Page 1

Operator’s Manual

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

IM10300-A | Issue D ate Nov-16

© Lincoln Global, Inc. All Rights Reserved.

For use with machines having Code Numbers:

12478

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

FlexCut™125

Page 2

THANK YOU FOR SELECTING

A QUALITY PRODUCT BY

LINCOLN ELEC TRIC.

PLEASE EXAMINE CARTON AND EQUIPMENT FOR

DAMAGE IMMEDIATELY

When this equipment is shipped, title passes to the purchaser

upon receipt by the carrier. Consequently, claims for material

damaged in shipment must be made by the purchaser against the

transportation company at the time the shipment is received.

SAFETY DEPENDS ON YOU

Lincoln arc welding and cutting equipment is designed and built

with safety in mind. However, your overall safety can be increased

by proper installation ... and thoughtful operation on your part.

DO NOT INSTALL, OPERATE OR REPAIR THIS EQUIPMENT

WITHOUT READING THIS MANUAL AND THE SAFETY

PRECAUTIONS CONTAINED THROUGHOUT. And, most importantly,

think before you act and be careful.

WARNING

This statement appears where the information must be followed

exactly to avoid serious personal injury or loss of life.

CAUTION

This statement appears where the information must be followed

to avoid minor personal injury or damage to this equipment.

KEEP YOUR HEAD OUT OF THE FUMES.

DON’T get too close to the arc.

se corrective lenses if necessary

U

to stay a reasonable distance

away from the arc.

READ and obey the Safety Data

Sheet (SDS) and the warning label

that appears on all containers of

welding materials.

USE ENOUGH VENTILATION or

exhaust at the arc, or both, to

keep the fumes and gases from

your breathing zone and the general area.

IN A LARGE ROOM OR OUTDOORS, natural ventilation may be

adequate if you keep your head out of the fumes (See below).

USE NATURAL DRAFTS or fans to keep the fumes away

from your face.

If you de velop unusual symptoms, see your supervisor.

Perhaps the welding atmosphere and ventilation system

should be checked.

WEAR CORRECT EYE, EAR &

BODY PROTECTION

PROTECT your eyes and face with welding helmet

properly fitted and with proper grade of filter plate

(See ANSI Z49.1).

PROTECT your body from welding spatter and arc

flash with protective clothing including woolen

clothing, flame-proof apron and gloves, leather

leggings, and high boots.

PROTECT others from splatter, flash, and glare

with protective screens or barriers.

IN SOME AREAS, protection from noise may be appropriate.

BE SURE protective equipment is in good condition.

Also, wear safety glasses in work area

AT ALL TIMES.

SPECIAL SITUATIONS

DO NOT WELD OR CUT containers or materials which previously

had been in contact with hazardous substances unless they are

properly cleaned. This is extremely dangerous.

DO NOT WELD OR CUT painted or plated parts unless special

precautions with ventilation have been taken. They can release

highly toxic fumes or gases.

Additional precautionary measures

PROTECT compressed gas cylinders from excessive heat,

mechanical shocks, and arcs; fasten cylinders so they cannot fall.

BE SURE cylinders are never grounded or part of an

electrical circuit.

REMOVE all potential fire hazards from welding area.

ALWAYS HAVE FIRE FIGHTING EQUIPMENT READY FOR

IMMEDIATE USE AND KNOW HOW TO USE IT.

Safety 01 of 04 - 06/15/2016

Page 3

SECTION A:

WARNINGS

CALIFORNIA PROPOSITION 65 WARNINGS

Diesel Engines

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and other

reproductive harm.

Gasoline Engines

The engine exhaust from this product contains chemicals known

to the State of California to cause cancer, birth defects, or other

reproductive harm.

ARC WELDING CAN BE HAZARDOUS. PROTECT

YOURSELF AND OTHERS FROM POSSIBLE SERIOUS

INJURY OR DEATH. KEEP CHILDREN AWAY.

PACEMAKER WEARERS SHOULD CONSULT WITH

THEIR DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For

additional safety information, it is strongly recommended

that you purchase a copy of “Safety in Welding & Cutting ANSI Standard Z49.1” from the American Welding Society,

P.O. Box 351040, Miami, Florida 33135 or CSA Standard

W117.2-1974. A Free copy of “Arc Welding Safety” booklet

E205 is available from the Lincoln Electric Company,

22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

BE SURE THAT ALL INSTALLATION, OPERATION,

MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

SAFETY

1.d. Keep all equipment safety guards, covers

and devices in position and in good repair.

Keep hands, hair, clothing and tools away

from V-belts, gears, fans and all other

moving parts when starting, operating or

repairing equipment.

1.e. In some cases it may be necessary to remove safety guards to

perform required maintenance. Remove guards only when

necessary and replace them when the maintenance requiring

heir removal is complete. Always use the greatest care when

t

working near moving parts.

1.f. Do not put your hands near the engine fan. Do not attempt to

override the governor or idler by pushing on the throttle control

rods while the engine is running.

1.g. To prevent accidentally starting gasoline engines while turning

the engine or welding generator during maintenance work,

disconnect the spark plug wires, distributor cap or magneto wire

as appropriate.

1.h. To avoid scalding, do not remove the radiator

pressure cap when the engine is

hot.

ELECTRIC AND

MAGNETIC FIELDS MAY

BE DANGEROUS

2.a. Electric current flowing through any conductor

causes localized Electric and Magnetic Fields (EMF).

Welding current creates EMF fields around welding cables

and welding machines

FOR ENGINE POWERED

EQUIPMENT.

1.a. Turn the engine off before troubleshooting

and maintenance work unless the

maintenance work requires it to be running.

1.b. Operate engines in open, well-ventilated

areas or vent the engine exhaust fumes outdoors.

1.c. Do not add the fuel near an open flame

welding arc or when the engine is running.

Stop the engine and allow it to cool before

refueling to prevent spilled fuel from

vaporizing on contact with hot engine parts

and igniting. Do not spill fuel when filling

tank. If fuel is spilled, wipe it up and do not start engine until

fumes have been eliminated.

2.b. EMF fields may interfere with some pacemakers, and

welders having a pacemaker should consult their physician

before welding.

2.c. Exposure to EMF fields in welding may have other health effects

which are now not known.

2.d. All welders should use the following procedures in order to

minimize exposure to EMF fields from the welding circuit:

2.d.1. Route the electrode and work cables together - Secure

them with tape when possible.

2.d.2. Never coil the electrode lead around your body.

2.d.3. Do not place your body between the electrode and work

cables. If the electrode cable is on your right side, the

work cable should also be on your right side.

2.d.4. Connect the work cable to the workpiece as close as possible to the area being welded.

2.d.5. Do not work next to welding power source.

Safety 02 of 04 - 06/15/2016

Page 4

SAFETY

ELECTRIC SHOCK

CAN KILL.

3.a. The electrode and work (or ground) circuits are

electrically “hot” when the welder is on. Do

not touch these “hot” parts with your bare skin or wet clothing.

Wear dry, hole-free gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full area

f physical contact with work and ground.

o

In addition to the normal safety precautions, if

welding must be performed under electrically

hazardous conditions (in damp locations or while

wearing wet clothing; on metal structures such as

floors, gratings or scaffolds; when in cramped

positions such as sitting, kneeling or lying, if there

is a high risk of unavoidable or accidental contact

with the workpiece or ground) use the following

equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel, welding head, nozzle or semiautomatic welding

gun are also electrically “hot”.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection should

be as close as possible to the area being welded.

3.e. Ground the work or metal to be welded to a good electrical (earth)

ground.

3.f. Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Never simultaneously touch electrically “hot” parts of electrode

holders connected to two welders because voltage

two can be the total of the open circuit voltage of both

welders.

3.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

between the

ARC RAYS CAN BURN.

4.a. Use a shield with the proper filter and cover plates to protect your

eyes from sparks and the rays of the arc when welding or

observing open arc welding. Headshield and filter lens should

conform to ANSI Z87. I standards.

4.b. Use suitable clothing made from durable flame-resistant material

to protect your skin and that of your helpers from the arc rays.

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

FUMES AND GASES

CAN BE DANGEROUS.

5.a. Welding may produce fumes and gases

hazardous to health. Avoid breathing these fumes and gases.

When welding, keep your head out of the fume. Use enough

ventilation and/or exhaust at the arc to keep fumes and gases

away from the breathing zone. When welding hardfacing

(see instructions on container or SDS) or on lead

or cadmium plated steel and other metals or

coatings which produce highly toxic fumes, keep

exposure as low as possible and within applicable

OSHA PEL and ACGIH TLV limits using local

exhaust or mechanical ventilation unless exposure

assessments indicate otherwise. In confined

spaces or in some circumstances, outdoors, a

respirator may also be required. Additional

precautions are also required when welding

on galvanized steel.

5. b. The operation of welding fume control equipment is affected by

various factors including proper use and positioning of the

equipment, maintenance of the equipment and the specific

welding procedure and application involved. Worker exposure

level should be checked upon installation and periodically

thereafter to be certain it is within applicable OSHA PEL and

ACGIH TLV limits.

5.c. Do not weld in locations near chlorinated hydrocarbon vapors

coming from degreasing, cleaning or spraying operations. The

heat and rays of the arc can react with solvent vapors to form

phosgene, a highly toxic gas, and other irritating products.

3.j. Also see It ems 6.c. and 8.

5.d. Shielding gases used for arc welding can displace air and

cause

injury or death. Always use enough ventilation, especially in

confined areas, to insure breathing air is safe.

5.e. Read and understand the manufacturer’s instructions for this

equipment and the consumables to be used, including the

Safety Data Sheet (SDS) and follow your employer’s safety

practices. SDS forms are available from your welding

distributor or from the manufacturer.

5.f. Also see item 1.b.

Safety 03 of 04 - 06/15/2016

Page 5

SAFETY

WELDING AND CUTTING

SPARKS CAN CAUSE

FIRE OR EXPLOSION.

6.a. Remove fire hazards from the welding area. If

this is not possible, cover them to prevent the welding sparks

rom starting a fire. Remember that welding sparks and hot

f

materials from welding can easily go through small cracks and

openings to adjacent areas. Avoid welding near hydraulic lines.

Have a fire extinguisher readily available.

6.b. Where compressed gases are to be used at the job site, special

precautions should be used to prevent hazardous situations.

Refer to “Safety in Welding and Cutting” (ANSI Standard Z49.1)

and the operating information for the equipment being used.

6.c. When not welding, make certain no part of the electrode circuit is

touching the work or ground. Accidental contact can cause

overheating and create a fire hazard.

6.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures

will not cause flammable or toxic vapors from substances inside.

They can cause an explosion even though they have been

“cleaned”. For information, purchase “Recommended Safe

Practices for the Preparation for Welding and Cutting of

Containers and Piping That Have Held Hazardous Substances”,

AWS F4.1 from the American Welding Society

(see address above).

6.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

6.f. Sparks and spatter are thrown from the welding arc. Wear oil free

protective garments such as leather gloves, heavy shirt, cuffless

trousers, high shoes and a cap over your hair. Wear ear plugs

when welding out of position or in confined places. Always wear

safety glasses with side shields when in a welding area.

