Page 1

Operator’s Manual

®

RETURN TO MAIN MENU

POWER WAVE

®

S350

For use with machines having Code Numbers:

11589

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM10007 | Issue D ate Oct- 13

© Lincoln Global, Inc. All Rights Reserved.

Need Help? Call 1.888.935.3877

to talk to a Service Representative

Hours of Operation:

8:00 AM to 6:00 PM (ET) Mon. thru Fri.

After hours?

Use “Ask the Experts” at lincolnelectric.com

A Lincoln Service Representative will contact you

no later than the following business day.

For Service outside the USA:

Email: globalservice@lincolnelectric.com

Page 2

THANK YOU FOR SELECTING

AT ALL

TIMES.

SPECIA L SI TUATIONS

Additional precautionary measures

A QUALITY PRODUCT BY

LINCOLN ELEC TRIC.

PLEASE EXAMINE CARTON AND EQUIPMENT FOR

DAMAGE IMMEDIATELY

When this equipment is shipped, title passes to the purchaser upon

receipt by the carrier. Consequently, Claims for material damaged in

shipment must be made by the purchaser against the transportation

company at the time the shipment is received.

SAFETY DEPENDS ON YOU

Lincoln arc welding and cutting equipment is designed and built with

safety in mind. However, your overall safety can be increased by

proper installation ... and thoughtful operation on your part.

DO NOT INSTALL, OPERATE OR REPAIR THIS EQUIPMENT

WITHOUT READING THIS MANUAL AND THE SAFETY PRECAUTIONS

CONTAINED THROUGHOUT. And, most importantly, think before you

act and be careful.

WARNING

This statement appears where the information must be followed

exactly to avoid serious personal injury or loss of life.

CAUTION

This statement appears where the information must be followed to

avoid minor personal injury or damage to this equipment.

KEEP YOUR HEAD OUT OF THE FUMES.

DON’T get too close to the arc. Use

corrective lenses if necessary to

stay a reasonable distance away

from the arc.

READ and obey the Material Safety

Data Sheet (MSDS) and the warning

label that appears on all containers

of welding materials.

USE ENOUGH VENTILATION or

exhaust at the arc, or both, to keep

the fumes and gases from your breathing zone and the general area.

IN A LARGE ROOM OR OUTDOORS, natural ventilation may be

adequate if you keep your head out of the fumes (See below).

USE NATURAL DRAFTS or fans to keep the fumes away from your

face.

If you de velop unusual symptoms, see your supervisor. Perhaps the

welding atmosphere and ventilation system should be checked.

WEAR CORRECT EYE, EAR & BODY PROTECTION

PROTECT your eyes and face with welding helmet

properly fitted and with proper grade of filter plate

(See ANSI Z49.1).

PROTECT your body from welding spatter and arc

flash with protective clothing including woolen

clothing, flame-proof apron and gloves, leather

leggings, and high boots.

PROTECT others from splatter, flash, and glare with

protective screens or barriers.

IN SOME AREAS, protection from noise may be

appropriate.

BE SURE protective equipment is in good condition.

Also, wear safety glasses in work area

DO NOT WELD OR CUT containers or materials which previously had

been in contact with hazardous substances unless they are properly

cleaned. This is extremely dangerous.

DO NOT WELD OR CUT painted or plated parts unless special

precautions with ventilation have been taken. They can release highly

toxic fumes or gases.

PROTECT compressed gas cylinders from excessive heat, mechanical

shocks, and arcs; fasten cylinders so they cannot fall.

BE SURE cylinders are never grounded or part of an electrical circuit.

REMOVE all potential fire hazards from welding area.

ALWAYS HAVE FIRE FIGHTING EQUIPMENT READY FOR

IMMEDIATE USE AND KNOW HOW TO USE IT.

Page 3

SECTION A:

Diesel Engines

Gasoline Engines

WARNINGS

CALIFORNIA PROPOSITION 65 WARNINGS

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and other

reproductive harm.

The engine exhaust from this product contains chemicals known

to the State of California to cause cancer, birth defects, or other

reproductive harm.

ARC WELDING CAN BE HAZARDOUS. PROTECT

YOURSELF AND OTHERS FROM POSSIBLE SERIOUS

INJURY OR DEATH. KEEP CHILDREN AWAY. PACEMAKER WEARERS SHOULD CONSULT WITH THEIR

DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For additional

safety information, it is strongly recommended that you purchase a

copy of “Safety in Welding & Cutting - ANSI Standard Z49.1” from the

American Welding Society, P.O. Box 351040, Miami, Florida 33135 or

CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety”

booklet E205 is available from the Lincoln Electric Company, 22801

St. Clair Avenue, Cleveland, Ohio 44117-1199.

BE SURE THAT ALL INSTALLATION, OPERATION,

MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

SAFETY

1.d. Keep all equipment safety guards, covers and

devices in position and in good repair.Keep

hands, hair, clothing and tools away from

V-belts, gears, fans and all other moving parts

when starting, operating or repairing

equipment.

1.e. In some cases it may be necessary to remove safety guards to

perform required maintenance. Remove guards only when

necessary and replace them when the maintenance requiring

their removal is complete. Always use the greatest care when

working near moving parts.

1.f. Do not put your hands near the engine fan. Do not attempt to

override the governor or idler by pushing on the throttle control

rods while the engine is running.

1.g. To prevent accidentally starting gasoline engines while turning

the engine or welding generator during maintenance work,

disconnect the spark plug wires, distributor cap or magneto wire

as appropriate.

1.h. To avoid scalding, do not remove the radiator

pressure cap when the engine is

hot.

ELECTRIC AND

MAGNETIC FIELDS MAY

BE DANGEROUS

2.a. Electric current flowing through any conductor

causes localized Electric and Magnetic Fields (EMF). Welding

current creates EMF fields around welding cables and welding

machines

FOR ENGINE POWERED

EQUIPMENT.

1.a. Turn the engine off before troubleshooting

and maintenance work unless the

maintenance work requires it to be running.

1.b. Operate engines in open, well-ventilated

areas or vent the engine exhaust fumes outdoors.

1.c. Do not add the fuel near an open flame

welding arc or when the engine is running.

Stop the engine and allow it to cool before

refueling to prevent spilled fuel from

vaporizing on contact with hot engine parts

and igniting. Do not spill fuel when filling

tank. If fuel is spilled, wipe it up and do not start engine until

fumes have been eliminated.

2.b. EMF fields may interfere with some pacemakers, and welders

having a pacemaker should consult their physician before

welding.

2.c. Exposure to EMF fields in welding may have other health effects

which are now not known.

2.d. All welders should use the following procedures in order to

minimize exposure to EMF fields from the welding circuit:

2.d.1. Route the electrode and work cables together - Secure

them with tape when possible.

2.d.2. Never coil the electrode lead around your body.

2.d.3. Do not place your body between the electrode and work

cables. If the electrode cable is on your right side, the

work cable should also be on your right side.

2.d.4. Connect the work cable to the workpiece as close as possible to the area being welded.

2.d.5. Do not work next to welding power source.

3

Page 4

SAFETY

ELECTRIC SHOCK

CAN KILL.

3.a. The electrode and work (or ground) circuits are

electrically “hot” when the welder is on. Do

not touch these “hot” parts with your bare skin

or wet clothing. Wear dry, hole-free gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full area

of physical contact with work and ground.

In addition to the normal safety precautions, if

welding must be performed under electrically

hazardous conditions (in damp locations or while

wearing wet clothing; on metal structures such as

floors, gratings or scaffolds; when in cramped

positions such as sitting, kneeling or lying, if there

is a high risk of unavoidable or accidental contact

with the workpiece or ground) use the following

equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel, welding head, nozzle or semiautomatic welding

gun are also electrically “hot”.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection should

be as close as possible to the area being welded.

3.e. Ground the work or metal to be welded to a good electrical (earth)

ground.

3.f. Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Never simultaneously touch electrically “hot” parts of electrode

holders connected to two welders because voltage

two can be the total of the open circuit voltage of both

welders.

3.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

between the

ARC RAYS CAN BURN.

4.a. Use a shield with the proper filter and cover plates to protect your

eyes from sparks and the rays of the arc when welding or

observing open arc welding. Headshield and filter lens should

conform to ANSI Z87. I standards.

4.b. Use suitable clothing made from durable flame-resistant material

to protect your skin and that of your helpers from the arc rays.

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

FUMES AND GASES

CAN BE DANGEROUS.

5.a. Welding may produce fumes and gases

hazardous to health. Avoid breathing these

fumes and gases. When welding, keep your head out of the fume.

Use enough ventilation and/or exhaust at the arc to keep fumes

and gases away from the breathing zone. When welding

with electrodes which require special ventilation

such as stainless or hard facing (see instructions

on container or MSDS) or on lead or cadmium

plated steel and other metals or coatings which

produce highly toxic fumes, keep exposure as low

as possible and within applicable OSHA PEL and

ACGIH TLV limits using local exhaust or

mechanical ventilation. In confined spaces or in

some circumstances, outdoors, a respirator may

be required. Additional precautions are also

required when welding on galvanized steel.

5. b. The operation of welding fume control equipment is affected by

various factors including proper use and positioning of the

equipment, maintenance of the equipment and the specific

welding procedure and application involved. Worker exposure

level should be checked upon installation and periodically

thereafter to be certain it is within applicable OSHA PEL and

ACGIH TLV limits.

5.c. Do not weld in locations near chlorinated hydrocarbon vapors

coming from degreasing, cleaning or spraying operations. The

heat and rays of the arc can react with solvent vapors to form

phosgene, a highly toxic gas, and other irritating products.

3.j. Also see It ems 6.c. and 8.

5.d. Shielding gases used for arc welding can displace air and

injury or death. Always use enough ventilation, especially in

confined areas, to insure breathing air is safe.

5.e. Read and understand the manufacturer’s instructions for this

equipment and the consumables to be used, including the

material safety data sheet (MSDS) and follow your employer’s

safety practices. MSDS forms are available from your welding

distributor or from the manufacturer.

5.f. Also see item 1.b.

4

cause

Page 5

SAFETY

WELDING AND CUTTING

SPARKS CAN CAUSE

FIRE OR EXPLOSION.

6.a. Remove fire hazards from the welding area. If

this is not possible, cover them to prevent the

welding sparks from starting a fire. Remember that welding

sparks and hot materials from welding can easily go through

small cracks and openings to adjacent areas. Avoid welding near

hydraulic lines. Have a fire extinguisher readily available.

6.b. Where compressed gases are to be used at the job site, special

precautions should be used to prevent hazardous situations.

Refer to “Safety in Welding and Cutting” (ANSI Standard Z49.1)

and the operating information for the equipment being used.

6.c. When not welding, make certain no part of the electrode circuit is

touching the work or ground. Accidental contact can cause

overheating and create a fire hazard.

6.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures will

not cause flammable or toxic vapors from substances inside.

They can cause an explosion even though they have been

“cleaned”. For information, purchase “Recommended Safe

Practices for the Preparation for Welding and Cutting of

Containers and Piping That Have Held Hazardous Substances”,

AWS F4.1 from the American Welding Society (see address

above).

6.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

6.f. Sparks and spatter are thrown from the welding arc. Wear oil free

protective garments such as leather gloves, heavy shirt, cuffless

trousers, high shoes and a cap over your hair. Wear ear plugs

when welding out of position or in confined places. Always wear

safety glasses with side shields when in a welding area.

