Page 1

Premium Pipe Welding Consumables

Page 2

About The Lincoln

Electric Company

Lincoln Electric is the world’s premier

manufacturer of welding equipment and

consumables. No company on earth is

more focused on the ever-changing

needs of the welding

professional. Our business is all about

helping companies make their welding

operations more effective, more

efficient, more profitable.

Lincoln is truly your “One Source” when

it comes to welding. We’re a company

that continually rededicates itself to the

equally important goals of exceptional

quality, and exceptional service. Our

field support team –– with hundreds of

field sales engineers and thousands of

knowledgeable and responsive Lincoln

distributors in countries all over the

world –– is the

largest in the industry.

Innovative thinking. A quality and

service-first attitude. Fresh

approaches to design, manufacturing,

and packaging. Worldwide strength.

That’s Lincoln Electric.

Pipeliner®– The Clear Choice For

Pipe Welding

Pipeliner is the world’s premier group of pipe welding

consumables.

Pipeliner is Lincoln Electric’s family of premium Stick (SMAW),

MIG (GMAW), Flux-Cored (FCAW) and Submerged Arc (SAW)

consumables developed specifically to meet the rigorous

demands of the global pipe welding industry. They are the most

thoroughly tested pipe welding consumables on the market

today.

Consistent performance

Performance consistency tops the list of what contractors want

from pipe consumables – and Pipeliner delivers. Lincoln Electric’s

Pipeliner manufacturing operations throughout the world are

tightly controlled, and routinely pass quality-assurance audits

by agencies and pipe welding professionals. This extraordinary

emphasis on the integrity of Pipeliner’s manufacturing processes

results in consumables with unmatched performance characteristics and consistency.

All Pipeliner products are lot-controlled and lot-tested, with actual

certified test results.

Packaging to meet the pipe industry’s needs

The world’s best pipe electrodes deserve to be protected

accordingly. So, Pipeliner electrodes are packaged in

hermetically-sealed, moisture-resistant containers that ensure

consistent performance — even when stored in the harshest

environments.

Global support

Pipe contractors need to mobilize and deploy resources quickly

and efficiently — no matter to what corner of the world the next

job calls them. That’s why Lincoln Electric’s global network of

manufacturing and distribution facilities is such an important part

of the Pipeliner story. Wherever your project, Lincoln is there with

the products and support you need.

2

Page 3

Complete pipe solutions from the name you trust.

By partnering with a single, comprehensive welding resource,

pipe contractors find that they can improve efficiencies and

maintain strong accountability.

For many of the world’s most successful pipe contractors,

Lincoln Electric has become that single-source welding partner.

Why? Because Lincoln offers an exceptional array of welldesigned and well-built pipe welding products, as well as the

deepest pool of welding expertise and experience on earth.

Behind those products and that expertise is Lincoln’s unique

total process engineering approach to welding. It means that

every Pipeliner consumable has been designed to work in

harmony with all other Lincoln Electric pipe welding products —

every Lincoln Electric wire feeder, power source, gun and cable

assembly and accessory has been engineered with an eye on

efficient, synergistic, system-wide performance.

That translates to less downtime, improved production rates,

and higher profit potential on every pipe project.

Contents Page

Product Introduction . . . . . 2-3

Electrode Selection

Guide . . . . . . . . . . . . . . . . . 4-7

Stick (SMAW)

Electrodes . . . . . . . . . . . . 8-13

MIG (GMAW)

Electrodes . . . . . . . . . . . . . . 14

Flux-Cored (FCAW)

Electrodes . . . . . . . . . . . .15 -18

Submerged Arc (SAW)

Electrode/Flux . . . . . . . . . . .19

3

Page 4

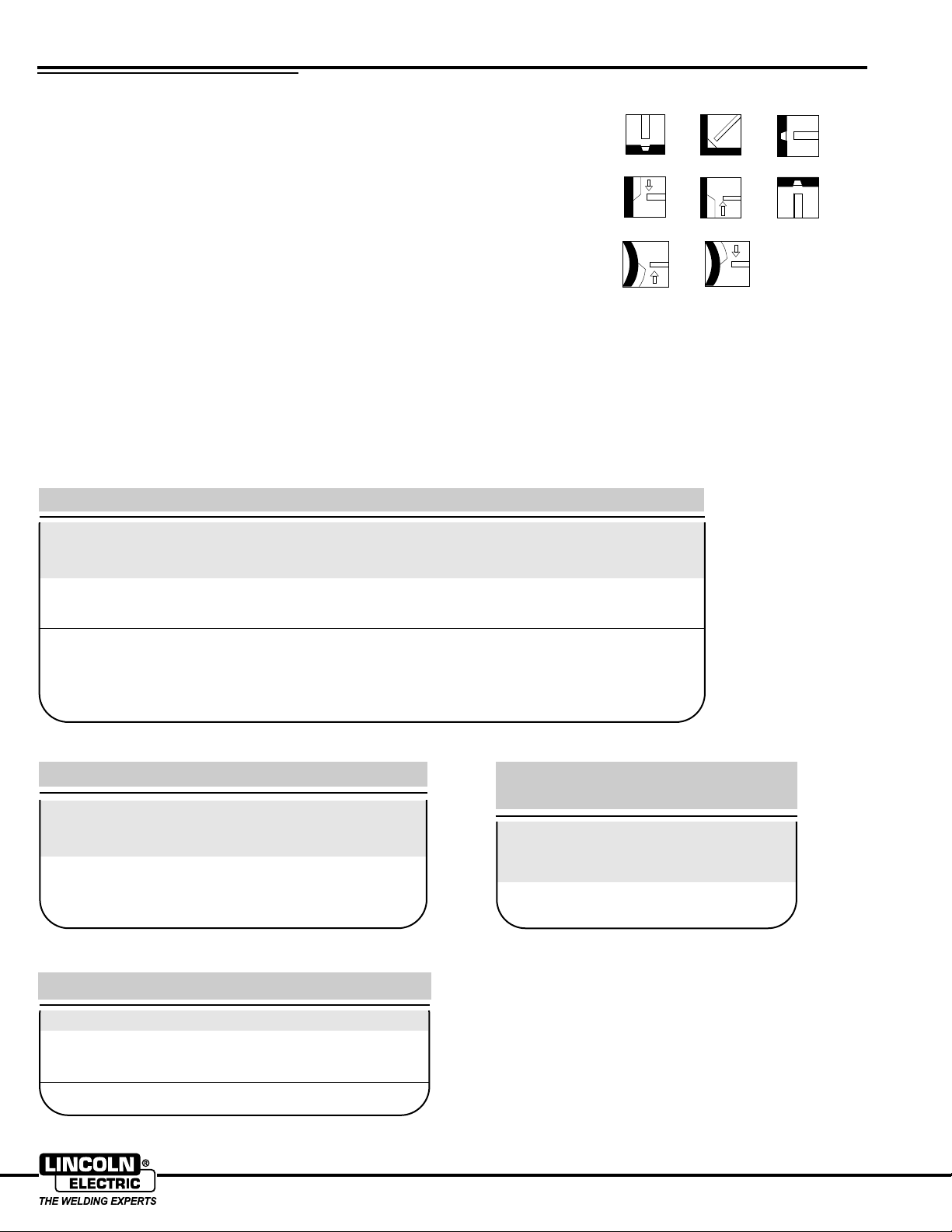

Pipe Grades

60˚

3/64-1/16 in.

