Page 1

Operator’s Manual

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

IM10197-B | Issue D ate Oct-16

© Lincoln Global, Inc. All Rights Reserved.

For use with machines having Code Numbers:

12249, 12589

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

FlexCut

™

80

Page 2

THANK YOU FOR SELECTING

A QUALITY PRODUCT BY

LINCOLN ELEC TRIC.

PLEASE EXAMINE CARTON AND EQUIPMENT FOR

DAMAGE IMMEDIATELY

When this equipment is shipped, title passes to the purchaser

upon receipt by the carrier. Consequently, claims for material

damaged in shipment must be made by the purchaser against the

transportation company at the time the shipment is received.

SAFETY DEPENDS ON YOU

Lincoln arc welding and cutting equipment is designed and built

with safety in mind. However, your overall safety can be increased

by proper installation ... and thoughtful operation on your part.

DO NOT INSTALL, OPERATE OR REPAIR THIS EQUIPMENT

WITHOUT READING THIS MANUAL AND THE SAFETY

PRECAUTIONS CONTAINED THROUGHOUT. And, most importantly,

think before you act and be careful.

WARNING

This statement appears where the information must be followed

exactly to avoid serious personal injury or loss of life.

CAUTION

This statement appears where the information must be followed

to avoid minor personal injury or damage to this equipment.

KEEP YOUR HEAD OUT OF THE FUMES.

DON’T get too close to the arc.

se corrective lenses if necessary

U

to stay a reasonable distance

away from the arc.

READ and obey the Safety Data

Sheet (SDS) and the warning label

that appears on all containers of

welding materials.

USE ENOUGH VENTILATION or

exhaust at the arc, or both, to

keep the fumes and gases from

your breathing zone and the general area.

IN A LARGE ROOM OR OUTDOORS, natural ventilation may be

adequate if you keep your head out of the fumes (See below).

USE NATURAL DRAFTS or fans to keep the fumes away

from your face.

If you de velop unusual symptoms, see your supervisor.

Perhaps the welding atmosphere and ventilation system

should be checked.

WEAR CORRECT EYE, EAR &

BODY PROTECTION

PROTECT your eyes and face with welding helmet

properly fitted and with proper grade of filter plate

(See ANSI Z49.1).

PROTECT your body from welding spatter and arc

flash with protective clothing including woolen

clothing, flame-proof apron and gloves, leather

leggings, and high boots.

PROTECT others from splatter, flash, and glare

with protective screens or barriers.

IN SOME AREAS, protection from noise may be appropriate.

BE SURE protective equipment is in good condition.

Also, wear safety glasses in work area

AT ALL TIMES.

SPECIAL SITUATIONS

DO NOT WELD OR CUT containers or materials which previously

had been in contact with hazardous substances unless they are

properly cleaned. This is extremely dangerous.

DO NOT WELD OR CUT painted or plated parts unless special

precautions with ventilation have been taken. They can release

highly toxic fumes or gases.

Additional precautionary measures

PROTECT compressed gas cylinders from excessive heat,

mechanical shocks, and arcs; fasten cylinders so they cannot fall.

BE SURE cylinders are never grounded or part of an

electrical circuit.

REMOVE all potential fire hazards from welding area.

ALWAYS HAVE FIRE FIGHTING EQUIPMENT READY FOR

IMMEDIATE USE AND KNOW HOW TO USE IT.

Safety 01 of 04 - 06/15/2016

Page 3

SECTION A:

WARNINGS

CALIFORNIA PROPOSITION 65 WARNINGS

Diesel Engines

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and other

reproductive harm.

Gasoline Engines

The engine exhaust from this product contains chemicals known

to the State of California to cause cancer, birth defects, or other

reproductive harm.

ARC WELDING CAN BE HAZARDOUS. PROTECT

YOURSELF AND OTHERS FROM POSSIBLE SERIOUS

INJURY OR DEATH. KEEP CHILDREN AWAY.

PACEMAKER WEARERS SHOULD CONSULT WITH

THEIR DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For

additional safety information, it is strongly recommended

that you purchase a copy of “Safety in Welding & Cutting ANSI Standard Z49.1” from the American Welding Society,

P.O. Box 351040, Miami, Florida 33135 or CSA Standard

W117.2-1974. A Free copy of “Arc Welding Safety” booklet

E205 is available from the Lincoln Electric Company,

22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

BE SURE THAT ALL INSTALLATION, OPERATION,

MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

SAFETY

1.d. Keep all equipment safety guards, covers

and devices in position and in good repair.

Keep hands, hair, clothing and tools away

from V-belts, gears, fans and all other

moving parts when starting, operating or

repairing equipment.

1.e. In some cases it may be necessary to remove safety guards to

perform required maintenance. Remove guards only when

necessary and replace them when the maintenance requiring

heir removal is complete. Always use the greatest care when

t

working near moving parts.

1.f. Do not put your hands near the engine fan. Do not attempt to

override the governor or idler by pushing on the throttle control

rods while the engine is running.

1.g. To prevent accidentally starting gasoline engines while turning

the engine or welding generator during maintenance work,

disconnect the spark plug wires, distributor cap or magneto wire

as appropriate.

1.h. To avoid scalding, do not remove the radiator

pressure cap when the engine is

hot.

ELECTRIC AND

MAGNETIC FIELDS MAY

BE DANGEROUS

2.a. Electric current flowing through any conductor

causes localized Electric and Magnetic Fields (EMF).

Welding current creates EMF fields around welding cables

and welding machines

FOR ENGINE POWERED

EQUIPMENT.

1.a. Turn the engine off before troubleshooting

and maintenance work unless the

maintenance work requires it to be running.

1.b. Operate engines in open, well-ventilated

areas or vent the engine exhaust fumes outdoors.

1.c. Do not add the fuel near an open flame

welding arc or when the engine is running.

Stop the engine and allow it to cool before

refueling to prevent spilled fuel from

vaporizing on contact with hot engine parts

and igniting. Do not spill fuel when filling

tank. If fuel is spilled, wipe it up and do not start engine until

fumes have been eliminated.

2.b. EMF fields may interfere with some pacemakers, and

welders having a pacemaker should consult their physician

before welding.

2.c. Exposure to EMF fields in welding may have other health effects

which are now not known.

2.d. All welders should use the following procedures in order to

minimize exposure to EMF fields from the welding circuit:

2.d.1. Route the electrode and work cables together - Secure

them with tape when possible.

2.d.2. Never coil the electrode lead around your body.

2.d.3. Do not place your body between the electrode and work

cables. If the electrode cable is on your right side, the

work cable should also be on your right side.

2.d.4. Connect the work cable to the workpiece as close as possible to the area being welded.

2.d.5. Do not work next to welding power source.

Safety 02 of 04 - 06/15/2016

Page 4

SAFETY

ELECTRIC SHOCK

CAN KILL.

3.a. The electrode and work (or ground) circuits are

electrically “hot” when the welder is on. Do

not touch these “hot” parts with your bare skin or wet clothing.

Wear dry, hole-free gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full area

f physical contact with work and ground.

o

In addition to the normal safety precautions, if

welding must be performed under electrically

hazardous conditions (in damp locations or while

wearing wet clothing; on metal structures such as

floors, gratings or scaffolds; when in cramped

positions such as sitting, kneeling or lying, if there

is a high risk of unavoidable or accidental contact

with the workpiece or ground) use the following

equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel, welding head, nozzle or semiautomatic welding

gun are also electrically “hot”.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection should

be as close as possible to the area being welded.

3.e. Ground the work or metal to be welded to a good electrical (earth)

ground.

3.f. Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Never simultaneously touch electrically “hot” parts of electrode

holders connected to two welders because voltage

two can be the total of the open circuit voltage of both

welders.

3.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

between the

ARC RAYS CAN BURN.

4.a. Use a shield with the proper filter and cover plates to protect your

eyes from sparks and the rays of the arc when welding or

observing open arc welding. Headshield and filter lens should

conform to ANSI Z87. I standards.

4.b. Use suitable clothing made from durable flame-resistant material

to protect your skin and that of your helpers from the arc rays.

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

FUMES AND GASES

CAN BE DANGEROUS.

5.a. Welding may produce fumes and gases

hazardous to health. Avoid breathing these fumes and gases.

When welding, keep your head out of the fume. Use enough

ventilation and/or exhaust at the arc to keep fumes and gases

away from the breathing zone. When welding hardfacing

(see instructions on container or SDS) or on lead

or cadmium plated steel and other metals or

coatings which produce highly toxic fumes, keep

exposure as low as possible and within applicable

OSHA PEL and ACGIH TLV limits using local

exhaust or mechanical ventilation unless exposure

assessments indicate otherwise. In confined

spaces or in some circumstances, outdoors, a

respirator may also be required. Additional

precautions are also required when welding

on galvanized steel.

5. b. The operation of welding fume control equipment is affected by

various factors including proper use and positioning of the

equipment, maintenance of the equipment and the specific

welding procedure and application involved. Worker exposure

level should be checked upon installation and periodically

thereafter to be certain it is within applicable OSHA PEL and

ACGIH TLV limits.

5.c. Do not weld in locations near chlorinated hydrocarbon vapors

coming from degreasing, cleaning or spraying operations. The

heat and rays of the arc can react with solvent vapors to form

phosgene, a highly toxic gas, and other irritating products.

3.j. Also see It ems 6.c. and 8.

5.d. Shielding gases used for arc welding can displace air and

cause

injury or death. Always use enough ventilation, especially in

confined areas, to insure breathing air is safe.

5.e. Read and understand the manufacturer’s instructions for this

equipment and the consumables to be used, including the

Safety Data Sheet (SDS) and follow your employer’s safety

practices. SDS forms are available from your welding

distributor or from the manufacturer.

5.f. Also see item 1.b.

Safety 03 of 04 - 06/15/2016

Page 5

SAFETY

WELDING AND CUTTING

SPARKS CAN CAUSE

FIRE OR EXPLOSION.

6.a. Remove fire hazards from the welding area. If

this is not possible, cover them to prevent the welding sparks

rom starting a fire. Remember that welding sparks and hot

f

materials from welding can easily go through small cracks and

openings to adjacent areas. Avoid welding near hydraulic lines.

Have a fire extinguisher readily available.

6.b. Where compressed gases are to be used at the job site, special

precautions should be used to prevent hazardous situations.

Refer to “Safety in Welding and Cutting” (ANSI Standard Z49.1)

and the operating information for the equipment being used.

6.c. When not welding, make certain no part of the electrode circuit is

touching the work or ground. Accidental contact can cause

overheating and create a fire hazard.

6.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures

will not cause flammable or toxic vapors from substances inside.

They can cause an explosion even though they have been

“cleaned”. For information, purchase “Recommended Safe

Practices for the Preparation for Welding and Cutting of

Containers and Piping That Have Held Hazardous Substances”,

AWS F4.1 from the American Welding Society

(see address above).

6.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

6.f. Sparks and spatter are thrown from the welding arc. Wear oil free

protective garments such as leather gloves, heavy shirt, cuffless

trousers, high shoes and a cap over your hair. Wear ear plugs

when welding out of position or in confined places. Always wear

safety glasses with side shields when in a welding area.

6.g. Connect the work cable to the work as close to the welding area

as practical. Work cables connected to the building framework or

other locations away from the welding area increase the

possibility of the welding current passing through lifting chains,

crane cables or other alternate circuits. This can create fire

hazards or overheat lifting chains or cables until they fail.

6.h. Also see item 1.c.

CYLINDER MAY EXPLODE IF

DAMAGED.