6.g. Connect the work cable to the work as close to the welding area

as practical. Work cables connected to the building framework or

other locations away from the welding area increase the

possibility of the welding current passing through lifting chains,

crane cables or other alternate circuits. This can create fire

hazards or overheat lifting chains or cables until they fail.

6.h. Also see item 1.c.

CYLINDER MAY EXPLODE IF

DAMAGED.

7.a. Use only compressed gas cylinders containing

the correct shielding gas for the process used

and properly operating regulators designed for

the gas and pressure used. All hoses, fittings,

etc. should be suitable for the application and

maintained in good condition.

7.b. Always keep cylinders in an upright position securely chained to

an undercarriage or fixed support.

7.c. Cylinders should be located:

• Away from areas where they may be struck or subjected

to physical damage.

• A safe distance from arc welding or cutting operations

and any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode holder or any other

electrically “hot” parts to touch a cylinder.

7.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. Valve protection caps should always be in place and hand tight

except when the cylinder is in use or connected for use.

7.g. Read and follow the instructions on compressed gas cylinders,

associated equipment, and CGA publication P-l, “Precautions for

Safe Handling of Compressed Gases in

Cylinders,” available

from the Compressed Gas Association 1235 Jefferson Davis

Highway, Arlington, VA 22202.

FOR ELECTRICALLY

POWERED EQUIPMENT.

8.a. Turn off input power using the disconnect

switch at the fuse box before working on the

equipment.

8.b. Install equipment in accordance with the U.S. National Electrical

Code, all local codes and the manufacturer’s recommendations.

6.I. Read and follow NFPA 51B “ Standard for Fire Prevention During

Welding, Cutting and Other Hot Work”, available from NFPA, 1

Batterymarch Park, PO box 9101, Quincy, Ma 022690-9101.

6.j. Do not use a welding power source for pipe thawing.

8.c. Ground the equipment in accordance with the U.S. National

Electrical Code and the manufacturer’s recommendations.

Refer to

http://www.lincolnelectric.com/safety

for additional safety information.

Welding Safety

Interactive Web Guide

for mobile devices

5

Page 6

SAFETY

ELECTROMAGNETIC

COMPATIBILITY (EMC)

CONFORMANCE

Products displaying the CE mark are in conformity with European

Community Council Directive of 3 May 1989 on the approximation of

the laws of the Member States relating to electromagnetic compatibility (89/336/EEC). It was manufactured in conformity with a national

standard that implements a harmonized standard: EN 60974-10

Electromagnetic Compatibility (EMC) Product Standard for Arc Welding

Equipment. It is for use with other Lincoln Electric equipment. It is

designed for industrial and professional use.

INTRODUCTION

All electrical equipment generates small amounts of electromagnetic

emission. Electrical emission may be transmitted through power lines

or radiated through space, similar to a radio transmitter. When

emissions are received by other equipment, electrical interference

may result. Electrical emissions may affect many kinds of electrical

equipment; other nearby welding equipment, radio and TV reception,

numerical controlled machines, telephone systems, computers, etc.

Be aware that interference may result and extra precautions may be

required when a welding power source is used in a domestic establishment.

INSTALLATION AND USE

The user is responsible for installing and using the welding equipment

according to the manufacturer’s instructions. If electromagnetic

disturbances are detected then it shall be the responsibility of the

user of the welding equipment to resolve the situation with the

technical assistance of the manufacturer. In some cases this remedial

action may be as simple as earthing (grounding) the welding circuit,

see Note. In other cases it could involve construction of an electromagnetic screen enclosing the power source and the work complete

with associated input filters. In all cases electromagnetic disturbances

must be reduced to the point where they are no longer troublesome.

Note: The welding circuit may or may not be earthed for safety reasons

according to national codes. Changing the earthing arrangements should

only be authorized by a person who is competent to access whether the

changes will increase the risk of injury, e.g., by allowing parallel welding

current return paths which may damage the earth circuits of other equipment.

ASSESSMENT OF AREA

Before installing welding equipment the user shall make an

assessment of potential electromagnetic problems in the surrounding

area. The following shall be taken into account:

a. other supply cables, control cables, signaling and telephone cables;

above, below and adjacent to the welding equipment;

b. radio and television transmitters and receivers;

c. computer and other control equipment;

d. safety critical equipment, e.g., guarding of industrial equipment;

e. the health of the people around, e.g., the use of pacemakers and

hearing aids;

f. equipment used for calibration or measurement

g. the immunity of other equipment in the environment. The user shall

ensure that other equipment being used in the environment is

compatible. This may require additional protection measures;

h. the time of day that welding or other activities are to be carried out.

The size of the surrounding area to be considered will depend on the

structure of the building and other activities that are taking place. The

surrounding area may extend beyond the boundaries of the premises.

METHODS OF REDUCING EMISSIONS

Mains Supply

Welding equipment should be connected to the mains supply

according to the manufacturer’s recommendations. If interference

occurs, it may be necessary to take additional precautions such as

filtering of the mains supply. Consideration should be given to

shielding the supply cable of permanently installed welding

equipment, in metallic conduit or equivalent. Shielding should be

electrically continuous throughout its length. The shielding should be

connected to the welding power source so that good electrical contact

is maintained between the conduit and the welding power source

enclosure.

Maintenance of the Welding Equipment

The welding equipment should be routinely maintained according to

the manufacturer’s recommendations. All access and service doors

and covers should be closed and properly fastened when the welding

equipment is in operation. The welding equipment should not be

modified in any way except for those changes and adjustments

covered in the manufacturers instructio ns. In particular, the spark

gaps of arc striking and stabilizing devices should be adjusted and

maintained according to the manufacturer’s recommendations.

Welding Cables

The welding cables should be kept as short as possible and should be

positioned close together, running at or close to floor level.

Equipotential Bonding

Bonding of all metallic components in the welding installation and

adjacent to it should be considered. However, metallic components

bonded to the work piece will increase the risk that the operator could

receive a shock by touching these metallic components and the

electrode at the same time. The operator should be insulated from all

such bonded metallic components.

Earthing of the Workpiece

Where the workpiece is not bonded to earth for electrical safety, not

connected to earth because of its size and position, e.g., ships hull or

building steelwork, a connection bonding the workpiece to earth may

reduce emissions in some, but not all instances. Care should be taken

to prevent the earthing of the work piece increasing the risk of injury

to users, or damage to other electrical equipment. Where necessary,

the connection of the workpiece to earth should be made by a direct

connection to the work piece, but in some countries where direct

connection is not permitted, the bonding should be achieved by

suitable capacitance, selected according to national regulations.

Screening and Shielding

Selective screening and shielding of other cables and equipment in

the surrounding area may alleviate problems of interference.

Screening of the entire welding installation may be considered for

special applications.

1

Portions of the preceding text are contained in EN 60974-10: “Electromagnetic

Compatibility (EMC) product standard for arc welding equipment.”

Page 7

TABLE OF CONTENTS

Page

Installation.......................................................................................................................Section A

Technical Specifications ...............................................................................................A-1, A-2

Safety Precautions ...............................................................................................................A-3

Location, Lifting .............................................................................................................A-3

Stacking ........................................................................................................................A-3

Tilting.............................................................................................................................A-3

Input and Ground Connections .....................................................................................A-3

Machine Grounding.......................................................................................................A-3

High Frequency Protection............................................................................................A-3

Input Connection ..................................................................................................................A-4

Input Fuse and Supply Wire..........................................................................................A-4

Input Voltage Selection .................................................................................................A-4

Power Cord Replacement .............................................................................................A-4

Connection Diagram .....................................................................................................A-5

Recommended Work Cable Sizes ................................................................................A-6

Cable Inductance and its Effects on Welding................................................................A-7

Remote Sense Lead Specifications.......................................................................A-7, A-8

Voltage Sensing Considerations for Multiple Arc Systems..................................A-9, A-10

Control Cable Connections ................................................................................................A-11

________________________________________________________________________________

Operation.........................................................................................................................Section B

Safety Precautions ...............................................................................................................B-1

Graphic Symbols...........................................................................................................B-1

Power-Up Sequence .....................................................................................................B-1

Duty Cycle.....................................................................................................................B-1

Product Description ..............................................................................................................B-2

Recommended Processes and Equipment ..........................................................................B-2

Equipment Limitations ..........................................................................................................B-2

Common Equipment Packages............................................................................................B-2

Design Features ...................................................................................................................B-3

Case Front Controls .............................................................................................................B-4

Case Back Controls..............................................................................................................B-4

Common Welding Procedures................................................................................B-5 thru B-7

________________________________________________________________________________

viivii

Accessories .....................................................................................................Section C

Kits, Options / Accessories....................................................................................C-1

Field Installed Options...........................................................................................C-1

Stick Operations ............................................................................................C-2, C-3

________________________________________________________________________

Maintenance........................................................................................................Section D

Safety Precautions ...............................................................................................................D-1

Routine Maintenance ...........................................................................................................D-1

Periodic Maintenance...........................................................................................................D-1

Calibration Specification.......................................................................................................D-1

________________________________________________________________________________

Troubleshooting ..............................................................................................Section E

Safety Precautions.................................................................................................E-1

How to Use Troubleshooting Guide.......................................................................E-1

Using Status LED, Error Fault Codes and Input Control Board....................................E-2, E-4

Troubleshooting Guide.............................................................................E-5 thru E-8

________________________________________________________________________________

Wiring Diagram and Dimension Print ............................................................Section F

________________________________________________________________________

Parts Pages ................................................................................................................P-609 Series

