Page 1

Operator’s Manual

COOL ARC ® 55 & COOL ARC ® 55 ALUMINUM

WATER COOLER

For use with machines having Code Numbers:

11859, 12377

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM10117-A | Issue D ate Mar-15

© Lincoln Global, Inc. All Rights Reserved.

Page 2

THANK YOU FOR SELECTING

A QUALITY PRODUCT BY

LINCOLN ELEC TRIC.

PLEASE EXAMINE CARTON AND EQUIPMENT FOR DAMAGE

IMMEDIATELY

When this equipment is shipped, title passes to the purchaser upon

receipt by the carrier. Consequently, Claims for material damaged in

shipment must be made by the purchaser against the transportation

company at the time the shipment is received.

SAFETY DEPENDS ON YOU

Lincoln arc welding and cutting equipment is designed and built with

safety in mind. However, your overall safety can be increased by

proper installation ... and thoughtful operation on your part.

DO NOT INSTALL, OPERATE OR REPAIR THIS EQUIPMENT

WITHOUT READING THIS MANUAL AND THE SAFETY PRECAUTIONS

CONTAINED THROUGHOUT. And, most importantly, think before you

act and be careful.

WARNING

This statement appears where the information must be followed

exactly to avoid serious personal injury or loss of life.

CAUTION

This statement appears where the information must be followed to

avoid minor personal injury or damage to this equipment.

KEEP YOUR HEAD OUT OF THE FUMES.

DON’T get too close to the arc. Use

corrective lenses if necessary to

stay a reasonable distance away

from the arc.

READ and obey the Material Safety

Data Sheet (MSDS) and the warning

label that appears on all containers

of welding materials.

USE ENOUGH VENTILATION or

exhaust at the arc, or both, to keep

the fumes and gases from your breathing zone and the general area.

IN A LARGE ROOM OR OUTDOORS, natural ventilation may be

adequate if you keep your head out of the fumes (See below).

USE NATURAL DRAFTS or fans to keep the fumes away from your

face.

If you de velop unusual symptoms, see your supervisor. Perhaps the

welding atmosphere and ventilation system should be checked.

WEAR CORRECT EYE, EAR & BODY PROTECTION

PROTECT your eyes and face with welding helmet

properly fitted and with proper grade of filter plate

(See ANSI Z49.1).

PROTECT your body from welding spatter and arc

flash with protective clothing including woolen

clothing, flame-proof apron and gloves, leather

leggings, and high boots.

PROTECT others from splatter, flash, and glare with

protective screens or barriers.

IN SOME AREAS, protection from noise may be

appropriate.

BE SURE protective equipment is in good condition.

Also, wear safety glasses in work area AT ALL

TIMES.

SPECIAL SITUATIONS

DO NOT WELD OR CUT containers or materials which previously had

been in contact with hazardous substances unless they are properly

cleaned. This is extremely dangerous.

DO NOT WELD OR CUT painted or plated parts unless special

precautions with ventilation have been taken. They can release highly

toxic fumes or gases.

Additional precautionary measures

PROTECT compressed gas cylinders from excessive heat, mechanical

shocks, and arcs; fasten cylinders so they cannot fall.

BE SURE cylinders are never grounded or part of an electrical circuit.

REMOVE all potential fire hazards from welding area.

ALWAYS HAVE FIRE FIGHTING EQUIPMENT READY FOR

IMMEDIATE USE AND KNOW HOW TO USE IT.

Page 3

SECTION A:

WARNINGS

CALIFORNIA PROPOSITION 65 WARNINGS

Diesel Engines

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and other

reproductive harm.

Gasoline Engines

The engine exhaust from this product contains chemicals known

to the State of California to cause cancer, birth defects, or other

reproductive harm.

ARC WELDING CAN BE HAZARDOUS. PROTECT YOURSELF AND

OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH. KEEP CHILDREN AWAY. PACEMAKER WEARERS SHOULD CONSULT WITH

THEIR DOCTOR BEFORE OPERATING.

Read and understand the following safety highlights. For additional

safety information, it is strongly recommended that you purchase a

copy of “Safety in Welding & Cutting - ANSI Standard Z49.1” from the

American Welding Society, P.O. Box 351040, Miami, Florida 33135 or

CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety”

booklet E205 is available from the Lincoln Electric Company, 22801

St. Clair Avenue, Cleveland, Ohio 44117-1199.

BE SURE THAT ALL INSTALLATION, OPERATION,

MAINTENANCE AND REPAIR PROCEDURES ARE

PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

AFETY

S

1.d. Keep all equipment safety guards, covers and

devices in position and in good repair.Keep

hands, hair, clothing and tools away from

-belts, gears, fans and all other moving parts

V

when starting, operating or repairing

equipment.

1.e. In some cases it may be necessary to remove safety guards to

perform required maintenance. Remove guards only when

necessary and replace them when the maintenance requiring

their removal is complete. Always use the greatest care when

working near moving parts.

1.f. Do not put your hands near the engine fan. Do not attempt to

verride the governor or idler by pushing on the throttle control

o

rods while the engine is running.

1.g. To prevent accidentally starting gasoline engines while turning

the engine or welding generator during maintenance work,

disconnect the spark plug wires, distributor cap or magneto wire

as appropriate.

1.h. To avoid scalding, do not remove the radiator

pressure cap when the engine is

hot.

ELECTRIC AND

MAGNETIC FIELDS MAY

BE DANGEROUS

2.a. Electric current flowing through any conductor

causes localized Electric and Magnetic Fields (EMF). Welding

current creates EMF fields around welding cables and welding

machines

FOR ENGINE POWERED

EQUIPMENT.

1.a. Turn the engine off before troubleshooting

and maintenance work unless the

maintenance work requires it to be running.

1.b. Operate engines in open, well-ventilated

areas or vent the engine exhaust fumes outdoors.

1.c. Do not add the fuel near an open flame

welding arc or when the engine is running.

Stop the engine and allow it to cool before

refueling to prevent spilled fuel from

vaporizing on contact with hot engine parts

and igniting. Do not spill fuel when filling

tank. If fuel is spilled, wipe it up and do not start engine until

fumes have been eliminated.

2.b. EMF fields may interfere with some pacemakers, and welders

having a pacemaker should consult their physician before

welding.

2.c. Exposure to EMF fields in welding may have other health effects

which are now not known.

2.d. All welders should use the following procedures in order to

minimize exposure to EMF fields from the welding circuit:

2.d.1. Route the electrode and work cables together - Secure

them with tape when possible.

2.d.2. Never coil the electrode lead around your body.

2.d.3. Do not place your body between the electrode and work

cables. If the electrode cable is on your right side, the

work cable should also be on your right side.

2.d.4. Connect the work cable to the workpiece as close as possible to the area being welded.

2.d.5. Do not work next to welding power source.

3

Page 4

AFETY

S

ELECTRIC SHOCK

CAN KILL.

3.a. The electrode and work (or ground) circuits are

electrically “hot” when the welder is on. Do

not touch these “hot” parts with your bare skin or wet clothing.

Wear dry, hole-free gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full area

of physical contact with work and ground.

In addition to the normal safety precautions, if welding must

be performed under electrically hazardous conditions (in

damp locations or while wearing wet clothing; on metal

structures such as floors, gratings or scaffolds; when in

cramped positions such as sitting, kneeling or lying, if there

is a high risk of unavoidable or accidental contact with the

workpiece or ground) use the following equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode reel, welding head, nozzle or semiautomatic welding

gun are also electrically “hot”.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection should

be as close as possible to the area being welded.

3.e. Ground the work or metal to be welded to a good electrical (earth)

ground.

3.f. Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Never simultaneously touch electrically “hot” parts of electrode

holders connected to two welders because voltage

two can be the total of the open circuit voltage of both

welders.

