Page 1

™

60

Hz

1

PHASE

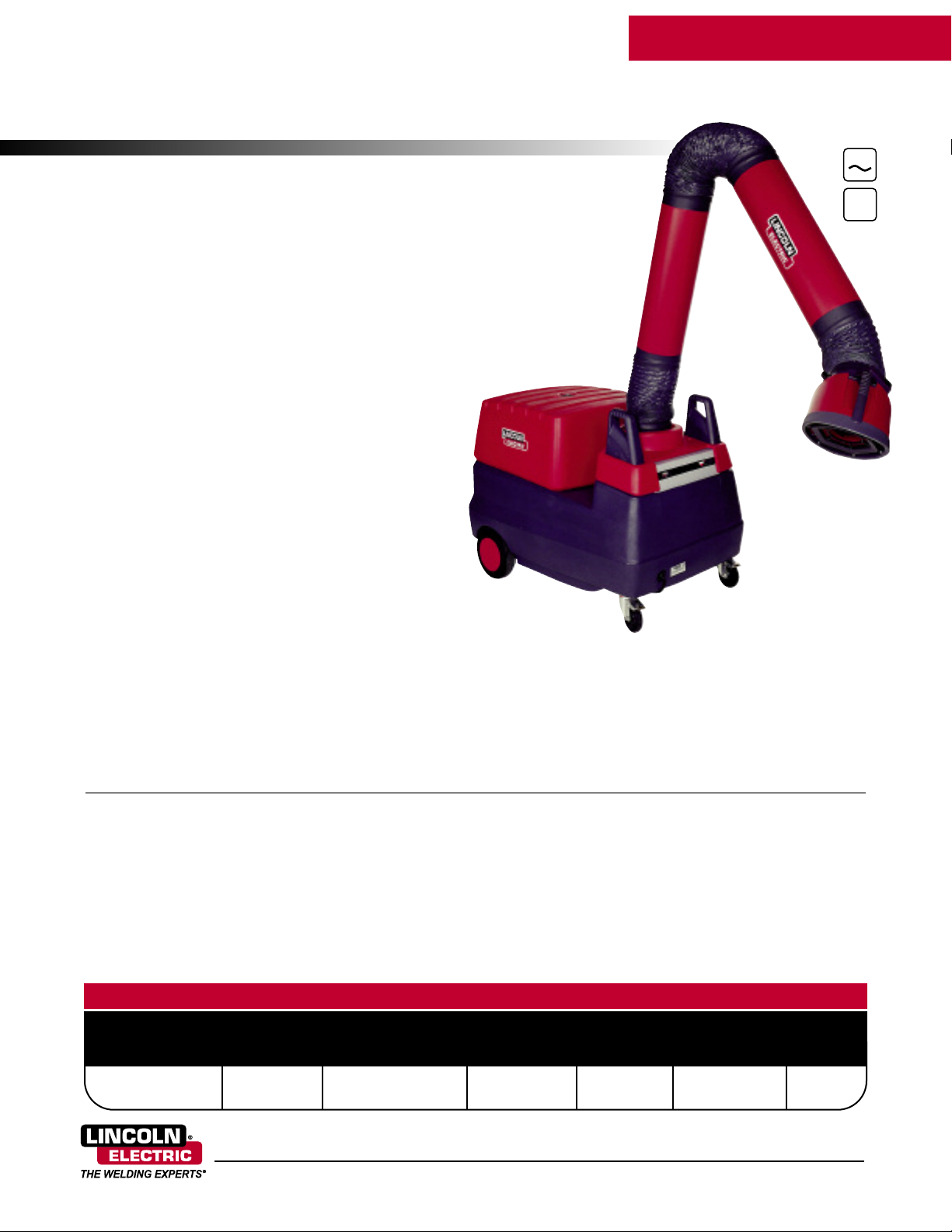

Mobiflex

Mobile Welding Fume Extractor

Lincoln Electric’s®Mobiflex™200-M is a portable, low vacuum/high volume disposable

filtration system designed for medium duty extraction and filtration of welding fumes.

The lightweight and rugged design of the Mobiflex

caster and rear wheels allows for easy portability. It is ideal for facilities that require welding

fume extraction in multiple locations, including maintenance departments, general fabrication

and job shops, and industrial welding environments.

200-M

™

200-M along with the standard front

NGINE DRIVEN WELDERS

E

ENVIRONMENTAL SYSTEMS

Input

The Mobiflex

arms or with the 152 mm (6 in.) diameter, 5 m (16 ft.) long flexible hose and hood set.