_______________________________________________________________________

________

Page 8

A-1

INSTALLATION

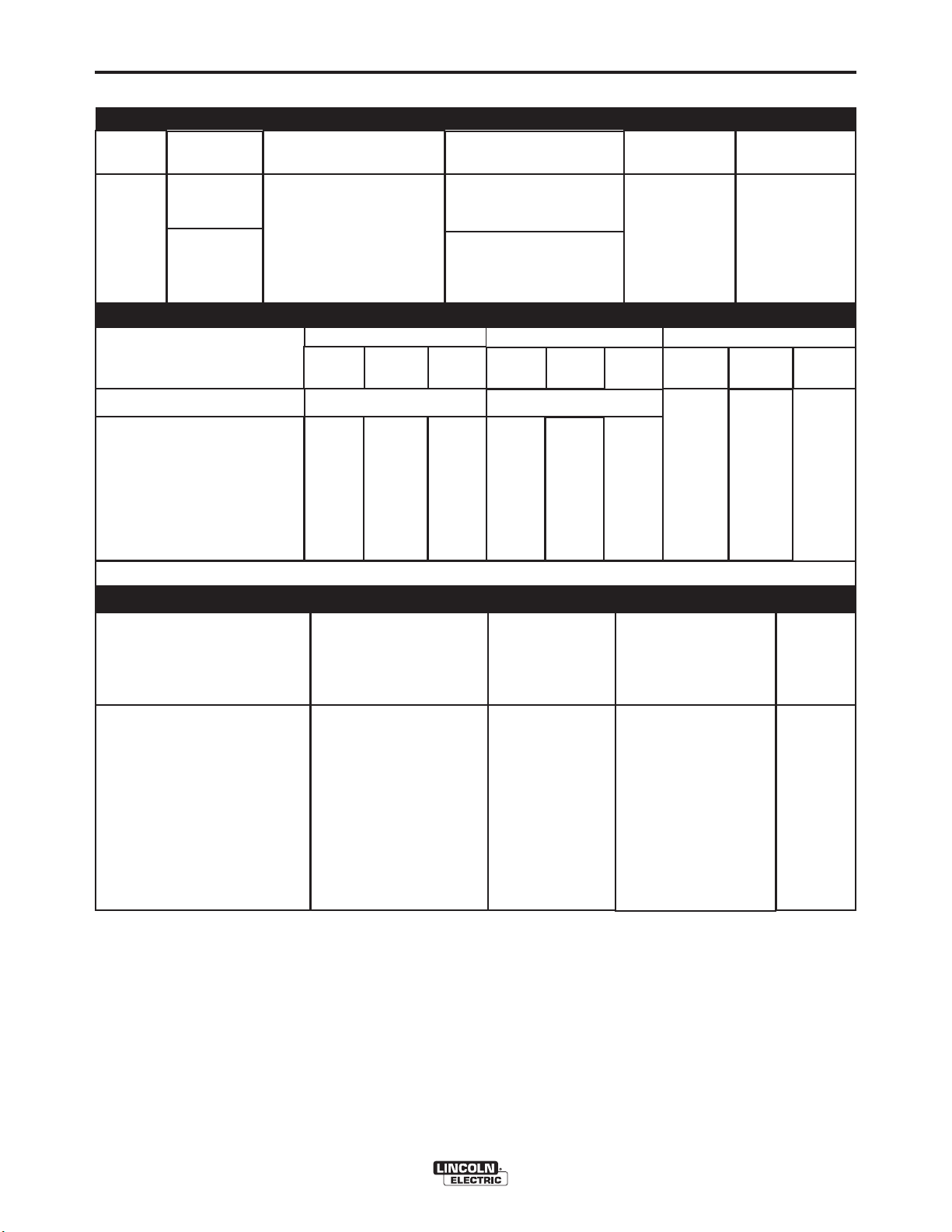

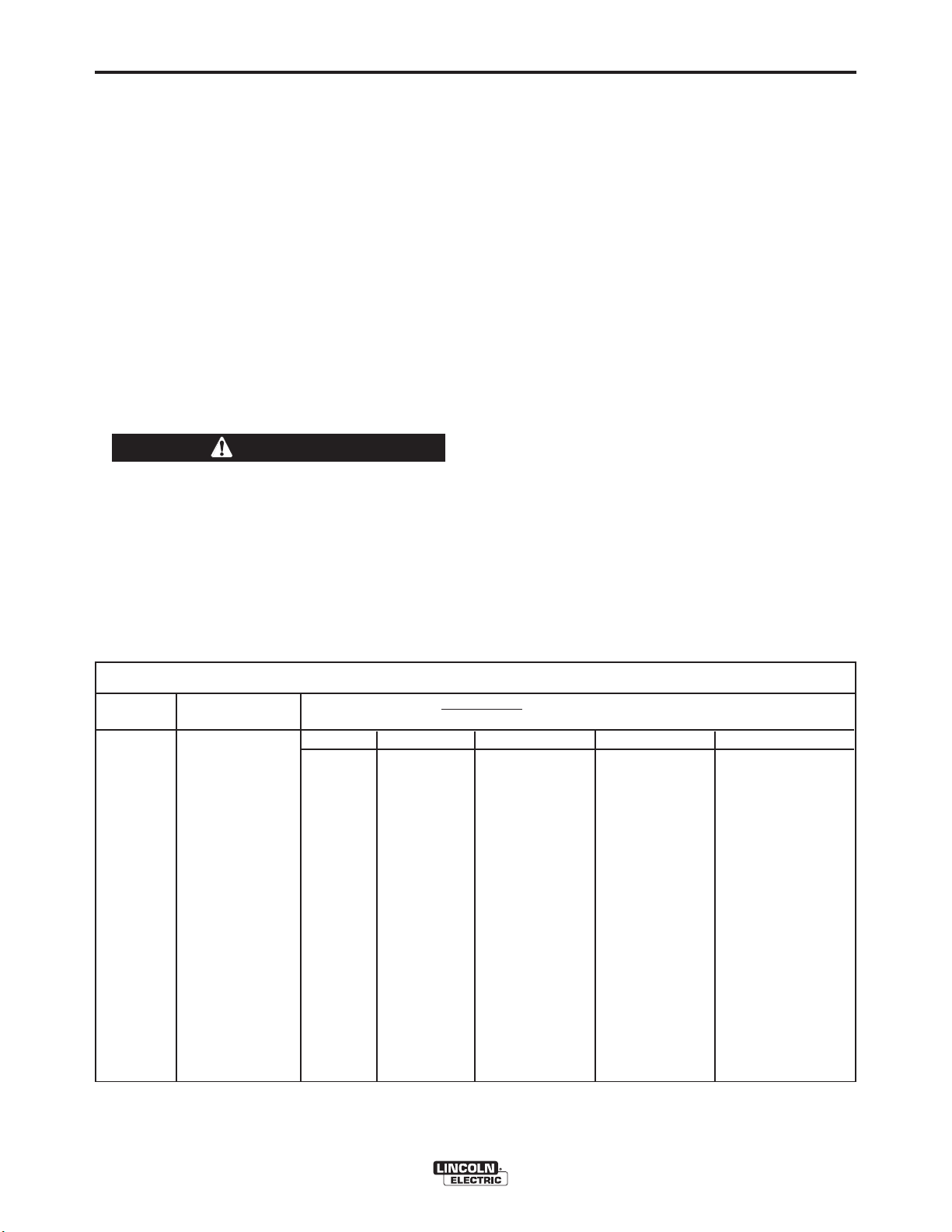

TECHNICAL SPECIFICATIONS - POWER WAVE®S350

POWER SOURCE-INPUT VOLTAGE AND CURRENT

Model

Duty Cycle

Input Voltage ± 10%

Input Amperes

(1 Phase in parenthesis)

Idle Power

A-1

Power Factor @

Rated Output

39/35/20/17/14

(NA/65***/37/32/25)

30/28/16/14/11

(56/51/29/25/20)

300 Watts Max.

(fan on)

K2823-1

40% rating

100% rating

200-208/230/380-415/

460/575

50/60 Hz

RATED OUTPUT

INPUT

VOLTAGE / PHASE /

FREQUENCY

200-208/1/50/60

230/1/50/60

460/1/50/60

575/1/50/60

200-208/3/50/60

230/3/50/60

380-415/3/50/60

460/3/50/60

575/3/50/60

*** On 230 Volt / 1 phase inputs the max. rating is at a duty cycle of 30%, except for GTAW processes.

40%***

350

Amps

31.5

Volts

RECOMMENDED INPUT WIRE AND FUSE SIZES

INPUT

VOLTAGE / PHASE/

FREQUENCY

INPUT AMPERE RAT-

ING AND DUTY CYCLE

GMAW

60%

300 Amps / 29 Volts

320

Amps

30

Volts

MAXIMUM

100%

300

Amps

29

Volts

SMAW

(mm

60%

275

Amps

31

Volts

2

)

100%

Amps

3

40%***

250 Amps / 30 Volts

325

Amps

33

Volts

CORD SIZE

AWG SIZES

GTAW-DC

40%

250

30

Volts

TIME DELAY FUSE

350

Amps

24 Volts

1

OR BREAKER

AMPERAGE

60%

325

Amps

23Volts

2

.95

100%

300

Amps

22 Volts

NOTES

200-208/1/50/60

200-208/3/50/60

230/1/50/60

230/3/50/60

380-415/1/50/60

380-415/3/50/60

460/1/50/60

460/3/50/60

575/1/50/60

575/3/50/60

1. Based on U.S. National electrical Code

2. Also called " inverse time" or "thermal / magnetic" circuit breakers; circuit breakers that have a delay in trip-

ping action that decreases as the magnitude of the current increases

3. Type SO cord or similar in 30° C ambient

4. When operating on these inputs, the line cord should be changed to an input conductor of 6 AWG or larger.

60A, 100%

39A, 40%

67A, 30%

35A, 40%

38A, 40%

19A, 40%

34A, 40%

17A, 40%

27A, 40%

14A, 40%

POWER WAVE®S350

6 (13)

8 (10)

4 (16)

8 (10)

8 (10)

12 (4)

8 (10)

12 (4)

10 (6)

14 (2.5)

80

50

80

45

50

30

45

25

35

20

NOTE 4

NOTE 4

Page 9

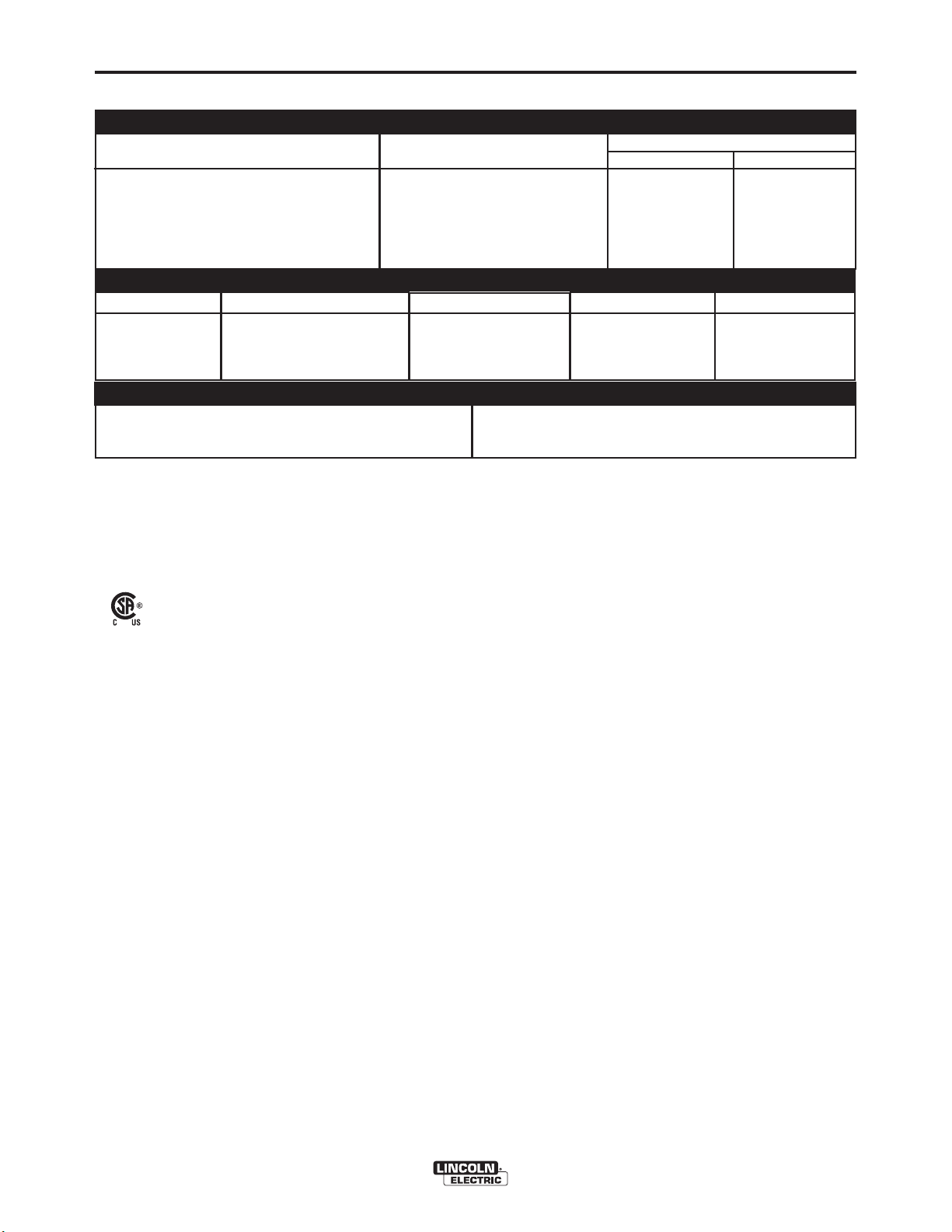

A-2

PROCESS

GMAW

GMAW-Pulse

FCAW

GTAW-DC

SMAW

PHYSICAL DIMENSIONS

MODEL

HEIGHT

INSTALLATION

WELDING PROCESS

OUTPUT RANGE (AMPERES)

5-350

WIDTH

OCV (Uo)

Mean Peak

40-70

40-70

40-70 100V

24

60

DEPTH

A-2

WEIGHT

K2823-1

20.40 in ( 518 mm)

14.00in ( 356 mm)

TEMPERATURE RANGES

OPERATING TEMPERATURE RANGE

Environmentally Hardened: -4°F to 104°F (-20C to 40C)

IP23 155º(F) Insulation Class

* Weight does not include input cord.

