Page 1

GMAW

Push-Pull Gun

OPERATOR'S MANUAL

IM774

MK 091-0525

December 2006

Rev. E

CobraMAX

™

Model numbers K2252-1 & K2252-2

Safety Depends on You

Lincoln arc welding equipment

is designed and built with safety

in mind. However, your overall safety can be increased by

proper installation...and thoughtful

operation on your part. DO NOT

INSTALL, OPERATE OR REPAIR

THIS EQUIPMENT WITHOUT

READING THIS MANUAL AND

THE SAFETY PRECAUTIONS

CONTAINED THROUGHOUT.

And, most importantly, think before

you act and be careful.

OPERATOR’S MANUAL

Sales and Service through Subsidiaries and Distibutors Worldwide

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

Copyright © 2006 Lincoln Global Inc.

World's Leader in Welding and Cutting Products

Page 2

Page 3

Safety Considerations

Table of Contents

Installation

Technical Specications .....................................................................................1

Support Equipment Required .............................................................................1

Coolant Recommendations ................................................................................1

Gun Lead Connections ......................................................................................1

............................................................................... Section A

Operation .................................................................................Section B

General ..............................................................................................................2

Controls and Settings .........................................................................................2

Drive Roll and Idler Rolls....................................................................................3

Accessories .............................................................................Section C

Optional Kits .......................................................................................................4

Conduits .............................................................................................................4

Snake Skins .......................................................................................................4

Contact Tips .......................................................................................................5

Gas Cups ...........................................................................................................5

Maintenance ............................................................................Section D

Periodic Maintenance.........................................................................................6

Maintenance Tools ............................................................................................. 6

Recommended Spare Parts List ........................................................................6

Troubleshooting .......................................................................Section E

Troubleshooting Guide .......................................................................................8

Testing The Gun .................................................................................................8

Appendices ..............................................................................Section F

Diagrams / Parts List ..........................................................................................9

Mechanical .......................................................................................................10

Electrical...........................................................................................................15

Safety Warnings

Warranty

CobraMAX™ Owner's Manual

Page 4

Declaration of Conformity for

European Community (CE) Products

Note This information is provided for units with CE certication (see rating label on unit).

Manufacturer’s Name:

16882 Armstrong Ave.

Irvine, CA 92606

Declares that the product: CobraMAX

conforms to the following Directives and Standards:

Arc Welding Equipment Part I: Welding Power Sources: IEC 60974-1

MK Products, Inc.

™

Directives

Low Voltage Directive: 73/23/EEC

Electromagnetic Compatibility (EMC) Directive: 89/336/EEC

Standards

(September 1998 - Second Edition)

Arc Welding Equipment: Wirefeed Systems: IEC 974-5

(September 1997 - Draft Revision)

Degrees of Protection Provided by Enclosures (IP Code): IEC 529:1989

(November 1989 - First Edition)

Insulation Coordination For Equipment With Low-Voltage Systems:

Part I: Principles, Requirements and Tests: IEC 664-1: 1992

(October 1992 - First Edition)

Electromagnetic Compatibility, (EMC): EN 50199

(August 1995)

