Page 1

Operator’s Manual

RETURN TO MAIN MENU

FLEXTEC ™650

For use with machines having Code Numbers:

11936

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM10132 | Issue D ate Sept- 13

© Lincoln Global, Inc. All Rights Reserved.

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Page 2

THANK YOU FOR SELECTING

AT ALL

TIMES.

SPECIAL SITUATIONS

Additional precautionary measures

A QUALITY PRODUCT BY

LINCOLN ELEC TRIC.

PLEASE EXAMINE CARTON AND EQUIPMENT FOR

DAMAGE IMMEDIATELY

When this equipment is shipped, title passes to the purchaser upon

receipt by the carrier. Consequently, Claims for material damaged in

shipment must be made by the purchaser against the transportation

company at the time the shipment is received.

SAFETY DEPENDS ON YOU

Lincoln arc welding and cutting equipment is designed and built with

safety in mind. However, your overall safety can be increased by

proper installation ... and thoughtful operation on your part.

DO NOT INSTALL, OPERATE OR REPAIR THIS EQUIPMENT

WITHOUT READING THIS MANUAL AND THE SAFETY PRECAUTIONS

CONTAINED THROUGHOUT. And, most importantly, think before you

act and be careful.

WARNING

This statement appears where the information must be followed

exactly to avoid serious personal injury or loss of life.

CAUTION

This statement appears where the information must be followed to

avoid minor personal injury or damage to this equipment.

KEEP YOUR HEAD OUT OF THE FUMES.

DON’T get too close to the arc. Use

corrective lenses if necessary to

stay a reasonable distance away

from the arc.

READ and obey the Material Safety

Data Sheet (MSDS) and the warning

label that appears on all containers

of welding materials.

USE ENOUGH VENTILATION or

exhaust at the arc, or both, to keep

the fumes and gases from your breathing zone and the general area.

IN A LARGE ROOM OR OUTDOORS, natural ventilation may be

adequate if you keep your head out of the fumes (See below).

USE NATURAL DRAFTS or fans to keep the fumes away from your

face.

If you de velop unusual symptoms, see your supervisor. Perhaps the

welding atmosphere and ventilation system should be checked.

WEAR CORRECT EYE, EAR & BODY PROTECTION

PROTECT your eyes and face with welding helmet

properly fitted and with proper grade of filter plate

(See ANSI Z49.1).

PROTECT your body from welding spatter and arc

flash with protective clothing including woolen

clothing, flame-proof apron and gloves, leather

leggings, and high boots.

PROTECT others from splatter, flash, and glare with

protective screens or barriers.

IN SOME AREAS, protection from noise may be

appropriate.

BE SURE protective equipment is in good condition.

Also, wear safety glasses in work area

DO NOT WELD OR CUT containers or materials which previously had

been in contact with hazardous substances unless they are properly

cleaned. This is extremely dangerous.

DO NOT WELD OR CUT painted or plated parts unless special

precautions with ventilation have been taken. They can release highly

toxic fumes or gases.

PROTECT compressed gas cylinders from excessive heat, mechanical

shocks, and arcs; fasten cylinders so they cannot fall.

BE SURE cylinders are never grounded or part of an electrical circuit.

REMOVE all potential fire hazards from welding area.

ALWAYS HAVE FIRE FIGHTING EQUIPMENT READY FOR

IMMEDIATE USE AND KNOW HOW TO USE IT.

Page 3

SECTION A:

Diesel Engines

Gasoline Engines

WARNINGS

CALIFORNIA PROPOSITION 65 WARNINGS

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and other

reproductive harm.

The engine exhaust from this product contains chemicals known

to the State of California to cause cancer, birth defects, or other

reproductive harm.

ARC WELDING CAN BE HAZARDOUS. PROTECT

YOURSELF AND OTHERS FROM POSSIBLE SERIOUS

INJURY OR DEATH. KEEP CHILDREN AWAY. PACEMAKER WEARERS SHOULD CONSULT WITH THEIR

DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For additional

safety information, it is strongly recommended that you purchase a

copy of “Safety in Welding & Cutting - ANSI Standard Z49.1” from the

American Welding Society, P.O. Box 351040, Miami, Florida 33135 or

CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety”

booklet E205 is available from the Lincoln Electric Company, 22801

St. Clair Avenue, Cleveland, Ohio 44117-1199.

BE SURE THAT ALL INSTALLATION, OPERATION,

MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

SAFETY

1.d. Keep all equipment safety guards, covers and

devices in position and in good repair.Keep

hands, hair, clothing and tools away from

V-belts, gears, fans and all other moving parts

when starting, operating or repairing

equipment.

1.e. In some cases it may be necessary to remove safety guards to

perform required maintenance. Remove guards only when

necessary and replace them when the maintenance requiring

their removal is complete. Always use the greatest care when

working near moving parts.

1.f. Do not put your hands near the engine fan. Do not attempt to

override the governor or idler by pushing on the throttle control

rods while the engine is running.

1.g. To prevent accidentally starting gasoline engines while turning

the engine or welding generator during maintenance work,

disconnect the spark plug wires, distributor cap or magneto wire

as appropriate.

1.h. To avoid scalding, do not remove the radiator

pressure cap when the engine is

hot.

ELECTRIC AND

MAGNETIC FIELDS MAY

BE DANGEROUS

2.a. Electric current flowing through any conductor

causes localized Electric and Magnetic Fields (EMF). Welding

current creates EMF fields around welding cables and welding

machines

FOR ENGINE POWERED

EQUIPMENT.

1.a. Turn the engine off before troubleshooting

and maintenance work unless the

maintenance work requires it to be running.

1.b. Operate engines in open, well-ventilated

areas or vent the engine exhaust fumes outdoors.

1.c. Do not add the fuel near an open flame

welding arc or when the engine is running.

Stop the engine and allow it to cool before

refueling to prevent spilled fuel from

vaporizing on contact with hot engine parts

and igniting. Do not spill fuel when filling

tank. If fuel is spilled, wipe it up and do not start engine until

fumes have been eliminated.

2.b. EMF fields may interfere with some pacemakers, and welders

having a pacemaker should consult their physician before

welding.

2.c. Exposure to EMF fields in welding may have other health effects

which are now not known.

2.d. All welders should use the following procedures in order to

minimize exposure to EMF fields from the welding circuit:

2.d.1. Route the electrode and work cables together - Secure

them with tape when possible.

2.d.2. Never coil the electrode lead around your body.

2.d.3. Do not place your body between the electrode and work

cables. If the electrode cable is on your right side, the

work cable should also be on your right side.

2.d.4. Connect the work cable to the workpiece as close as possible to the area being welded.

2.d.5. Do not work next to welding power source.

3

Page 4

SAFETY

ELECTRIC SHOCK

CAN KILL.

3.a. The electrode and work (or ground) circuits are

electrically “hot” when the welder is on. Do

not touch these “hot” parts with your bare skin

or wet clothing. Wear dry, hole-free gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full area

of physical contact with work and ground.

In addition to the normal safety precautions, if

welding must be performed under electrically

hazardous conditions (in damp locations or while

wearing wet clothing; on metal structures such as

floors, gratings or scaffolds; when in cramped

positions such as sitting, kneeling or lying, if there

is a high risk of unavoidable or accidental contact

with the workpiece or ground) use the following

equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel, welding head, nozzle or semiautomatic welding

gun are also electrically “hot”.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection should

be as close as possible to the area being welded.

3.e. Ground the work or metal to be welded to a good electrical (earth)

ground.

3.f. Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Never simultaneously touch electrically “hot” parts of electrode

holders connected to two welders because voltage

two can be the total of the open circuit voltage of both

welders.

3.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

between the

ARC RAYS CAN BURN.

4.a. Use a shield with the proper filter and cover plates to protect your

eyes from sparks and the rays of the arc when welding or

observing open arc welding. Headshield and filter lens should

conform to ANSI Z87. I standards.

4.b. Use suitable clothing made from durable flame-resistant material

to protect your skin and that of your helpers from the arc rays.

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

FUMES AND GASES

CAN BE DANGEROUS.

5.a. Welding may produce fumes and gases

hazardous to health. Avoid breathing these

fumes and gases. When welding, keep your head out of the fume.

Use enough ventilation and/or exhaust at the arc to keep fumes

and gases away from the breathing zone. When welding

with electrodes which require special ventilation

such as stainless or hard facing (see instructions

on container or MSDS) or on lead or cadmium

plated steel and other metals or coatings which

produce highly toxic fumes, keep exposure as low

as possible and within applicable OSHA PEL and

ACGIH TLV limits using local exhaust or

mechanical ventilation. In confined spaces or in

some circumstances, outdoors, a respirator may

be required. Additional precautions are also

required when welding on galvanized steel.

5. b. The operation of welding fume control equipment is affected by

various factors including proper use and positioning of the

equipment, maintenance of the equipment and the specific

welding procedure and application involved. Worker exposure

level should be checked upon installation and periodically

thereafter to be certain it is within applicable OSHA PEL and

ACGIH TLV limits.

5.c. Do not weld in locations near chlorinated hydrocarbon vapors

coming from degreasing, cleaning or spraying operations. The

heat and rays of the arc can react with solvent vapors to form

phosgene, a highly toxic gas, and other irritating products.

3.j. Also see It ems 6.c. and 8.

5.d. Shielding gases used for arc welding can displace air and

injury or death. Always use enough ventilation, especially in

confined areas, to insure breathing air is safe.

5.e. Read and understand the manufacturer’s instructions for this

equipment and the consumables to be used, including the

material safety data sheet (MSDS) and follow your employer’s

safety practices. MSDS forms are available from your welding

distributor or from the manufacturer.

5.f. Also see item 1.b.

4

cause

Page 5

SAFETY

WELDING AND CUTTING

SPARKS CAN CAUSE

FIRE OR EXPLOSION.

6.a. Remove fire hazards from the welding area. If

this is not possible, cover them to prevent the

welding sparks from starting a fire. Remember that welding

sparks and hot materials from welding can easily go through

small cracks and openings to adjacent areas. Avoid welding near

hydraulic lines. Have a fire extinguisher readily available.

6.b. Where compressed gases are to be used at the job site, special

precautions should be used to prevent hazardous situations.

Refer to “Safety in Welding and Cutting” (ANSI Standard Z49.1)

and the operating information for the equipment being used.

6.c. When not welding, make certain no part of the electrode circuit is

touching the work or ground. Accidental contact can cause

overheating and create a fire hazard.

6.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures will

not cause flammable or toxic vapors from substances inside.

They can cause an explosion even though they have been

“cleaned”. For information, purchase “Recommended Safe

Practices for the Preparation for Welding and Cutting of

Containers and Piping That Have Held Hazardous Substances”,

AWS F4.1 from the American Welding Society (see address

above).

6.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

6.f. Sparks and spatter are thrown from the welding arc. Wear oil free

protective garments such as leather gloves, heavy shirt, cuffless

trousers, high shoes and a cap over your hair. Wear ear plugs

when welding out of position or in confined places. Always wear

safety glasses with side shields when in a welding area.

6.g. Connect the work cable to the work as close to the welding area

as practical. Work cables connected to the building framework or

other locations away from the welding area increase the

possibility of the welding current passing through lifting chains,

crane cables or other alternate circuits. This can create fire

hazards or overheat lifting chains or cables until they fail.

6.h. Also see item 1.c.

CYLINDER MAY EXPLODE IF

DAMAGED.

7.a. Use only compressed gas cylinders containing

the correct shielding gas for the process used

and properly operating regulators designed for

the gas and pressure used. All hoses, fittings,

etc. should be suitable for the application and

maintained in good condition.

7.b. Always keep cylinders in an upright position securely chained to

an undercarriage or fixed support.

7.c. Cylinders should be located:

• Away from areas where they may be struck or subjected

to physical damage.

• A safe distance from arc welding or cutting operations

and any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode holder or any other

electrically “hot” parts to touch a cylinder.

