Lincoln Electric DURAWELD 500, DURAWELD 350, K60096-1, K60107-1, 76187 Operator's Manual

...

IM7017-1

April, 2016

Rev. 07

DURAWELD

™

350/500

For use with machine Code

DURAWELD™ 500 K60096-1 / 76187

DURAWELD™ 350 K60107-1 / 76245

• W

orld’s Leader in Welding and Cutting•

THE SHANGHAI LINCOLN ELECTRIC COMPANY

No. 195, Lane 5008, Hu Tai Rd. Baoshan, Shanghai, PRC 201907

www.lincolnelectric.com.cn

Copyright © 2008The Shanghai Lincoln Electric Company

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built with

safety in mind. However, your overall

safety can be increased by proper

installation and thoughtful operation on

your part. DO NOT INSTALL, OPERATE

OR REPAIR THIS EQUIPMENT

WITHOUT READING THIS MANUAL

AND THE SAFETY PRECAUTIONS

CONTAINED THROUGHOUT. Most

importantly, think before you act and be

careful.

Thank you for selecting QUALITY Lincoln Electric products.

Please examine the packaging and equipment for damage. Claims for material damaged in shipment must be

notified immediately to the authorized dealer from whom you purchased the machine.

For future reference, please record your equipment identification information in the table below. Model Name,

Code & Serial Number can be found on the machine rating plate.

Model Name

□ DURAWELD™ 350 □ DURAWELD™ 500

Code & Serial number

Date & Where Purchased

Authorized dealer’s chop

Declaration of conformity

THE SHANGHAI LINCOLN ELECTRIC COMPANY

Designed in conformance with the following norm:

EN 60974-1

THE SHANGHAI LINCOLN ELECTRIC COMPANY

No. 195, Lane 5008, Hu Tai Rd.,(Gao Jing Industry Park), Shanghai, PRC 201907

i

SAFETY

i

D

URAWELD

TM

350/500

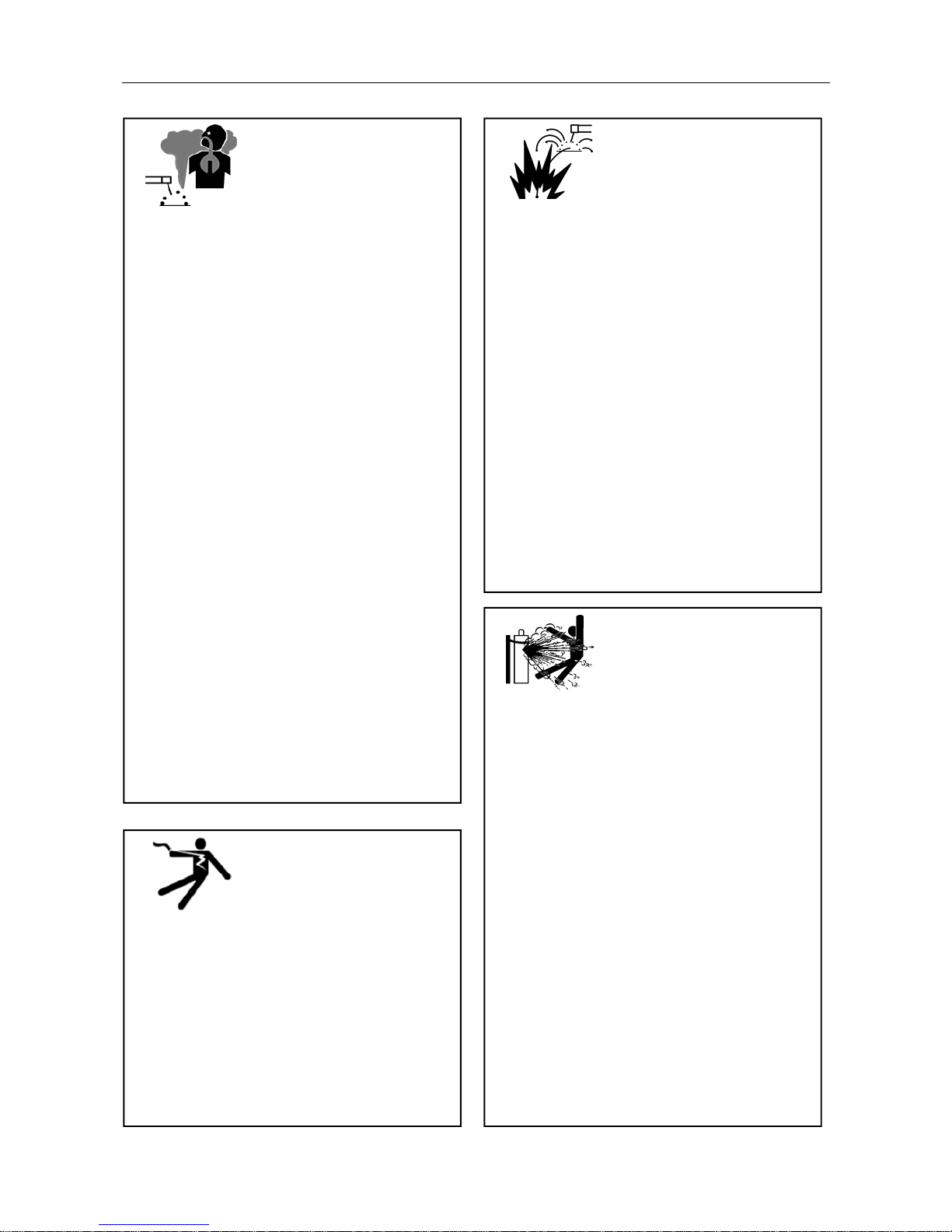

ARC WELDING CAN BE HAZARDOUS. PROTECT YOURSELF AND OTHERS FROM

POSSIBLE SERIOUS INJURY OR DEATH. KEEP CHILDREN AWAY. PACEMAKER

WEARERS SHOULD CONSULT WITH THEIR DOCTOR BEFORE OPERATING

EQUIPMENT.

BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR

PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

WARNING

ELECTRIC AND

MAGNETIC FIELDS

may be dangerous.

1.a Electric cu

rrent flowing through any conductor

causes localized Electric and Magnetic Field

(EMF). Welding current creates EMF fields

around welding cables and welding machines.

1.b EMF fields may interfere with some pacemakers,

and welders having a pacemaker should consult

their physican before welding.

1.c All welders should use the following procedures

in order to minize exposure to EMF fields from

the welding circuit:

1.d.1 Route the electrode and work cables

together – Secure them with tape when

possible.

1.d.2 Never coil the electrode lead around your

body.

1.d.3 Do not place your body between the

electrode and work cables. If the electrode

cable is on your right side, the work cable

should also be on your right side.

1.d.4 Connect the work cable to the workpiece

as close as possible to the area being

welded.

ARC RAYS can burn.

2.a Use a shield with the proper filter and cover

plates to protect your eyes from sparks and the

rays of the arc. Headshield and filter lens should

conform to ANSI Z87. I standards.

2.b Use suitable clothing made from durable flameresistant material to protect your skin and that of

your helpers from the arc rays.

2.c Protect other nearby personnel with suitable,

non-flammable screening and/or warn them not

to watch the arc nor expose themselves to the

arc rays or to hot spatter or metal.

ELECTRIC SHOCK

can kill.

3.a Electrod

e and work (or ground) circuits are

electrically “hot” when the welder is on. Do not

touch these “hot” parts with your bare skin or wet

clothing. Wear dry, hole-free gloves to insulate

hands.

3.b Insulate yourself from work and ground using dry

insulation. Make certain the insulation is large

enough to cover your full area of physical contact

with work and ground.

In addition to the normal safety precautions, if

welding must be performed under electrically

hazardous conditions (in damp locations or while

wearing wet clothing; on metal structures such as

floors, grating or scaffolds, when in cramped

positions such as sitting, kneeling or lying down, if

there is a high risk of unavoidable or accidental

contact with the workpiece or ground) use the

following equipment:

Semiautomatic DC Constant Voltage

(Wire)

Welder.

DC Man

ual (Stick) Welder.

AC Welder with Reduced Open Circuit Voltage.

3.c In semiautomatic or auto

matic wire welding, the

electrode, electrode reel, welding head, nozzle or

semiautomatic welding gun are also electrically

“hot”.

3.d Always be sure the work cable makes a good

electrical connection with the metal being

welded. The connection should be as close as

possible to the area being welded.

3.e Ground the work or metal to be welded to a good

electrical (earth) ground.

3.f Maintain the electrode holder, work clamp,

welding cable and welding machine in good, safe

operating condition. Replace damaged

insulation.

3.g Never dip the electrode in water for cooling.

3.h Never simultaneously touch electrically “hot”

parts of electrode holder to two welders because

voltage between the two can be total of the open

circuit voltage of both welders.

ii

SAFETY

ii

DURAWELD

TM

350/500

FUMES AND GASES

can be dangerous.

4.a Welding may produce fumes and gases

hazardous to health. Avoid breathing these

fumes and gases. When welding, keep your

head out of the welding fumes. Use enough

ventilation and/or exhaust at the arc to keep

fumes and gases away from the breathing zone.

When welding with electrodes which require

special ventilation such as stainless or hard

facing (see instructions on container or

MSDS) or on lead or cadmium plated steel

and other metals or coatings which produce

highly toxic fumes, keep exposure as low as

possible and below Threshold Limit Values

(TLV) using local exhaust or mechanical

ventilation. In confined spaces or in some

circumstances, outdoors, a respirator may be

required. Additional precautions are also

required when welding on galvanized steel.

4.b Do not weld in locations near chlorinated

hydrocarbon vapors coming from degreasing,

cleaning or spraying operations. The heat and

rays of the arc can react with solvent vapors to

form phosgene, a highly toxic gas, and other

irritating products.

4.c Shielding gases used for arc welding can

displace air and cause injury or death. Always

use enough ventilation, especially in confined

areas, to insure breathing air is safe.

4.d Read and understand the manufacturer’s

instructions for this equipment and the

consumables to be used, including the material

safety data sheet (MSDS) and follow your

employer’s safety practices. MSDS forms are

available from your welding distributor or from

the manufacturer.

FOR ELECTRONICALLY

powered equipment.

5.a Turn off input power using the disconnect switch

at the fuse box before working on the equipment.

5.b Install equipment in accordance with national

standards, all local standards and the

manufacturer’s recommendations.

5.c Ground the equipment in accordance with the

national standards and the manufacturer’s

recommendations.

WELDING SPARKS

can cause fire or

explosion.

6.a Remove fire hazards from the welding area. If

this is not possible, cover them to prevent the

welding sparks from starting a fire. Remember

that welding sparks and hot materials from

welding can easily go through small cracks and

openings to adjacent areas. Avoid welding near

hydraulic lines. Have a fire extinguisher readily

available.

6.b When not welding, make certain no part of the

electrode circuit is touching the work or ground.

Accidental contact can cause overheating and

create a fire hazard.

6.c Do not heat, cut or weld tanks, drums or

containers until the proper steps have been

taken to insure that such procedures will not

cause flammable or toxic vapors from

substances inside. They can cause an explosion

even though they have been “cleaned”.

6.d Sparks and spatter are thrown from the welding

arc. Wear oil free protective garments such as

leather gloves, heavy shirts, cuffless trousers,

high shoes and a cap over your hair.

CYLINDER may

explode if damaged.