3.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

between the

ARC RAYS CAN BURN.

4.a. Use a shield with the proper filter and cover plates to protect your

eyes from sparks and the rays of the arc when welding or

observing open arc welding. Headshield and filter lens should

conform to ANSI Z87. I standards.

4.b. Use suitable clothing made from durable flame-resistant material

to protect your skin and that of your helpers from the arc rays.

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

FUMES AND GASES

CAN BE DANGEROUS.

5.a. Welding may produce fumes and gases

hazardous to health. Avoid breathing these fumes and gases.

When welding, keep your head out of the fume. Use enough

ventilation and/or exhaust at the arc to keep fumes and gases

away from the breathing zone. When welding with electrodes

which require special ventilation such as stainless or hard

facing (see instructions on container or MSDS) or on lead or

cadmium plated steel and other metals or coatings which

produce highly toxic fumes, keep exposure as low as

possible and within applicable OSHA PEL and ACGIH TLV

limits using local exhaust or mechanical ventilation. In

confined spaces or in some circumstances, outdoors, a

respirator may be required. Additional precautions are also

required when welding on galvanized steel.

5. b. The operation of welding fume control equipment is affected by

various factors including proper use and positioning of the

equipment, maintenance of the equipment and the specific

welding procedure and application involved. Worker exposure

level should be checked upon installation and periodically

thereafter to be certain it is within applicable OSHA PEL and

ACGIH TLV limits.

5.c. Do not weld in locations near chlorinated hydrocarbon vapors

coming from degreasing, cleaning or spraying operations. The

heat and rays of the arc can react with solvent vapors to form

phosgene, a highly toxic gas, and other irritating products.

3.j. Also see It ems 6.c. and 8.

5.d. Shielding gases used for arc welding can displace air and

injury or death. Always use enough ventilation, especially in

confined areas, to insure breathing air is safe.

5.e. Read and understand the manufacturer’s instructions for this

equipment and the consumables to be used, including the

material safety data sheet (MSDS) and follow your employer’s

safety practices. MSDS forms are available from your welding

distributor or from the manufacturer.

5.f. Also see item 1.b.

4

cause

Page 5

AFETY

S

WELDING AND CUTTING

SPARKS CAN CAUSE

FIRE OR EXPLOSION.

6.a. Remove fire hazards from the welding area. If

this is not possible, cover them to prevent the welding sparks

from starting a fire. Remember that welding sparks and hot

aterials from welding can easily go through small cracks and

m

openings to adjacent areas. Avoid welding near hydraulic lines.

Have a fire extinguisher readily available.

6.b. Where compressed gases are to be used at the job site, special

precautions should be used to prevent hazardous situations.

Refer to “Safety in Welding and Cutting” (ANSI Standard Z49.1)

and the operating information for the equipment being used.

6.c. When not welding, make certain no part of the electrode circuit is

touching the work or ground. Accidental contact can cause

overheating and create a fire hazard.

6.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures will

not cause flammable or toxic vapors from substances inside.

They can cause an explosion even though they have been

“cleaned”. For information, purchase “Recommended Safe

Practices for the Preparation for Welding and Cutting of

Containers and Piping That Have Held Hazardous Substances”,

AWS F4.1 from the American Welding Society (see address

above).

6.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

6.f. Sparks and spatter are thrown from the welding arc. Wear oil free

protective garments such as leather gloves, heavy shirt, cuffless

trousers, high shoes and a cap over your hair. Wear ear plugs

when welding out of position or in confined places. Always wear

safety glasses with side shields when in a welding area.

6.g. Connect the work cable to the work as close to the welding area

as practical. Work cables connected to the building framework or

other locations away from the welding area increase the

possibility of the welding current passing through lifting chains,

crane cables or other alternate circuits. This can create fire

hazards or overheat lifting chains or cables until they fail.

6.h. Also see item 1.c.

6.I. Read and follow NFPA 51B “ Standard for Fire Prevention During

Welding, Cutting and Other Hot Work”, available from NFPA, 1

Batterymarch Park, PO box 9101, Quincy, Ma 022690-9101.

CYLINDER MAY EXPLODE IF

DAMAGED.

7.a. Use only compressed gas cylinders containing

the correct shielding gas for the process used

and properly operating regulators designed for

the gas and pressure used. All hoses, fittings,

etc. should be suitable for the application and

maintained in good condition.

7.b. Always keep cylinders in an upright position securely chained to

n undercarriage or fixed support.

a

7.c. Cylinders should be located:

• Away from areas where they may be struck or subjected

to physical damage.

• A safe distance from arc welding or cutting operations

and any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode holder or any other

electrically “hot” parts to touch a cylinder.

7.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. Valve protection caps should always be in place and hand tight

except when the cylinder is in use or connected for use.

7.g. Read and follow the instructions on compressed gas cylinders,

associated equipment, and CGA publication P-l, “Precautions for

Safe Handling of Compressed Gases in

Cylinders,” available

from the Compressed Gas Association 1235 Jefferson Davis

Highway, Arlington, VA 22202.

FOR ELECTRICALLY

POWERED EQUIPMENT.

8.a. Turn off input power using the disconnect

switch at the fuse box before working on the

equipment.

8.b. Install equipment in accordance with the U.S. National Electrical

Code, all local codes and the manufacturer’s recommendations.

8.c. Ground the equipment in accordance with the U.S. National

Electrical Code and the manufacturer’s recommendations.

6.j. Do not use a welding power source for pipe thawing.

Refer to http://www.lincolnelectric.com/safety

for additional safety information.

Welding Safety

Interactive Web Guide

for mobile devices

5

Page 6

TABLE OF CONTENTSCOOL ARC®55 & COOL ARC®55 ALUMINUM WATER COOLER

Page

Installation...............................................................................................................................Section A

Technical Specifications...............................................................................................................A-1

Safety Precautions .......................................................................................................................A-2

Unpacking the COOL ARC

Installation on Power Source ...............................................................................................A-2

®

55 ..............................................................................................A-2

Location and Mounting .........................................................................................................A-2

Filling the Coolant Reservoir .................................................................................................A-3

Coolant “In” and “out” Connections......................................................................................A-4

Input Power Connection........................................................................................................A-4

Installation of Water Cooled Accessories ......................................................................................A-5

Water Cooled TIG Torch and MIG Gun ...................................................................................A-5

Connection to Wire Feeders..................................................................................................A-5

K529-10 Power Input Cable with Water and Gas Hoses ........................................................A-5

________________________________________________________________________

Operation .................................................................................................................................Section B

Safety Precautions.......................................................................................................................B-1

Product Description

............................................................................................B-1

Recommended Processes and Equipment ............................................................................B-1

Turning the System “On” .....................................................................................................B-1

Cooling Efficiency.................................................................................................................B-2

________________________________________________________________________

Accessories .............................................................................................................................Section C

Optional Equipment (Field Installed) ............................................................................................C-1

________________________________________________________________________

Maintenance............................................................................................................................Section D

Safety Precautions.......................................................................................................................D-1

Routine Maintenance ...........................................................................................................D-1

Periodic Maintenance...........................................................................................................D-1

Pump Maintenance ..............................................................................................................D-1

Pump Motor .........................................................................................................................D-1

Heat Exchanger....................................................................................................................D-1

Reservoir Coolant Level........................................................................................................D-1

Coolant Treatment Recommendation....................................................................................D-2

Pump Inlet Strainer ..............................................................................................................D-2

Inspect Condition of Coolant.................................................................................................D-2

Service the Pump Inlet Strainer ............................................................................................D-3

Additional Service Notes.......................................................................................................D-3

________________________________________________________________________

Troubleshooting.......................................................................................................................Section E

Safety Precautions .......................................................................................................................E-1

How to Use Troubleshooting Guide .......................................................................................E-1

Troubleshooting Guide .................................................................................................................E-2

________________________________________________________________________

Wiring Diagrams......................................................................................................................Section F

Wiring Diagram ............................................................................................................................F-1

Dimension Print............................................................................................................................F-2

________________________________________________________________________

Parts List ........................................................................................................parts.lincolnelectric.com

Content/details may be changed or updated without notice. For most current Instruction Manuals, go to

parts.lincolnelectric.com.