7.a. Use only compressed gas cylinders containing

the correct shielding gas for the process used

and properly operating regulators designed for

the gas and pressure used. All hoses, fittings,

tc. should be suitable for the application and

e

maintained in good condition.

7.b. Always keep cylinders in an upright position securely chained to

an undercarriage or fixed support.

7.c. Cylinders should be located:

• Away from areas where they may be struck or subjected

to physical damage.

• A safe distance from arc welding or cutting operations

and any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode holder or any other

electrically “hot” parts to touch a cylinder.

7.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. Valve protection caps should always be in place and hand tight

except when the cylinder is in use or connected for use.

7.g. Read and follow the instructions on compressed gas cylinders,

associated equipment, and CGA publication P-l, “Precautions for

Safe Handling of Compressed Gases in Cylinders,” available from

the Compressed Gas Association, 14501 George Carter Way

Chantilly, VA 20151.

FOR ELECTRICALLY

POWERED EQUIPMENT.

8.a. Turn off input power using the disconnect

switch at the fuse box before working on

the equipment.

8.b. Install equipment in accordance with the U.S. National Electrical

Code, all local codes and the manufacturer’s recommendations.

6.I. Read and follow NFPA 51B “Standard for Fire Prevention During

Welding, Cutting and Other Hot Work”, available from NFPA, 1

Batterymarch Park, PO box 9101, Quincy, MA 022690-9101.

6.j. Do not use a welding power source for pipe thawing.

8.c. Ground the equipment in accordance with the U.S. National

Electrical Code and the manufacturer’s recommendations.

Refer to

http://www.lincolnelectric.com/safety

for additional safety information.

Safety 04 of 04 - 06/15/2016

Page 6

SAFETY

General Precautions

Whereas plasma cutting has been used safely for years, it does

r

equire certain precautions to ensure the safety of the operator and

other people around the equipment. The following safety information

must be provided to each person who will operate, observe, perform

maintenance, or work in close proximity to this piece of equipment.

Installation, operation, and repairs made to the system should only be

performed by qualified personnel. The system makes use of both A.C.

and D.C. circuitry for operation. Fatal shock hazard does exist.

Exercise extreme caution while working on the system. Safety decals

On the power supply should not be removed.

ULTRAVIOLET RADIATION

PROTECTION

Plasma cutting produces ultraviolet radiation similar to a welding arc.

This ultraviolet radiation can cause skin and eye burns. For this

reason, it is essential that proper protection be worn. The eyes are

best protected by using safety glasses or a welding helmet with an

AWS No. 12 shade or ISO 4850 No. 13 shade, which provides

protection up to 400 amperes. All exposed skin areas should be

covered with flame-retardant clothing. The cutting area should also

be prepared in such a way that ultraviolet light does not reflect. Walls

and other surfaces should be painted with dark colors to reduce

reflected light. Protective screens or curtains should be installed to

protect additional workers in the area from ultraviolet radiation.

NOISE PROTECTION

The system generates high noise levels while cutting. Depending on

the size of the cutting area, distance from the cutting torch, and arc

current cutting level, acceptable noise levels may be exceeded.

Proper ear protection should be used as defined by local or national

codes. See Section 2 for noise emission levels.

TOXIC FUME PREVENTION

Care should be taken to ensure adequate ventilation in the cutting

area. Some materials give off toxic fumes that can be harmful or fatal

to people in the vicinity of the cutting area. Also, some solvents

decompose and form harmful gases when exposed to ultraviolet

radiation. These solvents should be removed from the area prior to

cutting. Galvanized metal can produce harmful gases during the

cutting process. Ensure proper ventilation and use breathing

equipment when cutting these materials.

Certain metals coated with or containing lead, cadmium, zinc,

beryllium, and mercury produce harmful toxins. Do not cut these

metals unless all people subjected to the fumes wear proper air

breathing equipment.

ELECTRIC SHOCK PREVENTION

The system uses high open circuit voltages that can be

fatal. Extreme care should be used when operating or

performing maintenance on the system. Only qualified personnel

s

hould service the system. Observe the following guidelines to protect

against electric shock:

• A wall-mounted disconnect switch should be installed and fused

according to local and national electrical codes. The disconnect

switch should be located as close as possible to the power supply

so it can be turned off in case of an emergency.

• The primary power cord should have a 600 volt minimum rating in

order to protect the operator. In addition, it should be sized

according to local and national electrical codes. Inspect the primary

power cord frequently. Never operate the system if the power cord

is damaged in any way.

• Make sure the primary power ground wire is connected at the input

power ground location on the power supply. Make sure the

connection is securely tightened.

• Make sure the positive output (work ground) of the power supply is

connected to a bare metal area on the cutting table. A driven

ground rod should be placed no further than five feet from this

connection. Make sure this ground point on the cutting table is

used as the star ground point for all other ground connections.

• Inspect the torch leads frequently. Never use the system if the leads

are damaged in any way.

• Do not stand in wet, damp areas when operating or performing

maintenance on the system.

• Wear insulated gloves and shoes while operating or performing

maintenance on the system.

• Make sure the system is switched off at the wall disconnect before

servicing the power supply or torch.

• Never change torch consumable parts unless main power to the

system is switched off at the power supply or wall disconnect.

• Do not attempt to remove any parts from beneath the torch when

cutting. Remember that the workpiece forms the current path back

to the power supply.

• Never bypass the safety interlock devices.

• Before removing any of the covers, switch the system off at the wall

disconnect. Wait at least five (5) minutes before removing any

cover. This will give the capacitors inside the unit time to discharge.

See Section 5 for additional safety precautions.

• Never operate the system without all of the covers in place. See

Section 5 for additional safety precautions.

• Preventive maintenance should be performed daily to avoid

possible safety hazards.

2

FLEXCUT™ 80

SAFETY

Page 7

3

FLEXCUT™ 80

FIRE PREVENTION

When using the system , it is necessary to exercise good

judgment. While cutting, the arc produces sparks that could cause a

fire if they fall on flammable materials. Make sure that all flammable

m

aterials are a suitable distance away from the cutting area. All

flammable liquids should be at least 40 feet away from the cutting

area, preferably stored in a metal cabinet. Plasma cutting should

never be attempted on containers that contain flammable materials.

Make sure that fire extinguishers are readily accessible in the cutting

area.

EXPLOSION PREVENTION

The system uses compressed gases. Use proper

techniques when handling compressed gas cylinders and other

compressed gas equipment. Observe the following guidelines to

protect against explosion:

• Never operate the system in the presence of explosive gases or

other explosive materials.

• Never cut pressurized cylinders or any closed container.

• When using a water table and cutting aluminum under water or

with water touching the underside at the aluminum plate,

hydrogen gas is produced. This hydrogen gas may collect under

the plate and explode during the cutting process. Make sure the

water table is properly aerated to help prevent the accumulation

of hydrogen gas.

• Handle all gas cylinders in accordance with safety standards

published by the U.S. Compressed Gas Association (CGA),

American Welding Society (AWS), Canadian Standards

Association (CSA), or other local or national codes.

• Compressed gas cylinders should be maintained properly. Never

attempt to use a cylinder that is leaking, cracked, or has other

signs of physical damage.

• All gas cylinders should be secured to a wall or rack to prevent

accidental knock over.

• If a compressed gas cylinder is not being used, replace the

protective valve cover.

• Never attempt to repair compressed gas cylinders.

• Keep compressed gas cylinders away from intense heat, sparks,

or flames.

• Clear the compressed gas cylinder connection point by opening

the valve momentarily prior to installing a regulator.

• Never lubricate compressed gas cylinder valves or pressure

regulators with any type of oil or grease.

• Never use a compressed gas cylinder or pressure regulator for

any purpose other than which it is intended.

• Never use a pressure regulator for any gas other than which it is

intended.

• Never use a pressure regulator that is leaking or has other signs

of physical damage.

• Never use any gas hose that is leaking or has other signs of

physical damage.

HEALTH SUPPORT EQUIPMENT

The system creates electric and magnetic fields that

may interfere with certain types of health support

equipment, such as pacemakers. Any person who uses a pacemaker

o

r similar item should consult a doctor before operating, observing,

maintaining, or servicing the system. Observe the following guidelines

to minimize exposure to these electric and magnetic fields:

• Stay as far away from the~power supply, torch, and torch leads

as possible.

• Route the torch leads as close as possible to the work ground

cable.

• Never place your body between the torch leads and work ground

cable. Keep the work ground cable and the torch leads on the

same side of your body.

• Never stand in the center of a coiled up set of torch leads or work

ground cable.

SAFETY

Page 8

FLEXCUT™ 80

Safety Standards Booklet Index

For further information concerning safety practices to be exercised

with plasma arc cutting equipment, please refer to the following

p

ublications:

1

. AWS Standard AWN, Arc Welding and Cutting Noise, obtainable

from the American Welding Society, 550 NW LeJeune Road, Miami,

FL 33126.

2. AWS Standard C5.2, Recommended Practices for Plasma Arc

Cutting, obtainable from the American Welding Society, 550 NW

LeJeune Road, Miami, FL 33126.

3. AWS Standard FSW, Fire Safety in Welding and Cutting, obtainable

from the American Welding Society, 550 NW LeJeune Road, Miami,

FL 33126.

4. AWS Standard F4.1, Recommended Safe Practices for Preparation

for Welding and Cutting of Containers and Piping, obtainable from

the American Welding Society, 550 NW LeJeune Road, Miami, FL

33126.

5. AWS Standard ULR, Ultraviolet Reflectance of Paint, obtainable

from the American Welding Society, 550 NW LeJeune Road, Miami,

FL 33126.

6. AWS I ANSI Standard Z49.1, Safety in Welding, Cutting, and Allied

Processes, obtainable from the American Welding Society, 550 NW

LeJeune Road, Miami, FL 33126.

7. ANSI Standard Z41.1 , Standard For Men's Safety-Toe Footwear,

obtainable from the American National Standards Institute, 11 West

42nd Street, New York, NY 10036.

8. ANSI Standard Z49.2, Fire Prevention in the Use of Cutting and

Welding Processes, obtainable from the American National

Standards Institute, 11 West 42nd Street, New York, NY 10036.

9. ANSI Standard Z87.1, Safe Practices For Occupation and

Educational Eye and Face Protection, obtainable from the American

National Standards Institute, 11 West 42nd Street, New York, NY

10036.

10. ANSI Standard Z88.2, Respiratory Protection, obtainable from the

American National Standards Institute, 11 West 42nd Street, New

York, NY 10036.

11. OSHA Standard 29CFR 1910.252, Safety and Health Standards,

obtainable. from the U.S. Government Printing Office, Washington,

D.C. 20402.

12. NFPA Standard 51 , Oxygen - Fuel Gas Systems for Welding,

Cutting, and Allied Processes, obtainable from the National Fire

Protection Association, 1 Batterymarch Park, Quincy, MA 02269.

13. NFPA Standard 51 B, Cutting and Welding Processes, obtainable

from the National Fire Protection Association, 1 Batterymarch

Park, Quincy, MA 02269.

14. NFPA Standard 70, National Electrical Code, obtainable from the

National Fire Protection Association, 1 Batterymarch Park, Quincy,

MA 02269.

15. CGA booklet P-1 , Safe Handling of Compressed Gases in

Containers, obtainable from the Compressed Gas Association,

1725 Jefferson Davis Highway, Suite 1004, Arlington, VA 22202.

16. CGA booklet P-14, Accident Prevention in Oxygen-Rich and

Oxygen-Deficient Atmospheres, obtainable from the Compressed

Gas Association, 1725 Jefferson Davis Highway, Suite 1004,

Arlington, VA 22202.