6.g. Connect the work cable to the work as close to the welding area

as practical. Work cables connected to the building framework or

other locations away from the welding area increase the

possibility of the welding current passing through lifting chains,

crane cables or other alternate circuits. This can create fire

hazards or overheat lifting chains or cables until they fail.

6.h. Also see item 1.c.

CYLINDER MAY EXPLODE IF

DAMAGED.

7.a. Use only compressed gas cylinders containing

the correct shielding gas for the process used

and properly operating regulators designed for

the gas and pressure used. All hoses, fittings,

tc. should be suitable for the application and

e

maintained in good condition.

7.b. Always keep cylinders in an upright position securely chained to

an undercarriage or fixed support.

7.c. Cylinders should be located:

• Away from areas where they may be struck or subjected

to physical damage.

• A safe distance from arc welding or cutting operations

and any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode holder or any other

electrically “hot” parts to touch a cylinder.

7.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. Valve protection caps should always be in place and hand tight

except when the cylinder is in use or connected for use.

7.g. Read and follow the instructions on compressed gas cylinders,

associated equipment, and CGA publication P-l, “Precautions for

Safe Handling of Compressed Gases in Cylinders,” available from

the Compressed Gas Association, 14501 George Carter Way

Chantilly, VA 20151.

FOR ELECTRICALLY

POWERED EQUIPMENT.

8.a. Turn off input power using the disconnect

switch at the fuse box before working on

the equipment.

8.b. Install equipment in accordance with the U.S. National Electrical

Code, all local codes and the manufacturer’s recommendations.

6.I. Read and follow NFPA 51B “Standard for Fire Prevention During

Welding, Cutting and Other Hot Work”, available from NFPA, 1

Batterymarch Park, PO box 9101, Quincy, MA 022690-9101.

6.j. Do not use a welding power source for pipe thawing.

8.c. Ground the equipment in accordance with the U.S. National

Electrical Code and the manufacturer’s recommendations.

Refer to

http://www.lincolnelectric.com/safety

for additional safety information.

Safety 04 of 04 - 06/15/2016

Page 6

SAFETY

General Precautions

Whereas plasma cutting has been used safely for years, it does

r

equire certain precautions to ensure the safety of the operator and

other people around the equipment. The following safety information

must be provided to each person who will operate, observe, perform

maintenance, or work in close proximity to this piece of equipment.

Installation, operation, and repairs made to the system should only be

performed by qualified personnel. The system makes use of both A.C.

and D.C. circuitry for operation. Fatal shock hazard does exist.

Exercise extreme caution while working on the system. Safety decals

On the power supply should not be removed.

ULTRAVIOLET RADIATION

PROTECTION

Plasma cutting produces ultraviolet radiation similar to a welding arc.

This ultraviolet radiation can cause skin and eye burns. For this

reason, it is essential that proper protection be worn. The eyes are

best protected by using safety glasses or a welding helmet with an

AWS No. 12 shade or ISO 4850 No. 13 shade, which provides

protection up to 400 amperes. All exposed skin areas should be

covered with flame-retardant clothing. The cutting area should also

be prepared in such a way that ultraviolet light does not reflect. Walls

and other surfaces should be painted with dark colors to reduce

reflected light. Protective screens or curtains should be installed to

protect additional workers in the area from ultraviolet radiation.

NOISE PROTECTION

The system generates high noise levels while cutting. Depending on

the size of the cutting area, distance from the cutting torch, and arc

current cutting level, acceptable noise levels may be exceeded.

Proper ear protection should be used as defined by local or national

codes.

TOXIC FUME PREVENTION

Care should be taken to ensure adequate ventilation in the cutting

area. Some materials give off toxic fumes that can be harmful or fatal

to people in the vicinity of the cutting area. Also, some solvents

decompose and form harmful gases when exposed to ultraviolet

radiation. These solvents should be removed from the area prior to

cutting. Galvanized metal can produce harmful gases during the

cutting process. Ensure proper ventilation and use breathing

equipment when cutting these materials.

Certain metals coated with or containing lead, cadmium, zinc,

beryllium, and mercury produce harmful toxins. Do not cut these

metals unless all people subjected to the fumes wear proper air

breathing equipment.

ELECTRIC SHOCK PREVENTION

The system uses high open circuit voltages that can be

fatal. Extreme care should be used when operating or

performing maintenance on the system. Only qualified personnel

s

hould service the system. Observe the following guidelines to protect

against electric shock:

• A wall-mounted disconnect switch should be installed and fused

according to local and national electrical codes. The disconnect

switch should be located as close as possible to the power supply

so it can be turned off in case of an emergency.

• The primary power cord should have a 600 volt minimum rating in

order to protect the operator. In addition, it should be sized

according to local and national electrical codes. Inspect the primary

power cord frequently. Never operate the system if the power cord

is damaged in any way.

• Make sure the primary power ground wire is connected at the input

power ground location on the power supply. Make sure the

connection is securely tightened.

• Make sure the positive output (work ground) of the power supply is

connected to a bare metal area on the cutting table. A driven

ground rod should be placed no further than five feet from this

connection. Make sure this ground point on the cutting table is

used as the star ground point for all other ground connections.

• Inspect the torch leads frequently. Never use the system if the leads

are damaged in any way.

• Do not stand in wet, damp areas when operating or performing

maintenance on the system.

• Wear insulated gloves and shoes while operating or performing

maintenance on the system.

• Make sure the system is switched off at the wall disconnect before

servicing the power supply or torch.

• Never change torch consumable parts unless main power to the

system is switched off at the power supply or wall disconnect.

• Do not attempt to remove any parts from beneath the torch when

cutting. Remember that the workpiece forms the current path back

to the power supply.

• Never bypass the safety interlock devices.

• Before removing any of the covers, switch the system off at the wall

disconnect. Wait at least five (5) minutes before removing any

cover. This will give the capacitors inside the unit time to discharge.

See Section 5 for additional safety precautions.

• Never operate the system without all of the covers in place. See

Section 5 for additional safety precautions.

• Preventive maintenance should be performed daily to avoid

possible safety hazards.

2

FLEXCUT™ 125

SAFETY

Page 7

3

FLEXCUT™ 125

FIRE PREVENTION

When using the system , it is necessary to exercise good

judgment. While cutting, the arc produces sparks that could cause a

fire if they fall on flammable materials. Make sure that all flammable

m

aterials are a suitable distance away from the cutting area. All

flammable liquids should be at least 40 feet away from the cutting

area, preferably stored in a metal cabinet. Plasma cutting should

never be attempted on containers that contain flammable materials.

Make sure that fire extinguishers are readily accessible in the cutting

area.

EXPLOSION PREVENTION

The system uses compressed gases. Use proper

techniques when handling compressed gas cylinders and other

compressed gas equipment. Observe the following guidelines to

protect against explosion:

• Never operate the system in the presence of explosive gases or

other explosive materials.

• Never cut pressurized cylinders or any closed container.

• When using a water table and cutting aluminum under water or

with water touching the underside at the aluminum plate,

hydrogen gas is produced. This hydrogen gas may collect under

the plate and explode during the cutting process. Make sure the

water table is properly aerated to help prevent the accumulation

of hydrogen gas.

• Handle all gas cylinders in accordance with safety standards

published by the U.S. Compressed Gas Association (CGA),

American Welding Society (AWS), Canadian Standards

Association (CSA), or other local or national codes.

• Compressed gas cylinders should be maintained properly. Never

attempt to use a cylinder that is leaking, cracked, or has other

signs of physical damage.

• All gas cylinders should be secured to a wall or rack to prevent

accidental knock over.

• If a compressed gas cylinder is not being used, replace the

protective valve cover.

• Never attempt to repair compressed gas cylinders.

• Keep compressed gas cylinders away from intense heat, sparks,

or flames.

• Clear the compressed gas cylinder connection point by opening

the valve momentarily prior to installing a regulator.

• Never lubricate compressed gas cylinder valves or pressure

regulators with any type of oil or grease.

• Never use a compressed gas cylinder or pressure regulator for

any purpose other than which it is intended.

• Never use a pressure regulator for any gas other than which it is

intended.

• Never use a pressure regulator that is leaking or has other signs

of physical damage.

• Never use any gas hose that is leaking or has other signs of

physical damage.

HEALTH SUPPORT EQUIPMENT

The system creates electric and magnetic fields that

may interfere with certain types of health support

equipment, such as pacemakers. Any person who uses a pacemaker

o

r similar item should consult a doctor before operating, observing,

maintaining, or servicing the system. Observe the following guidelines

to minimize exposure to these electric and magnetic fields:

• Stay as far away from the~power supply, torch, and torch leads

as possible.

• Route the torch leads as close as possible to the work ground

cable.

• Never place your body between the torch leads and work ground

cable. Keep the work ground cable and the torch leads on the

same side of your body.

• Never stand in the center of a coiled up set of torch leads or work

ground cable.

SAFETY

Page 8

FLEXCUT™ 125

Safety Standards Booklet Index

For further information concerning safety practices to be exercised

with plasma arc cutting equipment, please refer to the following

p

ublications:

1

. AWS Standard AWN, Arc Welding and Cutting Noise, obtainable

from the American Welding Society, 550 NW LeJeune Road, Miami,

FL 33126.

2. AWS Standard C5.2, Recommended Practices for Plasma Arc

Cutting, obtainable from the American Welding Society, 550 NW

LeJeune Road, Miami, FL 33126.

3. AWS Standard FSW, Fire Safety in Welding and Cutting, obtainable

from the American Welding Society, 550 NW LeJeune Road, Miami,

FL 33126.

4. AWS Standard F4.1, Recommended Safe Practices for Preparation

for Welding and Cutting of Containers and Piping, obtainable from

the American Welding Society, 550 NW LeJeune Road, Miami, FL

33126.

5. AWS Standard ULR, Ultraviolet Reflectance of Paint, obtainable

from the American Welding Society, 550 NW LeJeune Road, Miami,

FL 33126.

6. AWS I ANSI Standard Z49.1, Safety in Welding, Cutting, and Allied

Processes, obtainable from the American Welding Society, 550 NW

LeJeune Road, Miami, FL 33126.

7. ANSI Standard Z41.1 , Standard For Men's Safety-Toe Footwear,

obtainable from the American National Standards Institute, 11 West

42nd Street, New York, NY 10036.

8. ANSI Standard Z49.2, Fire Prevention in the Use of Cutting and

Welding Processes, obtainable from the American National

Standards Institute, 11 West 42nd Street, New York, NY 10036.

9. ANSI Standard Z87.1, Safe Practices For Occupation and

Educational Eye and Face Protection, obtainable from the American

National Standards Institute, 11 West 42nd Street, New York, NY

10036.

10. ANSI Standard Z88.2, Respiratory Protection, obtainable from the

American National Standards Institute, 11 West 42nd Street, New

York, NY 10036.

11. OSHA Standard 29CFR 1910.252, Safety and Health Standards,

obtainable. from the U.S. Government Printing Office, Washington,

D.C. 20402.

12. NFPA Standard 51 , Oxygen - Fuel Gas Systems for Welding,

Cutting, and Allied Processes, obtainable from the National Fire

Protection Association, 1 Batterymarch Park, Quincy, MA 02269.

