Page 1

AUTOMATED SOLUTIONS

CV

3

PHASE

60

Hz

DC

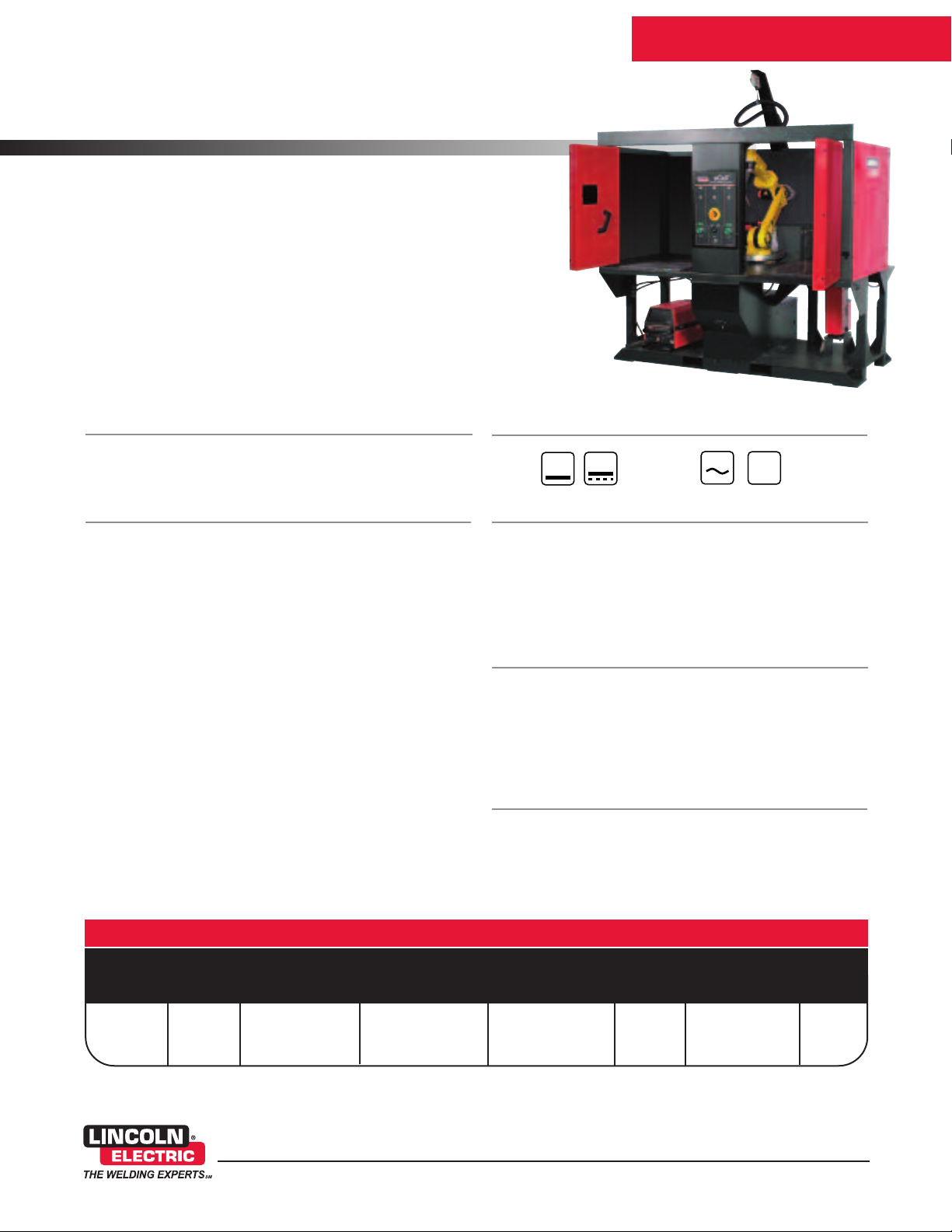

eCell

™

The eCell welding robot cell is a two-fixed table workstation designed for small to

medium sized parts that can be welded without reorientation. The layout is

optimized to maximize the work envelope of the robot, and is ideal for flexible

manufacturing systems allowing manufacturers to install multiple robots in close

proximity to save valuable floor space.