________________________________________________________________________

6

Page 7

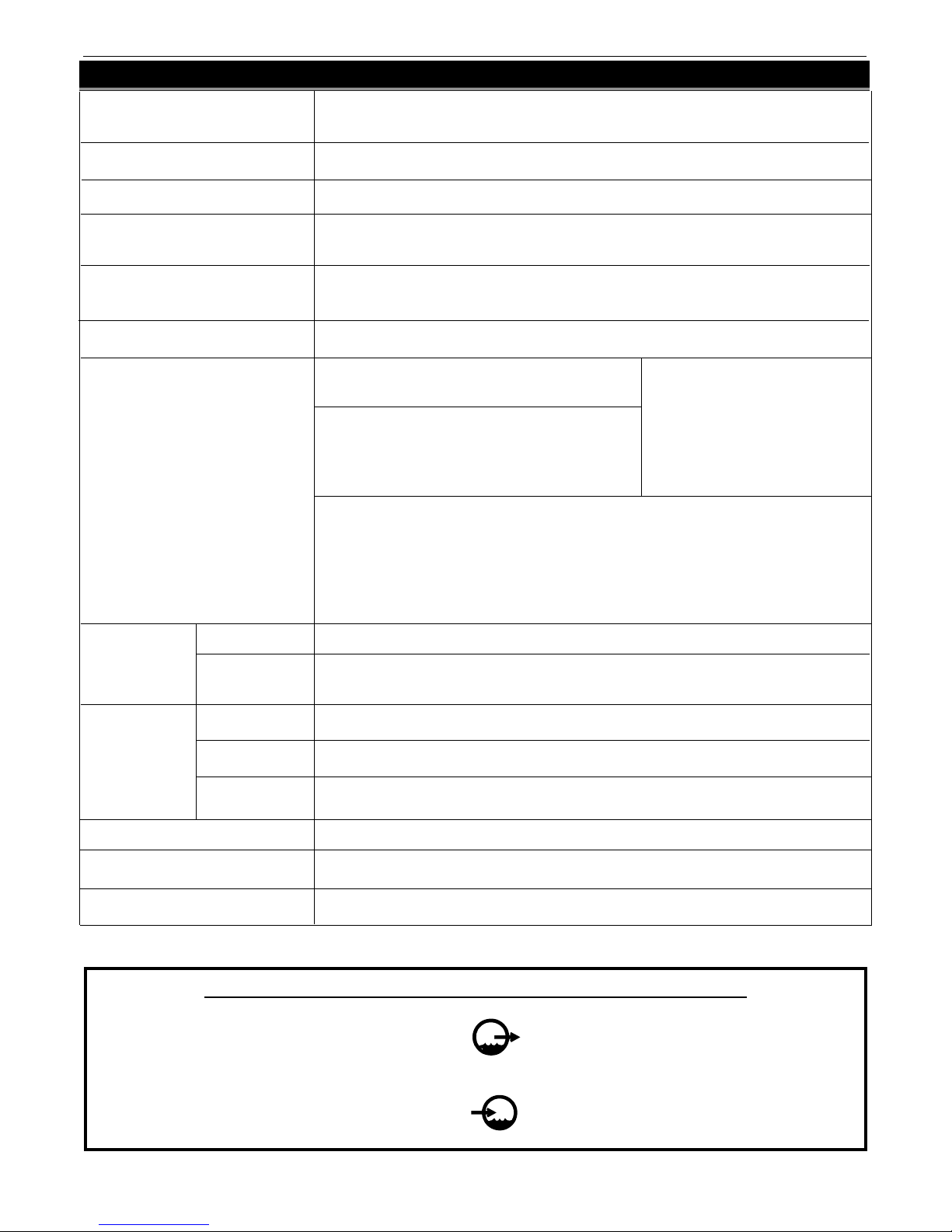

Product No. / Model

TECHNICAL SPECIFICATIONS – COOL ARC®55

3086-1 ( COOL ARC

K

VIA 3-Prong Plug NEMA Type 5-15P

®

5

INSTALLATIONCOOL ARC®55 & COOL ARC®55 ALUMINUM WATER COOLER

5 )

Input

Current Draw @ 60Hz Input

aximum Operating Pressure and Flow Rate

M

(Open Flow, Without Welding Torch Restriction)

Typical Operating Pressure and Flow Rate

(With Welding Torch Restriction)

Reservoir Size

Recommended Coolant

115VAC 60 Hz 1 Phase

3.8 Amps

60 psi (414 kPa) (4.14 bar) Max.

1.66 gal/min. (6.28 liter/min) Max.

53-57 psi (365-393 kPa)

.45-.60 gal/min. (1.7-2.3 liter/min)

2.375 gal. (9 liters)

For Use Above Freezing: Clean tap, distilled or de-ionized

water.

For Use Below Freezing:

DO NOT USE: Automotive anti-freeze that contains rust inhibitors or leak stoppers. These coolants will

damage the pump and block the small internal passageways of the heat exchanger, affecting cooling

performance. To acquire the proper coolant contact a local welding distributor.

DO NOT USE: Non-Lincoln branded industry coolants. These coolants may contain oil-based substances,

which attack the plastic components of the cooler. Once added to the cooler, these substances are

virtually impossible to purge from the water lines and heat exchanger.

50% water and 50% pure ethylene

glycol (reagent or industrial grade)

mixture.

A Magnum®PRO AL coolant may be

used in aluminum push-pull systems

where high frequency is NOT used.

Lincoln Electric Low Conductivity Coolant

may be used in MIG and TIG systems

(but NOT aluminum push-pull) where

high frequency may be present.

Shipping

Weight

Reservoir

Full (Water)

L

Dimensions W

H (Top Face)

EMC Classification

Temperature Range

Cooling Power

1.33 kW (4540 BTU/hr.) @ 1 L/min.*

62.6 lbs. (28.4 kg)

82.3 lbs. (37.3 kg)

26.5 in. (673.1mm)

13.9 in. (353.0mm)

11.5 in. (292.1mm)

Category 1

14°F to 104°F (-10°C to 40°C)

*Cooling Power is measured at a 1 L/min. flow rate with a 40°C coolant temperature rise in a 25°C (77ºF) environment.

EXPLANATION OF SYMBOLS THAT APPEAR ON THIS EQUIPMENT

ON

I

COOLANT

OUT

OFFOFF

O

COOLANT

IN

A-1

Page 8

INSTALLATIONCOOL ARC®55 & COOL ARC®55 ALUMINUM WATER COOLER

SAFETY PRECAUTIONS

WARNING

ELECTRIC SHOCK can kill.

nl y qualified person s should pe rf orm this

• O

installation.

• Turn off the power source at the disconnect

witch before connecting or working inside of

s

the equipment.

• Use only grounded receptacle.

• Do not remove the power cord ground prong.

HOT COOLANT CAN BURN SKIN

• Always be sure coolant is not hot before doing any

work on cooler parts.

ROTATING FAN BLADES ARE

HAZARDOUS

• Do not put your hands near operating fan.

• Keep all equipment safety guards, covers and

devic es i n po sition and in g ood repair.K eep hands, hair,

clothing and tools away from V-belts, gears, fans and all other

moving parts when starting, operating or repairing equipment.