13. NFPA Standard 51 B, Cutting and Welding Processes, obtainable

from the National Fire Protection Association, 1 Batterymarch

Park, Quincy, MA 02269.

14. NFPA Standard 70, National Electrical Code, obtainable from the

National Fire Protection Association, 1 Batterymarch Park, Quincy,

MA 02269.

15. CGA booklet P-1 , Safe Handling of Compressed Gases in

Containers, obtainable from the Compressed Gas Association,

1725 Jefferson Davis Highway, Suite 1004, Arlington, VA 22202.

16. CGA booklet P-14, Accident Prevention in Oxygen-Rich and

Oxygen-Deficient Atmospheres, obtainable from the Compressed

Gas Association, 1725 Jefferson Davis Highway, Suite 1004,

Arlington, VA 22202.

17. CGA booklet TB-3, Hose Line Flashback Arrestors, obtainable from

the Compressed Gas Association, 1725 Jefferson Davis Highway,

Suite 1004, Arlington, VA 22202.

18. CSA Standard W117 .2, Safety in Welding, Cutting, and Allied

P

rocesses, obtainable from Canadian Standards Association, 178

Rexdale Boulevard, Toronto, Ontario M9W IR3, Canada.

19. Canadian Electrical Code Part 1, Safety Standard for Electrical

Installations, obtainable from the Canadian Standards Association,

178 Rexdale Boulevard, Toronto, Ontario M9W 1 R3, Canada.

4

SAFETY

Page 9

5

F

LEXCUT™ 125

TABLE OF CONTENTS

Safety

General Description...........................................................................................................................10

Preheat Temperature For Plasma Cutting ..........................................................................................10

D

uty Cycle.........................................................................................................................................10

User Responsibility............................................................................................................................10

Design Features And Advantages ......................................................................................................10

Installation ..................................................................................................................................Section A

Select Suitable Location...................................................................................................................A-2

Lifting ............................................................................................................................................A-2

Stacking ..........................................................................................................................................A-2

Tilting ............................................................................................................................................A-2

High Frequency Interference Protection ...........................................................................................A-2

Input Connection..............................................................................................................................A-2

Machine Grounding..........................................................................................................................A-2

Input Plug Installation ......................................................................................................................A-3

Input Connection..............................................................................................................................A-3

Input Fuse And Supply Wire Considerations .....................................................................................A-3

Input Voltage Selection ....................................................................................................................A-4

Gas Supply Requirements................................................................................................................A-4

Connecting The Gas Supply .............................................................................................................A-4

Output Connections .........................................................................................................................A-4

Operation ..................................................................................................................................Section B

Controls And Settings ......................................................................................................................B-2

User Interface..................................................................................................................................B-3

Mechanized Cutting.........................................................................................................................B-5

Cut Charts .......................................................................................................................................B-7

Consumable Life............................................................................................................................B-13

Cut Quality.....................................................................................................................................B-13

Inspection Of Consumable Parts ....................................................................................................B-14

Suggestions For Extra Utility From The Flexcut™ 125 System: ....................................................B-15

Accessing Divided Arc Voltage.......................................................................................................B-16

Options/Accessories...................................................................................................................Section C

Maintenance ...............................................................................................................................Section D

Daily Procedures .............................................................................................................................D-1

Monthly Procedures.........................................................................................................................D-1

Troubleshooting ..........................................................................................................................Section E

Diagrams ..................................................................................................................................Section F

Wiring Diagram................................................................................................................................F-1

Dimension Print ...............................................................................................................................F-2

Parts List .........................................................................................................parts.lincolnelectric.com

Content/details may be changed or updated without notice. For most current Instruction Manuals, go to

parts.lincolnelectric.com.

Page 10

F

LEXCUT™ 125

GENERAL DESCRIPTION

The FLEXCUT™ 125 is a constant current, continuous control plasma

cutting power source. It provides superior and reliable starting

characteristics, cutting visibility and arc stability. The control system

h

as a safety mechanism to ensure that the nozzle and electrode are in

place before cutting or gouging. This is extremely important due to

the high voltages involved.

The FLEXCUT™ 125 comes standard with an air regulator and digital

pressure display.

The FLEXCUT™ 125 initiates the plasma arc with a simple, yet

reliable, contact start mechanism. This system eliminates many of the

failure problems associated with hi-frequency start systems.

PREHEAT TEMPERATURE FOR PLASMA CUTTING

Preheat temperature control is not necessary in most applications

when plasma arc cutting or gouging. Preheat temperature control

may be necessary on high carbon alloy steels and heat treated

aluminum for crack resistance and hardness control. Job conditions,

prevailing codes, alloy level, and other considerations may also

require preheat temperature control. The following minimum preheat

temperature is recommended as a starting point. Higher temperatures

may be used as required by the job conditions and/or prevailing

codes. If cracking or excessive hardness occurs on the cut face,

higher preheat temperature may be required. The recommended

minimum preheat temperature for plate thickness up to 1/2"

(12.7mm) is 70°F (21.1°C).

DUTY CYCLE

The duty cycle of a plasma machine is the percentage of time in a 10

minute cycle at which the operator can operate the machine at rated

cutting current.

Example: 60% duty cycle means that it is possible to cut for 6

minutes, then the machine stops for 4 minutes.

Refer to the Technical Specification section for more information

about the machine rated duty cycles.

USER RESPONSIBILITY

Because design, fabrication, erection and cutting variables affect the

results obtained in applying this type of information, the serviceability

of a product or structure is the responsibility of the user. Variation

s

uch as plate chemistry, plate surface condition (oil, scale), plate

thickness, preheat, quench, gas type, gas flow rate and equipment

may produce results different than those expected. Some adjustments

to procedures may be necessary to compensate for unique individual

conditions. Test all procedures duplicating actual field conditions.

DESIGN FEATURES AND ADVANTAGES

The FLEXCUT™ 125 design makes plasma cutting uncomplicated.

This list of design features and advantages will help you understand

the machine's total capabilities so that you can get maximum use

from your machine.

- Light weight and portable design for industrial use.

- Continuous control, 20 - 125 amps.

- Reliable touch start mechanism for plasma arc initiation.

- Rapid arc restrike for fast cutting of expanded metal.

- Input over voltage protection.

- Bright 5.0 second timed pilot arc.

- Gas purge selection.

- Air regulator and pressure gage included.

- Internal water separator included.

- Parts-in-Place mechanism to detect proper installation of

consumables and torch.

- Preflow/Postflow timing. Preflow is eliminated if arc is reinitiated in Postflow.

- Thermostatic Protection.

- Solid state over-current protection.

- Patented electrode, nozzle and shield cap for optimum cooling,

cut quality and long life.

6

Page 11

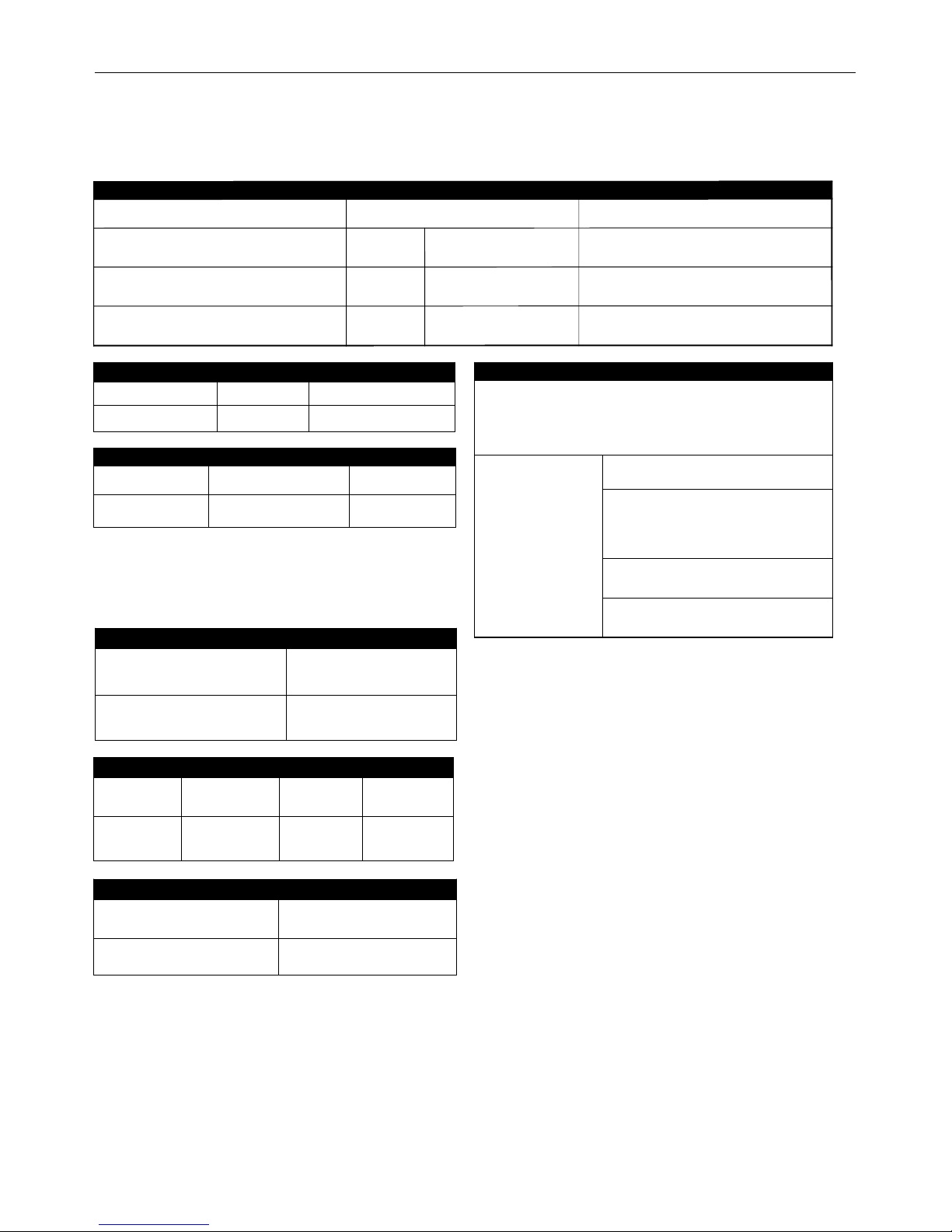

TECHNICAL SPECIFICATIONS K4160-1 FLEXCUT™ 125

A-1

I

NSTALLATION

F

LEXCUT™ 125

I

N

PU

T

-

T

H

R

EE

PH

ASE/

5

0

/

6

0

H

ER

T

Z

I

nput

V

o

l

t

a

ge

+

/-

1

0

%

I

n

p

u

t

Amp

er

es

@

Rated

Ou

tp

u

t

Ci

r

c

u

i

t

Br

e

a

k

e

r

(D

e

l

a

y

T

y

p

e

)

3

8

0

/4

0

0

/4

1

5

V

/3

/5

0

/6

0

4

0

1

0

0

%

D

u

t

y

C

y

c

l

e

5

0

Amp

s

4

6

0

V

/3

/5

0

/6

0

3

3

1

0

0

%

D

u

t

y

C

y

c

l

e

4

0

Amp

s

5

7

5

V

/3

/5

0

/6

0

2

8

1

0

0

%

D

u

t

y

C

y

c

l

e

3

0

Amp

s

RATED OUTPUT AT 40° C

Duty Cycle CURRENT VOLTAGE

100% 125A 175 VDC

RECOMMENDED INPUT WIRE

For all plasma cutting applications

Based on U.S. National Electrical Code

Ambient Temperature 30

o

C or Less

Input Cord Supplied

with Machine

STO, 600V

Type S, SO, ST, STO

or Extra Hard Usage Cord

AWG (IEC) Sizes

Input Supply Wires

#8 (8.4 mm2)

1 Ground Wire

#8 (8.4 mm

2

)

OUTPUT

Current Range Open Circuit Voltage Pilot Current

20 - 125 Amps 300 VDC 30 Amps

PHYSICAL DIMENSIONS

Height Width Depth Weight

20.72 in.