Torches And Guns For Arc Welding, EN 50078

CobraMAX™ Owner's Manual

Page 5

CobraMAX™ Owner's Manual - Page i

Page 6

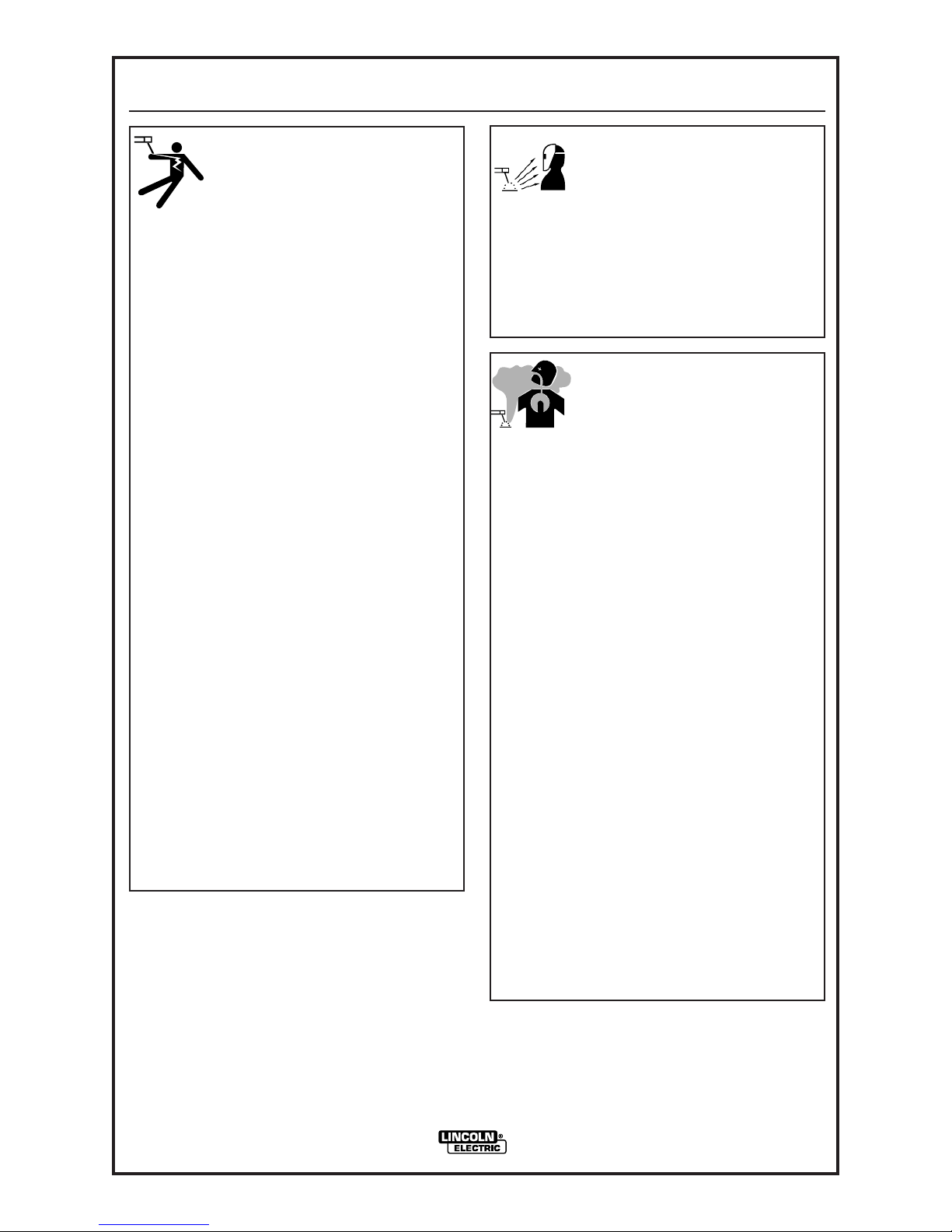

ARC RAYS can burn.

4.a. Use a shield with the proper filter and cover

plates to protect your eyes from sparks and

the rays of the arc when welding or observing

open arc welding. Headshield and filter lens

should conform to ANSI Z87. I standards.

4.b. Use suitable clothing made from durable flame-resistant

material to protect your skin and that of your helpers from

the arc rays.

4.c. Protect other nearby personnel with suitable, non-flammable

screening and/or warn them not to watch the arc nor expose

themselves to the arc rays or to hot spatter or metal.

ELECTRIC SHOCK can

kill.

3.a. The electrode and work (or ground) circuits

are electrically “hot” when the welder is on.

Do not touch these “hot” parts with your bare

skin o r wet clothing. Wear dry, ho le- free

gloves to insulate hands.

3.b. Insulate yourself from work and ground using dry insulation.

Make certain the insulation is large enough to cover your full

area of physical contact with work and ground.

In addition to the normal safety precautions, if welding

mu st b e p er forme d und er e lec tr ica ll y h az ard ou s

con ditions (i n damp loc ations or while wearing we t

clothing; on metal structures such as floors, gratings or

scaffolds; when in cramped positions such as sitting,

kneeling or lying, if there is a high risk of unavoidable or

accidental contact with the workpiece or ground) use

the following equipment:

• Semiautomatic DC Constant Voltage (Wire) Welder.

• DC Manual (Stick) Welder.

• AC Welder with Reduced Voltage Control.

3.c. In semiautomatic or automatic wire welding, the electrode,

electrode re el, welding head, no zzl e or semiautomatic

welding gun are also electrically “hot”.

3.d. Always be sure the work cable makes a good electrical

connection with the metal being welded. The connection

should be as close as possible to the area being welded.

3.e. Ground the work or metal to be welded to a good electrical

(earth) ground.

3.f.

Maintain the electrode holder, work clamp, welding cable and

welding machine in good, safe operating condition. Replace

damaged insulation.

3.g. Never dip the electrode in water for cooling.

3.h. Ne ver simult an eousl y touch electr ically “h ot” p arts of

electrode holders connected to two welders because voltage

between the two can be the total of the open circuit voltage

of both welders.

3.i. When working above floor level, use a safety belt to protect

yourself from a fall should you get a shock.

3.j. Also see Items 6.c. and 8.

FUMES AND GASES

can be dangerous.

5.a. Weldi ng m ay p roduce fum es a nd g ases

hazardous to health. Avoid breathing these

fumes and gases. When weld ing , k eep

your head out of the fum e. U se e noug h

ventilation and/or exhaust at the arc to keep

fumes and gases away from the br eathing zo ne. When

we ldi ng with el ect ro des wh ich req ui re spe cia l

ve nti la ti on s uc h as s tainl es s or h ard f ac in g (se e

in st ru ct io ns o n c on ta in er o r M SD S) o r on l ea d o r

cadmium p lat ed steel an d other metals o r coatings

which produce highly toxic fumes, keep exposure as

low as possible and below Threshold Limit Values (TLV)

us in g local e xh au st o r me ch anica l v entil at io n. I n

confined spaces or in some circumstances, outdoors, a

respirator may be required. Additional precautions are

al so r equ ir ed w hen w eldin g on g alv an ize d st eel .

5. b. The operation of welding fume control equipment is affected

by various factors including proper use and positioning of

the equipment, maintenance of the equipment and the specific welding procedure and application involved. Worker

exposure level should be checked upon installation and

periodically thereafter to be certain it is within applicable

OSHA PEL and ACGIH TLV limits.

5.c.

Do not weld in locations near chlorinated hydrocarbon

vapors

coming from degreasing, cleaning or spraying operations.

The heat and rays of the arc can react with solvent vapors

to

form phosgene, a highly toxic gas, and other irritating products.

5.d. Shielding gases used for arc welding can displace air and

cause i nju ry or deat h. Al ways use enou gh vent ilation,

especially in confined areas, to insure breathing air is safe.

5.e. Read and understand the manufacturerʼs instructions for this

equipment and the consumables to be used, including the

ma ter ia l s afety data she et (MS DS ) a nd fol lo w y our

employerʼs safety practices. MSDS forms are available from

yo ur w eld in g d is tri bu tor o r fro m the m anufa ct ure r.

5.f. Also see item 1.b.

AUG 06

ii

SAFETY

ii

CobraMAX™ Owner's Manual - Page ii

Page 7

FOR ELECTRICALLY

powered equipment.

8.a. Turn off input power using the disconnect

switch at the fuse box before working on

the equipment.

8.b. Insta ll equip ment in acc ordance with the U. S. Natio nal

Electri cal Code, al l local codes and the manufacturerʼs

recommendations.

