Page 1

IM2059

04/2014

REV01

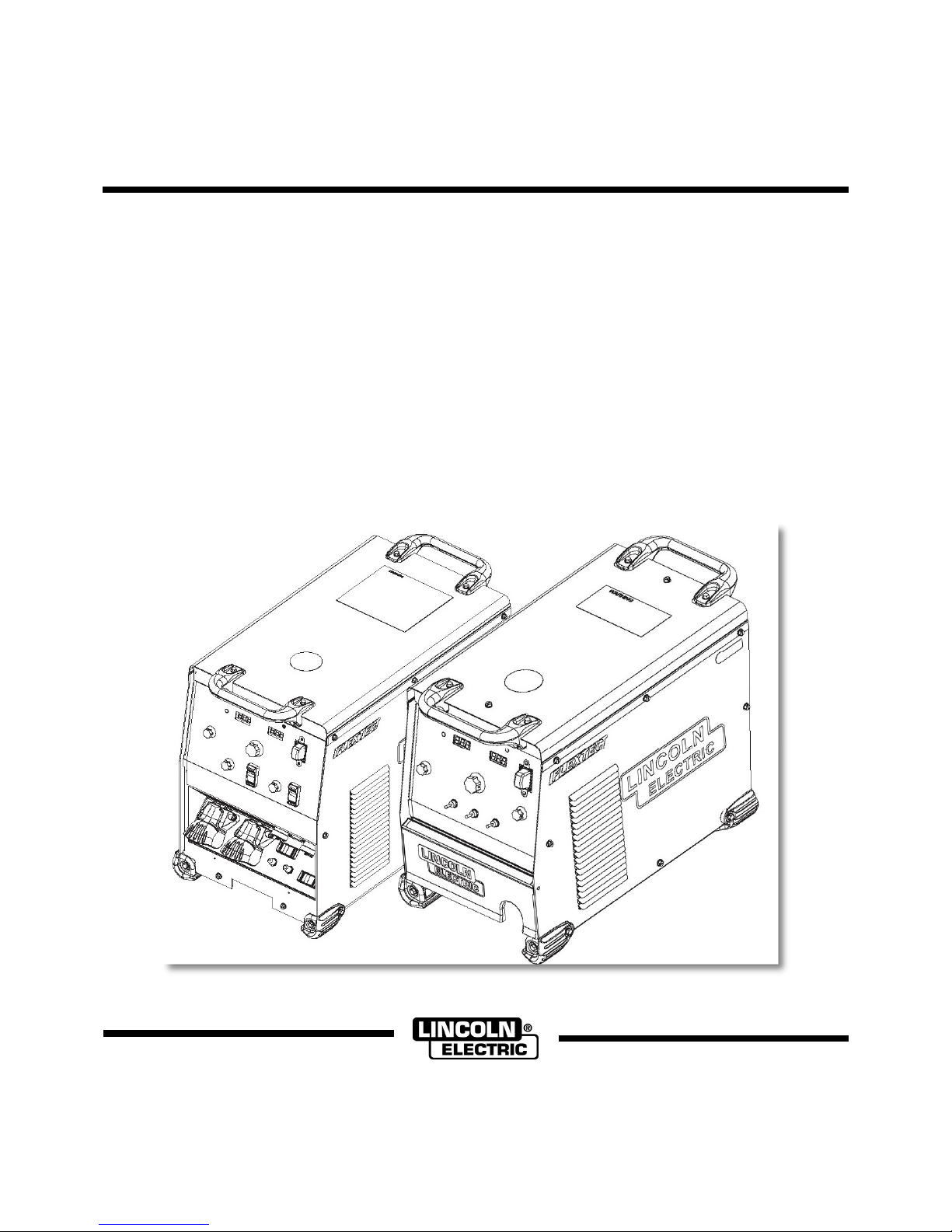

FLEXTEC™ 450&650 CE

OPERATOR’S MANUAL

ENGLISH

THE LINCOLN ELECTRIC COMPANY

22801 St. Clair Ave., Cleveland Ohio 44117-1199 USA

www.lincolnelectric.eu

Page 2

English English

I

THE LINCOLN ELECTRIC COMPANY

EC DECLARATION OF CONFORMITY FOR

FLEXTEC™450 CE

Manufacturer and technical documentation

holder:

The Lincoln Electric Company

Address:

22801 St. Clair Ave.

Cleveland Ohio 44117-1199 USA

EC Company:

Lincoln Electric Europe S.L.

Address:

c/o Balmes, 89 - 8

0 2a

08008 Barcelona

SPAIN

Hereby declare that welding equipment:

Flextec™ 450 CE, including options and accessories

Product numbers:

K3065

(Product numbers may also contain prefixes and suffixes)

Is in conformity with Council Directives

and amendments:

Electromagnetic Compatibility (EMC) Directive

2004/108/EC

Low Voltage Directive (LVD) 2006/95/EC

Standards: EN 60974-10 Arc Welding Equipment – Part 10:

Electromagnetic compatibility (EMC) requirements, 2003

EN 60974-1, Arc Welding Equipment – Part 1: Welding

Power Sources, 2005

CE marking affixed in ’11

Frank Stupczy, Manufacturer Dario Gatti, European Community Representative

Compliance Engineering Manager European Engineering Director Machines

03 March 2013 04 March 2013

MCD361a

Page 3

English English

II

THE LINCOLN ELECTRIC COMPANY

EC DECLARATION OF CONFORMITY FOR

FLEXTEC™650 CE

Manufacturer and technical documentation

holder:

The Lincoln Electric Company

Address:

22801 St. Clair Ave.

Cleveland Ohio 44117-1199 USA

EC Company:

Lincoln Electric Europe S.L.

Address:

c/o Balmes, 89 - 8

0 2a

08008 Barcelona

SPAIN

Hereby declare that welding equipment:

Flextec™ 650 with CE marking and installed CE filter.

Product numbers:

K3060 and K3129

(Product numbers may also contain prefixes and suffixes)

Is in conformity with Council Directives

and amendments:

Electromagnetic Compatibility (EMC) Directive

2004/108/EC

Low Voltage Directive (LVD) 2006/95/EC

Standards: EN 60974-10 Arc Welding Equipment – Part 10:

Electromagnetic compatibility (EMC) requirements, 2007

EN 60974-1, Arc Welding Equipment – Part 1: Welding

Power Sources, 2005

CE marking affixed in ’13

Frank Stupczy, Manufacturer Dario Gatti, European Community Representative

Compliance Engineering Manager European Engineering Director Machines

25 September 2013 1 October 2013

MCD390

Page 4

English English

III

12/05

THANKS! For having chosen the QUALITY of the Lincoln Electric products.

Please Examine Package and Equipment for Damage. Claims for material damaged in shipment must be notified

immediately to the dealer.

For future reference record in the table below your equipment identification information. Model Name, Code &

Serial Number can be found on the machine rating plate.

Model Name:

………………...…………………………….…………………………………………………………………………………………..

Code & Serial number:

………………….……………………………………………….. …………………………………………………….……………..

Date & Where Purchased:

…………………………………………………………………... ……………………….…………………………………………..