• In some cases it may be necessary to remove safety guards to

perform required maintenance. Remove guards only when

necessary and replace them when the maintenance requiring

their removal is complete.

working near moving

------------------------------------------------------------------

UNPACKING THE COOL ARC®55

The packaging of the Cooler is designed to withstand shipping abuse, and

contains a cardboard liner that surrounds the unit. If any shipping damage

has occurred, contact your certified Lincoln distributor or service center.

When unpacking the unit, avoid thrusting sharp objects through the carton

liner, which may puncture the plastic reservoir. Save the instruction manual

and service directory supplied with the

and future maintenance service.

Always use the greatest care when

parts.

COOL ARC®55

for parts orders

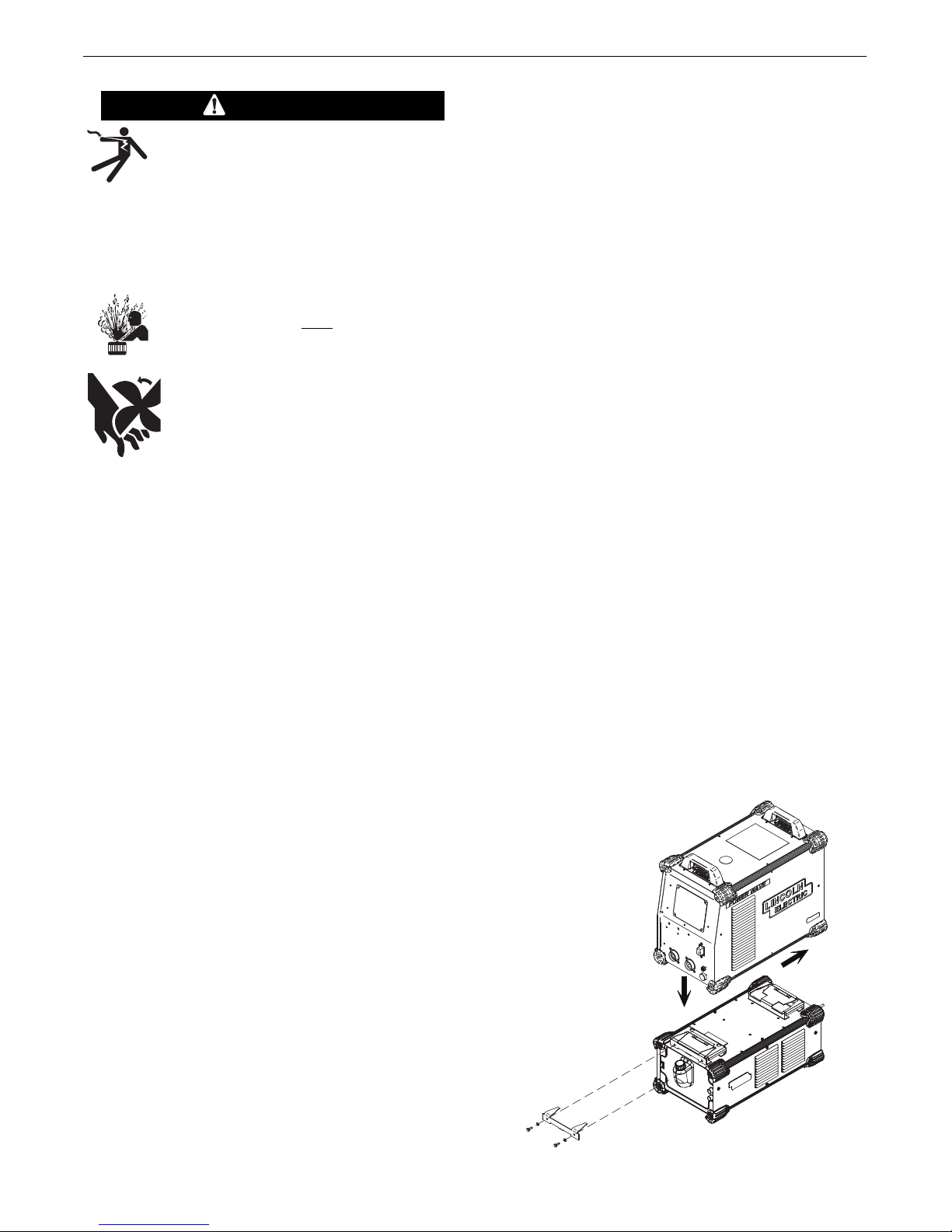

LOCATION AND MOUNTING

(See Figure A.1)

To mount the COOL ARC®55 to the bottom of a compatible

Power Wave “S” series power source utilize the quick lock

mechanism as shown.

f using the COOL ARC

I

such as the STT Module, always mount the COOL ARC

the bottom. The COOL ARC®55 will operate in harsh

environments and can be used outdoors. Even so, it is important

that simple preventative measures are followed in order to

assure long life and reliable operation.

• The machine must be located where there is free circulation

of clean air such that movement into and out of the louvers

will not be restricted.

• Dirt and dust that can be drawn into the machine should be

kept to a minimum. The use of air filters on the air intake is

not recommended because normal air flow may be

restricted. Failure to observe these precautions can result in

poor cooling performance.

• Keep the machine dry. Shelter from rain and snow. Do not

place on wet ground or in puddles.

• Always mount the COOL ARC®55 underneath other

machines. Never attach a module underneath the cooler.

• Do not mount the Power Wave “S” series power source and

COOL ARC®55 combination over combustible surfaces.

Where there is a combustible surface directly under

stationary or fixed electrical equipment, that surface shall be

covered with a steel plate at least .060” (1.6mm) thick,

which shall extend not less than 5.90” (150mm) beyond the

equipment on all sides.

• Avoid placing the cooler near areas of extreme heat.

• Avoid placing the cooler near a flux hopper or an area where

dust build-up is extreme.

®

5 in conjuntion with another module

5

FIGURE A.1

®

55 on

Readthis entire installation section before you start installation.

--------------------------------------------------------------------

INSTALLATION ON POWER SOURCE

The COOL ARC®55 can be used as a stand alone unit or

mounted directly to the bottom of the Power Wave “S” series

power source.

Always place the Cool Arc 55 on a level surface to avoid causing

the machine to topple over.

A-2

Page 9

INSTALLATIONCOOL ARC®55 & COOL ARC®55 ALUMINUM WATER COOLER

FILLING THE COOLANT RESERVOIR:

Recommended Coolant

• For Use Above Freezing: Clean tap, distilled or de-ionized

water.

For Use Below Freezing: 50% water and 50% pure ethylene

•

glycol (reagent or industrial grade) mixture.

• DO NOT USE: Automotive anti-freeze that contains rust

inhibitors or leak stoppers.

These coolants will damage the pump and block the small

internal passageways of the heat exchanger, affecting cooling

performance.

• DO NOT USE: Pre-packaged welding industry coolants. These

coolants may contain oil-based substances, which attack the

plastic components of the cooler. Once added to the cooler,

these substances are virtually impossible to purge from the

water lines and heat exchanger.

To avoid freeze damage and water leakage in shipment, the

COOL ARC®55 unit is delivered empty with no coolant in the

system. To fill the unit, locate the plastic screw on reservoir fill

cap at the front of the unit and remove by turning counterclockwise.

Clean tap water, distilled water, de-ionized water, a 50/50 mix of

pure ethylene glycol and water, or any other coolant specified by

the manufacturer of the water cooled product that the Cooler is

used with, can be added into the coolant reservoir. The opening

of the fill cap mates with most coolant containers but, to avoid

spillage of coolant, a funnel should be placed into the reservoir

hole when filling the COOL ARC®55.

CAUTION

DO NOT USE OIL BASED COOLANTS OR COOLANTS THAT CONTAIN RUST

INHIBITORS OR LEAK STOPPERS.