8.c. Ground the equipment in accordance with the U.S. National

Electrical Code and the manufacturerʼs recommendations.

CYLINDER may explode

if damaged.

7.a. Us e on ly com pr es se d ga s cy li nd er s

containing the correct shielding gas for the

pr ocess u sed a nd pr operl y ope ra ti ng

re gulat or s de si gn ed f or t he gas an d

pressure used. All hoses, fittings, etc. should be suitable for

the application and maintained in good condition.

7.b. A lwa ys ke ep cylin ders i n an up rig ht po sit ion se curel y

chained to an undercarriage or fixed support.

7.c. Cylinders should be located:

• Away from areas where they may be struck or subjected to

physical damage.

• A safe distance from arc welding or cutting operations and

any other source of heat, sparks, or flame.

7.d. Never allow the electrode, electrode ho lder or any other

electrically “hot” parts to touch a cylinder.

7.e. Keep your head and face away from the cylinder valve outlet

when opening the cylinder valve.

7.f. Valve protection caps should always be in place and hand

tight except when the cylinder is in use or connected for

use.

7.g. R ead and f ol low the i ns tructio ns on c ompre ss ed ga s

cylinders, associated equipment, and CGA publication P-l,

“Precautions for Safe Handling of Compressed Gases in

Cylinders,” available from the Compressed Gas Association

1235 Jefferson Davis Highway, Arlington, VA 22202.

Jan, 07

WELDING and CUTTING

SPARKS can

cause fire or explosion.

6.a.

Remove fire hazards from the welding area.

If this is not possible, cover them to prevent

the we ldi ng spark s fr om st art ing a fire.

Re membe r th at we ld in g spa rk s an d h ot

materials from welding can easily go through small cracks

an d o pe nings to a dj acent ar ea s. Avoid we ld ing near

hydraulic lines. Have a fire extinguisher readily available.

6.b. Where compressed gases are to be used at the job site,

special precautions should be used to prevent hazardous

situations. Refer to “Safety in Welding and Cutting” (ANSI

Standard Z49.1) and the operating information for th e

equipment being used.

6.c. When not welding, make certain no part of the electrode

circuit is touching the work or ground. Accidental contact

can cause overheating and create a fire hazard.

6.d. Do not heat, cut or weld tanks, drums or containers until the

proper steps have been taken to insure that such procedures

will not cause flammable or toxic vapors from substances

inside. They can cause an explosion even

though

they have

been “cleaned”. For information, purchase “Recommended

Safe Practices for the

Preparation

for Welding and Cutting of

Co ntain er s a nd P ip in g T hat Hav e H el d H aza rd ou s

Substances”, AWS F4.1 from the American Welding Society

(see address above).

6.e. Vent hollow castings or containers before heating, cutting or

welding. They may explode.

6.f.

Sparks and spatter are thrown from the welding arc. Wear oil

free protective garments such as leather gloves, heavy shirt,

cuffless trousers, high shoes and a cap over your hair. Wear

ear plugs when welding out of position or in confined places.

Always wear safety glas ses with side shields when in a

welding area.

6.g. Connect the work cable to the work as close to the welding

area as practical. Work cables connected to the building

framework or other locations away from the welding area

inc rea se t he p oss ibility of the welding curre nt p ass ing

through lifting chains, crane cables or other alternate circuits. This can create fire hazards or overheat lifting chains

or cables until they fail.

6.h. Also see item 1.c.

6.I. Read and follow NFPA 51B “ Standard for Fire Prevention

During Welding, Cutting and Other Hot Work”, availabl e

from NFPA, 1 Batterymarch Park,PO box 9101, Quincy, Ma

022690-9101.

6.j. Do not use a welding power source for pipe thawing.

iii

SAFETY

iii

CobraMAX™ Owner's Manual - Page iii

Page 8

CobraMAX™ Owner's Manual - Page iv

Page 9

CobraMAX™ Owner's Manual - Page v

Page 10

Thank You

for selecting a QUALITY product by Lincoln Electric. We want you

to take pride in operating this Lincoln Electric Company product

••• as much pride as we have in bringing this product to you!

Read this Operators Manual completely before attempting to use this equipment. Save this manual and keep it

handy for quick reference. Pay particular attention to the safety instructions we have provided for your protection.

The level of seriousness to be applied to each is explained below:

WARNING

This statement appears where the information must be followed exactly to avoid serious personal injury or loss of life.

This statement appears where the information must be followed to avoid minor personal injury or damage to this equipment.

CAUTION

Please Examine Carton and Equipment For Damage Immediately

When this equipment is shipped, title passes to the purchaser upon receipt by the carrier. Consequently, Claims

for material damaged in shipment must be made by the purchaser against the transportation company at the

time the shipment is received.

Please record your equipment identification information below for future reference. This information can be

found on your machine nameplate.

Product _________________________________________________________________________________

Model Number ___________________________________________________________________________

Code Number or Date Code_________________________________________________________________

Serial Number____________________________________________________________________________

Date Purchased___________________________________________________________________________

Where Purchased_________________________________________________________________________

Whenever you request replacement parts or information on this equipment, always supply the information you

have recorded above. The code number is especially important when identifying the correct replacement parts.

On-Line Product Registration

- Register your machine with Lincoln Electric either via fax or over the Internet.

• For faxing: Complete the form on the back of the warranty statement included in the literature packet

accompanying this machine and fax the form per the instructions printed on it.

• For On-Line Registration: Go to our

WEB SITE at www.lincolnelectric.com. Choose “Quick Links” and then

“Product Registration”. Please complete the form and submit your registration.

CUSTOMER ASSISTANCE POLICY

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the needs of our customers and to exceed their expectations. On occasion, purchasers may ask Lincoln

Electric for advice or information about their use of our products. We respond to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or advice. We expressly disclaim any warranty of any kind, including any warranty of fitness for any customerʼs particular purpose,

with respect to such information or advice. As a matter of practical consideration, we also cannot assume any responsibility for updating or

correcting any such information or advice once it has been given, nor does the provision of information or advice create, expand or alter any

warranty with respect to the sale of our products.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control

of, and remains the sole responsibility of the customer. Many variables beyond the control of Lincoln Electric affect the results obtained in

applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com

for any updated information.