17. CGA booklet TB-3, Hose Line Flashback Arrestors, obtainable from

the Compressed Gas Association, 1725 Jefferson Davis Highway,

Suite 1004, Arlington, VA 22202.

18. CSA Standard W117 .2, Safety in Welding, Cutting, and Allied

P

rocesses, obtainable from Canadian Standards Association, 178

Rexdale Boulevard, Toronto, Ontario M9W IR3, Canada.

19. Canadian Electrical Code Part 1, Safety Standard for Electrical

Installations, obtainable from the Canadian Standards Association,

178 Rexdale Boulevard, Toronto, Ontario M9W 1 R3, Canada.

4

SAFETY

Page 9

5

F

LEXCUT™ 80

Table Of Contents

Page

General Description....................................................................................................................................

Preheat Temperature For Plasma Cutting ............................................................................................6

D

uty Cycle...........................................................................................................................................6

User Responsibility..............................................................................................................................6

Design Features And Advantages ........................................................................................................6

Installation ..................................................................................................................................Section A

Select Suitable Location...................................................................................................................A-1

Lifting ............................................................................................................................................A-2

Stacking ..........................................................................................................................................A-2

Tilting ............................................................................................................................................A-2

High Frequency Interference Protection ...........................................................................................A-2

Input Connection..............................................................................................................................A-2

Machine Grounding..........................................................................................................................A-2

Input Plug Installation ......................................................................................................................A-3

Power Cord Replacement.................................................................................................................A-3

Engine Driven Generator ..................................................................................................................A-3

Gas Supply Requirements................................................................................................................A-3

Connecting The Gas Supply .............................................................................................................A-4

Output Connections .........................................................................................................................A-4

Operation ..................................................................................................................................Section B

Controls And Settings ......................................................................................................................B-2

Hand Cutting .................................................................................................................................B-4

Hand Cutting Charts.........................................................................................................................B-5

Mechanized Cutting.......................................................................................................................B-10

Mechanized Cutting Charts............................................................................................................B-12

Consumable Life............................................................................................................................B-16

Cut Quality.....................................................................................................................................B-16

Options/Accessories...................................................................................................................Section C

Maintenance ...............................................................................................................................Section D

Daily Procedures .............................................................................................................................D-1

Monthly Procedures.........................................................................................................................D-1

Troubleshooting ..........................................................................................................................Section E

Wiring Diagrams..........................................................................................................................Section F

Wiring Diagram ............................................................................................................................F-1

Dimension Print............................................................................................................................F-2

Parts List .........................................................................................................parts.lincolnelectric.com

Content/details may be changed or updated without notice. For most current Instruction Manuals, go to

parts.lincolnelectric.com.

Page 10

F

LEXCUT™ 80

GENERAL DESCRIPTION

The FLEXCUT™ 80 is a constant current, continuous control plasma

cutting power source. It provides superior and reliable starting

characteristics, cutting visibility and arc stability. The control system

h

as a safety mechanism to insure that the nozzle and electrode are in

place before cutting or gouging. This is extremely important due to

the high voltages involved.

The FLEXCUT™ 80 comes standard with an air regulator and

pressure gauge. The machine also comes with an input power cord.

Torches and consumables are included with FLEXCUT™ 80

One-Paks

®

, so that cutting can begin right out of the box.

Consumables and torches can also be ordered as individual

packages.

The FLEXCUT™ 80 initiates the plasma arc with a simple, yet

reliable, contact start mechanism. This system eliminates many of the

failure problems associated with hi-frequency start systems.

PREHEAT TEMPERATURE FOR PLASMA CUTTING

Preheat temperature control is not necessary in most applications

when plasma arc cutting or gouging. Preheat temperature control

may be necessary on high carbon alloy steels and heat treated

aluminum for crack resistance and hardness control. Job conditions,

prevailing codes, alloy level, and other considerations may also

require preheat temperature control. The following minimum preheat

temperature is recommended as a starting point. Higher temperatures

may be used as required by the job conditions and/or prevailing

codes. If cracking or excessive hardness occurs on the cut face,

higher preheat temperature may be required. The recommended

minimum preheat temperature for plate thickness up to 1/2"

(12.7mm) is 70°F (21.1°C).

DUTY CYCLE

The duty cycle of a plasma machine is the percentage of time in a 10

minute cycle at which the operator can operate the machine at rated

cutting current.

Example: 80% duty cycle means that it is possible to cut for 8

minutes, followed by 2 minutes of machine idling.

Refer to the Technical Specification section for more information

about the machine rated duty cycles.

USER RESPONSIBILITY

Because design, fabrication, erection and cutting variables affect the

results obtained in applying this type of information, the serviceability

of a product or structure is the responsibility of the user. Variation

s

uch as plate chemistry, plate surface condition (oil, scale), plate

thickness, preheat, quench, gas type, gas flow rate and equipment

may produce results different than those expected. Some adjustments

to procedures may be necessary to compensate for unique individual

conditions. Test all procedures duplicating actual field conditions.

DESIGN FEATURES AND ADVANTAGES

The FLEXCUT™ 80 design makes plasma cutting uncomplicated. This

list of design features and advantages will help you understand the

machine's total capabilities so that you can get maximum use from

your machine.

- Light weight and portable design for industrial use.

- Continuous control, 25 - 80 amps.

- Reliable touch start mechanism for plasma arc initiation.

- Rapid arc restrike for fast cutting of expanded metal.

- Input over voltage protection.

- Bright 5.0 second timed pilot arc.

- Gas purge selection.

- Air regulator and pressure gage included.

- Internal water separator included.

- Parts-in-Place mechanism to detect proper installation of

consumables and torch.

- Preflow/Postflow timing. Preflow is eliminated if arc is reinitiated in Postflow.

- Thermostatic Protection.

- Solid state over-current protection.

- Patented electrode, nozzle and shield cap for optimum cooling,

cut quality and long life.

