Page 1

IM3029

07/2009

Rev. 0

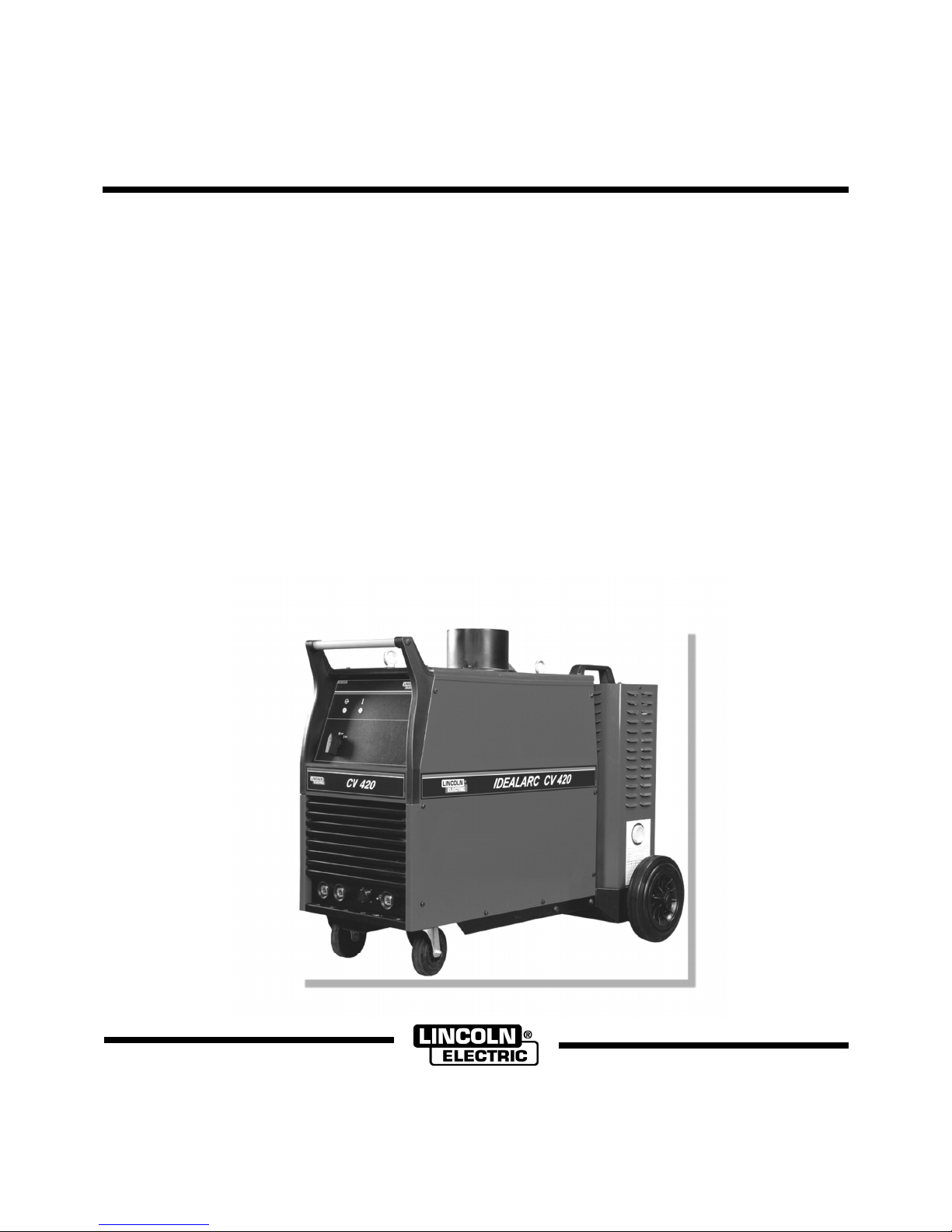

IDEALARC CV 420 & CV 505

OPERATOR’S MANUAL

MANUAL DE INSTRUÇÕES

LINCOLN ELECTRIC BESTER S.A.

ul. Jana III Sobieskiego 19A, 58-260 Bielawa, Poland

www.lincolnelectric.eu

Page 2

II

Declaration of conformity Declaração de conformidade

LINCOLN ELECTRIC BESTER S.A.

Declares that the welding machine: Declara que a maquina de soldar:

IDEALARC CV 420

conforms to the following directives: está em conformidade com as seguintes directivas:

2006/95/CEE, 2004/108/CEE

and has been designed in compliance with the following

standards:

e foi concebida de acordo com as seguintes normas:

EN 60974-1, EN 60974-10

(2009)

Paweł Lipiński

Operations Director

LINCOLN ELECTRIC BESTER S.A., ul. Jana III Sobieskiego 19A, 58-260 Bielawa, Poland

12/05

Page 3

III

Declaration of conformity Declaração de conformidade

LINCOLN ELECTRIC BESTER S.A.

Declares that the welding machine: Declara que a maquina de soldar:

IDEALARC CV 505

conforms to the following directives: está em conformidade com as seguintes directivas:

2006/95/CEE, 2004/108/CEE

and has been designed in compliance with the following

standards:

e foi concebida de acordo com as seguintes normas:

EN 60974-1, EN 60974-10

(2009)

Paweł Lipiński

Operations Director

LINCOLN ELECTRIC BESTER S.A., ul. Jana III Sobieskiego 19A, 58-260 Bielawa, Poland

12/05

Page 4

IV

07/06

English

Do not dispose of electrical equipment together with normal waste!

In observance of European Directive 2002/96/EC on Waste Electrical and Electronic Equipment (WEEE) and its

implementation in accordance with national law, electrical equipment that has reached the end of its life must be

collected separately and returned to an environmentally compatible recycling facility. As the owner of the equipment,

you should get information on approved collection systems from our local representative.

By applying this European Directive you will protect the environment and human health!

Português

Não deitar fora o equipamento eléctrico juntamente com o lixo normal!

Em conformidade com a directiva Europeia 2002/96/EC relativa a Resíduos Eléctricos e Equipamento Eléctricos (REEE)

e de acordo com a legislação nacional, os equipamentos deverão ser recolhidos separadamente e reciclados

respeitando o meio ambiente. Como proprietário do equipamento, deverá informar-se dos sistemas e lugares

apropriados para a recolha dos mesmos.

Ao aplicar esta Directiva Europeia protegerá o meio ambiente e a saúde humana!

12/05

THANKS! For having choosen the QUALITY of the Lincoln Electric products.

• Please Examine Package and Equipment for Damage. Claims for material damaged in shipment must be notified immediately to

the dealer.