CobraMAX™ Owner's Manual

Page 11

Section A Installation

Technical Specications

Wire Capacity

.030" - .045" (0.6mm - 1.2mm) solid and hard wire

.030" - 1/16" (0.8mm - 1.6mm) aluminum and cored wire

Wire Speed

800 IPM (20.3 mpm) Max at rated feeder input voltage (120VAC / 42VAC)

Duty Cycle

All ratings are using Argon gas

200 Amps/25 Volts Air cooled - 60%

250 Amps/25 Volts Water cooled - 60%

Support Equipment Required

• C.V. or C.C. power source of sufcient capacity for your needs.

• Regulated gas supply and hoses.

• Properly sized power leads from power source to wire feeder and

ground.

• Water source and hose capable of providing a minimum of 1 quart

(.95 liter) / min. at 45 psi when using water cooled guns.

Coolant Recommendations

Use a name-brand additive, which does not contain reactive sulphur or

chlorine and does not react with copper, brass or aluminum or create a

custom mix using this formula:

Use 3 Gallons (11.4 Liters) Distilled water.

Use 1 Gallon (3.8 Liters) ethylene glycol.

Use 1 tsp (5 ml) liquid glycerin

The Coolant rate should be 1 quart (.95 liter) / minute at 35 p.s.i.

Gun Lead Connections

Power Cable - Air Cooled

A #2 AWG power cable is used on the CobraMAX™ air cooled gun. The gun

end is threaded into the gun body with torque requirments of 100+5 IN-LB.

The power cable tting connects to the power block in the Cobramatic® wire

feed cabinet.

Power Cable - Water Cooled

The CobraMAX™ water cooled gun utilizes a power/water cable with a #4

AWG cable inside a 5/8” (16MM) diameter hose. The gun end is threaded

into the gun body with torque requirements of 100+5 IN-LB.

IMPORTANT

Water cooled guns MUST be WATER cooled.

Conduit

The CobraMAX™ gun comes standard with a poly-lined conduit, for feeding

aluminum wire. The longer tting with a shallow groove is used on the gun

end. A set screw located on top of the gun handle secures the conduit in

place.

CobraMAX™ Owner's Manual - Page 1

Page 12

Gas Hose

The gas hose is secured over the barbed gas tting with a tie wrap. The

cabinet end of the gas hose uses our standard gas tting (1/8” - 27 nps).

Water Hose

If so equipped, one end of the water hose is secured over the barbed water

tting with a tie wrap and the other end is connected to the center tting on

the power block.

Electric Cable

A seven conductor control cable is used on the CobraMAX™ gun. The gun

end of the control cable is secured to the gun with a boot clamp and soldered

to the pot assembly, tirgger and water leads. Slack is left in the electric cable

as it exits the back of the gun to prevent cable breakage. The cabinet end

has a seven pin “W” clocked amphenol connector.

Section B Operation

General

The CobraMAX™ gun maintains a constant, steady, uniform wire feed speed,

regardless of curved or looped wire conduit. The constant push exerted

by the slave motor in the cabinet, combined with the pull of the gun motor,

causes the wire to literally oat friction-free through the wire conduit. The

24VDC gun motor is controlled by a three and three-quarter (3 3/4) turn

potentiometer in the gun handle.

Controls and Settings

Potentiometer

The laterally-positioned potentiometer is located in the lower end of the

handle, providing up to 800 ipm with 3 3/4 turns.

Micro Switch

The micro switch assembly consists of the micro switch and leads.

Trigger Sensitivity

The amount of trigger level travel can

be shortened for a "quicker" or "more

responsive" action.

A more sensitive trigger lever is

produced by reducing the gap between

the trigger lever and the micro switch

lever. By turning-in the trigger sensitivity

adjustment screw, it closed the gap

between the trigger lever and the micro

switch lever.

This will enable the operator to increase

the sensitivity of the trigger lever.

Sensitivity Adjustment

With the wire feeder turned on (with

or without welding wire loaded), turn

the screw in until the micro-switch is

activated. Once activated, the tortch and

wire feeder motors will begin feeding

wire. Retract the screw accordingly until

the system is deactivated and adjusted to

the operators' liking.

CobraMAX™ Owner's Manual - Page 2

Page 13

Drive Roll and Idler Rolls

General

The CobraMAX™ gun comes standard with a knurled drive roll and a grooved

idler roll, which will handle both steel and aluminum wire with diameters from

.030-1/16 inch. Optional insulated V-groove drive rolls are also available for

aluminum wire if desired (see optional kits).

Drive roll tension is accomplished with a unique spring-loaded pressure

screw. The CobraMAX™ comes from the factory with the pressure

adjustment screw preset. NO ADJUSTMENT IS REQUIRED FOR

ALL SIZES AND TYPES OF WIRES.

Drive Roll Installation/Removal

Note:

Neither of the handles needs to be removed to access the

drive or idler rolls

1. Pull the cam lever away from the idler roll. This will relieve the pressure

against the drive roll (as shown in Figure 1).

2. Align the drive roll removal tool (P/N 931-0100) over the ats of the drive

roll (as shown in Figure 2). Hold the gun with one hand or on a table

top, with the other hand give the removal tool a quick snap-turn in the

CLOCKWISE DIRECTION.

3. Once the drive roll is loose, continue to spin drive roll in the clockwise

direction to remove the drive roll from the gun.

4. Install a new drive roll on the left-hand threaded shaft. The drive roll will

self-tighten when it is feeding wire.