(526 mm)

12.25 in.

(311 mm)

25.53 in.

(648 mm)

118 lbs.

(53.5 kgs)

TEMPERATURE RANGES

OPERATING TEMPERATURE

RANGE

STORAGE TEMPERATURE

RANGE

-10°C to +40°C -25°C to +55°C

GAS

REQUIRED GAS FLOW RATE

REQUIRED GAS INLET

PRESSURE

550 SCFH min @ 90 PSI

(260 SLPM min @ 6.21 bar)

90 to 120 PSI

(6.21 to 8.27 Bar.)

*In some countries Uois also known as OCV (see CAN/CSA - W117.2)

*Ground wire should be longer than the three current carrying conductors

inside the machine.

Page 12

A-2

I

NSTALLATION

F

LEXCUT™ 125

R

ead entire Installation Section before installing the

FLEXCUT™ 125 .

INSTALLATION

ELECTRIC SHOCK CAN KILL.

• Only qualified personnel should install

this machine.

• Turn the input power OFF at the

disconnect switch or fuse box and

discharge input capacitors before working inside the

equipment.

• Do not touch electrically hot parts.

• Turn the FLEXCUT™ 125 Power Switch OFF when

connecting power cord to input power.

SELECT SUITABLE LOCATION

Place the FLEXCUT™ 125 where clean cool air can freely circulate in

through the rear of the machine and out through the front and side

louvers. Maintain at least 10 inches of space on all sides of the unit.

Dirt, dust, or any foreign material that can be drawn into the machine

should be kept to a minimum. A properly installed machine will allow

for dependable service and reduce periodic maintenance time. Failure

to observe these precautions may result in excessive operating

temperatures and nuisance shutdowns of the machine.

Keep machine dry.

Shelter from rain and snow. Do not place on wet ground or

in puddles.

LIFTING

The FLEXCUT™ 125 power supply should be lifted by two people or a

hoist. In order to prevent damage, the power supply should be lifted

by both handles while keeping the unit as horizontal as possible. Only

hoisting straps approved for the weight of the machine should be

used.

STACKING

The FLEXCUT™ 125 cannot be stacked.

TILTING

The FLEXCUT™ 125 must be placed on a stable, level surface so it

will not topple over.

HIGH FREQUENCY INTERFERENCE PROTECTION

The FLEXCUT™ 125 employs a touch start mechanism for arc

i

nitiation which eliminates high frequency emissions from the

machine as compared with spark gap and solid state type high

frequency generators. Keep in mind though, that these machines may

be used in an environment where other high frequency generating

machines are operating. By taking the following steps, high frequency

i

nterference into the FLEXCUT™ 125 can be minimized:

(

1) Make sure the power supply chassis is connected to a good earth

ground. The work terminal ground does NOT ground the machine

frame.

(2) Keep the work clamp isolated from other work clamps that have

high frequency.

(3) If the work clamp cannot be isolated, then keep the clamp as far

as possible from other work clamp connections.

(4) When the machine is enclosed in a metal building, several good

earth driven grounds around the periphery of the building are

recommended.

INPUT CONNECTION

Only a qualified electrician should connect the input leads to

the FLEXCUT 125. Connections should be

made in accordance with all local and

national electrical codes and the

connection diagrams. Failure to do so may

result in bodily injure or death.

The FLEXCUT™ 125 is rated for 380 VAC through 575 VAC input

voltages, three phase and 50 or 60 Hertz. Before connecting the

machine to power, be sure the input supply voltage, phase and

frequency all match those listed on the machine’s rating plate.

MACHINE GROUNDING

The frame of the welder must be grounded. A ground terminal

marked with a ground symbol is located next to the input power

connection block.

See your local and national electrical codes for proper grounding

methods.

The FLEXCUT 125 ON/OFF switch is not intended as a

service disconnect for this equipment. Only a qualified

electrician should connect the input leads to the

FLEXCUT 125. Connections should be made in accordance

with all local and national electrical codes. Failure to do so

may result in bodily injury or death.

WARNING

WARNING

WARNING

CAUTION

Page 13

A-3

I

NSTALLATION

F

LEXCUT™ 125

INPUT PLUG INSTALLATION

A

10 ft.(3m) power cord is provided with the FLEXCUT 125.

Three Phase Input Only

Connect green lead to ground per National Electric Code.

Connect black, red and white leads to power.

In all cases, the green or green/yellow grounding wire must be

connected to the grounding pin of the plug, usually identified by a

green screw.

Attachment plugs must comply with the Standard for Attachment

Plugs and Receptacles, UL498.

The product is considered acceptable for use only when an

attachment plug as specified is properly attached to the supply cord.

Only a qualified electrician should connect the input leads to

the FLEXCUT 125. Connections should be made in

accordance with all local and national electrical codes and

the connection diagrams. Failure to do so may result in

bodily injure or death.

The FLEXCUT 125 ON/OFF switch is not

intended as a service disconnect for this

equipment. Only a qualified electrician should

connect the input leads to the FLEXCUT 125.

Connections should be made in accordance with all local

and national electrical codes and the connection diagram

l

ocated on the inside of the reconnect access door of the

machine. Failure to do so may result in bodily injury or

death.

POWER CORD REPLACEMENT

If the input cord is damaged or needs to be replaced, the new cord

should be routed through the strain relief and into the connection

block.

(See Figure A.1)

Use a three-phase supply line. A 1.40 inch diameter access hole with

strain relief is located on the case back. Route input power cable

through this hole and connect L1, L2, L3, and ground per connection

diagrams and National Electric Code. To access the input power

connection block, remove the seven screws and the left case side of

the machine as shown.

ALWAYS CONNECT THE GROUNDING LUG (LOCATED AS SHOWN IN

FIGURE A.1) TO A PROPER SAFETY (EARTH) GROUND.

INPUT FUSE AND SUPPLY WIRE CONSIDERATIONS

Refer to the Specification Section for recommended fuse, wire sizes,

and type of copper wires. Fuse the input circuit with the

recommended super lag fuses or delay type breakers (also called

“inverse time” or “thermal/magnetic” circuit breakers). Choose input

and grounding wire size according to local or national electric codes.

Using input wire sizes, fuses, or circuit breakers smaller than

recommended may result in “nuisance” shut-offs from high inrush

currents, even if the machine is not being used at high currents.

WARNING

WARNING

GROUND CONNECTION

CONNECT GROUND LEAD PER LOCAL

AND NATIONAL ELE CTRIC CODE

INPUT CORD STRAIN RELIEF

ROUTE INPUT CORD THROUGH RELIEF

AND TWIST NUT TO TIGHT EN

POWER CONNECTION BLOCK

CONNECT EACH PHASE OF A

THREE PHASE CONDUCTOR HERE

FIGURE A.1

Page 14

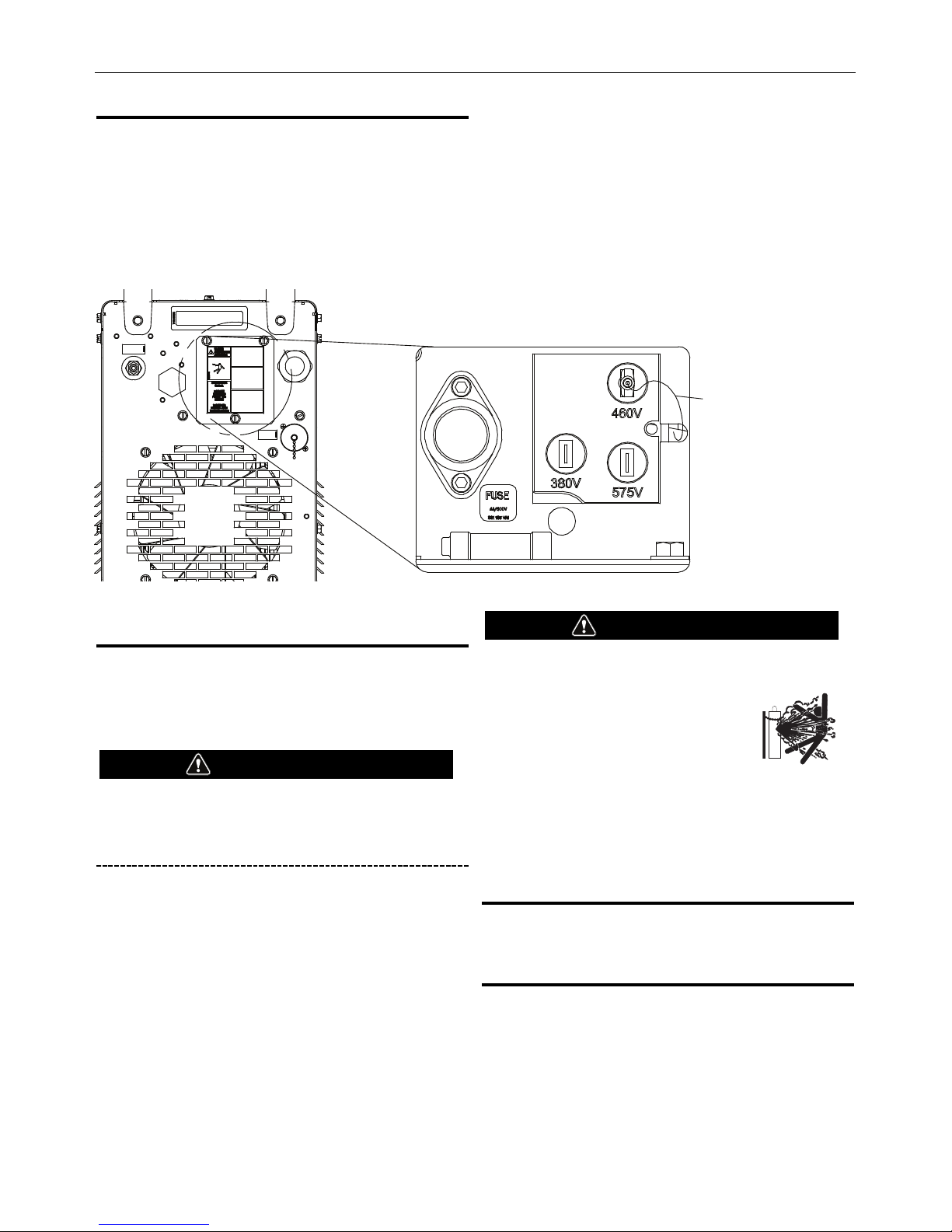

INPUT VOLTAGE SELECTION

The Flexcut™ 125 is shipped connected for 460 VAC input. To

reconfigure the machine for a different input voltage see the panel on

the rear of the unit (Figure A.2). With input power removed from the

m

achine, move the Auxiliary (“A”) lead from the 460V tap to the

desired input voltage. Always replace the cover when finished.