(1.0-1.6 mm)

1/16-5/64 in.

(1.6-2.0 mm)

1/16 in.

(1.6 mm)

1/3 T

2/3 T

1/16-5/64 in.

(1.6-2.0 mm)

10˚

30˚

T

The primary pipe grades are classified in accordance with

the API 5L:2000 specification. This specification establishes

requirements for two product specification levels – PSL 1

and PSL 2. PSL 1 includes mandatory requirements for

PSL1

Yield Strength Tensile Strength

Minimum Minimum

Grade psi MPa psi MPa

A25 25,000 (172) 45,000 (310)

A 30,000 (207) 48,000 (331)

B 35,000 (241) 60,000 (414)

X42 42,000 (290) 60,000 (414)

X46 46,000 (317) 63,000 (434)

X52 52,000 (359) 66,000 (455)

X56 56,000 (386) 71,000 (490)

X60 60,000 (414) 75,000 (517)

X65 65,000 (448) 77,000 (531)

X70 70,000 (483) 82,000 (565)

PSL2

chemistry, ductility, minimum yield strength and minimum

tensile strength. PSL 2 adds mandatory requirements for

maximum yield strength, maximum tensile strength and

Charpy impacts.

Ultimate

Yield Strength Yield Strength Tensile Strength Tensile Strength

Minimum Maximum Minimum Maximum

Grade psi MPa psi MPa psi MPa psi MPa

B 35,000 (241) 65,000 (448) 60,000 (414) 110,000 (758)

X42 42,000 (290) 72,000 (496) 60,000 (414) 110,000 (758)

X46 46,000 (317) 76,000 (524) 63,000 (434) 110,000 (758)

X52 52,000 (359) 77,000 (531) 66,000 (455) 110,000 (758)

X56 56,000 (386) 79,000 (544) 71,000 (490) 110,000 (758)

X60 60,000 (414) 82,000 (565) 75,000 (517) 110,000 (758)

X65 65,000 (448) 87,000 (600) 77,000 (531) 110,000 (758)

X70 70,000 (483) 90,000 (621) 82,000 (565) 110,000 (758)

X80 80,000 (552) 100,000 (690) 90,000 (621) 120,000 (827)

Joint Design

A customary joint preparation is commonly called an "API"

fitup. While this is not actually an API 1104 requirement,

the figures shown in the specification are drawn to have a

60 degree included angle with a 1/16" (1.6 mm) land and

1/16" (1.6 mm) gap.

Recommended joint preparation

Ultimate Ultimate

As an alternative, for thicker wall pipe (>3/4", >20 mm), a

compound bevel can be used. The amount of material

required to fill a compound bevel joint is less than a 60

degree included angle preparation, so productivity may be

increased.

Wall thickness <3/4 in. (<20mm) Wall thickness >3/4 in. (>20mm)