Cam Lever

Figure 1

Figure 2

Idler Roll Installation and Removal

(Reference Figure 3)

1. Using a slot type screwdriver, loosen idler screw, taking care not to lose

lock washer under idler roll.

2. Insert new idler roll and lock washer onto screw, insuring that idler groove

is toward top and lock washer is beneath.

Figure 3

3. Tighten.

NOTE: Lock washer must be under idler roll or it will not turn freely.

CobraMAX™ Owner's Manual - Page 3

Page 14

Section C Accessories LE P/N MK P/N

Optional Kits

Insulated Drive Roll Kits are used to prevent preheating of the wire which

may soften it and clog the liner. This picking up of current at the drive rolls

rather than at the contact tip is usually not a problem unless using too large

of a contact tip or excessively oxidized aluminum wire.

Insulated Groove Drive Roll Kit .......................... KP1594-030 ....... 005-0640

For .030" (0.8mm) dia. aluminum wire. Includes insulated groove drive roll

and insulated idler roll assy.

Insulated Groove Drive Roll Kit .......................... KP1594-035 ....... 005-0716

For .035" (0.9mm) dia. aluminum wire. Includes insulated groove drive roll

and insulated idler roll assy.

Insulated Groove Drive Roll Kit ................................. N/A .............. 005-0642

For .040" (1.0mm) dia. aluminum wire. Includes insulated groove drive roll

and insulated idler roll assy.

Insulated Groove Drive Roll Kit ......................... KP1594-3/64 ...... 005-0718

For 3/64" (1.2mm) dia. aluminum wire. Includes insulated groove drive roll

and insulated idler roll assy.

Insulated Groove Drive Roll Kit ......................... KP1594-1/16 ...... 005-0644

For .062" (1.6mm) dia. aluminum wire. Includes insulated groove drive roll

and idler insulated roll assy.

Replacement Kits

Handle Kit......................................................................................... 005-0700

Includes left and right handles, screws and drive roll door.

Trigger Kit..................................................................................... .... 005-0694

Trigger adjustment kit includes a spring and sensitivity adjustment screw

replacement for all Python®/CobraMAX™ guns.

Micro Switch Kit............................................................................... 005-0701

Replacement micro switch assembly for all Python®/CobraMAX™ guns.

Potentiometer Kit............................................................................. 005-0695

Replacement potentiometer assembly for all Python®/CobraMAX™ guns.

Barrel Insulator Kit .......................................................................... 005-0696

Replacement barrel insulator and taper lock nut.

Conduits

Flat spiral steel conduit for steel & cored wire

615-0208 ................................................................................... 15 ft./4.5m

615-0216 ................................................................................... 25 ft./7.6m

615-0218 ................................................................................. 50 ft./15.2m

Snake Skins

Snake Skin protective covers are now standard on all guns. You may order

spare replacement covers to protect the lead assy of the gun when the

factory one becomes damaged or worn. It can easily be replaced in the eld

by means of Velcro©.

Snake Skin Cover 13ft (for 15ft leads) ........................................931-0110

Snake Skin Cover 23ft (for 25ft leads) ....................................... 931-0122

Snake Skin Cover 48ft (for 50ft leads) ....................................... 931-0123

CobraMAX™ Owner's Manual - Page 4

Page 15

Contact Tips

Heavy Duty Contact Tip - 3/8" Diameter*

Wire Size Tip ID Arc Tip Length MK Part No LE Part No

.030” (0.8mm) .040” (1.0mm) Spray 1.57” (39.9mm) 621-0390-25 KP2217-1B1

Short 1.82” (46.2mm) 621-0396-25 --

.035” (0.9mm) .045” (1.1mm) Spray 1.57” (39.9mm) 621-0391-25 KP2217-2B1

621-0391-250

621-0391-500

.035" (0.9mm) .045" (1.1mm) Short 1.82” (46.2mm) 621-0397-25 --

.045" (1.1mm) .054" (1.37mm) Short 1.82” (46.2mm) 621-0398-25 --

3/64” (1.2mm)

(5356 Alloy)

.054” (1.37mm) Spray 1.57” (39.9mm)

621-0392-25 KP2217-3B1

621-0392-250

621-0392-500

3/64” (1.2mm)

(4043 Alloy)

.060” (1.5mm)

Spray 1.57” (39.9mm) 621-0393-25** KP2217-4B1

621-0393-250

621-0393-500

1/16” (1.6mm) .074” (1.9mm) Spray 1.57” (39.9mm) 621-0394-25 KP2217-5B1

.085” (2.16mm) Spray 621-0395-25

†

*

Use of tip removal tool is recommended

**This size tip furnished with gun

Also sold in quantities of 250

† †

Also sold in quantities of 500

†

††

†

††

†

††

Spring Loaded Tips

The use of the Spring Loaded Tips has shown to improve wire to tip

contact signicantly, especially while welding aluminum in DC Pulse Mode.

Incorporating a wrap-around spring material, a ceramic "puck" pushes up

against the wire forcing the wire to make 100% positive contact with the

internal face of the contact tip.

The constant touching of the wire to the tip eliminates "electrical gaps" in the

welding voltage sensing loop, which many welding power sources utilize for

sensing arc voltage values.

Spring Loaded Contact Tip - 3/8" Diameter*

Wire Size Tip ID Arc Tip Length MK Part No LE Part No

.030” (0.8mm) .040” (1.0mm) Spray 1.57” (39.9mm) 621-0331 KP2662-1

.035” (0.9mm) .045” (1.1mm) Spray 1.57” (39.9mm) 621-0332 KP2662-2

3/64” (1.2mm) .054” (1.37mm) Spray 1.57” (39.9mm) 621-0333 KP2662-3

3/64” (1.2mm) .060” (1.5mm) Spray 1.57” (39.9mm) 621-0334 KP2662-4

1/16” (1.6mm) .074” (1.9mm) Spray 1.57” (39.9mm) 621-0335 KP2262-5

*

Use of tip removal tool is recommended

Gas Cups

*standard - furnished with gun

Gas Cups

Cup Size Cup I.D. MK P/N LE P/N

No. 6 3/8" (9.5mm) 621-0420 KP2249-1

No. 8* 1/2" (15.8mm) 621-0421 KP2250-1

No. 10 5/8" (15.8mm) 621-0422 KP2251-1

CobraMAX™ Owner's Manual - Page 5

Page 16

Gun Barrel Liners

MK P/N LE P/N Description

615-0341

--

621-0423 KP2247-1 CobraMAX™ Tip Extender

615-0248

615-0177

--

--

931-0137 KP2226-1 Teon Liner Package, 5 pieces

Section D Maintenance

Periodic Maintenance

Your Cobramatic® System is designed to provide years of reliable service.