6

Page 11

A-1

I

NSTALLATION

F

LEXCUT™ 80

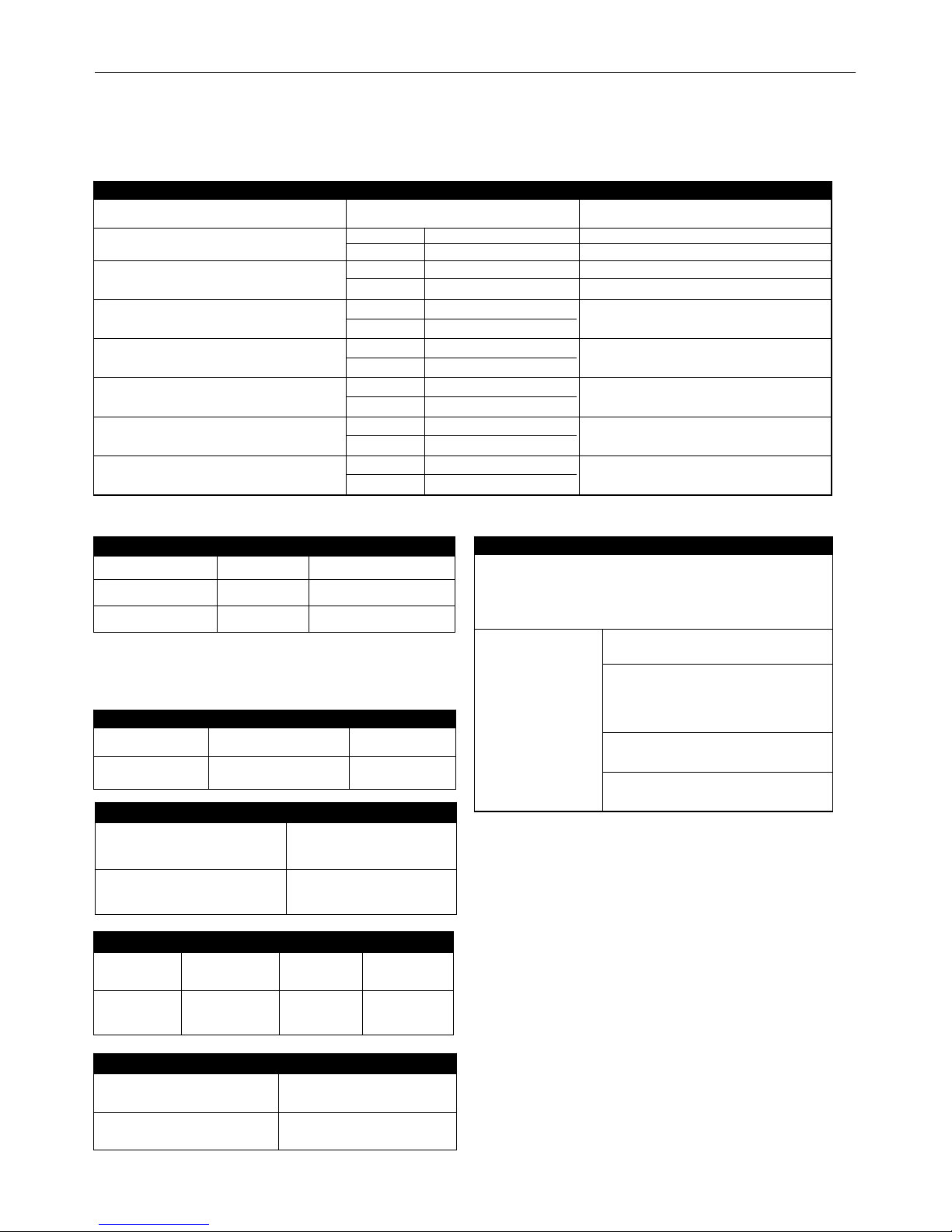

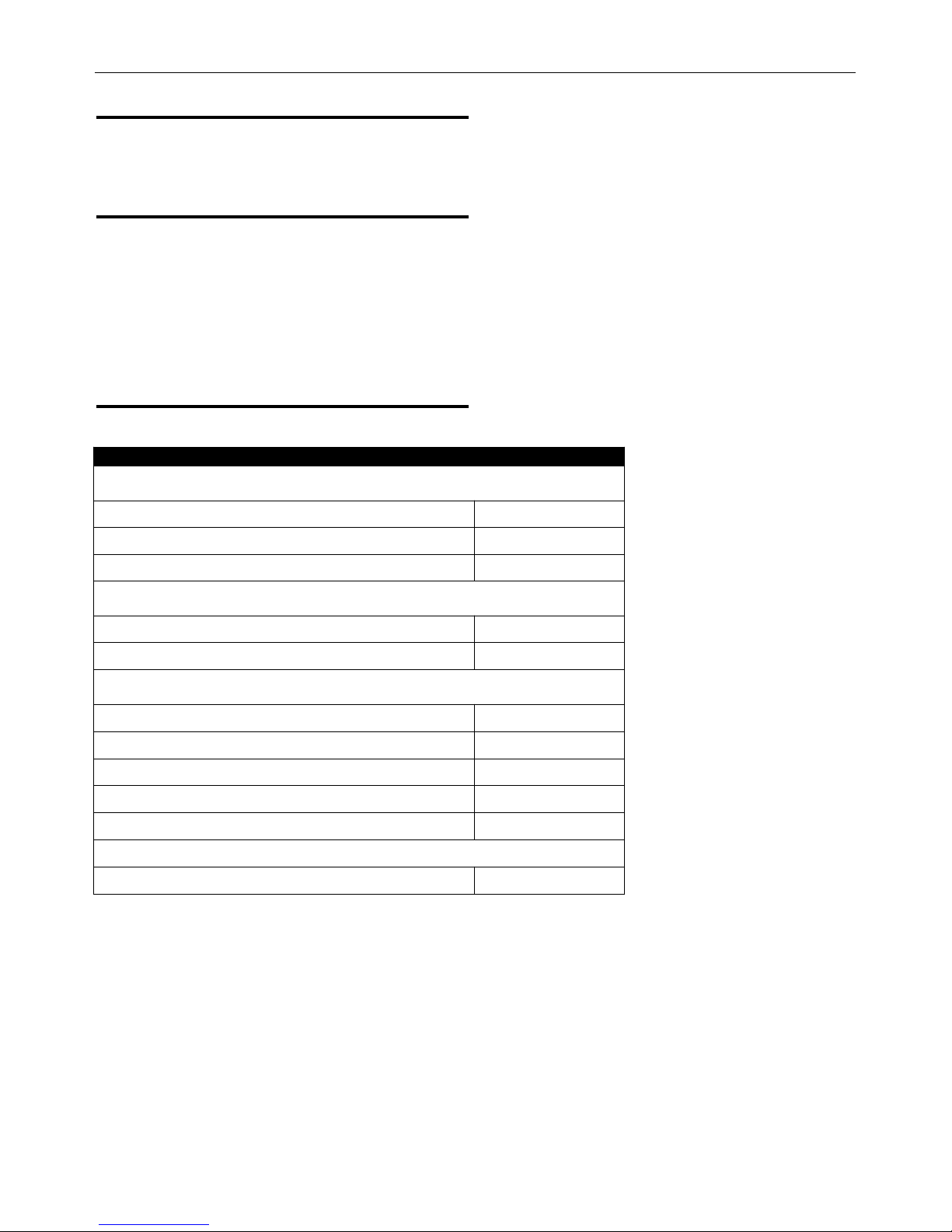

TECHNICAL SPECIFICATIONS K4809-1 FLEXCUT™ 80

INPUT - SINGLE PHASE/THREE PHASE/ 50 / 60 HERTZ

Input Voltage +/- 10%

Input Amperes @ Rated Output

Circuit Breaker (Delay Type)

200V/208V/1/50/60

71

52

80% Duty Cycle

100% Duty Cycle

80 Amps

60 Amps

230V/1/50/60

62

48

80% Duty Cycle

100% Duty Cycle

70 Amps

60 Amps

200V/208V/3/50/60

41

31

80% Duty Cycle

100% Duty Cycle

50 Amps

230V/3/50/60

37

28

80% Duty Cycle

100% Duty Cycle

50 Amps

400V/3/50/60

21

16

80% Duty Cycle

100% Duty Cycle

30 Amps

460V/3/50/60

18

14

80% Duty Cycle

100% Duty Cycle

25 Amps

575V/3/50/60

14

12

80% Duty Cycle

100% Duty Cycle

20 Amps

RATED OUTPUT AT 40° C

Duty Cycle CURRENT VOLTAGE

100% 60A 140 VDC

80%* 80A 140 VDC

RECOMMENDED INPUT WIRE

For all plasma cutting applications

Based on U.S. National Electrical Code

Ambient Temperature 30oC or Less

Input Cord Supplied

with Machine

5OOW, 600V

Type S, SO, ST, STO

or Extra Hard Usage Cord

AWG (IEC) Sizes

Input Supply Wires

#6 (13.3 mm

2

)

1 Ground Wire

#6 (13.3 mm2)

OUTPUT

Current Range Open Circuit Voltage Pilot Current

25 - 80 Amps 270 VDC 20 Amps

PHYSICAL DIMENSIONS

Height Width Depth Weight

17.9 in.

(454 mm)

11.8 in.

(300 mm)

25.4 in.

(645 mm)

96 lbs.

(44 kgs)

TEMPERATURE RANGES

OPERATING TEMPERATURE

RANGE

STORAGE TEMPERATURE

RANGE

-10°C to +40°C -25°C to +55°C

GAS

REQUIRED GAS FLOW RATE

REQUIRED GAS INLET

PRESSURE

300 SCFH min @ 90 PSI

(140 SLPM min @ 6.2 bar)

87.0 to 109.0 PSI

(6.0 Bar. to 7.5 Bar.)

*Derated to 60% on 200/208V 1~ input

Page 12

A-2

I

NSTALLATION

F

LEXCUT™ 80

R

ead entire Installation Section before installing the

FLEXCUT™ 80 .

SAFETY PRECAUTIONS

ELECTRIC SHOCK CAN KILL.

• Only qualified personnel should install

this machine.

• Turn the input power OFF at the

disconnect switch or fuse box and

discharge input capacitors before working inside the

equipment.

• Do not touch electrically hot parts.

• Turn the FLEXCUT™ 80 Power Switch OFF when

connecting power cord to input power.

SELECT SUITABLE LOCATION

Place the FLEXCUT™ 80 where clean cool air can freely circulate in

through the rear of the machine and out through the front and side

louvers. Maintain at least 10 inches of space on all sides of the unit.

Dirt, dust, or any foreign material that be drawn into the machine

should be kept to a minimum. A properly installed machine will allow

for dependable service and reduce periodic maintenance time. Failure

to observe these precautions may result in excessive operating

temperatures and nuisance shutdowns of the machine.

LIFTING

The FLEXCUT™ 80 power supply should be lifted by two people or a

hoist. In order to prevent damage, the power supply should be lifted

by both handles while keeping the unit as horizontal as possible. Only

hoisting straps approved for the weight of the machine should be

used.

STACKING

The FLEXCUT™ 80 cannot be stacked.

TILTING

The FLEXCUT™ 80 must be placed on a stable, level surface so it will

not topple over.

HIGH FREQUENCY INTERFERENCE PROTECTION

The FLEXCUT™ 80 employs a touch start mechanism for arc initiation

w

hich eliminates high frequency emissions from the machine as

compared with spark gap and solid state type high frequency

generators. Keep in mind though, that these machines may be used in

an environment where other high frequency generating machines are

operating. By taking the following steps, high frequency interference

i

nto the FLEXCUT™ 80 can be minimized:

(

1) Make sure the power supply chassis is connected to a good earth

ground. The work terminal ground does NOT ground the machine

frame.

(2) Keep the work clamp isolated from other work clamps that have

high frequency.

(3) If the work clamp cannot be isolated, then keep the clamp as far

as possible from other work clamp connections.

(4) When the machine is enclosed in a metal building, several good

earth driven grounds around the periphery of the building are

recommended.

INPUT CONNECTION

Only a qualified electrician should connect the input leads to

the FLEXCUT™ 80. Connections should be

made in accordance with all local and

national electrical codes and the

connection diagrams. Failure to do so may

result in bodily injure or death.

The FLEXCUT™ 80 is rated for 208 VAC through 575 VAC input

voltages, single or three phase and 50 or 60 Hertz. Before connecting

the machine to power, be sure the input supply voltage, phase and

frequency all match those listed on the machine’s rating plate.

The FLEXCUT™ 80 automatically senses and adjusts to work with

any input voltage, phase or frequency listed on the rating plate. No

reconnect switch settings are required.

MACHINE GROUNDING

The frame of the welder must be grounded. A ground terminal

marked with a ground symbol is located next to the

input power connection block.

See your local and national electrical codes for

proper grounding methods.

The FLEXCUT™ 80 ON/OFF switch is not intended as a

service disconnect for this equipment. Only a qualified

electrician should connect the input leads to the FLEXCUT

80. Connections should be made in accordance with all

local and national electrical codes. Failure to do so may

result in bodily injury or death.

WARNING

WARNING

WARNING

Page 13

A-3

I

NSTALLATION

F

LEXCUT™ 80

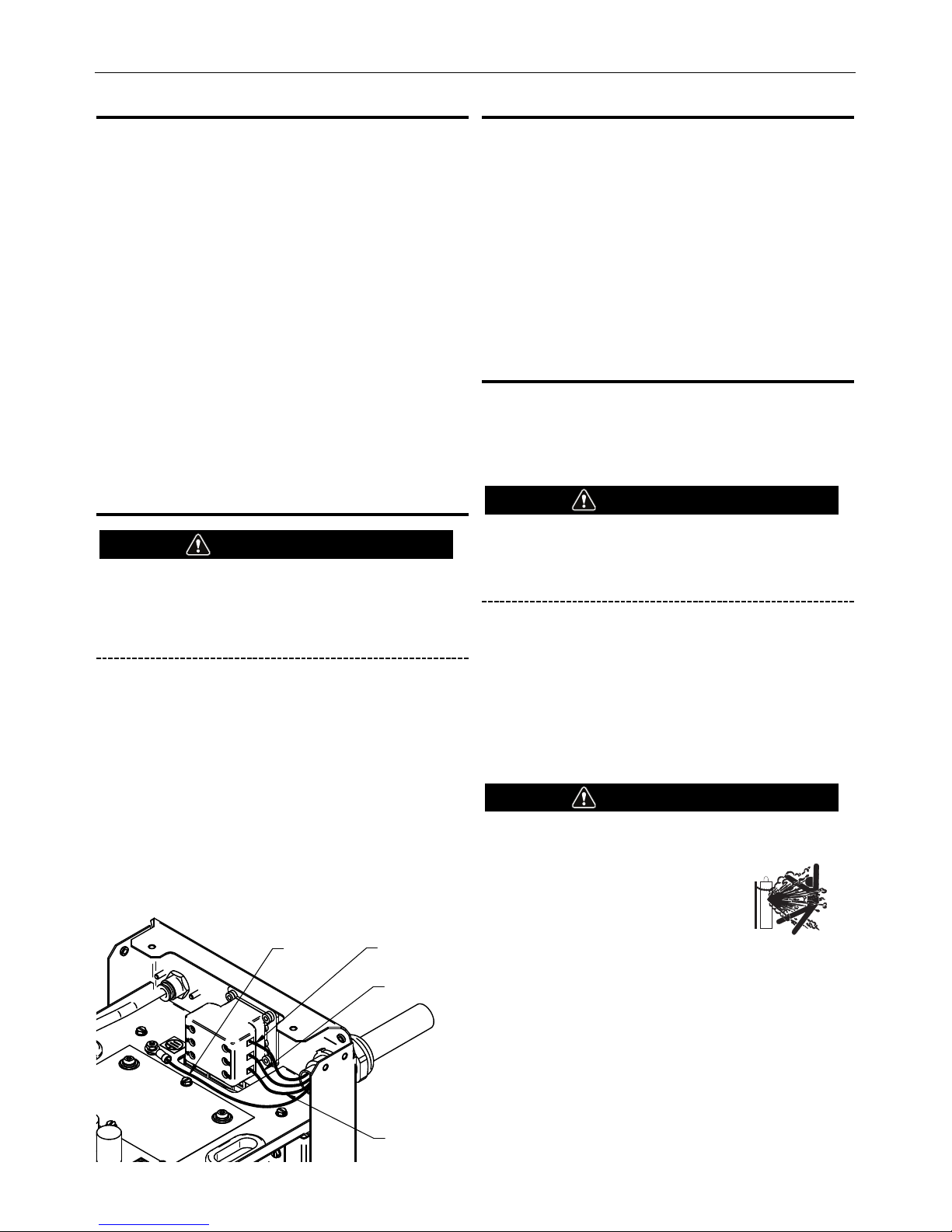

INPUT PLUG INSTALLATION

A 10 ft. (3m) power cord is provided with the

FLEXCUT™ 80.