4

www.lincolnelectric.com

Pipeliner

Page 5

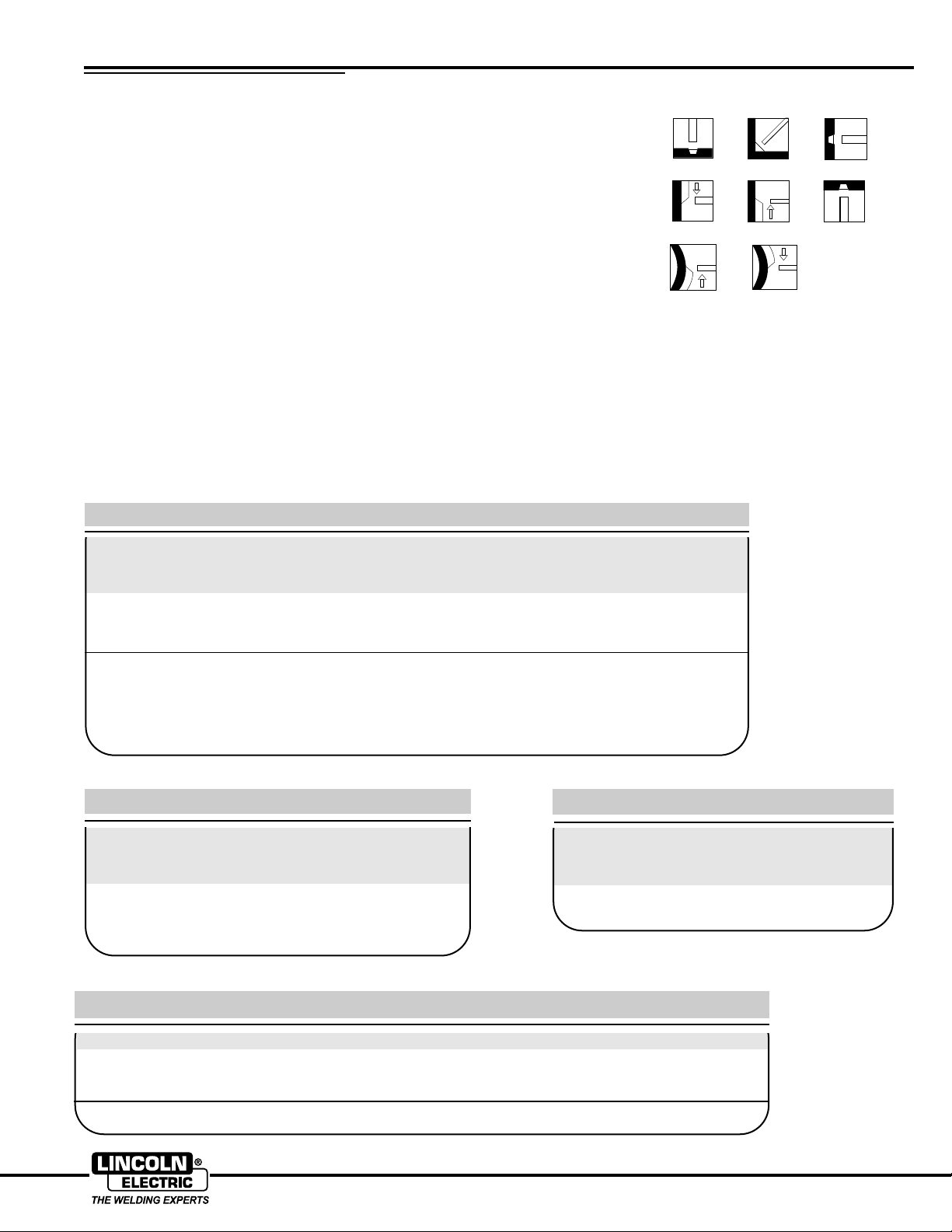

Product Selection

The table below can be used as a product selection

uide for each pipe grade. This table is for guidance

g

only and should be referenced against the appropriate

onstruction standard for each contract.

c

API 5L Pipe Grades

Products AWS Class A B X42 X46 X52 X56 X60 X65 X70 X80 X90 X100

Cellulosic All Position Stick (SMAW) Electrodes

Pipeliner 6P+ E6010

Pipeliner 8P+ E8010-P1

Low Hydrogen Stick (SMAW) Electrodes

Pipeliner 16P E7016 H4

Pipeliner 18P E8018-G H4

MIG (GMAW) Electrodes

Pipeliner 70S-G ER70S-G

Innershield®Self-Shielded Flux-Cored (FCAW-S) Electrodes

Pipeliner NR-207+ E71T8-K6

Pipeliner NR-207XP E71T8-K6

Outershield®Gas-Shielded Flux-Cored (FCAW-G) Electrodes

Pipeliner G70M E71T-1MJH8

E71T-9MJH8

Pipeliner Autoweld G70M E71T-1MJH8

E71T-9MJH8

Product Selection

Root Pass Welding Only

Pipeliner

5

www.lincolnelectric.com

Page 6

CONSUMABLE SELECTION GUIDE

Electrode AWS Recommended General Page

Name Class Polarity Description No.

Cellulosic All Position Stick (SMAW) Electrodes

Pipeliner 6P+ E6010 DC+ Pipeliner 6P+ is an all-position cellulosic pipe electrode 8

designed especially for vertical down root pass welding.

his electrode is based on a long-time favorite among

T

cross-country pipeline welders.

Pipeliner 8P+ E8010-P1 DC+ Here’s an electrode that makes short work of even the most 9

challenging high silicon pipe applications! Pipeliner 8P+ is an

outstanding choice for API 5L-X56 through X70 grade pipe. This

electrode features high stacking efficiency – formulated to carry and

deposit weld metal in difficult vertical down out-of-position

applications.

Low Hydrogen Stick (SMAW) Electrodes

Pipeliner 16P E7016 H4 DC+ We designed this quality electrode for optimum performance 10

AC for vertical up welding of pipe up to API 5L-X65 – especially

where a low hydrogen deposit is desired. Obtain Charpy

V-Notch impact values down to temperatures of -20°F (-29°C).

Pipeliner 18P E8018-G H4 DC+ A real workhorse for vertical up welding jobs up to X80 pipe! 11

AC Lincoln 18P offers low temperature impact properties down to

-50°F (-46°C).

Pipeliner

6

www.lincolnelectric.com

Page 7

CONSUMABLE SELECTION GUIDE

Electrode AWS Recommended General Page

Name Class Polarity/ Description No.

MIG (GMAW) Electrodes

Pipeliner 70S-G ER70S-G Pipeliner 70S-G MIG (GMAW) wire electrode is especially 14

Innershield®Self-Shielded Flux-Cored (FCAW-S) Electrodes

Pipeliner NR-207+ E71T8-K6 DC- Optimum performance on vertical down hot, fill and cap 15

Pipeliner NR-207XP E71T8-K6 DC- For consistently high impact values, choose 207XP. Optimum 16

Shielding Gas

intended and packaged for the needs of semiautomatic and

automatic root pass pipe welding. Delivering low hydrogen

deposits, 70S-G exhibits an extremely fluid puddle for outstanding

wash-in at the weld toes and uniform bead shape. Well-suited for

use on API 5L-X56 through X70 pipe.

passes on standard cross-country pipelines and arctic

grade pipe. Excellent crack resistance, CTOD, and Charpy

V-Notch properties. Recommended for API Pipe Grades

X42 through X70.

performance on vertical down, hot, fill and cap passes on standard

cross-country pipelines and arctic grade pipe. Recommended for

API Pipe Grades X42 through X70.

Outershield®Gas-Shielded Flux-Cored (FCAW-G) Electrodes

Pipeliner G70M E71T-1MJH8 DC+ Pipeliner G70M is designed to deliver outstanding weld 17

& E71T-9MJH8 75-80% Ar properties for semi-automatic applications. Robust impacts

/balance CO

Pipeliner Autoweld E71-T-1MJH8 DC+ Pipeliner Autoweld G70M is specifically designed for use 18

G70M & E71T-9MJH8 75-80% Ar with the Autoweld pipe welding system to deliver outstanding

/balance CO

mean consistently high CVN values.

2

weld properties.

2

Pipeliner

7

www.lincolnelectric.com

Page 8

PIPELINER 6P+ AWS: E6010 Cellulosic All-Position Stick (SMAW) Electrode

3G

➔

3

G

➔

5

G

➔

5G

➔

1G

2F

2G

4

G

Pipeliner 6P+ is an all-position

cellulosic pipe electrode designed

especially for vertical down root

• Manufactured under a quality

system certified to ISO 9001

requirements.

pass welding. This electrode is based

n a long-time favorite among cross-

o

country pipeline welders.

• Manufactured to actual lot control.

Actual certificates of conformance

are available upon request.

ADVANTAGE LINCOLN

• All-position; particularly good for

vertical and overhead.

TYPICAL APPLICATIONS

• Designed especially for all-position

vertical down root pass welding.

• Light slag with little slag interference

for easy arc control. Easy slag

removal, smooth bead.

• Deep penetration with maximum

dilution.

• Capable of x-ray quality welds,

even out-of-position.

MECHANICAL PROPERTIES

Yield Strength Tensile Strength Elongation ft•lbf (Joules)

Required 48,000 (330) 60,000 (410) 22 20 (27)

AWS E6010 (as-welded) min. min. min. min.