7.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. Valve protection caps should always be in place and hand tight

except when the cylinder is in use or connected for use.

7.g. Read and follow the instructions on compressed gas cylinders,

associated equipment, and CGA publication P-l, “Precautions for

Safe Handling of Compressed Gases in

Cylinders,” available

from the Compressed Gas Association 1235 Jefferson Davis

Highway, Arlington, VA 22202.

FOR ELECTRICALLY

POWERED EQUIPMENT.

8.a. Turn off input power using the disconnect

switch at the fuse box before working on the

equipment.

8.b. Install equipment in accordance with the U.S. National Electrical

Code, all local codes and the manufacturer’s recommendations.

6.I. Read and follow NFPA 51B “ Standard for Fire Prevention During

Welding, Cutting and Other Hot Work”, available from NFPA, 1

Batterymarch Park, PO box 9101, Quincy, Ma 022690-9101.

6.j. Do not use a welding power source for pipe thawing.

8.c. Ground the equipment in accordance with the U.S. National

Electrical Code and the manufacturer’s recommendations.

Refer to

http://www.lincolnelectric.com/safety

for additional safety information.

Welding Safety

Interactive Web Guide

for mobile devices

5

Page 6

vi vi

Installation .......................................................................................................Section A

Technical Specifications.................................................................................A-1, A-2

Safety Precautions ..........................................................................................A-3

VRD™ (Voltage Reduction Device) ..............................................................................A-3

Select Suitable Location..................................................................................A-3

Lifting...............................................................................................................A-3

Stacking ..........................................................................................................A-3

Environmental Limitations ...............................................................................A-3

Input and Grounding Connections ..................................................................A-3

High Frequency Protection..............................................................................A-3

High Temperature Operation.................................................................................A-3

Input Connection ...................................................................................................A-4

Input Fuse and Supply Wire Considerations .........................................................A-4

Input Voltage Selection..........................................................................................A-4

Cable Connections ................................................................................................A-5

Recommended Electrode and Work Cable for Arc Welding..................................A-6

Output Cable Guidelines........................................................................................A-6

Control Cable Connections, Paralleling.................................................................A-7

Connection Diagrams Flextec 650 to Wire Feeders and Tractor...........A-8 thru A-12

________________________________________________________________________

Operation .........................................................................................................Section B

Safety Precautions ................................................................................................B-1

Graphic Symbols............................................................................................B-1, B-2

Product Description ..............................................................................................B-2

Duty Cycle .............................................................................................................B-2

Design Features ....................................................................................................B-2

Recommended Processes and Equipment ...........................................................B-3

Case Front Controls...............................................................................................B-4

Case Back Controls...............................................................................................B-5

Internal Controls ....................................................................................................B-6

Power-Up Sequence..............................................................................................B-7

Common Welding Procedures, Weld Controls and Displays.................B-7 thru B-10

________________________________________________________________________

TABLE OF CONTENTS

Page

Accessories .....................................................................................................Section C

Options / Accessories............................................................................................C-1

________________________________________________________________________

Maintenance ....................................................................................................Section D

Safety Precautions ................................................................................................D-1

Visual Inspection ...................................................................................................D-1

Routine Maintenance.............................................................................................D-1

Periodic Maintenance............................................................................................D-1

________________________________________________________________________

Section E ..............................................................................................Troubleshooting

How to Use Troubleshooting Guide.......................................................................E-1

Troubleshooting Guide ..........................................................................................E-2

Error Codes....................................................................................................E-3, E-4

________________________________________________________________________

Wiring Diagram and Dimension Print ..............................................................Section F

________________________________________________________________________

Parts List .....................................................................................................P-711 Series

________________________________________________________________________

Page 7

A-1

INSTALLATION

A-1

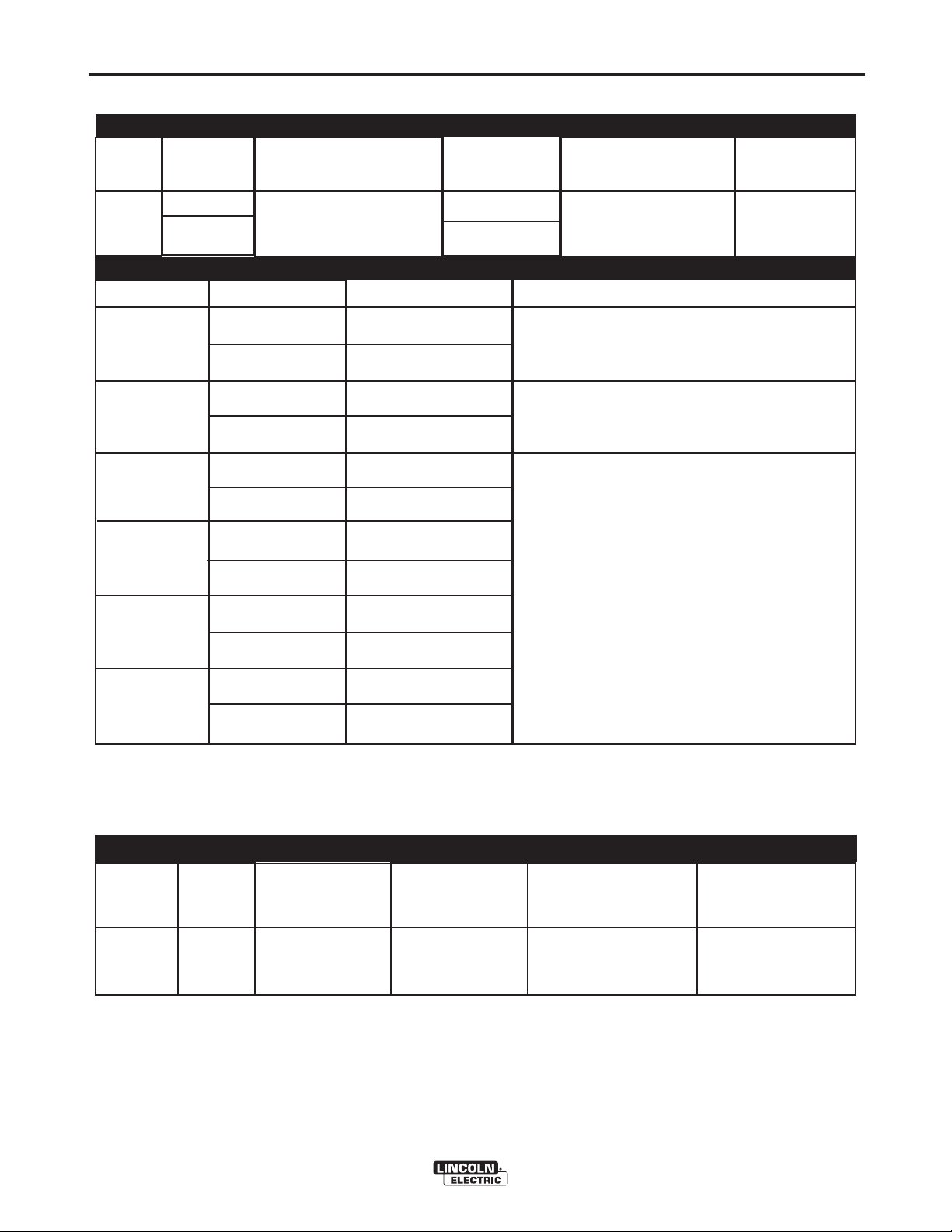

TECHNICAL SPECIFICATIONS -

POWER SOURCE-INPUT VOLTAGE AND CURRENT

Model

K3060-2

GMAW (CV)

GTAW (CC)

SMAW (CC)

FCAW-GS (CV)

FCAW-SS (CV)

Duty Cycle

60% rating

100% rating

Process

Input Voltage ± 10%

380 / 460 / 575 / 3 / 50 / 60

Duty Cycle

60%

100%

60%

100%

60%

100%

60%

100%

60%

100%

FLEXTEC™ 650

Input Amperes

61 / 50 / 40

57 / 47 / 38

RATED OUTPUT*

Amperes

750

*

650

*

750

650

750

*

650

*

750

*

650

*

750

*

650

*

Idle Power

(W)

230 MAX.( Fan On)

100 MAX. (Fan Off)

Volts at Rated Amperes

44V

34V

44V

Power Factor @

Rated Output

88%

60%

SAW (CV)

100%

750

650

*

*

* Output is limited to 600A / 100% and 700A / 60% when used with K3091-1 Multi-Process Switch.

RECOMMENDED INPUT WIRE AND FUSE SIZES

(mm)

4(25)

4(25)

6(16)

(3)

Type 75°C Copper

Wire in Conduit

AWG (mm

4(25)

6(16)

8 (10)

COPPER GROUNDING

CONDUCTOR

2

)

AWG (mm

8 (10)

8 (10)

10 (6)

VOLTAGE

50/60Hz

380/3/50

460/3/60

575/3/60

(1)

Cord and Fuse Sizes based upon the U.S. National Electric Code and maximum output for 40°C (104°) ambient.

(2)

Also called “inverse time” or “thermal/magnetic” circuit breakers; circuit breakers that have a delay in tripping action that decreases as the

magnitude of current increases.

(3)

Type SJ cord or similar in 30°C ambient.

Maximum

Input

Amperes

70 A

58 A

46 A

Cord Size

AWG SIZES

(1)

Fuse (Super Lag) or

2

)

Breaker Size

90

80

60

(2)

FLEXTEC™ 650

Page 8

A-2

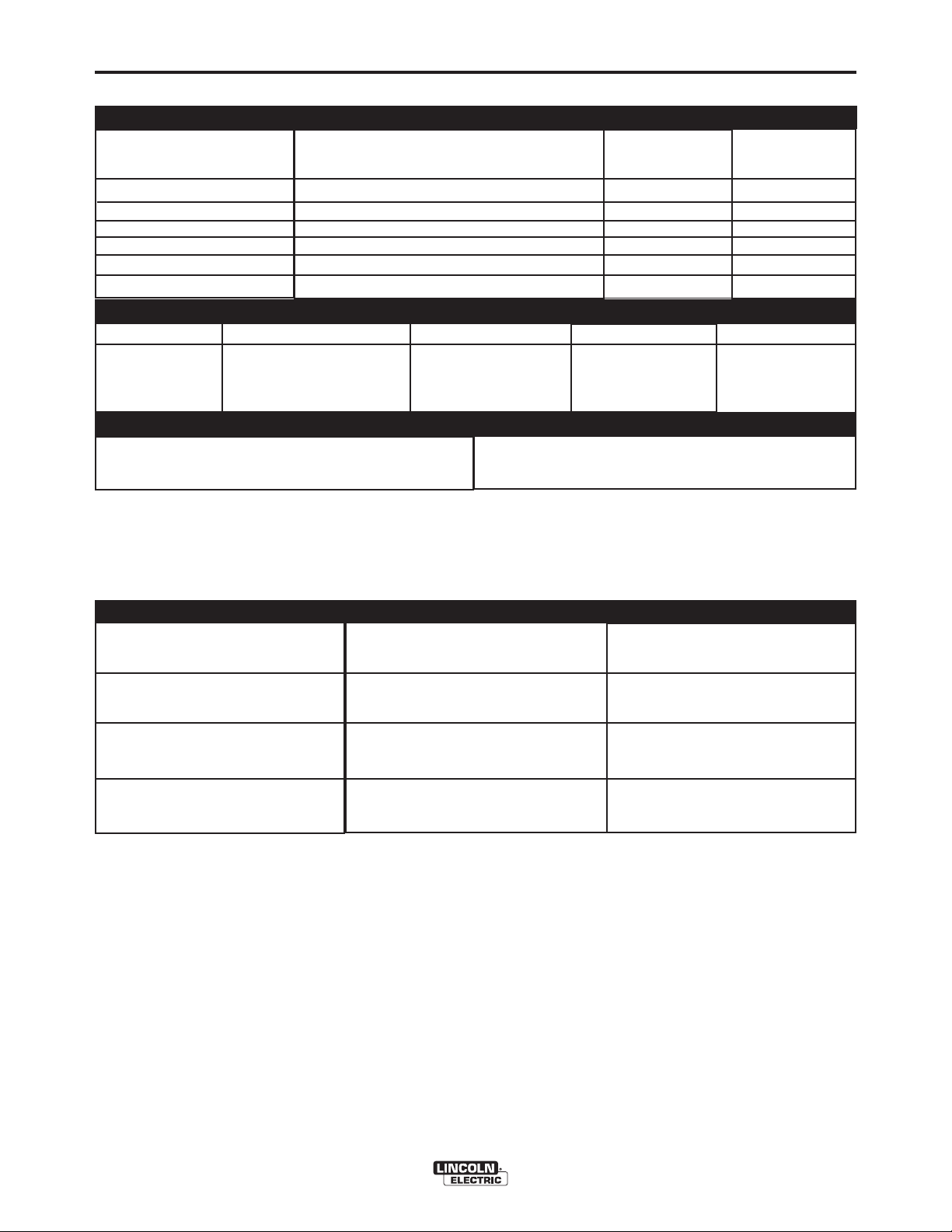

TECHNICAL SPECIFICATIONS -

PROCESS

OUTPUT RANGE (AMPERES)