7.a Use only compressed gas cylinders containing

the correct shielding gas for the process and

properly operating regulators designed for the

gas and pressure used. All hoses, fittings, etc.

should be suitable for the application and

maintained in good condition.

7.b Always keep cylinders in an upright position

securely chained to an undercarriage or fixed

support.

7.c Cylinders should be located:

Away from areas where they may be struck or

subjected to physical damage.

A safe distance from arc welding or cutting

operations and any other source of heat,

sparks, or flame.

7.d Never allow the electrode, electrode holder or

any other electrically “hot” parts to touch a

cylinder.

7.e Keep your head and face away from the cylinder

valve outlet when opening the cylinder valve.

7.f Valve protection caps should always be in place

and hand tight except when the cylinder is in use

or connected for use.

A-1 INSTALLATION A-1

DURAWELD

TM

350/500

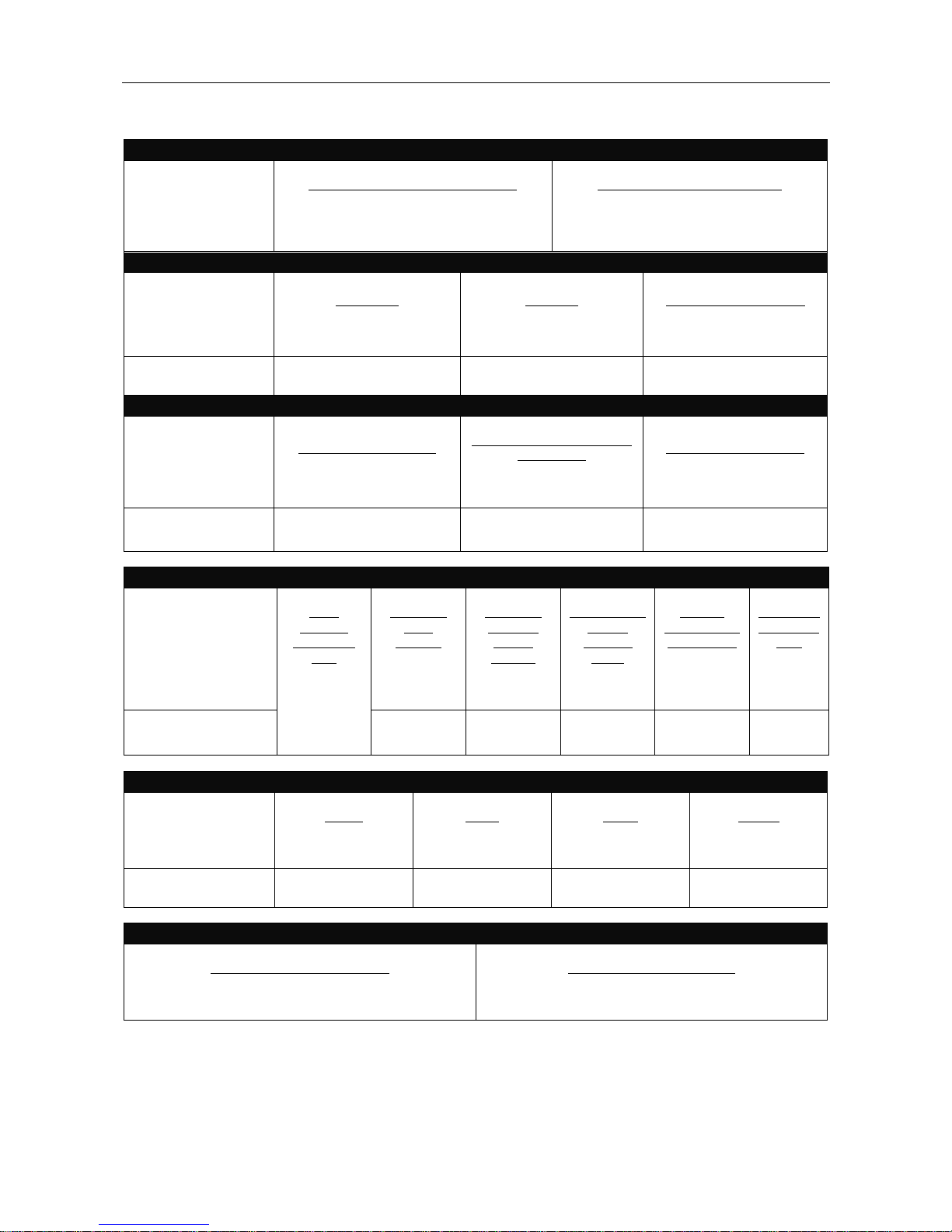

TECHNICAL SPECIFICATIONS – DURAWELD

TM

350/500

INPUT – THREE PHASE ONLY

DURAWELD

TM

350/500

Standard Voltage/Phase/Frequency

380V ~ 415V(±10%)/3/50 Hz

Input Power @ 60% Duty Cycle

DURAWELD

TM

350 18.1KVA/14.1KW

DURAWELD

TM

500 30.6KVA/25.3KW

RATED OUTPUT – DC ONLY

DURAWELD

TM

350

Duty Cycle

60%

100%

Amperes

350A

270A

Volts at Rated Amperes

31.5V

27.5V

DURAWELDTM 500

60%

100%

500A

390A

39V

33.5V

* OUTPUT RANGE

DURAWELD

TM

350

Welding Current Range

50A ~ 350A

Rated Open Circuit Voltage

RMS/PEAK

53V/60V

Welding Voltage Range

16.5 V ~ 31.5V

DURAWELDTM 500 50A ~ 500A 60V/66V 16.5V ~ 39V

RECOMMENDED INPUT WIRE AND FUSE SIZES

DURAWELDTM 350

Input

Voltage/

Frequency

(Hz)

342V ~

456.5V/

50Hz or

60Hz

Maximum

Input

Ampere

30A

Maximum

Effective

Supply

Current

22A

60°C Copper

Wire in

Conduct

Sizes

10 mm

2

Fuse or

Breaker Size

(Super Lag)

50A

Grounding

Conductor

Size

6mm2

DURAWELDTM 500 48A 38A 16 mm2 80A 10mm2

PHYSICAL DIMENSIONS

DURAWELD

TM

350

Height

755mm

Width

500mm

Depth

590mm

Weight

116Kg

DURAWELDTM 500 755mm 500mm 590mm 154Kg

Temperature Range

Operating Temperature Range

-10°C ~ +40°C

Storage Temperature Range

-25°C ~ +55°C

*Note: The output range is measured under conventional welding condition per IEC 60974-1:2000 standard.