Typical Results

As-welded 57,000 - 76,000 72,900 - 86,200

1)

Stress-relieved

1 hr @ 1150°F (612°C) (352 - 579) (462 - 538) (61 - 72)

(1)

Data provided for information only – not part of AWS classification.

(

51,000 - 64,000 67,000 - 78,000

- As Required per AWS A5.1-91

psi (MPa) psi (MPa) (%) @ -20ºF (-29ºC)

(393 - 524) (503 - 594) (51 - 85)

24 - 33

30 - 34

WELDING POSITIONS

CONFORMANCE

AWS A5.1: E6010

ASME SFA-5.1: E6010

CSA W48.01: E41010

EN499: E 42 3 C 25

Charpy V-Notch

38 - 63

45 - 53

NOTE: Pipeliner electrodes

are manufactured under

lot control. A Certificate

of Test showing actual

deposit chemistry and

mechanical properties

per AWS A5.1 (DC+ only)

is available on request

from the factory for every

lot of electrode.

(Fax 216-383-8386).

DIAMETERS / PACKAGING

Diameter 10 Lb. (4.5 kg)

in. (mm) Easy Open Cans

[ 60 lb. (27.2 kg) Master ]

1/8 (3.2) ED030845 ED030848

5/32 (4.0) ED030846 ED030849

3/16 (4.8) ED030847 ED030850

Manufactured in metric diameters, U.S. Customary sizes are approximate.

DEPOSIT COMPOSITION

%C %Mn %Si %S %P

Requirements

AWS E6010 Not Specified

Typical Results .10-.20 .40-.65 .11-.30 .009-.020 .005-.025

- As Required per AWS A5.1-91

50 Lb. (22.7 kg)

Easy Open Cans

TYPICAL OPERATING

PROCEDURES

Current (Amps)

Polarity

DC+ 65 - 130 90 - 175 140 - 225

NOTE: This AWS electrode classification is not

required to deposit weld metal that is low in diffusible

hydrogen. Therefore, these electrodes should not be

used in applications where the hydrogen content of the

weld metal is required to be controlled.

8

1/8” 5/32” 3/16”

(3.2mm) (4.0mm) (4.8mm)

Pipeliner

www.lincolnelectric.com

Page 9

PIPELINER 8P+ AWS: E8010-P1 Cellulosic All Position Stick (SMAW) Electrode

3G

➔

3

G

➔

5G

➔

5G

➔

1G

2F

2

G

4G

Excellent Resistance to Porosity –

Here’s an electrode that makes

short work of even the most

challenging high silicon pipe

pplications! Pipeliner 8P+ is an

a

outstanding choice for API 5L-X56

through X70 grade pipe. This electrode features high stacking efficiency

– formulated to carry and deposit weld

metal in difficult vertical down out-ofposition applications.

ADVANTAGE LINCOLN

• Manufactured to metric electrode

diameters – use anywhere in the

world.

• Fill and Cap Consistency – Approved

manufacturing sites deliver industryleading consistency in composition

and arc action.

•

Repeated x-ray testing shows outstanding results.

• High Stacking Efficiency –

Formulated to carry and deposit

weld metal in difficult vertical down

out-of-position applications. Fill

joints in fewer passes.

• Exceptional mechanical properties –

Consistent best-in-class performance.

• Manufactured to actual lot control.

Actual certificates of conformance

are available upon request.

TYPICAL APPLICATIONS

• Typical applications include highyield pipe steels.

WELDING POSITIONS

CONFORMANCE

AWS A5.5: E8010-P1

ASME SFA-5.5: E8010-P1

ABS: E8010-P1

CSA W48-01: E55010-P1

EN499: E 46 4 1Ni C 25

MECHANICAL PROPERTIES

Yield Strength Tensile Strength Elongation ft.-lbs. (Joules)

psi (MPa) psi (MPa) (%) @ -20ºF (-29ºC) @ -50°F (-46°C)

Required

AWS E8010-P1 67,000 (460) 80,000 (550) 19 20 (27) Not .

min. min. min. min. Required

Typical Results

As-welded 67,000-81,000 80,000-98,000 19-27 46-73 34-62 .

(460-559) (550-676) (62-99) (46-84) .

DIAMETERS / PACKAGING

4.5 kg (10 Lb.)

Diameter Easy Open Cans

mm (in.) [ 27.2 kg (60 lb.) Master ]

3.2 (1/8) ED030829 ED030826

4.0 (5/32) ED030830 ED030827

5.0 (3/16) ED030831 ED030828

Manufactured in metric diameters, U.S. Customary sizes are approximate.

- As Required per AWS A5.5-96

22.7 kg (50 Lb.)

Easy Open Cans

Charpy V-Notch

TYPICAL OPERATING PROCEDURES

Polarity

DC+ 75 - 130 100 - 185 140 - 225

3.2mm 4.0mm 5.0mm

(1/8") (5/32") (3/16")

NOTE: Pipeliner electrodes

are manufactured under lot

control. A Certificate of Test

showing actual deposit

chemistry and mechanical

properties per AWS A5.5

(DC+ only) is available on

request from the factory for

every lot of electrode.

(Fax 216-383-8386).

Current (Amps)

DEPOSIT COMPOSITION

Requirements

AWS E8010-P1 max. max. max. max. max. max. max. max. max.

Typical Results .15 -.19 .60 -.85 .15 -.32 .67 -.85 .01 -.04 .15 -.30 < .01 .005 -.010 .008 -.015

- As Required per AWS A5.5-96

%C %Mn %Si %Ni %Cr %Mo %V %S %P

.20

1.20 .60 1.00 0.30 .50 0.10 0.03 0.03

9

NOTE: This AWS electrode

classification is not required

to deposit weld metal that

is low in diffusible hydrogen.

Therefore, these electrodes

should not be used in

applications where the

hydrogen content of the

weld metal is required to

be controlled.

Pipeliner

www.lincolnelectric.com

Page 10

PIPELINER 16P AWS: E7016 H4 Low Hydrogen Stick (SMAW) Electrode

2F

2G

3G

➔

1G

4G

5G

➔

We designed this quality electrode

for optimum performance for vertical up welding of pipe up to API 5L-

• Manufactured under a quality

system certified to ISO 9001

requirements.

X65 – especially where a low hydro-

en deposit is desired. Obtain

g

Charpy V-Notch impact values down

to temperatures of -20°F (-29°C).

ADVANTAGE LINCOLN

• Excellent low temperature impact

properties.

• Square burnoff makes welding

easier, especially in critical pipe

welding applications.

• Manufactured to actual lot control.