• For future reference record in the table below your equipment identification information. Model Name, Code & Serial Number

can be found on the machine rating plate.

OBRIGADO! Por ter escolhido os produtos de QUALIDADE da Lincoln Electric.

• Por favor, examine a embalagem e o equipamento para que não tenham danos. A reclamação de danos do material no

transporte deverá ser notificada imediatamente ao revendedor.

• Para futura referência, registe abaixo a informação de identificação do equipamento. Modelo, Código e Número de Série podem

ser encontrados na chapa de características do equipamento.

Model Name, Modelo:

………………...…………………………….…………………………………………………………………………………………..

Code & Serial number, Código e Número de Série:

………………….……………………………………………….. …………………………………………………….……………..

Date & Where Purchased, Data e Local de Compra:

…………………………………………………………………... ……………………….…………………………………………..

ENGLISH INDEX

Safety ................................................................................................................................................................................................................ A-1

Installation and Operator Instructions................................................................................................................................................................ A-2

Electromagnetic Compatibility (EMC)................................................................................................................................................................ A-4

Technical Specifications.................................................................................................................................................................................... A-5

INDÍCE PORTUGUÊS

Segurança......................................................................................................................................................................................................... B-1

Instalação e Instruções de Funcionamento.......................................................................................................................................................B-2

Compatibilidade Electromagnética (EMC)......................................................................................................................................................... B-4

Especificações Técnicas...................................................................................................................................................................................B-5

Spare Parts, Lista de peças Sobressalentes.........................................................................................................................................................1

Electrical Schematic, Esquema Eléctrico ..............................................................................................................................................................4

Accessories, Accessórios......................................................................................................................................................................................5

Page 5

A

-1

Safety

11/04

WARNING

This equipment must be used by qualified personnel. Be sure that all installation, operation, maintenance and repair

procedures are performed only by qualified person. Read and understand this manual before operating this equipment.

Failure to follow the instructions in this manual could cause serious personal injury, loss of life, or damage to this

equipment. Read and understand the following explanations of the warning symbols. Lincoln Electric is not responsible

for damages caused by improper installation, improper care or abnormal operation.

WARNING: This symbol indicates that instructions must be followed to avoid serious personal injury,

loss of life, or damage to this equipment. Protect yourself and others from possible serious injury or

death.

READ AND UNDERSTAND INSTRUCTIONS: Read and understand this manual before operating

this equipment. Arc welding can be hazardous. Failure to follow the instructions in this manual could

cause serious personal injury, loss of life, or damage to this equipment.

ELECTRIC SHOCK CAN KILL: Welding equipment generates high voltages. Do not touch the

electrode, work clamp, or connected work pieces when this equipment is on. Insulate yourself from

the electrode, work clamp, and connected work pieces.

ELECTRICALLY POWERED EQUIPMENT: Turn off input power using the disconnect switch at the

fuse box before working on this equipment. Ground this equipment in accordance with local electrical

regulations.

ELECTRICALLY POWERED EQUIPMENT: Regularly inspect the input, electrode, and work clamp

cables. If any insulation damage exists replace the cable immediately. Do not place the electrode

holder directly on the welding table or any other surface in contact with the work clamp to avoid the

risk of accidental arc ignition.

ELECTRIC AND MAGNETIC FIELDS MAY BE DANGEROUS: Electric current flowing through any

conductor creates electric and magnetic fields (EMF). EMF fields may interfere with some

pacemakers, and welders having a pacemaker shall consult their physician before operating this

equipment.

CE COMPLIANCE: This equipment complies with the European Community Directives.

FUMES AND GASES CAN BE DANGEROUS: Welding may produce fumes and gases hazardous to

health. Avoid breathing these fumes and gases. To avoid these dangers the operator must use

enough ventilation or exhaust to keep fumes and gases away from the breathing zone.

ARC RAYS CAN BURN: Use a shield with the proper filter and cover plates to protect your eyes from

sparks and the rays of the arc when welding or observing. Use suitable clothing made from durable

flame-resistant material to protect you skin and that of your helpers. Protect other nearby personnel

with suitable, non-flammable screening and warn them not to watch the arc nor expose themselves to

the arc.

WELDING SPARKS CAN CAUSE FIRE OR EXPLOSION: Remove fire hazards from the welding

area and have a fire extinguisher readily available. Welding sparks and hot materials from the welding

process can easily go through small cracks and openings to adjacent areas. Do not weld on any

tanks, drums, containers, or material until the proper steps have been taken to insure that no

flammable or toxic vapors will be present. Never operate this equipment when flammable gases,

vapors or liquid combustibles are present.

WELDED MATERIALS CAN BURN: Welding generates a large amount of heat. Hot surfaces and

materials in work area can cause serious burns. Use gloves and pliers when touching or moving

materials in the work area.

SAFETY MARK: This equipment is suitable for supplying power for welding operations carried out in

an environment with increased hazard of electric shock.

Page 6

A

-2

CYLINDER MAY EXPLODE IF DAMAGED: Use only compressed gas cylinders containing the

correct shielding gas for the process used and properly operating regulators designed for the gas and

pressure used. Always keep cylinders in an upright position securely chained to a fixed support. Do

not move or transport gas cylinders with the protection cap removed. Do not allow the electrode,

electrode holder, work clamp or any other electrically live part to touch a gas cylinder. Gas cylinders

must be located away from areas where they may be subjected to physical damage or the welding

process including sparks and heat sources.

Installation and Operator Instructions

Read this entire section before installation or operation

of the machine.

Location and Environment

This machine will operate in harsh environments.

However, it is important that simple preventative

measures are followed to assure long life and reliable

operation:

• Do not place or operate this machine on a surface

with an incline greater than 15° from horizontal.

• Do not use this machine for pipe thawing.

• This machine must be located where there is free

circulation of clean air without restrictions for air

movement to and from the air vents. Do not cover

the machine with paper, cloth or rags when

switched on.

• Dirt and dust that can be drawn into the machine

should be kept to a minimum.

• This machine has a protection rating of IP23. Keep

it dry when possible and do not place it on wet

ground or in puddles.

• Locate the machine away from radio controlled

machinery. Normal operation may adversely affect

the operation of nearby radio controlled machinery,

which may result in injury or equipment damage.

Read the section on electromagnetic compatibility in

this manual.

• Do not operate in areas with an ambient

temperature greater than 40°C.

Duty cycle and Overheating

The duty cycle of a welding machine is the percentage of

time in a 10 minute cycle at which the welder can

operate the machine at rated welding current.

Example: 60% duty cycle:

Welding for 6 minutes. Break for 4 minutes.