Lincoln Electric’s®fume extraction arms are designed to provide welders optimal

motion and reach for their specific welding position(s) and work area.

The arm lengths range from 3.1 meter (10 ft.) to 4.1 meters (13 ft.).

For hard to reach areas such as confined spaces, the flexible hose

and set can be easily carried to locations where an extraction

arm just is not feasible.

The Mobiflex

is designed specifically for weld applications. It extracts weld fume

through the arm, into the internal spark arrestor and finally through

the unique LongLife

particulate. The particulate is collected on the inside of the cartridge,

minimizing exposure to particulate during filter maintenance and

disposal.

The Mobiflex

1500 lbs. (680 kg) of MIG wire or 1100 lbs. (500 kg) of stick and flux-cored wire before

replacing.

Filter performance will be affected by process and application variables including:

base metal(s), consumables(s), and coatings (oil) if applicable.

Processes

Stick, TIG, MIG, Flux-Cored

™

200-M can be configured with Lincoln’s®LFA 3.1 or LFA 4.1 fume extraction

™

200-M has an on-board internal extraction fan and

®

filter cartridge capturing the welding fume

™

200-M filter system is recommended for consumable use of approximately

Shown:

Mobiflex™200-M with

optional Extraction Arm

Advantage Lincoln

• Generous 735 CFM airflow with LFA 3.1/4.1 extraction arm.

• Filter efficiency up to 99%

2

(164 ft2) LongLife®filter with ExtraCoat®pretreatment.

• 50 m

• Pressure differential filter indicator gauges amount of particulate in

filter cartridge, indicating system maintenance and filter replacement.

• Internal aluminum mesh spark arrestor.

• One-year warranty on equipment; 30 days on filter cartridge.

• Low noise operation: 69dBA.

Product Product Filter Type/ Input Input H x W x D Net Weight

Name Number Filter Size Power Current mm (in.) kg (lbs.)

™

Mobiflex

200-M K1653-2 Pretreated Cellulose 115/1/60 12A 900 x 810 x 1210 111

Base Unit 50 m

(2)

.

(1)

TECHNICAL SPECIFICATIONS

2

(164 ft2) (36 x 32 x 48) (243)

™

Mobiflex

• Filter, plastic housing, 8" flexible hose, 6 meter (19ft.) 115VAC input

NOTE: Extraction Arm of your choice is required.

(1)

(2)

200-M System includes:

power cord and instruction manual.

CFM level is dependent upon arm length, fan type and system maintenance.

Per Din EN 60335-2-69 Standards.

Dimensions

Publication E13.12 2/07

Web Update 5/08

www.lincolnelectric.com

Page 2

A CLOSER LOOK

0 m

(0 ft.)

1 m

(3 ft.)

2 m

(6.5 m)

3 m

(10 ft.)

4 m

(13 ft.)

0 m

(0 ft.)

1 m

(3 ft.)

2 m

(6.5 ft.)

3 m

(10 ft.)

4 m

(13 ft.)

5 m

(16 ft.)