Single Phase Input

Connect green lead to ground per National Electrical Code.

Connect black and red leads to power.

Wrap white lead with tape to provide 600V insulation.

Three Phase Input

Connect green lead to ground per National Electric Code.

Connect black, red and white leads to power.

In all cases, the green or green/yellow grounding wire must be

connected to the grounding pin of the plug, usually identified by a

green screw.

Attachment plugs must comply with the Standard for Attachment

Plugs and Receptacles, UL498.

The product is considered acceptable for use only when an

attachment plug as specified is properly attached to the supply cord.

POWER CORD REPLACEMENT

Only a qualified electrician should connect the input leads to

the FLEXCUT 80. Connections should be made in

accordance with all local and national electrical codes and

the connection diagrams. Failure to do so may result in

bodily injure or death.

If the input cord is damaged or needs to be replaced, the new cord

must be wired directly into the switch on the back of the machine.

Be sure to disconnect the cord from input power before working

on the machine. Remove the sheetmetal wraparound from the

machine, loosen the strain relief on the rear of the machine, and

loosen the three input screws on the power switch as well as the

grounding nut. Remove the old cord and replace as shown below. Be

sure to torque the phillips screws on the input power switch and the

grounding nut to 18-25 in-lbs.

ALWAYS CONNECT THE GROUNDING LUG (LOCATED INSIDE THE

MACHINE) TO A PROPER SAFETY (EARTH) GROUND.

ENGINE DRIVEN GENERATOR

For use on engine drives, keep in mind the above input draw

restrictions and the following precaution.

The FLEXCUT™ 80 can be operated on engine driven generators as

long as the 230 volt auxiliary meets the following conditions:

• The AC waveform peak voltage is below 400 volts.

• The AC waveform frequency is between 45 and 65 Hz.

Lincoln Electric Vantage®and Ranger®engine drives meet these

specifications.

Operation of the FLEXCUT™ 80 is not recommended on engine drives

not conforming to these conditions. Such combinations may

overvoltage the FLEXCUT™ 80 power source.

GAS SUPPLY REQUIREMENTS

Supply the FLEXCUT™ 80 with clean, dry, oil-free compressed air or

nitrogen. A high pressure regulator MUST be used with a compressor

or a high pressure cylinder.

Supply pressure must be between 87-110 psi (6 - 7.6 bar) with flow

rates of at least 300 SCFH or 140 SLPM.

Air supply pressure should never exceed 110

psi or damage to the machine may occur!

The FLEXCUT™ 80 contains a built-in filter but depending on the

quality of the supply, additional filtration may be required. Be aware

that shop air systems are prone to oil and moisture contamination. If

shop air is used, it must be cleaned to ISO 8573-1:2010, Class 1.4.1.

Specify dry air when using compressed cylinders. Breathing quality

air conains moisture and should not be used.

A standard nominal 5 micron inline filter is recommended, but for

optimal performance, select a pre-filter with a 3 micron absolute

rating.

CYLINDER could explode if damaged.

• Keep cylinder upright and chained to a fixed support.

• Keep cylinder away from areas where

it could be damaged.

• Never lift machine with cylinder

attached.

• Never allow the cutting torch to touch the cylinder.

• Keep cylinder away from live electrical parts.

• Maximum inlet pressure 110 psi.

WARNING

WARNING

WARNING

BLACK

RED

WHITE

GREEN

Page 14

CONNECTING THE GAS SUPPLY

Air or gas must be supplied to the FLEXCUT™ 80 with 3/8” inside

diameter tubing and a ¼” NPT quick disconnect coupler.

OUTPUT CONNECTIONS

T

orch

The FLEXCUT™ 80 is sent from the factory with a work clamp

included. The work clamp must be securely connected to the work

piece. If the work piece is painted or extremely dirty it may be

necessary to expose the bare metal in order to make a good electrical

connection.

FlexCut 80 Cut and gouge CapaCities

* Maximum cut speeds are based on results obtained from

Lincoln Electric’s laboratory testing.

Different cutting applications may alter the actual cutting

speed.

A-4

I

NSTALLATION

F

LEXCUT™ 80

MAXIMUM OUTPUT CURRENT

Mechanized Cut Capacity - Material Thickness

Recommended cut capacity at 24 ipm 3/4 in.

Recommended cut capacity at 13 ipm 1 in.

Severance capacity at 8 ipm 1-1/4 in.

Pierce Capacity - Material Thickness

Pierce capacity with programmable torch height control 3/4 in.

Pierce capacity without programmable torch height control 5/8 in.

Maximum Cut Speeds - Mild Steel *

1/4 in. 148 ipm

1/2 in. 52 ipm

3/4 in. 26 ipm

1 in. 14 ipm

1-1/4 in. 9 ipm

Gouge Capacity - Mild Steel

Metal Removal Rate - 80 Amps 19.08 lbs/hr

Page 15

B-1

O

PERATION

OPERATION

SAFETY PRECAUTIONS

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts

or electrode with skin or wet

clothing.

• Insulate yourself from work and

ground.

• Always wear dry insulating gloves.

FUMES AND GASES can be

dangerous.

• Keep your head out of fumes.

• Use ventilation or exhaust to

remove fumes from breathing zone.

WELDING, CUTTING and

GOUGING SPARKS can cause

fire or explosion

• Keep flammable material away.

• Do not weld, cut or gouge on

containers that have held combustibles.

ARC RAYS can burn.

• Wear eye, ear and body protection.

PLASMA ARC can injure

• Keep your body away from nozzle

and plasma arc.

• Operate the pilot arc with caution.

The pilot arc is capable of burning

the operator, others or even

piercing safety clothing.

Observe additional Safety Guidelines detailed in the beginning

of this manual.

GRAPHIC SYMBOLS THAT APPEAR ON THIS

M

ACHINE OR IN THIS MANUAL

WARNING

FLEXCUT™ 80

INPUT VOLTAGE

WARNING OR CAUTION

HIGH TEMPERATURE

READ INSTRUCTION

MANUAL

CUT

GAS INPUT

SINGLE PHASE

CONTINUOUS PILOT

GOUGE

POWER ON

POWER OFF

PARTS IN PLACE - CONSUMABLES

MISSING OR LOOSE

PROTECTIVE

GROUND

OUTPUT ON

GAS PURGE

A

Page 16

B-2

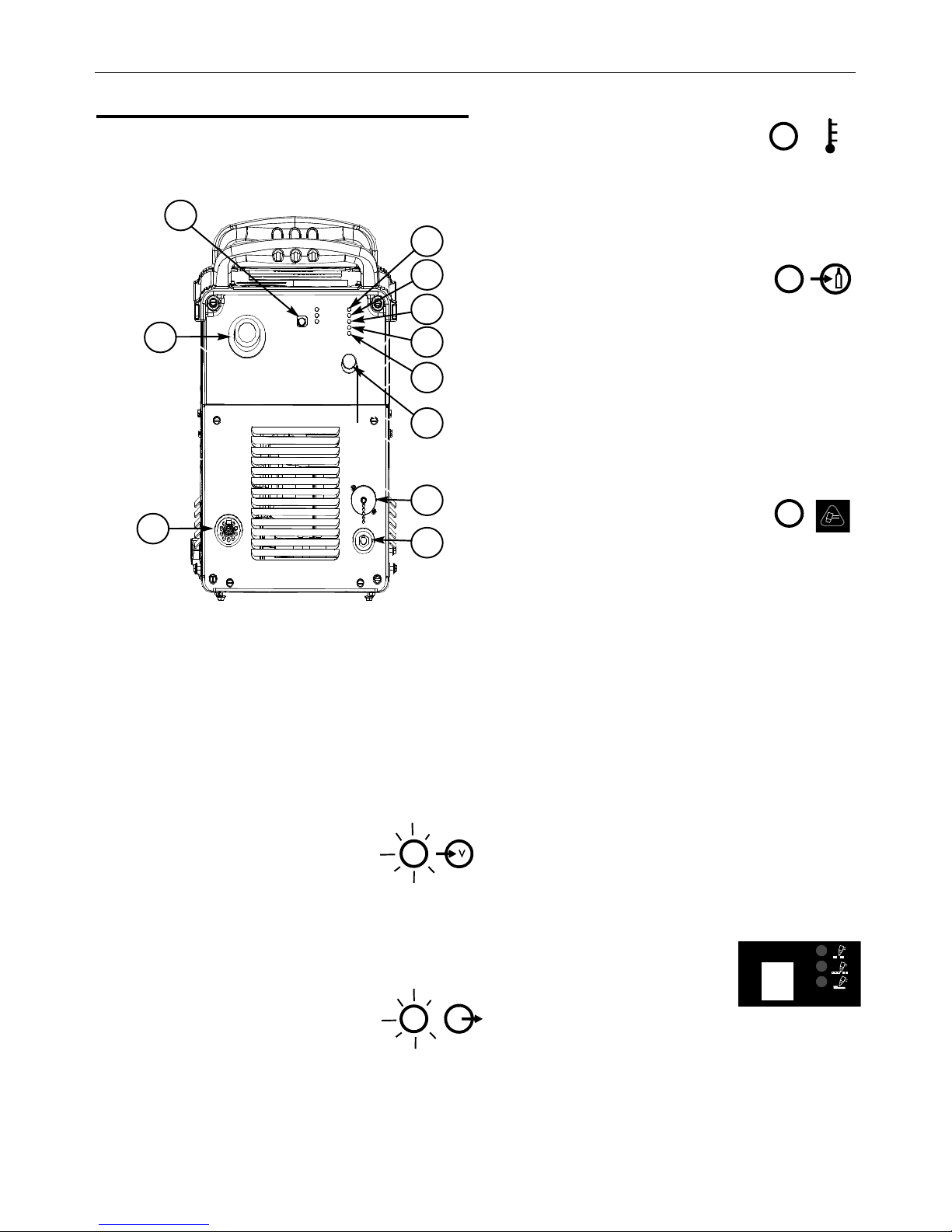

CONTROLS AND SETTINGS

FIGURE B.2

FLEXCUT™ 80 front command panel.

When the machine is turned ON, an auto-test is executed; during this

test all of the LEDs on the Control Panel light up.

1. Output Current Knob: For setting the output current used

during cutting. Refer to the Technical Specification section for

more information about the machine’s rated current range.

Air, Gas Purge: The Output Current Knob completely rotated

counterclockwise enables the air purge function.

2. Power ON/OFF green LED: Illuminates when the machine is

ON.

Blinking: Input voltage out of range condition.

The machine is disabled: When the input

voltage returns to the correct range, the

machine will restart automatically.

Note: The Fan may automatically turn OFF if the error condition

persists for more than 2 seconds.

3. Output red LED:

The cutting torch is energized.

Blinking: Internal auxiliary undervoltage

condition. The machine needs to be turned

OFF then ON again to restart.

4. Thermal yellow LED:

The machine is overheated and the output has

been disabled. This usually occurs when the

duty cycle of the machine has been exceeded. Leave

the machine ON to allow the internal components to cool.

When the thermal LED turns off, normal operation is again possible.

5. Gas Pressure yellow LED:

The Input Gas pressure is out of range. The

machine will restart automatically when a correct gas pressure is detected.

To check/adjust the primary gas pressure (see recommended

values in the Technical Specifications of this manual):

• When this LED illuminates, the machine will automatically enter

into Purge mode for 10 seconds.

• During Purge time verify and adjust the gas pressure using

the gas pressure regulator knob.

• If necessary, also verify and adjust the inlet gas pressure to

the unit.

