Page 1

ACN 000 040 308

THE LINCOLN ELECTRIC COMPANY

(AUSTRALIA) PTY. LTD.

A.C.N. 000 040 308

SYDNEY. AUSTRALIA

A Subsidiary of

THE LINCOLN ELECTRIC CO. U.S.A.

Associated Subsidiaries in Australasia, Europe, North and South America.

THE WORLD’S LEADER IN WELDING AND CUTTING PRODUCTS

SAFETY DEPENDS ON YOU

Lincoln Electric welders are designed and built with safety in mind. However, your overall safety can be increased by

proper installation . . . and thoughtful operation on your part. Read and observe the general safety precautions on

page 2 and follow specific installation and operating instructions included in this manual.

Most importantly, think before you act and be careful.

IMA 574B

OPERATING MANUAL

Part No. Code Desc Volts

KA1392 1447 CV320-I 415

KA1392-1 1473 CV320-I 380

KA1392 1509 CV320-I 415

KA1392-1 1510 CV320-I 380

KA1392 1535 CV320-I 415

This manual applies to

CV320-I

Semi automatic arc welding machine

Page 2

Page 2 CV320-I IMA 574B

PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH. READ AND UNDERSTAND

BOTH THE SPECIFIC INFORMATION GIVEN IN THE OPERATING MANUAL FOR THE WELDER AND/OR OTHER

EQUIPMENT TO BE USED AS WELL AS THE FOLLOWING GENERAL INFORMATION.

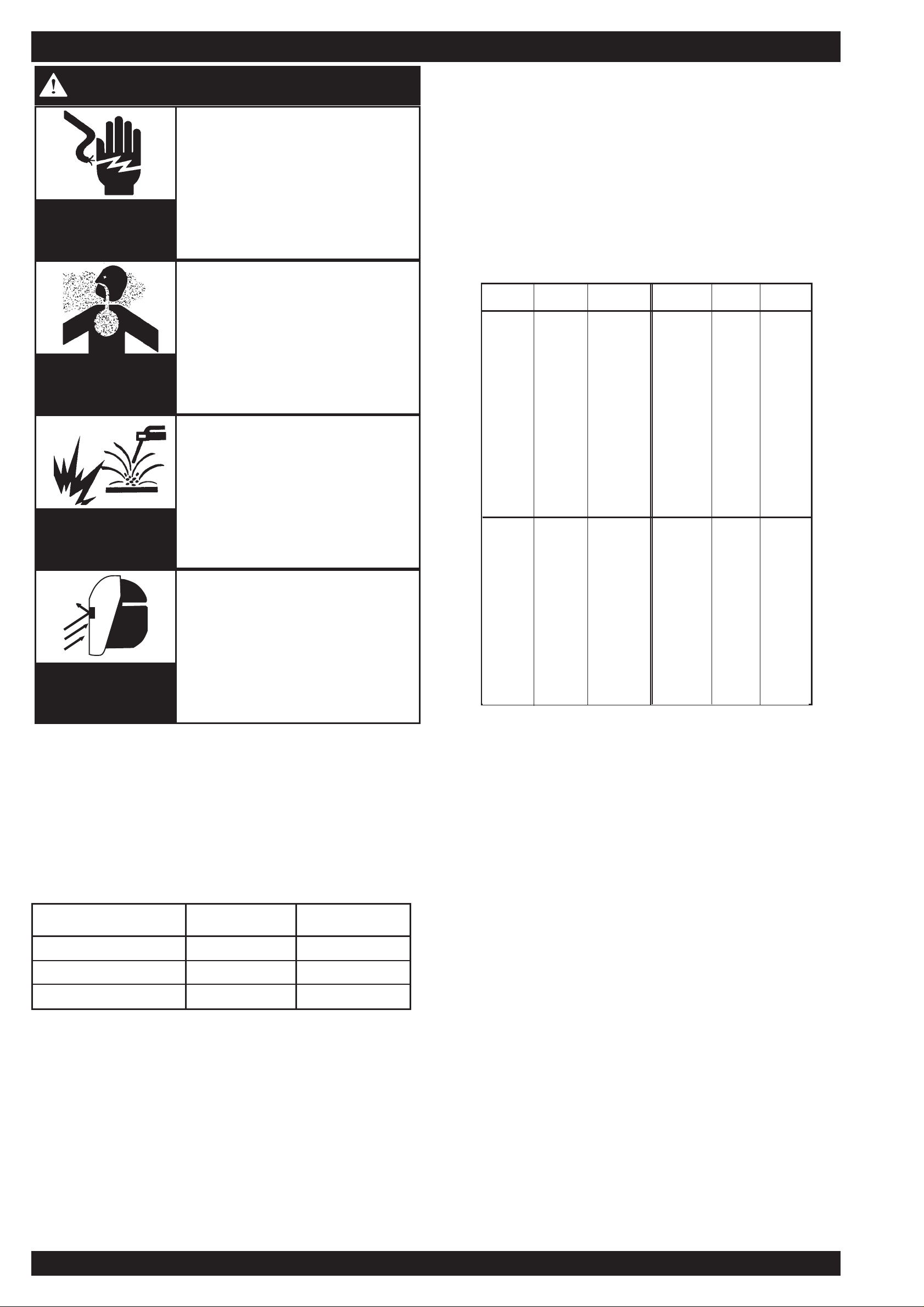

ARC WELDING SAFETY PRECAUTIONS

1.a. The electrode and work (or ground) circuits are

electrically “hot” when the welder is on. Do not touch

these “hot” parts with your bare skin or wet clothing.

Wear dry, hole-free gloves to insulate hands.

b. In semi-automatic and automatic wire welding, the

electrode, electrode reel, welding head and nozzle or

semi-automatic welding gun are also electrically “hot”.

c. Insulate yourself from work and ground using dry

insulation. When welding in damp locations, on metal

framework such as floors, gratings or scaffolds, and

when in positions such as sitting or Lying, make certain

the insulation is large enough to cover your full area of

physical contact with work and ground.

d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The

connection should be as close as possible to the area

being welded.

e. Ground the work or metal to be welded to a good

electrical (earth) ground.

f. Maintain the electrode holder, work clamp, welding

cable and welding machine in good, safe operating

condition. Replace damaged insulation.

g. Never dip the electrode holder in water for cooling.

h. Never simultaneously touch electrically “hot” parts of

electrode holders connected to two welders because

voltage between the two can be the total of the open

circuit voltage of both welders.

i. When working above floor level, protect yourself from

a fall should you get a shock.

j. Also see items 4c and 6.

2.a. Welding may produce fumes and gases hazardous to

health. Avoid breathing these fumes and gases. When

welding, keep your head out of the fume. Use enough

ventilation and/or exhaust at the arc to keep fumes and

gases away from the breathing zone. When welding

on galvanized, lead or cadmium plated steel and other

metals which produce toxic fumes, even greater care

must be taken.

b. Do not weld in locations near chlorinated hydrocarbon

vapours coming from degreasing, cleaning or spraying

operations. The heat and rays of the arc can react with

solvent vapours to form phosgene, a highly toxic gas,

and other irritating products.

c. Shielding gases used for arc welding can displace air

and cause injury or death. Always use enough

ventilation, especially in confined areas, to ensure

breathing air is safe.

d. Read and understand the manufacturer ’s instructions

for this equipment and the consumables to be used,

including the material safety data sheet (MSDS) and

follow your employer’s safety practices.

e. Also see Item 7b.

3. a. Use a shield with the proper filter and cover plates to

protect your eyes from sparks and the rays of the arc

when welding or observing open arc welding.

Headshield and filter lens should conform to AS 1674.21990 standards.

b. Use suitable clothing made from durable flame

resistant material to protect your skin and that of your

helpers from the arc rays.

c. Protect other nearby personnel with suitable non

flammable screening and/or warn them not to watch the

arc or expose themselves to the arc rays or to hot

spatter or metal.

4.a. Remove fire hazards from the welding area. If this is not

possible, cover them to prevent the welding sparks

from starting a fire. Remember that welding sparks and

hot materials from welding can easily go through small

cracks and openings to adjacent areas. Have a fire

extinguisher readily available.

b. Where compressed gases are to be used at the job

site, special precautions should be used to prevent

hazardous situations. Refer to AS1674 Parts 1 & 2

“Safety in Welding and Allied Processes”, WTIA

Technical Note 7 “Health and Safety in Welding” and

the operating information for the equipment being used.

c. When not welding, make certain no part of the

electrode circuit is touching the work or ground.

Accidental contact can cause overheating and create a

fire hazard.

d. Do not heat, cut or weld tanks, drums or containers until

the proper steps have been taken to insure that such

procedures will not cause flammable or toxic vapours

from substances inside. These can cause an explosion

even though the vessel has been “cleaned”. For

information purchase AS 1674-1990.

e. Vent hollow castings or containers before heating,

cutting or welding. They may explode.

f. Sparks and spatter are thrown from the welding arc.

Wear oil free protective garments such as leather

gloves, heavy shirt, cuffless trousers, high shoes and a

cap over your hair. Wear ear plugs when welding out of

position or in confined places. Always wear safety

glasses with side shields when in a welding area.

g. Connect the work cable to the work as close to the

welding area as possible. Work cables connected to the

building framework or other locations away from the

welding area increase the possibility of the welding

current passing through lifting chains, crane cables or

other alternate circuits. This can create fire hazards or

overheat lifting chains or cables until they fail.

h. Also see Item 7c.

ELECTRIC SHOCK can kill

FUMES AND GASES

can be dangerous

ARC RAYS can burn

WELDING SPARKS can

cause fire or explosion

Page 3

IMA 574B CV320-I Page 3

5. a. Use only compressed gas cylinders containing the

correct shielding gas for the process used and

properly operating regulators, designed for the gas

and pressure used. All hoses, fittings, etc. should be

suitable for the application and maintained in good

condition.

b. Always keep cylinders in an upright position and

securely chained to an undercarriage or fixed

support.

c. Cylinders should be located :

• Away from areas where they may be struck or

subjected to physical damage.

• A safe distance from arc welding or cutting

operations and any other source of heat, sparks or

flame.

d. Never allow the electrode, electrode holder, or any

other electrically “hot” parts to touch a cylinder.

e. Keep your head and face away from the cylinder

valve outlet when opening the cylinder valve.

f. Valve protection caps should always be in place and

hand-tight except when the cylinder is in use or

connected for use.

g. Read and follow the instructions on compressed gas

cylinders and associated equipment, and AS 2030

Parts 1 & 2.