200-M

LFA 4.1

LFA 3.1

PERFORMANCE

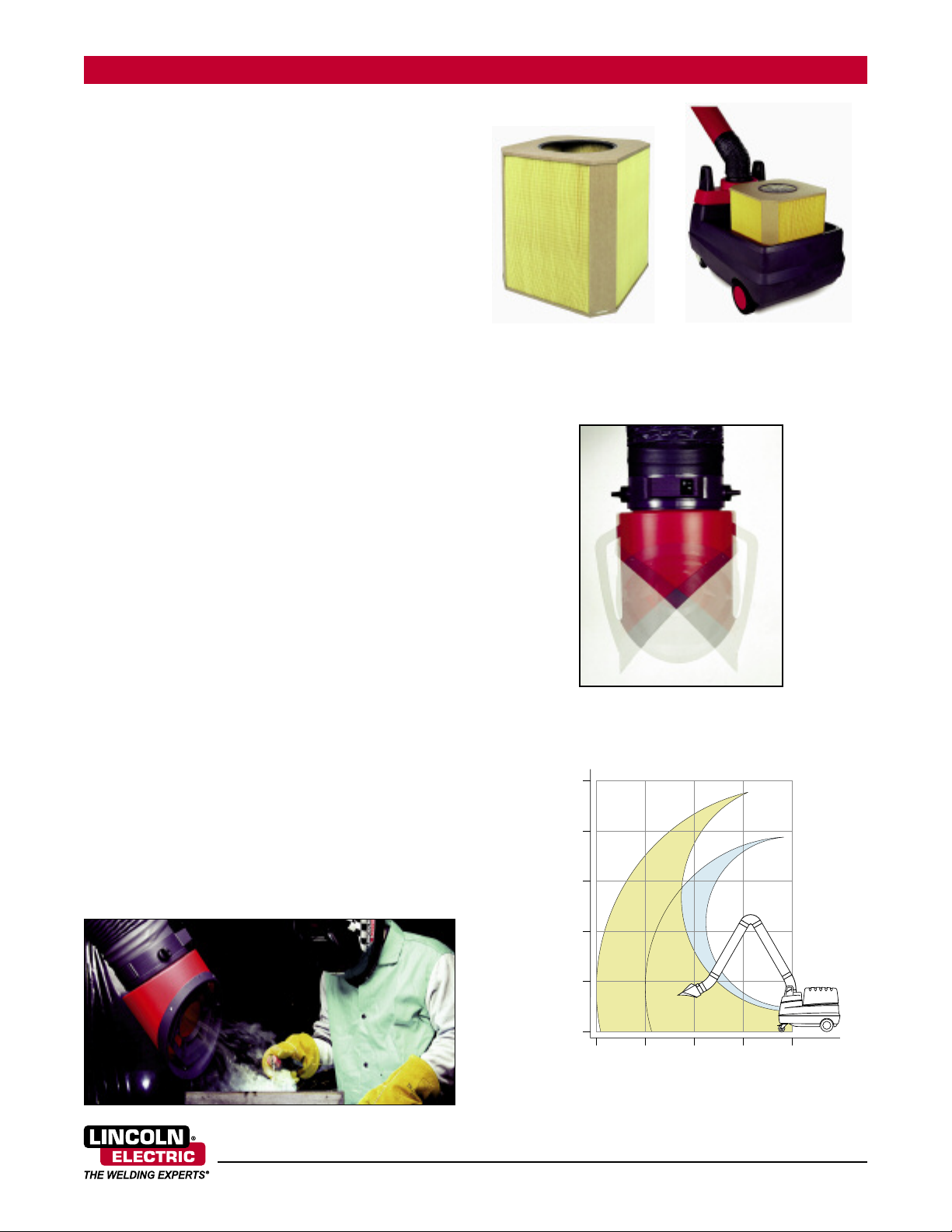

Mechanical Filtering Technique

The LongLife®filter has a surface area of 50 m2(164 ft2), making

it one of the largest disposable filter cartridges in its class for

collection of weld fume particulate. The combination of this with

an ExtraCoat®pretreatment and the unique 3D-pleated structure

results in a 99.8% filter efficiency, a longer life, and low operational

costs. The ExtraCoat®pretreatment fills the micro pleats in the filter

and reduces moisture. This increases its efficiency from the start of

usage.

A pressure differential filter indicator located at front of unit, moves

gradually from white to red as the filter becomes saturated with

welding fume particulate, indicating when system maintenance and

filter replacement is necessary. The washable aluminum prefilter sits

inside the LongLife®filter to remove the large particulates and provide spark entrapment.

Extraction Arms

No matter if you are working in a small work station, under a low

ceiling, or in a large fabrication area, one of Lincoln Electric’s

various fume extraction arms for welding will work for you. The

flexible extraction arms are built the Lincoln®way—rugged and

reliable. Low vacuum extraction arms are designed for high volume/low velocity air movement to enable the arm to be positioned

at a distance of 6-12 inches (152-304 mm) from the welding source.

Designed with the welder in mind, the arms provide welders optimal

motion and reach for their specific welding position(s) and work

area.

®

ongLife

L

®

ilter LongLife

F

®

ilter inside of unit

F

The arms come equipped with the 360° rotatable hood for optimal

positioning to welding source. This allows a larger work envelope

with less repositioning of the arm and increased operator visibility.

With the extraction arm correctly positioned, the welding fume particulate can be effectively drawn away from the operator’s breathing

zone, as well as eliminate the residual fume particulate that often

rises and hovers within the facility.