Excessive extension of the duty cycle will cause the

thermal protection circuit to activate.

Minutes or decrease

duty cycle

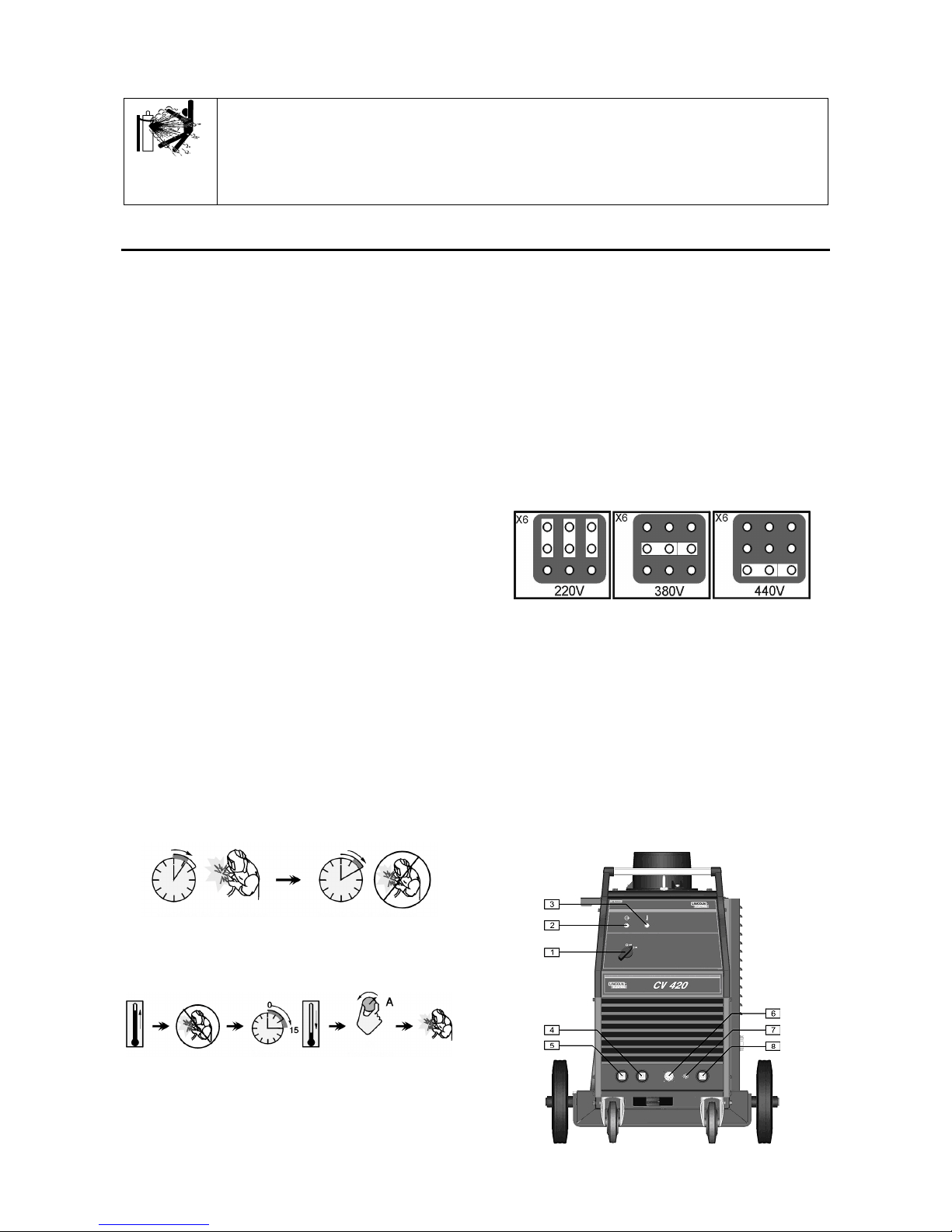

Input Supply Connection

Installation and mains outlet socket shall be made and

protected according to appropriate rules.

Check the input voltage, phase, and frequency supplied

to this machine before turning it on. Verify the

connection of grounding wires from the machine to the

input source. The allowable input are 3x220V and

3x380 V and 3x440V 50-60Hz (3x440V: factory default).

For more information about input supply refer to the

technical specification section of this manual and to the

rating plate of the machine.

If it is necessary to change the input voltage:

• The input cable must be disconnected from the

mains supply and the machine switched OFF.

• Remove the big side cover from the machine.

• Reconnect X6 according to the diagram below.

• Replace the big side cover.

Make sure that the amount of mains power available

from the input supply (connection) is adequate for

normal operation of the machine. The necessary

delayed fuse (or circuit breaker with "D" characteristic)

and cable sizes are indicated in the technical

specification section of this manual.

Refer to points [1] and [11] of the images below.

Output Connections

Refer to points [4], [5], [6] and [8] of the images below.

Controls and Operational Features

Page 7

A

-3

1. Power Switch ON/OFF (O/I): It controls the

machine power input. Be sure the power source is

connected to the mains supply before turning power

on ("I").

2. Power Indicator Light: It indicates that the power is

on.

3. Thermal Indicator Light: It indicates that the

machine is overloaded or that the cooling is not

sufficient.

4. Low Inductance Negative Output Socket: The low

inductance connection is typically used for short arc

welding of mild steel, particularly on thin materials or

when using CO

2

shielding gas.

5. High Inductance Negative Output Socket: The high

inductance connection is more suitable for short arc

welding in heavier work or when using 75% Argon /

25% CO2 shielding gas. The connection produces a

softer arc and a flatter bead with more wash-in than

the low inductance connection. Spray type transfer

is possible with either connection.

6. Wire Feeder Receptacle: 14-pins receptacle for

wire feeder. Provides connections for auxiliary

power of wire feeder.

7. Wire Feeder Voltmeter Switch: This switch selects

the polarity of the wire feeder voltmeter, if so

equipped. When the welding torch is positive (MIG,

Outershield and some Innershield processes), set

the switch to "+". When the welding torch is

negative (most Innershield applications), set the

switch to "-".

8. Positive Output Socket: Allows the connection, with

the power cable, to the wire feeder.

9. Covered Hole: For CO2 gas heater socket (see

accessories, K14009-1 CO2 Socket Kit).

10. Fuse: This fuse protects the wire feeder supply

circuit (see Spare Parts).

11. Power Input Cable: Connect the proper plug to the

input cable then into the rated output according to

appropriate rules. Only qualified personnel shall

connect this plug.

WARNING

Read and understand the cooler manual before

connecting it to the machine.