ENGLISH INDEX

Technical Specifications .................................................................................................................................................. 1

Electromagnetic Compatibility (EMC) .............................................................................................................................. 3

Safety .............................................................................................................................................................................. 4

Installation and Operator Instructions .............................................................................................................................. 5

WEEE ............................................................................................................................................................................ 16

Spare Parts .................................................................................................................................................................... 16

Electrical Schematic ...................................................................................................................................................... 16

Suggested Accessories ................................................................................................................................................. 16

Page 5

English English

1

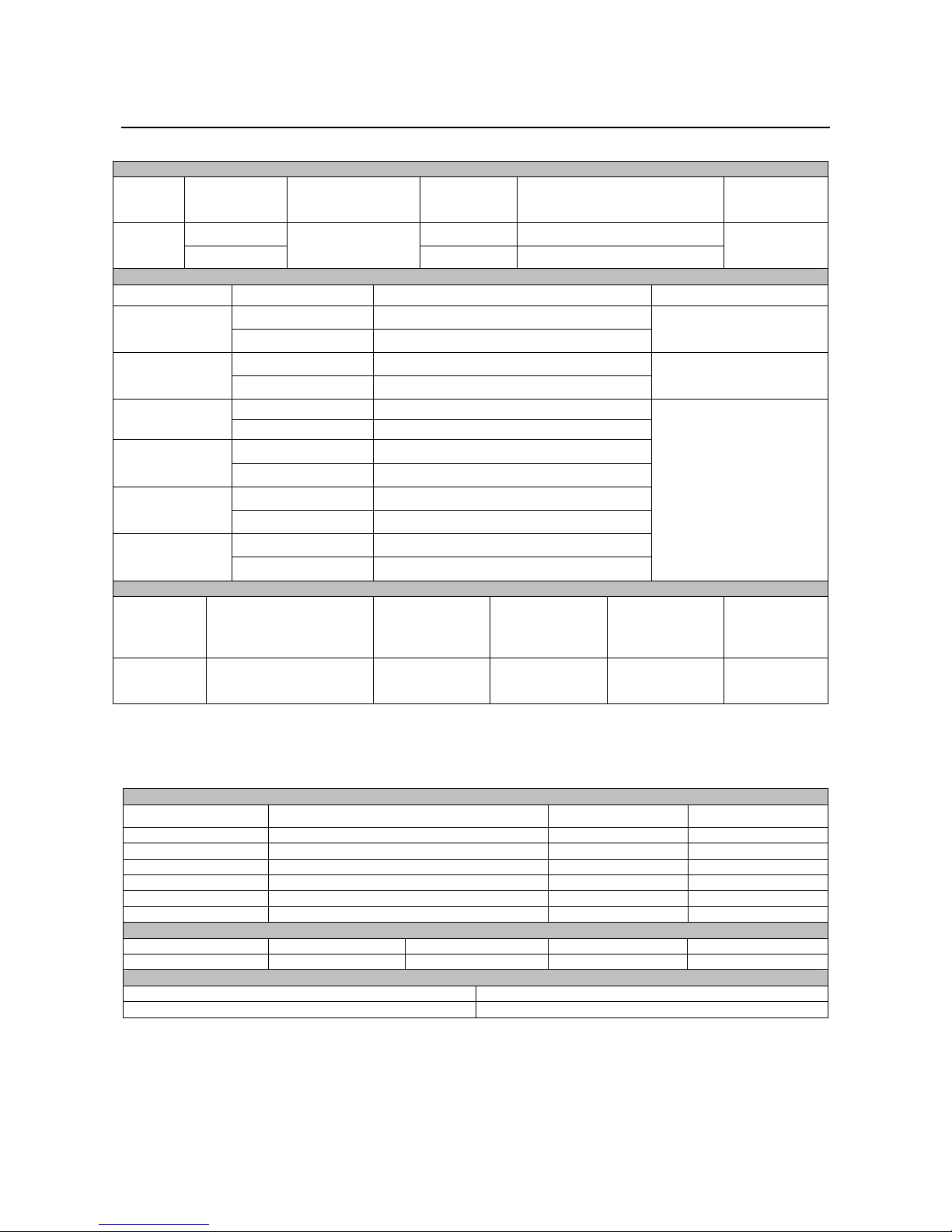

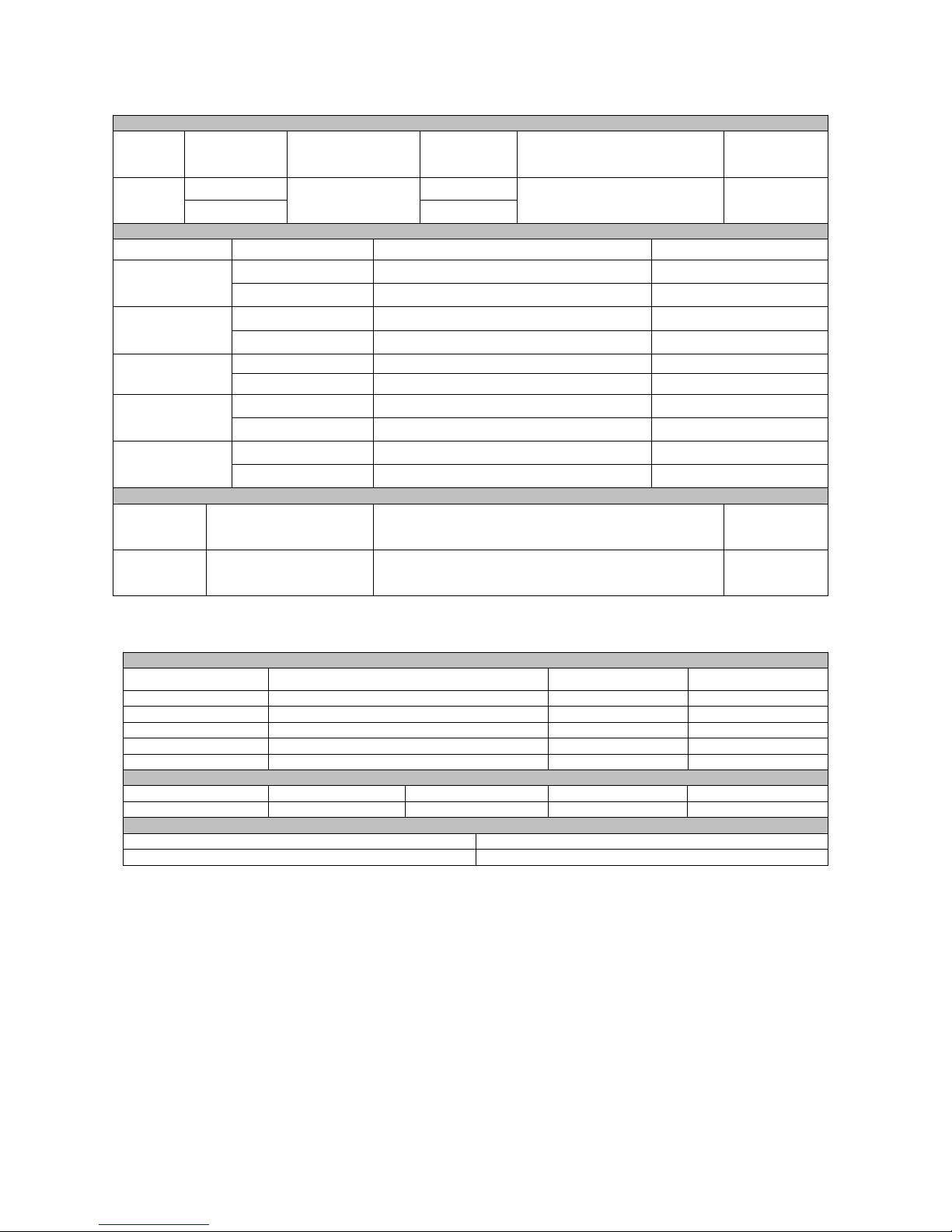

Technical Specifications

FLEXTEC™ 650

POWER SOURCE –INPUT VOLTAGE AND CURRENT

Model Duty Cycle Input Voltage ±10%

Input

Amperes

Idle Power (W)