--------------------------------------------------------------------------------

UNPLUG THE COOLER BEFORE FILLING THE COOLANT RESERVOIR:

Carefully add 2.375 gallons (9 liters) of coolant through a funnel

into the coolant reservoir fill hole.

The cooler is "FULL" when the coolant lies just below the coolant

reservoir opening .

NOTE: DO NOT ADD MORE THAN 2.375 GALLONS (9

LITERS) OF COOLANT INTO THE RESERVOIR. The fill cap

contains a pressure release air hole, which must not be blocked

by overfilling the reservoir with coolant.

Be certain to replace the reservoir fill cap when the reservoir is

full. Operation of the COOL ARC®55 without the fill cap in place

can cause poor cooling efficiency, evaporation loss of coolant

and reduced product life.

NOTE: Pure solutions and mixtures of, or materials (i.e.

towels) wetted with ethylene glycol are toxic to humans and

animals. They must not be haphazardly discarded, especially by

pouring liquids down the drain. Contact the local EPA office for

responsible disposal methods or for recycling information.

For best results when using the COOL ARC®55 with Lincoln guns

or torches, use distilled or de-ionized water, although if not

available, tap water can be used. If protection from freezing is

desired, use a 50% water and 50% pure ethylene glycol (reagent

or industrial grade) mixture. An alcohol and water mixture is also

acceptable.

®

When using the COOL ARC

55 with other products, consult the

manufacturer's instruction manual for recommended coolants.

A-3

Page 10

INSTALLATIONCOOL ARC®55 & COOL ARC®55 ALUMINUM WATER COOLER

COOLANT

IN

COOLANT

OUT

FFRROOMM HHEEAATT

SSOOURCURCEE ((RREEDD))

TTOO HHEEAATT

SSOOURCURCEE ((BBLLUUEE))

COOLANT "IN" AND "OUT" CONNECTIONS

The fittings located on the COOL ARC®55 are two female Quick

Disconnect fittings. These mate with water hoses typically

used in the welding industry. Two couplers converting from

quick disconnect to 5/8-18 left-hand thread (CGA style) are also

included.

Refer to Figure A.2.

Water or Coolant Line Connections

to the

COOL ARC®55

Take the male quick disconnect of the water hose and check if it

matches the coupler or the quick disconnect on the front of the

unit. When using water hoses with threaded nuts use the

supplied couplers to convert from 5/8-18 left hand female thread

to male quick disconnect.

(Reference FIG. A.2) Take the accessory "INLET" hose (colored

or tagged blue on most hoses) and plug it into the coolant "OUT"

fitting located on the front of the cooler. If necessary use the

supplied coupler, making sure to secure the connector nut of the

hose tightly into the fitting with a wrench so that leaking does

not occur. Then take the accessory "OUTLET" hose (colored or

tagged red on most hoses) and plug it into the coolant "IN" fitting

located on the front of the cooler. Again, if necessary use the

coupler, tightly securing the connector nut of the hose into the

fitting with a wrench to insure that no leaking occurs.

INPUT POWER CONNECTION

Plug the input power cord on the COOL ARC®55 into a standard

115V NEMA circuit breaker protected receptacle. The receptacle

must have overload protection and a grounding conductor pin.

NOTE: BE CERTAIN THAT NO LEAKS EXIST WHEN THE COOLER

IS TURNED ON. A LEAK WILL DEPLETE RESERVOIR VOLUME,

CAUSING POOR COOLING PERFORMANCE AND REDUCING

GUN OR TORCH LIFE.

FIGURE A.2

Inlet and Outlet Hose Connection Diagram

A-4

Page 11

INSTALLATIONCOOL ARC®55 & COOL ARC®55 ALUMINUM WATER COOLER

C

O

O

L

A

N

T

C

O

O

L

A

N

T

TO WORK

COOLANT

OUT

COOLANT

IN

=

BLUE HOSE

= RED HOSE

G

A

S

GAS

K1622-4 ADAPTER

FEMALE

TO FEMALE

CGA FITTING

K

P5

04 WATER HOSES AND

F

EMALE TO FEMALE

5/8" LH

CGA ADAPTER COUPLINGS

FEMALE TO FEMALE

CGA FITTING

COOLANT

COOLANT

GUN CABLE

COOLANT

OUT

COOLANT

IN

= BLUE HOSE

= RED HOSE

COOLANT

OUT

COOLANT

IN

= BLUE HOSE

= RED HOSE

COOLANT

COOLANT

GUN CABLE

C

O

O

L

A

N

T

C

O

O

L

A

N

T

TO WORK

GAS

ELECTRODE CABLE

NOTE:

ORDER K1859-1 FOR WIRE

FEEDERS WITH QUICK

DISCONNECT FITTINGS.

CONTOL

CABLE

COOLANT

OUT

COOLANT

IN

= BLUE HOSE

= RED HOSE

K1859-1 FOR

CONNECTING TO

WIRE FEEDERS

COOLANT

COOLANT

COOLANT

COOLANT

GUN CABLE

INSTALLATION OF WATER COOLED ACCESSORIES

After following the installation instructions above, the COOL ARC

5 is ready for connection to a water-cooled accessory.

5

WATER COOLED TIG TORCH AND MIG GUN

®

Follow Figure A.3 when using the COOL ARC

55 with watercooled TIG torches. Follow Figure A.5 when using the COOL

ARC®55 with water-cooled MIG gun. Consult the manufacturer's

nstruction manual when using the COOL ARC

i

®

5 with other

5

water-cooled TIG and MIG accessories.

CONNECTION TO WIRE FEEDERS

®

Follow Figure A.4 when using the COOL ARC

55 in conjunction

with a wire feeder. The feeder will need to have pass-through

water hoses installed in order to correctly function with the COOL

ARC®55, since the cooler requires continuous flow. DO NOT USE

A WATER SOLENOID VALVE with the COOL ARC®55. Water passthrough connection kits are available for wire feeders. Refer to

product literature or the wire feeder's instructions manual for kit

availability and further connection details. It is not required to run

the water lines through the wire feeder, but is does provide a

very neat MIG gun connection. If pass-through water hoses are

unavailable, connect the MIG gun as shown in

Figure A.5.

CAUTION

DO NOT USE A WATER SOLENOID VALVE with the COOL ARC

55. When a solenoid valve closes, the pump would deadhead, causing the pump to heat up excessively leading to

premature failure of the pump.

®

K529-10 POWER INPUT CABLE WITH WATER AND GAS HOSES

This cable assembly includes a (1) power cable, (1) control

cable, (1) gas hose and (2) water hoses to connect a power

ource to a wire feeder. The cable length is 10'. The water hoses

s

have 5/8"-18 left hand male hose fittings and the gas hose has a

5/8"-18 right hand male hose fitting. The cable and hose lengths

are designed to connect a wire feeder to a COOL ARC

to Figure A.6 for an illustration of this connection.

FIGURE A.5

Connection to Wire Feeder (Do Not Use Water Solenoid)

®

®

55. Refer

FIGURE A.3

Water Cooled TIG Torch Connection

FIGURE A.4

Water Cooled MIG Gun Connection

FIGURE A.6

Connection to Wire Feeder (Do Not Use Water Solenoid)

A-5

Page 12

OPERATIONCOOL ARC®55 & COOL ARC®55 ALUMINUM WATER COOLER

SAFETY PRECAUTIONS

WARNING

ELECTRIC SHOCK can kill.

• Do not operate with covers removed.

• Do not opera te i f ca bl es a re wet or

immersed in water.

• Moving part s can injure . Neve r plac e

fingers into openings of Cooler.

• Hot coolant can burn skin. Always be sure

coolant is NOT HOT before servicing the

cooler.

• Do not pour used ethylene glycol coolant

down the drain.

---------------------------------------------------------

See additional warning information at front of

this operator’s manual.