Welding Cables Connections

Insert the plug of the work cable into the socket [4] or [5].

The other end of this cable connects to the work piece

with the work clamp.

Connect the wire feeder LINC FEED 33 to the power

source:

• insert the positive welding cable into the output

socket [8].

• insert the wire feeder control cable into the

socket [6] (see Accessories, Source/wire feeder

cable K10347-PG-xM or K10347-PGW-xM).

Use the shortest possible cable lengths.

Machine and Circuit Protection

The CV420 / CV505 is protected against overheating,

overload and accidental short-circuits.

If the machine is overheated, the thermal protection

circuit will decrease the output current to 0. The thermal

protection indicator [3] will turn on. The thermal

protection circuit will turn on the output current again,

when the machine is cooled.

The CV420 / CV505 is also electronically protected

against overload and accidental short-circuit. The

overload and short-circuit protection circuit automatically

reduces the output current to a safe value when it

detects an overload.

Maintenance

WARNING

For any maintenance or repair operations it is

recommended to contact the nearest Technical Service

Center or Lincoln Electric. Maintenance or repairs

performed by unauthorized service centers or personnel

will null and void the manufacturer's warranty.

The frequency of the maintenance operations may vary

in accordance with the working environment where the

machine is placed.

Any noticeable damage should be reported immediately.

Routine maintenance (everyday)

• Check cables and connections integrity. Replace, if

necessary.

• Remove the spatters from the welding gun nozzle.

Spatters could interfere with the shielding gas flow

to the arc.

• Check the welding gun condition: replace it, if

necessary.

• Check condition and operation of the cooling fan.

Keep clean its airflow slots.

Periodic maintenance (every 200 working hours

but at list once every year)

Perform the routine maintenance and, in addition:

• Keep the machine clean. Using a dry (and low

Page 8

A

-4

pressure) airflow, remove the dust from the external

case and from the cabinet inside.

• Check and tighten all screws.

WARNING

Mains supply network must be disconnected from the

machine before each maintenance and service. After

each repair, perform proper tests to ensure safety.

Electromagnetic Compatibility (EMC)

11/04

This machine has been designed in accordance with all relevant directives and standards. However, it may still generate

electromagnetic disturbances that can affect other systems like telecommunications (telephone, radio, and television) or

other safety systems. These disturbances can cause safety problems in the affected systems. Read and understand

this section to eliminate or reduce the amount of electromagnetic disturbance generated by this machine.

This machine has been designed to operate in an industrial area. To operate in a domestic area it is

necessary to observe particular precautions to eliminate possible electromagnetic disturbances. The

operator must install and operate this equipment as described in this manual. If any electromagnetic

disturbances are detected the operator must put in place corrective actions to eliminate these disturbances

with, if necessary, assistance from Lincoln Electric.

Before installing the machine, the operator must check the work area for any devices that may malfunction because of

electromagnetic disturbances. Consider the following.

• Input and output cables, control cables, and telephone cables that are in or adjacent to the work area and the

machine.

• Radio and/or television transmitters and receivers. Computers or computer controlled equipment.

• Safety and control equipment for industrial processes. Equipment for calibration and measurement.

• Personal medical devices like pacemakers and hearing aids.

• Check the electromagnetic immunity for equipment operating in or near the work area. The operator must be sure

that all equipment in the area is compatible. This may require additional protection measures.

• The dimensions of the work area to consider will depend on the construction of the area and other activities that are

taking place.

Consider the following guidelines to reduce electromagnetic emissions from the machine.

• Connect the machine to the input supply according to this manual. If disturbances occur if may be necessary to take

additional precautions such as filtering the input supply.

• The output cables should be kept as short as possible and should be positioned together. If possible connect the

work piece to ground in order to reduce the electromagnetic emissions. The operator must check that connecting

the work piece to ground does not cause problems or unsafe operating conditions for personnel and equipment.

• Shielding of cables in the work area can reduce electromagnetic emissions. This may be necessary for special

applications.

WARNING

The Class A equipment is not intended for use in residential locations where the electrical power is provided by the public

low-voltage supply system. There may be potential difficulties in ensuring electromagnetic compatibility in those

locations, due to conducted as well as radiated disturbances.

WARNING

This equipment complies with IEC 61000-3-12 provided that the short-circuit power Ssc is greater than or equal to

7,76MVA for CV 420 and 9,95MVA for CV 505 at the interface point between the user’s supply and the public system. It

is the responsibility of the installer or user of the equipment to ensure, by consultation with the distribution network

operator if necessary, that the equipment is connected only to a supply with a short circuit power Ssc greater than or

equal to 7,76MVA (CV 420) and 9,95MVA (CV 505).

Page 9

A

-5

Technical Specifications

IDEALARC CV 420 & CV 505

INPUT

Input Power at Rated Output EMC Group / Class

420:

22kVA @ 60% Duty Cycle II / A

Input Voltage

220/380 / 440V ± 10%

Three Phase

505:

29kVA @ 60% Duty Cycle II / A

Frequency

50-60 Hz

RATED OUTPUT AT 40°C

Duty Cycle

(

Based on a 10 min. period)

Output Current Output Voltage

420:

60%

100%

420A

325A

35.0 Vdc

30.3 Vdc

505:

60%

100%

500A

385A

39.0 Vdc

33.3 Vdc

OUTPUT RANGE

Welding Current Range Maximum Open Circuit Voltage

420:

30A - 420A

420:

43 Vdc

505:

40A - 500A

505:

48 Vdc

RECOMMENDED INPUT CABLE AND FUSE SIZES

Fuse or Circuit Breaker Size Input Power Cable

420:

63A (for 220V) Superlag

32A (for 380V) Superlag

32A (for 440V) Superlag

420:

4 Conductor, 6mm

2

505:

63A (for 220V) Superlag

32A (for 380V) Superlag

32A (for 440V) Superlag

505:

4 Conductor, 10mm

2

PHYSICAL DIMENSIONS

Height Width Length Weight

420:

420 (water version):

870 mm

870 mm

565 mm

700 mm

1030 mm

1030 mm

139 kg

165 kg

505:

505 (water version):

870 mm

870 mm

565 mm

700 mm

1030 mm

1030 mm

147 kg

173 kg

Operating Temperature

-10°C to +40°C

Storage Temperature

-25°C to +55°C

Page 10

B-1

Segurança

11/04

AVISO

Este equipamento deve ser utilizado por pessoal qualificado. Verifique que toda a instalação, operação, manutenção e

procedimentos de reparação são realizados apenas por pessoal qualificado. Leia e compreenda este manual antes de

começar a usar este equipamento. Falha para com as seguintes instruções deste manual pode causar sérios danos

pessoais, perda de vida ou danos no equipamento. Leia e compreenda as seguintes explicações de símbolos de aviso.