If the “A” lead is not connected to the proper voltage tap, the machine

may not power on, it may throw an error, or the fuse may open.

Should the fuse open, replace the fuse, reconnect the “A” lead to the

correct voltage and re-apply power.

GAS SUPPLY REQUIREMENTS

Supply the FLEXCUT™ 125 with clean, dry, oil-free compressed air or

nitrogen. A high pressure regulator MUST be used with a compressor

or a high pressure cylinder.

Supply pressure must be between 90-120 psi (6.21 - 8.27 bar) with

flow rates of at least 550 SCFH or 260 SLPM.

Air supply pressure should never exceed 130

psi or damage to the machine may occur!

The FLEXCUT™ 125 contains a built-in filter but depending on the

quality of the supply, additional filtration may be required. Be aware

that shop air systems are prone to oil and moisture contamination. If

shop air is used, it must be cleaned to ISO 8573-1:2010, Class 1.4.1.

See the Maintenance Gas Supply Section for information on changing

the internal filter element.

Specify dry air when using compressed cylinders. Breathing quality

air contains moisture and should not be used.

A standard nominal 5 micron inline filter is recommended, but for

optimal performance, select a pre-filter with a 3 micron absolute

rating.

CYLINDER could explode if damaged.

• Keep cylinder upright and chained to a fixed support.

• Keep cylinder away from areas where it

could be damaged.

• Never lift machine with cylinder

attached.

• Never allow the cutting torch to touch

the cylinder.

• Keep cylinder away from live electrical parts.

• Maximum inlet pressure 130 psi.

CONNECTING THE GAS SUPPLY

Air or gas must be supplied to the FLEXCUT™ 125 with 3/8” inside

diameter tubing and a ¼” NPT quick disconnect coupler.

OUTPUT CONNECTIONS

The FLEXCUT™ 125 is sent from the factory with a work clamp

included. The work clamp must be securely connected to the work

piece. If the work piece is painted or extremely dirty it may be

necessary to expose the bare metal in order to make a good electrical

connection.

WARNING

WARNING

A-4

I

NSTALLATION

F

LEXCUT™ 125

AUXILIARY ("A") LEAD

FIGURE A.2

Page 15

B-1

O

PERATION

OPERATION

SAFETY PRECAUTIONS

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts

or electrode with skin or wet

clothing.

• Insulate yourself from work and

ground.

• Always wear dry insulating gloves.

FUMES AND GASES can be

dangerous.

• Keep your head out of fumes.

• Use ventilation or exhaust to

remove fumes from breathing zone.

WELDING, CUTTING and

GOUGING SPARKS can cause

fire or explosion

• Keep flammable material away.

• Do not weld, cut or gouge on

containers that have held combustibles.

ARC RAYS can burn.

• Wear eye, ear and body protection.

PLASMA ARC can injure

• Keep your body away from nozzle

and plasma arc.

• Operate the pilot arc with caution.

The pilot arc is capable of burning

the operator, others or even

piercing safety clothing.

Observe additional Safety Guidelines detailed in the beginning

of this manual.

GRAPHIC SYMBOLS THAT APPEAR ON THIS

M

ACHINE OR IN THIS MANUAL

WARNING

FLEXCUT™ 125

WARNING OR CAUTION

READ INSTRUCTION

MANUAL

CUT

GAS INPUT

GRID or EXPANDED METAL

GOUGE

POWER ON

POWER OFF

PROTECTIVE

GROUND

GAS PURGE

MARKING

Page 16

B-2

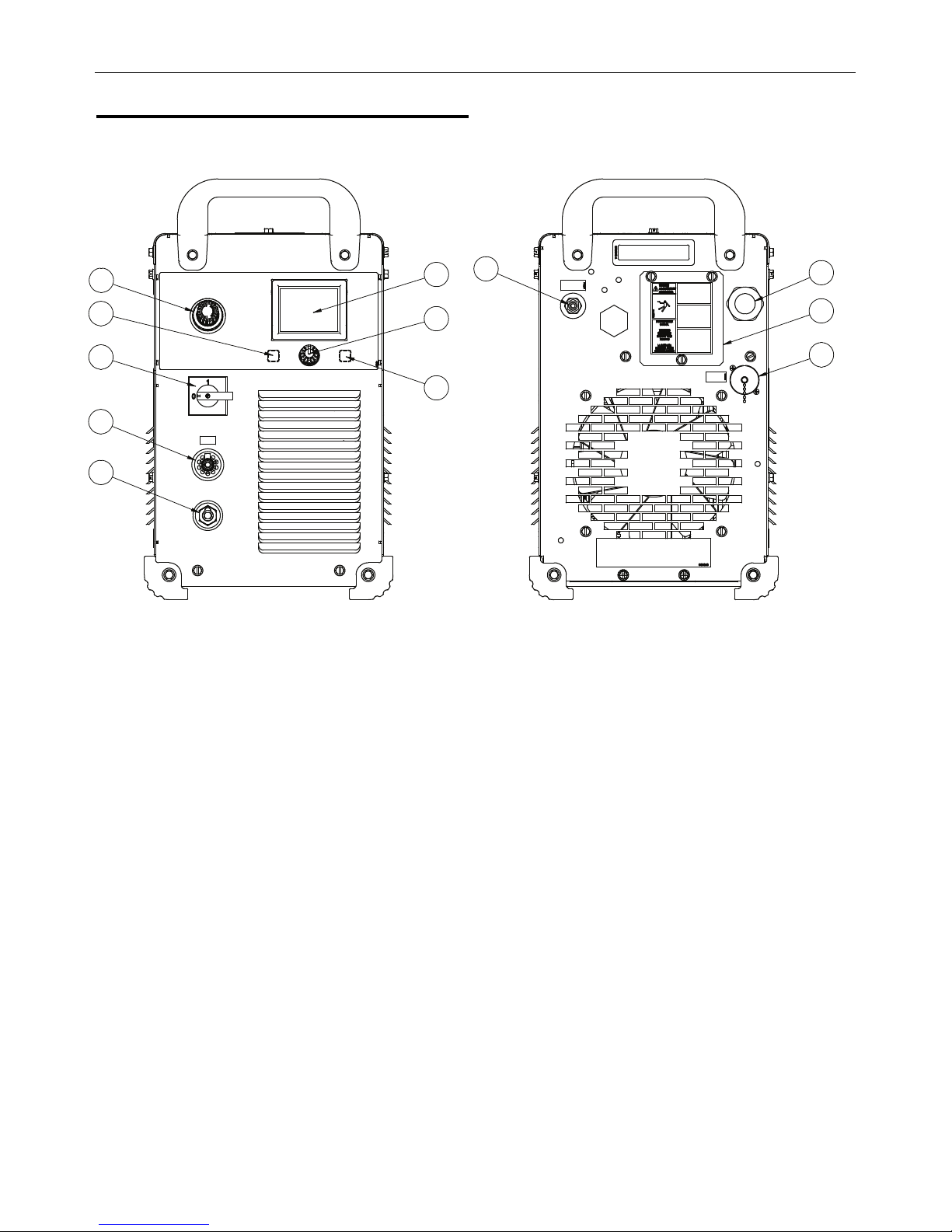

CONTROLS AND SETTINGS

FIGURE B.2 - Front Panel

1. LCD Display: Shows available modes and real time parame-

ters.

2. Home Button: Allows the user to return to the Home Screen.

3. Menu Control Knob/Button: Used to navigate and select

items on the display.

4. Pressure Regulator: Allows the regulation of the primary

air/gas pressure.

5. Purge: Allows the user to enable air flow from the machine.

6. On/Off Switch: Turns the input power to the machine

ON/OFF.

7. Torch Connection: Connect the torch.

8. Work Lead Connection: Connect cable with work clamp.

FIGURE B.3 - Back Panel

9. Input Cord Strain Relief: Used to connect the unit to input

power.

10. Reconnect Panel Access: Allows the unit to be configured

for 380, 460, or 575 VAC input.

11. 14-pin CNC Interface: Allows access to Arc Start Trigger,

Arc Initiated contact, raw or divided Arc Voltage, and

Forced Mark.

12. Air or Gas Inlet (1/4” NPT Quick Connect): Compressed air

or gas connection.

FLEXCUT™ 125

O

PERATION

1

2

5

3

7

8

6

4

9

11

12

10

Page 17

B-3

O

PERATION

USER INTERFACE

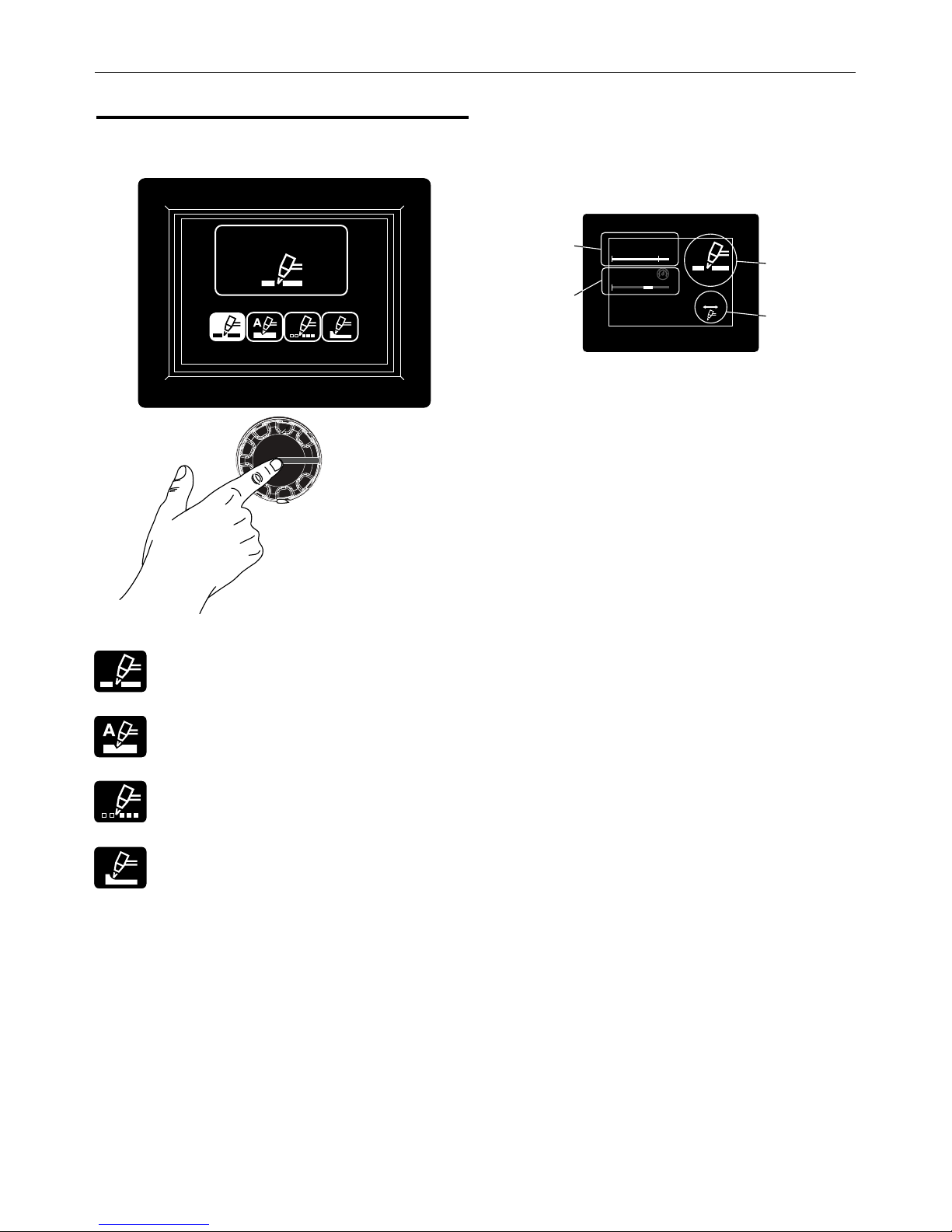

Mode Select Screen

Choose between four available modes:

Cut – For cutting operations on a solid workpiece.