INSTALLATION

FLEXTEC™ 650

WELDING PROCESS

OCV (Uo)

A-2

OCV (Ur)

GMAW (CV)

GTAW (CC)

SMAW (CC)

FCAW-GS (CV)

FCAW-SS (CV)

SAW (CV)

40-815

10-815

15-815

40-815

40-815

40-815

PHYSICAL DIMENSIONS

MODEL

K3060-2

HEIGHT

21.8 in (554 mm)

WIDTH

16.14 in (410 mm)

TEMPERATURE RANGES

OPERATING TEMPERATURE RANGE

Environmentally Hardened: 14°F to 131°F (-10°C to 55°C**)

IP23 180º(H) Insulation Class

* Weight does not include input cord.

** Power Source is de-rated at temperatures above 40C.

AUXILIARY RECONNECT INPUT RANGES

"A" LEAD

POSITION

VRD

Enabled

60

24

60

60

60

60

DEPTH

29.33 in (745 mm)

STORAGE TEMPERATURE RANGE

Environmentally Hardened: -40°F to 185°F (-40°C to 85°C)

165lbs (74.8kg)*

VRD

Disabled

--15

15

---

---

---

WEIGHT

380 Volt

Reconnect

460 Volt

Reconnect

575 Volt

Reconnect

Low Limit - 340 Vac

High Limit - 420 Vac

Low Limit - 390 Vac

High Limit - 505 Vac

Low Limit - 485 Vac

High Limit - 620 Vac

Low Limit - 340 Vac

High Limit - 455 Vac

Low Limit - 390 Vac

High Limit - 520 Vac

Low Limit - 485 Vac

High Limit - 655 Vac

FLEXTEC™ 650

Page 9

A-3

INSTALLATION

SAFETY PRECAUTIONS

WARNING

ELECTRIC SHOCK can kill.

ONLY QUALIFIED PERSONNEL

SHOULD PERFORM THIS INSTALLATION.

• TURN OFF INPUT POWER TO THE POWER

SOURCE AT THE DISCONNECT SWITCH OR

FUSE BOX BEFORE WORKING ON THIS

EQUIPMENT. TURN OFF THE INPUT POWER

TO ANY OTHER EQUIPMENT CONNECTED TO

THE WELDING SYSTEM AT THE DISCONNECT

SWITCH OR FUSE BOX BEFORE WORKING ON

THE EQUIPMENT.

• DO NOT TOUCH ELECTRICALLY HOT PARTS.

• ALWAYS CONNECT THE FLEXTEC™ 650

GROUNDING LUG (LOCATED INSIDE THE

RECONNECT INPUT ACCESS DOOR) TO A

PROPER SAFETY (EARTH) GROUND.

----------------------------------------------------------------------

VRD™ (VOLTAGE REDUCTION DEVICE)

The VRD™ feature provides additional safety in the CCStick mode. The VRD™ reduces the OCV (Open Circuit

Voltage) at the welding output terminals while not welding to

less than 35VDC peak.

A-3

When using a crane or overhead device to lift using

the handles, a lifting strap should be connected to

both handles. Do not attempt to lift the FLEXTEC™

650 with accessories attached to it.

STACKING

Multiple FLEXTEC™ 650ʼs cannot be stacked.

ENVIRONMENTAL LIMITATIONS

The FLEXTEC™ 650 is IP23 rated for use in an outdoor environment. The FLEXTEC™ 650 should not be

subjected to falling water during use nor should any

parts of it be submerged in water. Doing so may

cause improper operation as well as pose a safety

hazard. The best practice is to keep the machine in a

dry, sheltered area.

CAUTION

Do not mount the FLEXTEC™ 650 over combustible surfaces. Where there is a combustible

surface directly under stationary or fixed electrical

equipment, that surface shall be covered with a

steel plate at least .060” (1.6mm) thick, which shall

extend not less than 5.90” (150mm) beyond the

equipment on all sides.

-----------------------------------------------------------------------

INPUT AND GROUNDING CONNECTIONS

The VRD™ requires that the welding cable connections be

kept in good electrical condition because poor connections

will contribute to poor starting. Having good electrical connections also limits the possibility of other safety issues

such as heat-generated damage, burns and fires.

The machine is shipped with VRD™ “Disabled”. The VRD™

function can be disabled or enabled via dip switches on the

control P.C. board. Dip switch setting will differ depending

on input voltage.

The control board and dip switches can be accessed by

removing the case top and side as shown in the Operation

Section figure B.3.

SELECT SUITABLE LOCATION

LOCATION AND VENTILATION FOR COOLING

Place the welder where clean cooling air can freely

circulate in through the rear louvers and out through

the case sides. Dirt, dust, or any foreign material that

can be drawn into the welder should be kept at a minimum. Failure to observe these precautions can result

in excessive operating temperatures and nuisance

shutdowns.

LIFTING

The FLEXTEC™ 650 has 2 lifting eyelets and 2 handles that can be used to lift the machine. Both handles

or both eyelets should be used when lifting the FLEXTEC™ 650.

FLEXTEC™ 650

MACHINE GROUNDING

The frame of the welder must be grounded.

A ground terminal marked with the symbol

shown is located inside the reconnect/input

connection area for this purpose. See your local and

national electrical codes for proper grounding methods.

HIGH FREQUENCY PROTECTION

Locate the FLEXTEC™ 650 away from radio controlled machinery. The normal operation of the FLEXTEC™ 650 may adversely affect the operation of RF

controlled equipment, which may result in bodily injury

or damage to the equipment.

HIGH TEMPERATURE OPERATION

WELDER OUTPUT RATINGS AT 55°C

ELEVATED TEMPERATURES

AMPS

600

650

750

DUTY CYCLE

100%

50%

30%

VOLTS

44V

TEMPERATURES

55°C

Page 10

A-4

INSTALLATION

WARNING

ELECTRIC SHOCK can kill.

ONLY A QUALIFIED ELECTRICIAN

SHOULD CONNECT THE INPUT

LEADS TO THE FLEXTEC™ 650.

CONNECTIONS SHOULD BE MADE IN ACCORDANCE WITH ALL LOCAL AND NATIONAL

ELECTRICAL CODES AND THE CONNECTION

DIAGRAM LOCATED ON THE INSIDE OF THE

RECONNECT/INPUT ACCESS DOOR OF THE

MACHINE. FAILURE TO DO SO MAY RESULT

IN BODILY INJURY OR DEATH.

----------------------------------------------------------------------

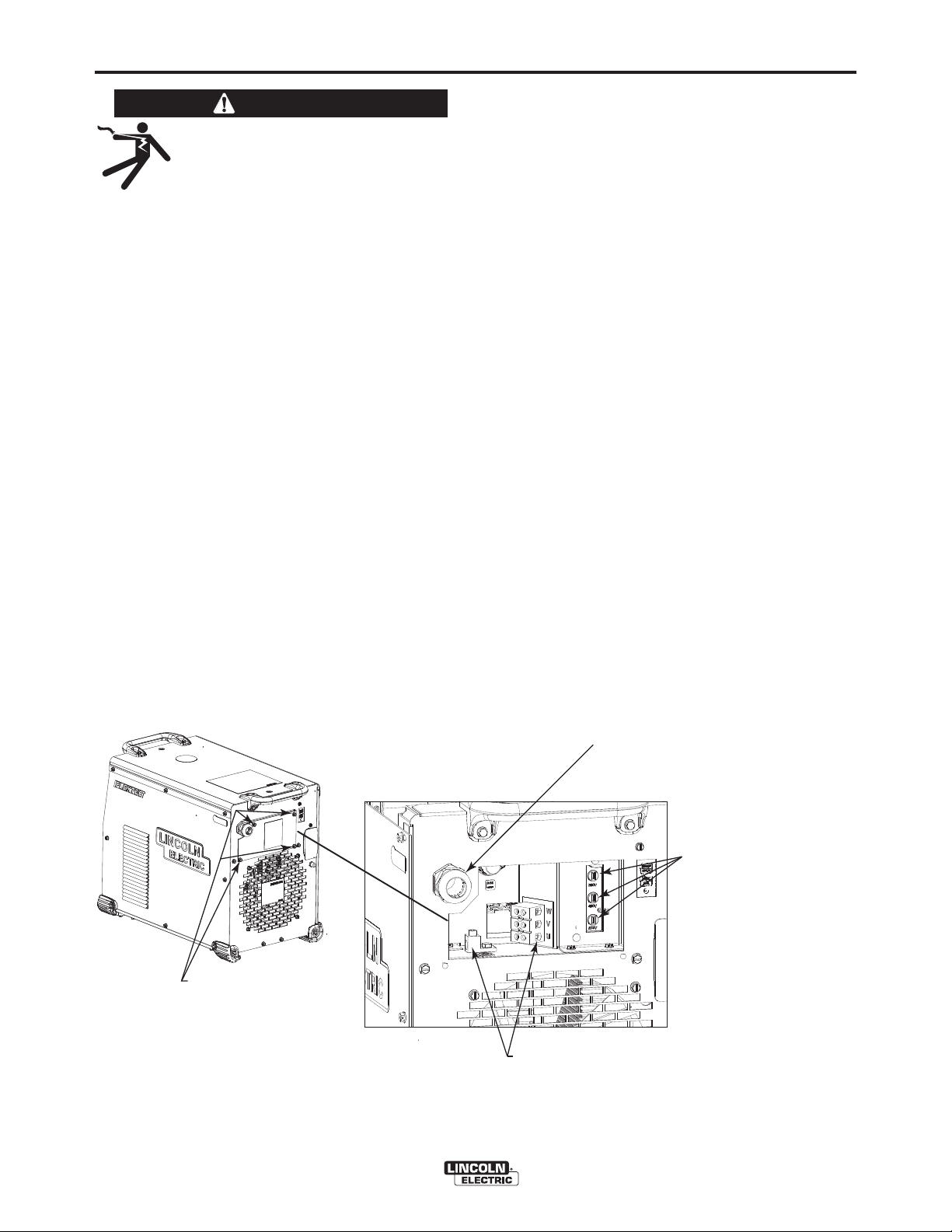

INPUT CONNECTION

(See Figure A.1)

Use a three-phase supply line. A 1.75 inch (45 mm)

diameter access hole for the input supply is located on

the case back. Remove the reconnect access panel

located on the case back and connect W, V, U and

ground according to the Input Supply Connection

Diagram decal.

A-4

INPUT FUSE AND SUPPLY WIRE

CONSIDERATIONS

Refer to Specification in this Installation Section for

recommended fuse, wire sizes and type of the copper

wires. Fuse the input circuit with the recommended

super lag fuse or delay type breakers (also called

"inverse time" or "thermal/magnetic" circuit breakers).