For any maintenance or repair operation it is recommended to contact the nearest technical service center or directly

consult the machine division of the Shanghai Lincoln Electric Co. Ltd.. Maintenance or repairs performed by

unauthorized service centers or personnel will void the manufacturer’s warranty.

A-2

INSTALLATION

A-2

DURAWELD

TM

350/500

SAFETY PRECAUTIONS

Read the entire installation section before starting

installation.

ELECTRIC SHOCK can kill.

Only qualified personnel

should perform this installation.

Turn the input power OFF

at the main switch or fuse box

before working on this

equipment. Turn off the input power to any other

equipment connected to the welding system at

the main switch or fuse box before working on

the equipment.

Do not touch electrically “Hot” parts.

Always connect the DURAWELDTM grounding lug

(located at the rear of the case) to a proper safety

(Earth) ground.

DURAWELDTM must only be used on three-

phase, MEN input power.

SELECT SUITABLE LOCATION

This power source should not be subjected to rain, nor

should any parts of it be submerged in water. Doing so

may cause improper operation as well as pose a safety

hazard. The best practice is to keep the machine in a

dry, sheltered area.

The bottom of machine must always be placed on a

firm, secure, level surface. There is a danger of the

machine toppling over if this precaution is not

taken.

Place the welder where clean cool air can freely

circulate in through the side and back louvers and out

through the case bottom. Water dust or any foreign

material that can be drawn into the welder should be

kept a minimum. Failure to observe these precautions

can result in excessive operating temperatures and

nuisance shutdowns.

Locate the DURAWELD

TM

machine away from radio

controlled machinery. Normal operation of the welder

may adversely affect the operation of RF controlled

equipment, which may result in bodily injury or damage

to the equipment.

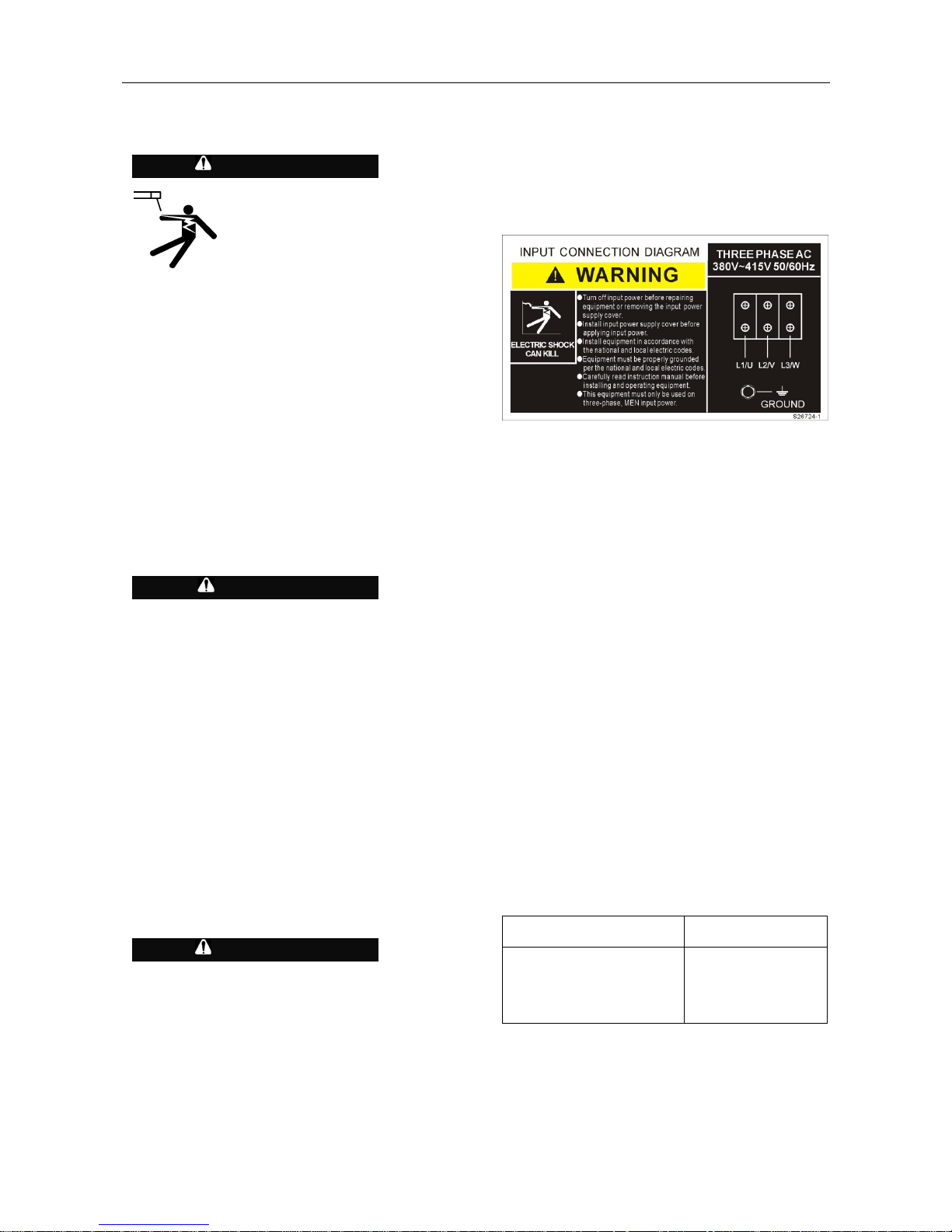

INPUT POWER AND GROUNDING

CONNECTION

Only a qualified electrician should connect the

input leads to the DURAWELD

TM

. Connections

should be made in accordance with the connection

diagram. Failure to do so may result in bodily injury

or death.