Mark – For discoloring or slight removal of material. Can

be used to add part numbers, bend lines, drill marks, or

many other surface modifications.

Grid – For cutting operations on a non-continuous

workpiece.

Gouge – For removing material from a workpiece

(removing a weld).

Active Mode Screen - See Figure B.4

Active Mode Icon – The currently selected mode icon will be

displayed here. Return to the mode select screen to choose a new

mode.

Output Current – Turn the control knob to adjust the desired output

current. While cutting, the screen will display the actual cutting

current in Amps. Output current range is dependent on Mode

selected.

Output Gas Pressure – The output gas pressure is displayed on a

linear scale, with the center of the green range as the recommended

output gas pressure based on selected mode and torch length. Use

the regulator knob on the front of the machine to adjust the output

gas pressure, but do so only while gas is flowing. Hold the purge

button while pulling and turning the regulator knob to adjust the

pressure as desired.

Torch Length – The selected torch length will be displayed here. Be

sure the torch length matches the torch that is being used with the

machine. The torch length can be modified in the settings menu.

FLEXCUT™ 125

Cutting

Press to Select

125

A

60

PSI

2

5ft

Active Mode Icon

Output Current

O

utput Gas Pressure

T

orch Length

F

IGURE B.4

Page 18

B-4

O

PERATION

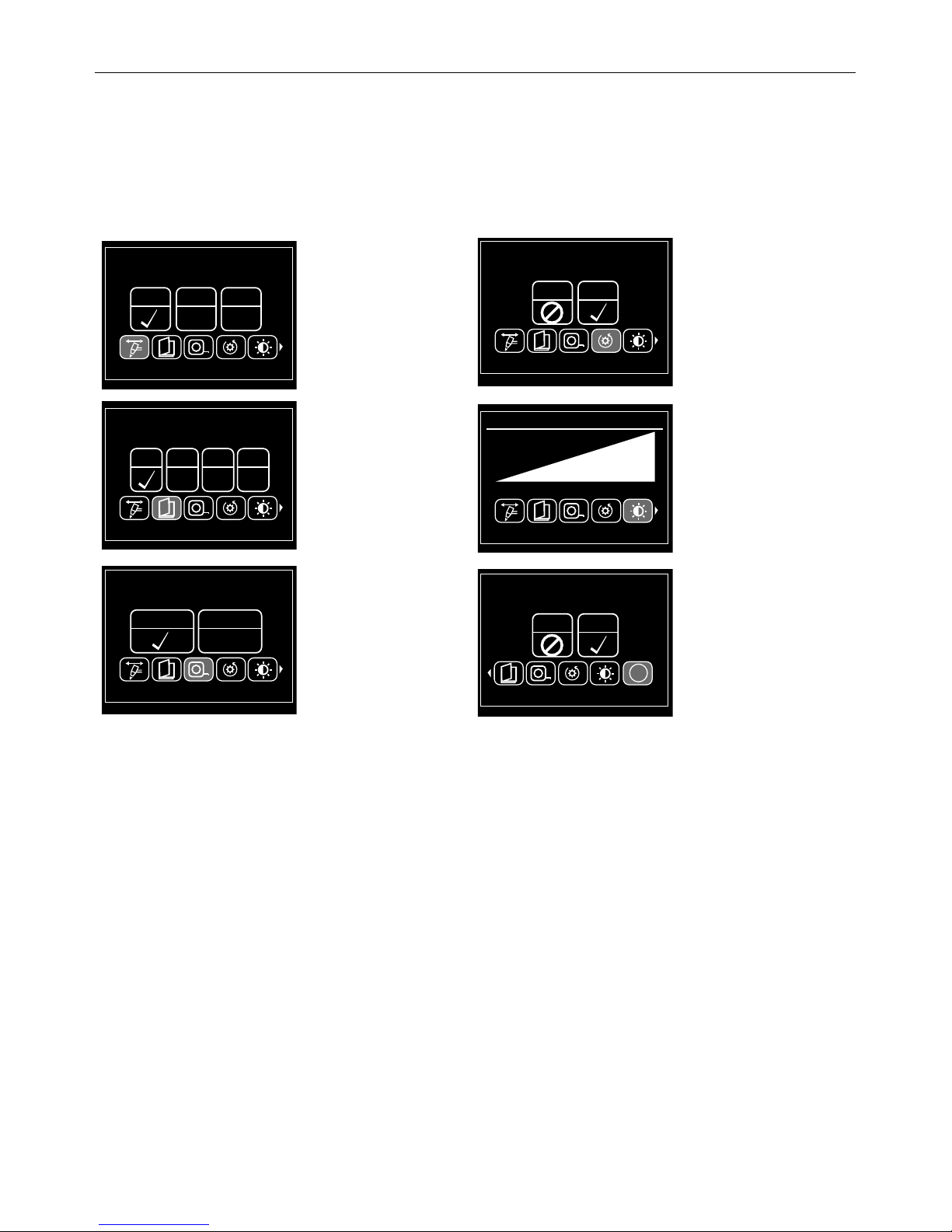

Settings

Press both the home and purge buttons at the same time to enter or

exit the settings menu.

Options (turn the knob to scroll and press the knob

to select):

Torch Size – Choose between

25 ft. (7.6m), 50 ft. (15.2m), or

75 ft. (22.9m) torch lengths.

This will change the

recommended output gas

pressure.

Language – Choose between

English, Spanish, French, or

German

Units – Choose between

English or Metric units

Reset Factory Settings – Use to

restore the machine back to the

factory settings

Brightness – Used to dim or

brighten the LCD display

Advanced – Used for diagnostic

purposes

FLEXCUT™ 125

25’

50’ 75’

P

ress to Select

Torch Size

EN SP FR GR

P

ress to Select

Language

English Metric

Press to Select

Units

No Yes

P

ress to Select

Reset Factory Settings

Press to Select

110

Brightness

10

No Yes

Press to Select

Information

i

Page 19

B-5

O

PERATION

FLEXCUT™ 125

MECHANIZED CUTTING

Mechanized Torch Installation

It is recommended that the FLEXCUT™ 125 mechanized torch be

i

nstalled on a positioner with an arc voltage control capable of

maintaining the cutting arc voltage within 1 volt. The positioner must

be rigid to ensure cut quality and a torch collision sensor is highly

recommended.

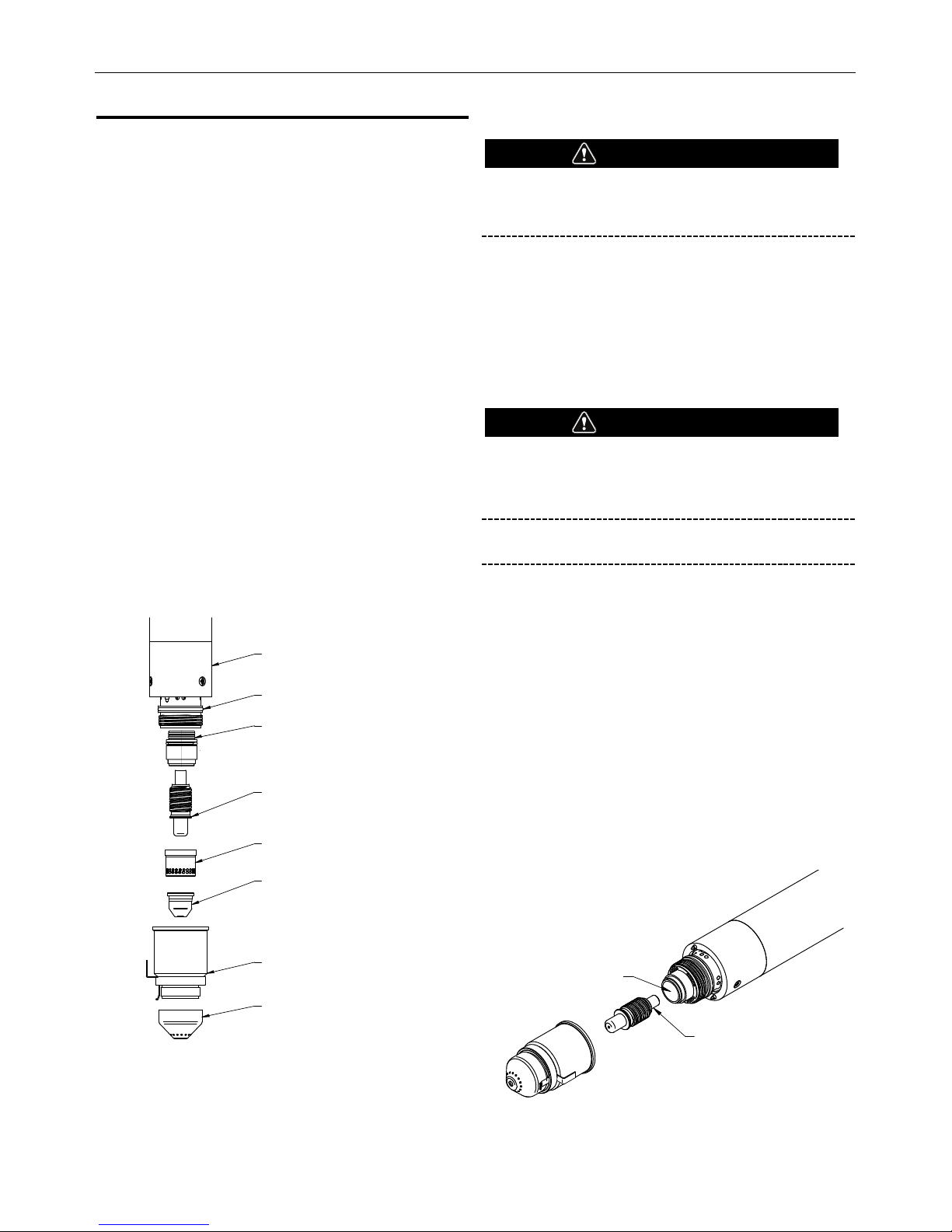

Installing the Mechanized Torch Consumables

To install the torch parts, perform the following

steps (See Figure B.5):

Note: Do not over tighten the consumables! Only tighten until the

parts are seated properly.