A Lincoln Electric não é responsável por danos causados por instalação imprópria, manutenção imprópria ou utilização

anormal.

AVISO: Este Símbolo indica que as instruções devem ser seguidas de forma a evitar danos

pessoais. Proteja-se a si próprio e os outros de possíveis danos sérios ou morte.

LER E COMPREENDER INSTRUÇÕES: Leia e compreenda este manual antes de utilizar este

equipamento. Arco soldadura pode ser perigosa. O não seguimento das instruções contidas neste

manual pode causar sérios danos pessoais, perda de vidas ou danos a este equipamento.

CHOQUES ELÉTRICOS PODEM MATAR: Equipamento de soldadura gera alta tensão. Não toque o

eléctrodo, grampo trabalho, ou peças ligadas trabalho quando este equipamento está ligado. Isolarse do eléctrodo, grampo de trabalho, e peças de trabalho conectadas.

EQUIPAMENTOS ELÉCTRICOS: Desligue a entrada de alimentação utilizando o interruptor na caixa

de fusível antes de trabalhar com este equipamento. Ligue este equipamento eléctrico á terra em

conformidade com a regulamentação local.

EQUIPAMENTOS ELÉCTRICOS: Inspeccionar regularmente o input, eléctrodo, cabos de fixação e

de trabalho. Se existe algum dano de isolamento substituir o cabo de imediato. Não coloque o

eléctrodo titular directamente sobre a mesa soldadura ou qualquer outra superfície em contacto com

o grampo de trabalho para evitar o risco de ignição arco acidental.

CAMPOS ELÉCTRICOS E MAGNÉTICOS PODEM SER PERIGOSOS: A corrente eléctrica flui

através de qualquer condutor cria campos eléctricos e magnéticos (EMF). Campos EMF podem

interferir com alguns pacemakers, e soldadores com um pacemaker devem consultar seu médico

antes de utilizar este equipamento.

CONFORMIDADE CE: Este equipamento está em conformidade com as directivas da Comunidade

Europeia.

FUMOS E GASES PODEM SER PERIGOSOS: Soldadura pode produzir fumos e gases nocivos

para a saúde. Evite respirar estes fumos e gases. Para evitar estes perigos, o operador deve utilizar

ventilação ou exaustão suficiente para manter fumos e gases de distância da zona de respiração.

RAIOS ARC PODEM QUEIMAR: Use um escudo com o bom filtro e cobrir chapas para proteger os

seus olhos de faísca e os raios do arco quando soldadura ou observando. Use roupas adequadas

chama-duráveis feitos de material resistente para protegê-lo de que a sua pele e ajudantes. Proteger

o pessoal próximo adequadamente, não inflamável rastreio e avisá-los a não assistir ao arco, nem se

exporem ao arco.

FAÍSCA DE SOLDADURA PODE CAUSAR INCÊNDIO OU EXPLOSÃO: Eliminar os riscos de

incêndio na área de soldadura e ter um extintor de incêndio, prontamente disponíveis. A faísca da

solda e materiais quentes a partir do processo de para assegurar que não inflamáveis ou vapores

tóxicos irão estar presente. Nunca operar este soldagem pode facilmente passar por pequenas

rachaduras e aberturas de áreas adjacentes. Não soldar em qualquer cisternas, tambores,

contentores, ou qualquer material até serem adoptadas medidas adequadas equipamento quando

gases inflamáveis, vapores ou líquidos combustíveis estão presentes.

MATERIAIS SOLDADOS PODEM QUEIMAR: Solda gera uma grande quantidade de calor.

Superfícies quentes e materiais na área de trabalho pode causar queimaduras graves. Use luvas e

alicates quando tocar ou mover materiais na zona de trabalho.

Page 11

B-2

MARCA DE SEGURANÇA: Este equipamento é adequado para fornecer energia para operações de

soldadura realizadas em um ambiente com maior perigo de choque eléctrico.

GARRAFA PODE EXPLODIR SE DANIFICADA: Use apenas cilindros de gás comprimido que

contêm a correcta blindagem de gás para o processo de funcionamento devidamente utilizados e

reguladores concebidos para o gás e da pressão utilizada. Mantenha sempre as garrafas em uma

posição vertical segura encadeada para um apoio fixo. Não mova ou transporte garrafas de gás com

a protecção tampa removida. Não permitir o eléctrodo, eléctrodo titular, grampo trabalho ou de

qualquer outra parte electricamente vivo para tocar um cilindro de gás. As garrafas de gás devem

estar situadas fora das áreas onde eles possam ser submetidos aos danos físicos ou a soldagem

processo incluindo faísca e de fontes de calor.

Instalação e Instruções de Funcionamento

Leia toda esta secção antes da instalação ou utilização

da máquina.

Localização e Ambiente

Esta máquina vai trabalhar em ambientes agressivos.

No entanto, é importante que umas simples medidas

preventivas sejam seguidas para garantir uma vida

longa e um trabalho confiável.

• Não coloque ou opere esta máquina em uma

superfície com uma inclinação superior a 15° da

horizontal.

• Não utilizar esta máquina para derreter tubos.

• Este aparelho deve estar localizado onde existe

livre circulação de ar limpo, sem restrições de

circulação de ar a partir do ar e ventiladores. Não

cubra a máquina com papel, tecido ou trapos

quando ligado.

• A sujidade e o pó que pode entrar na máquina

devem ser reduzido ao mínimo.

• Esta máquina tem um rating de protecção IP23.

Mantenha-a seca, quando possível, e não colocá-la

em solo húmido ou em poças.

• Localize a máquina fora de controlos de rádio de

máquinas. O funcionamento normal pode afectar

negativamente o funcionamento dos controlos de

rádio da máquina vizinha, o que pode resultar em

prejuízo ou dano material. Leia a sessão sobre

compatibilidade electromagnética neste manual.

• Não operar em áreas com uma temperatura

ambiente superior a 40° C.

Duty Cycle e Sobreaquecimento

O duty cycle de uma máquina de soldadura é a

percentagem de tempo num ciclo de 10 minutos em que

o soldador pode operar a máquina à escala de corrente

de soldadura.

Exemplo: 60% duty cycle:

Soldar durante 6 minutos. Pausa durante 4 minutos.

Extensão excessiva do duty cycle vai causar a activação

do circuito de protecção térmica.