Actual certificates of conformance

re available upon request.

a

TYPICAL APPLICATIONS

• Primarily designed for vertical up

root and fill pass welding of high

strength pipe up to and including

API 5L-X65.

• Open gap root pass welding with

2.5mm (3/32”) and 3.2mm (1/8”)

diameters using DC± polarity.

MECHANICAL PROPERTIES

Yield Strength Tensile Strength Elongation ft•lbf (Joules)

psi (MPa) psi (MPa) (%) @ -20ºF (-29ºC)

Required 58,000 (400) 70,000 (480) 22 20 (27)

AWS E7016 H4 min. min. min. min.

- As Required per AWS A5.1-91

Charpy V-Notch

WELDING POSITIONS

CONFORMANCE

AWS A5.1: E7016 H4

ASME SFA-5.1: E7016 H4

NOTE: Pipeliner electrodes are

manufactured under lot control.

A Certificate of Test showing

actual deposit chemistry and

mechanical properties per AWS

A5.1 (DC+ only) is available on

request from the factory

for every lot of electrode.

(Fax 216-383-8386).

Typical Results 65,000 - 82,000 80,000 - 93,000

As-welded (448 - 566) (550 - 641) (54 - 122)

DIAMETERS / PACKAGING

Diameter 22.7 kg (50 lb.)

mm (in.) Easy Open Cans

2.5 (3/32) ED030916

3.2 (1/8) ED030917

4.0 (5/32) ED030918

Manufactured in metric diameters,

U.S. Customary sizes are approximate.

DEPOSIT COMPOSITION

%C %Mn %Si %S %P %Cr %Mo %Ni %V

Requirements Not 1.60 .75 Not Not .20 .30 .30 .08

AWS E7016 H4 Specified max. max. Specified Specified max. max. max. max.

- As Required per AWS A5.1-91

TYPICAL OPERATING PROCEDURES

Polarity

DC+ 55 - 80 75 - 120 120 - 160

AC 60 - 80 80 - 120 120 - 160

25 - 32

Current (Amps)

2.5mm 3.2mm 4.0mm

(3/32") (1/8") (5/32")

40 - 90

DIFFUSIBLE

HYDROGEN

As Required per AWS A5.1-91

(mL/100g

weld deposit)

Requirements

AWS E7016 H4 4

Typical Results 2 - 4

Typical Results .05-.08 1.0-1.5 .40-.60 .010-.020 .008-.015 .02-.05 .01-.03 .01-.05 .01-.03

10

Pipeliner

www.lincolnelectric.com

Page 11

PIPELINER 18P AWS: E8018-G H4 Low Hydrogen Stick (SMAW) Electrode

5G

➔

1G

2G

3G

➔

4

G

2

F

A real workhorse for vertical up

welding jobs up to X80 pipe!

Lincoln 18P offers low temperature

• Manufactured to actual lot control.

Actual certificates of conformance

are available upon request.

WELDING POSITIONS

impact properties down to -50°F

-46°C).

(

ADVANTAGE LINCOLN

• Low temperature impact properties

down to -50°F (-46˚C).

• Square burnoff makes welding

easier, especially in critical pipe

welding applications.

TYPICAL APPLICATIONS

• Primarily designed for vertical up fill

and cap pass welding of high

strength pipe up to and including

API 5L-X80.

CONFORMANCE

AWS A5.5: E8018-G H4

ASME SFA-5.5: E8018-G H4

• Manufactured under a quality

system certified to ISO 9001

requirements.

MECHANICAL PROPERTIES

Yield Strength Tensile Strength Elongation ft•lbf (Joules)

psi (MPa) psi (MPa) (%) @ -20ºF (-29ºC) @-50°F (-46°C)

Required 67,000 (460) 80,000 (550) 19 Not Not

AWS E8018-G H4R min. min. min. Required Required .

Typical Results

As-welded 88,000 - 94,000 99,000 - 105,000

(607 - 648) (683 - 724) (100 - 112) (77 - 80) .

- As Required per AWS A5.5-96

28

Charpy V-Notch

74 - 83 57 - 59 .

NOTE: Pipeliner electrodes are manufactured

under lot control. A

Certificate of Test showing actual deposit chemistry and mechanical

properties per AWS A5.5

(DC+ only) is available on

request from the factory

for every lot of electrode.

(Fax 216-383-8386).

DIAMETERS / PACKAGING

TYPICAL OPERATING

PROCEDURES

Diameter 22.7 kg (50 lb.)

mm (in.) Easy Open Cans

3.2 (1/8) ED030919

4.0 (5/32) ED030920

Manufactured in metric diameters,

U.S. Customary sizes are approximate.

DEPOSIT COMPOSITION

%C %Mn

Requirements Not 1.00 .80 Not Not .30 .20 .50 .10 .20

AWS E8018-G H4 Specified min. min. Specified Specified min. min. min. min. min.

Typical Results .04-.08 1.30-1.60 .30-.60 .005-.020 .005-.020 .03-.07 .30-.45 .70-.95 .005-.015 .03-.08

(1)

Weld deposit must meet the minimum requirement of at least one of the elements listed.

- As Required per AWS A5.5-96

Polarity

DC+ 90 - 140 130 - 170

AC 100 - 140 140 - 180

NOTE: Preferred polarity is listed first.

(1)

%Si

(1)

Current (Amps)

3.2mm 4.0mm

(1/8”) (5/32”)

%S %P %Cr

DIFFUSIBLE HYDROGEN

- As Required per AWS A5.5-96

(mL/100g

weld deposit)

Requirements

AWS E7016 H4 4

Test Results 1 - 3

(1)

%Mo

(1)

%Ni

(1)

%V

(1)

%Cu

(1)

Pipeliner

11

www.lincolnelectric.com

Page 12

PIPELINER 70S-G AWS: ER70S-G All Position MIG (GMAW) Wire Electrode

1G

2F

2G

3G

➔

5

G

➔

4G

Pipeliner 70S-G MIG wire electrode

is especially intended and packaged for the needs of semiautomatic and automatic root pass pipe

elding. Delivering low hydrogen

w

deposits, 70S-G exhibits an extremely

fluid puddle for outstanding wash-in

at the weld toes and uniform bead

shape. Well-suited for use on

API 5L-X56 through X70 pipe.

ADVANTAGE LINCOLN

• Clean weld deposit.

• Uniform bead shape.

•Fluid puddle provides good wash-in

at the weld toes.

• Manufactured to actual lot control

and testing. Actual certificates of

conformance are available upon

request.

• Foil bag packaging guards against

moisture.

• Manufactured under a quality system certified to ISO 9001 requirements.