Power

Factor@ Rated

Input

K3060-2

60% rating

380/460/575/3/50/60

61/50/40 230 MAX (Fan On)

88%

100% rating 57/47/38 100 MAX. (Fan Off)

RATED OUTPUT

Process Duty Cycle Amperes Volts at Rated Amperes

GMAW (CV)

60% 750 *

44V

100% 650 *

GTAW (CC)

60% 750

34V

100% 650

SMAW (CC)

60% 750 *

44V

100% 650 *

FCAW-GS (CV)

60% 750 *

100% 650 *

FCAW-SS (CV)

60% 750 *

100% 650 *

SAW (CV)

60% 750 *

100% 650 *

RECOMMENDED INPUT WIRE AND FUSES SIZES

(1)

VOLTAGE

50/60Hz

Maximum Input Amperes

Cord Size

(3)

AWG SIZES

(mm)

Type 75°C

Copper Wire in

Conduit AWG

(mm

2

)

COPPER

GROUNDING

CONDUCTOR

AWG (mm2)

Fuse (Super

Lag)or Breaker

Sizes

(2)

380/3/50

460/3/60

575/3/60

70A

58A

46A

4 (25)

4 (25)

6 (16)

4 (25)

6 (16)

8 (10)

8 (10)

8 (10)

10 (6)

90

80

60

* Output is limited to 600A/100% and 700A/60% when used with K3091-1 Multi-Process Swith.

(1)

Cord and Fuse Sizes based upon the U.S. National Electric Code and maximum output for 40°C (104°) ambient.

(2)

Also called “inverse time” or “thermal/magnetic” circuit breakers; circuit breakers that have a delay in tripping action that decreases as

the magnitude of current increases.

(3)

Type SJ cord or similar in 30°C ambient

WELDING PROCESS

Process Output Range (A) OCV (U0) OCV (Ur)

GMAW (CV) 40-815 60 --

GTAW (CC) 10-815 24 15

SMAW (CC) 15-815 60 15

FCAW-GS (CV) 40-815 60 -FCAW-SS (CV) 40-815 60 --

SAW (CV) 40-815 60 --

PHYSICAL DIMENSIONS

Model Height Width Depth Weight

K3060-2 554 mm 410mm 754mm 74.8kg*

TEMPERATURE RANGES

Operating Temperature Range Storage Temperature Range

Environmentally Hardened: 14°F to 131°F (-10°C to 55°C**)

Environmentally

Hardened: -40°F to 185°F (-40°C to 85°C)

IP23 180º(H) Insulation Class

*Weight does not include input cord.

**Power Source is derated at Temperatures above 40°C.

Page 6

English English

2

FLEXTEC™ 450

POWER SOURCE –INPUT VOLTAGE AND CURRENT

Model Duty Cycle Input Voltage ±10%

Input

Amperes

Idle Power

Power

Factor@ Rated

Input

K3065-1

60% rating

380/400/415/3/50/60

Hz

37/35/34

72 W Max. (fan on) 95%

100% rating 29/28/27

RATED OUTPUT

Process Duty Cycle Volts at rated Amperes Amperes

GMAW (CV)

60% 36.5V 450

100% 34V 400

GTAW (CC)

60% 28V 450

100% 26V 400

MMAW (CC)

60% 38V 450

100% 36V 400

FCAW-GS (CV)

60% 36.5V 450

100% 34V 400

FCAW-SS (CV)

60% 36.5V 450

100% 34V 400

RECOMMENDED INPUT WIRE AND FUSES SIZES

(1)

VOLTAGE

50/60Hz

Maximum Input Amperes

4 CONDUCTOR

SOOW or similar Cord in 40°C (104°F) Ambient

Fuse (Super

Lag)or Breaker

Sizes

(2)

380/3/50

400/3/60

415/3/60

42A

40A

39A

8 AWG or 10 mm

2

50

(1)

Cord and Fuse Sizes based upon the U.S. National Electric Code and maximum output for 40°C (104°) ambient.

(2)

Also called “inverse time” or “thermal/magnetic” circuit breakers; circuit breakers that have a delay in tripping action that decreases as

the magnitude of current increases.

WELDING PROCESS

Process Output Range (A) OCV (U0) OCV (Ur)

GMAW (CV) 40-500 60 --

GTAW (CC) 10-500 24 15

MMAW (CC) 15-500 35 15

FCAW-GS (CV) 40-500 60 -FCAW-SS (CV) 40-500 60 --

PHYSICAL DIMENSIONS

Model Height Width Depth Weight

K3065-1 478 mm 359mm 677mm 59kg*

TEMPERATURE RANGES

Operating Temperature Range Storage Temperature Range

Environmentally Hardened: 14°F to 131°F (-10°C to 55°C**)

Environmentally

Hardened: -40°F to 185°F (-40°C to 85°C)

IP23 155º(F) Insulation Class

*Weight does not include input cord.

**Power Source is derated at Temperatures above 40°C.

Page 7

English English

3

Electromagnetic Compatibility (EMC)

11/04

This machine has been designed in accordance with all relevant directives and standards. However, it may still generate

electromagnetic disturbances that can affect other systems like telecommunications (telephone, radio, and television) or

other safety systems. These disturbances can cause safety problems in the affected systems. Read and understand

this section to eliminate or reduce the amount of electromagnetic disturbance generated by this machine.

This machine has been designed to operate in an industrial area. The operator must install and operate

this equipment as described in this manual. If any electromagnetic disturbances are detected the operator

must put in place corrective actions to eliminate these disturbances with, if necessary, assistance from

Lincoln Electric. The Class A equipment is not intended for use in residential locations where the electrical

power is provided by the public low-voltage supply system. There may be potential difficulties in ensuring

electromagnetic compatibility in those locations, due to conducted as well as radiated disturbances. This equipment

does not comply with IEC 61000-3-12. If it is connected to a public low-voltage system, it is responsibility of the installer

or user of the equipment to ensure, by consultation with the distribution network operator if necessary, that the

equipment may be connected.

Before installing the machine, the operator must check the work area for any devices that may malfunction because of

electromagnetic disturbances. Consider the following.

Input and output cables, control cables, and telephone cables that are in or adjacent to the work area and the

machine.

Radio and/or television transmitters and receivers. Computers or computer controlled equipment.

Safety and control equipment for industrial processes. Equipment for calibration and measurement.

Personal medical devices like pacemakers and hearing aids.

Check the electromagnetic immunity for equipment operating in or near the work area. The operator must be sure

that all equipment in the area is compatible. This may require additional protection measures.