---------------------------------------------------------

RECOMMENDED PROCESSES AND EQUIPMENT

Recommended Processes, Equipment and Accessories. The

COOL ARC®55 is designed for use with water-cooled TIG, MIG,

AC (Plasma Arc Cutting) and PAW (Plasma Arc Welding) guns

P

and torches. The COOL ARC

feeders and power sources as well as TIG power sources.

TURNING THE SYSTEM "ON"

Af ter connecting the COOL ARC®55 pe r t he installation

instructions above, plug the unit into a 115V NEMA electrical

receptacle for start-up operation. Be certain that the power input

into the unit matches the Cooler's rated input.

The LIGHTED POWER SWITCH is located on the left side of the

control panel. The cooler will be "ON" when pressed to " l " and

"OFF" when pressed to "O".

in the "ON" position.

You will be able to hear the fan running and feel airflow out of

the sides of the unit when the cooler is operating. The cooler will

run continuously unless it is plugged into a switched receptacle

on the power source.

®

55 can be used with MIG wire

The switch will also illuminate when

PRODUCT DESCRIPTION

The COOL ARC®55 is a stand alone re-circulation cooling system

designed for use with water-cooled TIG, MIG, PAC (Plasma Arc

Cutting) and PAW (Plasma Arc Welding) guns and torches. The

coolant "IN" and "OUT" connections are female quick disconnect

fittings. The COOL ARC®55 is a continuous duty cooler.

The COOL ARC®55 is very easy to use and understand with only

one power switch on the control panel. The cooler has a standard 115 V power input receptacle, making it very easy to power

up. Adding coolant to the reservoir is simple and connecting to

the coolant "IN" and "OUT" connections are easily made by hand

with the quick disconnects.

The COOL ARC®55 coolant flow is circulated through a heat

exchanger to remove heat energy from the coolant. The coolant

flow is then deposited into the coolant reservoir. The pump

draws its coolant supply from the coolant reservoir and delivers

coolant to the welding torch or gun. Refer to Figure B.1 and

B.2.

B-1

Page 13

COOL ARC 55

RESERVOIR

PUMP

HEAT

EXCHANGER

FAN

WELD ING

GUN OR

TORCH

HEAT IN

HEAT

OUT

COOLANT IN

COOLANT OUT

C

O

O

L

A

N

T

C

O

O

L

A

N

T

R

OOM AIR IN

HOT

AIR

OUT

H

OT

AIR

OUT

PUMP

HEAT

EXCHANGER

FAN

RESERVOIR

OPERATIONCOOL ARC®55 & COOL ARC®55 ALUMINUM WATER COOLER

The coolant FLOW INDICATOR is accessed by removal of the fill cap.

Actual return flow is directly visible, via the fill opening.

When first starting the unit, check all of the coolant hoses to insure that

o water leaks are present. Water leakage causes poor welding

n

performance, poor cooling performance, low welding component life

and potential electrical safety hazards.

• The cooler should be turned "OFF" when welding is not taking

lace for long periods of time.

p

• Be certain that the cooler is "ON" (power switch in the "l" position)

before beginning to weld.

• Never operate the cooler with the reservoir fill cap removed. Unless

checking coolant flow.

• Avoid kinking or putting sharp bends in any water lines.

• Keep all water lines clean and free of any blockage.

• Do not operate cooler without coolant in reservoir. Never run pump

dry.

FIGURE B.1

Coolant Circulation Diagram

COOLING EFFICIENCY

®

he high cooling efficiency of the COOL ARC

T

5 offers a cooler, more

5

comfortable weld than conventional air-cooled procedures as well as

leading competitors water cooled systems.

®

he COOL ARC

T

5 effectively removes the heat of the arc away from

5

the gun or torch handle and places it into the exiting air flow at the sides

of the cooler. Ambient air temperature affects the coolant temperature

®

of the COOL ARC

55.

For example:

Unlike other water coolers that depend on a bulky reservoir size, the

high efficiency components of the COOL ARC®55 allows the reservoir

size to be small. The result is a lightweight, portable unit.

FIGURE B.2

B-2

Page 14

ACCESSORIESCOOL ARC®55 & COOL ARC®55 ALUMINUM WATER COOLER

OPTIONAL EQUIPMENT (FIELD INSTALLED)

K1536-1 Magnum Flow Sensor:

rotects valuable torches, guns and robotic welding systems

P

from damage when loss of coolant flow has occurred for any

reason such as a blocked or kinked water line or a ruptured

hose.

KP1529-1 Quick Connect Water Adapter:

Converts a male 5/8"-18 left hand hose fitting (CGA Style) to a

female quick connect fitting. The female quick connect mates

with the male quick connects on water cooled MIG guns or

hoses.

K1859-1 Water Cooler to Wire Feeder Hoses:

This kit includes two 25’(7.6m) – 3/16 I.D. water hoses with a

5/8" LH CGA st yle fitt in g on one end an d a male qui ck

disconnect on the other. Most wire feeders have female quick

disconnects and this kit allows direct hook up between the water

cooler and the wire feeder.

5/8"-18 Left Hand Male Hose Fitting Parts: (CGA Style)

Fittings that convert a standard 3/16" I.D. hose to a 5/8"-18 left

hand male hose fitting. These male hose fittings mate with the

fittings on the back of the COOL ARC®55.

KP504 TIG Hook Up Kit:

The Hook-Up Kit includes: (2) water hoses, (1) gas hose, (2)

water adapter fittings, male to male 5/8" LH thread, (1) water

hose coupler, female to female 5/8" LH thread and (1) power

cable adapter. Threads on all hoses and fittings are CGA style.

CAUTION

DO NOT USE A WATER SOLENOID VALVE with the COOL ARC

55. When a solenoid valve closes, the pump would deadhead, causing the pump to heat up excessively leading to

premature failure of the pump.

Coolant Hoses:

Coolant hoses are readily available from an industrial welding

supplier or in various MIG or TIG hook-up kits provided by

Lincoln Electric. Refer to Magnum accessory literature sheets.

For lengths of coolant hoses over 25Ft(7.6m). and up to

50Ft.(15.2m), 5/16 I.D. hose is recommended. 5/16 I.D. hose

and accommodating fittings are available from an industrial

welding supplier.

COOLANTS

®

Order the following:

(See Parts Lists for Item’s below)

(2) Connector Nuts

(2) Nipples for 3/16" I.D. Hose

(2) Hose Clamps

The connector and nipple listed fit tightly onto 5/32” (4.0mm) to

3/16" (4.8mm) inner diameter hose, but if clamped tightly to the

hose, can fit up to a .25” (6.4mm) inner diameter hose. These

fittings are also readily available from any industrial welding

supplier.

K529-10

Power Input Cable with Water and Gas Hoses:

This cable assembly includes the following: (1) power cable, (1)

control cable, (1) gas hose and (2) water hoses. The cable

assembly connects a power source to a wire feeder for watercooled MIG applications. The cable length is 10'(3.1m). The

water hoses have 5/8"-18 left hand male hose fittings and the

gas hose has a 5/8"-18 right hand male hose fitting. The cable

and hose lengths are designed to connect a wire feeder to a

®

COOL ARC

55 that is vertically mounted at the rear of a power

source on a dual cylinder undercarriage. Refer to Figure A.6 for

an illustration of this connection.

KP3379-1 Magnum®PRO AL Coolant:

May be used in aluminum push-pull systems where hi gh

frequency is NOT used.

KP4159-1 Low Conductivity Coolant:

May be used in MIG and TIG systems (but NOT aluminum pushpull) where high frequency may be present.

C-1

Page 15

MAINTENANCECOOL ARC®55 & COOL ARC®55 ALUMINUM WATER COOLER

SAFETY PRECAUTIONS

WARNING

Have qualified personnel do the maintenance work. In some

cases, it may be necessary to remove safety guards to perform

required maintenance. Remove guards only when necessary and

replace them when the maintenance requiring their removal is

omplete. Always use the greatest care when working near

c

moving parts.