6. a. Turn off input power using the disconnect switch at

the fuse box before working on the equipment.

b. Install equipment in accordance with the SAA Wiring

Rules, all local codes and the manufacturer’s

recommendations.

c. Ground the equipment in accordance with the SAA

Wiring Rules and the manufacturer’s

recommendations.

7. a. Turn the engine off before troubleshooting and

maintenance work unless the maintenance

work requires it to be running.

b. Operate engines in open, well ventilated areas

or vent the engine exhaust fumes outdoors.

c.Do not add fuel near an open flame, welding

arc or when the engine is running. Stop the

engine and allow it to cool before refuelling to

prevent spilled fuel from vaporizing on contact

with hot engine parts and igniting. Do not spill

fuel when filling tank. If fuel is spilled, wipe it up

and do not start engine until fumes have been

eliminated.

d.Keep all equipment, safety guards, covers

and devices in position and in good repair.

Keep hands, hair, clothing and tools away

from V-belts, gears, fans and all other

moving parts when starting, operating or

repairing equipment.

e. In some cases it may be necessary to remove

safety guards to perform required

maintenance. Remove guards only when

necessary and replace them when the

maintenance requiring their removal is

complete. Always use the greatest care when

working near moving parts.

f. Do not put your hands near the engine fan.

Do not attempt to override the governor or

idler by pushing on the throttle control rods

while the engine is running.

g.To prevent accidentally starting petrol engines

while turning the engine or welding generator

during maintenance work, disconnect the

spark plug wires, distributor cap or magneto

wire as appropriate.

h.To avoid scalding do not remove the radiator

pressure cap when the engine is hot.

CYLINDER may explode if

damaged

FOR ELECTRICALLY

powered equipment

FOR ENGINE powered

equipment

HAVE ALL INSTALLATIONS, OPERATION, MAINTENANCE AND REPAIR WORK PERFORMED BY QUALIFIED PEOPLE

HOW TO ORDER REPLACEMENT PARTS

To ensure that you receive the correct replacement part the following procedure should be followed:

1. Quote Serial Number and Code Number.

2. Quote the Description, Item Number and Parts List Number of the desired part. When ordering parts for items

carrying brand names of other companies, such as fan motors, drive shafts, etc., be sure to include the other

company’s name and part number and other relevant information.

3. Should the primary cord be damaged, a special cord is required, and is available from Lincoln.

4. Parts should be ordered from Lincoln’s nearest authorised Field Service Shop. (The “Lincoln

Service Directory” listing these shops geographically is available on request.)

NOTE: “Hardware” in the Lincoln Parts Lists are not Lincoln stock items but can be obtained via the Field Service Shop network.

Component parts of assemblies such as stator coils or armature coils, etc., which require electrical testing or locating fixtures are

not considered replaceable items. This is to ensure that the customer receives parts which will keep the welder in the best

operating condition.

For more detailed information it is strongly recommended that you purchase a copy of “Safety in Welding and Cutting - ANSI

Standard Z 49.1” and WTIA Technical Note 7. All WTIA publications and ANSI/AWS Standards are available from the Welding

Technology Institute of Australia, P.O. Box 6165, Silverwater NSW 2128. For copies of various Australian Standards contact your

local S.A.A. office.

Page 4

Page 4 CV320-I IMA 574B

All welders should follow safe practices that minimize their

exposure to electric and magnetic fields (EMF).

For welders wearing implanted pacemakers, safe welding

practices are particularly important and additional procedures

should be followed by those who have decided to continue to

weld. (Hopefully in keeping with a doctor’s advice).

The following procedures will not eliminate exposure to EMF or

the possibility of arc welding having an effect on a pacemaker,

however if followed, they will significantly reduce exposure to

electric and magnetic fields. Electric and magnetic fields are

created any time electric current flows through a conductor,

however it is not clear whether such exposure affects ones health.

Some researchers have reported that exposure to EMF may

cause leukemia or other illnesses. These claims originally arose in

relation to high voltage electric power lines and are very much in

dispute in the medical and scientific arena, however the best

advice is to minimise your exposure to EMF to protect your health

should doctors eventually decide there is a risk.

There are four fundamental fact about EMF:

• With direct current (DC), the field strength is relatively

constant and does not change.

• With alternating current (AC), the field strength constantly

changes.

• The greater the current flow, i.e. the higher the amps, the

stronger the field created by the current

• The closer the conductor or electrical device is to the body,

the greater the exposure to the field.

Minimising Exposure

All welders should use the following procedures to minimise EMF

exposure.

• Route electrode or gun and work cables together. Secure

them with tape if possible.

• Never coil the electrode lead around your body.

• Do not place your body between the electrode and work

cables. If your electrode cable is on your right side the work

cable should also be on your right side.

• Connect the work cable to the work piece as close as possible

to the area being welded. (This is also a good practice to

eliminate a common problem on welding - a poor work

connection).

• Do not work next to the welding power source.

Welders with Pacemakers

There is no question that the fields in arc welding can interfere

with a pacemakers function. Generally the interference does not

permanently damage the pacemaker. Once the wearer leaves the

arc welding environment or stops welding, the pacemaker returns

to normal functioning. The welding arc has little or no effect on the

operation of some pacemakers, especially designs that are bipolar or designed to filter out such interference.

For a welder or anyone working around electrical equipment the

selection of a pacemaker is very important. Get a doctor’s advice

about which pacemaker is the least sensitive to interference from

welding while still being medically suitable.

In addition to the normal safety precautions, the following

additional procedures should be adopted by welders with

pacemakers.

• Use gas welding when the application is suitable.

• Use the lowest current setting appropriate for the application.

Do not exceed 400 amps. Low current (75-200 amps) direct

current (DC) welding should be used if arc welding is

necessary. Do not TIG weld with high frequency.

• Do not use repeated, short welds. Wait about ten seconds

between stopping one weld and starting the next. When

having difficulty starting an electrode, do not re-strike the rod

repeatedly.

• If you feel light headed, dizzy or faint, immediately stop

welding. Lay the electrode holder down so that it does not

contact the work and move away from any welding being

performed. Arrange your work in advance so that, if you

become dizzy and drop the electrode holder, the electrode

holder will not fall on your body or strike the work.

• Do not work on a ladder or other elevated position or in a

cramped, confined place.

• Do not work alone. Work only in the presence of an individual

who understands these precautions and the possible effect

welding may have on your pacemaker.

• Do not work near spot welding equipment.

• If you have a pacemaker and wish to continue arc welding,

discuss this an any other questions you may have with your

physician and follow his or her advice. The doctor may wish to

contact the pacemaker manufacturer for a recommendation.

As mentioned before, the design of the pacemaker

significantly affects the degree to which it is subject to

interference from a welding circuit. Do not rely on the fact that

you know another welder with a pacemaker who has welded

for years without experiencing a problem. That welder and his

or her pacemaker may be quite different from you and your

pacemaker.

WELDING, EMF AND PACEMAKERS

Page 5

IMA 574B CV320-I Page 5

INSTRUCTIONS FOR ELECTROMAGNETIC COMPATIBILITY

Conformance

Products displaying the C-Tick mark are in conformity with

Australian/New Zealand requirements for the Electromagnetic

Compatibility (EMC). They are:

• manufactured in conformity with Australian/New Zealand

Standard (Emission):- AS/NZS 3652 ‘Electromagnetic

Compatibility - Arc Welding Equipment’ (identical to and

reproduced from, British Standard EN 50199).

• for using with other Lincoln Electric/LiquidArc equipment.

• designed for industrial and professional use.

Introduction

All electrical equipment generates small amounts of

electromagnetic emission. Electrical emission may be transmitted

through power lines or radiated through space, similar to a radio

transmitter. When emissions are received by other equipment,

electrical interference may result. Electrical emissions may effect

many kinds of electrical equipment; other near by welding

equipment, radio and TV reception, numerical controlled

machines, telephone systems, computers, etc. Be aware that

interference may result and extra precautions may be required

when a welding power source is used in a domestic

establishment.

Installation and Use

The purchaser/user is responsible for installing and using the

welding equipment according to the manufacturer’s instructions. If

electromagnetic disturbances are detected then it shall be the

responsibility of the purchaser/user of the welding equipment to

resolve the situation with the technical assistance of the

manufacturer. In some cases this remedial action may be as

simple as earthing (grounding) the welding circuit (see note

below). In other cases it could involve constructing an

electromagnetic screen enclosing the power source and the work

complete with associated input filters. In all cases electromagnetic

disturbances must be reduced to the point where they are no

longer troublesome.

NOTE: The welding circuit may or may not be earthed for safety

reasons according to national codes. Changing the earthing

arrangements should only be authorised by a person who is

competent to assess whether the changes increase the risk of

injury, eg. by allowing parallel welding current return paths which

may damage the earth circuits of other equipment.

Assessment of Area

Before installing welding equipment the purchaser/user shall make

an assessment of potential problems in the surrounding area.

The following shall be taken into account:

a. Other supply cables, control cables, signalling and telephone

cables; above, below and adjacent to the welding equipment;

b. Radio and television transmitters and receivers;

c. Computer and other control equipment;

d. Safety critical safety equipment, eg. guarding of industrial

equipment;

e. The health of people around, eg. the use of pacemakers and

hearing aids;;

f. Equipment used for calibration or measurement;

g. The immunity of other equipment in the environment. The

purchaser/user shall ensure that other equipment being used

in the environment is compatible. This may require additional

protection measures;

h. The time of the day that welding or other activities are to be

carried out.

The size of the surrounding area to be considered will depend on the

structure of the building and other activities that are taking place. The

surrounding area may extend beyond the boundaries of the premises.

Methods of Reducing Emissions

Mains Supply

Welding equipment should be connected to the mains supply

according to the manufacturers recommendations.If interference

occurs, it may be necessary to take additional precautions such as

filtering the mains supply. Consideration should be given to

shielding the supply cable of permanently installed welding

equipment, in metallic conduit or equivalent. Shielding should be

electrically continuous throughout its length. The shielding should

be connected to the welding power source so that good electrical

contact is maintained between the conduit and the welding power

source enclosure.