Choose input and grounding wire size according to

local or national electrical codes. Using input wire

sizes, fuses or circuit breakers smaller than recommended may result in "nuisance" shut-offs from

welder inrush currents, even if the machine is not

being used at high currents.

INPUT VOLTAGE SELECTION

Welders are shipped connected for 460 Volt input

voltage. To move this connection to a different input

voltage, see Figure A.1 which is illustrated below.

Refer to Auxiliary Reconnect Input Ranges table in

the Technical Specification Section. If the Auxiliary

lead (indicated as ʻAʼ) is placed in the wrong position

and power is applied to the machine, the machine will

protect itself and display an error message:

• "Err" "713 or 714" will be shown on the display.

• The control board and switch boards will blink out

error 713 or 714 on their status leds.

• The weld output will be turned off and the control

board will force itself into an idle state.

• The machine will need to have the misconnect

condition removed before it will recover. Power

must be removed prior to changing reconnect position.

REMOVE FOUR SCREWS

AND ACCESS PANEL

FIGURE A.1

POWER SUPPLY TERMINAL BLOCK

• Line Cord/Cable attaches here.

• A ground terminal marked with the symbol shown

is provided separate from this block for connecting the ground

lead of the line cord. (See your local and national electrical

codes for proper grounding methods.)

FLEXTEC™ 650

POWER SUPPLY ACCESS HOLE

• Route input power cable through this hole.

• Strain relief required. See your local and

National Electrical codes for proper strain relief.

RECONNECT TERMINAL BLOCK

• Reconnects auxiliary

transformer for the

proper input voltage.

Page 11

A-5

INSTALLATION

CABLE CONNECTIONS

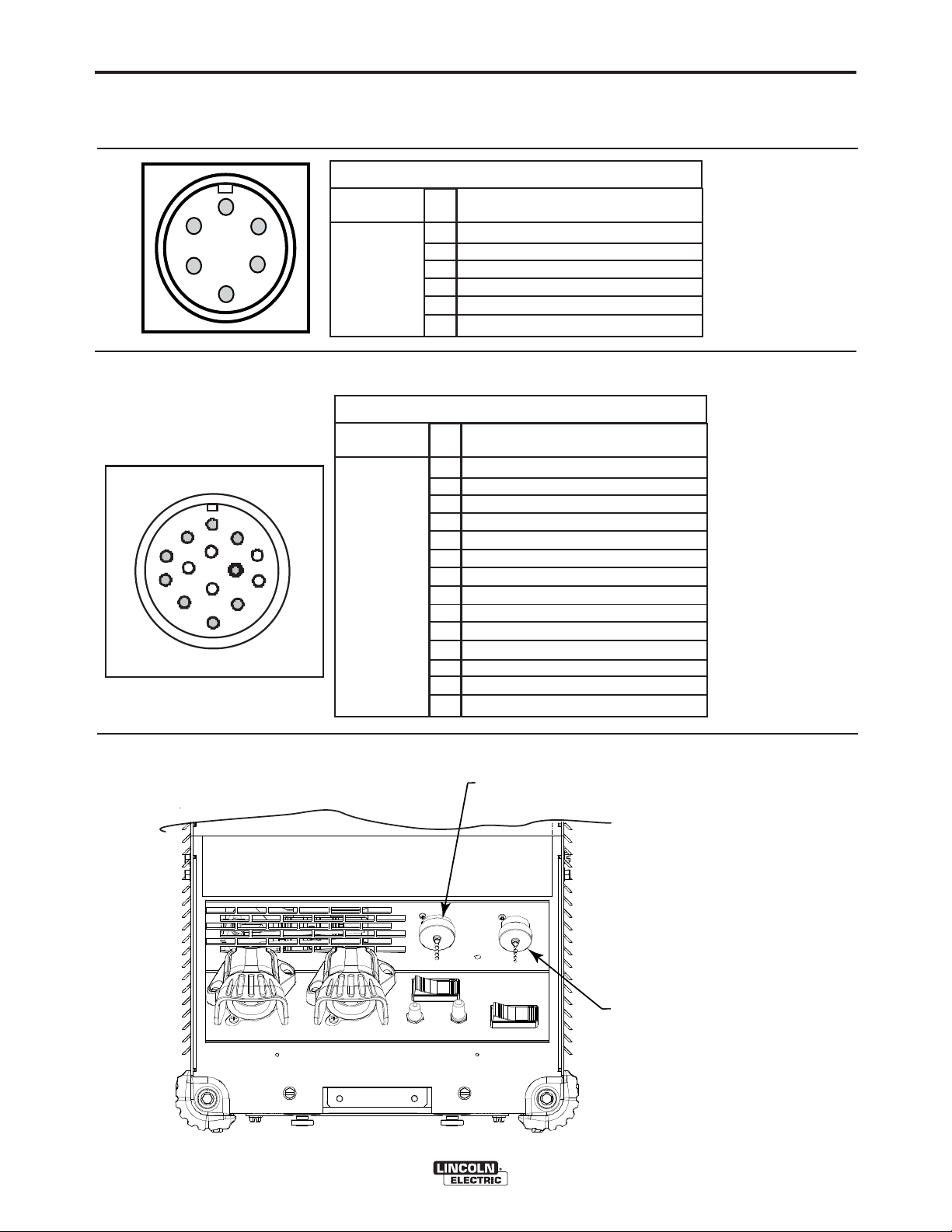

See FIGURE A.2 for locating 6-pin and 14-pin connectors on the front of the FLEXTEC™ 650.

6-PIN REMOTE CONTROL CONNECTOR

A-5

F

E

A

D

C

G

F

M

E

L

D

B

H

I

N

J

K

A

B

C

Function

6-pin remote

control connector for

remote or

hand/foot

amptrol.

14-PIN CONNECTOR FOR WIRE FEEDER

Function

14 pin connector for

wire feeder

connectivity.

Pin

77 Remote potentiometer, 5K

A

76 Remote potentiometer, wiper

B

75 Remote potentiometer, common

C

Trigger, common

D

Trigger, input

E

Ground

F

Pin

115 VAC

A

Ground

B

Trigger, Common

C

Trigger input

D

77 Remote potentiometer, 5K

E

76 Remote potentiometer, wiper

F

75 Remote potentiometer, common

G

Voltage Sense (21)

H

Motor (42 VAC)

I

115 VAC

J

Motor (42 VAC)

K

L

M

N

Wiring

Wiring

FIGURE A.2

14-PIN CONNECTOR

FOR WIRE FEEDER

FLEXTEC™ 650

6-PIN REMOTE

CONTROL CONNECTOR

Page 12

A-6

INSTALLATION

A-6

RECOMMENDED ELECTRODE AND

WORK CABLE SIZES FOR ARC WELDING

General Guidelines

Connect the electrode and work cables between the

appropriate output studs of the FLEXTEC™ 650 per

the following guidelines:

• Most welding applications run with the electrode

being positive (+). For those applications, connect

the electrode cable between the wire drive feed

plate and the positive (+) output stud on the power

source. Connect a work lead from the negative (-)

power source output stud to the work piece.

• When negative electrode polarity is required, such

as in some Innershield applications, reverse the output connections at the power source (electrode

cable to the negative (-) stud, and work cable to the

positive (+) stud).

The following recommendations apply to all output

polarities and weld modes:

• Select the appropriate size cables per the

“Output Cable Guidelines” (See Table A.1).

Excessive voltage drops caused by undersized

welding cables and poor connections often result in

unsatisfactory welding performance. Always use the

largest welding cables (electrode and work) that are

practical, and be sure all connections are clean and

tight.

Note: Excessive heat in the weld circuit indicates

undersized cables and/or bad connections.

• Route all cables directly to the work and wire

feeder, avoid excessive lengths and do not coil

excess cable. Route the electrode and work cables

in close proximity to one another to minimize the

loop area and therefore the inductance of the weld

circuit.

• Always weld in a direction away from the work

(ground) connection.

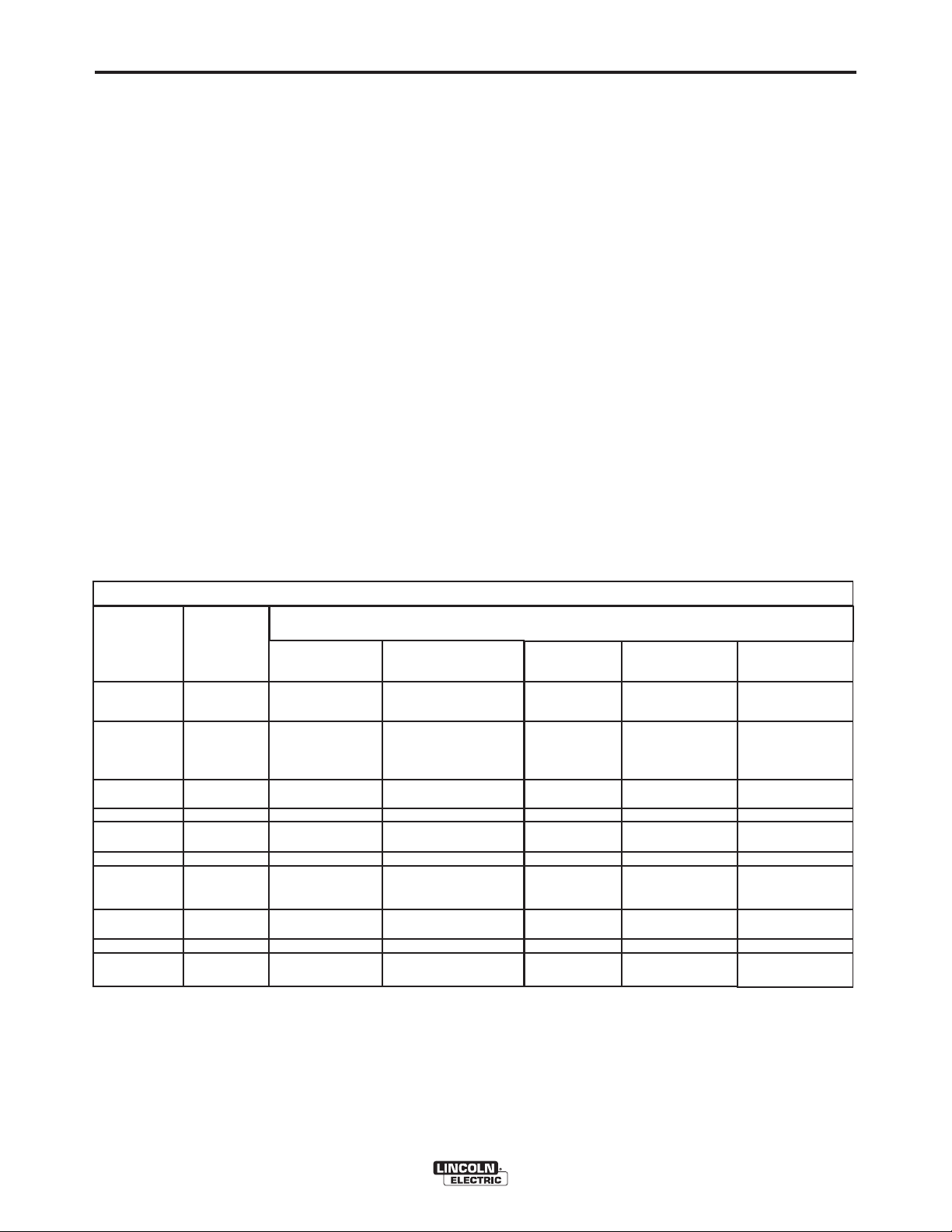

TABLE A.1

OUTPUT CABLE GUIDELINES

CABLE SIZES FOR COMBINED LENGTHS OF ELECTRODE AND WORK CABLES

AMPERES

200

200

250

250

250

250

300

300

350

400

400

500

600

600

600

650

650

700

800

800

** Tabled values are for operation at ambient temperatures of 104°F(40°C) and below. Applications above 104°F(40°C) may require cables

larger than recommended, or cables rated higher than 167°F(75°C).