--------------------------------------------------------------------------

• Disconnect input power by removing plug from receptacle

before working inside Cooler.

• Do not touch electrically “hot” parts inside Cooler.

• Have qualified personnel do the installation, maintenance and

troubleshooting work.

• Unplug the cooler before performing general maintenance.

---------------------------------------------------------

---------------------------------------------------------

Observe all Safety Guidelines detailed throughout this manual. Be

sure to disconnect the Cooler from the Power Source before

performing any maintenance procedures.

---------------------------------------------------------

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts or electrode

with skin or wet clothing.

• Insulate yourself from work and ground

• Always wear dry insulating gloves.

MOVING PARTS can injure.

• Do not operate with doors open or guards off.

• Keep away from moving parts.

PUMP MAINTENANCE

The pump head has a "built in" strainer on the inlet side of the pump. It is

recommended to clean or replace the pump's inlet strainer at least

nce a year. (See Above):

o

• Drain the coolant reservoir and all coolant lines. Dispose of the coolant

properly as specified above.

Hold the pump head firmly to apply a counter-torque when loosing the

•

strainer's 7/8" acorn nut located on the bottom. Do not confuse with 3/4"

acorn nut. Remove nut and slide inlet strainer down and out from the

pump head.

• Gently rinse the strainer under running water to thoroughly clean it.

• Use a mirror to inspect the inside of the pump for contamination. Carefully

remove hardened debris with a den tal pick if necessary, without

scratching the inside of the pump.

• Reinstall the strainer and 7/8 acorn nut, tightening with 75+/-15 in-lbs. of

torque. Wipe dry all area wetted with coolant. Dispose of coolant soaked

towels properly as specified above.

• For a more in depth procedure, See “Maintenace Section”, “Pump Inlet

Strainer”.

PUMP MOTOR

The COOL ARC®55 is rated for continuous operation. It is recommended to

re-oil the pump motor bearings once a year as follows:

• Remove the plastic plugs located on the top of both the inboard and

outboard bearing end-caps.

• Re-oil each bearing with 30-35 drops of SAE 20 oil then reinstall both

plugs.

ROUTINE MAINTENANCE

Remove accumulated dust and dirt from the internal components of the

cooler by blowing it out with a low pressure air hose or removing it with a

vacuum hose.

PERIODIC MAINTENANCE

In dirty or dusty environments or if biological growth occurs in the coolant, it

may be necessary to flush the coolant reservoir. Drain the old coolant, rinse

the inside of the reservoir and circulate rinsing solution through the coolant

system. Add new coolant when cleaning is finished. It is recommended to

flush the coolant at least once a year. A cooling system free from debris

offers increased cooling efficiency and longer pump and torch life. See the

Coolant Treatment Recommendation in this “Maintenace Section”.

NOTE: Pure solutions, mixtures of, or materials (i.e. towels wetted) with

ethylene glycol are toxic to humans and animals.

They must not be haphazardly discarded, especially by pouring liquids down

the drain. Contact the local EPA office for responsible disposal methods or

for recycling information.

HEAT EXCHANGER

To maintain maximum cooler efficiency, the heat exchanger should be kept

free of dust and dirt build-up. Clean the heat exchanger periodically using a

vacuum hose or a low-pressure air line. Avoid placing the unit near a flux

hopper or a flux waste container. A clean heat exchanger offers better cooling

performance and longer product life. In extremely dirty environments, it may

be necessary to remove the heat exchanger completely from the cooler and

clean the fins with soap and water. Use care to avoid damaging the fins.

RESERVOIR COOLANT LEVEL

The reservoir volume should be checked daily before using the cooler.

Remove the reservoir fill cap and check the coolant level. The reservoir is

full when the coolant level is just below the reservoir fill opening. Keep the

reservoir full, especially after disconnecting the water lines or changing the

accessory being cooled.

D-1

Page 16

MAINTENANCECOOL ARC®55 & COOL ARC®55 ALUMINUM WATER COOLER

COOLANT TREATMENT RECOMMENDATION

This procedure is intended to provide a means of reducing the

objectionable amount of fungal and bacterial contamination that

has occurred in COOL ARC®55 water coolers and cooling systems.

Additive:

The recommended additive can be purchased at local pool

supply stores. An example is "Maintain Pool Pro 30% Non-Foam

Algaecide"

Limitations:

• This additive should be used with fresh coolants containing

only pure water.

• This additive should not be used with coolants containing any

other substance, including antifreeze substances.

• No other additives shall be used with the specified coolant that

has been treated with the recommended additive.

• This procedure is no permanent substitute for a periodic

maintenance schedule for the specified coolers

• A 1 quart bottle of additive is sufficient to disinfect and treat

about 500 coolers.

• Check with the manufacturer of your guns or torches to be

sure th at th is pr ocedure is compat ib le wi th yo ur

equipment.

Prepare the disinfectant:

Make a quantity of only what is needed to avoid an excess Bulk

preparation (for coolers serviced in quantity):

2.75 gals. (10.41 liters) of pure, fresh water per cooler 1.922 ml of

additive per cooler. Example: for 100 coolers, add 192.2 ml to 275.0

gals. of pure fresh water. Pour 2.375 gals. (9 liters) of disinfectant

into the empty reservoir. Recap the reservoir, tape over the air vent in

the cap, roll disinfectant around the inside the reservoir to thoroughly

coat all of its surfaces. Remove the tape from the reservoir cap.

Prime the cooling system by positioning cooler horizontally and

circulate disinfectant through it for 10 to 15 minutes. Drain disinfectant from the cooling system. Do not reuse this solution. Add new,

fresh coolant to the cooling system. Add 0.375 gals. (1.42 liters) of

fresh disinfectant to the system by pouring it into the reservoir, then

reduce the concentration to the nominal 30 ppm:

Add the balance 2.0 gals. (7.55 liters) of fresh, pure water to the

reservoir to create the treated coolant concentration. Prime the

cooling system.

PUMP INLET STRAINER

Poor cooler performance can usually be traced to a partially or

co mpletely blocked pump in le t s trainer. This is a userserviceable item and can be cleaned and reused, or replaced.

Continued pump operation with a blocked strainer can cause:

• Voiding of cooler service warranty

• Cavitation damage to the pump head’s inlet areas

• Welding accessory damage from overheating due to insufficient coolant flow rate.

A new or properly cleaned pump inlet strainer should restore the

cooler’s performance.

For additional service and periodic maintenance details and for

recommended coolants, follow the recommendations listed

below.

Procedure and Preparation:

WARNING

• Always switch off the COOL ARC®55 machine power

• Always disconnect the COOL ARC®55 machine from

service input power.

• Always allow the coolant in the system to cool enough to

avoid burn injuries.

• Avoid co ntact wi th conta minat ed coola nt . Wear

waterproof gloves and protective eye wear.

• Do not remove the pump relief valve’s 3/4 in. acorn hex

nut or attempt to adjust the relief valve setting.

---------------------------------------------------------

INSPECT CONDITION OF COOLANT

If coolant is contaminated or old:

• Drain the system of coolant and dispose of it in an environmentally responsible manner.

• Flush system of old coolant.

• Fill with fresh tap or distilled water, run for ten minutes, and

drain.

• Proceed to adding coolant..

If coolant is clean and fresh:

Check coolant level. Add more fresh, pure water if required, without

adding more than 0.125 gal. (0.475 liters) of pure water to prevent

diluting the coolant additive.

• If clean, dedicated coolant handling equipment, including a

clean siphon pump and a clean holding tank are available then

proceed to servicing the Pump Inlet Strainer.