Minutos ou decrescente

duty cycle

Conexão da Alimentação de Entrada

Instalação e principal encaixe de saída devem ser feito e

protegido de acordo com as regras apropriadas.

Verifique a tensão de entrada, fase, e frequência de

alimentação desta máquina antes de a ligar. Verifique a

conexão dos fios terra da máquina á fonte de entrada.

As tensões de entrada permitidas são 3x220V e 3x380V

e 3x440V 50-60Hz (3x440V: padrão). Para mais

informação sobre a alimentação de entrada ver a

secção de especificações técnicas neste manual e a

placa de características da máquina.

Se for necessário mudar a fonte de alimentação de

tensão:

• Assegure-se que o cabo de entrada deve ser

desligado da fonte de alimentação e a máquina

deve ser desligada.

• Remova o grande painel lateral da máquina.

• Reconecte X6 de acordo com o diagrama abaixo.

• Coloque o grande painel lateral.

Assegure-se que a quantidade de potência disponível

da conexão de entrada é adequada para o

funcionamento normal da máquina. O fusível de atraso

necessário (ou disjuntor com característica “D”) e

tamanhos de cabos são indicados na secção de

especificação técnica deste manual.

Referência aos pontos [1] e [11] das imagens abaixo.

Conexões de Saída

Referência aos pontos [4], [5], [6] e [8] da imagem

abaixo.

Page 12

B-3

Controlos e Especificações de

Funcionamento

1. Interruptor de Potência ON/OFF (O/I): Controla a

potência de entrada da máquina. Certifique-se que

a fonte de alimentação está ligada á alimentação

principal antes de ligar a máquina ("I").

2. Luz Indicadora de Potência: Esta indica que a

alimentação está ligada.

3. Luz Térmica Indicadora: Esta indica que a máquina

está em sobreaquecimento ou que a refrigeração

não é suficiente.

4. Baixa Indução Negativa do Encaixe de Saída: A

conexão de baixa indutância é tipicamente usada

para um curto arco de soldadura de aço temperado,

particularmente em materiais finos ou quando se

usa protecção a gás CO

2

.

5. Alta Indução Negativa do Encaixe de Saída: A

conexão de alta indutância é mais apropriada para

um curto arco de soldadura em trabalho pesado ou

quando se usa um gás de protecção com 75%

Árgon / 25% CO

2

. A conexão produz um arco mais

macio e um colar adular com mais barrela que a

conexão de baixa indutância. A transferência tipo

spray é possível em ambas as conexões.

6. Receptáculo do Fio Alimentador: Receptáculo de

14-pinos para o fio alimentador. Fornece conexões

para potência auxiliar do fio alimentador.

7. Interruptor Voltímetro do Fio Alimentador: Este

interruptor selecciona a polaridade do voltímetro do

fio alimentador, se equipado. Quando a tocha de

soldadura é positiva (MIG, processos Outershield e

alguns Innershield), fixar o interruptor para o "+".

Quando a tocha de soldadura é negativa (a maioria

das aplicações Innershield), fixar o interruptor para

o "-".

8. Encaixe Positivo de Saída: Permite a conexão,

com o cabo de potência, ao fio alimentador.

9. Tampa de Cobertura: Para encaixe do radiador de

gás CO2 (ver acessórios, kit de encaixe CO

2

K14009-1).

10. Fusível: Este fusível protege o circuito de

alimentação do fio (ver Lista de Peças).

11. Cabo de Alimentação de Entrada: Ligue a ficha

adequada ao cabo de entrada, dentro da escala de

saída de acordo com as regras apropriadas.

Apenas pessoas qualificadas devem conectar esta

ficha.

AVISO

Ler e perceber o manual do refrigerador antes de o

conectar á máquina.

Conexão dos Cabos de Soldadura

Insira a ficha do cabo de trabalho no encaixe [4] ou [5].

A outra ponta deste cabo liga á peça de trabalho com o

grampo de trabalho.

Ligue o alimentador de fio LINC FEED 33 á fonte de

alimentação:

• Insira o cabo positivo de soldadura no encaixe

de saída [8].

• Insira o cabo de controlo do alimentador de fio

no encaixe [6] (ver Acessórios, Fonte/cabo

alimentador de fio K10347-PG-xM ou K10347PGW-xM).

Use o mínimo comprimento possível de cabo.

Máquina e Circuito de Protecção

O CV420 / CV505 é protegido contra o

sobreaquecimento, sobrecarga e curto-circuitos

acidentais.

Se a máquina está em sobreaquecimento, o circuito de

protecção térmica vai diminuir a corrente de saída para

0. O indicador de protecção térmica [3] vai acender-se.

O circuito de protecção térmica vai voltar a ligar a

corrente de saída, quando a máquina estiver arrefecida.

O CV420 / CV505 é também protegido electronicamente

Page 13

B-4

contra sobrecargas e curto-circuitos acidentais. A

protecção de sobrecarga e curto-circuito

automaticamente reduz a corrente de saída para um

valor seguro quando uma sobrecarga é detectada.

Manutenção

AVISO

Para qualquer tipo de manutenção ou reparação é

recomendado que contacte o centro de serviço técnico

mais próximo ou a Lincoln Electric. A manutenção e as

reparações realizadas por centros de serviço ou pessoal

não autorizado, anulará e terminará a garantia do

fabricante.

A frequência da operação de manutenção pode variar

de acordo com o ambiente de trabalho onde a máquina

está localizada.

Qualquer dano notável deve ser reportado

imediatamente.

Manutenção de Rotina (todos os dias)

• Verifique os cabos e as integridades das conexões.

Substitua, se necessário.

• Remova os salpicos do nariz da pistola. Os

salpicos podem interferir com a protecção do fluxo

de gás para o arco.

• Verifique a condição da pistola de soldadura:

substitua-a, se necessário.

• Verifique a condição e operação da ventoinha de

refrigeração. Mantenha limpa as fendas de fluxo de

ar.

Manutenção Periódica (a cada 200 horas de

trabalho mas raramente não mais do que uma

vez por ano)

Realize a manutenção de rotina e, em adicionalmente:

• Mantenha a máquina limpa. Usando um

compressor (e baixa pressão), remova a sujidade

da caixa externa e da cabine interior.

• Verifique e aperte todos os parafusos.

AVISO

A fonte de alimentação deve ser desligada da máquina

antes de cada manutenção e serviços. Após cada

reparação, realizar testes para garantir a segurança

adequada.