PERCENT

DUTY

CYCLE

60

100

30

40

60

100

60

100

40

60

100

60

60

80

100

60

80

100

80

100

0 to 50Ft.

(0 to15m)

2

2

3

2

1

1

1

2/0

1/0

2/0

3/0

2/0

3/0

2-1/0

2-1/0

3/0

2-1/0

2-2/0

3-1/0

2-3/0

(RUBBER COVERED COPPER - RATED 167°F or 75°C)**

50 to 100Ft.

(15 to 30m)

2

2

3

2

1

1

1

2/0

1/0

2/0

3/0

2/0

3/0

2-1/0

2-1/0

3/0

2-1/0

2-2/0

3-1/0

2-3/0

100 to 150 Ft.

(30 to 46m)

2

2

2

1

1

1

1

2/0

2/0

2/0

3/0

3/0

3/0

2-1/0

2-1/0

4/0

2-1/0

2-3/0

3-1/0

2-3/0

150 to 200 Ft.

(46 to 61m)

1

1

1

1

1

1

1/0

2/0

2/0

3/0

3/0

3/0

4/0

2-2/0

2-2/0

2-2/0

2-2/0

2-3/0

2-3/0

2-3/0

200 to 250 Ft.

(61 to 76m)

1/0

1/0

1/0

1/0

1/0

1/0

2/0

3/0

3/0

4/0

4/0

4/0

2-3/0

2-3/0

2-3/0

2-3/0

2-3/0

2-4/0

2-4/0

2-4/0

FLEXTEC™ 650

Page 13

A-7

POSITIVE

AT WWORK PPIECE

POSITIVE

AT WWORK PPIECE

POSITIVE

A

NEGATIVEVE

W

V

U

T

AL

V

W

ES

A

NEEGGAATTIIVEVE

TO GGROUNUND

ELECTRICAL

CODE

PER NNATIONAL

U

GND

VE

GROUNUND

GND

PER NNATIOONAL

ELECTRICAL

CODE

BLOCK

0

E

)

0

INN

)

T

AL

BLL

K

W

V

U

V

W

U

ES

U

INSTALLATION

A-7

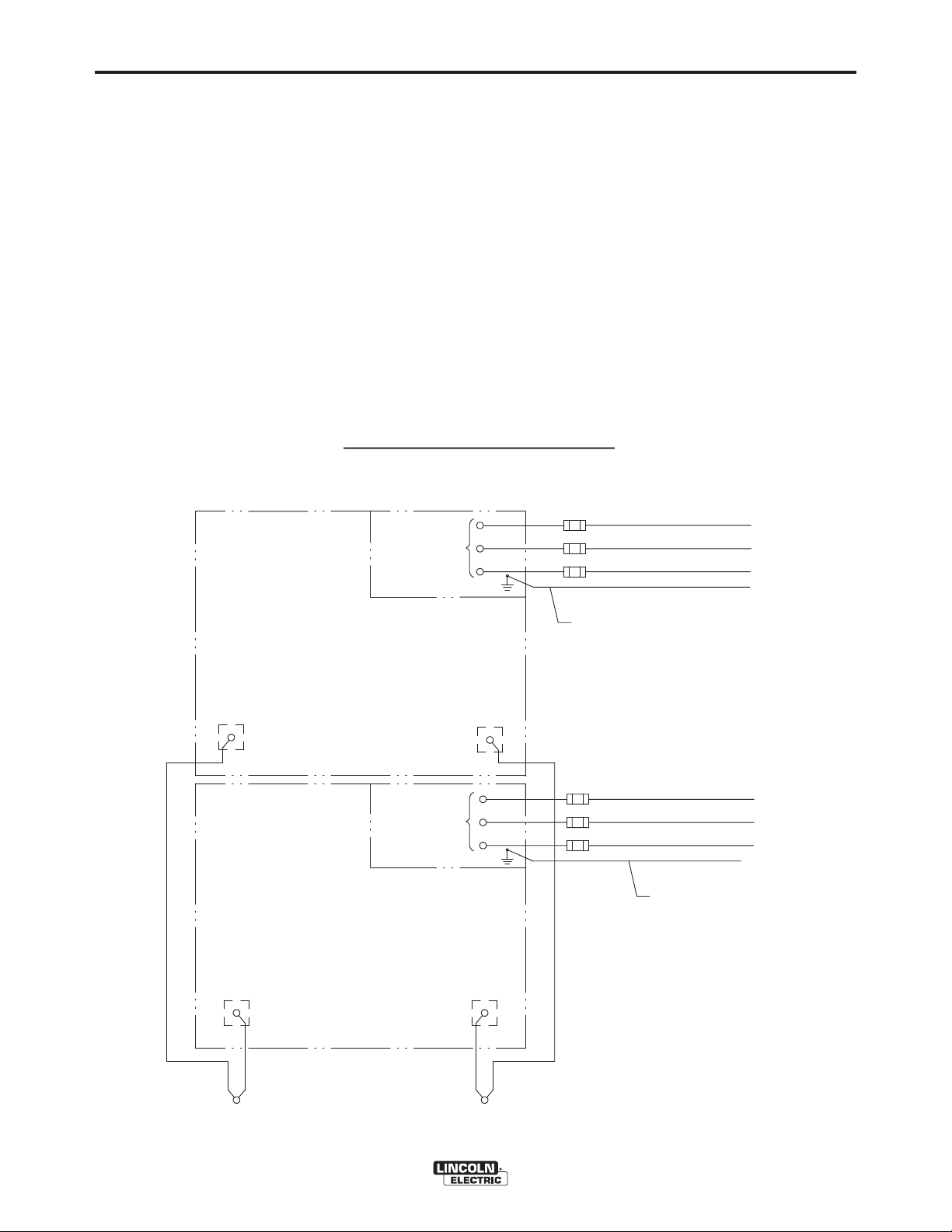

CONTROL CABLE CONNECTIONS

General Guidelines

Genuine Lincoln control cables should be used at all

times (except where noted otherwise). Lincoln cables

are specifically designed for the communication and

power needs of the FLEXTEC™ 650. Most are

designed to be connected end to end for ease of

extension. Generally, it is recommended that the total

length not exceed 100 feet (30.5 m). The use of nonstandard cables, especially in lengths greater than 25

feet, can lead to communication problems (system

shutdowns), poor motor acceleration (poor arc starting), and low wire driving force (wire feeding problems). Always use the shortest length of control cable

possible, and DO NOT coil excess cable.

FIGURE A.3

PARALLELING DIAGRAM

IINNPPUUT

TTEERRMMIINNAL

FFLLEEXXTTEECC 66550

((MMAACCHHIINNE

#1#1)

Regarding cable placement, best results will be

obtained when control cables are routed separate

from the weld cables. This minimizes the possibility of

interference between the high currents flowing

through the weld cables, and the low level signals in

the control cables.

PARALLELING

FLEXTEC™ 650 power sources may be paralleled for

increased output requirements. No kit is required for

paralleling of FLEXTEC™ 650 power sources. The

FLEXTEC™ 650 can only be paralleled for constant

current processes (mode switch must be in the SMAW

position). Connect the power sources as shown, and

set the output control of each power source to one

half of the desired arc current. (See Figure A.3)

W

U

A

PE

IINNPPUUTT LLIINNES

W

V

C

NNEEGGAATTIIVE

N

FFLLEEXXTTEECC 66550

((MMAACCHHI

IINNPPUUT

TTEERRMMIINNAL

B

OOCCK

EE #2#2)

FLEXTEC™ 650

W

U

IINNPPU

TT LLIINNES

A

TTO G

W

V

U

G

C

Page 14

A-8

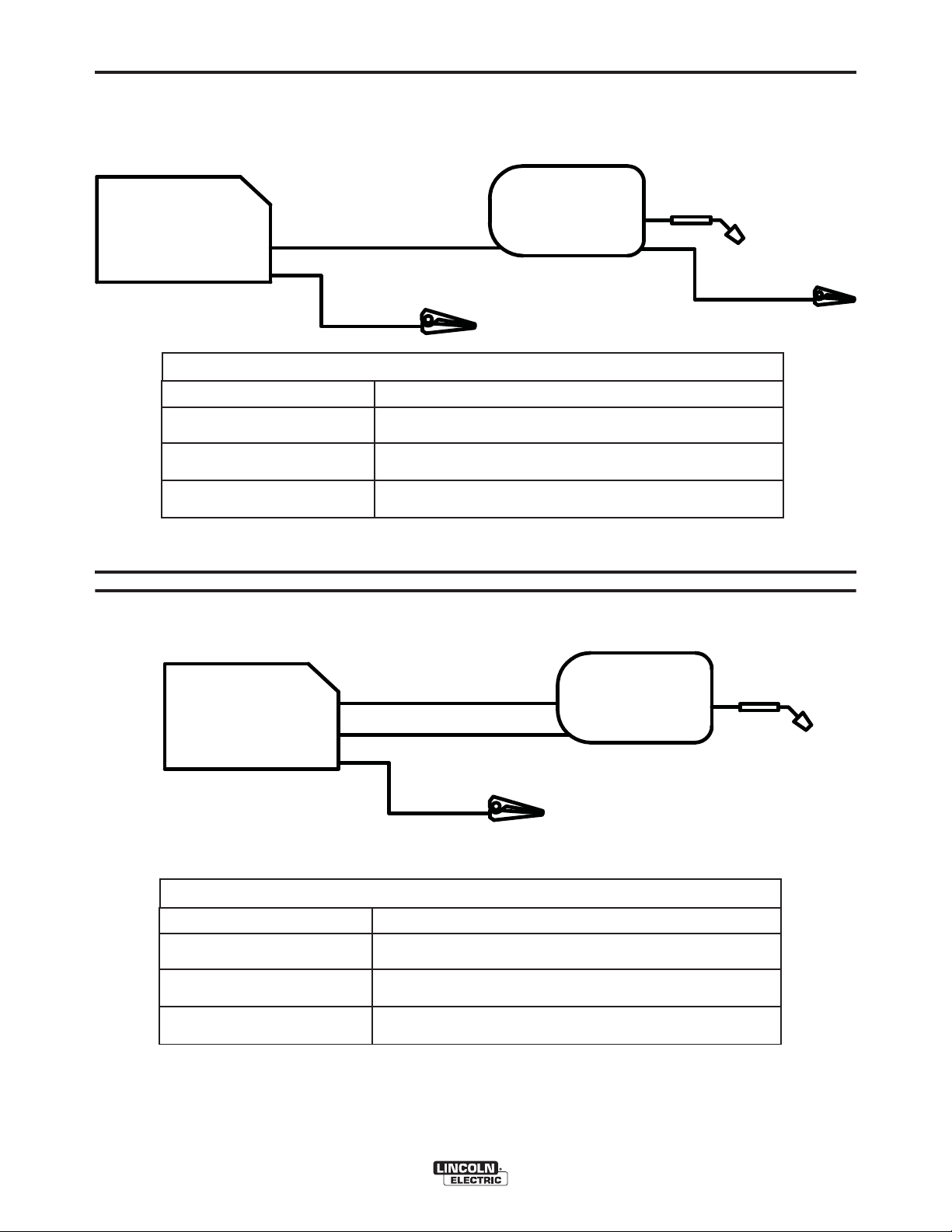

CONNECTING LF-72 AND LF-74 TO THE FLEXTEC™ 650

FLEXTEC™-650

WELD MODE

INSTALLATION

14-PIN CONTROL CABLE K1797-XX

ELECTRODE

WORK

CONTROL SETTING

CV, CV-INNERSHIELD

A-8

WIRE FEEDER

LF-72

LF-74

WELD TERMINALS

REMOTE/LOCAL

VOLTMETER POLARITY

OFF

LOCAL

(REMOTE IF K2329-1 INSTALLED)