IEC 60974-1

24.80in ( 630mm)

STORAGE TEMPERATURE RANGE

Environmentally Hardened: -40°F to 185°F (-40C to 85C)

85 lbs (39 kg)*

POWER WAVE®S350

Page 10

A-3

INSTALLATION

A-3

SAFETY PRECAUTIONS Read this

entire installation section before you start installa-

tion.

WARNING

ELECTRIC SHOCK can kill.

• Only qualified personnel should

perform this installation.

• Turn the input power OFF at the

disconnect switch or fuse box before working on

this equipment. Turn off the input power to any

other equipment connected to the welding system

at the disconnect switch or fuse box before working on the equipment.

• Do not touch electrically hot parts.

• Always connect the POWER WAVE

grounding lug to a proper safety (Earth) ground.

-------------------------------------------------------------

®

S350

SELECT SUITABLE LOCATION

The POWER WAVE®S350 will operate in harsh environments. Even so, it is important that simple preventative measures are followed in order to assure long

life and reliable operation.

LIFTING

Both handles should be used when lifting POWER WAVE

S350. When using a crane or overhead device a lifting strap

should be connected to both handles. Do not attempt to lift the

POWER WAVE

®

S350 with accessories attached to it.

®

WARNING

• Lift only with equipment of adequate lifting capacity.

• Be sure machine is stable when

lifting.

• Do not operate machine while

suspended when lifting.

FALLING

EQUIPMENT can

cause injury.

-------------------------------------------------------------

STACKING

The POWER WAVE®S350 cannot be stacked.

TILTING

Place the machine directly on a secure, level surface or on a

recommended undercarriage. The machine may topple over if

this procedure is not followed.

• The machine must be located where there is free

circulation of clean air such that air movement in

the back, out the sides and bottom will not be

restricted.

• Dirt and dust that can be drawn into the machine

should be kept to a minimum. The use of air filters

on the air intake is not recommended because normal air flow may be restricted. Failure to observe

these precautions can result in excessive operating

temperatures and nuisance shutdown.

• Keep machine dry. Shelter from rain and snow. Do

not place on wet ground or in puddles.

• Do not mount the POWER WAVE

bustible surfaces. Where there is a combustible

surface directly under stationary or fixed electrical

equipment, that surface shall be covered with a

steel plate at least .060” (1.6mm) thick, which shall

extend not less than 5.90” (150mm) beyond the

equipment on all sides.

®

S350 over com-

INPUT AND GROUND CONNECTIONS

Only a qualified electrician should connect the POWER WAVE

S350. Installation should be made in accordance with the

appropriate National Electrical Code, all local codes and the

information in this manual.

®

MACHINE GROUNDING

The frame of the welder must be grounded. A ground terminal

marked with a ground symbol is located next to the input

power connection block.

See your local and national electrical codes for proper grounding methods.

HIGH FREQUENCY PROTECTION

The EMC classification of the POWER WAVE

Industrial, Scientific and Medical (ISM) group 2, class A. The

®

POWER WAVE

L10093 for further details).

Locate the POWER WAVE

machinery. The normal operation of the POWER WAVE

may adversely affect the operation of RF controlled equipment,

which may result in bodily injury or damage to the equipment.

S350 is for industrial use only. (See print

®

S350 away from radio controlled

®

S350 is

®

S350

POWER WAVE®S350

Page 11

A-4

INSTALLATION

A-4

INPUT CONNECTION

WARNING

Only a qualified electrician should

connect the input leads to the

POWER WAVE

should be made in accordance with

all local and national electrical

codes and the connection diagrams. Failure to do

so may result in bodily injury or death.

-------------------------------------------------------------

A 10 ft. (3.0m) power cord is provided and wired into

the machine.

For Single Phase Input

Connect green lead to ground per National Electrical

Code.

Connect black and white leads to power.

Wrap red lead with tape to provide 600V insulation.

For Three Phase Input

Connect green lead to ground per National Electric

Code.

®

S350. Connections

WARNING

The POWER WAVE®S350 ON/OFF

switch is not intended as a service

disconnect for this equipment. Only

a qualified electrician should con-

®

nect the input leads to the POWER WAVE

S350.

Connections should be made in accordance with

all local and national electrical codes and the connection diagram located on the inside of the

reconnect access door of the machine. Failure to

do so may result in bodily injury or death.

------------------------------------------------------------------------

POWER CORD REPLACEMENT

WARNING

Only a qualified electrician should

connect the input leads to the

POWER WAVE

should be made in accordance with

all local and national electrical

codes and the connection diagrams. Failure to do so may result in bodily injury

or death.

®

S350. Connections

Connect black, red and white leads to power.

INPUT FUSE AND SUPPLY WIRE

CONSIDERATIONS

Refer to Specification Section for recommended fuse,

wire sizes and type of the copper wires. Fuse the

input circuit with the recommended super lag fuse or

delay type breakers (also called "inverse time" or

"thermal/magnetic" circuit breakers). Choose input

and grounding wire size according to local or national

electrical codes. Using input wire sizes, fuses or circuit breakers smaller than recommended may result in

"nuisance" shut-offs from welder inrush currents, even

if the machine is not being used at high currents.

INPUT VOLTAGE SELECTION

The POWER WAVE®S350 automatically adjusts to

work with different input voltages. No reconnect

switches settings are required.

------------------------------------------------------------------------

If the input power cord is damaged or needs to be

replaced an input power connection block is located

in the back of the machine with the access panel

removed as shown Figure A.1.

ALWAYS CONNECT THE POWER WAVE GROUND-

ING LUG (LOCATED AS SHOWN IN FIGURE A.1)

TO A PROPER SAFETY (EARTH) GROUND.

FIGURE A.1

CONNECTION

BLOCK

GROUND

LUG

INPUT

POWER

CORD

POWER WAVE®S350

Page 12

A-5

K87870

CONNECTION DIAGRAMS

INSTALLATION

SMAW (STICK) WELDING

A-5

GTAW (TIG) WELDING

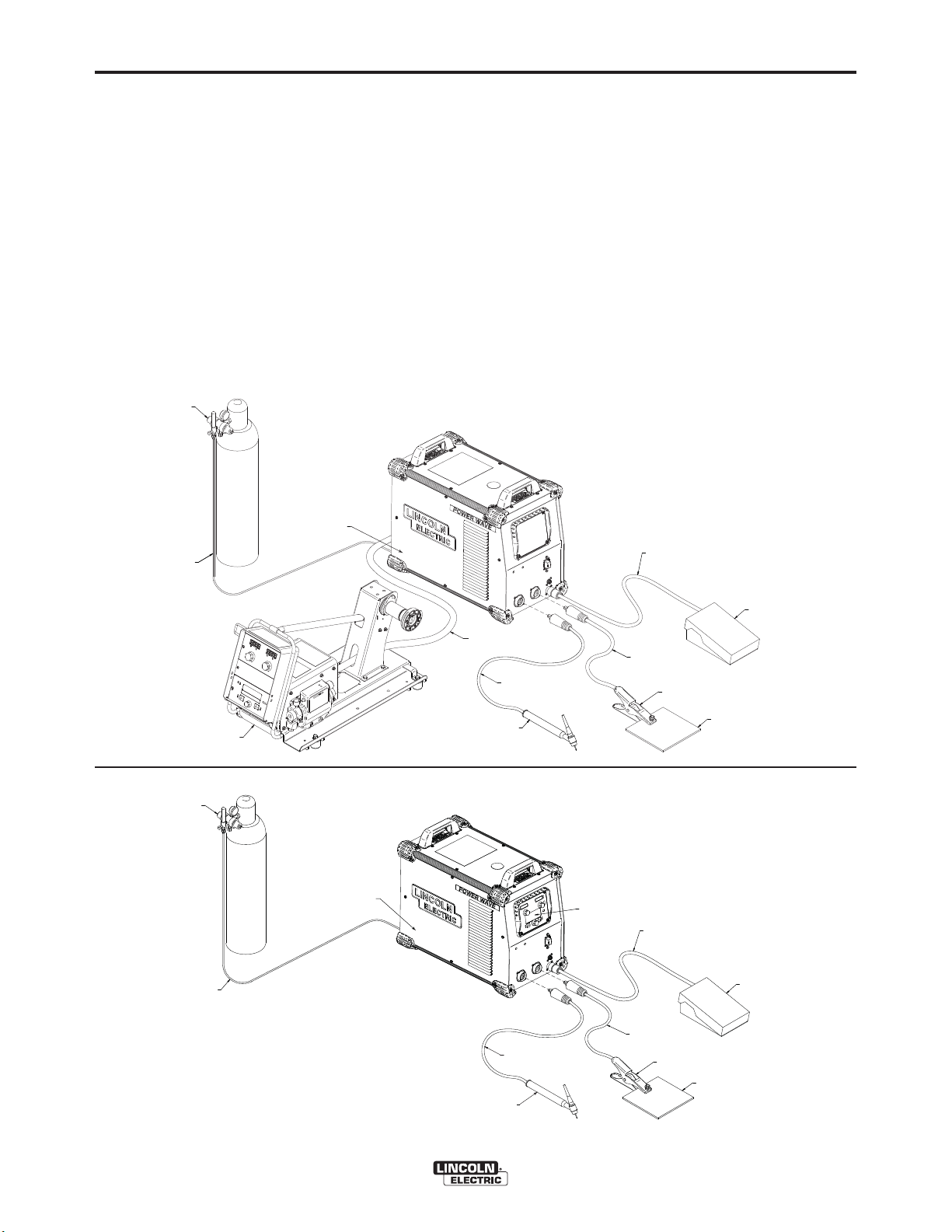

A user interface is required for adjusting the TIG welding settings. A Power Feed wire feeder can be used as

the user interface (Figure A.2), or a S-series user interface (K2828-1) can be installed into the power source

(Figure A.3). Refer to the connection diagrams based

on the user interface that is being used. For either setup the K2825-1 solenoid kit is recommended for controlling the gas. Alternate configurations are possible

depending on the wire feeder that is being used. Refer

to the wire feederʼs manual for alternative configurations.