With a unique spring-balanced internal mechanism, Lincoln’s®fume

extraction arms provide a long-lasting, user-friendly solution. The

extraction arms external shell is made of solid, lightweight 203 mm

(8 in.) diameter dent and scratch resistant tubing. Incorporated into

the arm is an airflow throttle valve and extraction focus spoiler. A

clear halogen lamp and automatic start/stop are available as recommended optional features. With the use of an arc sensor, the

system automatically starts and stops the fan unit, providing handsfree operation and helping to conserve energy. All this combined

provides a highly effective system with maximum efficiency and

minimal disruption to welder productivity.

Rotatable Hood

™

Mobiflex

200-M Reach

Mobiflex™200-M

[2]

www.lincolnelectric.com

Page 3

RECOMMENDED OPTIONS

GENERAL OPTIONS

LFA 3.1 (10 ft.) and LFA 4.1

(13 ft.) Extraction Arm

Extraction arms with 360° rotatable hood, airflow throttle valve,

extraction focus spoiler, and handle for every positioning. Hood

lamp and automatic start/stop

models available.

Order:

K2633-1 LFA 3.1

K2633-2

K2633-3 LFA 4.1

K2633-4

Hose and Hood Set

Completely flexible extraction

hose with magnetic hood set.

Ideal for those hard to access

fume extraction applications.

Comes with 152 mm (6") diameter

hose and reinforced outside steel

rings to protect against wear and

crushing.

Order K1668-1

LFA 3.1 with lamp/arc sensor

LFA 4.1 with lamp/arc sensor

Starter Overload Switch

for 230V

This overload switch retrofits the

extraction unit for 230V operation.

Order K1494-3

LongLife

Standard replacement LongLife

®

200-M Filter

®

filter with ExtraCoat®treatment

that provides a 99.8% filter efficiency.

Order K1673-1

Activated Carbon Filter

Mounts over LongLife

®

200-M

Filter and is recommended to

neutralize welding fume odors.

Order K1852-1

Lamp Kit with Arc Sensor

To conserve energy and extend

the life of your system, order the

lamp kit with arc sensor. It senses

an arc while the lamp illuminates

the work area. The arc sensor

turns on the unit when it senses

an arc flash and automatically

turns off 20 seconds after the arc

goes out. Also includes a manual

override on/off switch that works

independently of the arc sensor.

Kit includes work lamp with arc

sensor housing, switch bank,

and wiring.

Order K1706-2

Consult your local Lincoln Representative to help you decide which options are right for you!

Mobiflex™200-M

[3]

www.lincolnelectric.com

Page 4

MOBIFLEX™200-M ORDER FORM

PRODUCT DESCRIPTION ORDER NUMBER QUANTITY PRICE

PRODUCT DESCRIPTION ORDER NUMBER QUANTITY PRICE

Mobilflex™200-M Base Unit K1653-2

Choose an Extraction Arm or Hose

LFA 3.1 – 10 ft. Extraction Arm K2633-1

LFA 3.1 – 10 ft. Extraction Arm with Lamp/Arc Sensor K2633-2

LFA 4.1 – 13 ft. Extraction Arm K2633-3

LFA 4.1 – 13 ft. Extraction Arm with Lamp/Arc Sensor K2633-4

Hose and Hood Set, 5 meter (16 ft.) K1668-1

Options

Lamp Kit with Arc Sensor K1706-2

Starter Overload Switch for 230V K1494-3

Filter Options

LongLife®200-M Filter K1673-1

Active Carbon Filter K1852-1

TOTAL:

Environmental Systems Family

High & Low

Vacuum Solutions

The business of The Lincoln Electric Company®is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the needs of

our customers and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric for information or advice about their use of our products. Our employees respond to

inquiries to the best of their ability based on information provided to them by the customers and the knowledge they may have concerning the application. Our employees, however, are not

in a position to verify the information provided or to evaluate the engineering requirements for the particular weldment. Accordingly, Lincoln Electric does not warrant or guarantee or assume

any liability with respect to such information or advice. Moreover, the provision of such information or advice does not create, expand, or alter any warranty on our products. Any express or

implied warranty that might arise from the information or advice, including any implied warranty of merchantability or any warranty of fitness for any customers’ particular purpose is

specifically disclaimed.

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility of the

customer. Many variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

C U S T O M E R A S S I S T A N C E P O L I C Y

THE LIN COLN ELE CTRIC CO M PAN Y

22801 St. Clair Ave., Cleveland, OH 44117-1199 • 216.481.8100 • www.lincolnelectric.com

®

Loading...

Loading...