PROCESS DEPENDENT

FLEXTEC™ 650

Page 15

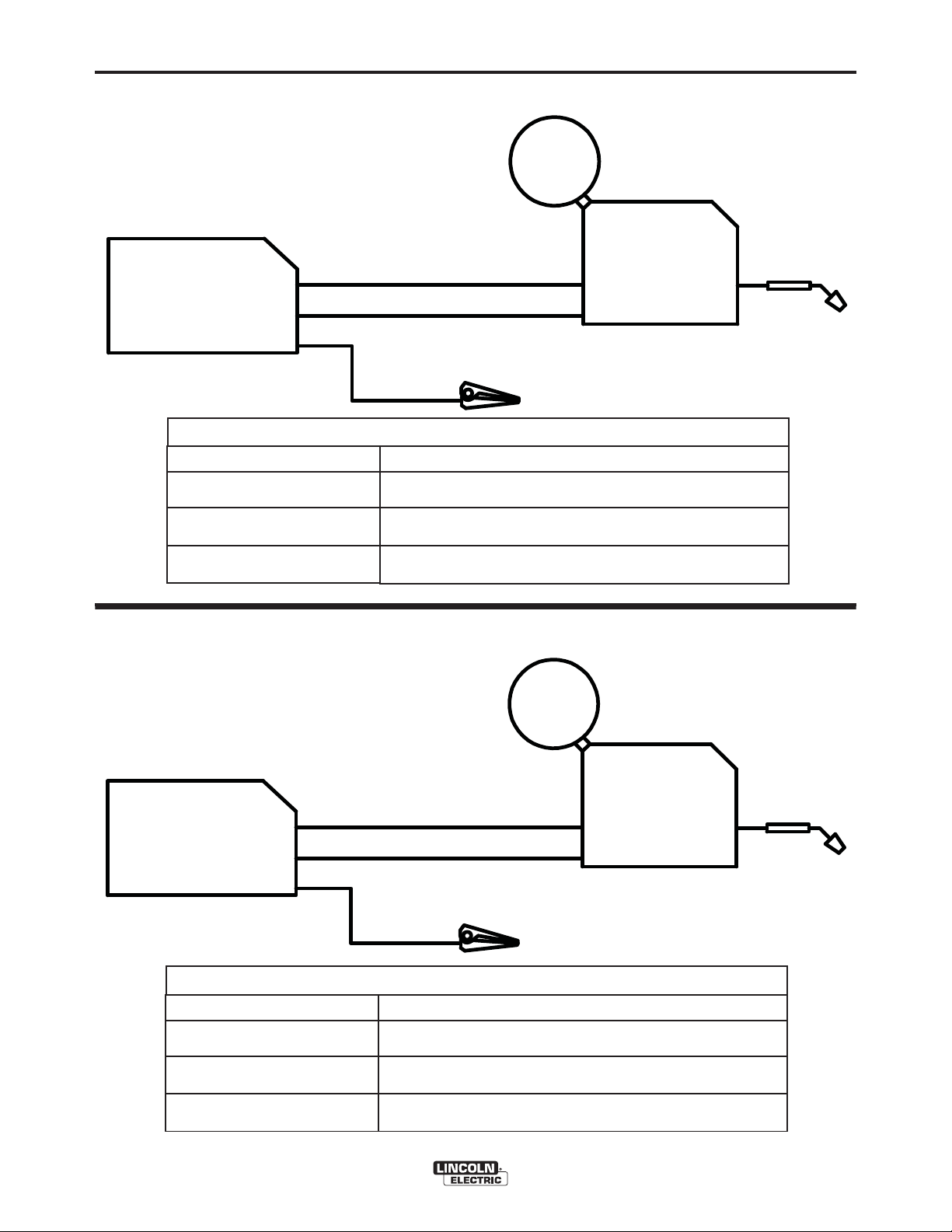

A-9

INSTALLATION

CONNECTING LN-10 AND DH-10 TO THE FLEXTEC™ 650

WIRE FEEDER

A-9

14-PIN CONTROL CABLE K1501-XX

FLEXTEC™-650

ELECTRODE

WORK

CONTROL SETTING

WELD MODE

WELD TERMINALS

REMOTE/LOCAL

VOLTMETER POLARITY

LN-10,DH-10 CONTROL SWITCH

SETUP

Initial set up of the LN-10, DH-10 control for the system components being used and for general operator

preferences is done using a pair of 8-pole DIP switches located inside the LN-10, DH-10 control box.

LN-10

DH-10

CV, CV-INNERSHIELD

OFF

REMOTE

PROCESS DEPENDENT

Setting the DIP Switches

The DIP switches are each labeled with an “ON”

arrow showing the on direction for each of the 8 individual switches in each DIP switch (S1 and S2). The

functions of these switches are also labeled and set

as described below:

Setup DIP Switch Access

1) Shut off the input power to the LN-10, DH-10 control by turning off the power at the welding power

source it is connected to.

2) Remove the two screws on the top of the LN-10,

DH-10 control box door and swing the door down

to open.

3) Locate the two 8-pole DIP switches, near the top

left corner of the LN-10, DH-10 Control P.C. board,

labeled S1 and S2.

4) Switch settings are only programmed during input

power-up restoration.

FLEXTEC™ 650

Pwr Sources

ON

12 3 456 7 8

S1

Head

S1

Pwr Sources

ON

12 345678

S1

S1

Page 16

A-10

FLEXTEC™-650

INSTALLATION

CONNECTING LN-25 PRO, LN-25 PIPE, ACTIVE8 TO THE FLEXTEC™ 650

WIRE FEEDER

LN-25 PRO

ELECTRODE

WORK

CONTROL SETTING

WELD MODE

LN-25 PIPE

ACTIVE8

WORK CLIP

CV, CV-INNERSHIELD

A-10

WELD TERMINALS

REMOTE/LOCAL

VOLTMETER POLARITY

PROCESS DEPENDENT

ON

LOCAL

CONNECTING LN-25 PRO DUAL POWER TO THE FLEXTEC™ 650

WIRE FEEDER

FLEXTEC™-650

CONTROL CABLE K1797-XX

ELECTRODE

WORK

*LN-25 PRO

DUAL POWER

CONTROL SETTING

WELD MODE

WELD TERMINALS

REMOTE/LOCAL

VOLTMETER POLARITY

*CONTROL CABLE SETUP SHOWN. REFER TO LN-25 PRO CONNECTION DIAGRAM IF SETTING UP

"ACROSS-THE-ARC" FEEDER.

FLEXTEC™ 650

CV, CV-INNERSHIELD

OFF

REMOTE

PROCESS DEPENDENT

Page 17

A-11

FLEXTEC™-650

WELD MODE

INSTALLATION

CONNECTING LN-7 TO THE FLEXTEC™ 650

WIRE FEEDER

14-PIN CONTROL CABLE K1818-XX

ELECTRODE

WORK

CONTROL SETTING

CV, CV-INNERSHIELD

LN-7

A-11

WELD TERMINALS

REMOTE/LOCAL

VOLTMETER POLARITY

CONNECTING LN-8 AND LN-9 TO THE FLEXTEC™ 650

FLEXTEC™-650

LOCAL

PROCESS DEPENDENT

14-PIN CONTROL CABLE K1820-XX

ELECTRODE

WORK

OFF

WIRE FEEDER

LN-8

LN-9

WELD MODE

WELD TERMINALS

REMOTE/LOCAL

VOLTMETER POLARITY

CONTROL SETTING

CV, CV-INNERSHIELD

OFF

REMOTE

PROCESS DEPENDENT

FLEXTEC™ 650

Page 18

A-12

INSTALLATION

CONNECTING NA-3, NA-5 TO THE FLEXTEC™ 650

WIRE FEEDER

A-12

14-PIN CONTROL CABLE K1820-XX

FLEXTEC™-650

FOR NA-3, NA-4 WIRE FEEDERS ONLY:

- MOVE JUMPER LEAD ON VARIABLE VOLTAGE BOARD TO "L" PIN.

FOR NA-5 WIRE FEEDER ONLY:

- MOVE "BLUE" JUMPER LEAD ON VOLTAGE BOARD TO "AUTO" TERMINAL.

WELD MODE

WELD TERMINALS

REMOTE/LOCAL

VOLTMETER POLARITY

CONNECTING LT-7 TO THE FLEXTEC™ 650

ELECTRODE

WORK

CONTROL SETTING

PROCESS DEPENDENT

NA-3

NA-5

CV- SAW

OFF

REMOTE

FLEXTEC™-650

WELD MODE

WELD TERMINALS

REMOTE/LOCAL

VOLTMETER POLARITY

14-PIN CONTROL CABLE K1822-XX

ELECTRODE

WORK

CONTROL SETTING

CV- SAW

REMOTE

PROCESS DEPENDENT

FLEXTEC™ 650

TRACTOR

LT-7

OFF

Page 19

B-1

OPERATION

B-1

SAFETY PRECAUTIONS

Read this entire section of operating instructions

before operating the machine.

WARNING

ELECTRIC SHOCK can kill.

• Unless using cold feed feature, when

feeding with gun trigger, the

electrode and drive mechanism are

always electrically energized and

could remain energized several

seconds after the welding ceases.

• Do not touch electrically live parts or electrodes

with your skin or wet clothing.

• Insulate yourself from the work and ground.

• Always wear dry insulating gloves.

FUMES AND GASES can be

dangerous.

• Keep your head out of fumes.

GRAPHIC SYMBOLS THAT

APPEAR ON THIS MACHINE

OR IN THIS MANUAL

INPUT POWER

ON

OFF

HIGH TEMPERATURE

CIRCUIT BREAKER

WIRE FEEDER

• Use ventilation or exhaust to remove

fumes from breathing zone.

WELDING SPARKS can cause

fire or explosion.

• Keep flammable material away.

• Do not weld on containers that have

held combustibles.

ARC RAYS can burn.

• Wear eye, ear, and body protection.

Observe additional guidelines detailed in the

beginning of this manual.

POSITIVE OUTPUT

NEGATIVE OUTPUT

3 PHASE INVERTER

INPUT POWER

THREE PHASE

DIRECT CURRENT

FLEXTEC™ 650

Page 20

B-2

OPERATION

B-2

GRAPHIC SYMBOLS THAT

APPEAR ON THIS MACHINE

OR IN THIS MANUAL

U

r

U

0

U

1

U

2

I

1

I

2

PRODUCT DESCRIPTION

The FLEXTEC™ 650 is a multi-process CC/CV DC

inverter and is rated for 650 amps, 44 volts at a 100%

duty cycle. The FLEXTEC™ 650 is intended for both

factory and field operation. It comes in a compact,

rugged case that is designed for portability and outdoor use with an IP23 environmental rating. The user

interface of the FLEXTEC™ 650 is simple and intuitive. Weld modes are selected via a 5 position selector switch. Volts and Amps are displayed on an easy

to view LED display, and the amps and volts are set

via a large output control knob. A hot start and an arc

control knob allow for finer tuning of the welding arc

for the application.

REDUCED OPEN

CIRCUIT VOLTAGE

OPEN CIRCUIT

VOLTAGE

INPUT VOLTAGE

OUTPUT VOLTAGE

INPUT CURRENT

OUTPUT CURRENT

PROTECTIVE

GROUND

WARNING or CAUTION

Explosion

Dangerous Voltage

Shock Hazard

The FLEXTEC™ 650 is designed for the North

America and export markets and operates on 3 phase

380V, 460V, or 575V 50hz or 60hz power.

DUTY CYCLE

The FLEXTEC™ 650 is capable of welding at a 100%

duty cycle (continuous welding) at 650 amps rated

output. The 60% duty cycle rating is 750 amps (based

off of a ten minute cycle – 6 minutes on time and 4

minutes off time). The maximum output of the

machine is 815 amps.

The FLEXTEC™ 650 is also rated for Desert Duty,

elevated temperature operation, in a 55°C ambient.