6. Parts In Place (PIP) yellow LED:

Torch consumables are not attached correctly.

To reset the machine:

• Firmly attach the torch shielding Cup by hand. Do not over

tighten.

• After the torch is restored, the machine will restart after 5

seconds. During this time the PIP LED will blink.

Note: When the LED is blinking, if another PIP error occurs or

if the Torch Trigger pushbutton is pressed the machine will

return to the error condition: PIP LED returns to steady ON

and the restoring procedure repeats.

• When the PIP LED turns OFF the machine is ready to operate.

7. Primary Air, Gas Pressure Gauge and Regulator Knob:

Allows the regulation and monitoring of the primary air/gas

pressure.

The inlet primary air/gas pressure is limited by this pressure

regulator, set at the factory to 80 PSI (5.5 bar). To adjust the

air/gas pressure, place the machine in Purge mode.

Pull out on regulator knob and turn to adjust.

8. Cutting Operating Mode Selection: Press the pushbutton to

select the desired operating mode (the LED indicates the selected mode):

• CUT (Upper LED): for cutting or piercing

operations on a solid work piece.

• GRID (Middle LED): for cutting operations on a grid work piece.

• GOUGE (Lower LED): for removing material from a solid work

piece (removing a weld).

The Operating Mode can only be changed with the machine at

idle or during Purge or Post Flow times.

Pressing the pushbutton during Pilot Arc or Cutting will have no

effect.

FLEXCUT™ 80

O

PERATION

A

2

3

4

5

6

8

7

9

1

11

10

Page 17

B-3

O

PERATION

9. Torch Connection:

Connect handheld or machine torch.

1

0. Work Connection:

Connect cable with work clamp.

11. Remote Connection (14-pin amphenol):

Allows access to Arc Start trigger, Arc Initiated contact and raw

Arc Voltage.

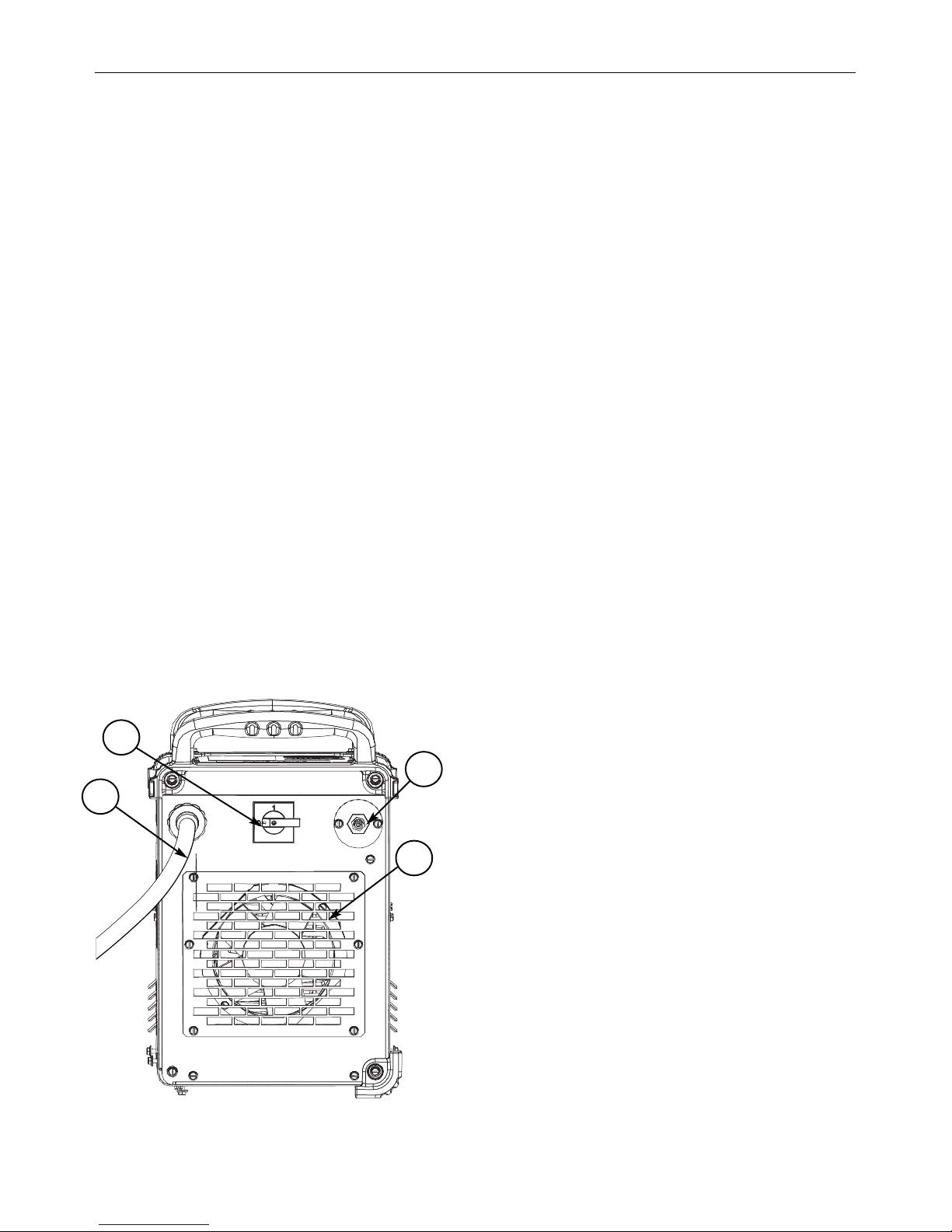

Items 12 thru 15 on the back of the

FLEXCUT™ 80 (See Figure B.3)

12. Fan: Provides machine cooling. When the machine is

switched ON, the fan runs continuously.

13. Power Switch:

Turns the input power to the machine ON/OFF.

14. Input Cord (10 ft.):

Connects the unit to input power.

15. Air or Gas Inlet (1/4” NPT Quick Connect):

Compressed air or gas connection.

FIGURE B.3

FLEXCUT™ 80

14

13

12

15

Page 18

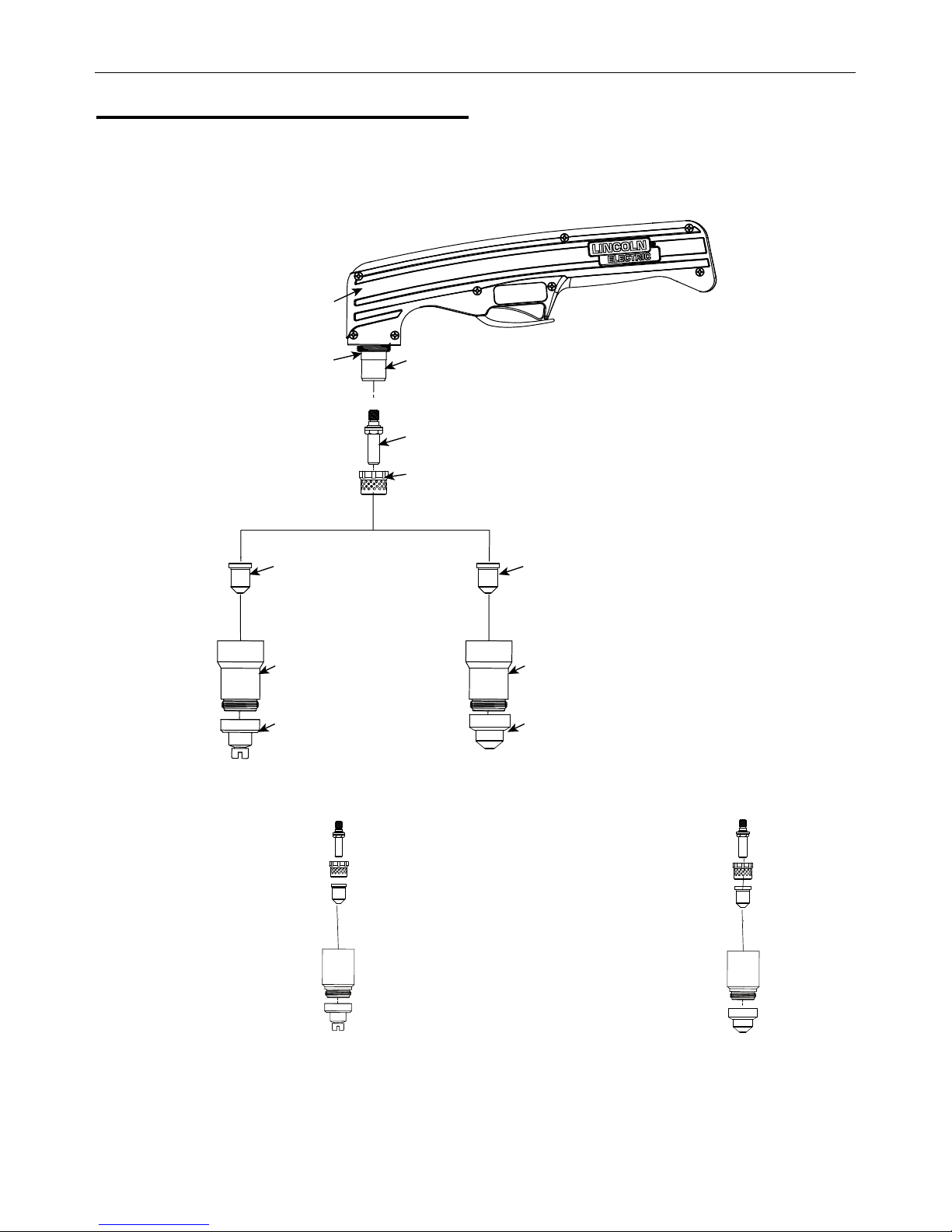

HAND CUTTING

The FLEXCUT 80 is designed for

Shielded contact. A special

insulated nozzle is used in

conjunction with a special drag

shield. Shielded contact set-ups

are for applications greater than

40 amps.

Gouging Setup:

If gouging metal and not cutting

completely through the part is required, a

special gouging nozzle is used in

conjunction with a gouge shield to

protect the nozzle from molten metal

blow back.

Refer to the torch parts decal located on

your machine or the parts pages at the

back of this manual for the specific part

numbers required for each of these

setups.

ALWAYS USE GENUINE LINCOLN

ELECTRIC ELECTRODES, NOZZLES,

AND EXPENDABLE PARTS FOR THE BEST CUTTING

PERFORMANCE.

H

andle

S28175-1

H

ead

S28176-1

I

nsulation Kit

S28176-4

Electrode

K

P4141-1

Retaining Cap

KP4141-8

Drag Shield

KP4141-14 (40A)

KP4141-15 (80A)

Swirl Ring

KP4141-9

Nozzle

40A - KP4141-4

60A - KP4141-5

80A - KP4141-6

Retaining Cap

KP4141-8

Gouge Shield

KP4141-17

Gouge Nozzle

KP4141-18 (80A)

Standard Gouging

B-4

O

PERATION

FLEXCUT™ 80

Electrode

Swirl Ring

Shielded Nozzle

Retaining Cap

Drag Shield

Shielded Contact

Electrode

Swirl Ring

Gouge Nozzle

Retaining Cap

Gouge Shield

Gouging

TORCH PART CONFIGURATIONS

Different hand held torch configurations are available depending on the cutting or gouging application.

Page 19

O

PERATION

Hand Cutting Process

The air plasma cutting process uses air or nitrogen as a cutting gas

and to cool the torch.

The FLEXCUT™ 80 provides constant current at the set value,

i

ndependent of the plasma arc length.