Compatibilidade Electromagnética (EMC)

11/08

Esta máquina foi concebida de acordo com todas as directivas e normas. No entanto, ela ainda pode gerar

perturbações electromagnéticas que podem afectar outros sistemas como o de telecomunicações (telefone, rádio e

televisão) ou outros sistemas de segurança. Estas perturbações podem causar problemas de segurança no sistema

afectado. Ler e compreender esta secção para eliminar ou reduzir a quantidade de perturbação electromagnética

gerada por esta máquina.

Esta máquina foi concebida para funcionar em uma área industrial. Para operar em uma área doméstica,

é necessário observar precauções especiais para eliminar possíveis perturbações electromagnéticas. O

operador deve instalar e operar este equipamento como descrito neste manual. Se forem detectadas

quaisquer perturbações electromagnéticas o operador deve pôr em prática acções correctivas para

eliminar a estes distúrbios, se necessário, com a assistência de Lincoln Electric.

Antes de instalar a máquina, o operador deve verificar a área de trabalho para qualquer dispositivo que pode mau

funcionamento devido a perturbações electromagnéticas. Considere o seguinte.

• Entrada e saída cabos, controle cabos, e que estão em cabos telefónicos ou adjacente à zona de trabalho e da

máquina.

• Rádio e / ou transmissores e receptores de televisão. Computadores ou equipamento informático controlada.

• Segurança e equipamentos de controlo de processos industriais. Equipamento para calibração e de medição.

• Dispositivos médicos pessoais tais como estimuladores cardíacos e de auxiliares de audição.

• Verifique a imunidade electromagnética dos equipamentos operando em ou perto da zona de trabalho. O operador

deve estar certo de que todos os equipamentos na área são compatíveis. Isto poderá exigir medidas

suplementares de protecção.

• As dimensões da área de trabalho para que considerar dependerão da construção do espaço e de outras

actividades que estão a ter lugar.

Considere as seguintes orientações para reduzir as emissões electromagnéticas a partir da máquina.

• Ligue a máquina para o fornecimento de entrada de acordo com este manual. Se ocorrerem perturbações pode ser

necessário tomar precauções adicionais, tais como filtragem da alimentação de entrada.

• A saída cabos devem ser mantidos tão curtas quanto possível e devem ser posicionado em conjunto. Se possível

conectar a peça de trabalho ao solo, a fim de reduzir as emissões electromagnéticas. O operador deve verificar

que ligar a peça de trabalho ao solo não causa problemas ou torna inseguras as condições de funcionamento para

pessoal e equipamento.

• Blindagem de cabos na zona de trabalho pode reduzir as emissões electromagnéticas. Isto pode ser necessário

para aplicações especiais.

Page 14

B-5

AVISO

Os equipamentos de Classe A não são destinados para uso em localizações residenciais onde a potência eléctrica é

fornecida pelo sistema público de fonte de baixa tensão. Podem haver potenciais dificuldades em assegurar a

compatibilidade electromagnética naqueles locais, devido á condução tal como distúrbios radioactivos.

AVISO

Este equipamento está em conformidade com IEC 61000-3-12 desde que a potência de curto-circuito Ssc é maior ou

igual a 7,76MVA para 420 CV e 9,95MVA para 505 CV no ponto de interface entre a fonte do utilizador e o sistema

público. Isto é responsável pela instalação ou uso dos equipamentos para assegurar, por consulta com o operador da

rede de distribuição se necessário, que o equipamento está conectado apenas a uma fonte com uma potência de curtocircuito Ssc maior ou igual a 7,76MVA (420 CV) e 9,95MVA (505 CV).

Especificações Técnicas

IDEALARC CV 420 & CV 505

ENTRADA

Potência de Entrada à Escala de Saída Grupo EMC / Classe

420:

22 kVA @ 60% Duty Cycle II / A

Tensão de Entrada

220 /380/ 440V ± 10%

Três Fases

505:

29 kVA @ 60% Duty Cycle II / A

Frequência

50-60 Hz

ESCALA DE SAÍDA A 40°C

Duty Cycle

(Baseado num período de 10 min.)

Corrente de Saída Tensão de Saída

420:

60%

100%

420A

325A

35.0 Vdc

30.3 Vdc

505:

60%

100%

500A

385A

39.0 Vdc

33.3 Vdc

ESCALA DE SAÍDA

Escala da Corrente de Soldadura Tensão Máxima em Circuito Aberto

420:

30A - 420A

420:

43 Vdc

505:

40A - 500A

505:

48 Vdc

CABOS DE ENTRADA E TAMANHOS DOS FUSÍVEIS RECOMENDADOS

Tamanho do Fusível ou Disjuntor Cabo de Potência de Entrada

420:

63A (for 220V) Superlag

32A (for 380V) Superlag

32A (for 440V) Superlag

420:

4 Condutor, 6mm

2

505:

63A (for 220V) Superlag

32A (for 380V) Superlag

32A (for 440V) Superlag

505:

4 Condutor, 10mm

2

DIMENSÕES FÍSICAS

Altura Largura Comprimento Peso

420:

420 (versão a água):

870 mm

870 mm

565 mm

700 mm

1030 mm

1030 mm

139 kg

165 kg

505:

505 (versão a água):

870 mm

870 mm

565 mm

700 mm

1030 mm

1030 mm

147 kg

173 kg

Temperatura de Funcionamento

-10°C a +40°C

Temperatura de Armazenamento

-25°C a +55°C

Page 15

1

Spare Parts, Lista de peças Sobressalentes

12/05

Part List reading instructions

• Do not use this part list for a machine if its code number is not listed. Contact the Lincoln Electric Service Department for any code

number not listed.

• Use the illustration of assembly page and the table below to determine where the part is located for your particular code machine.

• Use only the the parts marked "X" in the column under the heading number called for in the assembly page (# indicate a change in this

printing).

Leitura de instruções de lista de peças sobressalentes

• Não utilizar esta lista para participar de uma máquina se o seu número de código não estiver na lista. Contacte o Departamento Lincoln

Electric Serviço para qualquer número de códigos não listados.

• Use a ilustração de página e de montagem da tabela abaixo para determinar a parte onde está localizado o seu código de máquina.

• Utilize apenas as peças marcando o "X" na coluna sob o número da posição na chamada para a montagem página (# indicam uma

mudança nesta impressão).