The machine is de-rated for this application. (See

Table in the Installation Section.

DESIGN FEATURES

• Severe Duty Design for outdoor use (IP23 rating)

• Passive Power Factor Correction – reliably gives

88% power factor for lower installation costs.

• 91% Efficiency rating – reduces electrical utility

costs.

• Simple user interface - user interface is designed

with the operator in mind. Getting setup for the weld

is several clicks away and even the most novice

welder can be confident he is setup properly.

• F.A.N. (fan as needed). Cooling fan runs when the

output is energized and for a 5 minute cool down

period after output is disabled

• Thermal protection by thermostats with Thermal

Indicator LED.

• Reversible handles for ease of lifting and transporting

• Multiple options for lifting / transporting: Reversible

handles; eyelet lifting bolts; and single forklift fork

access

• Error Codes display on LED screen for ease of trouble shooting

• Electronic over current protection.

• Input voltage mis-connection protection.

• Utilizes digital signal processing and microprocessor

control.

• VRD™ (Voltage Reduction Device)- Enable this

function for reduced OCV in CC modes for added

safety.

FLEXTEC™ 650

Page 21

B-3

OPERATION

RECOMMENDED PROCESSES AND

EQUIPMENT

RECOMMENDED PROCESSES

The FLEXTEC™ 650 is designed for CC-SMAW, CCGTAW (lift tig), CV-GMAW, CV-FCAW-SS, CVFCAW-GS and CV-SAW welding processes. CAG

(arc gouging) is also supported.

PROCESS LIMITATIONS

The FLEXTEC™ 650 is suitable only for the processes listed.

Note: When used with K3091-1 Multi-Process Switch,

the output is limited to 600A / 100% and 700A / 60%.

EQUIPMENT LIMITATIONS

Operating Temperature Range is -10° C to + 55° C.

Output De-rated at Temperatures above 40°C.

B-3

COMMON EQUIPMENT PACKAGES

Basic Package

K3060-2

K2327-5

K2149-1

3100211

Common Optional Kits

K857

K857-1

K870

K963-3

K3091-1

K3129-1

Compatible Wire Feeders

All Models

Harris Regulator and gas hose

Remote Output Control (25 feet)

Remote Output Control (100 feet)

Flextec 650

LF-72 Bench Model

Work Cable

Foot Amptrol

Hand Amptrol

Multi-Process Switch

CE Filter Kit

LF-72

LF-74

LN-10

DH-10

LN-25 Pro

LT-7 Tractor

LN-8

LN-9

NA SERIES

FLEXTEC™ 650

Page 22

B-4

OPERATION

CASE FRONT CONTROL DESCRIPTIONS

(See Figure B.1)

1. Power Switch: Controls input power to the

Flextec 650.

2. Voltage Display Meter

3. Amperage Display Meter

4. Thermal LED: A yellow light that comes on

when an over temperature situation occurs.

Output is disabled until the machine cools

down. When cool, the light goes out and output

is enabled.

B-4

8. Local/Remote Selector Toggle Switch: Sets the

control of the output to local (output control

knob) or remote (K857 hand amptrol or K870

foot amptrol).

9. Arc Force Control Dial

10. Weld Terminals On/Remote selector switch.

11. 14 pin wire feeder circular connector.

12. 115V or 42V wire feeder selector switch.

13. Circuit breaker reset buttons for the 14 pin

wire feeder connector.

5. Weld Process Selector Switch: A rotary switch

that toggles through the five available weld

modes for the Flextec 650 – CC-SMAW; CCGTAW; CV; CV-Innershield; CV-SAW.

6. Hot Start Control Dial

7. Output Control Dial: Sets the output current or

voltage for the selected weld process.

FIGURE B.1

3

4

5

7

14. 6 pin remote circular connector.

15. Positive and negative welding output studs.

16. Wire Feeder Voltmeter Polarity Selection

Switch.

17. VRD™ (Voltage Reduction Device) Indicator

Lights

172

1

9

10

6

8

15

FLEXTEC™ 650

13

11

14

12

16

Page 23

B-5

OPERATION

CASE BACK CONTROLS

(See Figure B.2)

1. Input Power Cord Access Hole.

2. Access Panel – Allows access for connecting

input power and configuring the machine.

3. Input Power Reconnect – Configures the

machine for the input supply voltage.

4. OPTION – GFCI protection for the 115V auxiliary

output.

5. 115 volt, 15 amp auxiliary output duplex with

protective environmental cover.

6. 15 Amp Circuit Breaker for the 115V auxiliary

power.

FIGURE B.2

B-5

1

3

4

5

2

6

FLEXTEC™ 650

Page 24

B-6

OPERATION

B-6

INTERNAL CONTROLS -

Internal Controls Description

The Control PC Board has one bank of Dip Switches.

As shipped from the factory VRD™ mode is disabled

and the Dip Switches are all in the “off” position. For

proper operation ensure that the ”A” lead is connected

properly according to the Auxiliary Reconnect Input

Ranges table see Technical Specification Section.

ENABLING VRD™

1 2 3 4 5 6 7 8

ON

OFF

To Enter VRD™ Mode (VRD™ Enabled)

a. For 380V input: Switch #5 in the “ON”

Position.

1 2 3 4 5 6 7 8

ON

OFF

b. For 460V input: Switch #6 in the “ON”

Position.

1 2 3 4 5 6 7 8

ON

OFF

c. For 575V input: Switch #5 and #6 in the

“ON” Position

CONTROL PCB LOCATION

1 2 3 4 5 6 7 8

ON

OFF

FIGURE B.3

CONTROL PCB

FLEXTEC™ 650

DIP SWITCH LOCATION

Page 25

B-7

OPERATION

B-7

POWER-UP SEQUENCE

When power is applied to the FLEXTEC™ 650, the displays will illuminate and display the voltage and/or

amperage settings.

COMMON WELDING PROCEDURES

WARNING

MAKING A WELD

The serviceability of a product or structure utilizing the welding programs is and must be the sole

responsibility of the builder/user. Many variables

beyond the control of The Lincoln Electric

Company affect the results obtained in applying

these programs. These variables include, but are

not limited to, welding procedure, plate chemistry

and temperature, weldment design, fabrication

methods and service requirements. The available

range of a welding program may not be suitable

for all applications, and the build/user is and must

be solely responsible for welding program selec-

tion.

The FLEXTEC™ 650 is a multi-process inverter

welder. The Weld Process Selector Switch is used

to set the desired weld mode. The FLEXTEC™ 650

has 5 selectable welding modes:

1. SMAW – This is a CC (constant current) weld

mode used for the SMAW stick welding process.

2. GTAW – This is a CC (constant current) weld

mode used for the GTAW TIG welding process.

3. CV – This is CV (constant voltage) weld mode used

for welding the GMAW MIG welding process and

the FCAW-GS flux cored gas shielded welding

process.

4. CV-Innershield – This is a CV (constant voltage)

weld mode used for welding the FCAW-SS, flux

cored self shielded welding process.

5. CV-SAW – This is a CV (constant voltage) weld

mode used for welding the SAW submerged arc

welding process

The FLEXTEC™ 650 is also capable of gouging.

Gouging can be done in either the SMAW mode or the

CV and CV-Innershield modes.

In addition to the weld process selector switch, a hot

start control dial, output control dial and arc control dial

are provided to setup and fine tune the welding procedure.

WELD CONTROLS AND DISPLAYS

Weld Process Selector Switch

5 Position switch used to select the welding process.

Hot Start Control Dial

• The Hot Start control regulates the starting current at

arc initiation. Hot Start can be set to “0” and no additional current is added at arc start. Increasing from 0

to 10 will increase the additional current (relative to

the preset current) that is added at arc initiation.

Arc Control Dial

Full range selection of arc control from -10 to +10.

•

In CV mode, this control is an inductance control. In

stick mode, the control adjusts the arc force.

Output Control Dial

• Output control is conducted via a single turn potentiometer.

• Adjustment is indicated by the meters.

• When in REMOTE modes, this control sets the maximum welding current. Full depression of a foot or

hand amptrol results in the preset level of current.

Voltage Display Meter

• Prior to CV operation (current flow), the meter displays desired preset voltage value (+/- .5V).

• Prior to STICK or TIG operation, the meter displays

the Open Circuit Voltage of the Power Source or

three dashes if the output has not been turned on.

• During welding, this meter displays actual average

volts.

• After welding, the meter holds the actual voltage

value for 5 seconds. The displays blink indicating that

the machine is in the "Hold" period.

• Output adjustment while in the "Hold" period results

in the "prior to operation" characteristics.

Amperage Display Meter

• Prior to STICK or TIG operation (current flow), the

meter displays preset current value (either 2 amps or

+/- 3% (e.g. 3 amps on 100), whichever is greater).

• Prior to CV operation, the meter displays three dashes indicating non-presettable AMPS.

• During welding, this meter displays actual average

amps.

• After welding, the meter holds the actual current

value for 5 seconds. The displays blink indicating that

the machine is in the "Hold" period.

• Output adjustment while in the "Hold" period results

in the "prior to operation" characteristics.

FLEXTEC™ 650

Page 26

B-8

OPERATION

B-8

Weld Terminals On/Remote Toggle Switch

• This switch determines the trigger location.

• When set to the “ON” position, the weld terminals

are at OCV (open circuit voltage) and ready to weld.

• When set to the “REMOTE” position, output is

enabled through a remote trigger.

Control - Local/Remote Toggle Switch

• Set the switch to “LOCAL” to control output at the

Flextec via the Output Control dial.

• Set the switch to “REMOTE” to control output via a

remote device (K857 hand amptrol or K870 foot

amptrol) connected to the 6-pin remote connector or

a wire feeder connected to the 14-pin connector.

Wire Feeder Selector Switch

• This switch configures wire feeder supply voltage in

the 14 pin connector to either 42 volt or 115 volt.

• If the switch is in the incorrect position for the

attached wire feeder, there will be no power supplied to the wire feeder.

Wire Feeder Voltmeter Polarity Switch

• The switch provides a work connection for wire

feeder voltmeters. Place the switch in the position of

the electrode polarity indicated by the decal. The

switch does not change the welding polarity.

Thermal Light

• This status light indicates when the power source

has been driven into thermal overload. If the output

terminals were "ON", the output will be turned back

on once the unit cools down to an acceptable temperature level. If the unit was operating in the

"REMOTE" mode, the trigger will need to be opened

before or after the thermal has cleared and closed

after the machine has cooled down to an acceptable

temperature to establish output.

VRD™ (VOLTAGE REDUCTION DEVICE)

INDICATOR LIGHT

There are 2 indicator lights on the case front of the

Flextec™ 650 above the Voltage LED Display to indicate the status of VRD™ operation. As shipped, the

VRD™ function is disabled. VRD™ is enabled by setting dip switches on the Control P.C. board (See

Internal Controls Figure B.3 in this Operation

Section). When VRD™ is active:

• A green light indicates the OCV (open circuit voltage) is less than 35V peak.

• A red light indicates the OCV is at or above 35V

peak.

• Both lights will illuminate for 5 seconds at power up.

For each weld mode, the VRD™ lights function as

shown in Table B.1:

BASIC MODES OF OPERATION

SMAW

This weld mode is a constant current (CC) mode featuring continuous control from 15 – 815 amps. It is intended for the

SMAW stick welding processes and arc gouging.

Output Control Local/Remote – When the control is set to

“LOCAL” (no remote potentiometer/control plugged into the 6

pin or 14 pin connectors), the output is controlled through the

Output Control Dial on the front of the FLEXTEC™ 650. Set

this switch to “REMOTE” when an external potentiometer/control is connected.

• When a remote potentiometer is connected, the output con-

trol on the FLEXTEC™ 650 and the remote act as a master/slave configuration. Use the control dial on the

FLEXTEC™ 650 to set the maximum welding current. The

remote will control output from minimum to the pre-set maximum.