FIGURE A.2

REGULATOR

FLOWMETER

GAS HOSE

GAS SOLENOID KIT

(INSIDE MACHINE)

K2825-1

TIG WITH POWER FEED USER INTERFACE

Similar to TIG welding a user interface is required for

adjusting the Stick welding settings. A Power Feed

wire feeder can be used as the user interface, or a

K2828-1 (user interface control panel) can be installed

into the power source (Figure A.4). The connection

diagram shown is based on the S-Series user interface (K2828-1). In this diagram the remote control box

is optional.

GMAW (MIG) WELDING

An arclink compatible wire feeder is recommended for

Mig welding. Refer to Figure A.5 for the connection

details.

TO REMOTE CONTROL

RECEPTACLE

REGULATOR

FLOWMETER

GAS HOSE

PF10-M

WIRE FEEDER

GAS SOLENOID KIT

(INSIDE MACHINE)

K2825-1

ARCLINK CABLE

K1543-[XX]

TO NEGATIVE

(-) STUD

TIG TORCH

K2266-1 KIT

(INCLUDES WORK CLAMP,

ADAPTER, AND REGULATOR)

FIGURE A.3

TIG WITH S-SERIES USER INTERFACE

USER INTERFACE

CONTROL PANEL

K2828-1

TO NEGATIVE

(-) STUD

TIG TORCH

K2266-1 KIT

(INCLUDES WORK CLAMP,

ADAPTER, AND REGULATOR)

POWER WAVE®S350

TO POSITIVE

(+) STUD

TO POSITIVE

(+) STUD

WORK CLAMP

WORK PIECE

TO REMOTE CONTROL

RECEPTACLE

WORK CLAMP

WORK PIECE

FOOT AMPTROL

FOOT AMPTROL

K870

Page 13

A-6

INSTALLATION

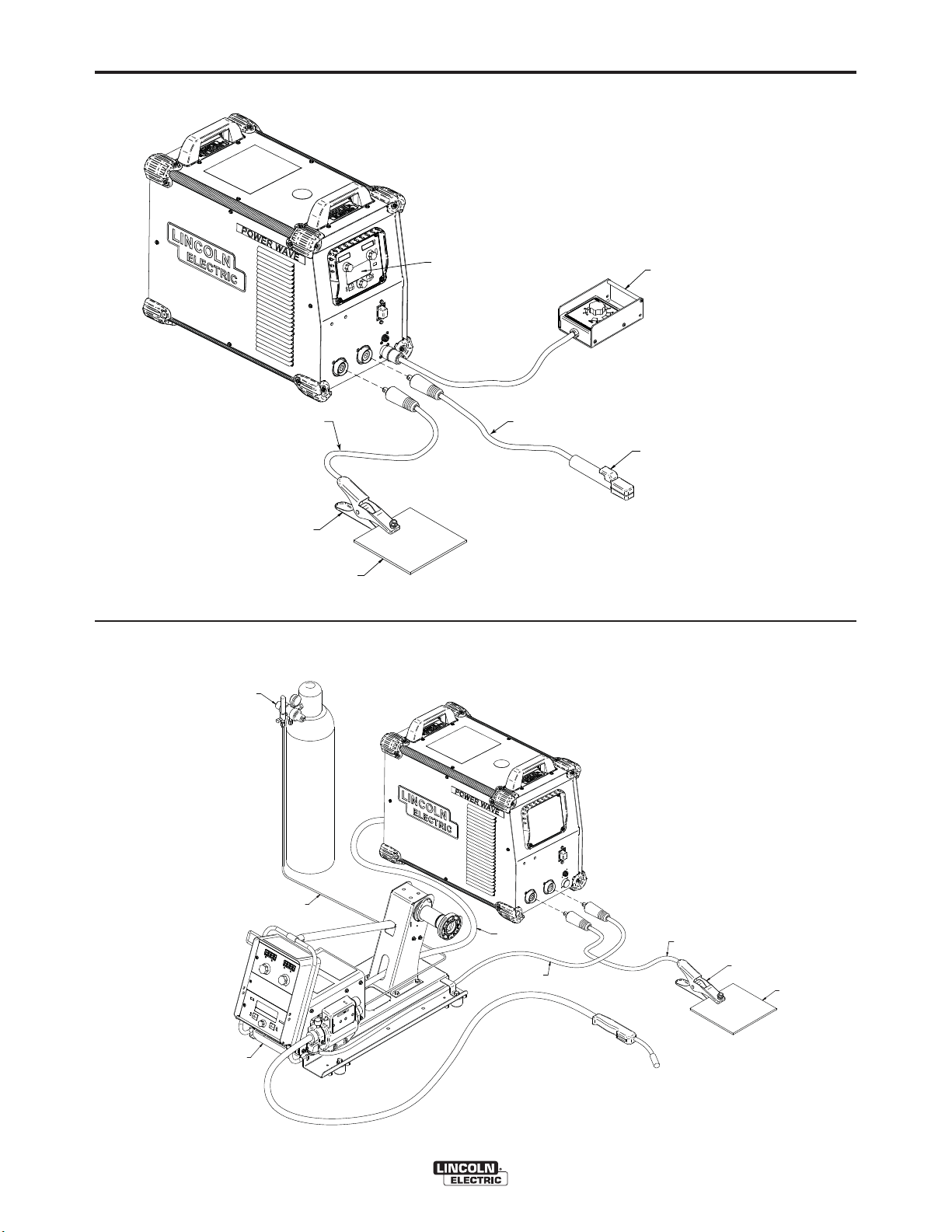

FIGURE A.4

STICK WITH S-SERIES USER INTERFACE

A-6

TO NEGATIVE

(-) STUD

WORK CLAMP

REGULATOR

FLOWMETER

WORK PIECE

USER INTERFACE

CONTROL PANEL

K2828-1

FIGURE A.5

MIG PROCESS

TO POSITIVE

(+) STUD

REMOTE CONTROL BOX

K857

ELECTRODE HOLDER KIT

K2394-1 KIT

(INICLUDES GROUND CLAMP)

PF10-M

WIRE FEEDER

GAS HOSE

ARCLINK CABLE

K1543-[XX]

TO POSITIVE

(+) STUD

POWER WAVE®S350

TO NEGATIVE (-) STUD

WORK CLAMP

WORK PIECE

Page 14

A-7

INSTALLATION

A-7

RECOMMENDED WORK CABLE

SIZES FOR ARC WELDING

Connect the electrode and work cables between the

appropriate output studs of the Power Wave

per the following guidelines:

• Most welding applications run with the electrode

being positive (+). For those applications, connect

the electrode cable between the wire drive feed plate

and the positive (+) output stud on the power source.

Connect a work lead from the negative (-) power

source output stud to the work piece

• When negative electrode polarity is required, such

as in some Innershield applications, reverse the output connections at the power source (electrode cable

to the negative (-) stud, and work cable to the positive (+) stud).

®

S350

CAUTION

Negative electrode polarity operation WITHOUT

use of a remote work sense lead (21) requires the

Negative Electrode Polarity attribute to be set. See

the Remote Sense Lead Specification section of

this document for further details.

-----------------------------------------------------------------------

For additional Safety information regarding the electrode and work cable set-up, See the standard “SAFETY INFORMATION” located in the front of the

Instruction Manuals.

OUTPUT CABLE GUIDELINES (Table A.1)

General Guidelines

• Select the appropriate size cables per the “Output

Cable Guidelines” below. Excessive voltage drops

caused by undersized welding cables and poor connections often result in unsatisfactory welding performance. Always use the largest welding cables (electrode and work) that are practical, and be sure all

connections are clean and tight.

Note: Excessive heat in the weld circuit indicates

undersized cables and/or bad connections.

• Route all cables directly to the work and wire feeder,

avoid excessive lengths and do not coil excess

cable. Route the electrode and work cables in close

proximity to one another to minimize the loop area

and therefore the inductance of the weld circuit.

• Always weld in a direction away from the work

(ground) connection.

Table A.1 shows copper cable sizes recommended for

different currents and duty cycles. Lengths stipulated

are the distance from the welder to work and back to

the welder again. Cable sizes are increased for

greater lengths primarily for the purpose of minimizing

cable drop.

Percent Duty

Amperes

200

200

250

250

250

250

300

300

350

** Tabled values are for operation at ambient temperatures of 104°F (40°C) and below. Applications above 104°F (40°C) may

require cables larger than recommended, or cables rated higher than 167°F (75°C).

Cycle

60

100

30

40

60

100

60

100

40

CABLE SIZES FOR COMBINED LENGTHS OF ELECTRODE AND WORK

CABLES [RUBBER COVERED COPPER - RATED

0 to 50 Ft.

2

2

3

2

1

1

1

2/0

1/0

50 to 100 Ft.

2

2

3

2

1

1

1

2/0

1/0

POWER WAVE®S350

100 to 150 Ft.

2

2

2

1

1

1

1

2/0

2/0

167°F (75°C)]**

150 to 200 Ft.

1

1

1

1

1

1

1/0

2/0

2/0

200 to 250 Ft.