Open the input box on the rear of the case. Use a

three-phase supply line, the three live wires should go

through the three holes of the input wire holder and be

securely clamped and fixed. Connect L1, L2, L3 and

ground according to the Input Supply Connection

Diagram decal, refer to Figure A.1 on this page.

FIGURE A.1 – Input Supply Connection Diagram

The DURAWELDTM is supplied connected for 50Hz

input. In regions where the frequency of electricity is

60HZ, the DURAWELDTM machine can identify the 60

HZ frequency automatically and work in terms of this

frequency.

Make sure the amount of power available from the input

connection is adequate for normal operation of the

machine. Refer to the Technical Specifications at the

beginning of this Installation section for recommended

fuse and wire sizes. Fuse the input circuit with the

recommended super lag fuse or delay type breakers.

Using fuses or circuit breakers smaller than

recommended may result in “nuisance” shut-offs from

welder inrush currents, even if the machine is not being

used at high currents.

OUTPUT AND WIRE FEEDER

CONNECTIONS

Connect a work lead of sufficient size and length (Per

Table A.1) between the Negative Output terminal on the

power source and the work. Be sure the connection to

the work makes tight metal-to-metal electrical contact.

To avoid interference problems with other equipment

and to achieve the best possible operation, route all

cables directly to the work and wire feeder. Avoid

excessive lengths and do not coil excess cable.

Minimum work and electrode cable sizes are as follows:

TABLE A.1

Current (60% Duty Cycle) Minimum Copper

Work Cable Size

200A

300A

400A

500A

Up To 30m Length

30 mm

2

50 mm

2

70 mm

2

95 mm

2

Note: Recommended cable sizes may vary due to

different cable quality. The overall voltage pressure of

grounding and welding cables is no more than 4V under

rated current.

WARNING

CAUTION

WARNING

A-3

INSTALLATION

A-3

DURAWELD

TM

350/500

PWF wire feeder connection instructions

(See Figure A. 2)

Turn the DURAWELD

TM

power switch “OFF”.

Connect the control cable from the PWF/LWF feeder

to the 6-pin connector. 2 wire feeder models are:

LWF-2/LWF-4Plus

Connect the electrode cable to the Positive Output

terminal.

For secure electrical connections, the Nuts

connecting the output terminals and cables must

be tightened. Damage to output studs and poor

performance may occur, if this instruction is not

followed.

GUN AND CABLE INSTALLATION

Optional guns with various cable length can be used

with the DURAWELD

TM

.

Turn the welder power switch off before installing

gun and cable.

Gun and cable assembly installation instruction

Unscrew the hexagon head screw in front of the wire

drive unit (inside wire feed compartment) until tip of

screw no longer protrudes into gun opening as seen

from front of wire feeder.

Insert the male end of gun cable into the female

casting. Make sure connector is fully inserted and

tighten the hexagon head screw.

Connect the two-pin gun trigger connector from the

gun and cable to the mating receptacle, then tighten

the retaining ring.

Connect the gas connector to the mating receptacle

at front of wire feeder, and tighten the copper

retaining ring.

CONNECTING SHIELDING GAS

DURAWELD

TM

supports MIG/MAG, FCAW-GS/SS

Welding Process.

User must provide gas cylinder of appropriate type

shielding gas for the process being used with the

DURAWELD™.

CYLINDER may explode if damaged.

Gas under pressure is explosive. Always keep

gas cylinders in an upright position and always

keep chained to undercarriage or stationary

support.

Install shielding gas supply as follows:

Remove the cylinder cap. Inspect the cylinder valve

and regulator for damaged threads, dirt, dust, oil or

grease. Remove dust and dirt with a clean cloth. DO

NOT ATTACH THE REGULATOR IF OIL, GREASE

OR DAMAGE IS PRESENT! Inform your gas

supplier of this condition. Oil or grease in the

presence of high pressure oxygen is explosive.

Stand to one side away from the outlet and open the

cylinder valve for an instant. This blows away any

dust or dirt which may have accumulated in the valve

outlet.

Attach the flow regulator to

the cylinder valve and tighten the

union nut(s) securely with a

wrench.

NOTE: When connecting to a CO

2

cylinder, please select a CO

2

Regulator Heater for the

prevention of ice build up. Failure to do so, may result

in poor welding performance. The power cord of the

gas heater must be plugged into the receptacle on the

rear of the DURAWELD

TM

case.

Attach the end of the inlet gas hose, from the wire

feeder, to the outlet fitting of the flow regulator, and

tighten the union nuts securely with a wrench.

Before opening the cylinder valve, turn the regulator

adjusting knob counterclockwise until the adjusting

spring pressure is released.

Standing to one side, open the cylinder valve slowly

a fraction of a turn. When the cylinder pressure

gauge pointer stops moving, open the valve fully.

Never stand directly in front of or behind the flow

regulator when opening the cylinder valve. Always

stand to the side.

The flow meter is adjustable. Adjust it to the flow rate

recommended for the weld procedure.

CAUTION

WARNING

WARNING

WARNING

FIGURE A. 2 – OUTPUT AND WIRE FEEDER CONNECTIONS

B-1

OPERATION

B-1

DURAWELD

TM

350/500

SAFETY PRECAUTIONS

ELECTRIC SHOCK can kill.