SP50166/50167 Rev. 0

07/03

IDEALARC CV 420 & CV 505

ASSEMBLY

PAGE NAME

Machine

Assembly

Machine

Assembly

(Rear side)

CODE

NO.:

K NO.: FIGURE NO.: A B

50166 K14028-3A CV 420 AIR 220/380/440V 3Ph 1 1

50167 K14029-3A CV 505 AIR 220/380/440V 3Ph 2 2

Figure A

Page 16

2

Figure A: Machine Assembly

Item Description Part Number QTY 1 2 3 4 5 6

1 MAIN TRANSFORMER T1 R-4034-097-1R 1 X

y

2 MAIN TRANSFORMER T1 R-4034-098-1R 1

y

X

3 RECTIFIER SET V1 R-0010-272-1AR 1 X

y

4 RECTIFIER SET V1 R-0010-273-1AR 1

y

X

5 CHOKE L1 R-4034-002-2R 1 X

y

6 CHOKE L1 R-4034-077-1R 1

y

X

7 FAN M1 R-8040-055-1R 1 X X

8 CAPACITORS C1,C2,C3 1158-125-374R 3 X X

9 SHUNT R2 0941-712-026R 1 X X

10 RESISTOR R1 1158-112-360R 1 X X

11 CONDUCTOR-RAIL R-1010-014-1R 1 X X

12 CONDUCTOR-RAIL R-1010-015-1R 1 X X

13 DIVIDER PANEL R-3019-160-1/08R 1

y

X

14 MAIN SWITCH S1 1115-260-009R 1 X

y

15 CONDUCTOR-RAIL R-1010-018-1R 1

y

X

16 CONDUCTOR-RAIL R-1010-019-1R 1 X

y

17 CONDUCTOR-RAIL R-1010-020-1R 1 X X

18 DIVIDER PANEL R-3019-159-1/08R 1 X X

19 DIVIDER PANEL R-3019-161-1/08R 1 X

y

20 TURNING WHEEL 1029-660-127R 2 X X

21 WHEEL 1029-660-250R 2 X X

22 MAIN SWITCH S1 1115-260-118R 1

y

X

23 SOCKET X2, X3, X4 C-2986-001-3R 3 X X

24 SOCKET X10 1158-641-130R 1 X X

25 VOLTMETER POLARITY SWITCH S9 1158-650-023R 1 X X

26 FRONT DECAL 2719-107-254R 1 X X

27 FRONT PANEL R-3019-028-1/08R 1 X X

28 COVER R-8040-035-2R 1 X X

29 LABEL 2719-107-992R 1 X

y

30 LABEL 2719-107-993R 1

y

X

31 SIGNAL LAMP H1 0917-421-041R 1 X X

32 SIGNAL LAMP H2 0917-421-024R 1 X X

33 LEFT HOLDER 1362-212-002R 1 X X

34 LEFT BRACKET (HANDLE) D-3631-908-1/08R 1 X X

35 RIGHT HOLDER 1362-212-003R 1 X X

36 RIGHT BRACKET (HANDLE) D-3631-908-2/08R 1 X X

37

LEFT SIDE HANDLE ASSEMBLY

+ CAP

1362-212-006R

1362-212-004R

1+1 X X

38

RIGHT SIDE HANDLE ASSEMBLY

+ CAP

1362-212-007R

1362-212-004R

1+1 X X

39 EDGE SHIELD 1362-212-010R 1 X X

40 HANDLE 0562-230-005R 1 X X

41 CARRIAGE SUPPORT 1361-598-181R 1 X X

42 CAPACITORS C5,C6,C7 1158-128-043R 3 X X

43 CAPACITOR C4 1158-121-001R 1 X X

44 CONTROL PCB R-8040-208-1R 1 X X

45 GROUND CABLE WITH WORK CLAMP -3m K14033-1 1 X X

46 POWER RESISSTOR R3 1158-112-008R 1 X X

47 DIVIDER PANEL R-8040-021-2/08R 1 X X

48 SHELF R-8040-066-1/08R 1 X X

49 TERMINAL BLOCK 1361-599-255R 2 X X

50 LABEL (U,V,W) R-0010-291-1AR 1 X X

51 WALL RING R-3019-030-1/08R 1 X X

52 SUPPORT R-8040-034-1/08R 1 X X

53 BOTTOM R-8040-080-2/08R 1 X X

54 TOP PANEL R-8040-020-1/02R 1 X X

55 LABEL (WARNING) 2719-107-728R 1 X X

56 TRAY R-8040-032-1/08R 1 X X

57 LEFT SIDE PANEL (not show) R-8040-019-1/02R 1 X X

58 LABEL (LEFT SIDE PANEL) (not show) 2719-107-995R 1 X

y

59 LABEL (LEFT SIDE PANEL) (not show) 2719-107-997R 1

y

X

60 RIGHT SIDE PANEL (not show) R-8040-019-2/02R 1 X X

61 RIGHT (LEFT SIDE PANEL) (not show) 2719-107-994R 1 X

y

62 RIGHT (RIGHT SIDE PANEL) (not show) 2719-107-996R 1

y

X

Page 17

3

Figure B

Figure B: Machine Assembly (Rear side)

Item Description Part Number QTY 1 2

REAR PANEL R-8040-031-1/08R 1 X

y

1

REAR PANEL R-3040-129-1/08R 1

y

X

MAINS CORD without PLUG -5m (4x6mm2) R-5041-026-1R 1 X

y

2

MAINS CORD without PLUG -5m (4x10mm

2

) R-5041-121-1R 1

y

X

CABLE BOX 1361-599-665R 1 X

y

3

CABLE BOX 1361-599-250R 1

y

X

CAMP 1361-599-633R 1 X

y

4

CAMP 1361-599-620R 1

y

X

5 FUSE F1 (6,3A, 400V) 1158-660-008R 1 X X

6 FUSE SOCKET 1158-632-032R 1 X X

7 FUSE CAP 1158-632-033R 1 X X

8 HOLE PLUG 1361-599-058R 1 X X

9 CHAIN SUPPORT C-2631-407-1/08R 1 X X

10 PANEL D-3721-403-2/08R 1 X X

11 SHELF R-3019-042-1/08R 1 X X

18 WIRING HARNESS (SECONDARY VOLTAGE) R-7040-034-1R 1 X X

19 WIRING HARNESS (MAIN VOLTAGE) R-7040-036-4R 1 X X

Page 18

4

Electrical Schematic, Esquema Eléctrico

Page 19

5

Accessories, Accessórios

K10347-PG-xM Source/wire feeder cable (gas). Available in 5, 10 or 15m.

Fonte/cabo alimentador de fio (gás). Disponível em 5, 10 ou 15m.

K10347-PGW-xM Source/wire feeder cable (gas and water). Available in 5, 10 or 15m.

Fonte/cabo alimentador de fio (gás e água). Disponível em 5, 10 ou 15m.

K14009-1 CO2 Socket Kit.

Kit de encaixe CO2.

Loading...

Loading...