1. Inspect the threads on the torch body and retaining cap and

clean as necessary. Apply lubricant to the torch o-ring as

necessary. Lubricant should be oxygen safe and inert in a

flammable environment.

2. Install the electrode (1) into the torch body and press into place.

3. Thread the shield cap (5) onto the retaining cap assembly. (4)

4. Insert the nozzle (3) into the swirl ring. (2)

5. Place the swirl ring / nozzle assembly into the retaining cap.

6. Thread and tighten the retaining cap assembly onto the torch

body. (6)

Removing the Torch Consumables

Turn off the machine prior to removing

consumables.

To remove the torch consumables, perform the

following steps:

1. Remove the retaining cap from the torch.

2. Remove the swirl ring and nozzle from the retaining cap.

3. Separate the shield cap from retaining cap.

4. Remove the electrode from the torch body.

5. Remove the swirl ring from the nozzle.

Contaminants such as dirt, metallic dust, oil and moisture

present on the surface of the electrode and/or torch body

can cause electrical arcing between these components and

ultimately result in failure of the torch and consumables.

Do not continue to try and cut excessively worn

consumables as this can cause damage to the Torch Head.

In order to avoid damaging the torch and/or consumables, adhere to

the following guidelines:

1. Ensure that the air supplied to the torch does not contain contaminants such as debris, moisture and oil.

2. Ensure that the torch cathode body and electrode body are clean

prior to assembling the consumables into the torch. Wipe away any

contaminants with a dry, lint free cloth.

3. Be sure that the consumables are properly tightened and fully

inserted when installing them into the torch. Check the installation

of the consumables before the start of each work shift and

frequently to ensure that the parts have not become loose as a

result of normal operation.

4. Inspect the surfaces of the cathode body and electrode body to

ensure no contaminants have collected during operation.

(Reference Figure B.6)

FIGURE B.6

WARNING

WARNING

ELECTRODE BODY

CATHODE BODY

(1) ELECTRODE

BK14300-1

BK500024

(2) SWIRL RING

BK14300-13

(3) NOZZLE

45A - BK14300-7

65A - BK14300-8

85A - BK14300-9

105A - BK14300-10

125A - BK14300-11

(4) RETAINING CAP

BK14300-15

(5) SHIELD CAP

45A - 65A - BK14300-3

85A - 125A - BK14300-4

O-RING

BK14300-18

(7) FRONT ISOLATOR ASSEMBLY

(6) LC125M TORCH BODY

FIGURE B.5

Page 20

B-6

O

PERATION

Making a Cut

Setting up a Cut

Use the following procedure to make a cut with the

F

LEXCUT™ 125.

1

. Using the charts, determine the proper torch parts and cutting

conditions for the material being cut.

2. Install the proper consumables into the torch.

3. Turn the power switch to the ON position to apply power to the

FLEXCUT™ 125. The LCD will turn on and display the FLEXCUT™

initialization screen.

4. Press the home button and choose the desired operating mode.

5. Turn the control knob to set the desired output current.

6. Press and hold the gas purge button while adjusting the regulator

to recommended output pressure (center of green range).

7. The cutting operation is initiated after a start signal is received. The

arc should establish approximately 2 seconds after application of

the start command. The cutting operation is terminated when the

start signal is removed. At the completion of a cut, gas flow

through the torch will continue for approximately 20 seconds. The

LCD will display the actual output current and gas pressure while

the cut is active.

Machine Interface

The FLEXCUT™ 125 comes standard with a machine interface.

Interface signals provided include: Arc Start, Arc Initiated,

Arc Voltage (raw or divided) and Force Mark. These signals are

a

ccessible through the 14 pin connector on the case back. (See

Figure B.7

Arc Start:

The Arc Start circuit allows for triggering of the power source to

commence cutting. This circuit can be accessed through pins K and

M of the 14 pin connector. The circuit has a 15 VDC nominal open

circuit voltage and requires a dry contact closure to activate.

Arc Initiated:

The Arc Initiated circuit provides information as to when a cutting arc

has transferred to the work piece. This circuit can be accessed

through pins I and J of the 14 pin connector. The circuit provides a

dry contact closure when the arc has transferred. Input to this circuit

should be limited to 0.3 A for either 120VAC or 30VDC.

Arc Voltage:

The Arc Voltage circuit can be used for activating a torch height

control. This circuit can be accessed through pins D and G of the 14

pin connector. The circuit provides full electrode to work arc voltage

(300VDC maximum). A divided arc voltage of 20:1, 30:1, 40:1 or 50:1

is available. See “Accessing Divided Arc Voltage.”

Force Mark:

The Force Mark circuit can be used to change between a cut or grid

operating mode and a marking mode quickly and while output is on.

This circuit can be accessed though pins A and B of the 14-pin

connector. This circuit requires a dry contact closure to operate and

both modes should be configured prior to cutting.

Users wishing to utilize the Machine Interface can order a K867

Universal Adapter (please adhere to the pin locations stated above) or

manufacture a 14 pin connector cable assembly.

FLEXCUT™ 125

14-PIN BOX RECEPTAC

LE,

FRO

N

T

V

IEW

Arc Star

t

Force Mark

Arc Voltage

A

rc

Initia

ted

J

I

H

N

G

F

E

D

C

L

M

K

A

B

FIGURE B.7

Page 21

B-7

O

PERATION

Cutting Charts

The cutting charts shown on the following pages are intended to give

t

he operator the best starting point to use when making a cut on a

particular material type and thickness. Small adjustments may have

to be made to achieve the best cut. Also, remember that the arc

voltage must be increased as the electrode wears in order to maintain

the correct cutting height.

FLEXCUT™ 125

C

URRENT

P

AGE

45 AMPS B-8

65 AMPS B-9

85 AMPS B-10

105 AMPS B-11

125 AMPS B-12

Page 22

!"#$%&#%'()*+,-'.#/),'0.#(1+/2%*30'/

4,0.#56''0

78'//28'

7,'8('#

9

'0*:

!! "#$ #%& $' !! $' !! ()*

+,&-

./0123%

()*

+,&-

./0123%

$' !!

45-32 67689 67: ;:6 8;: :66 8;< 676<: 878

44-32 676;6 679 ;56 8;: <56 8;< 676<: 878

8

9-32 676<9 874 ;:6 8;: <86 8;< 676:6 87;

85-32 67656 87: ;4: 8;: <66 8;< 676:6 87;

8<-32 676=: 87> 67;6 4>6 8<6 ;4: 8;> 67656 87:

84-32 6786: 47= 466 8<4 446 8;> 6765: 87=

86-32 678;: ;7< 886 8<< 85= 8<4 6765: 87=

;?85 67899 <79 67:6 96 8<5 886 8<; 6765: 87=

8?< 674:6 57< 6756 6784 ;76 <: 8:4 =; 8:6 67696 476

@-45@86-32-#1%%0-$#-&/0A-,/00%AB-;?85-2'A-8?<-$'-#1%%0-$#-C/1-,/00%A

56*,+0'//#56''0

78'//28'

7,'8('#

9'0*:

!! "#$ #%& $' !! $' !! ()*

+,&-

./0123%

()*

+,&-

./0123%

$' !!

45-32 6768> 67: <66 8:6 :86 8:6 676<6 876

44-32 676;8 679 ;=: 8:6 <=: 8:6 676;6 679

89-32 676:6 87; ;:6 8:6 <66 8:4 676;: 67>

85-32 6765; 875 ;8: 8:4 <66 8:4 676<6 876

8<-32 676=9 476 6746 4<6 8:< 4:6 8:< 676<: 878

84-32 6786> 479 67;6 8=: 8:5 89: 8:< 676:6 87;

86-32 678<8 ;75 67<6 866 8:5 8<6 8:< 676:: 87<

;?85 67899 <79 67:6 =6 8:9 9: 8:5 67656 87:

8?< 674:6 57< 6756 ;6 8:> <6 8:= 67656 87:

$02%,+2%

78'//28'

7,'8('#

9'0*:

!! "#$ #%& $' !! $' !! ()*

+,&-

./0123%

()*

+,&-

./0123%

$' !!

8?;4 676;8 679 6766 ;56 8:4 <:6 8:4 676:: 87<

8?85 6765; 875 6786 ;56 8:< ;>6 8:< 67656 87:

;?;4 676>< 47< 6746 4;: 8:5 ;66 8:4 67656 87:

8?9 6784: ;74 67<6 896 856 46: 8:9 6765: 87=

8?< 674:6 57< 67:6 6785 <78 :: 854 =: 856 6765: 87=

4*8;,+<

78'//28' =288'+6

"#$ +!"# $' !! $' !!

84 6786 47:< 6786 47:<

84 6786 47:< 6786 47:<

84 6786 47:< 6786 47:<

8==

7,'8('#9'0*:

#%&

6766

6766

6766

./01#

8==

4:6

8==

781.2(6,1+#5'66,+</

=266,+<#>',<)6

7,'8('#>',<)6

781.2(6,1+#5'66,+</

*$0A-D1%%0

D12$'0%##-D1%%0

+0E!$'E!

?8*@'0#5&''.

F+00-GC$&H'%##%#I

()*

4:6

4:6

;=J

4*6'8,*0

$8(#A106*<'

7,'8('#>',<)6

=266,+<#>',<)6

B'8C#D,.6)

676<

876

E&6,%2%#5'66,+</

B'8C#D,.6)

6786

47:

67<6

6786

6766

6769

4*6'8,*0#?),(;+'//

=266,+<#>',<)6

6785

<78

56J

6786

47:

4*6'8,*0#?),(;+'//

@-K/,-<:+-&E11$'3-/L-D12$'0%##-D1%%0-M$1C-2-=:-L17-1/,&CB-!$'$!E!-$'"E1-32#-",%##E,%-$#-866-"#$7

$'

E&6,%2%#5'66,+</

7,'8('#>',<)6

B'8C#D,.6)

$'

6786

47:

6746

:78

=6J

6766

6786

476

4*6'8,*0#?),(;+'//

E&6,%2%#5'66,+</

781.2(6,1+#5'66,+</

=266,+<#>',<)6

7,'8('#>',<)6

$'

6746

674:

57<

:78

56J

B-8

O

PERATION

FLEXCUT™ 125

Shield Retaining Cap Nozzle Swirl Ring Electrode

BK14300-3 BK14300-15 BK14300-7 BK14300-13 BK14300-1

LC125M Torch Body

* Listed Gas Pressures are for 25 ft. torches. Increase Gas Pressure by 5 psi

for each additional 25 ft. of torch length.

Explosion Hazard

Do not cut Aluminum over water tables

WARNING

Page 23

B-9

O

PERATION

FLEXCUT™ 125

!"#$%&#%'()*+,-'.#/),'0.#(1+/2%*30'/

4

,0.#56''0

78'//28'

7

,'8('#

9'0*:

!

!"#$ #%& $'!!$'!!()*

+,&-

.

/0123%

(

)*

+,&-

.

/0123%

$

'!!