The dimensions of the work area to consider will depend on the construction of the area and other activities that are

taking place.

Consider the following guidelines to reduce electromagnetic emissions from the machine.

Connect the machine to the input supply according to this manual. If disturbances occur if may be necessary to take

additional precautions such as filtering the input supply.

The output cables should be kept as short as possible and should be positioned together. If possible connect the

work piece to ground in order to reduce the electromagnetic emissions. The operator must check that connecting

the work piece to ground does not cause problems or unsafe operating conditions for personnel and equipment.

Shielding of cables in the work area can reduce electromagnetic emissions. This may be necessary for special

applications.

Only for Flextec™ 650: CE input filter kit K3129-1 must be installed. Instructions how to install the CE filter kit are

provided with the kit.

Page 8

English English

4

Safety

11/04

WARNING

This equipment must be used by qualified personnel. Be sure that all installation, operation, maintenance and repair

procedures are performed only by qualified person. Read and understand this manual before operating this equipment.

Failure to follow the instructions in this manual could cause serious personal injury, loss of life, or damage to this

equipment. Read and understand the following explanations of the warning symbols. Lincoln Electric is not responsible

for damages caused by improper installation, improper care or abnormal operation.

WARNING: This symbol indicates that instructions must be followed to avoid serious personal injury,

loss of life, or damage to this equipment. Protect yourself and others from possible serious injury or

death.

READ AND UNDERSTAND INSTRUCTIONS: Read and understand this manual before operating

this equipment. Arc welding can be hazardous. Failure to follow the instructions in this manual could

cause serious personal injury, loss of life, or damage to this equipment.

ELECTRIC SHOCK CAN KILL: Welding equipment generates high voltages. Do not touch the

electrode, work clamp, or connected work pieces when this equipment is on. Insulate yourself from

the electrode, work clamp, and connected work pieces.

ELECTRICALLY POWERED EQUIPMENT: Turn off input power using the disconnect switch at the

fuse box before working on this equipment. Ground this equipment in accordance with local electrical

regulations.

ELECTRICALLY POWERED EQUIPMENT: Regularly inspect the input, electrode, and work clamp

cables. If any insulation damage exists replace the cable immediately. Do not place the electrode

holder directly on the welding table or any other surface in contact with the work clamp to avoid the

risk of accidental arc ignition.

ELECTRIC AND MAGNETIC FIELDS MAY BE DANGEROUS: Electric current flowing through any

conductor creates electric and magnetic fields (EMF). EMF fields may interfere with some

pacemakers, and welders having a pacemaker shall consult their physician before operating this

equipment.

CE COMPLIANCE: This equipment complies with the European Community Directives.

FUMES AND GASES CAN BE DANGEROUS: Welding may produce fumes and gases hazardous to

health. Avoid breathing these fumes and gases. To avoid these dangers the operator must use

enough ventilation or exhaust to keep fumes and gases away from the breathing zone.

ARC RAYS CAN BURN: Use a shield with the proper filter and cover plates to protect your eyes from

sparks and the rays of the arc when welding or observing. Use suitable clothing made from durable

flame-resistant material to protect you skin and that of your helpers. Protect other nearby personnel

with suitable, non-flammable screening and warn them not to watch the arc nor expose themselves to

the arc.

WELDING SPARKS CAN CAUSE FIRE OR EXPLOSION: Remove fire hazards from the welding

area and have a fire extinguisher readily available. Welding sparks and hot materials from the welding

process can easily go through small cracks and openings to adjacent areas. Do not weld on any

tanks, drums, containers, or material until the proper steps have been taken to insure that no

flammable or toxic vapors will be present. Never operate this equipment when flammable gases,

vapors or liquid combustibles are present.

WELDED MATERIALS CAN BURN: Welding generates a large amount of heat. Hot surfaces and

materials in work area can cause serious burns. Use gloves and pliers when touching or moving

materials in the work area.

SAFETY MARK: This equipment is suitable for supplying power for welding operations carried out in

an environment with increased hazard of electric shock.

Page 9

English English

5

CYLINDER MAY EXPLODE IF DAMAGED: Use only compressed gas cylinders containing the

correct shielding gas for the process used and properly operating regulators designed for the gas and

pressure used. Always keep cylinders in an upright position securely chained to a fixed support. Do

not move or transport gas cylinders with the protection cap removed. Do not allow the electrode,

electrode holder, work clamp or any other electrically live part to touch a gas cylinder. Gas cylinders

must be located away from areas where they may be subjected to physical damage or the welding

process including sparks and heat sources.

NOISE APPEARES DURING WELDING CAN BE HARMFUL: Welding arc can cause noise with high

level of 85dB for 8-hour week day. Welders operating welding machines are obligated to wear the

proper ear protectors /appendix No. 2 for the Decree of the Secretary of Labor and Social Policy from

17.06 1998 – Dz.U. No. 79 pos. 513/. According to the Decree the Secretary of Health and Social

Welfare from 09.07.1996 /Dz.U. No. 68 pos. 194/, employers are obligated to carry examinations and

measurements of health harmful factors.

MOVING PARTS ARE DANGEROUS: There are moving mechanical parts in this machine, which

can cause serious injury. Keep your hands, body and clothing away from those parts during machine

starting, operating and servicing.

EQUIPMENT WEIGHT OVER 30kg: Move this equipment with care and with the help of another

person. Lifting may be dangerous for your physical health.

The manufacturer reserves the right to make changes and/or improvements in design without upgrade at the same time

the operator’s manual.

Installation and Operator Instructions

Read this entire section before installation or operation

of the machine.

Select Suitable Location

Location and Ventilation for Cooling

Place the welder where clean cooling air can freely

circulate in through the rear louvers and out through the

case sides. Dirt, dust, or any foreign material that can be

drawn into the welder should be kept at a minimum.

Failure to observe these precautions can result in

excessive operating temperatures and nuisance

shutdowns.

Lifting

The FLEXTEC™ 650 has 2 lifting eyelets and 2 handles

that can be used to lift the machine. Both handles or

both eyelets should be used when lifting the FLEXTEC™

650.

Both handles should be used when lifting the FLEXTEC™ 450 CE

When using a crane or overhead device to lift using the

handles, a lifting strap should be connected to both

handles. Do not attempt to lift the FLEXTEC™ 650&450

with accessories attached to it

Stacking

The FLEXTEC™ 650&450 cannot be stacked.

Environmental Limatations

The FLEXTEC™ 650&450 are IP23 rated for use in an

outdoor environment. The FLEXTEC™ 650&450 should

not be subjected to falling water during use nor should

any parts of it be submerged in water. Doing so may

cause improper operation as well as pose a safety

hazard. The best practice is to keep the machine in a

dry, sheltered area.

WARNING

Do not mount the FLEXTEC™ 650&450 over

combustible surfaces. Where there is a combustible

surface directly under stationary or fixed electrical

equipment, that surface shall be covered with a steel

plate at least 1.6mm thick, which shall extend not less

than 150mm beyond the equipment on all sides.

Input and Grounding Connections

Machine Grounding

The frame of the welder must be grounded. A

ground terminal marked with the symbol

shown is located inside the reconnect/input

connection area for this purpose. See your

local and national electrical codes for proper grounding

methods.