Maintenance of the Welding Equipment

The welding equipment should be routinely maintained according

to the manufacturer’s recommendations. All access and service

doors and covers should be closed and properly fastened when

the welding equipment is in operation. The welding equipment

should not be modified in any way except for those changes and

adjustments covered in the manufacturers instructions. In

particular, the spark gaps of arc initiation and stabilising devices

should be adjusted and maintained according to the

manufacturer’s recommendations.

Welding Cables

The welding cables should be kept as short as possible and

should be positioned close together, running at or close to the

floor level.

Equipotential Bonding

Bonding of all metallic components in the welding installation and

adjacent to it should be considered. However, metallic

components bonded to the work piece will increase the risk that

the operator could receive a shock by touching these metallic

components and the electrode at the same time. The operator

should be insulated from all such bonded metallic components.

Earthing of the Workpiece

Where the workpiece is not bonded to earth for electrical safety,

nor connected to earth because of its size and position, eg. ship’s

hull or building steelwork, a connection bonding the workpiece to

earth may reduce emissions in some, but not all instances. Care

should be taken to prevent the earthing of work pieces increasing

the risk of injury to users, or damage to other electrical

equipment. Where necessary, the connection to the workpiece to

earth should be made by direct connection to the workpiece, but in

some countries where direct connection is not permitted, the

bonding should be achieved by suitable capacitance, selected

according to national regulations.

Screening and Shielding

Selective screening and shielding of other cables and equipment

in the surrounding area may alleviate problems of interference.

Screening of the entire welding installation may be considered for

special applications.*

* Portions of the preceding text are contained in AS./NZS3652:

‘Electromagnetic Compatibility - Arc Welding Equipment’.

This welding machine must be used by trained operators

only. Read this manual carefully before attempting to use

the welding machine.

WARNING

Page 6

• Turn the input power off at the

disconnect switch before installing

or servicing this machine.

• Do not touch electrically “hot” parts

such as output terminals or internal

wiring.

• Connect grounding screw ( ) to a

good earth ground.

• Do not operate with covers removed.

• Turn power switch “off” before

connecting or disconnecting cables

or other equipment.

WARNING

HIGH

VOLTAGE

can kill

Page 6 CV320-I IMA 574B

PRODUCT DESCRIPTION

The CV320-I is a semi-automatic Constant Voltage DC arc welding power source and wire feeder. It combines a step controlled power

source with a separate solid state controlled wire feeder.

Excellent arc characteristics are provided for both gas shielded and self shielded welding within its current range.

For instructions on operation of the wire feeder refer to the separate instruction manual included. Standard features include output volt &

amp meters, a spot timer, gas purge facilities, a dual position 2 or 4 step trigger interlock, a Magnum FM400 gun, a regulator/flowmeter

and gas hose, a 10m electrode cable and wire feeder cable, a 3m ground cable assembly, a 3m long input lead and an undercarriage on

which a gas cylinder can be mounted.

Only qualified personnel should install or service this

equipment.

Location

Place the welder where clean cooling air can freely circulate in

through the intake louvers and out through the exhaust louvers.

Dirt, dust or any foreign material that can be drawn into the welder

should be kept at a minimum. Failure to observe these

precautions can result in excessive operating temperatures and

nuisance thermostat trips.

Wire Feeder Mounting

Locate the control cable at the rear of the CV320-I and plug into

the wire feeder. The control cable is already connected to the

CV320-I. Connect the supplied 1.5m electrode cable to the wire

feeder mechconnector and to the desired polarity terminal on the

front of the CV320-I.

Connection to Mains Supply

Before connecting the machine to the mains supply check that the

voltage and current capacity correspond to the machine voltage

and rated input current. Use a fuse or C/B per AS3000 or local

wiring rules.

The machine is supplied with an input lead fitted. Have a qualified

electrician fit a suitable input plug.

Once the above has been followed the machine can be plugged

into the mains outlet.

Shielding Gas Supply

(For the Gas Metal Arc Welding Process)

Refer “Safety in Welding and Cutting” - ANSI Standard Z49.1 and

WTIA Technical Note 7, available from the Welding Technology

Institute of Australia.

Obtain cylinder of appropriate type shielding gas for the process

being used.

1. Set gas cylinder on rear platform of the machine. Hook chain

in place to secure cylinder to rear of welder.

2. Remove the cylinder cap. Inspect the cylinder valve for

damaged threads, dirt and dust. For cylinders having an

external thread fitting, remove any dust and dirt from the

threads with a clean cloth.

CYLINDER may explode

if damaged

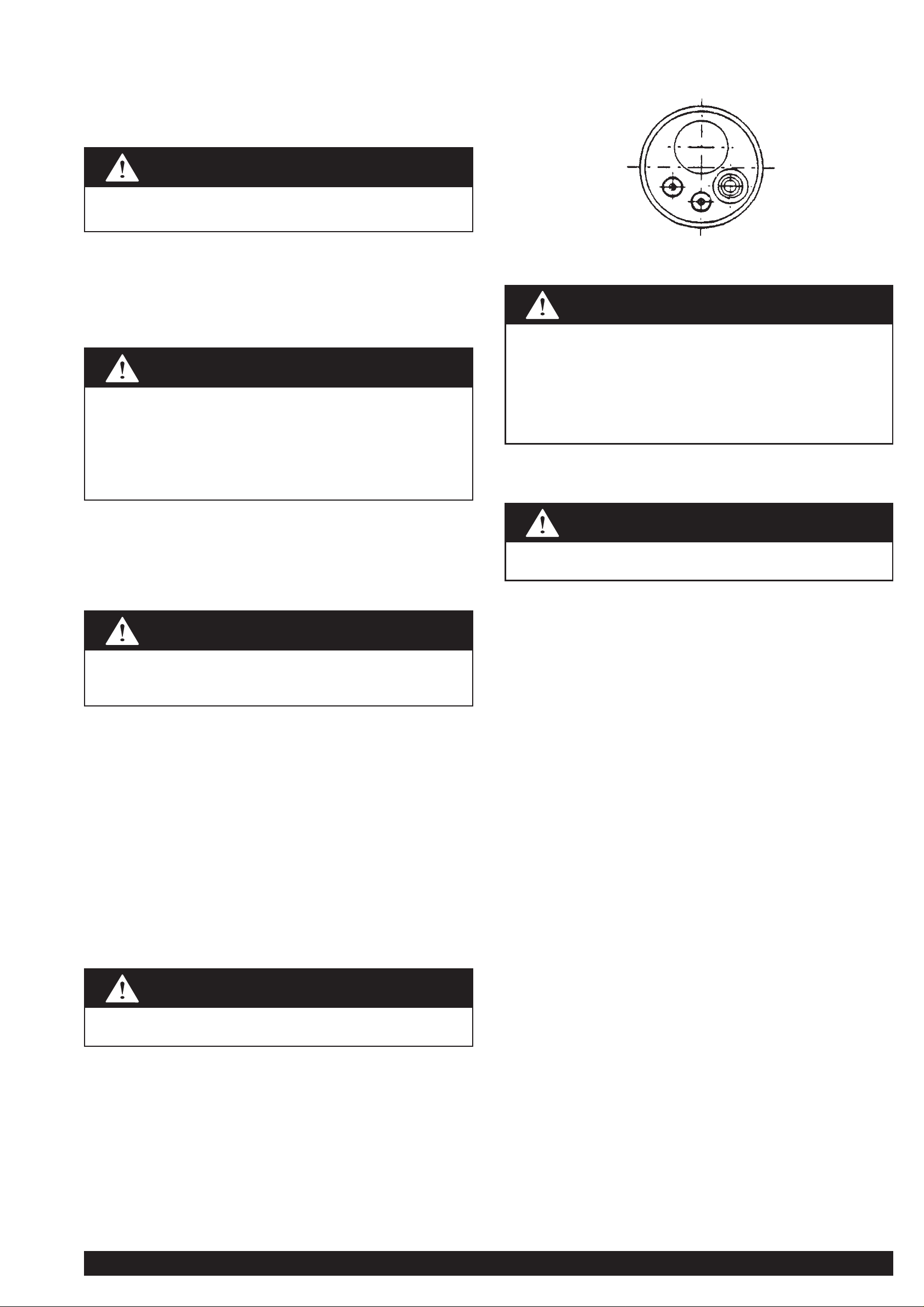

Part No. KA 1392 & KA1392-1

Maximum Open Circuit Voltage 45V

Output Current Range 20 to 400A

Duty Cycle 30% 60% 100%

Rated Output 320A/30V 240A/26V 190A/23.5V

Rated Input KA1392 415V 3ph 50Hz 13.5 amps KA1392-1 380V 3ph 50hz 14.7amps

Wire Speed Range 1-20 m/min

Weight (complete with u/c) 140 kg

H x W x L (mm) Over wire feeder,

cylinder tray & wheels

1220 x 580 x 842 mm

Operating Temperature -20˚C to 40˚C

Specifications

INSTALLATION

Never connect the green/yellow conductor to any of the

three active supply lines from the mains. This conductor is

to earth the machine as required by Electrical Regulations.

CAUTION

Page 7

IMA 574B CV320-I Page 7

DO NOT ATTACH THE REGULATOR/FLOWMETER IF

CYLINDER VALVE IS DAMAGED! Inform your gas supplier of this

condition.

3. Stand to one side away from the outlet and open the cylinder

valve for an instant. This blows away any dust or dirt which

may have accumulated in the valve outlet.

4. Inspect the regulator/flowmeter for damaged threads and

seals, dirt and dust. Remove dust and dirt with a clean cloth.

DO NOT USE THE REGULATOR/FLOWMETER IF DAMAGE

IS PRESENT! Have an authorised repair station repair any

damage.

5. Attach the regulator/flowmeter to the cylinder valve and

tighten the union nut(s) securely with a spanner.

6. Attach the inlet gas hose to the outlet fitting of the

regulator/flowmeter, and tighten the union nut securely with a

spanner.

7. Before opening the cylinder valve, turn the regulator adjusting

knob counter-clockwise until the adjusting spring pressure is

released.

8. Open the cylinder valve slowly a fraction of a turn. When the

cylinder pressure gauge pointer stops moving, open the valve

fully.

9. The regulator/flowmeter is adjustable. Set it for the flow rate

recommended for the procedure and process being used

before starting to weld.

Gun and Cable

The Magnum FM400 gun and cable provided with the machine is

set up for 0.9/1.2mm operation.

1. Lay the cable out straight.

2. Make sure all pins on the gun cable connector are aligned

with the proper mating sockets on the front panel gun

connector and then join the connectors and tighten the hand

nut on the gun cable connector.