45-32 67656 478 6746 986 4:; 9<8 4:4 67656 478

4

6-32 674;8 ;7: 67;6 4<8 4:8 995 4:; 676=6 47>

;?45 674>> :7> 6786 4:6 4:8 4=6 4:; 676=6 47>

4?: 67986 57: 67>6 <8 4:8 448 4:; 676=6 47>

;

?> 67;=8 <78 4796 86 489 5; 4:> 676=8 47<

4

?9 67866 497= 679 874 ;8 48; :6 486 676>8 979

8?> 67598 487< 67; =75 96 485 9: 488 676>8 979

;?: 67=86 4<74 48 459 4< 456 676<6 97; @%#

=?> 67>=8 9979 46 458 4: 45: 676<6 97; @%#

447666987: = 4=6 46 455676<997; @%#

A-45-2'B-46-32-#1%%0-$#-&/0B-,/00%BC-;?45-A-4-$'-#1%%0-$#-D/1-,/00%B

56*,+0'//#56''0

78'//28'

7,'8('#

9'0*:

!! "#$ #%& $' !! $' !! ()*

+,&-

./0123%

()*

+,&-

./0123%

$' !!

45-32 6765; 475 ;98 4:< :98 4:< 67686 47;

46-32 674:4 ;75 946 484 95: 4:< 67656 478

;?45 674>> :7> 6796 4:= 48; 45> 484 676=6 47>

4?: 67986 57: 67:6 =6 488 <6 48; 676>6 976

;?> 67;=8 <78 67>6 :; 48> 86 48= 676<6 97;

4?9 67866 497= 4796 96 45= ;9 48< 67466 978

8?> 67598 487< 4< 458 99 45; 67468 97= @%#

;?: 67=86 4<74 4: 45> 4> 455 67446 97> @%#

$02%,+2%

78'//28'

7,'8('#

9'0*:

!! "#$ #%& $' !! $' !! ()*

+,&-

./0123%

()*

+,&-

./0123%

$' !!

4?45 6765; 475 6746 ;:8 456 :9> 456 676=6 47>

4?> 67498 ;79 6796 988 486 ;98 486 67656 478

4?: 67986 57: 67:6 466 456 4:= 48< 676=8 47<

;?> 67;=8 <78 6756 88 458 =6 45; 676>8 979

4?9 67866 497= 4766 ;8 45> :8 45> 676<6 97;

8?> 67598 487< 99 4=6 ;6 45> 67466 978 @%#

;?: 67=86 4<74 4: 4=: 99 4=9 67468 97= @%#

4*8;,+<

78'//28' =288'+6

"#$ +!"# $' !! $' !!

4: 6746 978: 6746 978:

4: 6746 978: 6746 978:

4: 6746 978: 6746 978:

>'8?#@,.6)

A.<'#

5

6*86

./01#

$8(#B106*<'

>'8?#@,.6)

4=>

*$0B-E1%%0

7,'8('#C',<)6

>'8?#@,.6)

4*6'8,*0#D),(;+'//

781.2(6,1+#5'66,+</

=266,+<#C',<)6

6749

;76

$

'

E&6,%2%#5'66,+</

9766

56F

E12$'0%##-E1%%0

4=>

A.<'#

56*86

A.<'#

56*86

4=>

+0G!$'G!

D8*F'0#5&''.

H+00-ID$&J'%##%#K

()*

986

4*6'8,*0

986

;=F

7,'8('#C',<)6

=266,+<#C',<)6

6766

986

7,'8('#9'0*:

#%&

6766

6766

6746

4*6'8,*0#D),(;+'//

E&6,%2%#5'66,+</

781.2(6,1+#5'66,+</

=266,+<#C',<)6

7,'8('#C',<)6

$'

67;;

>7;

6796

874

6756

56F

$'

6796

874

4*6'8,*0#D),(;+'//

E&6,%2%#5'66,+</

=75

6798

57:

56F

781.2(6,1+#5'66,+</

=266,+<#C',<)6

7,'8('#C',<)6

6786

6745

:74

679

874

67;6

Shield Retaining Cap Nozzle Swirl Ring Electrode

BK14300-3 BK14300-15 BK14300-8 BK14300-13 BK14300-1

L

C125M Torch Body

* Listed Gas Pressures are for 25 ft. torches. Increase Gas Pressure

by 5 psi for each additional 25 ft. of torch length.

Explosion Hazard

Do not cut Aluminum over water tables

WARNING

Page 24

!"#$%&#%'()*+,-'.#/),'0.#(1+/2%*30'/

4,0.#56''0

78'//28'

7,'8('#

9'0*:

!! "#$ #%& $' !! $' !! ()*

+,&-

./0123%

()*

+,&-

./0123%

$' !!

45 56478 769 5655 :;5 47< 748 47= 56585 46:=

7>4; 564<< 96< 56:5 4?5 495 ::5 47? 5658< 469=

4>9 56:85 ;69 4:5 494 488 495 565;5 468:

7>< 567=8 ?68 =8 499 << 497 565;< 46=7

4>: 56855 4:6= 95 498 89 498 565=< 46?<

8>< 56;:8 486? 4655 75 485 95 49= 565<8 :64;

7>9 56=85 4?64 4685 5675 =6; :9 487 75 485 565<8 :64;

=>< 56<=8 ::6: 46:8 4; 48< :: 487 565?5 :6:? @%#

446555:869 47 4;5 4; 48;56455:689 @%#

4-4>9 46:85 746< = 4;< 45 4;4 56445 :6=? @%#

A-45-32-#1%%0-$#-&/0B-,/00%BC-7>4;-A-4-4>9-$'-#1%%0-$#-D/1-,/00%B

56*,+0'//#56''0

78'//28'

7,'8('#

9'0*:

!! "#$ #%& $' !! $' !! ()*

+,&-

./0123%

()*

+,&-

./0123%

$' !!

45 56494 76; 56:5 :<8 47? 798 47< 565=8 46?4

7>4; 564<< 96< 5675 :45 47? :85 47< 565=8 46?4

4>9 56:85 ;69 5695 478 47? 4=5 47< 565<5 :657

7>< 567=8 ?68 5685 ;5 497 <5 49: 565<5 :657

4>: 56855 4:6= 56=5 7; 49< 9; 49; 565<9 :647

8>< 56;:8 486? :; 485 77 49? 565?7 :67;

7>9 56=85 4?64 4< 489 :9 487 56458 :6;= @%#

=>< 56<=8 ::6: 4; 488 4? 489 56458 :6;= @%#

446555:869 44 48? 49 48<56458:6;= @%#

$02%,+2%

78'//28'

7,'8('#

9'0*:

!! "#$ #%& $' !! $' !! ()*

+,&-

./0123%

()*

+,&-

./0123%

$' !!

4>< 564:8 76: 56:5 745 489 7;5 489 565<8 :64;

4>9 56:85 ;69 5695 495 48< 4;= 48< 565?5 :6:?

7>< 567=8 ?68 56;5 =8 4;5 459 48< 565?8 :694

4>: 56855 4:6= 56<5 88 4;: =7 4;: 56455 :689

8>< 56;:8 486? 4655 7< 4;= 9< 4;= 56458 :6;=

7>9 56=85 4?64 :< 4;? 95 4;= 56458 :6;= @%#

=>< 56<=8 ::6: :: 4=: 75 4=4 56458 :6;= @%#

446555:869 48 4=8 :5 4=856458:6;= @%#

4*8;,+<

78'//28' =288'+6

"#$ +!"# $' !! $' !!

47 5645 :689 5645 :689

49 5645 :689 5645 :689

49 5645 :689 5645 :689

4<<

>.<'#

56*86

>.<'#

56*86

>.<'#

56*86

56<5

;64

56:9

7,'8('#9'0*:

#%&

5655

5655

5655

./01#

$8(#?106*<'

7,'8('#@',<)6

=266,+<#@',<)6

4<<

:85

4<<

*$0B-E1%%0

E12$'0%##-E1%%0

A8*B'0#5&''.

F+00-GD$&H'%##%#I

()*

:85

4*6'8,*0

:85

7,'8('#@',<)6

+0J!$'J!

5677

<67

7,'8('#@',<)6

$'

$'

7=K

;5K

C'8D#E,.6)

4*6'8,*0#A),(;+'//

4*6'8,*0#A),(;+'//

F&6,%2%#5'66,+</

781.2(6,1+#5'66,+</

=266,+<#@',<)6

$'

5685

4685

5

6:8;69

56:8

;69

=266,+<#@',<)6

7,'8('#@',<)6

F&6,%2%#5'66,+</

564:

765

56:4

867

=266,+<#@',<)6

C'8D#E,.6)

4*6'8,*0#A),(;+'//

F&6,%2%#5'66,+</

781.2(6,1+#5'66,+</

;5K

56:8

;69

5685

;5K

564:

765

C'8D#E,.6)

781.2(6,1+#5'66,+</

B-10

FLEXCUT™ 125

O

PERATION

Retaining Cap Nozzle Swirl Ring Electrode

BK14300-15 BK14300-9 BK14300-13 BK14300-1

S

hield

B

K14300-4

LC125M Torch Body

L

* Listed Gas Pressures are for 25 ft. torches. Increase

Gas Pressure by 5 psi for each additional 25 ft. of torch

length.

Explosion Hazard

Do not cut Aluminum over water tables

WARNING

Page 25

B-11

O

PERATION

FLEXCUT™ 125

$ $ $ $

5-1/$67((1

89(0039(

8-(9)($

:(1+;

!! "#$ #%& $' !! $' !! ()*

+,&-

./0123%

()*

+,&-

./0123%

$' !!

456 789:7 ;86 7867 4:7 46: 4<7 46: 78477 98:

=5< 78=>: ?8: 78:7 47: 46> 446 46; 78477 98:

459 78:77 498> 78;7 ;7 4:7 >= 4:7 7847: 98>

:5< 78;9: 4:8? 69 4:= :7 4:7 7847: 98>

=56 78>:7 4?84 == 4:6 => 4:9 7847: 98>

>5< 78<>: 9989 9877 9: 4:; =4 4:: 78447 98<

4487779:86 48<7 4? 4;7 9= 4:?78497=87 @%#

4-456 489:7 =48< 9877 46 4;: 4; 4;6 7849: =89 @%#

A-+00-B/1-,/00%C-#1%%0

67+-,1(00$67((1

89(0039(

8-(9)($

:(1+;

!! "#$ #%& $' !! $' !! ()*

+,&-

./0123%

()*

+,&-

./0123%

$' !!

456 789:7 ;86 78=7 >8; 4?< 4:< 94: 46: 78477 98:

=5< 78=>: ?8: ?7 4:7 479 46< 7847: 98 >

459 78:77 498> :: 4:= ;? 46? 7847: 98>

:5< 78;9: 4:8? 4897 7867 4789 =< 4;; 69 4:; 7844: 98?

=56 78>:7 4?84 786= 478< 9; 4;7 =7 4:< 78497 =87

>5< 78<>: 9989 94 4;: 9: 4:? 78499 =84 @%#

4487779:86 4> 4>6 97 4;=784=7=8= @%#

4-456 489:7 =48< 98:7 44 4;< 46 4;; 784=7 =8= @%#

%13&-,3&

89(0039(

8-(9)($

:(1+;

!! "#$ #%& $' !! $' !! ()*

+,&-

./0123%

()*

+,&-

./0123%