D-2

Page 17

MAINTENANCECOOL ARC®55 & COOL ARC®55 ALUMINUM WATER COOLER

Removing Coolant:

a. Drain coolant from the reservoir using clean siphoning

equipment

b. Coolant level should be drained below the strainer’s pressure

fitting:

• This prevents coolant from streaming out of unit when

trainer nut is removed

s

SERVICE THE PUMP’S INLET STRAINER:

a. Place absorbent towels underneath pump head to prevent

stray coolant from wetting cooler’s electrical components.

b. See figure D.1. Hold pump head to apply countertorque when

loosening strainer’s 7/8 acorn nut. Do not confuse with 3/4

acorn nut. Remove nut and slide inlet strainer down and out

from pump head.

c. Inspect strainer for damage or excessive clogging:

• Replace or Gently rinse strainer under running water to

thoroughly clean it.

d. Use a mirror to inspect inside of pump for contamination. If

hardened debris is present and interferes with filter seating,

carefully remove it with dental pick without scratching inside

of the pump. Use care not to drop debris into pump.

e. Reinstall strainer and acorn nut, tightening with 75±15 in.-lbs.

of torque.

• Hold pump head to apply counter-torque when loosening

strainers 7/8 acorn nut.

f. Wipe dry all areas wetted by coolant. Dispose of towels in an

environmentally responsible manner.

Add coolant:

a. Add 2.375 gallons of coolant, either the recommendations off

the water cooled accessory or if none, see the design specification summary listed in this manual.

ADDITIONAL SERVICE NOTES:

1. Always use a back-up wrench on pump head when loosening

or tightening pump fittings.

2. Never run the pump dry. Always use a recommended coolant,

otherwise pump damage may result.

3. Fl ush coolant f rom system and rep lace with fre sh,

recommended coolant at least once a year. More frequent

flushing may be necessary, depending upon the user’s

particular system or its usage, especially if it is prone to

clogging from biological growth in the coolant.

FIGURE D.1

D-3

Page 18

TROUBLESHOOTINGCOOL ARC®55 & COOL ARC®55 ALUMINUM WATER COOLER

HOW TO USE TROUBLESHOOTING GUIDE

WARNING

Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs

performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory

warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed

throughout this manual.

__________________________________________________________________________

This Troubleshooting Guide is provided to help you locate and

repair possible machine malfunctions. Simply follow the threestep procedure listed below.

Step 1. LOCATE PROBLEM (SYMPTOM).

Look under the column labeled “PROBLEM (SYMPTOMS)”. This

column describes possible symptoms that the machine may

exhibit. Find the listing that best describes the symptom that the

machine is exhibiting.

Step 2. POSSIBLE CAUSE.

The second column labeled “POSSIBLE CAUSE” lists the obvious

externa l possibilities tha t may c ontribute to the machine

symptom.

Step 3. RECOMMENDED COURSE OF ACTION

This column provides a course of action for the Possible Cause,

generally it states to contact your local Lincoln Authorized Field

Service Facility.

If you do not unders tand or ar e un able to pe rform the

Recommended Course of Action safely, contact your local

Lincoln Authorized Field Service Facility.

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized

Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

E-1

Page 19

PROBLEMS

(SYMPTOMS)

Observe all Safety Guidelines detailed throughout this manual

POSSIBLE

CAUSE

TROUBLESHOOTINGCOOL ARC®55 & COOL ARC®55 ALUMINUM WATER COOLER

RECOMMENDED

COURSE OF ACTION

Cooler does not operate with power switch

"ON".

(Switch pushed to "I" position.)

Internal water leak.

Torch or gun runs hot.

Fan operates but there is low coolant flow.

1. Input cord unplugged.

2. Power switch faulty

3. Power harness damaged.

. Water lines blocked or crimped.

4

5. Leak in gun or water hoses.

6. Coolant reservoir empty.

7. The system needs to be primed

1. Hose clamp loose on one of internal

hoses.

2. Internal hose punctured.

3. Heat exchanger leaking.

4. Pump seal is leaking

1. Unit placed by area of extreme heat.

2. Low coolant flow.

3. No coolant flow.

4. Fan not operating.

5. Heat exchanger clogged.

1. Leak in torch/gun or hoses.

2.Torch/gun or hoses partially obstructed.

3. Reservoir empty or very low.

4. Pump strainer is dirty.

If all recommended possible areas of

misadjustment have been checked and the

problem persists, Contact your local

Lincoln Authorized Field Service Facility.

Fan operates but there is no coolant flow.

Pump operates, but fan does not.

Cooler trips outlet circuit breaker.

Cooler trips outlet circuit breaker.

1. Pump or pump motor failure.

2. Pump strainer is blocked.

1. Loose or disconnected fan lead.

2. Obstruction in fan blade.

3. Fan motor failure.

1. Circuit overloaded.

2. Fan or pump motor failure.

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized

Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

E-2

Page 20

P1

M22842PRINT

ELECTRICAL SYMBOLS PER E1537

COLOR CODE: B - BLACK OR GRAY

W - WHITE

G - GREEN

G1 - FAN SHROUD GROUND

COOL ARC 55 WATER COOLER

CONNECTION(CUSTOMER

GROUND)

G2 - CASE BACK GROUND CONNECTION

G3 - CHASSIS GROUND CONNECTION

(FAN SHROUD)

P1 - INPUT POWER PLUG

SW1 - LIGHTED POWER SWITCH

MTR1 - PUMP MOTOR

MTR2 - FAN MOTOR

W

W

G

W

B

B

B

B

B

W

SW1

R

3

21

W

1

4

MTR1

MTR2

G1

G3

G2

A

INPUT: 115 V

60 HZ

TO GROUND

PER NATIONAL

ELECTRIC CODE

DIAGRAMSCOOL ARC®55 & COOL ARC®55 ALUMINUM WATER COOLER

F-1

panels. If the diagram is illegible, write to the Service Department for a replacement. Give the equipment code number.

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The specific diagram for a particular code is pasted inside the machine on one of the enclosure

Page 21

DIAGRAMSCOOL ARC®55 & COOL ARC®55 ALUMINUM WATER COOLER

L16090

F-2

Page 22

NOTESCOOL ARC®55 & COOL ARC®55 ALUMINUM WATER COOLER

F-3

Page 23

NOTESCOOL ARC®55 & COOL ARC®55 ALUMINUM WATER COOLER

F-4

Page 24

CUSTOMER ASSISTANCE POLICY

The business of The Lincoln Electric Company is manufacturing and

selling high quality welding equipment, consumables, and cutting

quipment. Our challenge is to meet the needs of our customers and

e

to exceed their expectations. On occasion, purchasers may ask

Lincoln Electric for advice or information about their use of our

products. We respond to our customers based on the best information

in our possession at that time. Lincoln Electric is not in a position to

warrant or guarantee such advice, and assumes no liability, with

respect to such information or advice. We expressly disclaim any

warranty of any kind, including any warranty of fitness for any

customer’s particular purpose, with respect to such information or

advice. As a matter of practical consideration, we also cannot assume

any responsibility for updating or correcting any such information or

advice once it has been given, nor does the provision of information

or advice create, expand or alter any warranty with respect to the sale

of our products.

Lincoln Electric is a responsive manufacturer, but the selection and

use of specific products sold by Lincoln Electric is solely within the

control of, and remains the sole responsibility of the customer. Many

variables beyond the control of Lincoln Electric affect the results

obtained in applying these types of fabrication methods and service

requirements.

Subject to Change – This information is accurate to the best of our

knowledge at the time of printing. Please refer to

www.lincolnelectric.com for any updated information.

TABLE OF CONTENTS

INSTALLATION

OPERATION

ACCESSORIES

MAINTENANCE

TROUBLESHOOTING

DIAGRAMS

Loading...

Loading...