TYPICAL APPLICATIONS

• Primarily intended for all-position

root pass welding on pipe steels

such as API 5L, 5L-X56 through

5L-X70

• Capable of consistent x-ray quality

welds.

• Typical applications include highyield pipe steels.

WELDING POSITIONS

CONFORMANCE

AWS A5.18-2001: ER70S-G

ASME SFA-5.18: ER70S-G

MECHANICAL PROPERTIES

Yield Strength Tensile Strength Elongation ft•lbf (Joules)

Required 58,000 (400) 70,000 (480) 22 Not

AWS ER70S-G min. min. min. Required

As welded with CO

Typical Results

As welded with CO

2

2

DIAMETERS / PACKAGING

- As Required per AWS A5.18:2001

psi (MPa) psi (MPa) (%) @ 0ºF (-18ºC)

63,700 76,200 30 70 (95)

(439) (525)

TYPICAL OPERATING

PROCEDURES

Diameter 10 Lb. (4.5 kg) 30 Lb. (13.6 kg)

in. (mm) Plastic Spool Plastic Spool

in Foil Bag in Foil Bag

.045 (1.1) ED030904 ED030905

ELECTRODE COMPOSITION

%C %Mn %Si %S %P %Cu

Requirements

AWS A5.18

Typical Results .06-.15 .90-1.40 .45-.75 .035 max. .025 max. .50 max.

Typical Range

-As Required per AWS A5.18:2001

Not Specified

Parameters .045 in. (1.1 mm)

Polarity DC+

CTWD

Wire Weight – lbs/in (g/m) NA

Wire Feed Speed – in/min (m/min) 125-500 (3.2-12.7)

Arc Voltage (volts) 19-30

Approx. Current (amps) 145-340

Melt-off Rate – lbs/hr (kg/hr) 3.4-13.2 (1.5-6.0)

Deposition Rate – lbs/hr (kg/hr) NA

(1)

CTWD (Contact Tip to Work Distance). Subtract 1/4" to

calculate Electrical Stickout.

Charpy V-Notch

(1)

– in (mm) 1/2-3/4 (12-19)

NOTE: Pipeliner electrodes

are manufactured under

lot control. A Certificate

of Test showing actual

deposit chemistry and

mechanical properties

per AWS A5.18 is available

on request from the

factory for every lot of

electrode.

(Fax 216-383-8386).

Diameter

Pipeliner

12

www.lincolnelectric.com

Page 13

PIPELINER NR-207+ AWS: E71T8-K6 Self-Shielded Flux-Cored (FCAW-S) Wire Electrode

1G

2F

4G

2G

5G

➔

3G

➔

Optimum performance on vertical

down hot, fill and cap passes on

tandard cross-country pipelines

s

and arctic grade pipe. Excellent

crack resistance, CTOD, and Charpy

V-Notch properties. Recommended for

characteristics and superior

feedability.

Manufactured to actual lot control.

•

Actual certificates of conformance

are available upon request.

WELDING POSITIONS

API Pipe Grades X42 through X70.

TYPICAL APPLICATIONS

ADVANTAGE LINCOLN

• Produces quality welds in moderate

wind conditions with no tenting.

• Our quality driven manufacturing

system – certified to ISO 9001 –

and our exceptionally high grade raw

materials mean every coil of

Innershield delivers great arc

MECHANICAL PROPERTIES

Yield Strength Tensile Strength

psi (MPa) psi (MPa) (%) @ -20°F (-29°C) @-40°F (-40°C) Rockwell B

Requirements 58,000 (400) 70,000 - 90,000 20 20 (27) Not . Not

AWS E71T-K6 min. (483 - 620) min. min. Required Required

Typical Results 58,000 - 64,000 75,000 - 80,000 20 - 33 103 - 116 109

(400 - 441) (517 - 551) (176 - 230) (147) ..

(1)

The strength and elongation properties reported were obtained from a .505” tensile specimen artificially aged at 220°F

(104°C) for 48 hours, as permitted by AWS A5.29-98. A naturally aged tensile specimen may take months to achieve the

specified properties. The time required for the natural aging of weld deposits is dependent upon ambient conditions, weldment geometry, the metallurgical structure of the weld deposit and other factors.

• Standard cross country pipelines.

• Arctic grade pipe.

• Use these wires instead of stick for

improved productivity on pipeline

projects.

- As Required per AWS A5.29-98

(1)

Elongation

(1)

Charpy V-Notch

ft•lbf (Joules) Hardness

CONFORMANCE

AWS A5.29-98: E71T8-K6

ASME SFA-5.29: E71T8-K6

.

84 - 90

NOTE: Pipeliner electrodes are manufactured

under lot control. A

Certificate of Test showing actual deposit chemistry and mechanical

properties per AWS

A5.29 is available on

request from the factory

for every lot of electrode.

(Fax 216-383-8386).

DIAMETERS / PACKAGING

Diameter 14 Lb. (6.3 kg) Coil

in. (mm) [ 56 Lb. (25.4 kg)

Master Sealed Pail ]

5/64 (2.0) ED030924

DEPOSIT COMPOSITION

%C %Mn %P %S %Si %Al %Ni %Cr %Mo %V

Requirements

AWS E71T8-K6

Typical Results .06 1.21 .007 <.003 .25 .96 .82 .03 .02 <.01

.15 .50- .03 .03 .80 1.80 .40- .20 .15 .05

max. 1.50 max. max. max. max. 1.00 max. max. max.

TYPICAL OPERATING

PROCEDURES

Parameters 5/64 in. (2.0 mm)

Polarity DC-

(1)

CTWD

– in (mm) 3/4 (19)

Wire Weight – lbs/in (g/m) 1.04/1000 (18.57)

Wire Feed Speed – in/min (m/min) 70-130 (1.7-3.3)

Arc Voltage (volts) 18-21

Approx. Current (amps) 210-305

Melt-off Rate – lbs/hr (kg/hr) 4.3-8.1 (2.0-3.7)

Deposition Rate – lbs/hr (kg/hr) 3.6-6.7 (1.6-3.0)

- As Required per AWS A5.29-98

13

Diameter

(1)

CTWD (Contact Tip to Work

Distance). Subtract 1/4" to

calculate Electrical Stickout.

www.lincolnelectric.com

Pipeliner

Page 14

PIPELINER NR-207XP AWS: E71T8-K6 Self-Shielded Flux-Cored (FCAW-S) Wire Electrode

1

G

2F

4G

2G

5G

➔

3G

➔

04020 60 80 100 120 140 160 180 200 220 240

0

2.0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

18.0

20.0

CVN (ft-lbs)

% of Total Samples

Figure 1 – CVN Distribution

E6010 Root Pass on Simulated Pipe Joint

@ -4˚F (-20˚C)

For consistently high impact values,

choose 207XP. Optimum perfor-

mance on vertical down, hot, fill and

cap passes on standard cross-country

ipelines and arctic grade pipe.

p

Recommended for API Pipe Grades

X42 through X70.