Duty Cycle

The FLEXTEC™ is capable of welding at a 100% duty

cycle (continuous welding) at 650 (for Flextec 650) amps

rated output, and at 450 (for Flextec 450) amps rated

output. The 60% duty cycle rating is 750 amps (for

Flextec 650) and 38volts (for Flextec 450) (based off of a

ten minute cycle – 6 minutes on time and 4 minutes off

time). The maximum output of the Flextec 650 is 815

amps, and for Flextec 450 is 500 amps.

Page 10

English English

6

Example: 40% Duty Cycle:

Welding for 4 minutes. Break for 6 minutes.

Minutes or decrease

Duty Cycle

The FLEXTEC™ 650&450 are also rated for Desert

Duty, elevated temperature operation, in a 55°C

ambient. The machine is de-rated for this application.

(See Table below).

High Temperature Operation

FLEXTEC™ 650

WELDER OUTPUT RATINGS AT 55°C ELEVATED

TEMPERATURES

AMPS DUTY CYCLE VOLTS TEMPERATURES

600 100%

44V 55°C

650 50%

750 30%

FLEXTEC™ 450

WELDER OUTPUT RATINGS AT 55°C ELEVATED

TEMPERATURES

AMPS DUTY CYCLE VOLTS TEMPERATURES

340 100% 34VDC

55°C

375 60% 35VDC

400 40% 36VDC

450 20% 38VDC

High Frequency Protection

Locate the FLEXTEC™ 650&450 away from radio

controlled machinery. The normal operation of the

FLEXTEC™ 650&450 may adversely affect the

operation of RF controlled equipment, which may result

in bodily injury or damage to the equipment.

WARNING

ELECTRIC SHOCK can kill. Only a qualified eletrician

should connect the input leads to the Flextec™

650&450. Connections should be made in accordance

with local and national electrical codes and the

connection diagram located on the inside of the

reconnect/input access door of the machine. Failure to

do so may result in bodily injury or death.

Input Connection

Use a three-phase supply line.

For Flextec™ 650 (see figure #1): a 45 mm diameter

access hole for the input supply is located on the case

back. Remove the reconnect access panel located on

the case back and connect W, V, U and ground

according to the Input Supply Connection Diagram

decal.

For Flextec™ 450 (see figure #2): a 36 mm diameter

access hole for the input supply is located on the case

back. Connect L1, L2, L3 and ground according to the

Input Supply Connection Diagram decal located on the

internal horizontal panel. To access the reconnect/input

supply connection blocks, remove the 8 screws that

secure the case top of the welder and remove the case

top.

For CE markets (only for Flextec™ 650): CE input

filter kit (K3129-1) must be installed. Instructions how to

install the CE filter kit are provided with the kit.

Input Voltage Selection (Only for

Flextec™650)

Welders are shipped connected for 460 Volt input

voltage. To move this connection to a different input

voltage, see Figure #1 which is illustrated above. Refer

to Auxiliary Reconnect Input Ranges table in the

Technical Specification Section.

Page 11

English English

7

Figure #1: Flextec™650

A: POWER SUPPLY ACCESS HOLE:

Route input power cable through this hole.

Strain relief required. See your local and National Electrical codes for proper strain relief.

B: RECONNECT TERMINAL BLOCK:

Reconnects auxiliary transformer for the proper input voltage.

C: POWER SUPPLY TERMINAL BLOCK:

Line Cord/Cable attaches here.

A ground terminal marked with the symbol shown is provided separate from this block for connecting the ground

lead of the line cord. (see your local and national electrical codes for proper grounding methods).

D: REMOVE FOUR SCREWS AND ACCESS PANEL.

Figure #2: Flextec™ 450

Welding Cable Connections

Connect the electrode and work cables between the

appropriate output studs of the FLEXTEC™ 650&450

per the following guidelines:

Most welding applications run with the electrode

being positive (+). For those applications, connect

the electrode cable between the wire drive feed

plate and the positive (+) output stud on the power

source. Connect a work lead from the negative (-)

power source output stud to the work piece.

When negative electrode polarity is required, such

as in some Innershield applications, reverse the

output connections at the power source (electrode

cable to the negative (-) stud, and work cable to the

positive (+) stud).

POWER SUPPLY ACCESS HOLE

Route input power cable through this hole

RECONNECT PROCEDURE

POWER SUPPLY TERMINAL BLOCK

Line Cord/Cable attaches here

A ground terminal marked withe the

symbol shown is provided separate

from this block for connecting the

ground lead of the line cord. (see your

local and national electrical code for

proper grounding methods).

Page 12

English English

8

Control Cable Connections

General guidelines

Genuine Lincoln control cables should be used at all

times (except where noted otherwise). Generally, it is

recommended that the total length not exceed 100 feet

(30.5 m). The use of non-standard cables, especially in

lengths greater than 25 feet, can lead to communication

problems (system shutdowns), poor motor acceleration

(poor arc starting), and low wire driving force (wire

feeding problems). Always use the shortest length of

control cable possible, and DO NOT coil excess cable.

Regarding cable placement, best results will be obtained

when control cables are routed separate from the weld

cables. This minimizes the possibility of interference

between the high currents flowing through the weld

cables, and the low level signals in the control cables.

Paralleling (only for Flextec™ 650)

FLEXTEC™ 650 power sources may be paralleled for

increased output requirements. No kit is required for

paralleling of FLEXTEC™ 650 power sources. The

FLEXTEC™ 650 can only be paralleled for constant

current processes (mode switch must be in the SMAW

position). Connect the power sources as shown, and set

the output control of each power source to one half of

the desired arc current. (See Figure #3)

Figure #3: Paralleling Diagram

INPUT

TERMINAL

BLOCK

INPUT

TERMINAL

BLOCK

(MACHINE #1)

(MACHINE #2)

NEGATIVE

POSITIVE

NEGATIVE

AT WORK PIECE

POSITIVE

AT WORK PIECE

NEGATIVE POSITIVE

INPUT LINES

INPUT LINES

TO GROUND PER

NATIONAL ELECTRICAL

CODE

TO GROUND PER

NATIONAL ELECTRICAL

CODE

Page 13

English English

9

VRD™ (VOLTAGE REDUCTION

DEVICE)

The VRD™ feature provides additional safety in the CCStick mode. The VRD™ reduces the OCV (Open Circuit

Voltage) at the welding output terminals while not

welding to less than 35VDC.

The machine is shipped with VRD™ “enabled”. The

VRD™ function can be disabled or enabled via a dip

switch on the control P.C. board.

Location of Control

P.C. Board

Dip Switch Location on Control

P.C. Board

VRD Mode Setting

-Switch #5 in the “ON” Position

ON

OFF

Page 14

English English

10

Product Description

The FLEXTEC™ 650 is a multi-process CC/CV DC

inverter and is rated for 650 amps, 44 volts at a 100%

duty cycle. The FLEXTEC™ 450 is a multi-process

CC/CV DC inverter and is rated for 450 amps, 38 volts at

a 60% duty cycle. The FLEXTEC™ 650&450 are

intended for both factory and field operation. It comes in

a compact, rugged case that is designed for portability

and outdoor use with an IP23 environmental rating. The

FLEXTEC™ 650 operates on 3 phase 380V, 460V, or

575V 50hz or 60hz power. The FLEXTEC™ 450 CE

operates on 380V, 400V, or 415V 50hz or 60hz power.