Maintenance of the gun will normally consist of a general cleaning of the wire

guide system, including barrel, drive rolls, and conduit at regular intervals

Remove spatter build-up from inside of nozzles with a hardwood stick.

The only parts on the Cobramatic® system that are subject to normal wear

are the conduit, contact tips, gas cups, front body liners, wire guides, drive

and idler rolls. A supply of these parts should be maintained on hand.

The number of units in operation and the importance of minimal “down time”

will determine to what extent spare parts should be stocked on hand. See

the “Recommended Spare Parts List” for the most commonly replaced parts.

If repairs do become necessary, qualied shop maintenance personnel can

easily replace any part.

Spiral Steel, .030 - .045" (0.8mm - 1.1mm)

Spiral Steel Liner for Tip Extender

Bulk Teon liner material for .030 - .035"

Maintenance Tools

Tool Part Number

Drive Roll Removal Tool 931-0100

Recommended Spare Parts List

Qty. Part No. Description

1

1

1

1 437-0253 Drive roll door

2 005-0694 Trigger assy kit

2 005-0695 Potentiometer assy kit

1 005-0700 Handle kit

2 005-0701 Micro switch assy kit

10

5

LE KP2072-30

MK 615-0601-15

LE KP2072-28

MK 615-0601-25

LE KP2072-29

MK 615-0601-50

LE KP2219-1

MK 511-0101

LE KP2220-1

MK 005-0686

Drive Roll Removal Tool

931-0100

Conduit - 15 ft

Conduit - 25 ft

Conduit - 50 ft

Drive roll

Idler roll kit

Knurled Drive Roll

LE P/N KP2219-1

MK P/N 511-0101

Idler Roll Kit

LE P/N KP2220-1

MK P/N 005-0686

CobraMAX™ Owner's Manual - Page 6

MICRO SWITCH ASSY

005-0701

Page 17

Section E Troubleshooting

Trouble Cause Remedy

115 VAC Control fuse in feeder/

No wire feed at gun,

feeder not operating, i.e., no

slave motor or brake solenoid.

No wire feed at gun, feeder

operating properly

Wire feeds, but welding wire is

not energized.

Wire feeds erratically.

Wire feeds one speed only.

Wire walks out of the drive

rolls.

Control box blown.

Micro-switch defective/not

being activated.

Broken electrical cable.

24 VAC Control fuse in feeder/

Control box blown.

Bad Potentiometer.

Broken Electrical Cable

Bad Speed control/PCB.

Loose or no cable connections. Check all power connections.

Contactor control cable loose or

in wrong position

Welding power source. Check power source.

Dirty or worn conduit. Blow out or replace conduit.

Wrong size contact tip. See contact tip table.

Idler roll stuck.

Bad potentiometer. Check with meter.

Broken electrical cable.

Bad speed control.

Idler roll upside-down.

Rear wire guide missing. Replace wire guide.

Replace fuse.

Replace switch. Check switch

for operation.

Check micro-switch wires for

continuity.

Check motor leads for shorts;

then replace fuse.

Check potentiometer with

meter.

Check motor and potentiometer

for continuity.

See specic cabinet/control

box owners manual for speed

control operation.

Check power supply owners

manual for location and type of

contactor signal required.

Check for lock washer under

idler roll, or replace if damaged.

Check potentiometer wires for

continuity or short.

See specic cabinet/control

owners manual for speed

control operation.

Place groove in idler roll toward

top.

CobraMAX™ Owner's Manual - Page 7

Page 18

Troubleshooting Guide

Regardless of which gun or feeder used, all MK Products’ push-pull guns

operate on the same principle. The slave motor in the feeder runs at a fast,

constant speed, but has very low torque. It is always trying to feed more wire

than the gun motor wants, and when the motor gets all it wants, it slows the

slave motor, preventing a bird’s nest. Because of the low torque produced by

the slave motor, a brake system is used to prevent wire overrun rather than

tension. The drag adjustment in the feeder is used simply to keep the wire

slightly taut, so it will not pull off the spool while feeding wire.

The high torque 24VDC gun motor is controlled by a solid state speed

control located in the feeder, and a pot located in the gun. The gun motor,

potentiometer, and micro switch are connected to the cabinet/control box via

a control cable and amphenol connector. If this cable becomes damaged, a

variety of symptoms can occur, depending on which wire(s) break. To test,

check each wire for continuity and shorts.

Remember, the micro switch in the gun activates both the slave motor and

gun motor circuits in the cabinet. Therefore, if the slave motor and brake

solenoid operate, but the gun does not, look more toward the gun motor’s

24V circuits, speed control, control cable, or the gun motor. If nothing

operates, look more toward the slave motor’s input, micro switch leads, or

micro switch.

Testing The Gun

Reference the "W" clocked gun wiring diagram on

the CobraMAX™ electrical diagram (in appendix) for information

about pin-outs and locations.

Motor Check

Remove the gun connector from the cabinet.

Using the gun amphenol connector, check the resistance across pins “A”

and “B” (motor leads). The resistance across the motor should be between

5 - 10 ohms as the potentiometer is turned.

If an open circuit or short exist, check the motor leads and motor

independently.