Do not touch electrically

live parts or electrode with skin

or wet clothing.

Insulate yourself from

work and ground.

Always wear dry

insulating

gloves.

FUMES AND GASES can be

dangerous.

Keep your head out of

fumes.

Use ventilation or exhaust

to remove fumes from breathing

zone.

WELDING SPARKS can cause

fire or explosion.

Keep flammable material

away.

Do not weld on closed

containers.

ARC RAYS can burn eyes and

skin.

Wear eyes, ear and body

protection.

PLEASE SEE ADDITIONAL WARNING

INFORMATION AT THE FRONT OF THIS

OPERATOR’S MANUAL.

GENERAL DESCRIPTION

The DURAWELDTM is a semiautomatic DC arc welding

machine offering CV DC welding. It is rated as follows:

DURAWELD

TM

350: 350amps, 31.5volts at 60% duty

cycle.

DURAWELD

TM

500: 500amps, 39volts at 60% duty

cycle.

DUTY CYCLE

The duty cycle of a welding machine is the percentage

of time in a 10 minute cycle at which the welder can

operate the machine at rated welding current.

60% duty cycle:

Weld for 6 minutes Break for 4 minutes

Excessive extension of the duty cycle will cause the

thermal protection circuits to activate.

The DURAWELD

TM

machine is equipped with a

thermostat overheating protection device. When the

machine detects overheating, the output will turn off,

and the Thermal Indicator Light will turn “ON“. When

the machine has cooled to a safe temperature, the

Thermal Indicator Light will go out and the machine will

resume normal operation.

Note: For safety reasons the machine will not come out

of thermal shutdown if the trigger on the welding gun

has not been released.

Wait for machine

to cool down

Or decrease

duty cycle

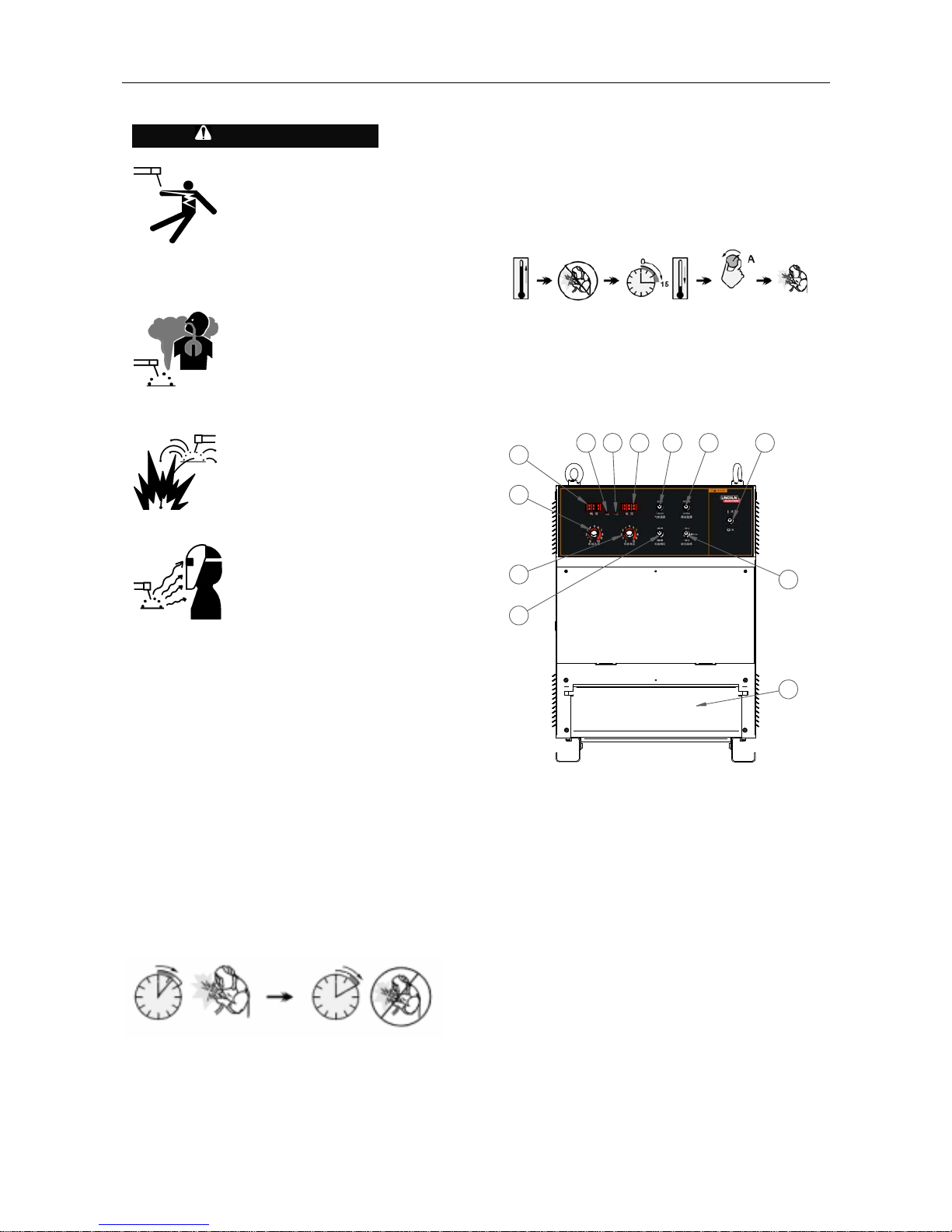

OPERATIONAL FEATURES AND

CONTROLS

Front Panel (Please see figure B.1)

123456

7

8

9

10

11

12

1. ON/OFF POWER SWITCH

After input power is connected and the power switch is

turned on, the digit meters are active. Voltage meter will

show pre-set value.