ADVANTAGE LINCOLN

• Consistently high CVN properties,

• Our quality driven manufacturing

system – certified to ISO 9001 –

and our exceptionally high grade

raw materials mean every coil of

nnershield delivers great arc

I

characteristics and superior

feedability.

• Manufactured to actual lot control.

Actual certificates of conformance

are available upon request.

WELDING POSITIONS

even down to -40˚F (-40˚C).

• Virtually eliminates CVN values

below 42 ft•lbf (56 joules).

• Self-shielded, flux-cored. No need

for external gas or flux.

• Produces quality welds in moderate

wind conditions with no tenting.

TYPICAL APPLICATIONS

• Suggested for use on applications

demanding consistently high toughness.

• Standard cross country pipelines.

CONFORMANCE

AWS A5.29-98: E71T8-K6

ASME SFA-5.29: E71T8-K6

• Arctic grade pipe.

MECHANICAL PROPERTIES

Yield Strength Tensile Strength

psi (MPa) psi (MPa) (%) @ -20°F (-29°C) @-40°F (-40°C) Rockwell B

Requirements 58,000 (400) 70,000 - 90,000 20 20 (27) Not . Not

AWS E71T8-K6 min. (483 - 620) min. min. Required . Required

Typical Results 63,000 79,000 30 173 - 251 147 . NA

(434) (545) (234 - 340) (199) ..

(1)

The strength and elongation properties reported were obtained from a .505" tensile specimen artificially aged at 220°F

(104°C) for 48 hours, as permitted by AWS A5.29-98. A naturally aged tensile specimen may take months to achieve the

specified properties. The time required for the natural aging of weld deposits is dependent upon ambient conditions, weldment geometry, the metallurgical structure of the weld deposit and other factors.

(2)

Standard testing completed to AWS test plate specifications.

Figure 1 below shows results on a simulated pipe joint.

- As Required per AWS A5.29-98 (Standard AWS Test Plate)

(1)

Elongation

(1)

Charpy V-Notch

ft•lbf (Joules)

(2)

Hardness

NOTE: Pipeliner electrodes are manufactured

under lot control. A

Certificate of Test showing

actual deposit chemistry

and mechanical properties

per AWS A5.29 is available on request from the

factory for every lot of

electrode.

(Fax 216-383-8386).

DIAMETERS / PACKAGING

Diameter 14 Lb. (6.3 kg) Coil

in. (mm) [ 56 Lb. (25.4 kg)

Master Sealed Pail ]

5/64 (2.0) ED030925

Typical Operating Procedures – See page 15.

DEPOSIT COMPOSITION

%C %Mn %P %S %Si %Al %Ni %Cr %Mo %V

Requirements

AWS E71T8-K6

Typical Results .055 .98 .009 <.003 .07 .80 .61 .04 .03 <.003

.15 .50- .03 .03 .80 1.80 .40- .20 .15 .05

max. 1.50 max. max. max. max. 1.00 max. max. max.

- As Required per AWS A5.29

14

42 ft•lbf (56 joules)

NR-207XP virtually eliminates CVN values below 42 ft•lbf (56 joules).

Pipeliner

www.lincolnelectric.com

Page 15

1G

2F

2G

3G

➔

4G

5

G

➔

PIPELINER G70M AWS E71T-1MJH8 & E71T-9MJH8 Gas-Shielded Flux-Cored (FCAW-G) Wire Electrode

Pipeliner G70M is designed to

deliver outstanding weld properties

for semi-automatic applications.

• Manufactured under a quality

system certified to ISO 9001

requirements.

Robust impacts mean consistently

igh CVN values.

h

ADVANTAGE LINCOLN

• Manufactured to actual lot control.

ctual certificates of conformance

A

are available upon request.

• Impacts are typically in the 60 ft•lbf

@ -20°F (-29°C), as-welded.

• Smooth, spray type arc transfer and

low spatter level.

• Slag system provides for puddle

TYPICAL APPLICATIONS

• All position single and multiple pass

wire designed to join pipe up to

X70.

support, good wetting and bead

shape in all positions.

MECHANICAL PROPERTIES

Yield Strength Tensile Strength Elongation ft•lbf (Joules)

Required 58,000 (400) 70,000 (480) 22 20 (27)

AWS E71T-1MJH8 min. min. min. min.

& E71T-9MJH8

Typical Results

75% Ar / 25% CO

2

- As Required per AWS A5.20-95

psi (MPa) psi (MPa) (%) @ -40ºF (-40ºC)

80,000 89,000 26 78 (106)

(550) (612)

WELDING POSITIONS

SHIELDING GAS

75-80% Ar / Balance CO

Flow Rate 40-50 CFH (19-24 l/min.)

2

CONFORMANCE

AWS A5.20-95: E71T-1MJH8

E71T-9MJH8

ASME SFA-5.20: E71T-1MJH8

E71T-9MJH8

NOTE: Pipeliner electrodes are manufactured

Charpy V-Notch

under lot control. A

Certificate of Test showing actual deposit chemistry and mechanical

properties per AWS

A5.20 is available on

request from the factory

for every lot of electrode.

(Fax 216-383-8386).

DIAMETERS / PACKAGING

Diameter 10 Lb. (4.5 kg) 25 Lb. (11 kg)

in. (mm) Plastic Spool Plastic Spool

Foil Bag Foil Bag

.045 (1.1) ED030926 ED030927

DEPOSIT COMPOSITION

%C %Mn %P %S %Si %Ni

Requirements

AWS E71T-1MJH8 .18 1.75 .03 .03 .90 .50

AWS E71T-9MJH8 max. max. max. max. max. max.

Typical Results

75% Ar / 25% CO2.05 1.60 .013 .011 .45 .36

-As Required per AWS A5.20-95

15

TYPICAL OPERATING

PROCEDURES

Parameters .045 in. (1.1mm)

Polarity DC+

(1)

CTWD

– in. (mm) 3/4 (19)

Wire Weight – lbs/in. (g/m) .361/1000 (6.45)

Wire Feed Speed – in/min (m/min) 175-525 (4.4-13.3)

Arc Voltage (volts) 23-30

Approx. Current (amps) 130-275

Melt-off Rate – lbs/hr (kg/hr) 3.9-11.9 (1.8-5.4)

Deposition Rate – lbs/hr (kg/hr) 3.2-9.8 (1.4-4.4)

DIFFUSIBLE HYDROGEN

- As Required per AWS A5.20-95

(mL/100g

weld deposit)

Requirements

E71T-1MJH8 8

& E71T-9MJH8

Typical Results 4 - 8

75-80% Ar/CO

2

Diameter

(1)

CTWD (Contact

Tip to Work

Distance).