Testing the Potentiometer - “W” Clocked

Using the gun amphenol connector, check the resistance across pin “D”

(wiper) and pin “C”. The resistance should vary from 0 - 5K ohms as the

potentiometer is turned.

Check the resistance across pin “D” (wiper) and pin “G”. The resistance

should vary from 5K - 0 ohms as the potentiometer is turned.

Testing the Micro Switch

Using the gun amphenol connector, check for continuity across pins “E” and

“F” when the trigger is pressed.

CobraMAX™ Owner's Manual - Page 8

Page 19

Section F Appendices

Diagrams / Parts List

001-1420 CobraMAX™ Exploded View . . . . . . . . . . . . . . . . . . 12

003-2141 Front Body Assembly

Ultra-Flex Air Cooled Lead Assembly

. . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . 15

Water Cooled Lead Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 16

Wiring Diagram

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

CobraMAX™ Owner's Manual - Page 9

Page 20

CobraMAX™ Exploded View

100+5 IN-LB

TORQUE REQUIRES

APPLY ITEM 49 TO CONTACT SURFACES

APPLY ITEM 48 BEFORE INSTALLING

APPLY ITEM 45 TO CONTACT SURFACES

APPLY ITEM 46 TO THREADS

APPLY ITEM 47 TO THREADS

ITEMS 25 AND 44 NOT SHOWN FOR CLARITY

APPLY ITEM 45 TO THREADS

CobraMAX™ Owner's Manual - Page 10

Page 21

CobraMAX™ Parts List

Handle Kit: includes line items 18, 31,34,

and 37

1 005-0700

Tip HD Spray .060

1 1 Ref. 227 Series Ultra Flex Air Cooled Assembly 26 - -- --

1 1 Ref. 228 Series Ultra Flex Liquid Cooled Assembly 27 - -- --

2 1 002-0629 Assy Cam Idler Arm 28 1 421-0018 Dowel Pin 3/32 x 7/8 SST

3 1 002-0631 Brazed Rear Body 29 1 431-1549 Nut Drag Pot

No. Qty. Part No. Description No. Qty. Part No. Description

4 1 002-0635 Assy Brazed Barrel CobraMAX 30 1 003-2209 Wire Guide (includes item 16)

5 1 005-0695 Pot Assy Kit* 31 1 431-1622 Shoulder Screw 1/8 x 4-40

6 1 003-2125 Pot Knob Assy 32 1 431-1637 Hex Screw 3/8-20 x 3/8

7 1 005-0701 Micro Swx Assy Kit 33 1 431-3263 Locator Pot

8 1 003-2141 Assy CobraMAX Front Body 34 1 431-4054 Front Nut Cobra Gun

9 1 211-0077 Pitman Motor 35 1 435-1585 Strap Motor Python

11 12 303-0096 O-Ring .145 ID x .07 W 37 1 437-0253 Door Molded Python

10 1 003-2153 Gun Boot 36 1 003-0857 Trigger Assy

12 1 303-0540 O-Ring .426 ID x.07 W 38

CobraMAX™ Owner's Manual - Page 11

13 2 319-0254 Screw FH Phil 82 4-40 x 3/8 SST 39

16 1 321-0424 Set Screw 4-40 x .12 SST 42 1 621-0421 Assy Gas Cup #8 CobraMAX

14 1 319-0258 Screw FH Phil 82 4-40 x 5/8 SST 40 1 931-0137 5 Piece Telfon Liner Package

15 2 320-0084 Screw Button 4-40 x 3/16 ST 41 1 621-0393

17 1 321-1104 Set Screw Mod 43 0.30ft 737-0048 Tube Insulation 9AWG Clear

18 9 328-0012 Scr Shc 6-32 x 3/8 44 1 186-0102 Terminal block 2.5 nn, 4 pos

19 5 328-0025 Scr Shc 8-32 x 1/2 St. 45 A/R 823-0029 Naolox Compound

20 1 331-0311 Washer Flat 0.39 ID x 0.63 OD 46 A/R 823-0043 Thread Locking Cmpd Med Str

21 4 333-0005 Wshr Spr Lk #6 47 A/R 823-0050 Thread Locking Cmpd Low Str

22 4 333-0006 Wshr Spr Lk #8 48 A/R 835-0006 Silicon Lubricant

23 1 336-0020 Scr Ph Phil 4-40 x 5/16 SST 49 A/R 835-0011 Compound Grease

24 2 338-0153 Scr Shc 1-72 x 3/8 50 1 437-0268 MAX Pot Cover

25 5 411-0045 Tie Wrap

* Includes line items 12, 20, 29, and 33 assembled.

Page 22

003-2141 Front Body Assembly

NOTE: Items #3, 4, and 9

can be ordered together in

Kit LE P/N KP2220-1, MK

P/N 005-0686.

Front Body Assembly

No. Qty. Part No. Description

1 - - Not Available Separately

2 - - Not Available Separately

3 1 325-0206 SCR Ph 10-24-3/8

4 1 333-0082 Washer Lock 10

5 1 419-0092 Spring Comp 0.31 OD x 0.20 ID

6 1 421-0525 Pin Dowel 1/8 x 7/8 Sst

7 1 431-1663 Scr Adjust Idler

8 1 431-1598 Arm Idler

9 1

10 1

CobraMAX™ Owner's Manual - Page 12

LE KP2220-1

MK 005-0686

LE KP2219-1

MK 511-0101

003-2141

Assy Idler Wire Feed

Drive Roll

Page 23

Ultra-Flex Air Cooled Lead Assembly*

TORQUE REQUIRES

100+5 IN-LB

This power cable has a boot

that is common to many

assemblies but must be

removed from this end

when used on the

CobraMAX™.