W

hen preparing to operate, make sure you have all materials needed

to complete the job and have taken all safety precautions. Install the

machine as instructed in this manual and remember to attach the

work clamp to the work piece.

• With the machine switched OFF, prepare the torch with the

consumables adequate to the desired process (CUT / GRID /

GOUGE).

• Connect the Torch and the work cable to the machine.

• Turn ON the Power Switch on the back of the machine; the Input

Power LED on the front panel will illuminate. The unit is now

ready to operate.

• Verify correct gas pressure using the Gas Purge function.

• Select the desired process using Operating Mode pushbutton.

• Set the desired cutting current using the Output Current knob.

Once the process is completed releasing the torch trigger will

cause the plasma arc to turn off. The gas flow will continue,

allowing the torch to cool.

• Pilot Arc

- The air will flow for a preflow time of 2 seconds and the pilot arc

will start. (Exceptions: after a thermal, the initial trigger will be

ignored. This is a safety feature to prevent the pilot arc from

firing unexpectedly. The other exception is if the machine is in

postflow, then the preflow time is skipped and the pilot arc will

start immediately.)

- The pilot arc will run for 5.0 seconds and shut off unless the arc

is brought in contact with the work and the arc is transferred.

Avoid excessive pilot arc time by transferring the arc to the

workpiece quickly. This will extend consumable life.

- When the arc is brought within 1/8” - 1/4" from the work piece

the arc will transfer, the current will ramp to the setting on the

control panel, and the cut can last indefinitely (or until the duty

cycle of the FLEXCUT™ 80 is exceeded).

•

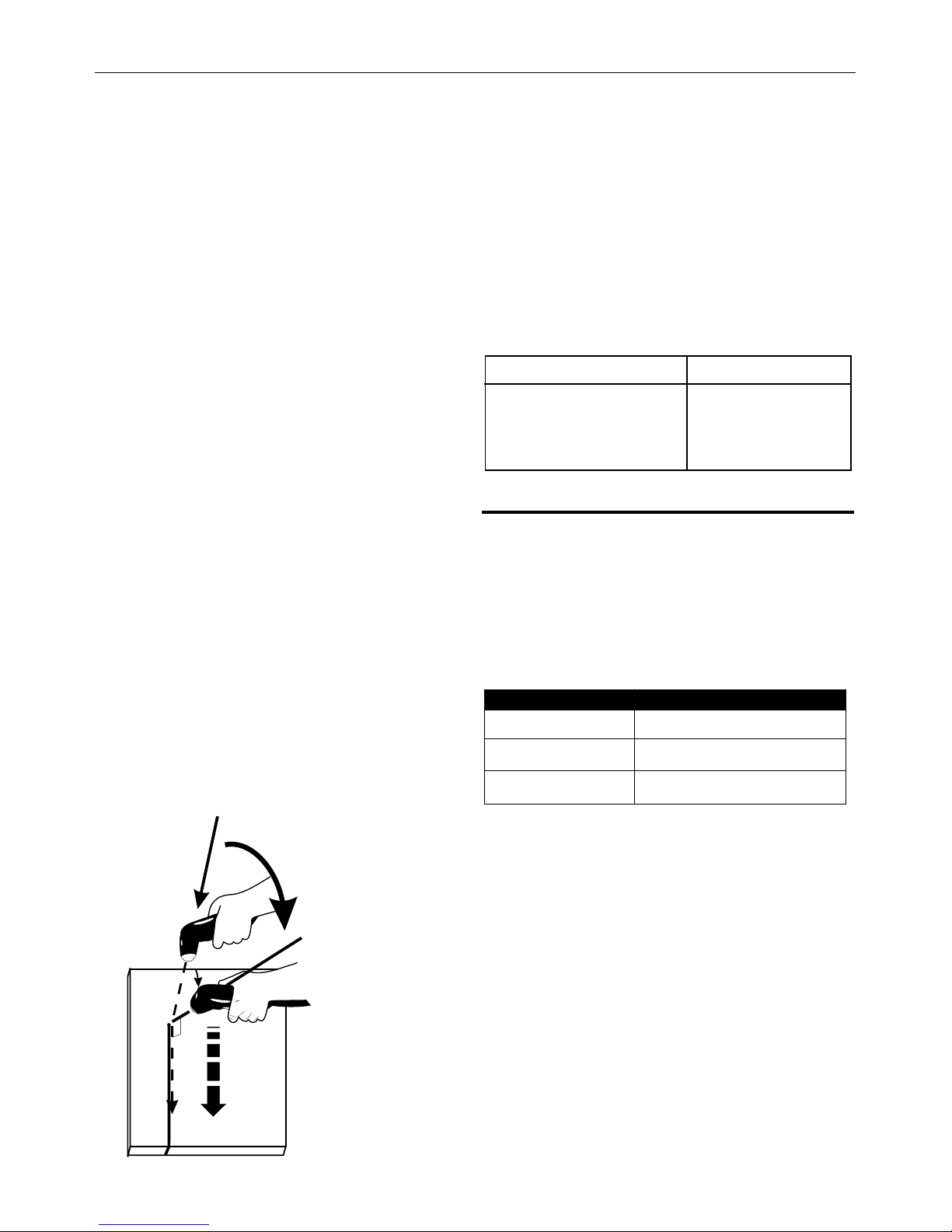

Pierce the work piece by slowly lowering the torch onto the metal

at a 30º angle away from the operator. This will blow the dross

away from the torch tip. Slowly rotate the torch to vertical

position as the arc becomes deeper.

• Keep moving while cutting. Cut at a steady speed without

p

ausing. Maintain the cutting speed so that the arc lag is 10° to

20° behind the travel direction.

• Use a 5° - 15° leading angle in the direction of the cut.

• Finish the cut to be made and release the trigger.

• If the dross is difficult to remove, reduce the cutting speed. High

speed dross is more difficult to remove than low speed dross.

•

The Post Flow time is proportional to the selected cutting

current and it is divided into 4 time ranges:

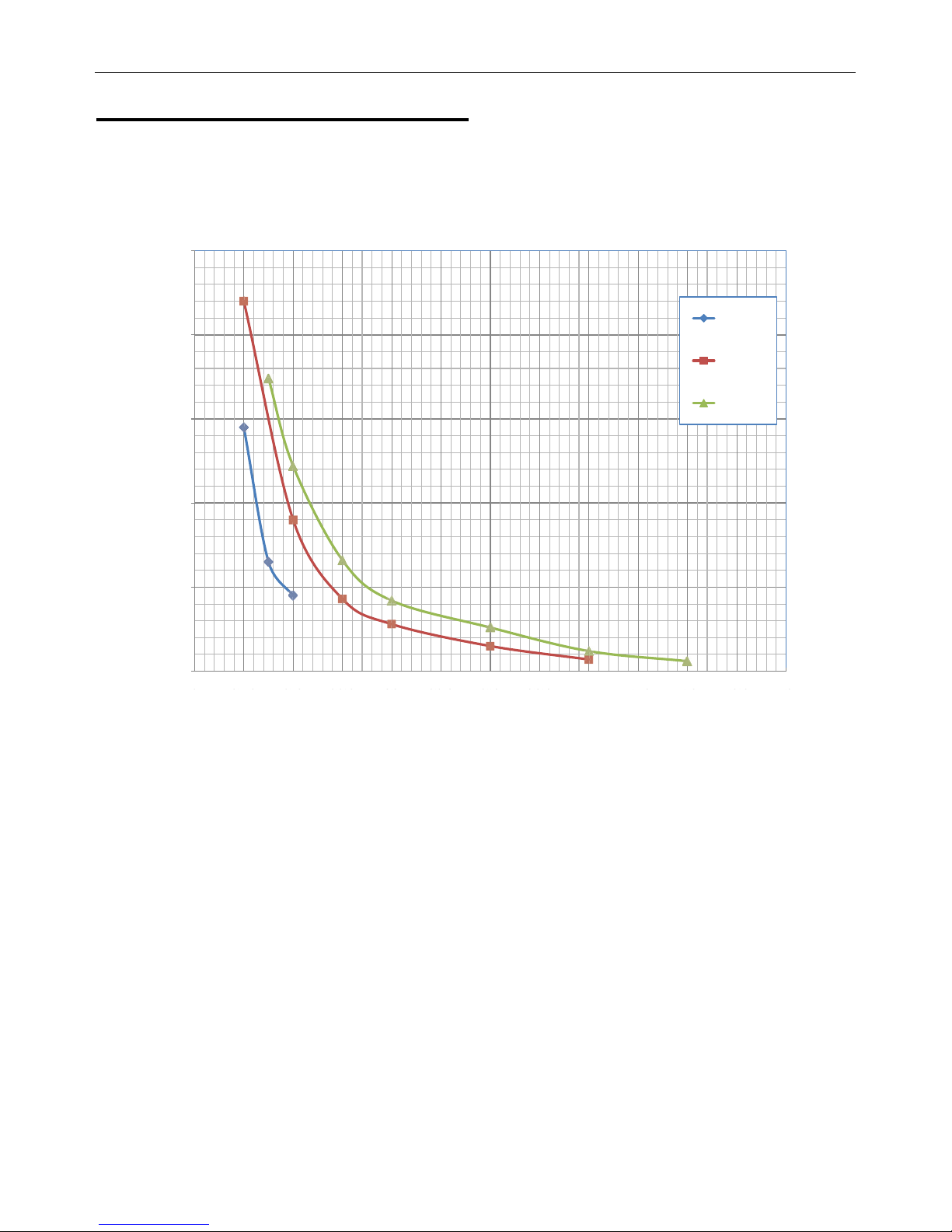

Hand Cutting CHarts

The cutting charts shown on the following pages are intended to give

the operator the best starting point to use when making a cut on a

particular material type and thickness. Small adjustments may have

to be made to achieve the best cut. Also, remember that the arc

voltage must be increased as the electrode wears in order to maintain

the correct cutting height.

FLEXCUT™ 80

3030

00

VERVERTICAL ANGLETICAL ANGLE

FOR CUTTINGFOR CUTTING

CUT

90

0

TORCH AT 300ANGLE

TO PIERCE

ROTATE TO

90

0

ANGLE TO CUT

B-5

Selected Cutting Current Post Flow Time

Less than 30A 15 seconds

Between 30A and 40A 20 seconds

Between 40A and 50A 25 seconds

Greater than 50A 30 seconds

MATERIAL PAGE

MILD STEEL B-6

STAINLESS STEEL B-7

ALUMINUM B-8

Page 20

B-6

O

PERATION

Mild steel Cut CHarts F

lexCut 80; lC105 Hand torCH

TOMAHAWKTM1500

##

##

##

##

#

### #### # # #

%!!"

%#!"

##

##

##

##

#

### #### # # #

+

'&$%"!

'&$%"(

'&$%")

-=E*5/<DC"B:A@")?:>'9=<+:9;:80094587,

##

##

##

##

#

### #### # # #

$!!"

$#!"

5#04&0

73621

##

##

##

##

#

### #### # # #

!"

#!"

##

##

##

##

#

### #### # # #

!" $%#"!& %#"!& '(#"!& #"!& )%#"!& (#"!& *(#"!& $" $%#"$& %#"$& '(#"$& #"$&

3/21''0./-,+*

*Above listed speeds provide best cut quality - best cut angle, least dross, best cut surface finish.

Page 21

B-7

O

PERATION

s

tainless steel Cut CHarts -

FlexCut 80; lC105 Hand torCH

TOMAHAWKTM1500

))

)

))) )))) ) ) "

&$!"

&%$"

#!!"