2. Wire selection

Solid and Flux-cored

3.GAS SELECTION

There is a selection switch on CO2 and mix gas

according to actual welding condition.

WARNING

B-3

OPERATION

B-3

DURAWELD

TM

350/500

4. VOLTAGE METER

Actual welding voltage will be shown in welding state;

pre-set value will be shown if no welding operation.

Crater pre-set value will be shown when any crater

parameter is adjusted.

5. SYNERGIC STATE INDICAITOR

The indicator will be lighted when this function is turned

on to indicate synergic function.

Otherwise, it will be in the independent adjustment

state.

6. CRATER ADJUSTMENT INDICATOR

The indicator will be lighted when adjusting crator

voltage or current to indicate pre-set value of crater

voltage and current.

7. AMPERAGE METER

During the welding process, this meter displays the

welding current value. This meter displays pre-set value

if there is no welding operation; Crator current pre-set

value will be shown when crator parameter is adjusted.

8. Crater Current Potentiometer

This knob adjusts the output current (wire feed speed),

when the Dura Weld

TM

machine is in crater mode.

9. Crater Voltage & spot weld time Potentiometer

This knob adjusts the value of output voltage, when the

Dura Weld

TM

weld mode switch is selected to 4-step.

This Knob adjust the persistence time of spot weld,

when the weld mode switch is selected to spot

weld.(Only for Duraweld 350)

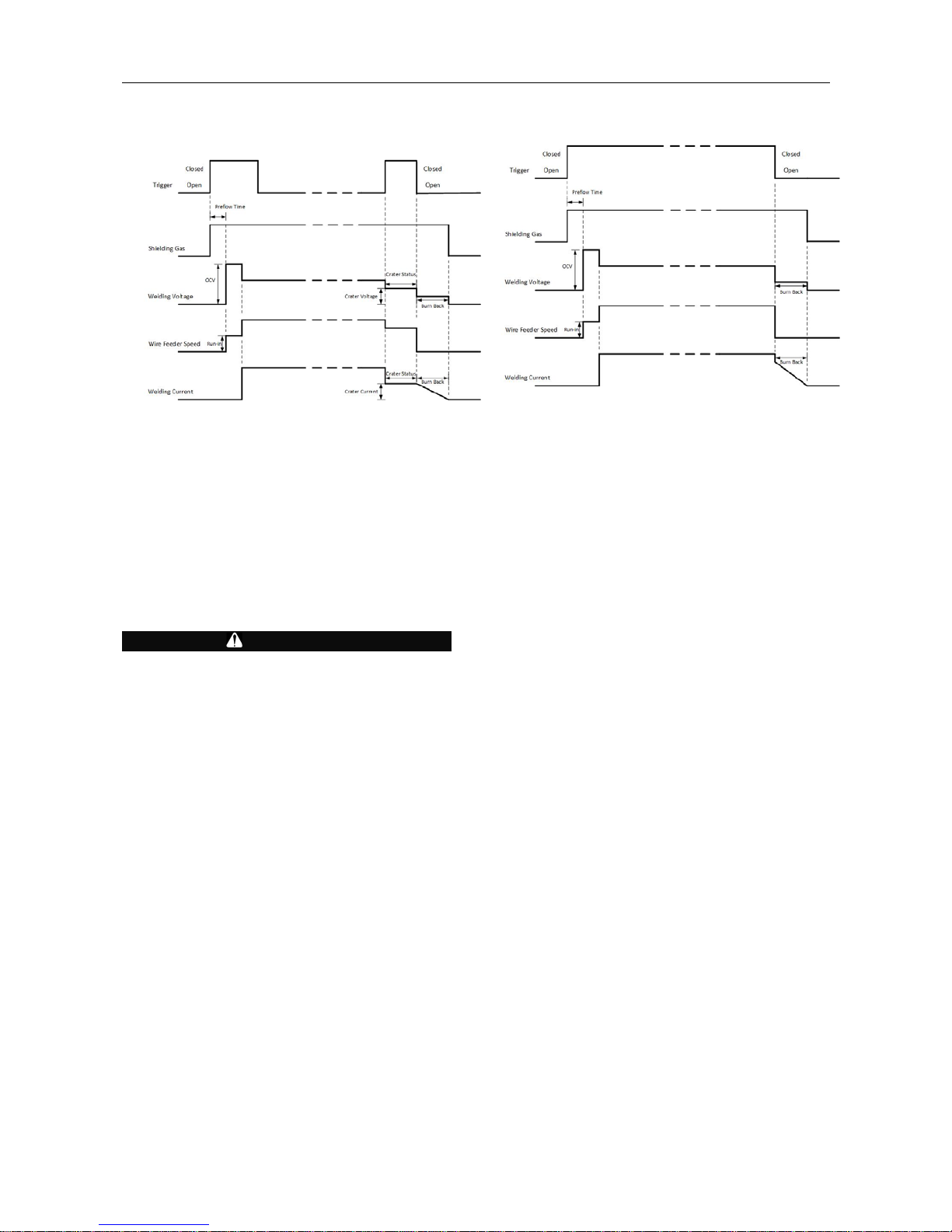

10. Weld Mode SWITCH

This switch enables the selection of 2-step or 4-step

mode(Enable or disable the crater mode) by this switch.

And also can use this switch enable the spot weld

mode on Duraweld 350.

NOTE: The DURAWELD

TM

machine also features a

Crater mode. During 2-step mode, there is no crater

output. During the 4-step mode, after the welder

activates the trigger, the DURAWELD shifts to crater

mode.

Please see FIGURE B.4 for an understanding of the

detailed working process for 2 and 4 step modes.

11. WIRE DIAMETER SELECTION

There are three diameter selection switch;

For Duraweld 500,1.0, 1.2, 1.6 can be select with this

switch.

For Duraweld 350,1.2,1.0, 0.8 can be select with this

switch.