Subtract 1/4" to

calculate Electrical

Stickout.

www.lincolnelectric.com

Pipeliner

Page 16

1G

2

F

2G

3G

➔

4G

5

G

➔

PIPELINER AUTOWELD G70M AWS E71T-1MJH8 & E71T-9MJH8 Gas-Shielded Flux-Cored (FCAW-G) Wire Electrode

ipeliner Autoweld G70M is

P

specifically designed for use with

the Autoweld pipe welding system

to deliver outstanding weld

properties.

Smooth, spray type arc transfer and

•

low spatter level.

• Slag system provides for puddle

upport, good wetting and bead

s

shape in all positions.

• Manufactured under a quality

ystem certified to ISO 9001

ADVANTAGE LINCOLN

s

requirements.

• Specifically designed for use with

Autoweld™ pipe welding system on

pipe up to X70.

• Tightly controlled cast and helix

• Manufactured to actual lot control.

Actual certificates of conformance

are available upon request.

assure proper wire placement every

time.

• Excellent mechanical properties —

impacts are normally in the 60 ft•lbf

TYPICAL APPLICATIONS

• All position wire designed to weld

pipe up to X70.

@ -20°F (-29°C), as welded.

MECHANICAL PROPERTIES

Yield Strength Tensile Strength Elongation ft•lbf (Joules)

Required 58,000 (400) 70,000 (480) 22 20 (27)

AWS E71T-1MJH8 min. min. min. min.

& E71T-9MJH8

Typical Results

75% Ar / 25% CO

2

- As Required per AWS A5.20-95

psi (MPa) psi (MPa) (%) @ -40ºF (-40ºC)

82,700 93,200 26 63 (85)

(570) (642)

WELDING POSITIONS

SHIELDING GAS

75-80% Ar / Balance CO

Flow Rate 40-50 CFH (19-24 l/min.)

Charpy V-Notch

NOTE: Pipeliner electrodes

are manufactured under

lot control. A Certificate

of Test showing actual

deposit chemistry and

mechanical properties

per AWS A5.20 is available

on request from the

factory for every lot

of electrode.

(Fax 216-383-8386).

2

DIAMETERS / PACKAGING

Diameter 10 Lb. (4.5 kg)

in. (mm) Plastic Spool

Foil Bag

.052 (1.3) ED030928

DEPOSIT COMPOSITION

%C %Mn %P %S %Si %Ni

Requirements

AWS E71T-1MJH8 .18 1.75 .03 .03 .90 .50

AWS E71T-9MJH8 max. max. max. max. max. max.

Typical Results

75% Ar / 25% CO2.05 1.62 .01 <.01 .46 .39

-As Required per AWS A5.20-95

TYPICAL OPERATING

PROCEDURES

Parameters .052 in. (1.3 mm)

Polarity DC+

(1)

CTWD

– in. (mm) 3/4 (19)

Wire Weight – lbs/in. (g/m) .482/1000 (8.61)

Wire Feed Speed – in/min (m/min) 150-450 (3.8-11.4)

Arc Voltage (volts) 22-31

Approx. Current (amps) 155-315

Melt-off Rate – lbs/hr (kg/hr) 4.4-13.3 (2.0-6.0)

Deposition Rate – lbs/hr (kg/hr) 3.6-10.9 (1.6-4.9)

DIFFUSIBLE HYDROGEN

- As Required per AWS

Requirements

E71T-1MJH8 8

& E71T-9MJH8

Typical Results 4 - 8

75-80% Ar/CO

2

A5.20-95

(mL/100g

weld deposit)

Diameter

(1)

CTWD (Contact

Tip to Work

Distance).

Subtract 1/4" to

calculate Electrical

Stickout.

Pipeliner

16

www.lincolnelectric.com

Page 17

TEST RESULTS

Test results for mechanical properties, deposit or electrode composition and diffusible hydrogen levels were obtained from

a weld produced and tested according to prescribed standards, and should not be assumed to be the expected results in

a particular application or weldment. Actual results will vary depending on many factors, including, but not limited to, weld

procedure, plate chemistry and temperature, weldment design and fabrication methods. Users are cautioned to confirm by

qualification testing, or other appropriate means, the suitability of any welding consumable and procedure before use in the

intended application.

CUSTOMER ASSISTANCE POLICY

The business of The Lincoln Electric Company is manufacturing and selling high quality welding equipment, consumables,

and cutting equipment. Our challenge is to meet the needs of our customers and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric for advice or information about their use of our products. We respond to

our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant

or guarantee such advice, and assumes no liability, with respect to such information or advice. We expressly disclaim any

warranty of any kind, including any warranty of fitness for any customer’s particular purpose, with respect to such information or advice. As a matter of practical consideration, we also cannot assume any responsibility for updating or correcting

any such information or advice once it has been given, nor does the provision of information or advice create, expand or

alter any warranty with respect to the sale of our products.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely

within the control of, and remains the sole responsibility of the customer. Many variables beyond the control of Lincoln

Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to

www.lincolnelectric.com for any updated information.

17

Pipeliner

www.lincolnelectric.com

Page 18

LINCOLN INTERNATIONAL HEADQUARTERS

Lincoln at a Glance

INCOLN ELECTRIC MANUFACTURING

L

REGIONAL HEADQUARTERS

CLEVELAND, OHIO, U.S.A.

MIAMI, FLORIDA, U.S.A.

ARCELONA, SPAIN

B

SINGAPORE

ASIA PACIFIC

Singapore

Phone: 65 276 0878

Australia

Phone: 61 2 9772 7222

WORLD HEADQUARTERS

Cleveland, Ohio U.S.A.

Phone: (216) 481-8100

EUROPE

Barcelona, Spain

Phone: 34 93 492 20 00

NORTH AMERICA

Cleveland, Ohio U.S.A.

Phone: (216) 481-8100

LATIN AMERICA

Miami, Florida U.S.A.

Phone: (305) 888-3203

RUSSIA, AFRICA & MIDDLE EAST

Cleveland, Ohio U.S.A.

Phone: (216) 481-8100

Pipeliner Consumables

C1.100 6/03

Loading...

Loading...