1/0

1/0

1/0

1/0

1/0

1/0

2/0

3/0

3/0

Page 15

A-8

INSTALLATION

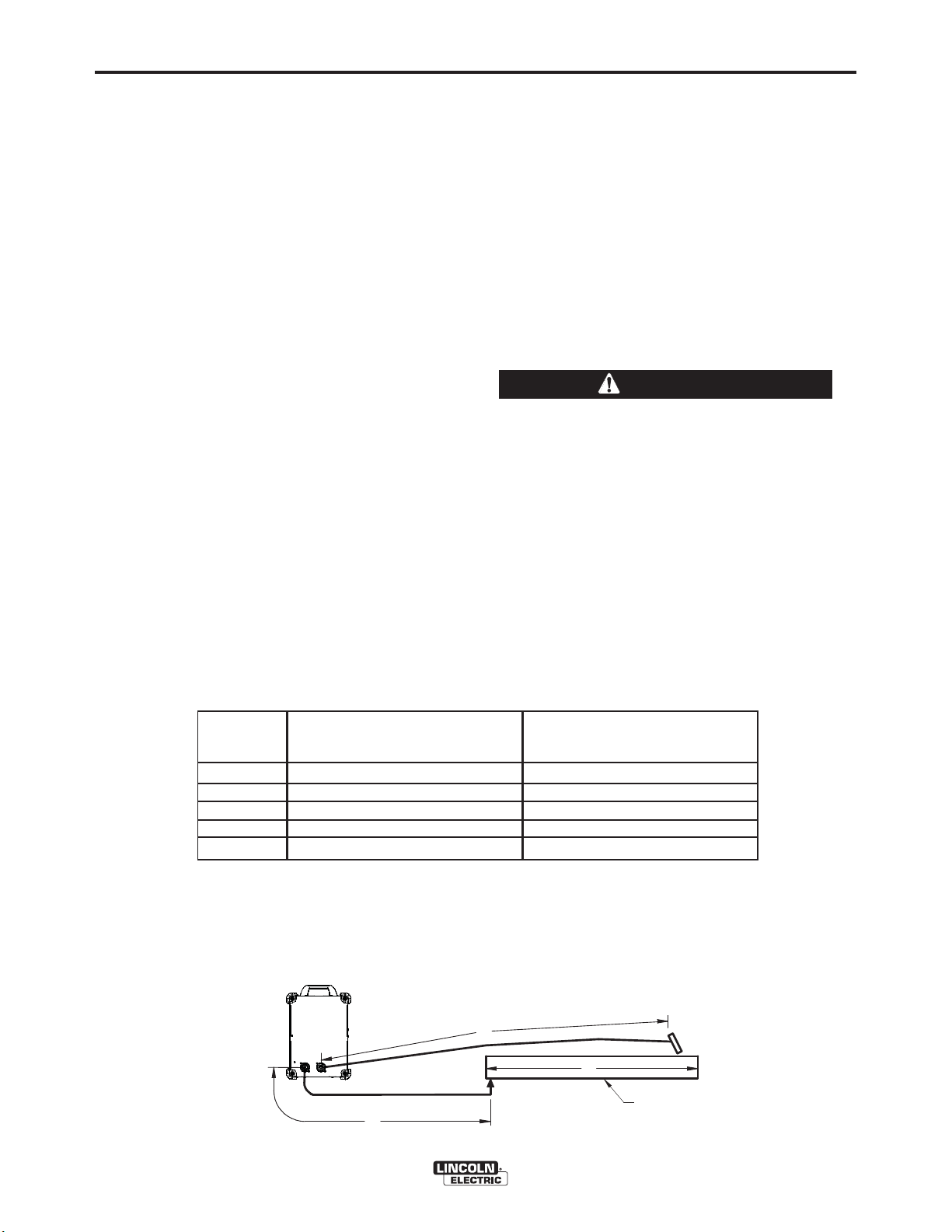

CABLE INDUCTANCE AND ITS

EFFECTS ON WELDING

Excessive cable inductance will cause the welding

performance to degrade. There are several factors

that contribute to the overall inductance of the cabling

system including cable size, and loop area. The loop

area is defined by the separation distance between

the electrode and work cables, and the overall welding

loop length. The welding loop length is defined as the

total of length of the electrode cable (A) + work cable

(B) + work path (C) (See Figure A.6).

To minimize inductance always use the appropriate

size cables, and whenever possible, run the electrode

and work cables in close proximity to one another to

minimize the loop area. Since the most significant factor in cable inductance is the welding loop length,

avoid excessive lengths and do not coil excess cable.

For long work piece lengths, a sliding ground should

be considered to keep the total welding loop length as

short as possible.

REMOTE SENSE LEAD

SPECIFICATIONS

Voltage Sensing Overview

The best arc performance occurs when the Power

®

Wave

tions.

S350 has accurate data about the arc condi-

TABLE A.2

Process

Electrode Voltage Sensing

67 lead

A-8

Depending upon the process, inductance within the

electrode and work cables can influence the voltage

apparent at the studs of the welder, and have a dramatic effect on performance. Remote voltage sense

leads are used to improve the accuracy of the arc voltage information supplied to the control pc board.

Sense Lead Kits (K940-xx) are available for this purpose.

The Power Wave

ly sense when remote sense leads are connected.

With this feature there are no requirements for settingup the machine to use remote sense leads. This feature can be disabled through the Weld Manager Utility

(available at www.powerwavesoftware.com) or

through the set up menu (if a user interface is installed

into the power source).

®

S350 has the ability to automatical-

CAUTION

If the auto sense lead feature is disabled and

remote voltage sensing is enabled but the sense

leads are missing, improperly connected extremely high welding outputs may occur.

------------------------------------------------------------------------

General Guidelines for Voltage Sense Leads

Sense leads should be attached as close to the weld

as practical, and out of the weld current path when

possible. In extremely sensitive applications it may be

necessary to route cables that contain the sense

leads away from the electrode and work welding

cables.

Voltage sense leads requirements are based on the

weld process (See Table A.2)

(1)

Work Voltage Sensing

21 lead

(2)

GMAW

GMAW-P

FCAW

GTAW

SMAW

(1)

The electrode voltage sense lead (67) is automatically enabled by the weld process, and integral to the 5 pin arclink control cable (K1543xx).

(2)

When a work voltage sense lead (21) is connected the power source will automatically switch over to using this feedback (if the auto

sense feature is enable).

POWER

WAVE

S350

67 lead required

67 lead required

67 lead required

Voltage sense at studs

Voltage sense at studs

FIGURE A.6

A

B

POWER WAVE®S350

21 lead optional

21 lead optional

21 lead optional

Voltage sense at studs

Voltage sense at studs

C

WORK

Page 16

A-9

Electrode Voltage Sensing

The remote ELECTRODE sense lead (67) is built into

the 5-pin arclink control cable (K1543-xx) and is

always connected to the wire drive feed plate when a

wire feeder is present. Enabling or disabling electrode

voltage sensing is application specific, and automatically configured by the active weld mode.

Work Voltage Sensing

®

The Power Wave

sense work voltage at the negative output stud (positive output polarity with remote Work Voltage Sensing

disabled).

S350 is configured at the factory to

INSTALLATION

A-9

Negative Electrode Polarity

The Power Wave

ly sense the polarity of the sense leads. With this feature there are no set-up requirements for welding with

negative electrode polarity. This feature can be disabled through the Weld Manager Utility (available at

www.powerwavesoftware.com) or through the set up

menu (if a user interface is installed into the power

source).

®

S350 has the ability to automatical-

CAUTION

If the auto sense lead feature is disabled and the

weld polarity attribute is improperly configured

extremely high welding outputs may occur.

------------------------------------------------------------------------

While most applications perform adequately by sensing the work voltage directly at the output stud, the

use of a remote work voltage sense lead is recommended for optimal performance. The remote WORK

sense lead (21) can be accessed through the four-pin

voltage sense connector located on the control panel

by using the K940 Sense Lead Kit. It must be

attached to the work as close to the weld as practical,

but out of the weld current path. For more information

regarding the placement of remote work voltage

sense leads, see the section entitled "Voltage Sensing

Considerations for Multiple Arc Systems."

POWER WAVE®S350

Page 17

A-10

INSTALLATION

A-10

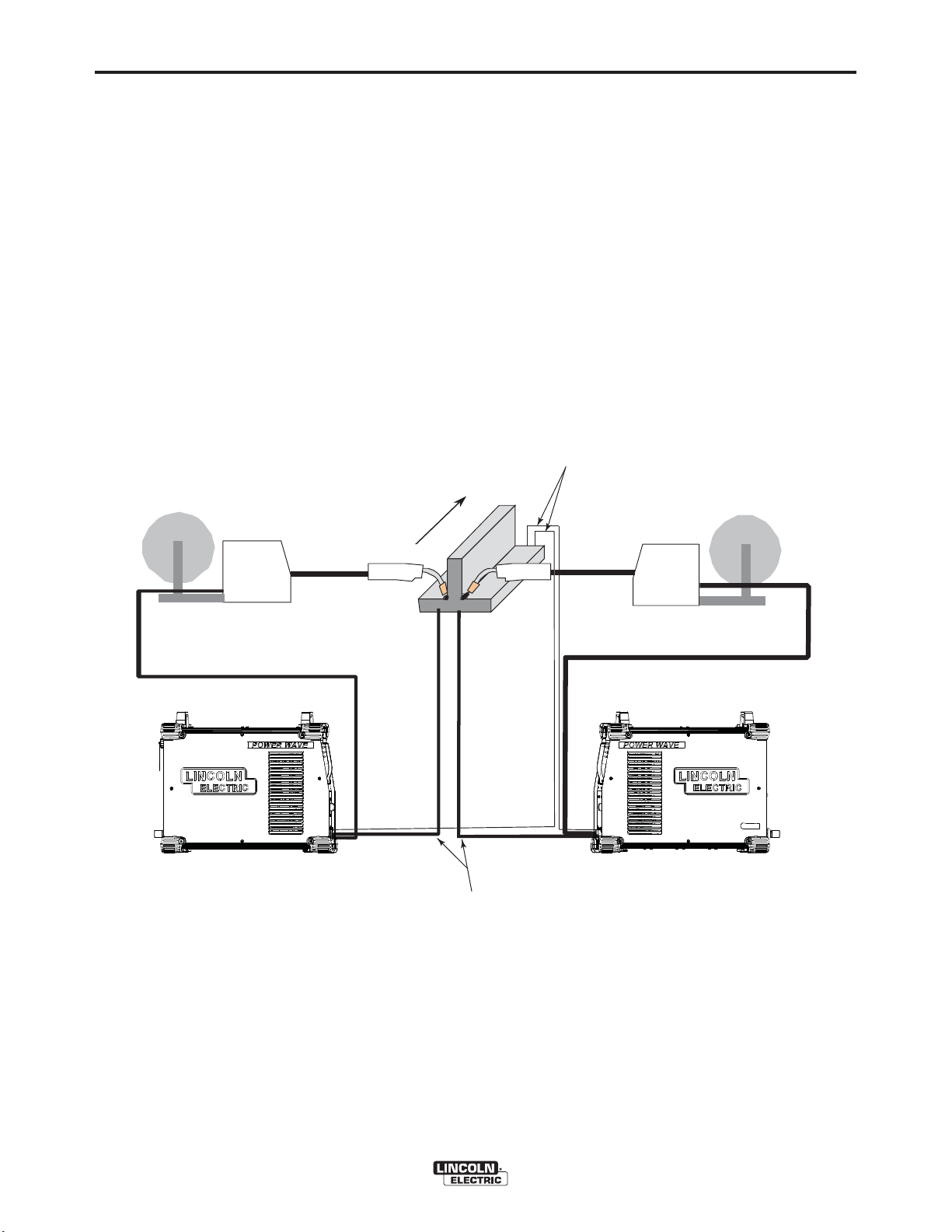

VOLTAGE SENSING

CONSIDERATIONS FOR MULTIPLE

ARC SYSTEMS

Special care must be taken when more than one arc

is welding simultaneously on a single part. Multiple arc

applications do not necessarily dictate the use of

remote work voltage sense leads, but they are strongly recommended.

If Sense Leads ARE NOT Used:

• Avoid common current paths. Current from adjacent arcs can induce voltage into each others current paths that can be misinterpreted by the power

sources, and result in arc interference.

FIGURE A.7

DIRECTION

OF TRAVEL

If Sense Leads ARE Used:

• Position the sense leads out of the path of the weld

current. Especially any current paths common to

adjacent arcs. Current from adjacent arcs can

induce voltage into each others current paths that

can be misinterpreted by the power sources, and

result in arc interference.

• For longitudinal applications, connect all work leads

at one end of the weldment, and all of the work voltage sense leads at the opposite end of the weldment. Perform welding in the direction away from

the work leads and toward the sense leads.

(See Figure A.7)

CONNECT ALL SENSE

LEADS AT THE END

OF THE WELD.

CONNECT ALL

WORK LEADS AT

THE BEGINNING

OF THE WELD.