NOTE: If a gun and cable other than the Magnum FM400 gun are

to be used, they must conform to standard European-style

connector specifications. See diagram under.

The gun trigger switch must be capable of switching 10 milliamps

at 60 volts DC—resistive.

Output Polarity Connection

Connect the lead from the wire feeder to the output stud of the

desired polarity.

Connect the work lead to the other output stud.

Be sure to keep your face away from the valve outlet

when “cracking” the valve.

Gas under pressure is explosive. Always keep gas

cylinders in an upright position and always keep chained

to undercarriage or stationary support. Refer “Safety in

Welding and Cutting” - ANSI Standard Z49-1 and WTIA

Technical Note 7 available from the Welding Technology

Institute of Australia.

Turn the welder power switch off before installing gun

and cable.

The gun trigger switch connected to the gun trigger

control cable must be a normally open, momentary

switch. The terminals of the switch must be insulated

from the welding circuit. Improper operation of, or

damage to, the machine might result if this switch is

common to an electrical circuit other than the machine

trigger circuit.

Turn the welder power switch off before changing output

connection.

Never stand directly in front of or behind the

regulator/flowmeter when opening the cylinder valve.

Always stand to one side.

WARNING

WARNING

WARNING

WARNING

CAUTION

WARNING

Page 8

Page 8 CV320-I IMA 574B

IMPORTANT SAFETY NOTE: In 2T mode, this DC Constant

Voltage wire welder provides “COLD” electrode when the gun

trigger is not operated. Conversely, the output terminals are

“LIVE” when the gun trigger is “activated” when pressed in 2T

mode, or triggered on in 4T mode.

Refer to wire feeder manual for a description of the 2T/4T trigger

operation.

Duty Cycle

The machine is rated at the following duty cycles:

* Based on 10 min. time period (i.e., for 60% duty cycle, it is 6

minutes actual welding and 4 minutes with no welding output,

but with the input power remaining on keeping the cooling fans

operative.)

Control Panel

Power Switch

The mains power switch is incorporated in the “coarse” output

voltage control rotary switch. In the “0” position (fully counter

clockwise) the input mains power is switched off.

ARC RAYS

can burn

Pilot Light

This light illuminates when the input mains power is switched on

Volts Control

The output voltage is controlled by two rotary switches. One rotary

switch provides four “coarse” voltage settings as well as switching

the mains power on. The other rotary switch provides the user with

a selection of eight “fine” voltage settings. The selection between

these two rotary switches allows the user to select any one of

thirty-two welding voltages.

The approximate weld voltages for the rotary switch positions are:

Current Control

Use the wire feed speed control on the wire feeder to adjust the

speed at which the electrode wire feeds when welding. This is in

effect a current control as the power source will deliver the current

necessary to melt the wire. The higher the speed, the more current

will be required.

Over temperature light

Indicates that the thermostats have operated to protect unit from

over temperature.

Setting Up for Welding

(Also refer to the wire feeder instruction manual.)

The following items are required:

1) A reel of wire of suitable size and type .

2) A suitable gun and cable assembly with a “Euro” connector

and the correct tip and, if necessary gas nozzle for the

consumable being used. (A Magnum FM400 gun is supplied).

3) A work return cable and clamp. (supplied)

4) Normal welding accessories including helmet or hand shield

with suitable lens, gloves etc.

5) If a gas shielded process is to be used, a cylinder of

appropriate gas is required. (Regulator/flowmeter and hose

are supplied.)

Coarse Fine Volts Coarse Fine Volts

1 1 13.0 2 1 18.0

1 2 14.0 2 2 18.5

1 3 15.0 2 3 19.0

1 4 16.0 2 4 19.5

1 5 16.5 2 5 20.0

1 6 17.0 2 6 20.5

1 7 17.5 2 7 21.0

1 8 18.0 2 8 21.5

3 1 21.5 4 1 25.0

3 2 22.0 4 2 25.5

3 3 22.5 4 3 26.0

3 4 23.0 4 4 26.5

3 5 23.5 4 5 27.0

3 6 24.0 4 6 28.0

3 7 24.5 4 7 29.0

3 8 25.0 4 8 30.0

WARNING

ELECTRIC

SHOCK

can kill

FUMES AND

GASES can be

dangerous

WELDING SPARKS

can cause fire or

explosion

• Do not touch electrically live parts or

electrode with skin or wet clothing.

• Insulate yourself from work and

ground.

• Always wear dry insulating gloves.

• Keep your head out of fumes.

• Use ventilation or exhaust to remove

fumes from breathing zone.

• Keep flammable material away.

• Do not weld upon containers which

have held combustibles.

• Wear eye, ear and body protection.

Duty Cycle* Output Amps Arc V olts

30% 320 30

60% 240 26

100% 190 23.5

OPERATING INSTRUCTIONS

Page 9

IMA 574B CV320-I Page 9

If gas shielding is required, see Section 1.4. Connect the gas

hose.

Remember that gas cylinders may explode if damaged, so ensure

that all gas cylinders are securely mounted.

Ensure there are no kinks or sharp bends in the gun cable and

hold the wire inch button until the wire emerges from the gun. It is

good practice to remove the tip when first feeding a new coil of

wire, then refit over the wire and tighten.

Cut off the end of the wire leaving 10mm to 15mm stick-out.

The gun polarity is selected by connecting the wire feeder cable to

the required output stud. e.g. electrode (+) - connect the lead to

the (+) output stud. For electrode (-) - connect the lead to the (-)

output stud.

Connect the work lead to the other output stud.

Welding

Put into 2T mode.

Select the output voltage required to suit the job by setting the

coarse and fine rotary switches.

Before beginning welding, ensure the wire protrudes from the gun

tip by approximately 10-15mm. Ensure welding shield and other

protective clothing are in place. Present the protruding electrode

just off the work. Maintain a steady grip on the gun, protect your

eyes with a welding shield, then press and hold the gun trigger to

create the arc.

If it is necessary to adjust the weld voltage, stop welding before

changing either or both of the rotary switches.

Adjust the wire feed speed as necessary to suit the job. At the

completion of the weld, release the gun trigger and pull the gun

away from the work to stop the arc.

4T mode should only be used by experienced operators for long

welds.

Maintenance

Safety Precautions

Routine Maintenance

General

In extremely dusty locations, dirt may clog the air passages and

cause the welder to run hot. Blow dirt out of the welder with lowpressure air at regular intervals to eliminate excessive dirt and

dust build-up on internal parts.

The fan motor has sealed ball bearings which require no service.

Welding Thermal Overload Protection

The CV320-I has built-in protective thermostats that respond to

excessive temperature. They open the wire feed and welder

output circuits if the machine exceeds the maximum safe

operating temperature because of a frequent overload, or high

ambient temperature plus overload. The over temperature light

glows when the thermostats open. The thermostats automatically

reset when the temperature reaches a safe operating level.

Gun and Cable Maintenance

Cable Cleaning

Clean cable liner after using approximately 150kg of electrode.

Remove the cable from the wire feeder and lay it out straight on

the floor. Remove the contact tip from the gun. Using an air hose

and approx. 350 kPa (50psi) pressure, gently blow out the cable

liner from the gas diffuser end.

Flex the cable over its entire length and again blow out the cable.

Repeat this procedure until no further dirt comes out.

Gun Tips and Nozzles

The gun tip should be replaced when worn. Replace with the

correct size for the wire type and diameter. Too large a tip for the

electrode wire will cause arcing within the gun cable and possible

jamming of the wire within the cable .

Remove spatter from inside of gas nozzle and from tip after each

10 minutes of arc time or as required.

Procedure for Replacing PC Boards

When a PC Board is to be replaced, the following procedure must

be followed:

Visually inspect PC Board in question.

1. Are any of the components damaged?

2. Is a conductor on the back side of the board damaged?

3. If there is no damage to the PB Board, insert a new PC Board

and see if this remedies the problem. If the problem is

remedied, reinstall the old PC Board and see if the problem

still exists with the old PC Board.

a) If the problem does not exist with the old board, check the

PC Board lead harness plugs.

b) Check leads in the harness for loose connections.

When the gun trigger is pressed (2T mode) or pressed and

released the first time (4T mode), the wire is at welding

voltage. The wire should never touch the case of the wire

feeder. If it does, it is possible for the wire to arc to the case.

Any wire overrun should be avoided.

(Refer wire feeder instruction manual.)

WARNING

ELECTRIC

SHOCK

can kill

• Have an electrician install and

service this equipment.

• Turn the input power off at the fuse

box,or unplug input lead before

working on equipment.

• Do not touch electrically hot parts.

WARNING

Excessive air pressure at the start of cable cleaning may

cause dirt to form a plug.

WARNING

Turn the welder power switch off before removing gun tips

and nozzles.

WARNING

Page 10

Page 10 CV320-I IMA 574B

WARNING

ELECTRIC

SHOCK

can kill

• Have an electrician install and

service this equipment.

• Turn the input power off at the fuse

box before working on equipment.

• Do not touch electrically hot parts.

Problem

Rough wire feeding or wire

not feeding but drive rolls

turning.

Variable or “hunting” arc.

Poor arc striking with

sticking or “blast offs”,

weld porosity, narrow and

ropey looking bead, or

electrode stubbing into

plate while welding.

Tip seizes in diffuser.

Possible Cause

Gun cable kinked and/or twisted.

Wire jammed in gun and cable.

Incorrectly fitted drive roll.

Drive roll loose.

Gun cable dirty.

Worn drive roll.

Electrode rusty and/or dirty.

Worn nozzle or cable liner.

Partially flashed or melted contact tip.

Incorrect idle roll pressure.

Wrong size, worn and/or melted contact tip.

Worn work cable or poor work connection.

Loose electrode connections.

Wrong polarity.

Improper procedures or techniques.

Improper gas shielding.

Tip overheating due to prolonged or

excessive high current and/or duty cycle

welding.

What To Do

Inspect gun cable and replace if necessary.

Remove wire from gun and cable - feed in new wire.

Note any obstructions in gun and cable. Replace gun

and cable if necessary.

See Wire Drive Roll Section in this manual for proper

installation of drive roll.

Remove, clean, install and tighten.

Clean cable or replace liner.

Replace.

Replace.

Replace.

Replace contact tip.

Set idle roll pressure.