It can be set according to actual welding request. Preset current is more accurate when the wire diameter

above is selected. Otherwise, it will stray from pre-set

value.

12. PROTECTION DOOR

This door is used to protect the output terminal and wire

feeder connector. Only after turning off the power,

Open protection door to connect the welding cables and

LWF feeder.

Do NOT operate the DURAWELD

TM

machine with

this door open.

Output Stud

(Fig B.2)

1 Negtive Stud.

2 The connector of Wire feeder.

3 Positive Stud.

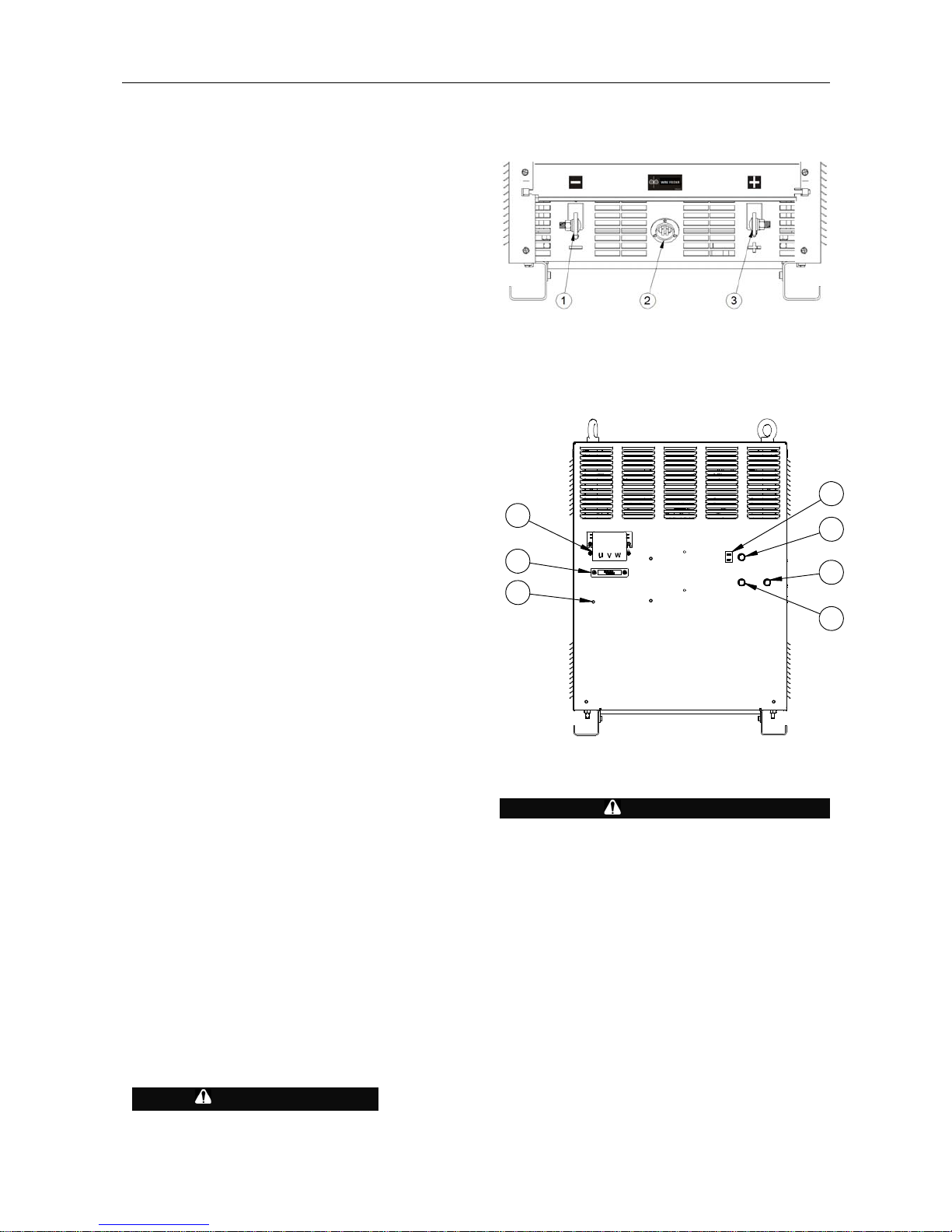

REAR PANEL (FIGURE B.3)

1

2

3

4

6

7

5

1. INPUT POWER PROTECTIVE BOX

Insulation box is used to cover the input connections,

offering insulating protection to the operator.

WARNING

Insulation box must be installed before turning on

the main power supply.

2. INPUT CABLE HOLDING BRACKET

This bracket holds the three phase power cables

securely.

3. GROUND CABLE CONNECTION

Connect the input earth cable to the rear of the case. A

earth Hex. Screw is located on the lower rear of the

case. Secure the earth cable lug-end with the screw

into the case hole.

4. WIRE FEEDER 8A FUSE AND FUSE HOLDER

250V 8A fuse is used to protect wire feeder control

circuit from short circuit so that control board is not

damaged.

WARNING

B-3

OPERATION

B-3

DURAWELD

TM

350/500

5. GAS HEATING 2A FUSE AND FUSE HOLDER

This machine is equipped with AC220V(200W) heating

power. This fuse is used to protect heating circuit.

6. GAS HEATING SOCKET

This is output socket of Max Aux 220v power, used

to connect with gas heater.

WARNING

Only 220V gas heater could be connected at the plug of

low voltage, do not connect other electrical device,

otherwise, the machine could be damaged.

7. 2 A FUSE FOR CONTROL BOARD

An 2-amp slow blow fuse on the machine’s rear

panel protects the control board and contactor from

excessive overloads or short circuits.

Function and schedule See B.4

FIGURE B.4

FOUR STEP

TWO STEP

Loading...

Loading...