##$"

))

)

))) )))) ) ) "

"

/"+!",-.

/")!",-.

/"*!",-.

$7A!/&3@?;>5=<;:958(273"52654''2-(('4 -

))

)

))) )))) ) ) "

%$"

&!!"

&#$"

/)'-.'

1,0+*

))

)

))) )))) ) ) "

!"

#$"

$!"

))

)

))) )))) ) ) "

!" &#$"!' #$"!' (%$"!' $"!' )#$"!' %$"!' *%$"!' &" &#$"&' #$"&'

,&+*(('%&$#"!

*Above listed speeds provide best cut quality - best cut angle, least dross, best cut surface finish.

Page 22

B-8

O

PERATION

aluMinuM Cut CHarts F

lexCut 80; lC105 Hand torCH

TOMAHAWKTM1500

))

)) )))) ) ) )

%#!"

&!!"

&#!"

/)'-.'

1*+0 0"

2

))

)) )))) ) ) )

"

/"+!",-.

/")!",-.

/"*!",-.

$9C!/&8BA=@6?>=<;6:(798"674654423

))

)) )))) ) ) )

$%#"$' %#"$'

))

)) )))) ) ) )

$#!"

%

!!"

* 0"

))

)) )))) ) ) )

!"

#!"

$!!"

))

)) )))) ) ) )

))

)) )))) ) ) )

))

)) )))) ) ) )

*(#"!' $"

))

)) )))) ) ) )

!" $%#"!' %#"!' &(#"!' #"!' )%#"!' (#"!'

,&+*(('%&$#"!

When using a water table and cutting aluminum under water or with

water touching the underside at the aluminum plate, hydrogen gas is

produced. This hydrogen gas may collect under the plate and explode

during the cutting process. Make sure the water table is properly

aerated to help prevent the accumulation of hydrogen gas.

WARNING

*Above listed speeds provide best cut quality - best cut angle, least dross, best cut surface finish.

Page 23

B-9

O

PERATION

Gouging Process

Gouging is a process used to remove material without cutting entirely

through the workpiece. The FLEXCUT™ 80 has the capability of

p

erforming plasma gouging with the proper consumables attached to

the torch. In general, gouging consumables provide a wider plasma

arc compared to a cutting arc. As the material melts, it is blown

forward by the pressurized gas coming out of the torch. The dross will

land on the surface of the workpiece and can easily be removed after

t

he gouging process is complete.

Applications:

Removing weld imperfections – cracks, porosity, inclusions, etc.

Back gouging for welding preparation

Removal of temporary fit up methods – tack welds, bracketing, etc.

Technique:

Hold the torch at a 45º angle to the workpiece. Pull the torch trigger

to start the gouging arc. As the material is removed move the torch

forward to continue removing material. When the desired amount of

material has been removed, release the torch trigger to stop the

gouging process.

Typically, the larger the angle between the torch and the workpiece,

the deeper and slower the gouging. As the torch angle is decreased,

less material is removed and the travel speeds can be increased.

Keeping the torch fixed while moving forward will remove a straight

line of material. Using a side-to-side, weaving motion will remove a

wider area of material. The output of the FLEXCUT™ 80 can also be

increased or decreased to control the amount of material being

removed. Most users tend to maximize the output in order to remove

the most material in a short amount of time.

General Recommendations

• Follow safety precautions as printed throughout this operating

manual and on the machine.

• Where possible, start the cut from the edge of the work piece.

(This helps in longevity of consumable life.)

• If piercing is required, slowly lower the torch at an angle of about

30° to blow the dross away from the torch tip and slowly rotate

the torch to a vertical position as the arc becomes deeper. This

process will blow a lot of molten metal and dross. Be careful!

Blow the dross away from the torch, the operator and any

flammable objects.

• The nozzle should not be dragged on the metal surface. A drag

shield is provided to maintain a consistant torch height. Refer to

Toch Parts Configurations in this Section.

• Clean spatter and scale from the nozzle frequently.

• Avoid unnecessary pilot arc starts as this will reduce consumable

life. The pilot arc should only be fired as a means to transfer the

arc to the work piece.

ELECTRIC SHOCK CAN KILL.

• Turn off machine at the disconnect switch

on the rear of the machine before tightening,

c

leaning or replacing consumables.

• During operation, if the “Parts in Place” Yellow LED turns on:

- Turn OFF the machine. Allow torch to cool.

- Check the assembly of the torch consumables. If they are not

properly in place, the machine will not start. Make sure that

the shield cup is hand tight. Do not use pliers or over tighten.

- Check the conditions on the inside of the nozzle. If debris has

collected, rub the inside of the nozzle to remove any oxide

layer that may have built up. Refer to "Suggestions for Extra

Utility from the FLEXCUT™ 80 system.”

- Check the condition of the electrode. If the end has a craterlike appearance, replace it along with the nozzle. The

maximum wear depth of the electrode is approximately .060.”

A green and erratic arc will indicate definite electrode failure

and the electrode should be replaced immediately.

- Replace the nozzle when the orifice exit is eroded away or oval

shaped.

- After the problem is found, or if there is nothing apparently

wrong, the machine may need to be reset by turning the power

switch OFF and then ON again. (It is possible for electrical

noise to trip the safety circuit on rare occasions. This should

not be a regular occurrence.)

• If the machine does not reset or continues to trip, consult the

Troubleshooting Section.

WARNING

FLEXCUT™ 80

Page 24

B-10

O

PERATION

FLEXCUT™ 80

MECHANIZED CUTTING

Mechanized Torch Installation

It is recommended that the FLEXCUT™ 80 mechanized torch be

i

nstalled on a positioner with an arc voltage control capable of

maintaining the cutting arc voltage within 1 volt. The positioner must

be rigid to ensure cut quality and a torch collision sensor is highly

recommended.

Installing the Mechanized Torch Consumables

To install the torch parts, perform the following

steps:

Note: Do not over tighten the consumables! Only tighten until the

parts are seated properly.

1. Inspect the threads on the torch body and retaining cap and

clean as necessary.

2. Install the electrode (1) into the torch body using a standard 3/8"

socket. Do not over tighten! 11-13 in-lbs is recommended.

Torque must never exceed 15 in-lbs.

3. Thread the shield cap (5) onto the retaining cap assembly. (4)

4. Insert the swirl ring (2) into the nozzle. (3)

5. Place the swirl ring / nozzle assembly into the retaining cap.

6. Thread and tighten the retaining cap assembly onto the torch

body. (6)

Removing the Torch Consumables

To remove the torch consumables, perform the

following steps:

1. Remove the retaining cap from the torch.

2. Remove the swirl ring and nozzle from the retaining cap.

3. Separate the shield cap from retaining cap.

4. Remove the electrode from the torch body using the 3/8" socket.

5. Remove the swirl ring from the nozzle.

Contaminants such as dirt, metallic dust, oil and moisture present on

the surface of the electrode and/or torch body can cause electrical

arcing between these components and ultimately result in failure of

the torch and consumables. In order to avoid damaging the torch

and/or consumables, adhere to the following guidelines:

1. Ensure that the air supplied to the torch does not contain contaminants such as debris, moisture and oil.

2. Ensure that the torch cathode body and electrode body are clean

prior to assembling the consumables into the torch. Wipe away any

contaminants with a dry, lint free cloth.

3. Be sure that the consumables are properly tightened when

installing them into the torch to ensure that there is no gap

between the electrode body and cathode body. Check the

installation of the consumables before the start of each work shift

and frequently during each work shift to ensure that the parts have

not become loose as a result of normal operation.

4. Inspect the surfaces of the cathode body and electrode body to

ensure no contaminants have collected during operation.

(Reference Figure Below)

WARNING

(1) ELECTRODE

BK12849-1

(2) SWIRL RING

BK12849-9

(4) RETAINING CAP

BK12849-10

(5) SHIELD CAP

40A - BK12849-13

60-80A - BK12849-2

(3) NOZZLE

40A - BK12849-4

60A - BK12849-5

80A - BK12849-6

CATHODE BODY

ELECTRODE BODY

Page 25

B-11

O

PERATION

Making a Cut

Setting up a Cut

Use the following procedure to make a cut with the

F

LEXCUT™ 80.

1

. Using the charts, determine the proper torch parts and cutting

conditions for the material being cut.

2. Install the proper consumables into the torch.

3. Turn the power switch to the ON position to apply power to the

FLEXCUT™ 80. The Power ON/OFF Status led on the front panel

should illuminate.

4. Turn the Output Current knob fully CCW and adjust the regulator

pressure to 80 psi for 25’ torches and 90 psi for 50’ torches while

gas is flowing through the torch. Return the knob to the correct

current setting per the cut chart.

5. Set the Cutting Operating Mode to CUT (Upper LED), as previously

described in the Controls & Settings section.

6. The cutting operation is initiated after a start signal is received

from the CNC. The arc should establish approximately 2 seconds

after application of the start command. Throughout the cut, the red

OUTPUT LED on the front panel should be illuminated to indicate

that current is flowing through the torch. The cutting operation is

terminated when the start signal is removed. At the completion of a

cut, gas flow through the torch will continue for approximately 20

seconds, depending on the cutting current.

Machine Interface

The FLEXCUT™ 80 comes standard with a machine interface.

Interface signals provided include: arc start, arc initiated, and arc

voltage. These signals are accessible through the 14 pin connector on

t

he case front.

A

rc Start:

The Arc Start circuit allows for triggering of the power source to

commence cutting. This circuit can be accessed through pins K and

M of the 14 pin connector. The circuit has a 15 VDC nominal open

circuit voltage and requires a dry contact closure to activate.

Arc Initiated:

The Arc Initiated circuit provides information as to when a cutting arc

has transferred to the work piece. This circuit can be accessed

through pins I and J of the 14 pin connector. The circuit provides a

dry contact closure when the arc has transferred. Input to this circuit

should be limited to 0.3 A for either 120VAC or 30VDC.

Arc Voltage:

The Arc Voltage circuit can be used for activating a torch height

control. This circuit can be accessed through pins D and G of the 14

pin connector. The circuit provides full electrode to work arc voltage

(no voltage divider, 270VDC maximum).

Users wishing to utilize the Machine Interface can order a K867

Universal Adapter (please adhere to the pin locations stated above) or

manufacture a 14 pin connector cable assembly.

FLEXCUT™ 80

14-PIN BOX RECEPTACLE, FRONT VIEW

J

I

H

N

G

F

E

D

C

L

A

rc Start

Arc Voltage

A

rc Initiated

M

K

Page 26

B-12

O

PERATION

MeCHanized Cutting CHarts

The cutting charts shown on the following pages are intended to give

t

he operator the best starting point to use when making a cut on a

particular material type and thickness. Small adjustments may have

to be made to achieve the best cut. Also, remember that the arc

voltage must be increased as the electrode wears in order to maintain

the correct cutting height.

FLEXCUT™ 80

C

URRENT

P

AGE

40 AMPS B-10

60 AMPS B-11

80 AMPS B-12

Page 27

B-13

FLEXCUT™ 80

O

PERATION

## # #

// ///// / // ///// / //// /

#

###

###

// /// ///////

## # #

// ///// / // ///// / //// /

#

###

###

// /// ///////

## # #

// ///// / // ///// / //// /

#

###

###

// /// ///////

%%

@.>'

:9:*5

#D,.:)C5

## # #

// ///// / // ///// / //// /

#

###

###

// /// ///////

!" #$ %

45 68967 67

44 64967 67

89 6=>67 87

'':908,

//'<+(,);0*,5':8*

## # #