Replace tip - remove any spatter on end of tip.

Inspect - repair or replace as necessary.

Be sure electrode lead is tight, gun cable tight in wire

feeder contact block, gun nozzle and gun tip tight. All

work lead connections must be tight.

Check connection at output studs for polarity required

by welding process.

See “Gas Metal Arc Welding Guide”(GS100).

Clean gas nozzle. Make certain that gas diffuser is

not restricted. Make certain that gas cylinder is not

empty or turned off. Make certain gas solenoid valve

is operating and gas flow rate is correct.

Remove gun liner and check rubber seal for any sign

of deterioration or damage. Be sure set screw in

brass connector is in place and tightened against the

liner bushing.

Do not exceed current and duty cycle rating of gun.

A light application of high temperature antiseize

lubricant may be applied to tip threads.

TROUBLESHOOTING GUIDE

Page 11

IMA 574B CV320-I Page 11

Possible Cause

Defective wire feed motor or wire drive

control PC board.

Defective wire drive control PC board.

Over-temperature protection circuit

actuated due to overload or short. Overtemperature light should be illuminated.

Faulty gun trigger switch or damaged

control cable connected to gun trigger.

Defective control PC board.

Defective contactor.

Improper settings for wire feed speed and

volts.

Faulty rotary switch either coarse control

(on/off) or fine control.

Faulty pilot transformer.

Faulty main transformer.

Faulty rectifier.

Faulty choke.

What To Do

Measure the voltage between Red motor lead

(54) and the Green motor lead (53) when the

wire inch push button is depressed. If this

voltage is over 10V DC, replace the wire feed

motor. If no voltage is registered, replace the

wire drive PCB. (Refer PCB replacement

procedure at end of Trouble Shooting Guide).

Replace PCB. (Refer PCB replacement

procedure at end of Trouble Shooting Guide).

Allow machine to cool down and reduce on

time and/or wire feed speed.

Repair.

Refer Procedure for Replacing PC Boards at

end of Trouble Shooting Guide, if no fault is

detected in trigger-thermostat circuit.

Replace defective contactor.

Set controls correctly.

Replace rotary switch.

Replace.

Replace.

Replace.

Replace.

Problem

No wire feed, although arc

voltage is present.

No control of wire feed.

No wire feed and no arc voltage.

Pilot light indicates input power to

machine.

Poor welding characteristics

and/or cannot obtain full rated

output as per nameplate.

Also see the LN21 wire feeder instruction manual

Note: This procedure is for ‘machines as built’ many modifications

could have taken place over the life of a particular machine, so

details of this procedure may need to be ‘adjusted’ to suit these

modifications.

For prompt service contact your local Lincoln Field Service Shop.

The insulation resistance values listed below are from Australian

Standard AS1966.1.

1) Disconnect input cable from power outlet.

2) Disconnect all output cables (control & weld).

3) Remove the roof panel.

4) Jumper the three (3) AC terminals and the (+) & (-) terminals

of the thre phase bridge rectifier (A total of five (5) places).

5) Jumper the four (4) meter terminals together.

6) Switch the fine control rotary switch to position one (1) &

switch the coarse control rotary switch to position

one (1).

7)

Primary test: Connect one lead of the mega tester to the

frame of the machine and the other lead to each of the three

(3) input conductors and to the main transformer primary

leads L1A, L2A & L3A. Apply the test(s).

8)

Welding circuit test: Connect one lead of the mega tester to

the frame of the machine and the other lead to the positive

output stud. Apply the test. (Min resistance 1MΩ).

9)

Welding circuit to primary test: Connect one lead of the

mega tester to the positive output stud and the other lead to

each of the three (3) input conductors and to the main

transformer primary leads L1A, L2A & L3A. Apply the test.

(Min resistance 10MΩ).

10)

Transformer thermostat test: Connect one lead of the mega

tester to the frame of the machine and the other lead to the

positive output stud. Apply the test.(Min resistance 1MΩ).

11) Remove all jumper leads.

12) Refit the roof panel.

ELECTRIC SHOCK

can kill

GROUND TEST PROCEDURE FOR CV320-I

WARNING

If any problems are encountered, refer to your nearest Lincoln Field Service Shop.

TROUBLESHOOTING GUIDE (cont)

This procedure is only suitable for applications using DC

mega testers up to 500V.

Page 12

Page 12 CV320-I IMA 574B

Machine Machine

Code 1508 Code 1413

Wire Size Part No. Part No.

Solid Wire

0.6 - 0.8mm AS4449-9 AM3023C

0.8 - 1.0mm AS4449-1 AM3023D

1.0 - 1.2mm AS4449-2 AM3023E

0.9 - 1.2mm AS4449-8

Cored Wire

0.8 - 1.0mm AS4449-3 -

1.2 - 1.6mm AS4449-4 AM3023J

Aluminium Wire

0.8 - 1.0mm AS4449-5 -

1.0 - 1.2mm - AM3023F

1.2 - 1.6mm AS4449-6 AM3023K

DRIVE ROLLS

Note: LN-21 Code Nos less than Code No. 1508 use drive roll part No.

starting with ‘AM’.

For LN-21 Code Nos greater than or equal to Code No. 1508 use drive

roll part Nos starting with ‘AS’.

Page 13

IMA 574B CV320-I Page 13

The Lincoln Electric Company (Australia) Propriety Limited

A.C.N. 000 040 308

AP-80

Operative: 2/7/99

Supercedes: 18/6/97

CV320-I

PARTS LIST AP-80

Sub Assembly

Item No. 1 2 3

Sub Assembly

Page Name

Machine Part List No. AP-80-C AP-80-D

Description Code No.

CV320-I 415V 1447 KA1392 1 1 AL2513 IMA574A

380V 1473 KA1392-1 2 1 AL2513 IMA574A

415V 1509 KA1392 1 1 AL2513 IMA574B

380V 1510 KA1392-1 2 1 AL2513 IMA574B

415V 1535 KA1392 1 1 AL2513 IMA574B

LN-21 1413 KA1389 AP-68 N/A AM3392 IMA565A

1508 KA1389 AP-68 N/A AM3392 IMA565B

Do not use this Parts List for a machine if its code number is not listed. Contact the Service Department for any code numbers not listed.

Numbers in the table below indicate which column to use in each parts list for each individual code number.

General Assembly

Control Panel Assembly

Wiring Diagram

Specification No.

Instruction Manual

Page 14

Page 14 CV320-I IMA 574B

General Assembly AP-80-C

Roof and side panels

not shown for clarity.

Platform shown this

view only.

Front panel not shown for clarity.

Ref: AG1369

A15-5-96M

AP-80-C

Operative: 2/7/99

Supercedes: 18/6/97

Page 15

IMA 574B CV320-I Page 15

General Assembly AP-80-C.1

When ordering parts quote AP-80-C-1, Machine Serial & Code Numbers, Part Description and Item Number.

Item Part No. Description Qty. 1 2

34 M6819-4A Fan 1 X X

Loctite #262 1.0mL X X

35 M7468-2 Fan Motor 1 X X

36 M15562F Fan Motor Bracket 1 X X

Items Not shown

36 AT2980-2 Cable Tie 9 X X

37 T12068-1 Insulating Splice 6 X X

38 AS4453-2 Resistor/Diode & Lead Assembly 1 X X

39 Multi-Lead /41/41B 1 X X

40 Lead /4 1 X X

41 Lead Earth 1 X X

42 Lead /44 1 X X

43 Lead /43A 1 X X

44 Lead /L1B 1 X X

45 Lead /L1A 1 X X

46 Lead /L2A 1 X X

47 Lead /L3A 1 X X

48 Lead /L1 1 X X

49 Lead /L2 1 X X

50 Lead /L3 1 X X

51 Lead L3B 1 X X

52 Sleeving-Aux. Tran. Leads to Fan 1 X X

53 Sleeving-Aux. Tran. to Front Panel 1 X X

54 Sleeving-Aux. Tran./Fan to Contactor 1 X X

55 Sleeving-Contactor to Rotary.SW.1 1 X X

56 AP80 Wiring Diagram 1 X X

57 AS4244 Warning Decal 1 X X

58 AT3378 Warning Decal 1 X X

59 Input Decal Typed 1 X X

60 AS3234 Warning Tag - Input Connection 1 X X

AT2980-2 Cable Tie 1 X X

61 AL1369-115 Literature Envelope 1 X X

62 K476-9 Magnum FM400 12ft Mig Gun 1 X X

63 801E30LKAR21 Argon Regulator Flowmeter 30L/min 1 X X

64 AS4092-5 Ground cable assembly 1 X X

65 AS4050-1 Gas Hose assembly 1 X X

66 AT3873 Chain 1 X X

67 AT4069 Liftbale Washer 1 X X

[NC]

