output and

wire feed speed skips to the weld settings.

START & UPSLOPE: Once the wire touches the work and an arc is established, both the machine output and the wire feed speed

ramp to the weld settings throughout the start time. The time period of ramping from the start settings to the

weld settings is called UPSLOPE.

WELD: After upslope, the power source output and the wire feed speed continue at the weld settings.

BURNBACK: After the crater time expires, the wire feed speed is turned OFF and the machine output continues for the burn-

back time.

POSTFLOW: Next, the machine output is turned OFF and shielding gas continues until the post flow timer expires.

2-Step trigger: Special considerations

The weld sequence response depends upon when the trigger is pulled and released and whether or not START or CRATER are active.

An example sequence:

Pull the trigger to start feed of wire. When arc is established the sequencer will begin START/UPSLOPE. If trigger is released during

UPSLOPE and CRATER/DOWNSLOPE is active, the machine will begin CRATER/DOWNSLOPE and sloping down over the CRATER time,

regardless of when the trigger release occurred.

If the CRATER is disabled and the trigger is released during START/UPSLOPE, the sequencer will move to the BURNBACK state to end

the weld.

B-15

Page 31

POWER FEED™ 25M NNS

OPERATION

4-Step T rigger

4-step trigger allows the operator to release the trigger once an arc has been established. To end the weld, the trigger is pulled and

then released again.

Two types of 4-Step Trigger are available. Use the set-up menu to select the desired type of operation.

With current interlock, if the arc goes out for more than 0.5 seconds while the trigger is released, the welding process stops and goes

to the idle state.

Without the current interlock, if the arc goes out while the trigger is released, output to the power source remains on and the wire

feeder will continue to feed wire.

Example 1: 4-Step Trigger: Trigger Interlock

The 4-Step trigger can be configured as a trigger interlock. Trigger interlock adds to the welder’s comfort when making long welds by

allowing the trigger to be released after an initial trigger pull. Welding stops when the trigger is pulled a second time and then

released, or if the arc is interrupted.

For this sequence,

PREFLOW: Shielding gas begins to flow immediately when the gun trigger is pulled.

RUN-IN: After preflow time expires, the power source regulates to the welding output and wire is advanced towards the work

piece at the Run-In WFS. If an arc is not established within 1.5 seconds, the wire feed speed will jump to the

welding wire feed speed.

WELD: The power source output and the wire feed speed continue at the weld settings. The trigger is released and welding

continues. Welding continues when the trigger is pulled a second time

POSTFLOW: As soon as the trigger is released for the second time, the power source output and the wire feed speed are turned

OFF. Shielding gas flows until the post flow timer expires.

Trigger Pulled

Arc Established

Trigger Released

Trigger Pulled

Trigger Released

B-16

Page 32

POWER FEED™ 25M NNS

:

OPERATION

4-Step T rigger

Example 2: 4-Step Trigger: Manual Control of Start and Crater times with Burnback ON.

The 4-Step trigger sequence gives the most flexibility when the Start, Crater and Burnback functions are active. This is a popular

choice when welding aluminum because extra heat may be needed during Start and less heat desired during crater. With 4-Step

trigger, the welder chooses the amount of time to weld at the Start, Weld and Crater settings by using the gun trigger. Burnback

reduces the occurrence of wire to sticking into the weld pool at the end of a weld and conditions the end of the wire for the next arc

start.

In this sequence,

PREFLOW: Shielding gas begins to flow immediately when the gun trigger is pulled.

RUN-IN: After preflow time expires, the power source regulates to the start output and wire is advanced towards the work

piece at the run-in WFS. If an arc is not established within 2.0 seconds, the power source output and wire feed

speed skips to the weld settings.

START: The power source welds at the start WFS and voltage until the trigger is released.

UPSLOPE: During upslope, the power source output and the wire feed speed ramp to the weld settings throughout the start

time. The time period of ramping from the start settings to the weld settings is called UPSLOPE. If the trigger is

pulled before upslope is complete, WELD is skipped and the sequence jumps to DOWNSLOPE.

WELD: After upslope, the power source output and the wire feed speed continue at the weld settings.

DOWNSLOPE

CRATER: During CRATER, the power source continues to supply output at the crater WFS and voltage.

BURNBACK: When the trigger is released, the wire feed speed is turned OFF and the machine output continues for the burnback

POSTFLOW: Next, the machine output is turned OFF and shielding gas continues until the post flow timer expires.

As soon as the trigger is pulled, the wire feed speed and power source output ramp to the crater settings throughout

the crater time. The time period of ramping from the weld settings to the crater settings is called DOWNSLOPE

time.

Trigger Pulled

Arc Established

Trigger Released

Trigger Pulled

Trigger Released

B-17

Page 33

POWER FEED™ 25M NNS

OPERATION

Spot T rigger

The Spot Trigger may only be selected if the Spot Time has previously been set to a value other than 0.0 (OFF) and the Start and Crater

are both OFF.

Spot time causes the welding system to turn on for a fixed time, regardless if the trigger is held for a longer period of time. If the trigger is released before the spot timer is complete, welding stops.

If the Spot Time is set to 0.0 (OFF), the left display will be blank and the right display will show “OFF”. The Spot Time LED from the

timer menu will blink twice. After 2.0 seconds,

the trigger menu cycles back to the Cold Feed

Trigger option.

If Start is not set to OFF, the left display will be

blank and the right display will show “On”. The

Start LED from the sequence menu will blink

twice. After 2.0 seconds, the trigger menu

cycles back to the Cold Feed Trigger option.

If Crater is not set to OFF, the left display will be

blank and the right display will show “On”. The

Crater LED from the sequence menu will blink

twice. After 2.0 seconds, the trigger menu

cycles back to the Cold Feed Trigger option.

B-18

Page 34

POWER FEED™ 25M NNS

OPERATION

4-Step T rigger: Special Considerations

The response to the trigger with 4-step trigger active is dependent upon when the trigger is pulled/released and the settings for START

and CRATER.

Example 1.

Pull the trigger to start feed of wire. When arc is established the sequencer will remain in START until the trigger is released. When the

trigger is released, UPSLOPE begins. If trigger is pulled again during UPSLOPE and CRATER/DOWNSLOPE is active, the feeder will

begin the DOWNSLOPE, sloping down over the CRATER time, regardless of when the trigger pull occurred.

If the CRATER/DOWNSLOPE state is disabled and the trigger is pulled during UPSLOPE, the sequencer will remain in the UPSLOPE state

and continue with the weld. If the fourth step (trigger release) occurs during UPSLOPE, the sequencer will jump to the BURNBACK to

end the weld.

Example 2:

Pull the trigger to start feed of wire. When arc is established the sequencer will remain in START until the trigger is released. When the