POWER WAVE®S350

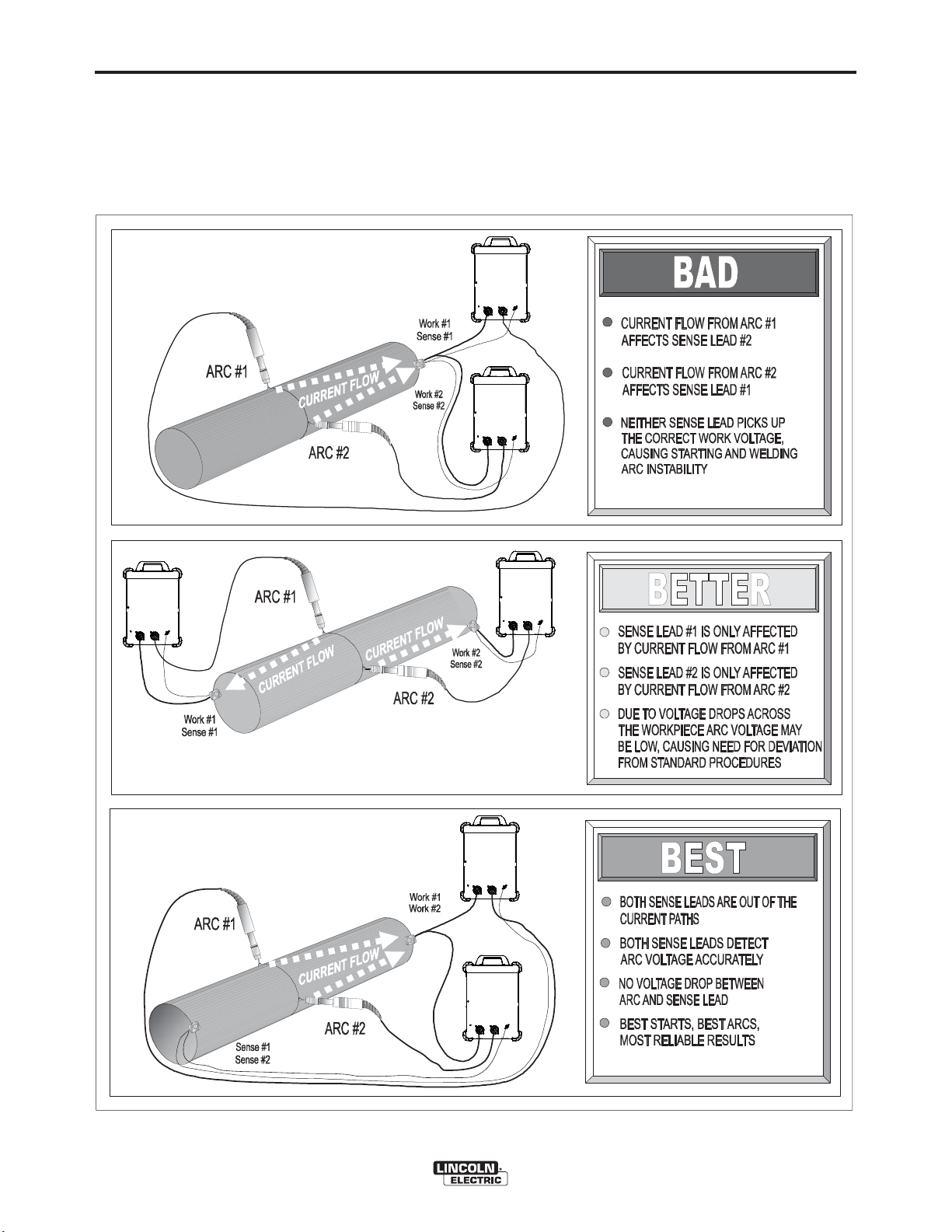

Page 18

A-11

INSTALLATION

• For circumferential applications, connect all work

leads on one side of the weld joint, and all of the

work voltage sense leads on the opposite side,

such that they are out of the current path.

(See Figure 8.A)

FIGURE A.8

POWER

SOURCE

#1

WER

PO

SOURCE

#2

A-11

POWER

SOURCE

#1

WER

PO

SOURCE

#1

POWER

SOURCE

#2

WER

PO

SOURCE

#2

POWER WAVE®S350

Page 19

A-12

INSTALLATION

A-12

CONTROL CABLE CONNECTIONS

General Guidelines

Genuine Lincoln control cables should be used at all

times (except where noted otherwise). Lincoln cables

are specifically designed for the communication and

power needs of the Power Wave

tems. Most are designed to be connected end to end

for ease of extension. Generally, it is recommended

that the total length not exceed 100ft. (30.5m). The

use of non-standard cables, especially in lengths

greater than 25 feet, can lead to communication problems (system shutdowns), poor motor acceleration

(poor arc starting), and low wire driving force (wire

feeding problems). Always use the shortest length of

control cable possible, and DO NOT coil excess

cable.

Regarding cable placement, best results will be

obtained when control cables are routed separate

from the weld cables. This minimizes the possibility of

interference between the high currents flowing

through the weld cables, and the low level signals in

the control cables. These recommendations apply to

all communication cables including ArcLink

Ethernet connections.

®

/ Power Feed sys-

®

and

Connection Between Power Source and Ethernet

Networks

The Power Wave

®

S350 is equipped with an IP67

rated ODVA compliant RJ-45 Ethernet connector,

which is located on the rear panel. All external

Ethernet equipment (cables, switches, etc.), as

defined by the connection diagrams, must be supplied

by the customer. It is critical that all Ethernet cables

external to either a conduit or an enclosure are solid

conductor, shielded cat 5e cable, with a drain. The

drain should be grounded at the source of transmission. For best results, route Ethernet cables away

from weld cables, wire drive control cables, or any

other current carrying device that can create a fluctuating magnetic field. For additional guidelines refer to

ISO/IEC 11801. Failure to follow these recommendations can result in an Ethernet connection failure during welding.

Product specific Installation Instructions

Connection Between Power Source and ArcLink

Compatible Wirefeeders (K1543 – ArcLink Control

Cable)

The 5-pin ArcLink control cable connects the power

source to the wire feeder. The control cable consists

of two power leads, one twisted pair for digital communication, and one lead for voltage sensing. The 5pin ArcLink connection on the Power Wave

®

S350 is

located on the rear panel above the power cord. The

control cable is keyed and polarized to prevent

improper connection. Best results will be obtained

when control cables are routed separate from the

weld cables, especially in long distance applications.

The recommended combined length of the ArcLink

control cable network should not exceed 200ft.

(61.0m).

®

POWER WAVE®S350

Page 20

B-1

OPERATION

B-1

SAFETY PRECAUTIONS

READ AND UNDERSTAND ENTIRE SECTION

BEFORE OPERATING MACHINE.

WARNING

• ELECTRIC SHOCK CAN KILL.

• Do not touch electrically live

part or electrode with skin or

wet clothing.

• Insulate yourself from work and

ground.

• Always wear dry insulating gloves.

• Do not operate with covers, panels or guards

removed or open.

---------------------------------------------------------------------

• FUMES AND GASSES can be

dangerous.

• Keep your head out of fumes.

Use ventilation or exhaust to

•

remove fumes from breathing

zone.

---------------------------------------------------------------------

• WELDING SPARKS can cause

fire or explosion.

• Keep flammable material away.

GRAPHIC SYMBOLS THAT APPEAR ON

THIS MACHINE OR IN THIS MANUAL

WARNING OR

CAUTION

DANGEROUS

VOLTAGE

POSITIVE OUTPUT

NEGATIVE OUTPUT

HIGH TEMPERATURE

STATUS

---------------------------------------------------------------------

ARC RAYS can burn.

Wear eye, ear and body protec-

•

tion.

---------------------------------------------------------------------

SEE ADDITIONAL WARNING INFORMATION

UNDER ARC WELDING SAFETY PRECAUTIONS

AND IN THE

UAL.

---------------------------------------------------------------------

FRONT OF THIS OPERATING MAN-

PROTECTIVE

GROUND

EXPLOSION

POWER-UP SEQUENCE

When the POWER WAVE®S350 is powered up, it can

take as long as 30 seconds for the machine to be

ready to weld. During this time period the user inter-

face will not be active.

DUTY CYCLE

The duty cycle is based on a ten-minute period. A

40% duty cycle represents 4 minutes of welding and 6

minutes of idling in a ten-minute period. Refer to the

technical specification section for the Power Wave®

S350ʼs duty cycle ratings.

POWER WAVE®S350

Page 21

B-2

OPERATION

B-2

PRODUCT DESCRIPTION

PRODUCT SUMMARY

The Power Wave

power source with high-end functionality capable of

Stick, DC TIG, MIG, Pulsed MIG and Flux-Cored

welding. It is ideal for a wide variety of materials

including aluminum, stainless, and nickel — where arc

performance is critical.

The Power Wave

ble welding system. Like existing Power Waveʼs, the

software based architecture allows for future upgradeability. One significant change from the current range

of Power Wave units is that the Ethernet communication feature is standard on the Power Wave

which allows for effortless software upgrades through

Powerwavesoftware.com. The Ethernet communication also gives the Power Wave

run Production Monitoring™ 2. Also a Devicenet

option which will allow the Power Wave

used in a wide range of configurations. Also, the

Power Wave

ble with future advanced welding modules like STT

®

S350 is a portable multi-process

®

S350 is designed to be a very flexi-

®

S350

®

S350 the ability to

®

S350 to be

®

S350 is being designed to be compati-

PROCESS LIMITATIONS

The software based weld tables of the Power Wave

S350 limit the process capability within the output

range and the safe limits of the machine. In general

the processes will be limited to .030-.052 solid steel

wire, .030-.045 stainless wire, .035-1/16 cored wire,

and .035 and 1/16 Aluminum wire.

EQUIPMENT LIMITATIONS

Only ArcLink compatible semiautomatic wire feeders

and users interfaces may be used. If other Lincoln

wire feeders or non-Lincoln wire feeders are used

there will be limited process capability and performance and features will be limited.

®

RECOMMENDED PROCESSES AND

EQUIPMENT

The Power Wave®S350 is recommended for semiautomatic

welding, and may also be suitable for basic hard automation

applications. The Power Wave

number of configurations, some requiring optional equipment or welding programs.

RECOMMENDED EQUIPMENT

The Power Wave®S350 is designed to be compatible

with the current range of Power Feed™ systems

including future versions of ArcLink

RECOMMENDED PROCESSES

The Power Wave® S350 is a high speed, multiprocess power source capable of regulating the current, voltage, or power of the welding arc. With an output range of 5 to 350 amperes, it supports a number

of standard processes including synergic GMAW,

GMAW-P, FCAW, FCAW-SS, SMAW, GTAW and

GTAW-P on various materials especially steel, aluminum and stainless.

®

S350 can be set up in a

®

feeders.

POWER WAVE®S350

Page 22

B-3

OPERATION

DESIGN FEATURES

Loaded with Standard Features

• Multiple process DC output range: 5 - 350 Amps

• 200 – 600 VAC, 1/3 phase, 50-60Hz input power

• New and Improved Line Voltage Compensation

holds the output constant over wide input voltage

fluctuations.

B-3

• Utilizes next generation microprocessor control,

based on the ArcLink

• State of the art power electronics technology yields

superior welding capability.

• Electronic over current protection

• Input over voltage protection.

• F.A.N. (fan as needed). Cooling fan only runs

when needed.

• Thermostatically protected for safety and reliability.

• Recessed connection panel for protection against

accidental impact.