1

⁄2˝ UNC. x 1⁄2˝ Hex. Hd. Screw 1 X X

1

⁄2˝ UNC. Hex. Nut. 1 X X

1

⁄2˝ UNC. Springwasher 1 X X

5

⁄16˝ UNC. x 3⁄4˝ Hex. Hd. Screw 4 X X

5

⁄16˝ UNC. Hex. Nut 4 X X

5

⁄16˝ dia. Flatwasher 4 X X

5

⁄16˝ dia. Springwasher 4 X X

68 Plastic Bag 9˝ x 12˝ 1 X X

69 Staple 3 X X

70 KA1389 LN21 1 X X

71 Plastic Bag 1 X X

72 Pallet 1 X X

Item Part No. Description Qty. 1 2

1 AT3070-3 Connector Block 1 X X

2 AM3423 Contactor SC35 1 X X

3 AL2494-1 Main Transformer Assembly 415V 1 X

AL2494-2 Main Transformer Assembly 380V 1 X

4 Sleeving 2 X X

6 AM3388-1 Rotary Switch 8 Pos. 1 X X

7 AM3388-2 Rotary Switch 5 Pos. 1 X X

8 Cotton Tape 25.4mm wide 3.0m X X

9 AM3275-1 Choke Assembly 1 X X

10 T7028-226 Insulation Tube 2 X X

AT2882 Insulation Washer 6 X X

11 AL2480 Rectifier 1 X X

13 AL2527 Liftbale Welded Assembly 1 X X

14 S12934 Cover Seal 1 X X

15 AS4525-2 Resistor & Tag Strip Assembly 1 X X

AT3425-5 Blind Rivet

5

⁄52˝ dia. x 5⁄16˝1XX

16 G2017R Case Side Right 1 X X

17 AS4070 4˝ dia. Swivel Castor 2 X X

18 AS4071-1 8˝ Wheel 2 X X

AT2876 Push Nut 2 X X

19 AS4303 Input Lead 1 X X

T9639-1 Box Connector 1 X X

20 AT2980-2 Cable Tie 3 X X

21 AL2530 Case Rear Assembly 1 X X

22 AS4407-3 Amphenol & Lead Assembly 3m 1 X X

T9639-2 Box Connector 1 X X

AL2651-1 Cable Assy 10m (Code 1535 only) 1 X X

23 AG1358 Gas Bottle & Wire Feeder Support 1 X X

24 AG1365 Base Welded Assembly 1 X X

26 PT0051 Auxiliary Transformer 415V 1 X

PT0053 Auxiliary Transformer 380V 1 X

27 AM3040B108 Cable - Rect. (-) to Choke 1 X X

28 AM3040B107 Cable - Rect. (+) to Shunt 1 X X

29 L7699R Roof 1 X X

30 AL2524 Front panel Assembly 1 X X

32 G2018R Case Side-Left 1 X X

33 G2017R Case Side Right 1 X X

AP-80-C.1

Operative: 2/7/99

Supercedes: 18/6/97

NOTE: All screws and bolts listed in FSS release 288

Page 16

Page 16 CV320-I IMA 574B

Control Panel AP-80-D

Item Part No. Description Qty. 1

1 AG1355 Front Panel 1 X

2 AL2516 Nameplate 1 X

3 T14659-1 Fastener Button (Black) 4 X

4 AM3397-1 Voltmeter 1 X

5 AM3398-1 Ammeter 1 X

8 AM2464-1 Moulded Output Stud 2 X

9 T3960 Flange Nut 2 X

10 AS1733-3Z Self Tapping Screw 4 X

11 AS4460 Indicator Light 1 X

12 T13486-1 Pilot Light 1 X

13 S6602-22 Shunt 1 X

15 Lead / 48 1 X

16 AM3400 Meter Lead Harness 1 X

A1 AM3388-2 Output Control Switch (Coarse) 1 X

A2 AM3388-1 Output Control Switch (Fine) 1 X

1

2

3

4 5

When ordering parts quote AP-80-D, Machine serial & Code numbers, part description and item number.

AP-80-D

Operative: 2/7/99

Supercedes: 18/6/97

Ref: AL2524

(AL21-2-96M)

Page 17

IMA 574B CV320-I Page 17

This diagram is typical of the machine’s wiring. For specific detail refer to the diagram attached to the

machine itself. If the diagram has been destroyed or defaced, contact the factory quoting the machine

serial number and code number from the nameplate.

WIRING DIAGRAM CV320-I

AL2513

A5-5-99M

Page 18

Page 18 CV320-I IMA 574B

LN21 WIRE FEEDER

PARTS LIST AP-68

AP-68

Operative: 18/6/97

Supersedes: 26/11/96

Do not use this Parts List for a machine if its code number is not listed. Contact the Service Department for any code numbers not

listed.

Numbers in the table below indicate which column to use in each parts list for each individual code number.

Sub Assembly

Item No. 1 2 3

Sub Assembly

Page Name

Machine Part List No. AP-68-C

Description AP-68-C-1

Code No.

LN-21 1413 KA1389 1 AM3392 IMA565A

LN-21 1508 KA1389 2 AM3392 IMA565B

General Assembly

Wiring Diagram

Specification No.

Instruction Manual

Page 19

IMA 574B CV320-I Page 19

NOTE: All screws and bolts listed in FSS release 288

Item Part Name and Description No. Req. Part Number 1 2

1 BASE, FRONT AND REAR PANEL 1 AG1344 x -

BASE, FRONT AND REAR PANEL 1 AM3161 - x

2 PLASTIC FOOT 4 AT4084-1 x x

4 BULKHEAD 1 AM3379 x x

5 SELF TAPPING SCREW 8 AS1733-3Z x x

6 GROMMET 1 AS3086-9 x x

7 NUTSERT 4 AT3937 x x

8 SEMS SCREW 4 T10082-27 x x

9 PCB ASSEMBLY 1 AS4212-4 x x

10 NAMEPLATE MAXIDRIVE 2 1 AM3382-1 - x

NAMEPLATE MAXIDRIVE 4 1 AM3382-2 - -

NAMEPLATE LN21 1 AM3382-3 x -

11 FASTENER BUTTON 2 TI4659-1 - x

11A FASTENER BUTTON 1 T14659 x -

12 GUN ADAPTOR 1 AS4456 x x

13 HEX HD. SCREW 3 x -

SPRINGWASHER 3 x -

FLATWASHER 3 x -

HEX NUT 3 x -

13A THREAD FORMING SCREW 3 S9225-17 - x

14 RED MICROSWITCH 2 AT3561-1 x x

15 HARNESS (not shown) 1 AL2495 x x

16 CASE AND DOOR ASSEMBLY 1 AM3378U - x

CASE AND DOOR ASSEMBLY 1 AM3378R x -

17 BUFFER GROMMET 1 AS4404-2 x x

18 PLUG BOTTOM (BLACK) 1 AS4450 x x

19 TOGGLE SWITCH 1 T13562 x x

20 KNOB 2 T10491D x x

21 INSULATION 2 T12792-1 x x

22 WIRING DIAGRAM (inside panel) 1 SEE AP-68-A

General Assembly AP-68-C

AP-68-C

Operative: 18/6/97

Supercedes: 26/11/96

Ref: AG1346A

(16.7.97)

Page 20

Page 20 CV320-I IMA 574B

Item Part Name and Description No. Part Number 1 2

Req’d

25 WIRE PANEL INSULATION 1 AS4436 x x

27 DRIVE PLATE 1 AM3391-1 x -

DRIVE PLATE 1 AM3391 - -

DRIVE PLATE 1 AM3391-8 - x

28 WIRE DRIVE MOTOR AND GEARBOX 1 AM3185 x x

29 CHEESE HEAD SCREW 3 AM3054-181 x x

30 DRIVE PLATE INSULATION 1 AS4435-1 x -

DRIVE PLATE INSULATION 1 AS4435 - -

30A DRIVE PLATE INSULATION WASHER 2 AT2882 - x

32 LEAD 1 AM3040A907 x x

33 BOX CONNECTOR 1 T9639-1 x x

34 SOLENOID 1 AM3399-1 x x

36 GAS SOLENOID NIPPLE 1 AS4457 x x

36A STRAIGHT BARB TAIL 1 AT3730-11 - x

37 SELF T APPING SCREW 4 S8025-73 x x

38 SPINDLE AND READI-REEL ADAPTOR 1 K377 x -

SPINDLE & SMALL MOUNTING STAND 1 KA1395 - x

41 DISHED WASHER 1 AT2943Z x x

42 WIRE REEL DUST STRIP 1 AS4451 x x

43 DUST STRIP RETAINING PLATE 1 AS4452 x x

45 SELF T APPING SCREW 2 AS1733-3Z x x

46 WARNING DECAL 1 AS4244 x x

47 CODE AND SERIALNo. DECAL 1 x x

49 SPACERS 2 AS4463 x 50 SLEEVING (over motor leads) 1 AM3058-412 x x

51 INSULATED SPLICE (motor conn) 2 T12068-1 x x

52 DUST STRIP SUPPORT BKT. ASSY. 1 AM3402 x x

53 INSULATING BUSHES 2 AM3391-1S x x

54 DRIVE ROLL CAP SCREW 1 AM3391-1R x x

55 DRIVE ROLL 0.9 - 1.2mm SOLID 1 AS4449-8 - x

DRIVE ROLL 1.0 - 1.2mm SOLID 1 AM3023E x 56 DRIVE ROLLADAPTER 1 AM3391-3H - x

57 DRIVE PLATE MOUNTING BRACKET 1 AM3390-2 - x

58 CABLE END PLUG 1 S12020-9 x x

58 MACHINE END CONNECTOR 1 S12021-1 x x

General Assembly AP-68-C.1

AP-68-C.1

Operative: 18/6/97

Supercedes: 26/11/96

Ref: AG1346B (25.6.97)

Note: To upgrade from

the AM3391-1 drive

plate to AM3391-7 drive

plate you will also need

to purchase AM3390-2

plus S9225-7.

Note: 4 Wheel Shown.

See Fig.1 or Fig.2 for

two wheel drive.

NOTE

: All screws and bolts listed in FSS release 288

Page 21

IMA 574B CV320-I Page 21

This diagram is typical of the machine’s wiring. For specific detail refer to the diagram attached to the

machine itself. If the diagram has been destroyed or defaced, contact the factory quoting the machine serial

number and code number from the nameplate.

WIRING DIAGRAM LN21

AM 3392

(A22.1.97M)

Page 22

Page 22 CV320-I IMA 574B

Magnum Fastmate Guns

AP-202-G

AP-202-G

Operative: 10/3/97

Supercedes: New

Part No. K479-7

Magnum FM400

3.65m long

Item Part No. Description

1 Gas nozzle, Fixed, Tip recessed:

M16080-1 Magnum 400FM (9.5 mm ID)

M16080-2 Magnum 400FM (12.7 mm ID)

M16080-3 Magnum 400FM (15.9 mm ID)

M16080-4 Magnum 400FM (19.1 mm ID)

1A Gas nozzle, Fixed, Tip flush:

M16081-1 Magnum 400FM (9.5 mm ID)

M16081-2 Magnum 400FM (12.7 mm ID)

M16081-3 Magnum 400FM (15.9 mm ID)

M16081-4 Magnum 400FM (19.1 mm ID)

2 Gas nozzle, Adjustable slip-on

(requires Item 2A):

M16093-1 Magnum 200FM (15.9 mm ID)

M16082-1 Magnum 400FM (15.9 mm ID)

M16093-2 Magnum 200FM (12.7 mm ID)

M16082-2 Magnum 400FM (12.7 mm ID)

2 Gas nozzle, Recessed slip-on

(requires Item 2A):

M16082-3 Magnum 400FM (15.9 mm ID)

M16082-4 Magnum 400FM (12.7 mm ID)

Item Part No. Description

2A Nozzle insulator assembly:

S19417-1 Magnum 200FM

S19394-1 Magnum 400FM

3 Gas nozzle, Coarse thread, Tip recessed

4mm (requires Item 3A):