The FLEXTEC™ 650&450 are designed for CC-SMAW,

CC-GTAW (lift tig), CV-GMAW, CV-FCAW-SS, CVFCAW-GS and CV-SAW (only for Flextec™ 650)

welding processes. CAG (arc gouging) is also supported

Design Features

Severe Duty Design for outdoor use (IP23 rating)

Passive Power Factor Correction – reliably gives

88% (for Flextec™ 650) and 95% (for Flextec™

450) power factor for lower installation costs.

91% (for Flextec™ 650) and 89% (for Flextec™

450) Efficiency rating – reduces electrical utility

costs.

F.A.N. (fan as needed). Cooling fan runs when the

output is energized and for a 5 minute cool down

period after output is disabled.

Thermal protection by thermostats with Thermal

Indicator LED.

Error Codes display on LED screen for ease of

trouble shooting.

Electronic over current protection.

Input voltage misconnection protection.

Utilizes digital signal processing and microprocessor

control.

VRD™ Voltage Reduction Device - Enable this

function for reduced OCV in CC modes for added

safety.

Capabilities

The following capabilities are supported: Wire Feeders:

LF33, LN10, DH10, LN25-Pro, LT-7Tractor and NA

series (only for Flextec™ 650).

Case Front Control Desciptions for

Flextec™ 650

(see Figure #4)

1. Power Switch: Controls input power to the Flextec

650.

2. Voltage Display Meter

3. Amperage Display Meter

4. Thermal LED: A yellow light that comes on when

an over temperature situation occurs. Output is

disabled until the machine cools down. When coll,

the light goes out and output is enabled.

5. Weld Process Selector Switch: A rotary switch

that toggles through the five available weld modes

for the Flextec 650 – CC-SMAW, CC-GTAW, CV,

CV-Innershield, CV-SAW.

6. Hot Start Control Dial.

7. Output Control Dial: sets the output current or

voltage for the selected weld process.

8. Local/Remote Selector Toggle Switch: Sets the

control of the outoput to local (output control knob)

or remote (K857 hand amptrol or K870 foot

amptrol).

9. Arc Force Control Dial.

10. Weld Terminals On/Remote selector switch.

11. 14 pin wire feeder circular connector.

12. 115V or 42V wire feeder selector switch.

13. Circuit breaker reset buttons for the 14 pin wire

feeder connector.

14. 6-pin remote circular connector.

15. Positive and negative welding output studs.

16. Wire Feeder Voltmeter Polarity Selection Switch.

17. VRD™ (Voltage Reduction Device) Indicator

lights.

Figure #4: Flextec™650

Page 15

English English

11

Case Front Control Desciptions for

Flextec™ 450

(see Figure #5)

1. Power Switch

2. Voltage Display Meter

3. Amperage Display Meter

4. Thermal LED

5. Output Control Dial

6. Weld Process Selector Switch

7. Hot Start Toggle Switch

8. Output Control Local/Remote Toggle Switch

9. Arc Control Dia

10. Weld Terminals On/Remote toggle selector switch

11. Wire feeder voltmeter polarity selection toggle

switch

12. Circuit breaker reset button for the 14-pin wire

feeder connector

13. 14-pin wire feeder circular connector

14. 6-pin remote circular connector

15. Positive and negative welding output studs

16. VRD™ (Voltage Reduction Device) Indicator lights

Figure #5:Flextec™450

Case Back Control Desciptions for

Flextec™ 650

(see Figure #6)

1. Input Power Cord Access Hole

2. Access Panel – Allows access dor connecting input

power and configuring the machine.

3. Input Power Reconnect – Configures the machine

for the input supply voltage.

4. OPTION – GFCI protection for the 115V auxiliary

output.

5. 115 volt, 15 amp auxiliary output duplex with

protective environmental cover.

6. 15 Amp Circuit Breaker for the 115V auxiliary

power.

Figure #6: Flextec™ 650

Case Back Control Desciptions for

Flextec 450

(see Figure #7)

1. Input Power Cord Access Hole

Figure #7: Flextec™ 450

Page 16

English English

12

Common Welding Procedures

The FLEXTEC™ 450&650 are a multi-process inverter

welder. The Weld Process Selector Switch is used to

set the desired weld mode. The FLEXTEC™ 650 has 5

selectable welding modes, The FLEXTEC™ 450 has 4

selectable welding modes:

1. SMAW – This is a CC (constant current) weld mode

used for the SMAW stick welding process.

2. GTAW – This is a CC (constant current) weld mode

used for the GTAW TIG welding process.

3. CV – This is CV (constant voltage) weld mode used

for welding the GMAW MIG welding process and

the FCAW-GS flux cored gas shielded welding

process.

4. CV-Innershield – This is a CV (constant voltage)

weld mode used for welding the FCAW-SS, flux

cored self shielded welding process.

5. CV-SAW (only for Flextec™ 650). – This is a CV

(constant voltage) weld mode used for welding the

SAW submerged arc welding process

The FLEXTEC™ 450&650 are also capable of gouging.

Gouging can be done in MMA mode for Felxtec™450

and for Flexec™650 in either the SMAW mode or the CV

and CV-Innershield modes.

In addition to the weld process selector switch, a hot

start control dial, output control dial and arc control dial

are provided to setup and fine tune the welding

procedure.

Weld Controls and Displays

Weld Process Selector Switch

For Flextec™ 650: 5 Position switch used to select the

welding process.

For flextec™ 450: 4 Position switch used to select the

welding process.

Hot Start Control Dial (only for Flextec™650)

• The Hot Start control regulates the starting current

at arc initiation. Hot Start can be set to “0” and no

additional current is added at arc start. Increasing

from 0 to 10 will increase the additional current

(relative to the preset current) that is added at arc

initiation.

Hot Start Toggle Switch (only for Flextec™450)

• The Hot Start control regulates the starting current

at arc initiation. Hot Start can be set to “Off” and no

additional current is added at arc start. When set to

the “On” position, additional current (relative to the

preset current) is added at arc initiation.

Arc Control Dial

• Full range selection of arc control from -10 to +10.

In CV mode, this control is an inductance control. In

stick mode, the control adjusts the arc force.

Output Control Dial

• Output control is conducted via a single turn

potentiometer.

• Adjustment is indicated by the meters.

• When in REMOTE modes, this control sets the

maximum welding current. Full depression of a foot

or hand amptrol results in the preset level of current.

Voltage Display Meter

• Prior to CV operation (current flow), the meter

displays desired preset voltage value (+/- .5V only

for Flextec™650).

• Prior to STICK or TIG operation, the meter displays

the Open Circuit Voltage of the Power Source or

three dashes if the output has not been turned on.

• During welding, this meter displays actual average

volts.

• After welding, the meter holds the actual voltage

value for 5 seconds. The displays blink indicating

that the machine is in the "Hold" period.

• Output adjustment while in the "Hold" period results

in the "prior to operation" characteristics.

Amperage Display Meter

• Prior to STICK or TIG operation (current flow), the

meter displays preset current value (only for

Flextec™650 either 2 amps or +/- 3% (e.g. 3 amps

on 100), whichever is greater).