• Ethernet connectivity via IP-67 rated ODVA compliant RJ-45 connector.

• Panel mounted Status and Thermal LED indicators

facilitate quick and easy troubleshooting.

• Potted PC boards for enhanced ruggedness/reliability.

®

platform.

• Enclosure reinforced with heavy duty aluminum

extrusions for mechanical toughness

• Remote control/Foot amptrol ready.

• Waveform Control Technology™ for good weld

appearance and low spatter, even when welding

nickel alloys.

POWER WAVE®S350

Page 23

B-4

OPERATION

B-4

CASE FRONT CONTROLS

(See Figure B.1)

1. USER INTERFACE (optional)

2. STATUS LED - (See Troubleshooting Section for

operational functions)

3. THERMAL LED - Indicates when machine has

thermal fault.

4. POWER SWITCH - Controls power to the Power

5. WORK STUD

6. ELECTRODE STUD

7. WORK SENSE LEAD

8. 6-PIN REMOTE

Wave

®

S350.

CASE BACK CONTROLS

(See Figure B.2)

1. 115 VAC RECEPTACLE AND CIRCUIT BEAKER

(OPTIONAL)

2. ARCLINK (RECEPTACLE AND CIRCUIT

BREAKER)

3. RESERVED FOR FUTURE DEVELOPMENT

4. DEVICENET KIT (OPTIONAL)

5. ETHERNET

6. RESERVED FOR FUTURE DEVELOPMENT

7. SOLENOID KIT (OPTIONAL)

8. INPUT POWER CORD

FIGURE B.1

1

1

2

2

3

4

5

3

4

8

FIGURE B.2

5

6

7

6

7

8

POWER WAVE®S350

Page 24

B-5

OPERATION

B-5

COMMON WELDING PROCEDURES

WARNING

MAKING A WELD

The serviceability of a product or structure utilizing the welding programs is and must be the sole

responsibility of the builder/user. Many variables

beyond the control of The Lincoln Electric

Company affect the results obtained in applying

these programs. These variables include, but are

not limited to, welding procedure, plate chemistry

and temperature, weldment design, fabrication

methods and service requirements. The available

range of a welding program may not be suitable

for all applications, and the build/user is and must

be solely responsible for welding program selection.

Choose the electrode material, electrode size, shielding gas, and process (GMAW, GMAW-P etc.) appropriate for the material to be welded.

Select the weld mode that best matches the desired

welding process. The standard weld set shipped with

the Power Wave

common processes that will meet most needs. If a

special weld mode is desired, contact the local Lincoln

Electric sales representative.

All adjustments are made through the user interface.

Because of the different configuration options your

system may not have all of the following adjustments.

See Accessories Section for Kits and Options avaliable to use with the Power Wave

®

S350 encompasses a wide range of

®

S350.

Basic Welding Controls

Weld Mode

Selecting a weld mode determines the output characteristics of the Power Wave

®

power source. Weld

modes are developed with a specific electrode material, electrode size, and shielding gas. For a more complete description of the weld modes programmed into

®

the Power Wave

S350 at the factory, refer to the

Weld Set Reference Guide supplied with the machine

or available at www.powerwavesoftware.com.

Wire Feed Speed (WFS)

In synergic welding modes (synergic CV, GMAW-P),

WFS is the dominant control parameter. The user

adjusts WFS according to factors such as wire size,

penetration requirements, heat input, etc. The Power

®

Wave

S350 then uses the WFS setting to adjust the

voltage and current according to settings contained in

the Power Wave.

In non-synergic modes, the WFS control behaves like

a conventional power source where WFS and voltage

are independent adjustments. Therefore, to maintain

proper arc characteristics, the operator must adjust

the voltage to compensate for any changes made to

the WFS.

Amps

In constant current modes, this control adjusts the

welding amperage.

Volts

In constant voltage modes, this control adjusts the

welding voltage.

Definition of Welding Modes

NON-SYNERGIC WELDING MODES

• A Non-synergic welding mode requires all welding

process variables to be set by the operator.

SYNERGIC WELDING MODES

• A Synergic welding mode offers the simplicity of single knob control. The machine will select the correct

voltage and amperage based on the Wire Feed

Speed (WFS) set by the operator.

POWER WAVE®S350

Trim

In pulse synergic welding modes, the Trim setting

adjusts the arc length. Trim is adjustable from 0.50 to

1.50. 1.00 is the nominal setting and is a good starting point for most conditions.

UltimArc™ Control

UltimArc™ Control allows the operator to vary the arc

characteristics. UltimArc™ Control is adjustable from

–10.0 to +10.0 with a nominal setting of 0.0.

Page 25

B-6

SMAW (STICK) WELDING

The welding current and Arc Force settings can be set

through a Power Feed 10M or Power Feed 25M wire

feeder. Alternatively an optional Stick / TIG UI (K2828-

1) can be installed into the power source to control

these settings locally.

In a SMAW (STICK mode), Arc Force can be adjusted. It can be set to the lower range for a soft and less

penetrating arc characteristic (negative numeric values) or to the higher range (positive numeric values)

for a crisp and more penetrating arc. Normally, when

welding with cellulosic types of electrodes (E6010,

E7010, E6011), a higher energy arc is required to

maintain arc stability. This is usually indicated when

the electrode sticks to the work-piece or when the arc

becomes unstable during manipulative technique. For

low hydrogen types of electrodes (E7018, E8018,

E9018, etc.) a softer arc is usually desirable and the

lower end of the Arc Control suits these types of electrodes. In either case the arc control is available to

increase or decrease the energy level delivered to the

arc.

OPERATION

B-6

The nominal preprogrammed voltage is the best average voltage for a given wire feed speed, but may be

adjusted to preference. When the wire feed speed

changes, the Power Wave

adjusts the voltage level correspondingly to maintain

similar arc characteristics throughout the WFS range.

Non Synergic CV

In non-synergic modes, the WFS control behaves

more like a conventional CV power source where

WFS and voltage are independent adjustments.

Therefore to maintain the arc characteristics, the operator must adjust the voltage to compensate for any

changes made to the WFS.

All CV Modes

Pinch adjusts the apparent inductance of the wave

shape. The “pinch” function is inversely proportional

to inductance. Therefore, increasing Pinch Control

greater than 0.0 results in a crisper arc (more spatter)

while decreasing the Pinch Control to less than 0.0

provides a softer arc (less spatter).

®

S350 automatically

GTAW (TIG) WELDING

The welding current can be set through a Power Feed

10M or Power Feed 25M wire feeder. Alternatively an

optional Stick / TIG UI (K2828-1) can be installed into

the power source to control these settings locally.

The TIG mode features continuous control from 5 to

350 amps with the use of an optional foot amptrol

(K870). The Power Wave

Touch Start TIG mode or Scratch start TIG mode.

CONSTANT VOLTAGE WELDING

Synergic CV

For each wire feed speed, a corresponding voltage is

preprogrammed into the machine through special software at the factory.

®

S350 can be run in either a

FIGURE B.3

PULSE WELDING

Pulse welding procedures are set by controlling an

overall “arc length” variable. When pulse welding, the

arc voltage is highly dependent upon the waveform.

The peak current, back ground current, rise time, fall

time and pulse frequency all affect the voltage. The

exact voltage for a given wire feed speed can only be

predicted when all the pulsing waveform parameters

are known. Using a preset voltage becomes impractical and instead the arc length is set by adjusting

“trim”.

Trim adjusts the arc length and ranges from 0.50 to

1.50 with a nominal value of 1.00. Trim values greater

than 1.00 increase the arc length, while vales less

than 1.00 decrease the arc length. (See figure B.3)

POWER WAVE®S350

Page 26

B-7

OPERATION

Most pulse welding programs are synergic. As the

wire feed speed is adjusted, the Power Wave

®

S350

will automatically recalculate the waveform parameters to maintain similar arc properties.

B-7

The Power Wave

®

S350 utilizes “adaptive control” to

compensate for changes in the electrical stick-out

while welding. (Electrical stick-out is the distance

from the contact tip to the work piece.) The Power

®

Wave

S350 waveforms are optimized for a 0.75”

stick-out. The adaptive behavior supports a range of

stick-outs from 0.50 to 1.25”. At very low or high wire

feed speeds, the adaptive range may be less due to

reaching physical limitations of the welding process.

UltimArc™ Control adjusts the focus or shape of the

arc. UltimArc™ Control is adjustable from -10.0 to

+10.0 with a nominal setting of 0.0. Increasing the

UltimArc™ Control increases the pulse frequency and

background current while decreasing the peak current. This results in a tight, stiff arc used for high

speed sheet metal welding. Decreasing the

UltimArc™ Control decreases the pulse frequency

and background current while increasing the peak current. This results in a soft arc good for out of position

welding. (See Figure B.4)

FIGURE B.4

POWER WAVE®S350

Page 27

C-1

ACCESSORIES

C-1

KITS, OPTIONS AND ACCESSORIES

All Kits Options and Accessories are found on the

Web site: (www.lincolnelectric.com)

FACTORY INSTALLED

None Available

FIELD INSTALLED OPTIONS

GENERAL OPTIONS

Stick / Tig User Interface Kit

Mounts inside the front panel of the Power Wave®

S350. Allows stick and Tig operation without having a

wire feeder.

Order K2828-1

115 VAC Auxiliary Power Kit

Mounts inside the back of the Power Wave® S350.

Adds 115 VAC / 60 Hz auxiliary power capability to

the Power Wave® S350 ( only compatible with the

K2823-1 power source)

Order K2829-1

DeviceNet Kit

Mounts inside the back of the Power Wave® S350.

Allows Devicenet objects to communicate with the

Power Wave® S350.

Order K2827-1

Work Voltage Sense Lead Kit

Required to accurately monitor voltage at the arc.

Order K940-25 for 25 ft. (7.6 m)

Order K1811-75 for 75 ft. (22.9 m)

Deluxe Adjustable Gas Regulator & Hose Kit

Accommodates CO

ders. Includes a cylinder pressure gauge, dual scale

flow gauge and 4.3 ft. (1.3 m) gas hose.

Order K586-1

Work and Wire Feeder 2/0 Weld Cable Package

Includes Twist-Mate™ connectors, work clamps, 15 ft.

(4.5 m) work cable and 10 ft. (3.0 m) electrode cable.

Rated 350 amps, 60% duty cycle.

Order K1803-1

, Argon, or Argon-blend gas cylin-

2

Twist-Mate™ Cable Receptacle

For connecting welding cable to Twist-Mate™ Cable

Plug.

Order K1759-70 for 1/0-2/0 (50-70 mm2) cable

Order K1759-95 for 2/0-3/0 (70-95mm2) cable

Twist-Mate™ to Lug Adapter

For connection of lugged cable to Twist-Mate™ connectors. 18" (457 mm) long.

Order K2176-1

Inverter and Wire Feeder Cart

Rear-wheeled cart includes front casters and no-lift

gas bottle plat¬form. Convenient handles allow for

easy cable storage while full length side trays store

parts and tools. Shipped fully assembled. Small footprint fits through 30" (762 mm) door.

Order K1764-1 Dual Cylinder Kit

Dual Cylinder Kit

Permits side-by-side mounting of two full size gas

cylinders, with easy loading. For use with K1764-1

cart.

Order K1702-1

Coaxial Welding Cable

Optimum weld cables for minimizing cable inductance