M16830-1 Magnum 400FM (15.9 mm ID)

M16830-2 Magnum 400FM (19.1 mm ID)

3 Gas nozzle, Coarse thread, Tip recessed

12.7mm (requires Item 3A):

M16830-3 Magnum 400FM (15.9 mm ID)

M16830-4 Magnum 400FM (19.1 mm ID)

3A M16937-1 Nozzle Insulator Ass., Magnum 400FM

4 Contact tip, Tapered:

S19393-5 Magnum 200FM (0.6mm)

S19393-6 Magnum 200FM (0.8mm)

S19393-1 Magnum 200FM, 400FM (0.9mm)

S19393-7 Magnum 200FM, 400FM (1.0mm)

S19393-2 Magnum 200FM, 400FM (1.2mm)

S19393-3 Magnum 400FM (1.3mm)

S19393-4 Magnum 400FM (1.6mm)

Page 23

IMA 574B CV320-I Page 23

Item Part No. Description

5 Contact tip, Heavy duty:

S19392-1 Magnum 200FM, 400FM (0.9mm)

S19392-6 Magnum 200FM, 400FM (1.0mm)

S19392-2 Magnum 200FM, 400FM (1.2mm)

S19392-3 Magnum 400FM (1.3mm)

S19392-4 Magnum 400FM (1.6mm)

S19392-5 Magnum 400FM (2.0mm)

6 Contact tip, Standard duty:

S19391-6 Magnum 200FM (0.6mm)

S19391-7 Magnum 200FM (0.8mm)

S19391-1 Magnum 200FM, 400FM (0.9mm)

S19391-8 Magnum 200FM, 400FM (1.0mm)

S19391-2 Magnum 200FM, 400FM (1.2mm)

S19391-3 Magnum 400FM (1.3mm)

S19391-4 Magnum 400FM (1.6mm)

S19391-5 Magnum 400FM (2.0mm)

6A Contact tip, Notched, for Aluminium:

S18697-44 Magnum 200FM (0.8mm)

S18697-45 Magnum 200FM (0.9mm)

S18697-46 Magnum 200FM (1.2mm)

7 Gas Diffuser assembly:

S19418-2 Magnum 200FM (0.6-0.8mm)

S19418-1 Magnum 200FM (0.9-1.2mm)

S19395-1 Magnum 400M (0.6-2.0mm)

8 Cable Liner (trim to fit):

M16087-2 Magnum 200FM (0.6-0.8mm)

M16087-1 Magnum 200FM (0.9-1.2mm)

M16083-1 Magnum 400FM (0.9-1.2mm)

M16083-2 Magnum 400FM (1.3-1.6mm)

M16083-3 Magnum 400FM (1.6-2.0mm)

8 Cable Liner for Aluminium (trim to fit):

M16107-1 Magnum 200FM (0.9-1.2mm)

9 Gun tube, 60˚:

M15659-1 Magnum 200FM§, 400FM (400amp)

M15659-2 Magnum 200FM§, 400FM (300amp)

S19440 Magnum 200FM (200amp)

10 Gun tube, 45˚:

M15685-1 Magnum 200FM§, 400FM (400amp)

M15685-2 Magnum 200FM§, 400FM (300amp)

10 Gun Tube Insulator

T10642-172 Magnum 200FM, 400FM

11 M15693 Hanger

12 S18831 Collar assembly

13 S9776-7 Retaining ring

14 S15921-2 Clamp for gun tube

15 G1927 Gun housing, left, Magnum 400FM

G1928 Gun housing, right, Magnum 400FM

G2090 Gun housing, left, Magnum 200FM

G2091 Gun housing, right, Magnum 200FM

16 S18825-1 #6 x 32 screw

17 T14438 Clamping screw

18 S18932 Trigger assembly

19 T13483-8 ‘O’ ring

20 S18655-1 Connector assembly, Magnum 400FM

Connector assembly includes:

Retaining ring (S9776-7)

Clamping screw (T14438)

Clamp for gun tube (S15921-2)

‘O’ ring (T13483-8)

21 S19067 Connector nut (gun tube) Magnum 200FM

S18749-2 Connector nut (gun tube) Magnum 400FM

22 S19492-2 Terminals (trigger switch)

23 L7761-11 Cable assembly, 3m (10ft)

Magnum 200FM

ItemPart No. Description

23 L7761-16 Cable assembly 3.6m (12ft)

Magnum 400FM

24 S18787 Strain relief, Magnum 400FM

S18787-1 Strain relief, Magnum 200FM

25 S18786 Strain relief housing, Magnum 400FM

S18786-1 Strain relief housing, Magnum 200FM

26 M15751 Handle boot, Magnum 400FM

M15751-1 Handle boot, Magnum 200FM

27 S18930 Boot nut (moulded)

28 S18895-1 Cable boot, Magnum 200FM

S18895-2 Cable boot, Magnum 400FM

29 T11141-8 Cable clamp, Magnum 400FM

T11141-9 Cable clamp, Magnum 200FM

30 M15808 Cable handle (moulded)

31 S19067 Incoming connector nut, Magnum 200FM

S19126-2 Incoming connector nut, Magnum 400FM

32 S19153-1 Incoming connector assembly

Magnum 200FM

32 S19153 Incoming connector assembly

Magnum 400FM

33 S19008-1 Terminal lead assembly (feeder end)

(2 required).

34 S18929 Collar nut (moulded)

35 S18948-2 Central adaptor assembly

36 S18991 Liner nut

37 T1473-19 Screw

Magnum Gun

Replacement Parts AP-202-G.1

When ordering parts quote machine code and serial numbers, parts list number, item and part number and description.

AP-202-G.1

Operative: 10/3/97

Supercedes: New

§ 300 & 400 amp gun tubes can be used with 200 amp guns. Use corresponding amperes gas diffuser, nozzle and nozzle insulator.

Page 24

Page 24 CV320-I IMA 574B

Industry Lincoln ID

Ref No. Part No. Qty mm (Inches)

21T-37 M16294 1 9.5 (0.38)

21T-50 M16684-1 1 12.7 (0.50)

21T-62 M16684-1 1 15.9 (0.62)

M16080-1 1

23-37 M16080-1D 5 9.5 (0.38)

M16080-1M 25

M16080-2 1

23-50 M16080-2D 5 12.7 (0.50)

M16080-2M 25

M16080-3 1

23-62 M16080-3D 5 15.9 (0.62)

M16080-3M 25

M16080-4 1

23-75 M16080-4D 5 19.1 (0.75)

M16080-4M 25

23H-62 M17256-1 1 15.9 (0.62)

M17256-1M 25

Industry Lincoln ID

Ref No. Part No. Qty mm (Inches)

21-50-F M16294 1 12.7 (0.50)

M16081-1 1

23-37F M16081-1D 5 9.5 (0.38)

M16081-1M 25

M16081-2 1

23-50F M16081-2D 5 12.7 (0.50)

M16081-2M 25

M16081-3 1

23-62F M16081-3D 5 15.9 (0.62)

M16081-3M 25

M16081-4 1

23-75F M16081-4D 5 19.1 (0.75)

M16081-4M 25

Industry Lincoln ID

Ref No. Part No. Qty mm (Inches)

M16093-2 1

22-50 M16093-2D 5 12.7 (0.50)

M16093-2M 25

M16093-1 1

22-62 M16093-1D 5 15.9 (0.62)

M16093-1M 25

M16082-2 1

24A-50 M16082-2D 5 12.7 (0.50)

M16082-2M 25

M16093-1 1

24A-62 M16093-1D 5 15.9 (0.62)

M16093-1M 25

Industry Lincoln ID

Ref No. Part No. Qty mm (Inches)

M16082-4 1

24A-50-SS M16082-4D 5 12.7 (0.50)

M16082-4M 25

M16082-3 1

24A-62-SS M16082-3D 5 15.9 (0.62)

M16082-3M 25

Industry Lincoln ID

Ref No. Part No. Qty mm (Inches)

24CT-62-R M16830-3 1 15.9 (0.62)

M16830-3M 25

24CT-62-S M16830-1 1 15.9 (0.62)

M16830-1M 25

24CT-75-R M16830-4 1 19.1 (0.75)

M16830-4M 25

24CT-75-S M16830-2 1 19.1 (0.75)

M16830-2M 25

25CT-62 M16831-1 1 15.9 (0.62)

M16831-1M 25

25CT-75 M16831-2 1 19.1 (0.75)

M16831-2M 25

26CT-62 M16832-1 1 15.9 (0.62)

M16832-1M 25

26CT-75 M16832-2 1 19.1 (0.75)

M16832-2M 25

26CT-62-R M16832-3 1 15.9 (0.62)

M16832-3M 25

26CT-75-R M16832-4 1 19.1 (0.75)

M16832-4M 25

Industry Lincoln ID

Ref No. Part No. Qty mm (Inches)

M16970-1 1

26I-62 M16970-1D 5 15.9 (0.62)

M16970-1M 25

M16970-2 1

26I-75 M16970-2D 5 19.1 (0.75)

M16970-2M 25

M16970-3 1

26I-87 M16970-3D 5 22.1 (0.87)

M16970-3M 25

Industry Lincoln

Ref No. Part No. Qty

32 S19417-1D 5

S19417-1M 25

34A S19394-1D 5

S19394-1M 25

34CT M16937-1 1

M16937-1M 25

35CT M16937-2 1

M16937-2M 25

36CT M16937-3 1

M16937-3M 25

NOZZLE INSULATOR ASSEMBLIES

SELF-INSULATED GAS NOZZLES

FIXED GAS NOZZLES, COARSE THREAD

RECESSED SLIP-ON GAS NOZZLES

ADJUSTABLE SLIP-ON GAS NOZZLES

FIXED GAS NOZZLES, TIP FLUSH

FIXED GAS NOZZLES, TIP RECESSED

Magnum Replacement Parts

CROSS REFERENCE GUIDE FOR MAGNUM MIG CONSUMABLE PARTS

Page 25

IMA 574B CV320-I Page 25

Industry Lincoln Wire Size

Ref No. Part No. Qty mm (Inches)

11-23 S19726-1D 10

S19726-1M 25 0.6 (0.025)

11-30 S19726-2D 10

S19726-2M 25 0.8 (0.030)

11-35 S19726-3D 10

S19726-3M 25 0.9 (0.035)

11-45 S19726-4D 10

S19726-4M 25 1.2 (0.045)

14-23 S19391-6D 10

S19391-6M 25 0.6 (0.025)

14-30 S19391-7D 10

S19391-7M 25 0.8 (0.030)

14-35 S19391-1D 10

S19391-1M 25 0.9 (0.035)

14-40 S19391-8D 10

S19391-8M 25 1.0 (0.040)

14-45 S19391-2D 10

S19391-2M 25 1.2 (0.045)

14-52 S19391-3D 10

S19391-3M 25 1.3 (0.052)

14-116 S19391-4D 10

S19391-4M 25 1.6 (1/16)

14-564 S19391-6D 10

S19391-6M 25 2.0 (4/64)

Industry Lincoln Size

Ref No. Part No. Qty mm (Inches)

14H-35 S19392-1D 10

S19392-1M 25 0.9 (0.035)

14H-40 S19392-6D 10

S19392-6M 25 1.0 (0.040)

14H-45 S19392-2D 10

S19392-2M 25 1.2 (0.045)

14H-52 S19392-3D 10

S19392-3M 25 1.3 (0.052)

14H-116 S19392-4D 10

S19392-4M 25 1.6 (1/16)

14H-564 S19392-5D 10

S19392-5M 25 2.0 (5/64)

Machine Machine

Code 1508 Code 1413

Wire Size Part No. Part No.