Shipped completely assembled and ready for immediate installation and production,

the eCell is designed to be an attractive and low cost alternative to labor intensive

arc welding.

Processes

CV-MIG Pulsed-MIG Flux-Cored Metal-Cored

Advantage Lincoln

• Simple to set-up, easy to operate.

• Four side fork-lift access.

• Pre-wired with one disconnect switch and fuse protection.

• Integrated user interface.

• 15 User inputs/outputs available.

• 115V 15 Amp auxiliary power receptacle.

• High speed digital communication featuring Arclink™.

• Complete metal surround flash and safety barrier.

• Multi-voltage, offering 230/460/575 Volts, 3-Phase.

• Work Zone: H x W x D = 41 x 30 x 39 in. (1.0 x 0.8 x 1.0 m)

• Manufactured under a quality system certified to ISO 9001

requirements and ISO 14001 environmental standards.

• ANSI/RIA 15.06-99, and compliant design.

Description

Output Input

Unit Includes

• Fanuc®ArcMate®100iBe 6-axis robot

• Power Wave®355M power source

• Power Feed®wire drive system (4-Roll)

• 360 Amp Air-Cooled Welding Torch

• Collision Guard - Torch Protection Software

• (2) - 24 X 24 in. (0.6 X 0.6 m) Precision Machined Tooling Plates

Recommended Options

• Power Ream™ (Torch Reaming Station with Sprayer/Clipper)

• Fume Exhaust Environmental System

• Password Protection Software

• TorchMate 2 – Automatic Tool Center Point Adjustment Software

• PCMCIA 64MB Memory Card

• AccuTrak

• Simple Fixturing Required

Order

AD1222-10 eCell

®

Payoff Kit

TECHNICAL SPECIFICATIONS

Power Source Dimensions Net

Product Product Input Current/Voltage/ H x W x D Weight

Name Number Power Duty Cycle Feeder/Torch Robot inches (mm) lbs. (kg)

eCell AD1222-10 230/460/575/3/60 Power Wave 355M 4-Roll Feeder ArcMate 80x90x60 2200

(20KVA Max) 350A/34V/60% 360 Amp A/C Torch 100iBe (2032x2286x1524) (998)

(300A/32V/100%) (100% CO2) (6 axis)