TABLE B.1

VRD™ Indicator Lights

Mode

CC-SMAW

CC-GTAW

CV-GAS

CV-Innershield

CV-SAW

* It is normal for the lights to alternate between colors while welding.

OCV

While welding

OCV

While welding

Green (OCV reduced)

Green or Red (depends on weld voltage)*

Red (OCV Not Reduced)

Weld Terminals ʻONʼ

Red (OCV Not Reduced)

Weld Terminals Remotely Controlled

Gun Trigger Closed

Green (NO OCV)

Weld Terminals Remotely Controlled

Gun Trigger Open

Green or Red (depends on weld voltage)*

FLEXTEC™ 650

VRD™ “ON”

VRD™ “OFF”

No lights are

active

Page 27

B-9

Hot Start - The Hot Start control regulates the starting current

at arc initiation. Hot Start can be set to “0” and no additional

current is added at arc start. Increasing from 0 to 10 will

increase the additional current (relative to the preset current)

that is added at arc initiation.

Arc Control - The Arc Control regulates the Arc Force to adjust

the short circuit current. The minimum setting (-10) will produce

a "soft" arc and will produce minimal spatter. The maximum setting (+10) will produce a "crisp" arc and will minimize electrode

sticking.

Weld Terminals On/Remote – Set to “ON” and the machine is

in the ready to weld state.

Voltage Display Meter – This display will display three dashed

lines when the machine is in the idle state. This indicates that

voltage is not settable in this weld mode. While output is

enabled, the actual welding voltage will be displayed. After

welding, the meter holds the actual voltage value for 5 seconds. Output adjustment while in the "hold" period results in the

"prior to operation" characteristics stated above. The displays

blink indicating that the machine is in the "hold" period.

GTAW

This weld mode is a constant current (CC) mode featuring continuous control from 10 – 815 amps. It is intended for the

GTAW tig welding processes.

OPERATION

Output Control Local/Remote – When the control is set to

“LOCAL” (no remote potentiometer/control plugged into the 6

pin or 14 pin connectors), the output is controlled through the

Output Control Dial on the front of the FLEXTEC™ 650. Set

this switch to “REMOTE” when an external potentiometer/control is connected.

• When a remote potentiometer is connected, the output con-

Output Control Dial

• When the Local/Remote is set to “LOCAL”, this dial sets the

• When the Local/Remote is set to “REMOTE”, this dial sets

CV-Gas

This weld mode is a constant voltage (CV) mode featuring continuous control from 10 to 45 volts. It is intended for the

GMAW, FCAW-GS, MCAW welding processes and arc gouging.

Hot Start – Rotate from the “0” position to the “10” position to

provide more energy during the start of a weld.

B-9

trol on the FLEXTEC™ 650 and the remote act as a master/slave configuration. Use the control dial on the

FLEXTEC™ 650 to set the maximum welding current. The

remote will control output from minimum to the pre-set maximum.

welding amperage.

the maximum welding amperage. The remote potentiometer

controls the amperage from minimum to this pre-set maximum.

Hot Start - Hot start regulates the arc initiation current. A setting of +10 results in the most positive arc initiation.

Arc Control – This control is not used in the GTAW mode.

Weld Terminals On/Remote

• When set to the “ON” position, the weld terminals are at

OCV (open circuit voltage) and ready to weld.

• When set to the “remote” position, output is enabled through

a remote trigger.

Voltage Display Meter – This display will display three dashed

lines when the machine is in the idle state.

This indicates that voltage is not settable in this weld mode.

While output is enabled, the actual welding voltage will be displayed. After welding, the meter holds the actual voltage value

for 5 seconds. Output adjustment while in the "hold" period

results in the "prior to operation" characteristics stated above.

The displays blink indicating that the machine is in the "hold"

period.

Amperage Display Meter – This display will display the pre-

set welding current when the machine is in the idle state. After

welding, the meter holds the actual amperage value for 5 sec-

onds. Output adjustment while in the "hold" period results in the

"prior to operation" characteristics stated above. The displays

blink indicating that the machine is in the "hold" period.

Arc Control – The Arc Control regulates pinch effect. At the

minimum setting (-10), minimizes pinch and results in a soft

arc. Low pinch settings are preferable for welding with gas

mixes containing mostly inert gases. At the maximum setting

(+10), maximizes pinch effect and results in a crisp arc. High

pinch settings are preferable for welding FCAW and GMAW

with CO

Weld Terminals On/Remote

• When set to the “ON” position, the weld terminals are at

OCV (open circuit voltage) and ready to weld. This selection

is used for across the arc wire feeders.

• When set to the “REMOTE” position, output is enabled

through a remote trigger.

Amperage Display Meter – This display will display

three dashed lines when the machine is in the idle

state.

mode. While output is enabled, the actual welding amperage

will be displayed. After welding, the meter holds the actual

amperage value for 5 seconds. Output adjustment while in the

"hold" period results in the "prior to operation" characteristics

stated above.

The displays blink indicating that the machine is in the "hold"

period.

.

2

This indicates that amperage is not settable in this weld

FLEXTEC™ 650

Page 28

B-10

Voltage Display Meter – This display will display the pre-set

welding voltage when the machine is in the idle state. After

welding, the meter holds the actual voltage value for 5 seconds. Output adjustment while in the "hold" period results in the

"prior to operation" characteristics stated above. The displays

blink indicating that the machine is in the "hold" period.

OPERATION

Output Control Local/Remote – When the control is set to

“LOCAL” (no remote potentiometer/control plugged into the 6

pin or 14 pin connectors), the output is controlled through the

Output Control Dial on the front of the FLEXTEC™ 650. Set

this switch to “REMOTE” when an external potentiometer/con-

trol is connected.

B-10

Output Control Local/Remote – When the control is set to

“LOCAL” (no remote potentiometer/control plugged into the 6

pin or 14 pin connectors), the output is controlled through the

Output Control Dial on the front of the FLEXTEC™ 650. Set

this switch to “REMOTE” when an external potentiometer/control is connected.

Output Control Dial

• When the Local/Remote is set to “LOCAL”, this dial sets the

welding voltage.

• When the Local/Remote is set to “REMOTE”, this dial is disabled.

CV-Innershield

This weld mode is a constant voltage (CV) mode featuring continuous control from 10 to 45 volts. It is intended for the FCAWSS welding process and arc gouging.

Hot Start – Toggle from the “0” position to the “10” position to

provide more energy during the start of a weld.

Arc Control – The Arc Control regulates pinch effect. At the

minimum setting (-10), minimizes pinch and results in a soft

arc. At the maximum setting (+10), maximizes pinch effect and

results in a crisp arc.

Weld Terminals On/Remote

• When set to the “ON” position, the weld terminals are at

OCV (open circuit voltage) and ready to weld. This selection

is used for across the arc wire feeders.

• When set to the “REMOTE” position, output is enabled

through a remote trigger.

Amperage Display Meter – This display will display three

dashed lines when the machine is in the idle state. This indicates that amperage is not settable in this weld mode. While

output is enabled, the actual welding amperage will be displayed. After welding, the meter holds the actual amperage

value for 5 seconds. Output adjustment while in the "hold" period results in the "prior to operation" characteristics stated

above. The displays blink indicating that the machine is in the

"hold" period.

Voltage Display Meter – This display will display the pre-set

welding voltage when the machine is in the idle state. After

welding, the meter holds the actual voltage value for 5 seconds. Output adjustment while in the "hold" period results in the

"prior to operation" characteristics stated above. The displays

blink indicating that the machine is in the "hold" period.

Output Control Dial

• When the Local/Remote is set to “LOCAL”, this dial sets the

welding voltage.

• When the Local/Remote is set to “REMOTE”, this dial is disabled.

CV-SAW

This weld mode is a constant voltage (CV) mode featuring continuous control from 10 to 45 volts. It is intended for the CVSAW submerged arc welding process.

Hot Start – Not used for this welding process.

Arc Control – Not used for this welding process .

Weld Terminals On/Remote

• When set to the “ON” position, the weld terminals are at

OCV (open circuit voltage) and ready to weld. This selection

is used for across the arc wire feeders.

• When set to the “REMOTE” position, output is enabled

through a remote trigger.

Amperage Display Meter – This display will display three

dashed lines when the machine is in the idle state. This indicates that amperage is not settable in this weld mode. While

output is enabled, the actual welding amperage will be displayed. After welding, the meter holds the actual amperage

value for 5 seconds. Output adjustment while in the "hold" period results in the "prior to operation" characteristics stated

above. The displays blink indicating that the machine is in the

"hold" period.

Voltage Display Meter – This display will display the pre-set

welding voltage when the machine is in the idle state. After

welding, the meter holds the actual voltage value for 5 seconds. Output adjustment while in the "hold" period results in the

"prior to operation" characteristics stated above. The displays

blink indicating that the machine is in the "hold" period.

Output Control Local/Remote – When the control is set to

“LOCAL” (no remote potentiometer/control plugged into the 6

pin or 14 pin connectors), the output is controlled through the

Output Control Dial on the front of the FLEXTEC™ 650. Set

this switch to “REMOTE” when an external potentiometer/control is connected.

Output Control Dial

• When the Local/Remote is set to “LOCAL”, this dial

• When the Local/Remote is set to “REMOTE”, this dial

sets the welding voltage.

is disabled.

FLEXTEC™ 650

Page 29

C-1

ACCESSORIES

C-1

OPTIONS / ACCESSORIES

General Options

K2149-1 Work Lead Package.

K1842-10 10ft. Weld Power Cable (Lug to Lug).

K3091-1 Multi-Process

Switch

Inverter and Wire Feeder Cart

Rear-wheeled cart with front casters

and gas bottle platform. Convenient

handles allow for easy cable storage. Small footprint fits through 30

in. (762 mm) door. Not intended for

use with double head wire feeders.

Order K3059-2

Fume Extracting Systems

TIG Options

Pro-Torch™ TIG Torches – PTA9, PTA-17, PTA-26 – 2 piece

power cord.

Foot Amptrol®

Provides 25 ft. (7.6 m) of remote

current control for TIG welding.

(6-pin plug connection).

Order K870

Hand Amptrol® - Provides 25 ft.

(7.6 m) of remote current control

for TIG welding. (6-pin plug connection).

Order K963-3

Arc Start Switch - May be used

in place of the Foot or Hand

Amptrol®. Comes with a 25 ft.

(7.6m) cable. Attaches to the TIG

torch for convenient finger control

to start and stop the weld cycle at

the current set on the machine.

Order K814

GFCI KIT - Order K3157-1

Accessory Kit For stick welding. Includes 35 ft. (10.7 m) 2/0

electrode cable with lug, 30 ft.

(9.1 m) 2/0 work cable with lugs,

head shield, filter plate, cover

plate, work clamp and electrode

holder. 400 amp capacity. Order

K704

Remote Output Control

Consists of a control box with

choice of two cable lengths.

Permits remote adjustment of output.

Order K857 for 25 ft. (7.6 m)

Order K857-1 for 100 ft. (30 m)

K3129-1 CE Filter Kit

Dual Cylinder Inverter and Wire

Feeder Cart - Rear-wheeled cart

with front casters and dual gas bottle platform. Convenient handles

allow for easy cable storage. Small

footprint fits through 30in. (762 mm)

door. Can be used with dual head

wire feeders.

Order K3059-3

FLEXTEC™ 650

Page 30

D-1

MAINTENANCE

D-1

SAFETY PRECAUTIONS

WARNING

ELECTRIC SHOCK can kill.

• Only Qualified personnel should

perform this maintenance.

• Turn the input power OFF at the

disconnect switch or fuse box before

working on this equipment.

• Do not touch electrically hot parts.

------------------------------------------------------------------------

See additional warning information

throughout this Operatorʼs Manual

-----------------------------------------------------------

VISUAL INSPECTION

Clean interior of machine with a low pressure air

stream. Make a thorough inspection of all components. Look for signs of overheating, broken leads or

other obvious problems. Many problems can be