Solid Wire

0.6, 0.8mm AS4449-9 AM3023C

0.8, 1.0mm AS4449-1 AM3023D

1.0, 1.2mm AS4449-2 AM3023E

0.9, 1.2mm AS4449-8

Cored Wire

0.8, 1.0mm AS4449-3 -

1.2, 1.6mm AS4449-4 AM3023J

Aluminium Wire

0.8, 1.0mm AS4449-5 -

1.0, 1.2mm - AM3023F

1.2, 1.6mm AS4449-6 AM3023K

Industry Lincoln Wire Size

Ref No. Part No. Qty mm (Inches)

11T-23 S20278-1D 10

S20278-1M 25 0.6 (0.025)

11T-30 S20278-2D 10

S20278-2M 25 0.8 (0.030)

11T-35 S20278-3D 10

S20278-3M 25 0.9 (0.035)

11T-45 S20278-4D 10

S20278-4M 25 1.2 (0.045)

14T-23 S19393-5D 10

S19393-5M 25 0.6 (0.025)

14T-30 S19393-6D 10

S19393-6M 25 0.8 (0.030)

14T-35 S19393-1D 10

S19393-1M 25 0.9 (0.035)

14T-40 S19393-7D 10

S19393-7M 25 1.0 (0.040)

14T-45 S19393-2D 10

S19393-2M 25 1.2 (0.045)

14T-52 S19393-3D 10

S19393-3M 25 1.3 (0.052)

14T-116 S19393-4D 10

S19393-4M 25 1.6 (1/16)

15HFC-35 S20476-1M 25 0.9 (0.035)

15HFC-45 S20476-2M 25 1.2 (0.045)

15HFC-52 S20476-3M 25 1.3 (0.052)

15HFC-116 S20476-4M 25 1.6 (1/16)

15HFC-564 S20476-5M 25 2.0 (5/64)

15AHFC-364 S20476-9M 25 1.2 (3/64A)

15AHFC-116 S20476-10M 25 1.6 (1/16A)

Industry Lincoln Size

Ref No. Part No. Qty mm (Inches)

35-50 S19728 1 0.6 - 0.9 (0.025 - .035)

52 S19418-1D 5

S19418-1M 25 0.9 - 1.2 (0.035 - .045)

52-23 S19418-2D 5

S19418-2M 25 0.6 - 0.8 (0.025 - .030)

54A S19395-1D 5

S19395-1M 25 0.6 - 2.0 (0.025 - 5/64)

55 S21098-2 1

S21098-2M 25 1.6 - 2.0 (1/16 - 5/64)

55H S21098-3 1

S21098-3M 25 2.4 - 3.2 (3/32 - 1/8)

55S-H S21098-5 1

S21098-5M 25 2.4 - 3.2 (3/32 - 1/8)

55S-HL S21098-7 1

S21098-7M 25 2.4 - 3.2 (3/32 - 1/8)

55SW S21098-1 1

S21098-1M 25 0.9 - 1.6 (0.035 - 1/16)

55S-SW S21098-4 1

S21098-4M 25 0.9 - 1.6 (0.035 - 1/16)

55S-SWL S21098-6 1

S21098-6M 25 0.9 - 1.6 (0.035 - 1/16)

56S-H S20478-2 1

S20478-2M 25 1.6 - 3.2 (1/16 - 1/8)

56S-SW S20478-1 1

S20478-1M 25 0.9 - 1.6 (0.035 - 1/16)

GAS DIFFUSERS

CONTACT TIPS TAPERED

DRIVE ROLLS

CONTACT TIPS HEAVY DUTY (300A & 400A)

CONTACT TIPS STANDARD

Magnum Replacement Parts

When ordering parts, quote machine code and serial numbers,

parts list number, item and part number and description.

Note: LN-21 Code Nos. less than Code No. 1508 use drive

roll Part Nos. starting with ‘AM’.

For LN-21 Code Nos. greater than or equal to Code No. 1508

use drive roll Part Nos. starting with ‘AS’.

Page 26

The Lincoln Electric Company (Australia) Pty Limited (“Lincoln”) warrants all new

machinery and equipment (“goods”) manufactured by Lincoln against defects in

workmanship and material subject to certain limitations hereinafter provided.

Certain conditions warranties and obligations are implied by law (for example

under the Trade Practices Act 1974) and cannot be excluded or modified (“the

statutory warranties”).

Where the statutory warranties do apply then any express warranties given by

Lincoln (the “express warranties”) are given in addition and without derogation from

the statutory warranties. Apart from the express warranties and (in cases where

they apply by law but not otherwise) the statutory warranties Lincoln gives no

warranties whether express or implied by operation of law or otherwise in respect

of any goods manufactured or supplied by Lincoln or by its authorised distributor.

Any warranty whether express or statutory and the term of any such warranty as

set out herein commences on the date Lincoln or Lincoln’s authorised

distributorship forwards the goods from the premises of Lincoln or Lincoln’s

authorised distributor to the purchaser.

In respect of any claim under the warranty herein provided a purchaser must

furnish Lincoln with written notice of any claim under the warranty within the time

period of the warranty as further specified herein.

The extent of Lincoln’s warranty whether express or statutory is limited to a liability

to repair, replace or pay to the purchaser an amount equal to:

a) The cost of replacing the goods;

b) The cost of obtaining equivalent goods; or

c) The cost of having the goods repaired, whichever remedy in its absolute

discretion Lincoln chooses.

Upon request by Lincoln the purchaser must permit Lincoln to inspect the goods

the subject of any claim under this warranty and Lincoln may at its absolute

discretion repair or replace the goods F.O.B. at its own premises or at such other

premises as Lincoln may designate provided that all freight charges to and from

Lincoln’s premises or such other premises as Lincoln may designate shall be paid

by the purchaser.

Period of Warranty

The period of warranty in respect of goods covered by this warranty shall be as

follows:

a) In respect of manual and semi-automatic and fully automatic wire feeders

and welders (except belted, engine driven welders and alternator sets) - 3

years from the date of commencement of the warranty;

b) In respect of the Invertec V130-S inverter - 1 year from the date of sale.

c) In respect of belted, engine driven welders and alternator sets designed for

operating speeds under 2,000 rpm - 3 years from the date of

commencement of the warranty;

d) In respect of Tractapac mobile rural welders mounted in approved fixtures

- 3 years from the date of commencement of the warranty;

e) In respect of belted, engine driven welders and alternator sets designed for

operating speeds over 2,000 rpm - 2 years from the date of

commencement of the warranty;

f) Other goods manufactured by Lincoln including gun and cable assemblies,

undercarriages, field installed options, unattached options, welding

supplies, standard accessory sets and replacement parts -1 year from the

date of commencement of the warranty;

g) In respect of all alternators irrespective of the manufacturer of those

alternators - 12 months in respect of labour and parts from the date of

commencement of the warranty;

h) To the extent permitted by law Lincoln shall be entitled to in its absolute

discretion repair all engines and engine accessories however Lincoln shall

not be held responsible for any such repair which shall be the sole

responsibility of the engine manufacturer which provides for warranties for

the period and subject to any limitations provided for by those

manufacturers of the respective engines and engine accessories.

At the date of this warranty the details of those manufacturers warranties are as

follows:

Engine Manufacturer Labour Parts

i) Perkins Engines and Accessories *24 months *24 months

(The Perkins Distributor Organisation *Subject to conditions

provides all warranty service (accessories imposed by Perkins

included) for the Perkins Engines powering

goods manufactured by Lincoln.)

ii) Onan, Lombardini, Kubota & 12 months 12 months

Ruggerini Engines and their

Accessories

(warranty service can only be carried out by

authorised Lincoln Field Service Shop or

the engine distributors authorised by the

Lincoln branch office)

iii) Intermotor Engines and Accessories 12 months 12 months

(warranty services can only be carried out

by an authorised Lincoln F.S.S. or other

agency approved by the Lincoln branch

office)

iv) Briggs & Stratton Vanguard Engines *24 months *24 months

and Accessories •The Magnetron ignition

(warranty service can only be carried system is warranted by

out by an authorised Briggs & Stratton Briggs & Stratton for 5 years.

service dealer).

Exclusions

Subject to the express and statutory warranties hereinbefore provided Lincoln

provides no other warranties in respect of the manufacture or sale of goods and

in particular Lincoln shall have no responsibility or liability in respect of:

a) Repairs done to Lincoln’s goods and undertaken by the purchaser outside

Lincoln’s premises without written authority from Lincoln obtained prior to any

such repair;

b) Any damage or failure of the goods as a result of normal wear and tear or the

neglect misuse abuse or failure to properly service goods by any purchaser.

The liability of Lincoln is limited as hereinbefore provided and Lincoln shall not be

liable for any incidental special or consequential damage suffered by a purchaser

whether or not arising out of circumstances known or foreseeably known by

Lincoln and in particular arising out of the supply of goods to a purchaser or the

use of goods by a purchaser whether based on breach of contract negligence or

tort.

Lincoln supplies certain batteries in connection with its supply of goods and the

purchaser acknowledges that any such battery is warranted by its manufacturer