Publication E10.120 8/07

www.lincolnelectric.com

Page 2

A CLOSER LOOK

FEATURES

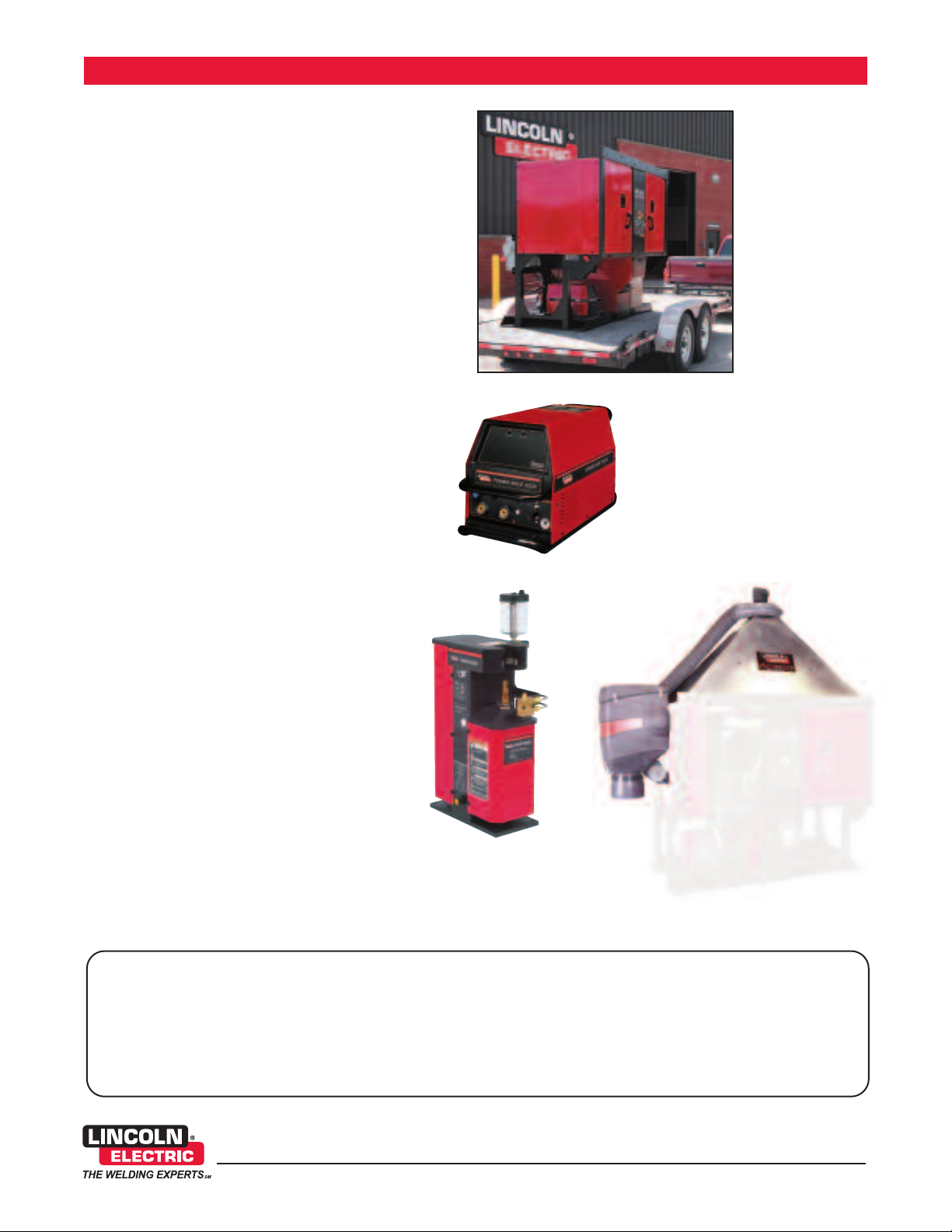

• Compact Design

– 4’ X 8’ (1.2-2.4m) Base

– Four side fork-lift access

– Ideal for flexible manufacturing systems

– Conserves valuable floor space

– Can be transported via 1 ton pick-up truck

• Easy Installation

– Pre-wired with one disconnect switch / fuse box

• Quick Set Up

– Ready to Weld

– All accessories are included

– Just add wire, shielding gas and fixturing

• User Friendly

– Integrated user interface

– 115V auxiliary power

– 230/460/575 3-phase, 60 Hz

– Convenient lockable storage drawer

– 15 User inputs/outputs available

Compact design is

easy to transport and

set in place.

Features

Power Wave 355M

Digital Communication

Waveform Control Technology

®

• High Performance

– Digital Communication - ArcLink™

– Waveform Control Technology™

– 4-Roll Wire Drive System

– 350 Amps 60% Duty Cycle Power Source

• Designed to Comply with:

– ANSI/RIA 15.06-99

• Manufactured under a quality system certified

to ISO 9001 requirements and ISO 14001

environmental standards.

Power REAM Torch

Fume Exhaust Hood Assembly

Statiflex Filter Unit

(Option) Contact Lincoln Automation

for ordering.

Cleaning Station

(Option)

Order K2391-1

CUSTOMER ASSISTANCE POLICY

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the

needs of our customers and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric for advice or information about their use of our products. We respond

to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability,

with respect to such information or advice. We expressly disclaim any warranty of any kind, including any warranty of fitness for any customer’s particular purpose, with respect to

such information or advice. As a matter of practical consideration, we also cannot assume any responsibility for updating or correcting any such information or advice once it has

been given, nor does the provision of information or advice create, expand or alter any warranty with respect to the sale of our products.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility

of the customer. Many variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

TH E LI NCO LN E LEC TRI C CO MPA NY

22801 St. Clair Ave., Cleveland, OH 44117-1199 • 216.481.8100 • www.lincolnelectric.com

Loading...

Loading...