• Prior to CV operation, the meter displays three

dashes indicating non-presettable AMPS.

• During welding, this meter displays actual average

amps.

• After welding, the meter holds the actual current

value for 5 seconds. The displays blink indicating

that the machine is in the "Hold" period.

• Output adjustment while in the "Hold" period results

in the "prior to operation" characteristics.

Weld Terminals On/Remote Toggle Switch

• This switch determines the trigger location.

• When set to the “ON” position, the weld terminals

are at OCV (open circuit voltage) and ready to weld.

• When set to the “REMOTE” position, output is

enabled through a remote trigger.

Control - Local/Remote Toggle Switch

• Set the switch to “LOCAL” to control output at the

Flextec via the Output Control dial.

• Set the switch to “REMOTE” to control output via a

remote device (K857 hand amptrol or K870 foot

amptrol) connected to the 6-pin remote connector or

a wire feeder connected to the 14-pin connector.

Wire Feeder Selector Switch (only for Flextec™650)

• This switch configures wire feeder supply voltage in

the 14 pin connector to either 42 volt or 115 volt.

• If the switch is in the incorrect position for the

attached wire feeder, there will be no power

supplied to the wire feeder.

Wire Feeder Voltmeter Polarity Switch

• The switch provides a work connection for wire

feeder voltmeters. Place the switch in the position of

the electrode polarity indicated by the decal. The

switch does not change the welding polarity.

Thermal Light

• This status light indicates when the power source

has been driven into thermal overload. If the output

terminals were "ON", the output will be turned back

on once the unit cools down to an acceptable

temperature level. If the unit was operating in the

"REMOTE" mode, the trigger will need to be opened

before or after the thermal has cleared and closed

after the machine has cooled down to an acceptable

temperature to establish output.

Page 17

English English

13

Basic Modes of Operation

SMAW

This weld mode is a constant current (CC) mode

featuring continuous control from 15 – 815 amps (for

Flextec™650) and from 15 – 500 amps (for

Felxtec™450). It is intended for the SMAW stick welding

processes and arc gouging.

Output Control Local/Remote – When the control is

set to “LOCAL” (no remote potentiometer/control

plugged into the 6 pin or 14 pin connectors), the output

is controlled through the Output Control Dial on the front

of the FLEXTEC™450&650. Set this switch to

“REMOTE” when an external potentiometer/control is

connected.

• When a remote potentiometer is connected, the

output control on the FLEXTEC™450&650 and the

remote act as a master/slave configuration. Use the

control dial on the FLEXTEC™450&650 to set the

maximum welding current. The remote will control

output from minimum to the pre-set maximum.

Hot Start - The Hot Start control regulates the starting

current at arc initiation. Hot Start can be set to “0” (for

Flextec™650) and “Off” (for Felxtec™ 450) and no

additional current is added at arc start. For Flextec™

650: increasing from 0 to 10 will increase the additional

current (relative to the preset current) that is added at

arc initiation.

For Flextec™ 450 When set to the “On”

position, additional current (relative to the preset current)

at arc initiation

Arc Control - The Arc Control regulates the Arc Force to

adjust the short circuit current. The minimum setting

(-10) will produce a "soft" arc and will produce minimal

spatter. The maximum setting (+10) will produce a

"crisp" arc and will minimize electrode sticking.

Weld Terminals On/Remote – Set to “ON” and the

machine is in the ready to weld state.

Voltage Display Meter – This display will display three

dashed lines when the machine is in the idle state. This

indicates that voltage is not settable in this weld mode.

While output is enabled, the actual welding voltage will

be displayed. After welding, the meter holds the actual

voltage value for 5 seconds. Output adjustment while in

the "hold" period results in the "prior to operation"

characteristics stated above. The displays blink

indicating that the machine is in the "hold" period.

Output Control Dial

• When the Local/Remote is set to “LOCAL”, this dial

sets the welding amperage.

• When the Local/Remote is set to “REMOTE”, this

dial sets the maximum welding amperage. The

remote potentiometer controls the amperage from

minimum to this pre-set maximum.

Amperage Display Meter – This display will display the

pre-set welding current when the machine is in the idle

state. After welding, the meter holds the actual

amperage value for 5 seconds. Output adjustment while

in the "hold" period results in the "prior to operation"

characteristics stated above. The displays blink

indicating that the machine is in the "hold" period.

GTAW

This weld mode is a constant current (CC) mode

featuring continuous control from 10 – 815 amps (for

flextec™ 650) and 10 – 500 amps (for Flextec™ 450). It

is intended for the GTAW tig welding processes.

Hot Start - The Hot Start control regulates the starting

current at arc initiation. For Flextec™650 a setting of

+10 results in the most positive arc ignition

For Flextec

450 can be set to “OFF” and no additional current is

added to arc start. When set to the “On” position,

additional current (relative to the preset current) at arc

initiation

Arc Control – This control is not used in the GTAW

mode.

Weld Terminals On/Remote

• When set to the “ON” position, the weld terminals

are at OCV (open circuit voltage) and ready to weld.

• When set to the “remote” position, output is enabled

through a remote trigger.

Voltage Display Meter – This display will display three

dashed lines when the machine is in the idle state.

This indicates that voltage is not settable in this weld

mode. While output is enabled, the actual welding

voltage will be displayed. After welding, the meter holds

the actual voltage value for 5 seconds. Output

adjustment while in the "hold" period results in the "prior

to operation" characteristics stated above. The displays

blink indicating that the machine is in the "hold" period.

Amperage Display Meter – This display will display the

pre-set welding current when the machine is in the idle

state. After welding, the meter holds the actual

amperage value for 5 seconds. Output adjustment while

in the "hold" period results in the "prior to operation"

characteristics stated above. The displays blink

indicating that the machine is in the "hold" period.

Output Control Local/Remote – When the control is

set to “LOCAL” (no remote potentiometer/control

plugged into the 6 pin or 14 pin connectors), the output

is controlled through the Output Control Dial on the front

of the FLEXTEC™ 650&450. Set this switch to

“REMOTE” when an external potentiometer/control is

connected.

• When a remote potentiometer is connected, the

output control on the FLEXTEC™ 450&650 and the

remote act as a master/slave configuration. Use the

control dial on the FLEXTEC™ 450&650 to set the

maximum welding current. The remote will control

output from minimum to the pre-set maximum.

Output Control Dial

• When the Local/Remote is set to “LOCAL”, this dial

sets the welding amperage.

• When the Local/Remote is set to “REMOTE”, this

dial sets the maximum welding amperage. The

remote potentiometer controls the amperage from

minimum to this pre-set maximum.

CV-Gas

This weld mode is a constant voltage (CV) mode

featuring continuous control from 10 to 45 volts. It is

intended for the GMAW, FCAW-GS, MCAW welding

processes and arc gouging.

Page 18

English English

14

Hot Start For Flextec™ 650– Rotate from the “0”

position to the “10” position to provide more energy

during the start of a weld.

Hot Start For Flextec™ 450– Toggle to “ON” position

to provide more energy during the start of a weld.