*Leads shown for reference only

227 Series Ultra-Flex Cable Assemblies

Length Conduit Power Cable Electrical Cable Gas Hose Snake Skin

15"/4/5m 615-0601-15 001-2527 005-0690 001-0537 931-0110

25"/7.6m 615-0601-25 001-2528 005-0691 001-0538 931-0122

50'/15.2 615-0601-50 001-1042 005-0692 001-0665 931-0123

®

CobraMAX™ Owner's Manual - Page 13

Page 24

Water Cooled Lead Assembly*

This power cable has a boot

that is common to many

assemblies but must be

removed from this end

when used on the

CobraMAX™.

TORQUE REQUIRES

100+5 IN-LB

*Leads shown for reference only

228 Series Ultra-Flex Cable Assemblies

Length Conduit #4 Power/Water

15'/4.5m 615-0601-15 001-2521 005-0690 001-0537 001-0529 931-0110

25'/7.6m 615-0601-25 001-2524 005-0691 001-0538 001-0530 931-0122

50'/15.2m 615-0601-50 843-0338 005-0692 001-0665 001-0667 931-0123

Electrical

Cable

CobraMAX™ Owner's Manual - Page 14

Cable

Gas Hose Water Hose Snake Skin

®

Page 25

A

F

G

E

D

C

B

"W" Clocked

Amphenol Connector

Viewed from front of connector

E

C

A

B

D

G

F

+

-

TORCH

MOTOR

TORCH

POT

TORCH

TRIGGER

5K

Red

Red

Black

Black

Blue

Blue

Yellow

Yellow

Brown

Brown

White

White

Green

Green

1

3

2

Cabinet End

Amphenol Connector

Torch Functions

Torch Lead

CobraMAX™ Electrical

CobraMAX™ Owner's Manual - Page 15

Page 26

CobraMAX™ Owner's Manual - Page 16

Page 27

CobraMAX™ Owner's Manual - Page 17

Page 28

LIMITED WARRANTY

Effective October 1, 2006

This warranty supersedes all previous MK Products warranties and is

exclusive, with no other guarantees or warranties expressed or implied.

LIMITED WARRANTY - MK Products Inc., Irvine, California

warrants that all new and unused equipment furnished by MK

Products is free from defects in workmanship and material as of

the time and place of delivery by MK Products. No warranty is

made by MK Products with respect to trade accessories or other

items manufactured by others. Such trade accessories and other

items are sold subject to the warranties of their respective manufacturers, if any.

MK Products’ warranty does not apply to components having

normal useful life of less than one (1) year, such as relay points,

wire conduit, tungsten, and welding gun parts that come in contact

with the welding wire, including gas cups, gas cup insulators, and

contact tips where failure does not result from defect in workmanship or material.

MK Products shall, exclusively remedy the limited warranty or

any duties with respect to the quality of goods, based upon the

following options:

(1) repair

(2) replacement

(3) where authorized in writing by MK Products, the reasonable

cost of repair or replacement at our Irvine, California plant.

As a matter of general policy only, MK Products may honor an

original user’s warranty claims on warranted equipment in the event

of failure resulting from a defect within the following periods from

the date of delivery of equipment to the original user:

1. Power Supplies and Wire Feed Cabinets ....... 3 years

2. Weldheads, Positioners, Prince XL and Prince XL

Spool Guns, Python, CobraMAX, Cobra SX, Cobra MX

......................................................................... 1 year

3. Sidewinder® Spool Gun, Prince SG Spool Guns,

Modules .......................................................180 days

4. Repairs/Exchanges/Parts ............................90 days

Classication of any item into the foregoing categories shall be at

the sole discretion of MK Products. Notication of any failure must

be made in writing within 30 days of such failure.

A copy of the invoice showing the date of sale must accompany

products returned for warranty repair or replacement.

All equipment returned to MK Products for service must be properly

packaged to guard against damage from shipping. MK Products

will not be responsible for any damages resulting from shipping.

Normal surface transportation charges (one way) for products

returned for warranty repair or replacement will be borne by MK

Products, except for products sold to foreign markets.

ANY EXPRESS WARRANTY NOT PROVIDED HEREIN AND ANY

IMPLIED WARRANTY, GUARANTY, OR REPRESENTATION AS TO

PERFORMANCE, AND ANY REMEDY FOR BREACH OF CONTRACT

WHICH, BUT FOR THIS PROVISION, MIGHT ARISE BY IMPLICATION, OPERATION OF LAW, CUSTOM OF TRADE, OR COURSE OF

DEALING, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR OF FITNESS FOR PARTICULAR PURPOSE, WITH

RESPECT TO ANY AND ALL EQUIPMENT FURNISHED BY MK PRODUCTS, IS EXCLUDED AND DISCLAIMED BY MK PRODUCTS.

EXCEPT AS EXPRESSLY PROVIDED BY MK PRODUCTS IN WRITING, MK’s PRODUCTS ARE INTENDED FOR ULTIMATE PURCHASE

BY COMMERCIAL/INDUSTRIAL USERS AND FOR OPERATION BY

PERSONS TRAINED AND EXPERIENCED IN THE USE AND MAINTENANCE OF WELDING EQUIPMENT AND NOT FOR CONSUMERS

OR CONSUMER USE. MK PRODUCTS’ WARRANTIES DO NOT

EXTEND TO, AND NO RE-SELLER IS AUTHORIZED TO EXTEND

MK PRODUCTS’ WARRANTIES TO ANY CONSUMER.

USE O F O T HER T HAN

CONSUMABLES,

YOUR PRODUCT WARRANTY.

PARTS, AND ACCESSORIES MAY INVALIDATE

GENUINE

M K P R O D U C TS’

MK Products, Inc.

16882 Armstrong Ave.

Irvine, CA 92606

Tel (949)863-1234

Fax (949)474-1428

Sales and Service through Subsidiaries and Distibutors Worldwide

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

October 1, 2006

Copyright © 2006 Lincoln Global Inc.

World's Leader in Welding and Cutting Products

Loading...

Loading...