Arc Control – The Arc Control regulates pinch effect. At

the minimum setting (-10), minimizes pinch and results

in a soft arc. Low pinch settings are preferable for

welding with gas mixes containing mostly inert gases. At

the maximum setting (+10), maximizes pinch effect and

results in a crisp arc. High pinch settings are preferable

for welding FCAW and GMAW with CO

2

.

Weld Terminals On/Remote

• When set to the “ON” position, the weld terminals

are at OCV (open circuit voltage) and ready to weld.

This selection is used for across the arc wire

feeders.

• When set to the “REMOTE” position, output is

enabled through a remote trigger.

Amperage Display Meter – This display will display

three dashed lines when the machine is in the idle state.

This indicates that amperage is not settable in this weld

mode. While output is enabled, the actual welding

amperage will be displayed. After welding, the meter

holds the actual amperage value for 5 seconds. Output

adjustment while in the "hold" period results in the "prior

to operation" characteristics stated above.

The displays blink indicating that the machine is in the

"hold" period.

Voltage Display Meter – This display will display the

pre-set welding voltage when the machine is in the idle

state. After welding, the meter holds the actual voltage

value for 5 seconds. Output adjustment while in the

"hold" period results in the "prior to operation"

characteristics stated above. The displays blink

indicating that the machine is in the "hold" period.

Output Control Local/Remote – When the control is

set to “LOCAL” (no remote potentiometer/control

plugged into the 6 pin or 14 pin connectors), the output

is controlled through the Output Control Dial on the front

of the FLEXTEC™ 650&450. Set this switch to

“REMOTE” when an external potentiometer/control is

connected.

Output Control Dial

When the Local/Remote is set to “LOCAL”, this dial

sets the welding voltage.

When the Local/Remote is set to “REMOTE”, this

dial is disabled.

CV-Innershield

This weld mode is a constant voltage (CV) mode

featuring continuous control from 10 to 45 volts. It is

intended for the FCAW-SS welding process and arc

gouging.

Hot Start For Flextec™ 650– Rotate from the “0”

position to the “10” position to provide more energy

during the start of a weld.

Hot Start For Flextec™ 450– Toggle to “ON” position

to provide more energy during the start of a weld.

Arc Control – The Arc Control regulates pinch effect. At

the minimum setting (-10), minimizes pinch and results

in a soft arc. At the maximum setting (+10), maximizes

pinch effect and results in a crisp arc.

Weld Terminals On/Remote

When set to the “ON” position, the weld terminals

are at OCV (open circuit voltage) and ready to weld.

This selection is used for across the arc wire

feeders.

When set to the “REMOTE” position, output is

enabled through a remote trigger.

Amperage Display Meter – This display will display

three dashed lines when the machine is in the idle state.

This indi-cates that amperage is not settable in this weld

mode. While output is enabled, the actual welding

amperage will be displayed. After welding, the meter

holds the actual amperage value for 5 seconds. Output

adjustment while in the "hold" period results in the "prior

to operation" characteristics stated above. The displays

blink indicating that the machine is in the "hold" period.

Voltage Display Meter – This display will display the

pre-set welding voltage when the machine is in the idle

state. After welding, the meter holds the actual voltage

value for 5 seconds. Output adjustment while in the

"hold" period results in the "prior to operation"

characteristics stated above. The displays blink

indicating that the machine is in the "hold" period.

Output Control Local/Remote – When the control is

set to “LOCAL” (no remote potentiometer/control

plugged into the 6 pin or 14 pin connectors), the output

is controlled through the Output Control Dial on the front

of the FLEXTEC™ 450&650. Set this switch to

“REMOTE” when an external potentiometer/control is

connected.

Output Control Dial

When the Local/Remote is set to “LOCAL”, this dial

sets the welding voltage.

When the Local/Remote is set to “REMOTE”, this

dial is disabled.

CV-SAW (only for Flextec™650)

This weld mode is a constant voltage (CV) mode

featuring continuous control from 10 to 45 volts. It is

intended for the CV-SAW submerged arc welding

process.

Hot Start – Not used for this welding process.

Arc Control – Not used for this welding process .

Weld Terminals On/Remote

When set to the “ON” position, the weld terminals

are at OCV (open circuit voltage) and ready to weld.

This selection is used for across the arc wire

feeders.

When set to the “REMOTE” position, output is

enabled through a remote trigger.

Page 19

English English

15

Amperage Display Meter – This display will display

three dashed lines when the machine is in the idle state.

This indicates that amperage is not settable in this weld

mode. While output is enabled, the actual welding

amperage will be displayed. After welding, the meter

holds the actual amperage value for 5 seconds. Output

adjustment while in the "hold" period results in the "prior

to operation" characteristics stated above. The displays

blink indicating that the machine is in the "hold" period.

Voltage Display Meter – This display will display the

pre-set welding voltage when the machine is in the idle

state. After welding, the meter holds the actual voltage

value for 5 seconds. Output adjustment while in the

"hold" period results in the "prior to operation"

characteristics stated above. The displays blink

indicating that the machine is in the "hold" period.

Output Control Local/Remote – When the control is

set to “LOCAL” (no remote potentiometer/control

plugged into the 6 pin or 14 pin connectors), the output

is controlled through the Output Control Dial on the front

of the FLEXTEC™ 650. Set this switch to “REMOTE”

when an external potentiometer/control is connected.

Output Control Dial

When the Local/Remote is set to “LOCAL”, this dial

sets the welding voltage.

When the Local/Remote is set to “REMOTE”, this

dial is disabled

Maintenance

WARNING

For any maintenance or repair operations it is

recommended to contact the nearest technical service

center or Lincoln Electric. Maintenance or repairs

performed by unauthorized service centers or personnel

will null and void the manufacturer’s warranty.

The frequency of the maintenance operations may vary

in accordance with the working environment. Any

noticeable damage should be reported immediately.

Check cables and connections integrity. Replace, if

necessary.

Keep clean the machine. Use a soft dry cloth to

clean the external case, especially the airflow inlet /

outlet louvers.

WARNING

Do not open this machine and do not introduce anything

into its openings. Power supply must be disconnected

from the machine before each maintenance and service.

After each repair, perform proper tests to ensure safety.

Page 20

English English

16

WEEE

07/06

English

Do not dispose of electrical equipment together with normal waste!

In observance of European Directive 2002/96/EC on Waste Electrical and Electronic Equipment (WEEE)

and its implementation in accordance with national law, electrical equipment that has reached the end of its

life must be collected separately and returned to an environmentally compatible recycling facility. As the

owner of the equipment, you should get information on approved collection systems from our local

representative.

By applying this European Directive you will protect the environment and human health!

Spare Parts

12/05

Part List reading instructions

Do not use this part list for a machine if its code number is not listed. Contact the Lincoln Electric Service

Department for any code number not listed.

Use the illustration of assembly page and the table below to determine where the part is located for your particular

code machine.

Use only the parts marked "X" in the column under the heading number called for in the assembly page (# indicate

a change in this printing).

First, read the Part List reading instructions above, then refer to the "Spare Part" manual supplied with the machine, that

contains a picture-descriptive part number cross-reference.

Electrical Schematic

Refer to the "Spare Part" manual supplied with the machine.

Suggested Accessories

Item number Description

K870 Foot Amptrol

K10095-1-15M Hand Amptrol

K10376 Terminal/twist-mate adapter (2 pieces necessary)

Loading...

Loading...